95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci. , 30 September 2022

Sec. Structural Geology and Tectonics

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.1029309

This article is part of the Research Topic Quantitative Characterization and Engineering Application of Pores and Fractures of Different Scales in Unconventional Reservoirs – Volume II View all 39 articles

The coupling relationship between polymer gel system and reservoir pores is an important basis for scientific formulation of tertiary oil recovery programs. The polymer gel profile control agent can significantly modify the fluid migration path inside the reservoir. In this study, artificial cores were used to carry out indoor water flooding experiments after polymer gel injection that considering formation permeability, polymer concentration and polymer injection rates. Based on the accurate records of the breakthrough pressure and injection volume during water flooding, as well as a large number of observations of the microscopic morphology of the cores after the polymer gel profile control and displacement, a set of criteria for determining reservoir-matched polymer gel profile control agents is proposed. The experimental results show that a complex spatial network structure is formed after the gelation of the polymer gel system. As the polymer concentration increases, the network structure of the gel system becomes denser. At the same time, the unit network structure is becoming smaller, and the order of the grid chain structure becomes clearer. Under the condition of low polymer concentrations, the backbone structures of the gel are obvious, but there are a lot of fine pores. When the polymer concentration is greater than 1,500 mg/L and the injection rate is less than 0.15 ml/min, the water flooding breakthrough pressure is greater than 0.2 MPa, the plugging rate is greater than 95%, and a good plugging effect is obtained.

In the middle and late stages of the development of strong heterogeneity reservoirs, the oil saturation in the large pores will be greatly reduced (Liu, 2000; Liu, 2019; Zhao, 2012). Furthermore, the pore structures of the reservoir has undergone significant changes due to the continuous scouring of fluids for a long time. Then, a large amount of injected fluids preferentially enter the large pores and continue to perform inefficient circulation, thereby reducing the displacement effect (Fan, 2013; Niu et al., 2003).

Low permeability, low productivity, fractured heterogeneous sandstone reservoirs are widely developed in China (Liu et al., 2014a; Wang et al., 2016a). In the process of water injection development, a large number of secondary large pores are formed due to the long-term scouring of the formation by the injected water (Li et al., 2006; You et al., 2009). The large pores exacerbate the injection-production contradiction and cause the injected water to continuously intrude into the oil wells along the large pores and fractures. Therefore, the water flooding sweep coefficient is reduced (Liang, 2008; Liu et al., 2018; Xu et al., 2002). At this time, the water cut of the oil well rises rapidly when the recovery degree is not high, and the oil field enters the high water cut period. The use of composite slug profile control technology for plugging large pores in the deep formation has been proved to be effective in terms of the oil enhancement effect by many field tests. Particle profile control agent is a new type of liquid flow diverting agent (Qing et al., 2017; Yang et al., 2017). It migrates in the strata in four modes: blockage, smooth passage, deformation passage, and broken passage. Therefore, it can effectively improve the reservoir heterogeneity and enhance the displacement effect. In recent years, particle profile control agents have been widely used in different oil fields (Jia et al., 2016; Nie, 2017). In addition, the depth profile control agent is a deep liquid flow diverting agent with unique physicochemical properties and can significantly improve the heterogeneity and water injection development effect of deep reservoirs in the high water cut or ultra-high water cut stage (Sun et al., 2016; Tian, 2013; Zhao et al., 2015). In recent years, it has been successfully applied in some oil fields, and has attracted more and more attention of oilfield chemical engineers.

Old oil fields usually undergo several adjustments during their development, such as water drive, carbon dioxide drive, acidizing, fracturing and reservoir reconstruction, the general well spacing of a well group is 150 m. At present, most of the old oil fields in China have entered the later development stage of ultra-high water cut, the maximum water content can reach to 95%. Serious inefficiency and ineffective circulation further increase the difficulty of oil recovery (Liang, 2008; Liu et al., 2018). The previous have made some achievements in the application of gel profile control technology to improve the ineffective water circulation. It can be said that whether the gel profile control agent dynamically gels in the deep formation determines the feasibility of the deep profile control technology (Liu et al., 2014; Liu et al., 2014a). The gel-forming effect of the gel profile control agent is related to whether the technology is really effective and can be applied on a large scale (Qing et al., 2017; Yang et al., 2017). At present, short cores are usually used to evaluate the short-distance plugging pressure of gel profile control agents. Therefore, the long-distance plugging performance of the gel cannot be well understood. Quantitative evaluation of the dynamic gel-forming properties of gel profile control agents in deep formations will help people better understand their plugging mechanisms.

After the oilfields entered the late stage of ultra-high water cut, the inefficient and ineffective circulation intensified, and the development of remaining oil became more and more difficult. Deep profile control measures are effective means to improve the inefficient and ineffective circulation in the well (Guo et al., 2007; Wang et al., 2006; Yuan et al., 2006). The compatibility of profile control agent system and reservoir closely affects the effect of deep control measures. Different types of reservoirs have different requirements on the performance of profile control and plugging systems. Therefore, it is necessary to carry out flooding experiments under different control conditions of polymer concentration, core permeability and polymer injection rate. Through this study, the relationship between the breakthrough pressure under different reservoir conditions and the microstructures of the polymer profile control agent can be elucidated, and the matching relationship between the polymer gel profile control agent and the pores can be determined.

Cr3+ cross-linking agent: its effective content is 90%; stabilizer: its effective content is 90%; experimental water: The polymer gel profile control agent solution is prepared with water. The composition and content of the water used in this experiment are shown in Table 1.

First, a graduated cylinder is used to measure an amount of the formulated polymer, to which a certain amount of crosslinking agent is added while stirring. Then, the stabilizer and additives are added, and stirring is continued until the crosslinker, stabilizer, and additives are uniformly dispersed in the solution. The prepared gel profile control agent was put into jars of different labels in turn, and put into a 45 °C incubator for constant temperature treatment. The basic parameters of the configured polymer gel profile control agents are shown in Table 2.

In this paper, the rock samples from the Jian 255 coring well in China’s A Oilfield are selected as the research object (Figure 1), and the instruments of the displacement experiment are shown in Figure 2. The permeability distribution of the samples is between 1,130 mD and 3542 mD. It can effectively represent the distribution range of rock permeability in strong water wash, low-efficiency-ineffective circulation area. Core flooding experiments were performed in a high-speed, high-pressure environment. Its essence is to study the process of the formation or plugging of large pores during the flushing treatment of natural cores. In this study, the parameters of natural cores after water flooding were used to determine the preparation method of artificial cores. The coincidence rate between artificially prepared cores and natural cores is greater than 80%.

(1) Preparation of fine quartz sand and cement for making artificial cores.

(2) Mixing sand: The quartz sand required for making the model is mixed in proportion and placed in a square plate and stirred evenly. The medicines required to configure the cement are weighed separately as required, and after mixing, they are poured into the quartz sand and stirred thoroughly. The agitated sand sample is sieved to make the sand and cement mix more uniform.

(3) Molding: acetone is used to clean the mold before the sand is loaded into the mold. The scraper is used to move back and forth in the horizontal direction, and the depth of the scraper needs to be adjusted continuously until the sand is uniform. This step ensures that the sand is filled evenly. The press plate is then used to compact the sand.

(4) Applying pressure: The sand-loaded mold is placed on the pressure testing machine and the mold is kept horizontal. It is placed on the center line of the press platen and the platen is to be actuated vertically. Moreover, the press is slowly boosted to the design value (usually 3 MPa) and the pressure is released for 15 min. Then, the side and end plates of the mold are carefully removed.

(5) Heating and curing: The pressed core is put into the oven, the oven temperature is adjusted to 85 °C, and the baking time is set to 6–8 h. Then, the core is taken out and left to cool naturally.

(6) Cutting: The solidified cores are cut to the required specifications with a cutting machine.

The conformity of the parameters of the artificial and natural cores after strong water washing was compared. The lowest coincidence values of permeability, porosity and average pore radius are 88, 92.6 and 93.6%, respectively. It is obvious that the conformity of all parameters has reached more than 80% (Table 3).

High temperature and high pressure incubator, RS6000 rheometer (Germany HAAKE company), ISCO pump, FEI Tecnai G2 F20 scanning electron microscope (American Gatan company), core holder, vacuum pump, intermediate container, pipelines.

Experimental water: shown in Table 1; polymer: effective content of 90%; Cr3+ crosslinking agent: effective content of 90%; stabilizer: effective content of 90%; experimental core: artificial core.

(1) First, polymer gel profile control agents with polymer concentrations of 700 mg/L, 1,000 mg/L, 1,500 mg/L, and 2500 mg/L were prepared, respectively. Then, their peak viscosity and gelling time were recorded. The microscopic morphology of the polymer gel profile modifiers under different polymer concentrations after gelation was observed;

(2) Polymer gel profile control agents with polymer concentrations of 700 mg/L, 1,000 mg/L, 1,500 mg/L and 2500 mg/L were prepared respectively. Their viscosity peaks and gelling times after shearing were recorded. After gelation, the microscopic morphology of the polymer gel profile control agent at different polymer concentrations was observed. In addition, the properties of polymer gel profile modifiers subjected to and not subjected to shearing were compared.

(1) Before the experiment, the cores were put into the experimental water to be emptied and saturated until no bubbles overflowed. After the cores were saturated with experimental water, they were transferred to a 45 °C incubator for constant-speed water flooding experiments. The pressure of the water flooding experiment was recorded every 20 min until the displacement pressure no longer changed;

(2) A certain volume of polymer gel profile control agent was injected into the experimental core. At the same time, the pressure change data during the injection of the gel system was recorded. When the injection was completed, the experimental core was placed in a 45 °C incubator for 4 days;

(3) Further, the core is subjected to subsequent water flooding experiments at the same injection rate as in step (1), and the data of displacement pressure changes are recorded until they no longer change;

(4) Calculation of core plugging rate and evaluation of gel plugging performance;

(5) After the completion of the subsequent water flooding experiments, the experimental cores were cut into four equal parts according to 1/4, 2/4, and 3/4. A scanning electron microscope was used to observe the fresh end face after cutting and the retention of the gel. The results are shown in Figure 3.

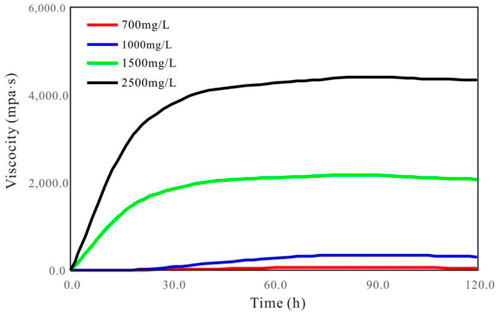

Under the conditions of 700 mg/L, 1,000 mg/L, 1,500 mg/L and 2500 mg/L polymer concentration, the results of the variation law of the viscosity of the polymer gel system with time are shown in Figure 4. It can be seen that with the increase of the polymer concentration, the gel viscosity of the polymer gel profile control agent will increase firstly, and the viscosity will tend to be stable after gelation. When the polymer concentration is lower than 1,500 mg/L, the viscosity of the polymer gel profile modifier will decrease after reaching the peak value.

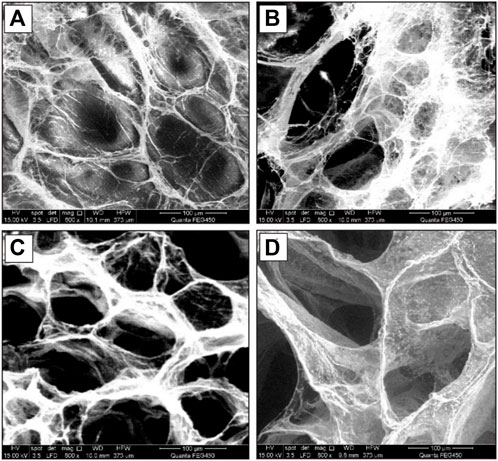

The microscopic morphology observations show that the network structures of the gel profile control agent became denser with the increase of polymer concentration before gelation (Figure 5). In addition, the wall thickness is increased, the voids are reduced, and the overall surface is rough. After gelation, the surface of the colloid was smoother, and its grid structure was clearer (Figure 5).

FIGURE 5. Micromorphology of profilers with different polymer viscosities before and after gelling. (A) 700 mg/L, before, Sample 1; (B) 2500 mg/L, after, Sample 1; (C) 700 mg/L, before, Sample 2; (D) 2500 mg/L, after, Sample 2.

First, the polymer gel systems with concentrations of 700 mg/L, 1,000 mg/L, 1,500 mg/L and 2500 mg/L were injected into cores with gas permeabilities of 3000 mD, 2000 mD and 1,000 mD respectively according to the injection volume of 0.3 PV. They were held at 45°C for 4 d, and then brine was used to carry out flooding experiments. The pressure changes of the cores are recorded, and then the breakthrough pressure and plugging rate are obtained.

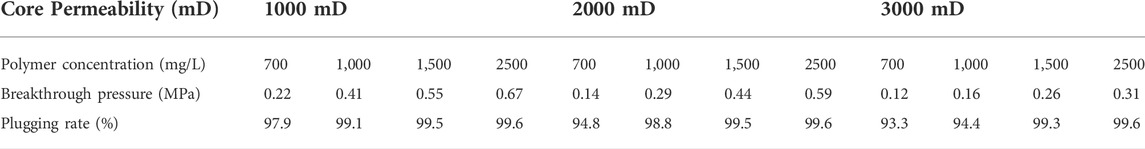

According to the experimental results in Figure 6; Table 4, it can be seen that the core permeability has the greatest influence on the plugging effect. When the permeability is 1,000 mD, the decrease of polymer concentration has little effect on the plugging rate and effective plugging is formed. The second is the effect of polymer concentration on the plugging effect, that is, with the increase of core permeability, only higher polymer concentration can achieve effective plugging of cores.

TABLE 4. In-core breakthrough pressure and plugging coefficient under different polymer concentrations and core permeability.

The microscopic observations in Table 5 are consistent with the macroscopic experimental results. For example, in a core with a permeability of 3000 mD, when the polymer concentration is 700 mg/L, the breakthrough pressure is low, and the pressure difference before and after the breakthrough is small. Observed under the electron microscope, there is a very small amount of gel at the front of the core, so the breakthrough pressure is low. There is no gel at the middle and back ends of the core, so the pressure drops quickly after the breakthrough and the difference is small compared to before the breakthrough.

Combined with the observation results of the microscopic morphology of the polymer gel profile control agents, it can be found that the final determination of the plugging effect is the network structures after the final gelation of the polymer gel profile control agents. The large pores inside the core can be effectively plugged only if the conditions of a tight and smooth network structure, few voids, thick trunks and branches are met.

We performed physical shear simulations of laboratory-formulated polygel profile modifiers. The variation law of solution viscosity before and after shearing is shown in Figure 7. It can be seen that the gel-forming viscosity of the polymer gel profile modifier increases with the increase of the polymer concentration. When the polymer concentration is lower than 1,500 mg/L, the viscosity of the polymer gel profile control agent after gelation first reaches a peak value, and then decreases significantly.

FIGURE 7. Variation of viscosity with time of polymer gel profile control agent system under shearing action.

It was found by scanning electron microscopy that the network structure of the polymer gel profile control agent was destroyed after being subjected to shear stress. When the polymer concentration is lower, the network structure is destroyed at a higher rate (Lu, 2016; Wang et al., 2005; Wang et al., 2016). Furthermore, the structure after gelation is not strong and the polymer gel system cannot effectively seal the formation.

When the polymer gel profile control agent is injected into the reservoir, and if the injection speed is too slow, the volume of the profile control agent injected within a certain period of time will be too small and the reservoir cannot be effectively plugged (Xie et al., 2016). However, if the injection speed is too fast, the shearing effect of the profile control agent during the migration process is relatively large, so that the spatial structures of the profile control agent are destroyed and the plugging performance is reduced.

The effect of different injection rates on the plugging performance of the polymer gel system was systematically analyzed. First, the polymer gel profile control agent was formulated with a concentration of 1,500 mg/L polymer, 0.30% crosslinking agent and 0.03% stabilizer. It was injected into the cores at constant rates of 0.05 ml/min, 0.10 ml/min, 0.150 ml/min, and 0.5 ml/min, respectively. Brine was used for core flooding after 4 days of holding at 45°C. Finally, the pressure change data in the core is used to calculate the breakthrough pressure and the plugging rate.

It can be seen from Figure 8; Table 6 that when the injection rate of the profile control agent is increased to 0.5 ml/min, the injection rate has a great influence on the plugging ability of the profile control agent in the cores. The faster the injection rate, the lower the plugging performance of the profile control agent in the cores.

Combined with the observation results of the microscopic morphology of the polymer gel profile control agent, it can be found that when the injection speed is increased, the shear effect of the polymer gel profile control agent is enhanced. It causes the network structure of the polymer gel profile control agent to be destroyed after gelation, and the plugging strength is significantly affected.

In this study, three plugging state models “absolute plugging”, “plugging-migration” and “absolute migration” were established. These models comprehensively consider the breakthrough pressures of polymer gel profile control agent in the cores, the plugging rates, the microscopic morphology of the gel profile control agents, and the gel display in the cores after displacement.

Based on the experimental results, we propose three criteria for evaluating the compatibility of polymer gel profile control agent and reservoir. A detailed description of the pressure conduction law, the plugging rate range, and the distribution state and morphological characteristics of the gel system under different matching relationships is shown in Table 7.

Finally, the effects of polymer viscosity and core permeability on the plugging effect under different experimental conditions are summarized, and the results are shown in Table 8. This study can provide a guiding reference for similar studies.

(1) In this study, artificial cores were used to carry out indoor water flooding experiments after polymer gel injection, considering formation permeability, polymer concentration and polymer injection rate. Based on the accurate records of the breakthrough pressure and injection volume during water flooding, as well as a large number of observations of the microscopic morphology of the cores after the polymer gel profile control and displacement, a set of criteria for determining reservoir-matched polymer gel profile control agents is proposed.

(2) A complex spatial network structure is formed after the gelation of the polymer gel system. As the polymer concentration increases, the network structure of the gel system becomes denser. At the same time, the unit network structure is becoming smaller, and the order of the grid chain structure becomes clearer. Under the condition of low polymer concentration, the backbone structure of the gel is obvious, but there are a lot of fine pores.

(3) There are three situations for the distribution of polymer gel system in the cores: a. When a small amount of polymer gel system stays in the front surface and pores of the core, the plugging is ineffective; b. When a large amount of polymer gel system stays in the pores and the front and middle parts of the core, some pores can be effectively blocked; c. When a large amount of polymer gel system blocks the front surface of the core, it can effectively block the pores inside the core.

(4) When the polymer concentration is greater than 1,500 mg/L and the injection rate is less than 0.15 ml/min, the water flooding breakthrough pressure is greater than 0.2 MPa, the plugging rate is greater than 95%, and a good plugging effect is obtained.

The original contributions presented in the study are included in the article/supplementary material further inquiries can be directed to the corresponding author.

SY is responsible for the idea and writing of this paper and ZS, QZ, YZ, ZC, and LZ are responsible for the experiments.

Author SY was employed by the Sinopec Huadong Oilfield Service Corporation; Author QZ was employed by the Gepetto Oil Technology Group Co., Ltd; Author YZ was employed by the Oil Production Plant four of PetroChina Changqing Oilfield Company; Authors ZC and LZ were employed by the Great Wall Drilling Corporation, CNPC.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Fan, Y. (2013). Performance evaluation of deep profile control agent, 88–92 [Northeast Petroleum University]. doi:10.3863/j.issn.1674-5086.2013.02.018

Guo, Y., Li, S., Lv, S., Yang, L., and Wang, K. (2007). Synthesis and properties evaluation of pre-crosslinking particles as profile modification agent. Prog. fine Petrochem. industry 21 (10), 78–82. doi:10.3969/j.issn.1009-8348.2007.10.002

Jia, X., Xiong, C., and Zhang, S. (2016). A method for evaluating reservoir adaptability of polymer gel profile control agent. cn103995083b, 8–11.

Li, H., Zhao, H., and Zhao, P. (2006). Study on hydrophobically associating polymer gel profile control agent for high temperature and high salt reservoirs in Zhongyuan. Oilfield Chem. 23 (1), 50–53. doi:10.1016/j.asw.2014.12.001

Liang, W. (2008). Study on preparing artificial cores. Petroleum pipes Instrum. 22 (2), 72–74. doi:10.3969/j.issn.1004-9134.2008.02.023

Liu, C., Wang, Q., Sun, Y., Gao, M., Liu, W., and Wang, Z. (2014a). Research and application of new technology limits for polymer flooding field application. Petroleum Geol. recovery factor 14 (2), 36–40. doi:10.1684/bdc.2014.1970

Liu, J., Chang, C., Yu, J., and Zhao, H. (2014). Comprehensive potential tapping test before tertiary oil recovery for class II and III reservoirs in the east of Block 1 (2), 41–45 [Daqing Petroleum Geology and development]. doi:10.3969/J.ISSN.1000-3754.2014.02.014

Liu, J., Lu, X., and Zhang, Y. (2018). Effect of surfactant and alkali on the gelling effect of cr3+ polyacrylamide gel and its mechanism. J. Petroleum (petroleum Process. 34 (3), 614–622. doi:10.3969/j.issn.1001-8719.2018.03.023

Liu, X. (2019). Evaluating method of the strength and elasticity of the particle profile-controlling agent for strong-alkali ASP flooding. Daqing Petroleum Geol. Dev. 38 (2), 99–104. doi:10.19597/j.issn.1000-3754.201809028

Liu, X., and Shang, H. (2020). Evaluation of dynamic gelling performance of gel profile control agent in deep formation. Daqing Petroleum Geol. Dev. 39 (1), 86–90. doi:10.13840/j.cnki.cn21-1457/tq.2022.07.009

Liu, Z. (2000). Research and application of deep profile control technology in Laojunmiao Oilfield, 22–25 [Southwest Petroleum Institute]. doi:10.1016/S0022-0248(99)00406-6

Lu, Y., and Ho, R. C. M. (2016). An association between neuropeptide Y levels and leukocyte subsets in stress-exacerbated asthmatic mice. Neuropeptides 15 (4), 53–58. doi:10.1016/j.npep.2015.11.091

Nie, C. (2017). Injection pressure variation and prediction of ASP flooding in Daqing Oilfield. Special oil gas reservoirs 12 (1), 77–80. doi:10.3969/j.issn.1006-6535.2017.01.023

Niu, Q., Cai, S., and Hu, X. (2003). Deep profile control and plugging technology for large channel. Drill. Prod. Technol. 26 (1), 30–31. doi:10.1088/1755-1315/252/5/052076

Qing, H., Song, R., Yang, H., Li, S., Jin, Y., and Liu, J. (2017). Influencing factors of EOR after strong alkali ASP flooding. Daqing Petroleum Geol. Dev. 23 (4), 88–92. doi:10.19597/J.ISSN.1000-3754.201609026

Sun, Y., Long, Y., Song, F., and Yu, J. (2016). Evaluation of plugging performance of nano micron polymer particle dispersion system in low permeability reservoir. Petroleum Geol. recovery factor 13 (4), 22–27. doi:10.13673/j.cnki.cn37-1359/te.2016.04.014

Tian, X. (2013). Research and application of ASP flooding depth profile control technology. Drill. Prod. Technol. 12 (1), 33–36. doi:10.3969/J.ISSN.1006-768X.2013.01.18

Wang, J., Zhang, X., Yuan, Y., Liu, J., and Peng, X. (2006). Application performance evaluation of particle profile control agent under high salinity. Prog. fine Petrochem. industry 11 (12), 23–28. doi:10.1016/S1003-9953(10)60145-4

Wang, P., lin, Y., and Luo, J. (2016). Application of flexible steering agent technology in oil field water shutoff and profile control, 101–105 [China Petroleum Society China Petroleum Institute]. doi:10.3969/j.issn.1004-275X.2019.07.069

Wang, Z., Li, Y., Lv, C., and Meng, J. (2005). Performance evaluation of pre-gelled swellable particle profile control agent. Daqing Petroleum Geol. Dev. 12 (6), 77–79. doi:10.3969/j.issn.1000-3754.2005.06.028

Wang, Z., Lu, X., Zhang, J., and Zhang, B. (2016a). Comparison of oil displacement effects of various profile control and displacement agents after strong alkali ASP flooding. J. Xi'an Petroleum Univ. 22 (4), 88–92. doi:10.1016/S1876-3804(19)30011-4

Xie, B., Wang, L., and Lu, Q. (2016). Experiment on influence of oil displacement agent on cementing quality. Daqing Petroleum Geol. Dev. 21 (1), 101–105. doi:10.3969/J.ISSN.1000-3754.2016.01.018

Xu, W., Wei, Z., and Bai, B. (2002). Study on the performance of low temperature weak gel profile control and displacement agent//national rheological academic conference Chinese Chemical Society, 123–127 [Chinese society of mechanics]. doi:10.4028/www.scientific.net/AMM.587-589.1332

Yang, Z., Wang, L., Gao, T., and Song, K. (2017). A new method for optimizing injection slug combination parameters of ASP flooding. Daqing Petroleum Geol. Dev. 13 (3), 44–49. doi:10.3969/J.ISSN.1000-3754.2017.03.021

You, Q., Yu, H., and Wang, Y. (2009). Research progress of deep profile control technology in domestic oilfields. Fault block oil gas field 13 (4), 74–77. doi:10.1088/1755-1315/384/1/012134

Yuan, Y., Wang, J., Huang, Y., and Liu, J. (2006). Development and performance evaluation of composite crosslinked polymer weak gel profile control and flooding agent. Inn. Mong. Petrochem. Ind. Co. Ltd. 23 (2), 43–47. doi:10.13534/j.cnki.32-1601/te.2014.01.007

Zhao, G. (2012). Preparation and performance evaluation of gel dispersion, 44–47 [China University of Petroleum (East China)]. doi:10.19346/j.cnki.1000-4092.2017.02.014

Keywords: polymer gel profile control agent, microscopic morphology, artificial core, pores, plugging rate, compatibility

Citation: Yang S, Shu Z, Zhang Q, Zhao Y, Chen Z and Zhang L (2022) Experimental study on compatibility of reservoir and polymer gel profile control agent. Front. Earth Sci. 10:1029309. doi: 10.3389/feart.2022.1029309

Received: 27 August 2022; Accepted: 13 September 2022;

Published: 30 September 2022.

Edited by:

Wenlong Ding, China University of Geosciences, ChinaReviewed by:

Jishun Pan, North China University of Water Conservancy and Electric Power, ChinaCopyright © 2022 Yang, Shu, Zhang, Zhao, Chen and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Sen Yang, eXNlZHUyN0AxNjMuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.