- Department of Mechanical Engineering, College of Engineering, Imam Mohammad Ibn Saud Islamic University, Riyadh, Saudi Arabia

This study consists of an investigation of the 3D convective flow of hybrid nanofluids (HNFs) within a bi-truncated pyramid equipped with adiabatic cylinders, with a focus on the enhancement of natural convection (NC) heat transfer (HT). The use of HNFs, which is based on the combination of two different nanoparticles (NPs), provides improved thermal conductivity and stability, and leads to significant advantages in thermal management systems. Numerical simulations based of the FEM were performed to analyze the effects of Rayleigh number (Ra), nanoparticle volume fraction (

1 Introduction

With a growing demand for improvements in heat transfer performances, the development of advanced technologies to manage thermal issues more efficiently are one of today’s hottest topics across different engineering and industrial segments. An innovative technique that recently attracted much attention consist of the utilization of HNFs to enhance NC HT. HNFs are formulated via an innovative process in which two different types of NPs are suspended in a base fluid (BF), with the intention to capture substantial heat transfer qualities from each type. For this purpose, a wide variety of applications are found in the literature for natural convection use of hybrid nanofluids. These are used in electronics cooling such as microprocessors or power electronic components, solar thermal systems and building thermal management. Recent works mainly dedicated to the use of HNFs, which is a combination of different nanoparticles, have shown their advantage in the improvement of the convective HT coefficient. Due to their enhanced properties, better stability and optimized thermal performance/cost, the applications of HNFs in convective heat transfer became the interest of several researchers.

Studies related to hybrid nanofluids showed important improvements in thermal conductivity (TC) and HT performance. Omri et al. (2022) presented a study on the performance’s enhancement of a vertical coiled heat exchanger working with CuO-Gp/water HNF. After ultrasonic dispersion (to avoid agglomeration), the authors measured the TC and viscosity of the HNF. It was found that the HT coefficient increased by 23.65% at a 0.2% mass fraction and by up to 79.68% at a 1% mass fraction. In addition, the increase of Reynolds number (Re) caused the augmentation of the HT coefficient. The HT and FF in a wavy cross-flow micro heat exchanger working with HNF have been studied by Ghachem et al. (2021). They considered a 3D configuration and studied the effects of different factors, like the fluid velocity, the waves number, and nanoparticles concentration. The HNF, which combines carbon nanotubes (CNT) and aluminum oxide (Al2O3) nanoparticles, showed significant improvements in both thermal conductivity and heat transfer rates, especially when the flow velocity was high. The researchers discovered that finding the optimal combinations of these parameters could reduce the size of the heat exchanger while boosting its efficiency. Dero et al. (2022) used the bvp4c solver to study the thermal stability of HNFs in a porous media using. The dual branch framework was used to highlight the effects of viscous dissipation and suction/injection effects on the thermal performances and stability of Cu-Al2O3/water hybrid nanofluid. Under certain conditions, dual solutions were found, this behavior indicates the complex nature of the thermal and fluid dynamics.

Natural convection corresponds to fluid motions caused by density variations due to temperature gradients. It occurs in several applications such as cooling electronic devices, solar energy, and in buildings. The conventional HT fluids such as water, ethylene glycol, and lubricants frequently lead to low thermal performances. Single nanofluids, are efficient in the enhancements of thermal conductivity and convective heat transfer, but they have limitations related to particle aggregation and sedimentation. The use of hybrid nanofluids solve these problems, in fact dispersing different nanoparticles in a base fluid allows to benefit from the distinct thermal, chemical, and mechanical characteristics of each nanoparticle type to attain better stability, higher TC, and enhanced specific heat capacity. HNFs exhibit enhanced effective thermal conductivity in comparison to conventional nanofluids, leading to enhanced heat transfer efficiency. Jino et al. (2024) introduced a new technique for cooling electric vehicle batteries. They used hybrid nanofluids in inverted right-angled triangular porous cavities. This study emphasises the significance of thermal management in the enhancement of the performances, safety, and longevity of electric vehicle batteries. The authors analyzed the impact of various parameters (Ra, Da, Ha, and

The use of internal obstacles in cavities filled with hybrid nanofluids corresponds to an effective strategy for the enhancement of the convective HT. When strategically placed, the obstacles cause the disruption of the FF, and create secondary vortices that lead to a more uniform temperature distribution and increased heat transfer rates. Hybrid nanofluids, consist of the combination of the superior thermal properties of different nanoparticles, for the enhancement of the thermal conductivity and the convective heat transfer. This method is highly beneficial for applications such as electronic cooling, solar collectors, and energy-efficient building designs. Some recent studies have examined the impact of the internal obstacles, like heat-generating bodies and fins, on the HT performance in cavities filled with HNF. In the study of Hassen et al. (2022) the thermocapillary and buoyancy-driven convection in a cavity containing a heated obstacle filled with a MWCNT-Fe3O4/oil HNF was numerically studied. The study was based on 2D simulations for the examination of the effects of the obstacle’s position, size, Marangoni number, Ra, and

Based on the above presented literature review it can be concluded that the studies related to 3D natural convection of hybrid nanofluids in complex geometries are very limited. The 3D convective flow in hybrid nanofluid-filled bi-truncated-pyramid cavities equipped with adiabatic cylinders represents a critical advancement in the application of hybrid nanofluids for the enhancement of the thermal management. The aim of this paper is to investigate the complex interactions of natural convection within such geometrically intricate enclosures, taking in account the role of adiabatic cylinders in disrupting the FF and the creation of secondary vortices that cause the augmentation of the heat transfer. This numerical investigation consists of analyzing the effects of varying Rayleigh numbers, nanoparticle volume fractions, and cylinder size on the thermal and fluid dynamic behaviors within the cavity. This approach highlights the enhancements of the thermal properties of the hybrid nanofluids and provides a detailed understanding of the effects of geometric modifications on the optimization of the heat transfer in practical applications.

2 Problem statement and mathematical modeling

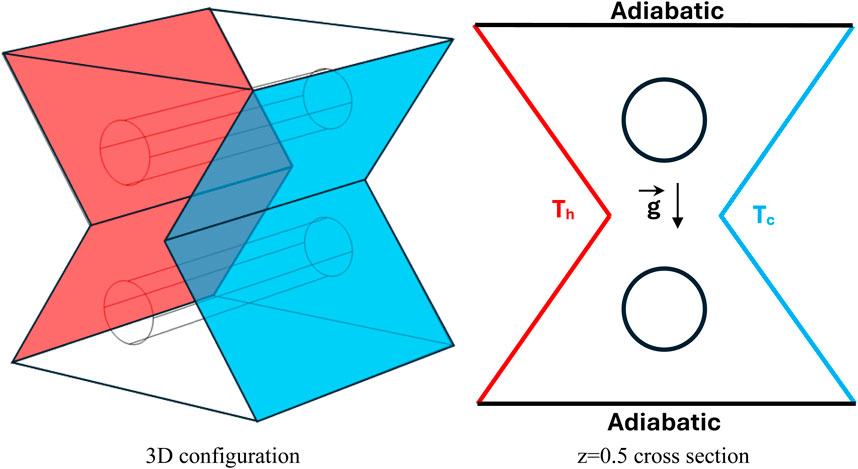

The configuration considered in this investigation (Figure 1) consist of a bi-truncated pyramid filled with a hybrid nanofluid and containing two adiabatic cylindrical obstacles (with a diameter of “D”). The left walls are maintained at a higher temperature (Th) and the right walls are maintained at a lower temperature (Tc). The heat transmission across these boundaries is prevented by the inclusion of the adiabatic cylinders (with a diameter of “D”) and the adiabatic pyramid’s top and bottom walls.

The dimensional PDEs Equations 1–3 governing the 3D NC are as follows (Almeshaal et al., 2020):

Using the following dimensionless variables:

The governing equations are converted to the dimensionless form:

With:

The dimensionless Boundary conditions are:

The local and average Nusselt numbers are Equations 7, 8:

And

The following expressions Equations 9–15 are used to evaluate the thermophysical properties (Almeshaal et al., 2020; Gal et al., 2022):

Density:

Heat capacitance:

Thermal conductivity.

- For CNT-nanofluid:

- For Al2O3-nanofluid:

Dynamic viscosity:

- For CNT-nanofluid:

- For Al2O3-nanofluid:

The properties of HNF are evaluated as follows:

where y is any thermophysical property and

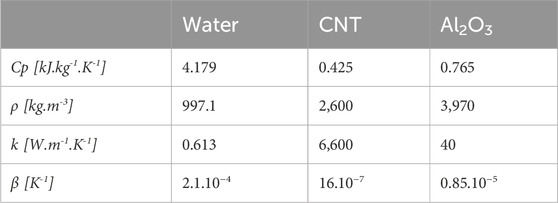

The properties of water and NPs are presented in Table 1.

The FEM, based on the Galerkin’s Weighted Residual technique, is used to solve the set of Equations 4–6 along with the applied boundary conditions.

The Lagrange polynomials are expressed as:

where

2.1 Validation of the numerical model and gris sensitivity analysis

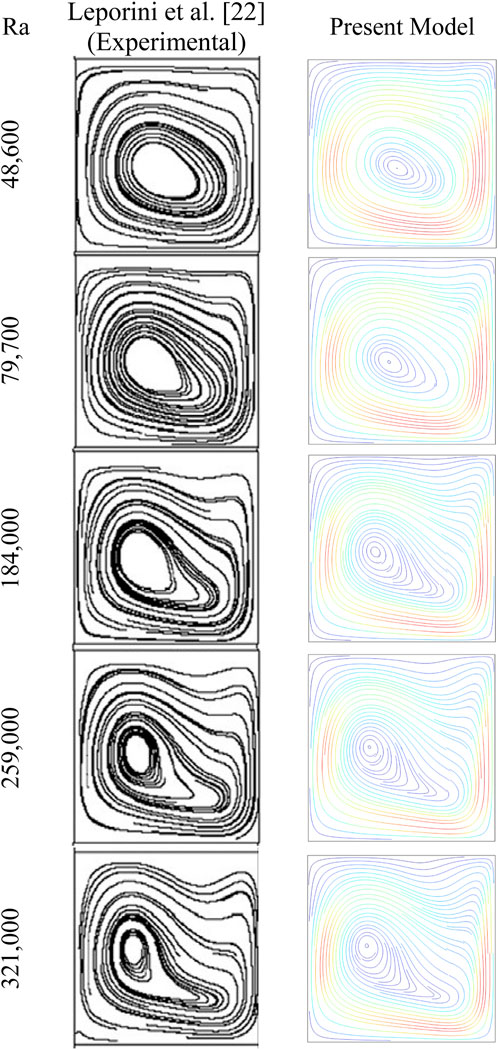

To validate the established numerical model, a qualitative comparison with the experimental results of Leporini et al. (2018) was performed for various Ra values (Figure 2). The work, conducted by Leporini et al. (2018), involved analyzing natural convection in a tilted 3D cavity. The study provided detailed measurements of flow structures and heat transfer rates across a range of Rayleigh numbers. It is clear from the comparison that a good concordance exists between the experimental flow structures provided by Leporini et al. (2018) and those issued from the current numerical model.

Figure 2. Comparison of the flow structures with the experimental results of Leporini et al. (Leporini et al., 2018), for various Ra Values.

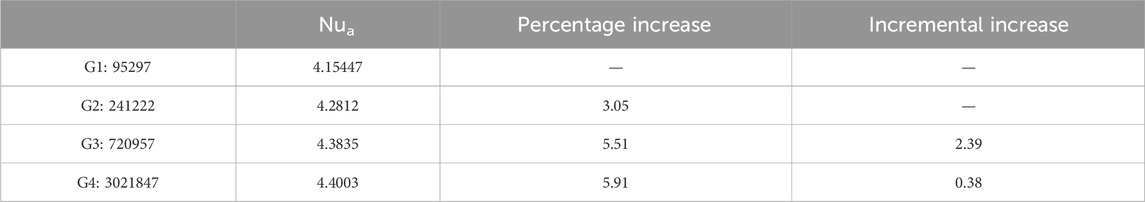

The grid sensitivity analysis is illustrated in Table 2, which illustrates the effect of grid refinement from coarse (G1) to fine (G4) on Nua for Ra = 105, φ = 0.045, and D = 0.1. The calculation becomes more precise as the grid captures more detailed physical phenomena, as evidenced by the increase in Nua as the grid is refined. Percentage and incremental increases are indicative of this. The minimal increase in Nua’s from G3 to G4 indicates that the nearing of grid independence is reached, as further refinement does not substantially alter the obtained results. This is indicative of the potential for G3 to provide a mesh that is sufficient to achieve accurate and stable results without the unnecessary computational cost of further refinement, demonstrating a balance between computational time efficiency and accuracy.

3 Results and discussion

This study aims to explore the enhancement of NC HT using HNF within a bi-truncated pyramid equipped with adiabatic cylinders. The purpose is to understand how varying Ra,

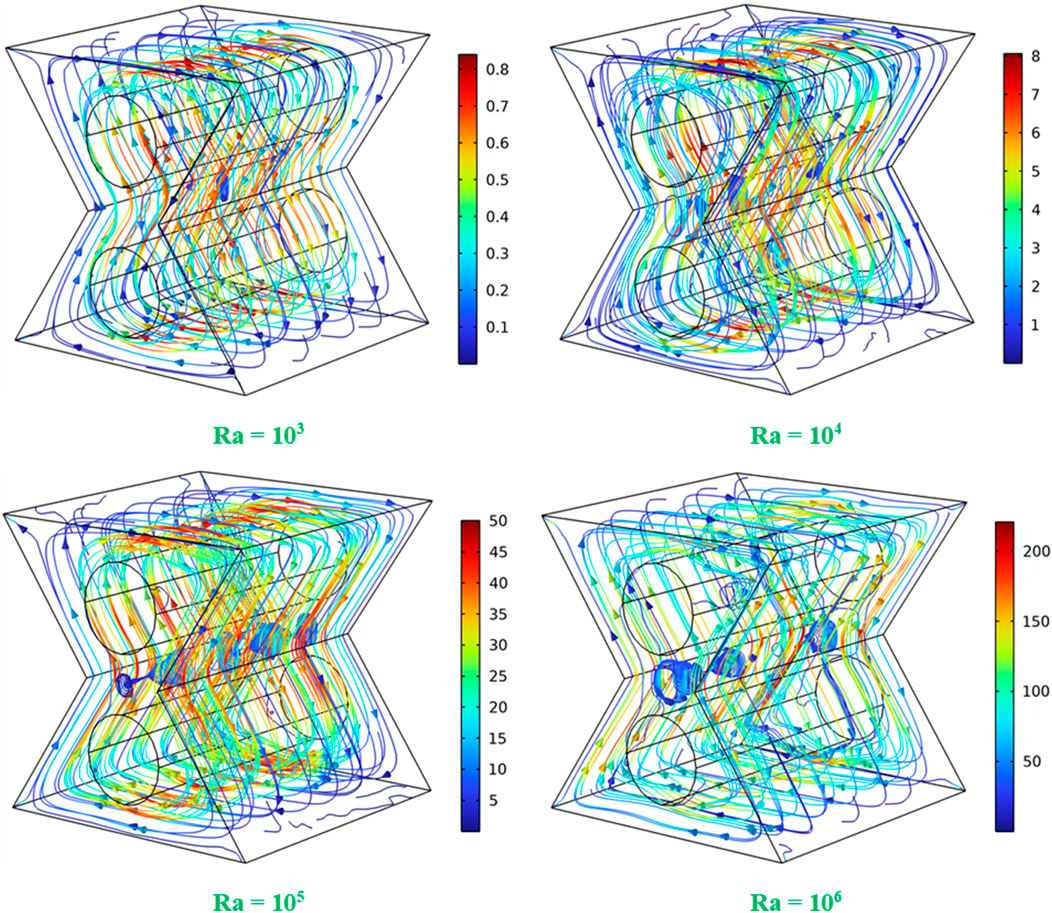

Figure 3 shows the flow patterns of the 3D convective flow in the hybrid nanofluid within the bi-truncated pyramid enclosure equipped with two internal adiabatic cylinders, for various Ra values (103–106). The left walls of the bi-truncated pyramid are hot, and the right walls are cold. This temperature differential is the driving force for the convective flow within the pyramid. As can be remarked from the figure’s legends, higher Ra numbers correspond to higher velocities within the fluid due to the increase of the buoyancy force with Ra. At Ra = 103, the flow is more orderly with lower velocities. As Ra increases, higher velocities and more complex flow patterns, occur with the apparition of secondary flows between the cylinders. The most complex and intense flow structure occurs at Ra = 106, where the highest velocities are reached, and additional secondary flow appear close to the cylinders. The figure illustrates the transition from orderly to complex convective flow as Ra increases from 103 to 106. Initially, at Ra = 103, the HT is domination by conduction mode, and is characterized by smooth and coherent flow structures that indicate less intense convection due to the lower thermal driving force. As Ra increases, the impact of buoyancy forces overcomes the viscous damping and conduction, and the flow becomes more complex, signifying enhanced heat transfer. The presence of the two adiabatic cylinders, adds to the complexity by disrupting the flow, creating additional vortices and flow patterns around them.

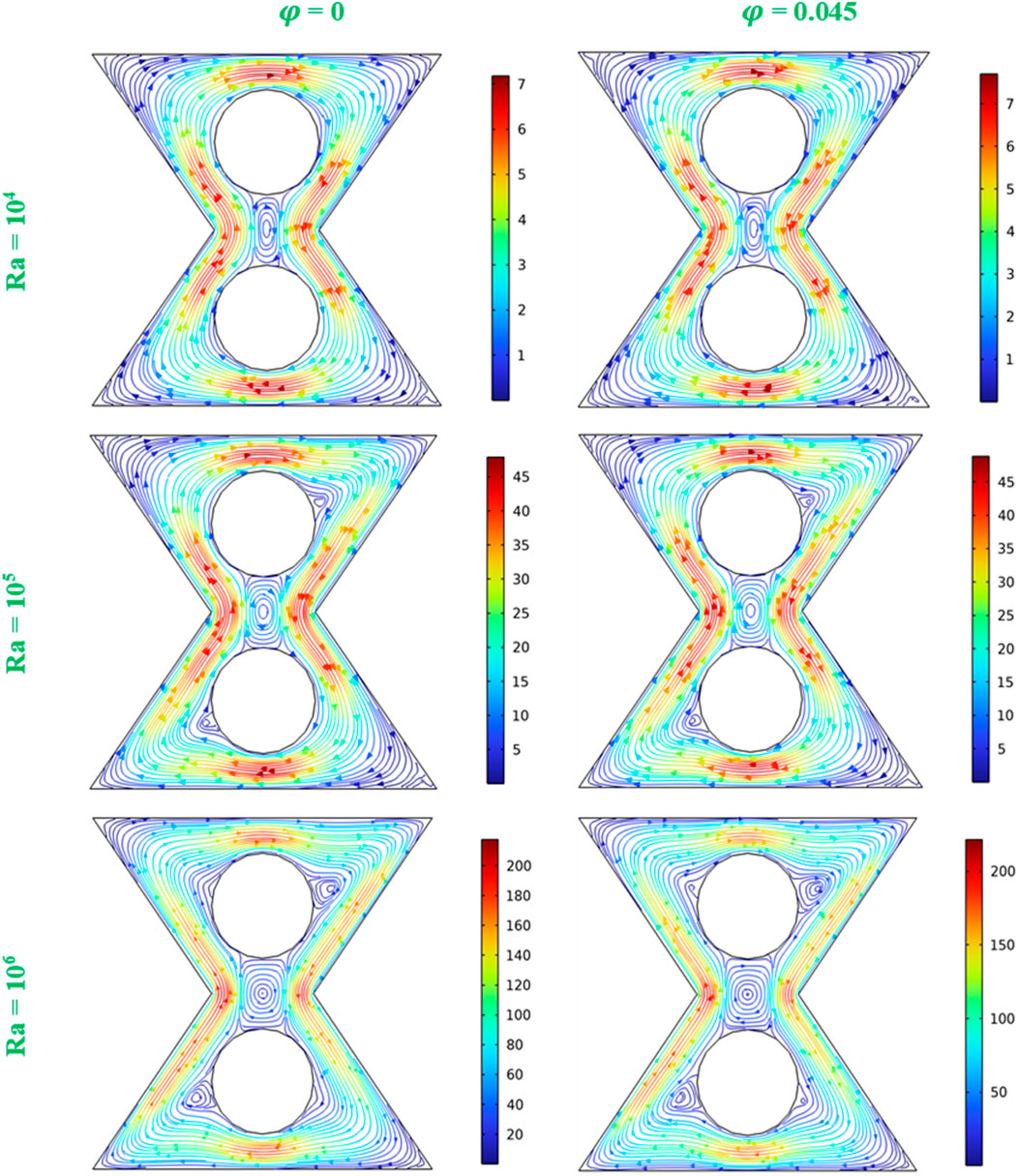

Figure 4 displays the streamlines at the central plane of the bi-truncated pyramid, comparing the flow patterns without nanoparticles (

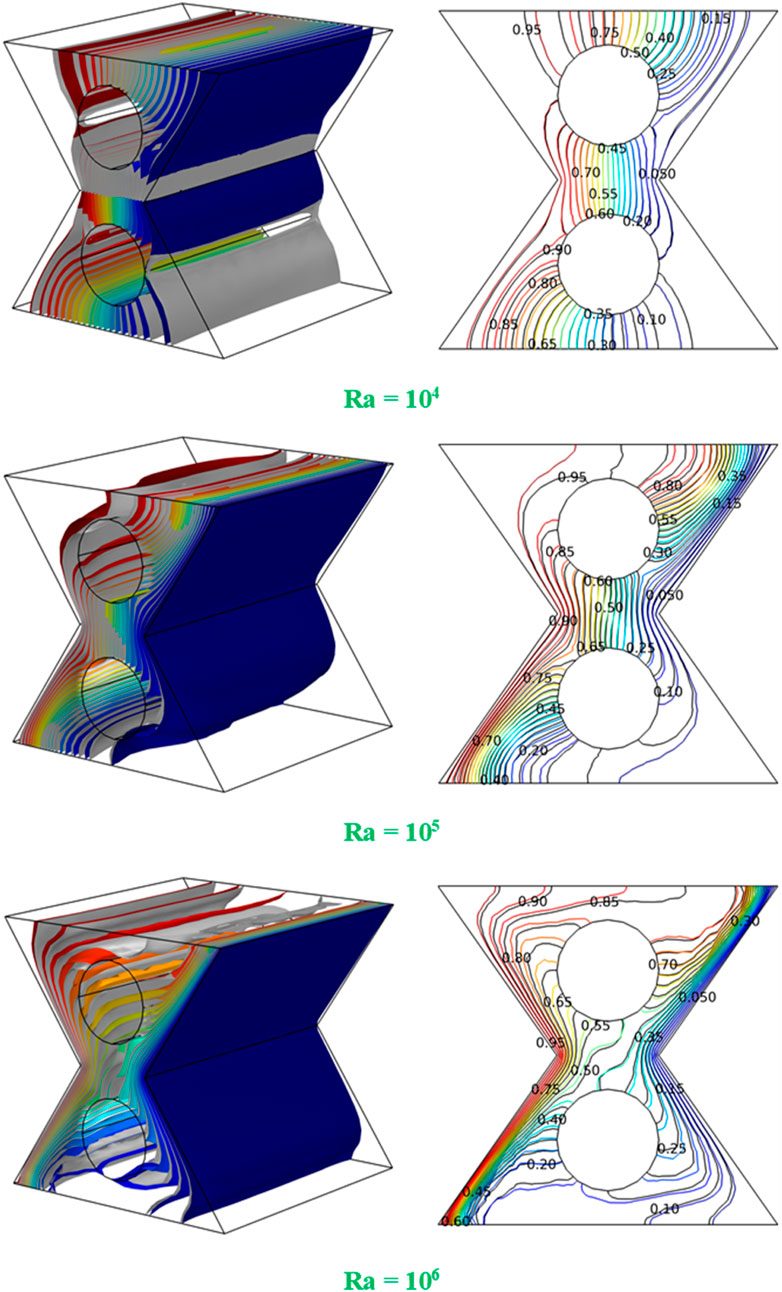

Figure 5 presents the 3D temperature field (left) and isotherms (right) at the central plane of the bi-truncated pyramid equipped with two internal adiabatic cylinders, for various Ra, and with a contrast between the pure fluid (

Figure 5. 3D temperature field (left) and isotherm at the central plan for, D = 0.15 and various Ra; Colored (

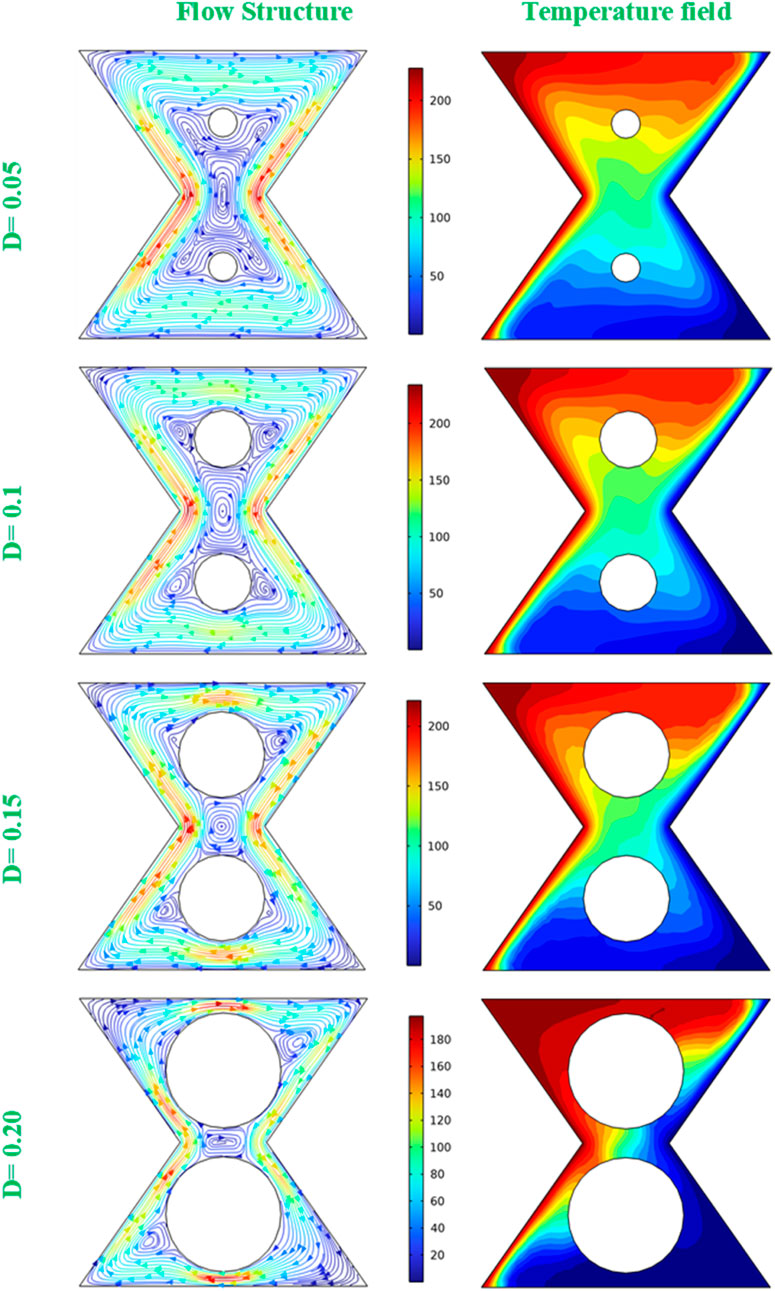

Figure 6 presents the flow structure and temperature field at the central plane of the bi-truncated pyramid at

Figure 6. Flow structure (left) and temperature field (right) at the central plane for Ra = 106,

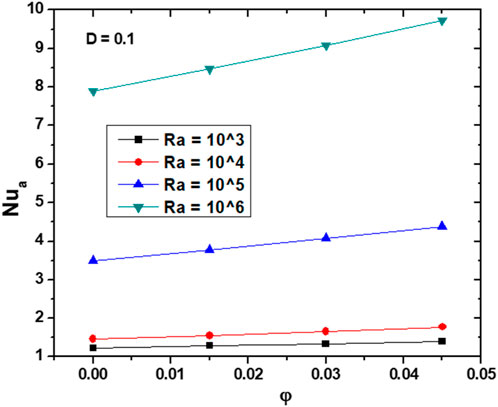

Figure 7illustrates the effect of

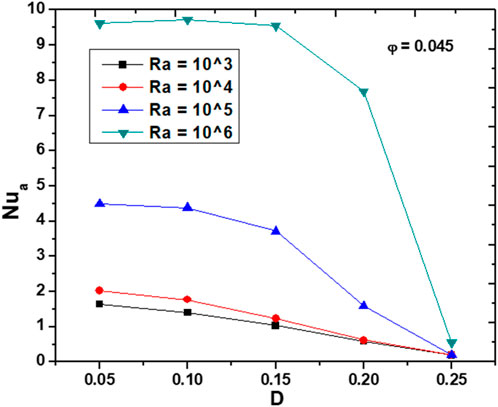

Figure 8 illustrates the impact of increasing the diameter of internal adiabatic obstacles (D) on Nua at

3.1 Regression analysis

The inclusion of regression analysis provides a predictive tool for understanding the influence of key parameters, such as Rayleigh number, nanoparticle volume fraction, and cylinder diameter, on heat transfer performance. Practically, this regression model can be utilized by engineers and designers to optimize thermal systems without the need for extensive simulations. For instance, it can help determine the ideal combination of geometric and fluid properties to maximize heat transfer efficiency. The used polynomial regression extends linear regression by including polynomial terms in the model, which helps capture non-linear relationships between the independent and dependent variables. In our case, we fit a polynomial regression model to better represent the relationship between Nua and the governing parameters D, Ra, and ϕ. The resulting equation is as follows:

With: R2 = 0.97.

The Mean Squared Error (MSE) value is 0.24 for the polynomial regression model indicating that, on average, the squared deviation between the predicted and actual values of Nua is minimal. An MSE of 0.24 indicates that the model accurately captures the relationship between Nua and the governing parameters.

This regression model elucidates the interplay between D, Ra, and

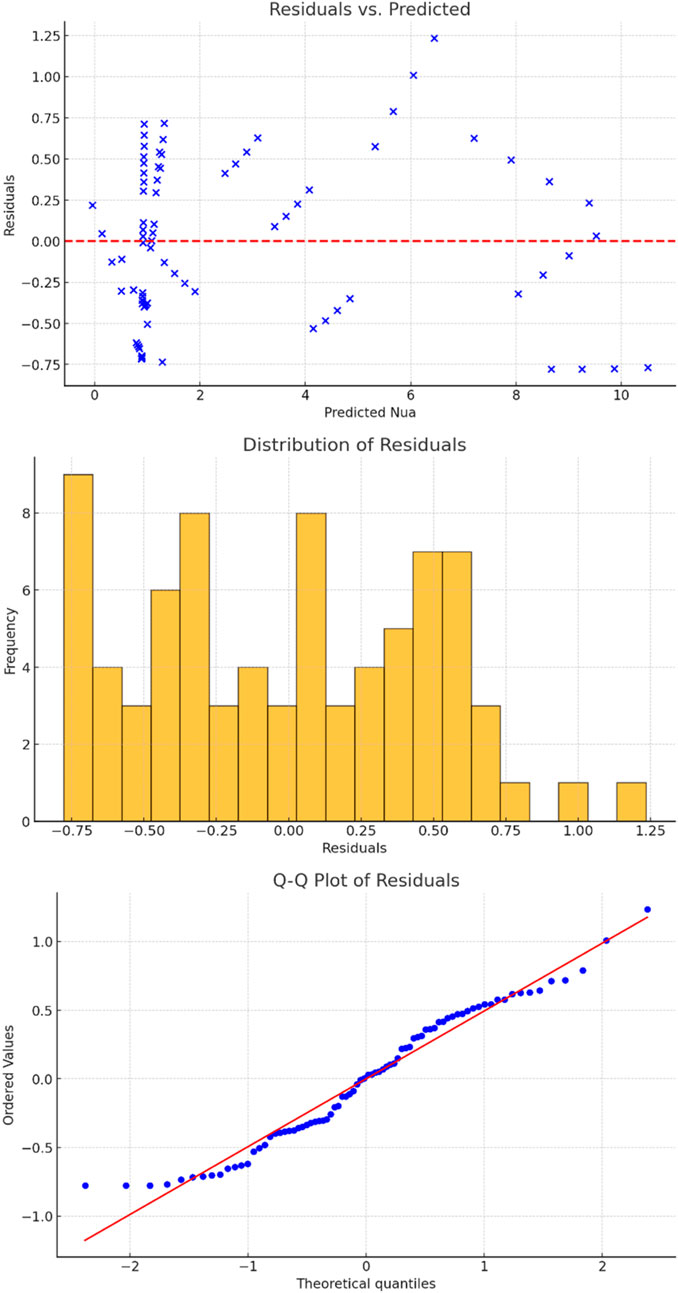

As presented in Figure 9, the residual diagnostics give an idea on the performance of the regression model. The Residuals vs. Predicted plot shows a mostly random scatter of residuals around zero, which indicates that the model does not exhibit strong bias or systematic error. Thus, it can be concluded that the model captures the overall trend in the data effectively, though there may be minor non-linear effects that are not fully accounted for. The Distribution of Residuals (histogram) reveals that the residuals are symmetrically distributed around zero, closely resembling a normal distribution, which is a key assumption of linear regression models. However, there are slight deviations from perfect normality, as evidenced by the Q-Q Plot. While most points lie along the reference line, indicating that the residuals follow a near-normal distribution, there are small deviations at the tails. These deviations may indicate the presence of outliers or slight non-normality, but overall, the model performs well. In summary, the residual analysis suggests that the model fits the data well, with no significant violations of assumptions, though some refinement could be explored for extreme values.

Figure 9. Residuals vs. Predicted, Distribution of Residuals and Q-Q plot for average Nusselt number.

4 Conclusion

The current study investigates the effectiveness of HNFs in enhancing natural convection HT within a bi-truncated pyramid. The simulations demonstrate that increasing Ra and

• The Nusselt number increased by up to 23% at Ra = 106 and

• Optimal heat transfer efficiency was observed at a cylinder diameter of D = 0.15, which provided a balance between flow disturbance and thermal performance.

• Higher Rayleigh numbers contributed to more complex convective patterns, enhancing the overall HT efficiency.

• The presence of adiabatic cylinders created secondary vortices, further intensifying the FF and HT.

• The residual diagnostics of the regression model showed that the established expression of Nua fits well with the original data.

Future research will focus on optimizing heat transfer in 3D geometries by exploring the effects of varying cylinder shapes, positions, and materials, as well as incorporating advanced hybrid nanofluid formulations with enhanced thermophysical properties. Additionally, the integration of external influences such as magnetic fields, vibration effects, or transient thermal boundary conditions.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

MA: Conceptualization, Formal Analysis, Investigation, Methodology, Software, Validation, Writing–original draft, Writing–review and editing.

Funding

The author declares that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author declares that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aich, W., Chaabane, R., Öztop, H., Almeshaal, M. A., Maatki, C., Kahouli, O., et al. (2023). Numerical simulation of buoyancy-induced heat transfer and entropy generation in 3D C-shaped cavity filled with CNT-Al2O3/water hybrid nanofluid. Int. J. Nonlinear Sci. Numer. Simul. 24 (4), 1403–1423. doi:10.1515/ijnsns-2021-0246

Almeshaal, M. A., Kalidasan, K., Askri, F., Velkennedy, R., Alsagri, A. S., and Kolsi, L. (2020). Three-dimensional analysis on natural convection inside a T-shaped cavity with water-based CNT–aluminum oxide hybrid nanofluid. J. Therm. Anal. Calorim. 139 (3), 2089–2098. doi:10.1007/s10973-019-08533-w

Cheng, H., Sajadi, S. M., and Jouzdani, M. Z. (2023). Control of hybrid nanofluid natural convection with entropy generation: a LBM analysis based on the irreversibility of thermodynamic laws. Eng. Anal. Bound Elem. 155, 108–120. doi:10.1016/j.enganabound.2023.05.053

Çiçek, O., Sheremet, M. A., and Baytaş, A. C. (2023). Effect of natural convection hybrid nanofluid flow on the migration and deposition of MWCNT-Fe3O4 in a square enclosure. Int. J. Therm. Sci. 190 (Aug), 108318. doi:10.1016/j.ijthermalsci.2023.108318

Dero, S., Smida, K., Lund, L. A., Ghachem, K., Khan, S. U., Maatki, C., et al. (2022). Thermal stability of hybrid nanofluid with viscous dissipation and suction/injection applications: dual branch framework. J. Indian Chem. Soc. 99 (6), 100506. doi:10.1016/j.jics.2022.100506

Dey, S., and Rathish Kumar, B. V. (2024). Finite element analysis of a thermal non-equilibrium hybrid nanofluid model for natural convection in a complex porous enclosure. Comput. Math. Appl. 169, 177–194. doi:10.1016/j.camwa.2024.06.016

Gal, S., Kolsi, L., Hassen, W., Ben Ali, N., Ben Khedher, N., and Chamkha, A. J. (2022). Three-dimensional study of magnetohydrodynamic natural convection, entropy generation, and electromagnetic variables in a nanofluid filled enclosure equipped with inclined fins. ACS Omega 7 (14), 12365–12373. doi:10.1021/acsomega.2c00923

Ghachem, K., Aich, W., and Kolsi, L. (2021). Computational analysis of hybrid nanofluid enhanced heat transfer in cross flow micro heat exchanger with rectangular wavy channels. Case Stud. Therm. Eng. 24 (Apr), 100822. doi:10.1016/j.csite.2020.100822

Goudarzi, S., Shekaramiz, M., Omidvar, A., Golab, E., Karimipour, A., and Karimipour, A. (2020). Nanoparticles migration due to thermophoresis and Brownian motion and its impact on Ag-MgO/Water hybrid nanofluid natural convection. Powder Technol. 375, 493–503. doi:10.1016/j.powtec.2020.07.115

Hassen, W., Kolsi, L., Rajhi, W., Alshammari, F., Alshammari, N., Ben Khedher, N., et al. (2022). Thermocapillary and buoyancy driven convection analysis for a hybrid nanofluids enclosed in a cavity with heated obstacle. Eur. Phys. J. Special Top. 231 (13–14), 2669–2681. doi:10.1140/epjs/s11734-022-00598-3

Hidki, R., El Moutaouakil, L., Boukendil, M., Charqui, Z., Zrikem, Z., and Abdelbaki, A. (2023). “Impact of Cu,Al2O3-water hybrid nanofluid on natural convection inside a square cavity with two heat-generating bodies,” in Materials today: proceedings (Elsevier Ltd), 3749–3756.

Iftikhar, B., Javed, T., and Siddiqui, M. A. (2023). Natural convective flow of non-isothermal hybrid nanofluid inside the cavity with the influence of a heated fin and non-linear thermal radiation: second law analysis. Mater Today Commun. 34 (Mar), 105341. doi:10.1016/j.mtcomm.2023.105341

Islam, M. S., Islam, S., and Siddiki, M. N. A. A. (2023). Numerical simulation with sensitivity analysis of MHD natural convection using Cu-TiO2-H2O hybrid nanofluids. Int. J. Thermofluids 20 (Nov), 100509. doi:10.1016/j.ijft.2023.100509

Jino, L., Kumar, A. V., Doley, S., Berlin, M., Jacob, A., and Natarajan, N. (2024). Revolutionizing EV battery cooling: innovative hybrid nanofluid solution in an inverted right-angled triangular porous cavities for enhanced thermal regulation via natural convection. J. Energy Storage 94 (Jul), 112470. doi:10.1016/j.est.2024.112470

Khan, M. S., Ahmad, S., Shah, Z., Vrinceanu, N., and Alshehri, M. H. (2024). Natural convection heat transfer of a hybrid nanofluid in a permeable quadrantal enclosure with heat generation. Case Stud. Therm. Eng. 56 (Apr), 104207. doi:10.1016/j.csite.2024.104207

Khan, N. H., Paswan, M. K., and Hassan, M. A. (2022a). Natural convection of hybrid nanofluid heat transport and entropy generation in cavity by using Lattice Boltzmann Method. J. Indian Chem. Soc. 99 (3), 100344. doi:10.1016/j.jics.2022.100344

Khan, S. A., Siddiqui, M. A., Khan, Z. A., Asjad, M., and Husain, S. (2022b). Numerical investigation and implementation of the Taguchi based entropy-ROV method for optimization of the operating and geometrical parameters during natural convection of hybrid nanofluid in annuli. Int. J. Therm. Sci. 172 (Feb), 107317. doi:10.1016/j.ijthermalsci.2021.107317

Leporini, M., Corvaro, F., Marchetti, B., Polonara, F., and Benucci, M. (2018). Experimental and numerical investigation of natural convection in tilted square cavity filled with air. Exp. Therm. Fluid Sci. 99, 572–583. doi:10.1016/j.expthermflusci.2018.08.023

Mokaddes Ali, M., Akhter, R., and Alim, M. A. (2021). Hydromagnetic natural convection in a wavy-walled enclosure equipped with hybrid nanofluid and heat generating cylinder. Alexandria Eng. J. 60 (6), 5245–5264. doi:10.1016/j.aej.2021.04.059

Nayak, M. K., Karimi, N., Chamkha, A. J., Sattar Dogonchi, A., El-Sapa, S., and Galal, A. M. (2022). Efficacy of diverse structures of wavy baffles on heat transfer amplification of double-diffusive natural convection inside a C-shaped enclosure filled with hybrid nanofluid. Sustain. Energy Technol. Assessments 52 (Aug), 102180. doi:10.1016/j.seta.2022.102180

Omri, M., Aich, W., Rmili, H., and Kolsi, L. (2022). Experimental analysis of the thermal performance enhancement of a vertical helical coil heat exchanger using copper oxide-graphene (80-20%) hybrid nanofluid. Appl. Sci. Switz. 12 (22), 11614. doi:10.3390/app122211614

Keywords: 3D natural convection, hybrid nanofluid, bi-truncated-pyramid, regression analysis, FEM

Citation: Almeshaal MA (2025) 3D convective flow in a hybrid nanofluid filled bi-truncated-pyramid equipped with adiabatic cylinders. Front. Chem. 12:1522372. doi: 10.3389/fchem.2024.1522372

Received: 04 November 2024; Accepted: 04 December 2024;

Published: 22 January 2025.

Edited by:

Younes Menni, University Center Salhi Ahmed Naama, AlgeriaReviewed by:

Naveed Khan, City University of Science and Information Technology, PakistanNoureddine Kaid, University Center Salhi Ahmed Naama, Algeria

Aboulbaba Eladeb, Northern Border University, Saudi Arabia

Copyright © 2025 Almeshaal. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mohammed A. Almeshaal, bWFhbG1lc2hhYWxAaW1hbXUuZWR1LnNh

Mohammed A. Almeshaal

Mohammed A. Almeshaal