94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Chem., 28 May 2024

Sec. Inorganic Chemistry

Volume 12 - 2024 | https://doi.org/10.3389/fchem.2024.1400375

This article is part of the Research TopicInorganic Chemistry, Polymer Chemistry, and Solid State Chemistry Editor's Pick 2024View all 14 articles

The article discusses the promising synergy between MXenes and polymers in developing advanced nanocomposites with diverse applications in biomedicine domains. MXenes, possessing exceptional properties, are integrated into polymer matrices through various synthesis and fabrication methods. These nanocomposites find applications in drug delivery, imaging, diagnostics, and environmental remediation. They offer improved therapeutic efficacy and reduced side effects in drug delivery, enhanced sensitivity and specificity in imaging and diagnostics, and effectiveness in water purification and pollutant removal. The perspective also addresses challenges like biocompatibility and toxicity, while suggesting future research directions. In totality, it highlights the transformative potential of MXenes-polymer nanocomposites in addressing critical issues across various fields.

MXenes are a family of two-dimensional (2D) transition metal carbides, nitrides, or carbonitrides that exhibit a unique combination of properties, making them highly versatile materials (Naguib et al., 2014). MXenes are derived from layered ternary carbide, nitride, or carbonitride precursors known as MAX phases. The structure involves selective etching (Ghidiu et al., 2014) of the “A” element layers (typically aluminum) from the MAX phase, leaving behind a 2D layered structure. The general formula for MXenes is Mn+1XnTx, where M represents a transition metal (e.g., titanium, tantalum, or niobium), X is carbon and/or nitrogen, T represents surface terminations (such as hydroxyl or fluorine), and n is the number of metal layers (Halim et al., 2014). Without the hydroxyl or oxygen termination, they are hydrophilic (Harris et al., 2015; Halim, Cook, et al., 2016). MXenes typically exhibit metallic conductivity, making them suitable for applications in electronics, sensors (Guo et al., 2019), and energy storage devices (Simon and Gogotsi, 2008; Meng et al., 2014; Kurra, Hota, and Alshareef, 2015). The presence of transition metal layers contributes to their excellent electronic conductivity. MXenes possess impressive mechanical properties, including high stiffness and strength, making them suitable for applications where mechanical integrity is crucial (Ling et al., 2014). MXenes are chemically stable in various environments, showing feasibility for oxidation and resistance to corrosion. MXenes and their oxides are promising topological materials that are experimentally and computationally studied (Parajuli and Samatha, 2022; 2019; Parajuli, Kaphle, and Samatha, 2019; Parajuli and Samatha, 2022; Parajuli, Uppugalla, et al., 2023) (S. Huang and Mochalin, 2019)(S. Huang and Mochalin, 2019). This stability contributes to their applicability in a wide range of conditions. The surface of MXenes is rich in functional groups, such as hydroxyl (OH-) and/or fluorine (F-) terminations, providing reactive sites for further functionalization. Surface functionalization enhances their compatibility with other materials and expands their application range (Harris et al., 2015; Halim, Cook, et al., 2016). MXenes typically have a high specific surface area due to their layered structure, which is advantageous for applications such as energy storage, catalysis, and sensing. MXenes exhibit interesting optical properties, including strong light absorption, which can be exploited in various optoelectronic and sensing applications. Their incorporation for energy storage were found more efficient that those we studied earlier (Parajuli, Murali, Samatha, and Veeraiah, 2022; Parajuli, Taddesse, Murali, Veeraiah, et al., 2022). MXenes demonstrate good thermal conductivity, making them promising candidates for applications in thermal management and electronic devices (Forrest, 2004; Y; Shi et al., 2015; Reese et al., 2004). The unique combination of electronic, mechanical, chemical, and optical properties makes MXenes a promising class of materials with diverse applications in fields ranging from electronics and energy storage to catalysis and biomedicine (Z. Liu et al., 2018; C; Dai, Chen, et al., 2017; Lin et al., 2018; X; Han et al., 2018) (C. Dai, Lin, et al., 2017).

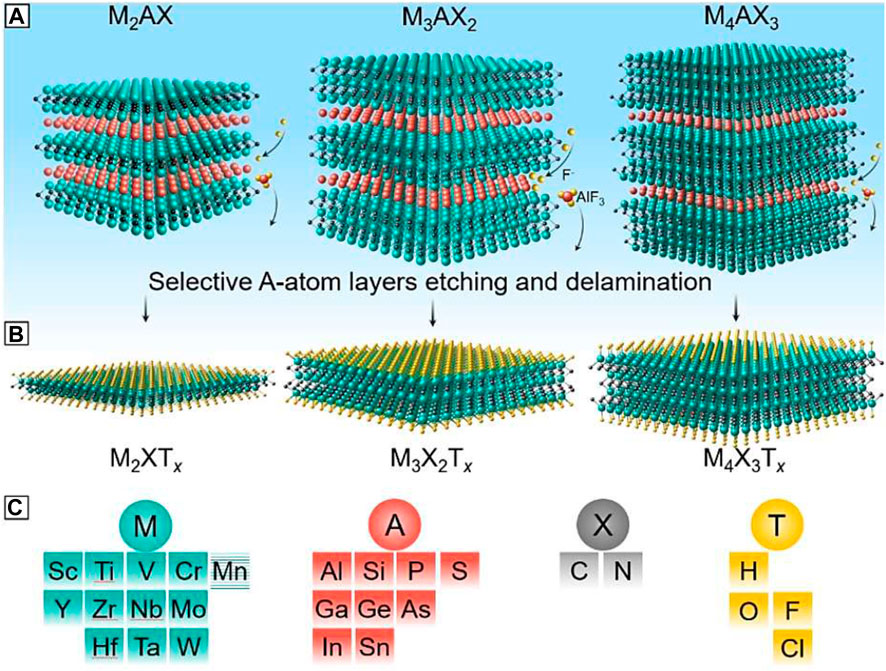

The different types of MXenes derived from their precursors through their selective etching processes are shown in Figure 1A, it showcases three categories of mono-M MAX phases: M2AX, M3AX2, and M4AX3, along with the selective etching procedure targeting the A-group layers (depicted by red atoms). In Figure 1B, it follows the selective etching process, MXenes emerge, characterized by the formation of surface terminations (depicted by yellow atoms) denoted as T. Figure 1C presents the potential elements for M, A, X, and T in both MAX and MXene phases. Additionally, although MXenes with orders as high as M5X4 have been successfully synthesized, they are not included in this table. It’s noteworthy that while Mn occupies the M sites in MAX phases, MXenes containing Mn have not been synthesized to date, indicated by the horizontally patterned background of Mn.

Figure 1. Different types of MXenes with different compositions with their precursor MAX phases. (A) MAX phases, (B) terminated MXenes after etching of MAX phases and (C) representation of M, A, X, and T. Adapted with the permission of (Hong et al., 2020)©Springer Nature 2020.

MXenes in addition to their exhibiting excellent electrical conductivity, mechanical strength, and chemical stability, often lack certain properties required for specific applications (Bilibana, 2023). By incorporating MXenes into different matrices such as polymers, ceramics, or metals, it can be exploited synergistic effects to achieve desired functionalities. For instance, MXene nanocomposites can offer improved mechanical strength, electrical conductivity, thermal stability, and even functionalities like electromagnetic interference shielding or energy storage (Gao et al., 2020). These nanocomposites find applications across various fields including energy storage devices like batteries and supercapacitors, electromagnetic shielding materials, sensors, catalysis, and biomedical devices. The versatility and tunability of MXene nanocomposites make them highly desirable for addressing specific needs in diverse technological domains (Perera et al., 2023). MXenes exhibit chemical stability, resisting oxidation and corrosion, contributing to the durability of nanocomposites in various environments (W. Wu et al., 2019a; M; Zhu et al., 2016b). MXenes can be synthesized with different transition metals, providing versatility in tailoring their properties for specific nanocomposite applications (Naguib et al., 2016).

In nanocomposite applications, MXenes are often combined with polymers, ceramics, or other materials to create hybrid materials with enhanced or multifunctional properties. The combination of these MXene properties allows for the development of advanced nanocomposites with diverse applications across various fields.

MXene nanocomposites, combining the unique properties of MXenes with the versatility of polymers, offer enhanced mechanical, thermal, and electrical properties. These materials hold promise in applications such as flexible electronics and energy storage. Understanding fabrication techniques and interface engineering is crucial for tailoring MXene-polymer nanocomposites to specific needs. The MXene, Polymer, and their classification and nanocomposites are described briefly below.

MXenes possess a distinctive set of properties that make them highly suitable for nanocomposite applications, particularly in the fields of biomedical science. MXenes have a unique 2D layered structure, providing a large surface area for interactions within nanocomposites. MXenes exhibit excellent electrical conductivity (Wang et al., 2019), making them advantageous for applications in electronics, sensors (Guo et al., 2019), and energy storage devices (George and Kandasubramanian, 2020). MXenes demonstrate impressive mechanical strength and stiffness, contributing to enhanced mechanical properties when incorporated into nanocomposites (Jimmy and Kandasubramanian, 2020). The surface of MXenes is rich in functional groups, such as hydroxyl and/or fluorine terminations, enabling easy surface modification and compatibility with other materials (Chen et al., 2020). MXenes typically possess a high specific surface area due to their layered structure, facilitating improved adsorption and reactivity in nanocomposite applications (Oyedotun et al., 2009). MXenes exhibit good thermal conductivity, making them suitable for applications in thermal management and devices requiring efficient heat dissipation. MXenes often demonstrate biocompatibility, a crucial property for their integration into nanocomposites for biomedical applications, such as drug delivery systems and medical implants. Some MXenes, like titanium carbide (Ti3C2Tx), possess excellent photothermal properties, making them useful in nanocomposites for applications like cancer therapy (Z. Liu et al., 2018; C; Dai, Chen, et al., 2017; Lin et al., 2018; X; Han et al., 2018; C; Dai, Lin, et al., 2017). MXenes are available in various compositions (carbides, nitrides, or carbonitrides), allowing for versatility in tailoring nanocomposites for specific applications. MXenes display interesting optical properties, including strong light absorption, which can be harnessed for applications in sensing and optoelectronics (McKeen, 2017).

MXenes can be classified based on several different criteria, including composition, synthesis method, structural properties, and applications. The classification of MXenes based on various factors is listed in Table 1.

This classification scheme highlights the diverse nature of MXenes and their potential across multiple fields, from energy storage and electronics to catalysis, sensing, and biomedical applications depending also on the transitional metals.

Polymers are large molecules composed of repeating structural units called monomers. These molecules are characterized by their long chains and versatile properties, making them essential in various industries and everyday products (Painter and Coleman, 2019). They can be natural, such as proteins and DNA, or synthetic, like plastics and rubbers. Synthetic polymers are typically created through polymerization processes, where monomers are chemically bonded together to form long chains or networks (McCrum, Buckley, and Bucknall, 1997). This process allows for the manipulation of properties like strength, flexibility, and durability, making polymers highly customizable for specific applications. Polymers play a vital role in modern society, being used in countless products ranging from packaging materials and textiles to medical devices and electronics. Their versatility, affordability, and ease of manufacturing have led to their widespread adoption across industries, driving innovation and technological advancement. However, concerns about environmental impact and sustainability have prompted efforts to develop biodegradable and eco-friendly alternatives to traditional polymers, reflecting the ongoing evolution of polymer science and engineering (Young and Lovell, 2008).

Polymers can be classified into several types based on their structure, origin, properties and applications. Some common types of polymers are listed in Table 2 (Young and Lovell, 2008).

MXene nanocomposites are a class of materials that have garnered significant attention due to their unique properties and potential applications. (Parajuli et al., 2022). MXene nanocomposites are formed by incorporating MXene nanosheets into a matrix material, such as polymers, ceramics, or metals, to enhance or impart specific properties. The addition of MXenes can improve mechanical strength, electrical conductivity, and thermal stability of the composite material. Research in MXene nanocomposites has demonstrated their potential in various fields (Aghamohammadi, Amousa, and Eslami-Farsani, 2021). For instance, MXene/polymer nanocomposites have shown promise in flexible electronics and sensors due to their excellent electrical conductivity and mechanical flexibility. In energy storage applications, MXene-based nanocomposites have been explored for supercapacitors and batteries, where they offer high specific capacitance and stability. One example of a study in MXene nanocomposites is the work by Liu et al. (2021), where they developed MXene/polymer nanocomposites for electromagnetic interference shielding applications. The study demonstrated that the incorporation of MXene nanosheets into the polymer matrix significantly enhanced the electromagnetic interference shielding effectiveness of the composite material (Zhang and Gu, 2022).

Polymer nanocomposites are a class of materials composed of a polymer matrix reinforced with nanoscale fillers or additives. These nanofillers typically have at least one dimension in the nanometer range, providing unique properties and enhanced performance compared to traditional composite materials (Koo, 2019). The incorporation of nanofillers into polymers can result in significant improvements in mechanical, thermal, electrical, and barrier properties (Pinto et al., 2023). Common types of nanofillers used in polymer nanocomposites include nanoparticles such as metal oxides (e.g., silica, alumina), carbon-based materials (e.g., carbon nanotubes, graphene), and clay minerals (e.g., montmorillonite).

Polymer nanocomposites offer numerous advantages over conventional composites, including:

• Enhanced mechanical properties such as increased stiffness, strength, and toughness.

• Improved thermal stability and flame retardancy due to the barrier effect of nanofillers.

• Enhanced electrical conductivity or dielectric properties, making them suitable for electronic and electrical applications.

• Increased gas barrier properties, making them ideal for packaging materials.

• Reduced weight and improved fuel efficiency in transportation applications.

The fabrication of polymer nanocomposites involves various techniques such as melt blending, solution mixing, in situ polymerization, and electrospinning. The selection of nanofillers, their dispersion within the polymer matrix, and the processing conditions play crucial roles in determining the properties and performance of the nanocomposite material. Polymer nanocomposites find applications in diverse industries, including automotive, aerospace, electronics, packaging, biomedical, and energy storage. Ongoing research in this field aims to further optimize the properties of nanocomposites and explore novel applications, paving the way for the development of advanced materials with tailored properties and multifunctionality.

By integrating MXenes, renowned for their exceptional conductivity and mechanical properties, into polymer matrices, the resulting nanocomposites exhibit enhanced functionalities such as improved electrical conductivity, mechanical strength, and thermal stability (Gong et al., 2021). These tailored properties make MXene polymer nanocomposites highly promising for a wide array of applications, including flexible electronics, energy storage devices like batteries and supercapacitors, electromagnetic interference shielding materials, and even biomedical applications (Bilibana, 2023). Moreover, the versatility of polymers allows for easy processing and shaping, further expanding the potential applications and manufacturability of MXene polymer nanocomposites. The synthesis of MXene polymer nanocomposites represents a synergistic approach to harnessing the strengths of both materials, paving the way for advancements in numerous fields (Riazi et al., 2021).

From few years back, we have studied the MXenes and Ferrites (Parajuli, Raghavendra, et al., 2021; Parajuli, Murali, Rao, Ramakrishna, et al., 2022; Parajuli, Taddesse, Murali, and Samatha 2022; Parajuli, Murali, Raghavendra, et al., 2023; Parajuli, Murali, Samatha, et al., 2023) separately and their mixtures with the most exploited material in the society polymer in the form of their nanocomposites (Parajuli et al., 2022; Parajuli, Uppugalla, et al., 2023). We found them most efficient combination among the recently developed other nanocomposites which are far efficient than their pristine form.

Nanocomposites represent a cutting-edge technology with transformative potential in biomedical fields. Their ability to address specific challenges and provide tailored solutions underscores their significance in advancing healthcare and promoting environmental sustainability. The need for advanced materials like MXenes-polymer nanocomposites stems from their exceptional properties, versatility, and potential to address challenges in diverse applications, ranging from healthcare protection to energy storage and beyond. Their unique combination of attributes positions them as key players in advancing technological solutions for the future. In this article, the synthesis of MXene Polymer nanocomposites, their biomedical and environmental aspects along with the issues, challenges, and perspectives are discussed. MXenes properties for nanocomposite applications.

The compatibility of MXene with polymers is a crucial aspect in the formation of nanocomposites, determining the effectiveness and performance of the resulting hybrid materials (X. Chen et al., 2020). The compatibilities of MXene with polymers for nanocomposite formation are:

MXenes possess surface functional groups, such as hydroxyl (-OH) or fluorine (-F), which enhance their compatibility with polymers. These functional groups provide active sites for bonding and interactions with polymer chains.

The surface chemistry of MXene allows for strong interactions with various polymers. The presence of transition metal terminations and surface functional groups promotes chemical compatibility, ensuring a stable interface between MXene and polymer components.

The charged nature of MXene surfaces facilitates electrostatic interactions with polymers, especially those with opposite charges. This can contribute to improved dispersion and stability of MXene within the polymer matrix.

The mechanical strength of MXene, coupled with its compatibility with polymer matrices, results in nanocomposites with enhanced mechanical properties. This is particularly beneficial in applications requiring increased strength and durability.

The combination of MXene and polymers often leads to synergistic effects, where the unique properties of each component complement and enhance the overall performance of the nanocomposite. This synergy can result in improved conductivity, mechanical strength, or other desired characteristics.

MXenes can be compatible with a wide range of polymers, including but not limited to, thermoplastics, thermosets, and elastomers. This versatility allows for the tailoring of nanocomposite properties to suit specific applications.

MXene’s compatibility with polymers facilitates the processing and fabrication of nanocomposites. Techniques such as solution mixing, melt blending, or in situ polymerization can be employed to achieve homogeneous dispersion and integration.

MXenes can be engineered to be biocompatible, making them suitable for integration into biopolymer matrices. This opens up opportunities for applications in biomedical nanocomposites, such as drug delivery systems and tissue engineering (K. Chen et al., 2017).

The compatibility of MXene with polymers is a critical factor in the successful formation of nanocomposites. The chemical affinity, surface functional groups, and synergistic effects contribute to creating hybrid materials with tailored properties, expanding the range of applications in various fields.

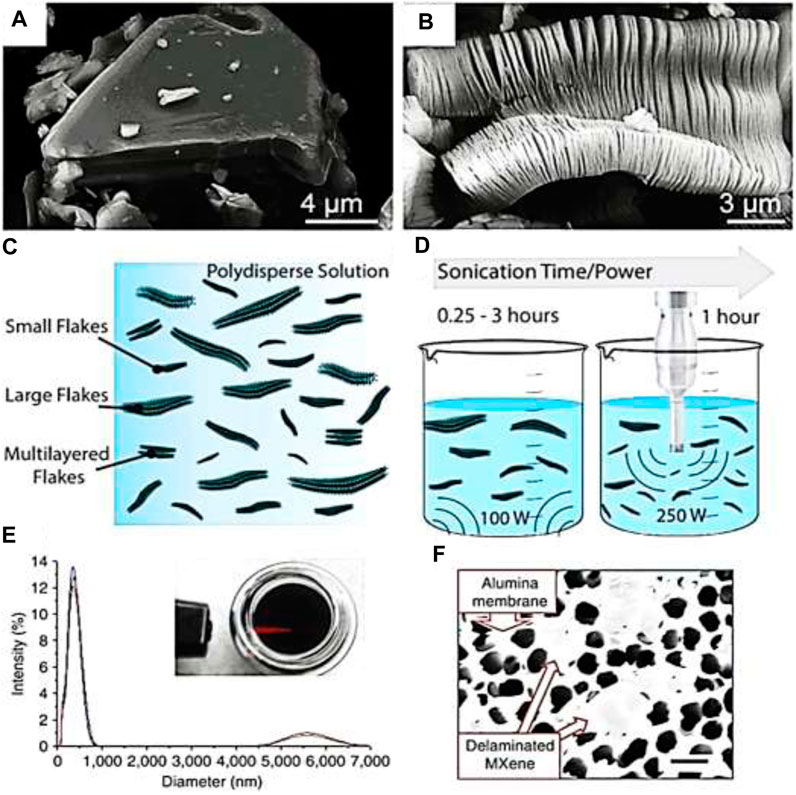

Synthesizing MXene-polymer nanocomposites involves various techniques, each with its advantages, limitations, and recent advancements. In most cases, the MXenes are synthesized from etching processes. The layered structures in colloidal solution form obtained from etching can be sonicated and delaminated to get a few layered MXenes (Carey and Barsoum, 2021) as shown in Figure 3. Their synthesis involves integrating MXene nanosheets into a polymer matrix to create materials with enhanced properties. The detail of the synthesis of MXene-Polymer nanocomposites is found in our recently published articles (Parajuli et al., 2022; Parajuli, Uppugalla, et al., 2023).

Figure 3. (A) Scanning electron microscopy (SEM) depiction of Ti3AlC2 particle (B) Formation of Ti3C2Tz after etching in hydrofluoric acid (HF). (C) Diagrammatic representation illustrating MXene suspension exhibiting various flake sizes. (D) Representation demonstrating the impact of sonication on dimensions of MXene flakes, with increasing sonication time and power. (E) Light scattering analysis of a typical colloidal MXene suspension post-sonication, accompanied by an inset image demonstrating the Tyndall effect. (F) SEM micrograph displaying drop-cast colloidal MXene on a porous alumina substrate, showcasing transparent delaminated MXene sheets. (A, B) are reproduced from Naguib et al., 2012. (C, D) are reproduced from Maleski et al., 2018. (E, F) are reproduced from Mashtalir et al., 2013.

The synthesis typically involves the following steps.

1 Preparation of MXene Nanosheets: MXene nanosheets are synthesized through methods such as chemical etching of MAX phases or exfoliation of precursor materials. The resulting MXene nanosheets are typically functionalized to improve their dispersion and compatibility with the polymer matrix.

2 Preparation of Polymer Matrix: The polymer matrix is prepared separately, often by dissolving the polymer in a suitable solvent to form a polymer solution. The choice of polymer depends on the desired properties of the nanocomposite and the intended application.

3 Dispersion of MXene in Polymer solution: The MXene nanosheets are then dispersed in the polymer solution using techniques such as sonication or mechanical stirring. Proper dispersion is crucial to ensure uniform distribution of MXene within the polymer matrix and to prevent aggregation.

4 Fabrication of Nanocomposite: The dispersed MXene-polymer solution is then subjected to a suitable fabrication method to form the nanocomposite material. Common techniques include solution casting, spin-coating, or electrospinning, depending on the desired morphology and application of the nanocomposite.

5 Characterization and Optimization: The synthesized MXene-polymer nanocomposite is characterized to evaluate its structural, mechanical, electrical, and thermal properties. Optimization of synthesis parameters may be performed to achieve desired properties such as improved mechanical strength, conductivity, or thermal stability.

6 Application Testing: The MXene-polymer nanocomposite is then evaluated for its performance in specific applications such as energy storage, electromagnetic interference shielding, sensors, or biomedical devices. The nanocomposite’s properties are tailored to meet the requirements of the intended application.

The synthesis of MXene-polymer nanocomposites involves careful control of MXene dispersion, polymer compatibility, and fabrication techniques to achieve nanocomposites with enhanced properties suitable for various practical applications.

The synthesis of MXenes and hence the MXene Nanocomposites, involves a multistep process, primarily starting with the selective etching of layers from a precursor material known as a MAX phase. The etching of MXene typically refers to a process of selectively removing the “A” layer (typically aluminum) from the MXene structure, leaving behind a porous 2D material with various applications. The etching process is essential because it alters the surface chemistry and structure of MXene, allowing for tuning of its properties and enabling various applications. The etching of MXene can be used to control the surface chemistry, surface area, and interlayer spacing, which are crucial for applications such as energy storage devices (like batteries and supercapacitors), electromagnetic interference shielding, catalysis, sensors, and more. The steps for the synthesis of MXene Polymer nanocomposite by selective etching process are as below.

The primary step in MXene synthesis involves the selective etching of the A-element layers from the MAX phase. Common etchants include hydrofluoric acid (HF) or a combination of hydrochloric acid (HCl) and an oxidizing agent. The etching process exposes the MXene layers, creating a 2D structure (Naguib et al., 2012).

After etching, the resulting MXene flakes are thoroughly washed to remove residual etchants and by-products. This step is crucial for the removal of any remaining A-element residues. Delamination processes, such as intercalation of ions or molecules, may be employed to exfoliate MXene layers and enhance their dispersibility (Ling et al., 2014).

MXene surfaces often have terminations, such as hydroxyl (-OH) or fluorine (-F), which affect their properties. Surface functionalization can be performed to introduce desired functional groups, enhancing their compatibility with other materials or improving specific characteristics.

MXenes are frequently integrated into polymer matrices to form nanocomposites. This can be achieved through methods like solution mixing, melt blending, or in situ polymerization. The choice of polymer and the synthesis method can be tailored to achieve the desired properties for specific applications (Khazaei et al., 2013; Ashton et al., 2016; T; Hu et al., 2015).

The resulting MXene dispersion is often dried to produce a powder form for ease of handling and storage. Techniques like freeze-drying or spray-drying are commonly employed to preserve the 2D structure.

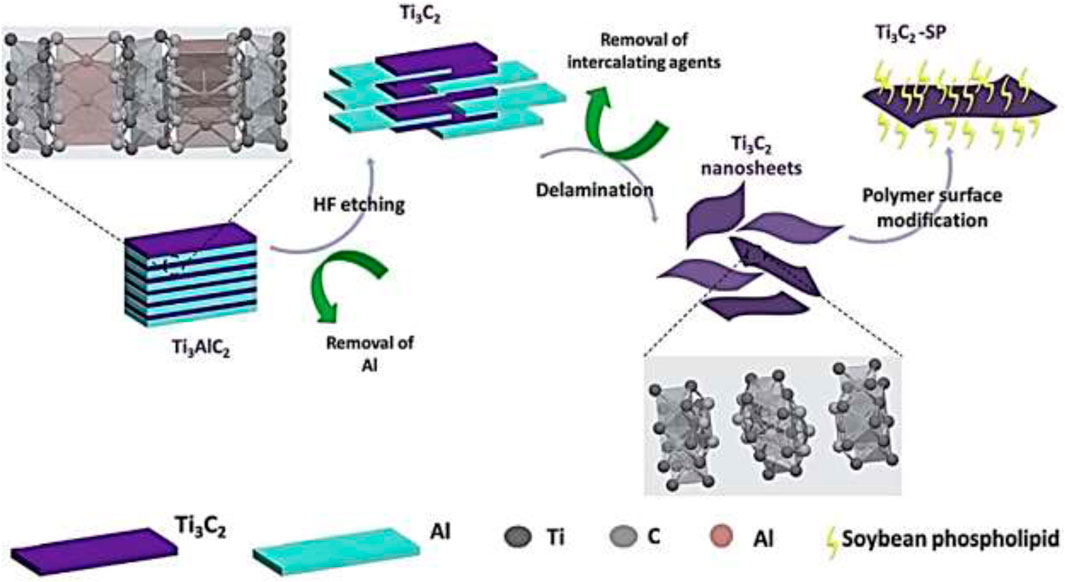

The schematic representation of the synthesis cycle for the MXene-SP composite is illustrated in Figure 4. The bottom-up methodology can also be employed for MXene synthesis through techniques such as EVD (Manawi et al., 2018).

Figure 4. Synthesis cycle of Ti3C2-SP nanocomposite (Jain et al., 2013).

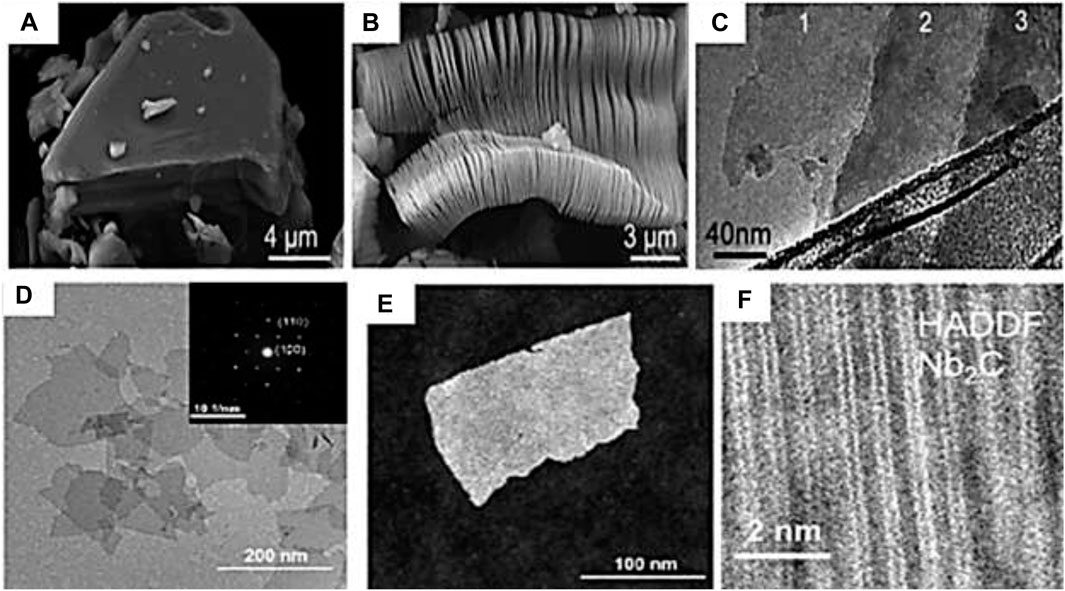

Figure 5 presents scanning transmission electron microscopy (STEM) images of Ti3AlC2 before and after etching, high-resolution transmission electron microscope (HRTEM) of Ti3C2 after etching, bright and dark selected area electron diffraction (SAED) of Nb2C, high angular annular dark field (HAADF) respectively, and showcasing hexagonally layered intercalated nanosheets with a space group of P63/mmc and atomic arrangement dependent on “n,” with lateral dimensions ranging from 0.5 to 200 nm and a thickness of a few nanometers (Naguib et al., 2014) (X. Ren et al., 2019).

Figure 5. (A) SEM micrographs of Ti3AlC2 before and (B) after etching. (C) TEM images of Ti3C2 after etching (Naguib et al., 2012) © American Chemical Society (2012). (D, E) TEM images (Bright and dark field Nb2C). (F) High resolution HAADF-STEM image. © American Chemical Society (2019).

They are simple and cost-effective, suitable for a wide range of polymers, and allow for precise control over the composition. However, they are limited to polymers soluble in the chosen solvent and may require additional steps for complete mixing and dispersion. Advanced mixing techniques, such as sonication or high-shear mixing, can be used to improve dispersion. Solution mixing is a common and straightforward method for preparing MXene-polymer nanocomposites (Maleski, Mochalin, and Gogotsi, 2017).

The MXene of interest, such as titanium carbide (Ti3C2Tx) or others, is prepared through appropriate synthesis methods. The chosen polymer, compatible with the solvent is used for MXene dispersion. Common polymers include polyvinyl alcohol (PVA), polyethylene glycol (PEG), or others. A solvent in which both MXene and the polymer are soluble. Common solvents include water, N-methyl-2-pyrrolidone (NMP), or dimethyl sulfoxide (DMSO). A sonicator is needed to assist in dispersing MXene and polymer in the solvent. For continuous mixing during the preparation is done by magnetic stirrer or stirring rod. A suitable container is used for mixing and storing the nanocomposite solution.

The MXene is dispersed in the chosen solvent, with uniform dispersion often achieved through sonication. For example, a desired amount of MXene powder is added to the solvent, and the mixture is sonicated for a specific duration until a well-dispersed MXene solution is obtained. The polymer is dissolved in the same solvent used for MXene dispersion, with the solution stirred until the polymer is fully dissolved, forming a clear polymer solution. The MXene solution is slowly added into the polymer solution while continuously stirring, with this process carried out dropwise to ensure a gradual and homogeneous mixture. The combined solution is stirred for an extended period to ensure proper mixing and distribution of MXene within the polymer matrix. Depending on the desired concentration of MXene in the nanocomposite, the ratio of MXene to polymer solutions is adjusted, with this step potentially requiring optimization based on the specific application. The resulting nanocomposite solution is characterized to ensure the desired properties, with techniques such as UV-Vis spectroscopy, Fourier-transform infrared spectroscopy (FTIR), or other relevant methods employed. Depending on the application, the nanocomposite solution can be cast into films or coatings or dried to obtain the final nanocomposite material.

In this process, some special considerations are needed. The concentration of MXene, polymer, and the ratio between them should be optimized based on the desired properties of the nanocomposite. The choice of solvent is critical, as it affects the solubility of both MXene and the polymer. Consideration should be given to environmental and safety aspects when selecting solvents. Proper sonication is essential to ensure a well-dispersed MXene solution, preventing agglomeration. Sufficient stirring time is crucial for achieving a homogeneous nanocomposite solution.

They are a direct synthesis of nanocomposites during polymerization and have good control over the nanocomposite structure. They are suitable for a variety of polymer matrices. However, they are limited to polymers that can undergo in situ polymerization, and reaction conditions may affect MXene properties. The development of controlled polymerization methods for better control over nanocomposite structure. In situ polymerization is a method for preparing MXene-polymer nanocomposites in which the polymerization of monomers occurs directly in the presence of dispersed MXene sheets.

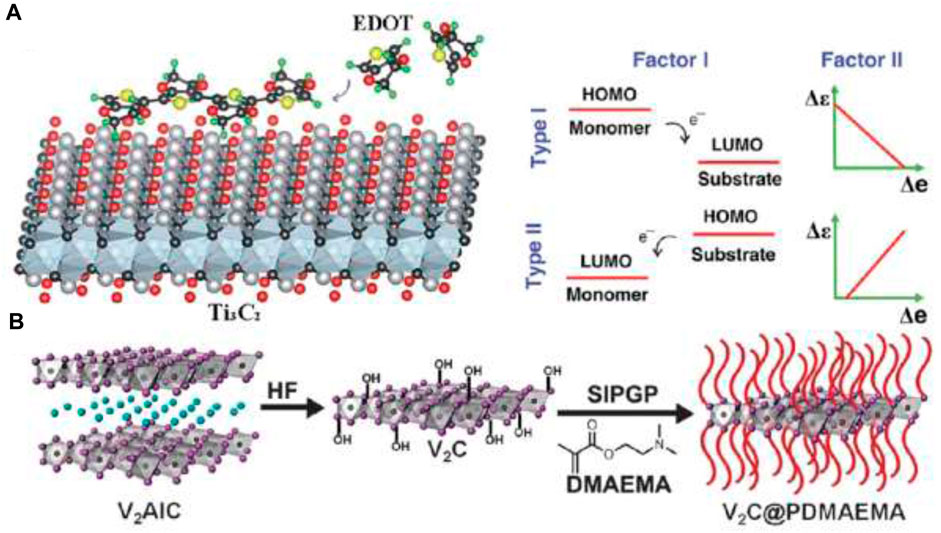

Due to limited polymerization energy, only certain types of monomers can undergo polymerization on the surface of MXenes through methods such as physical agitation, UV radiation, or electrochemical processes (C. Chen et al., 2017) (J. Chen et al., 2014; Boota et al., 2016). Chen et al. proposed two primary electron transfer mechanisms during the charge-transfer-induced polymerization of 3, 4-ethylenedioxythiophene (EDOT) under agitation. In one mechanism, electrons transition from the high-energy orbits (HOMOs) of the monomer to the lower-energy orbits (LUMOs) of the MXene, while in the other, electrons shift from the HOMOs of the MXene to the LUMOs of the monomer (Figure 6A) (C. Chen et al., 2017). Additionally, proximity between the monomer and MXene surface is crucial for efficient electron transfer during polymerization. Leveraging hydroxyl and fluorine terminations, 2-(dimethylamino) ethyl methacrylate (DMAEMA) was successfully polymerized on the surface of V2C (Figure 6B) (J. Chen et al., 2014), leading to the formation of PDMAEMA grafted V2C with demonstrated sensitivity to CO2 and temperature. Furthermore, MXene/polypyrrole (PPy) composites were synthesized via electrochemical polymerization by Zhu et al., involving the electrolysis of a pyrrole-containing solution with a Ti3C2-modified electrode. Although in situ polymerization ensures a uniform distribution of polymers on the MXene surface, it may alter the properties of MXene materials during the process.

Figure 6. Synthesis of MXene/polymer composites through in situ polymerization: (A) Schematic depiction of the polymerization of EDOT on the surface of MXene and the process of charge transfer during polymerization, adapted from (C. Chen et al., 2017) ©2017 Royal Society of Chemistry and (B) Schematic illustration of the preparation of V2C@PDMAEMA composite. (A): Adapted with permission from reference (J. Chen et al., 2014) ©2015 Royal Society of Chemistry.

In this method, the monomers are required for polymerization to make nanocomposite with the MXene of interest, such as titanium carbide (Ti3C2Tx). Common monomers include acrylic acid, acrylamide, or other suitable monomers compatible with the polymerization conditions. A suitable initiator to initiate the polymerization reaction. Common initiators include ammonium persulfate (APS), azobisisobutyronitrile (AIBN), or others, depending on the polymerization mechanism. A solvent in which both MXene and the monomers are dispersible. Common solvents include water, N-methyl-2-pyrrolidone (NMP), or dimethyl sulfoxide (DMSO). A suitable reaction vessel equipped with a stirring mechanism and temperature control is needed.

The MXene is dispersed in the chosen solvent to achieve a stable MXene dispersion, potentially involving sonication for uniform dispersion. The desired monomers are dissolved in the solvent to prepare the monomer solution, with the concentration adjusted based on the nanocomposite (NC) properties. e.g., epoxies (Sliozberg et al., 2020; H; Zhang et al., 2016; Zou et al., 2018) and polydimethylsiloxane (PDMS) like polymers are mixed from one side.

The most common reports of insitu polymerizations for MXene polymer NCs are of curing systems, such as epoxies (Hatter et al., 2020; Sliozberg et al., 2020) (A. Feng et al., 2020) and PDMS (D. Hu et al., 2020) (X. Wu et al., 2020)(D. Wang et al., 2020) aqueous solutions have been reported in the case of PPy (Zhu et al., 2016a; Boota et al., 2016; Zhang et al., 2020), polyaniline (Vahidmohammadi et al., 2018; Y; Ren et al., 2018; Wei et al., 2019; Vahidmohammadi et al., 2018; Xu et al., 2020), PAM(Zhang et al., 2019), PAM/PVA (Liao et al., 2019) and PEDOT (Chen et al., 2017; Qin et al., 2019), that can be polymerized with acetonitrile (Li et al., 2019).

The initiator is added to the monomer solution, its amount is determined by polymerization kinetics and reaction rate preferences. The MXene dispersion is slowly added into the monomer solution while continuously stirring to uniformly disperse MXene sheets. Polymerization is initiated by raising the temperature or other suitable methods activating the initiator. The polymerization reaction proceeds for the specified duration under controlled conditions. The resulting MXene-polymer nanocomposite is characterized using techniques such as FTIR, SEM, or other relevant methods. The nanocomposite material is isolated from the reaction mixture through filtration or other separation techniques and washed to remove unreacted monomers or by-products. Finally, the nanocomposite material is dried to obtain the final product.

The polymerization conditions, including temperature, initiator concentration, and reaction time, to achieve the desired properties of the nanocomposite are optimized. Continuous stirring are ensured during the polymerization reaction to promote uniform dispersion of MXene sheets and facilitate homogeneous polymerization. Thorough characterization of the nanocomposite material are done to evaluate its structure, morphology, and properties.

In-situ polymerization offers precise control over the nanocomposite structure and properties, making it a valuable method for preparing MXene-polymer nanocomposites with tailored characteristics for specific applications. Adjustments can be made to this general procedure based on the choice of monomers, initiators, or MXene types.

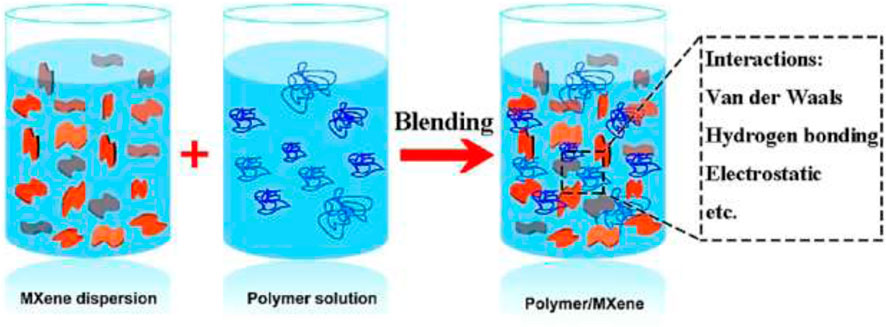

Melt blending is a commonly used method for preparing MXene-polymer nanocomposites, particularly when working with thermoplastic polymers (Figure 7). They are scalable and applicable to various polymer matrices, suitable for industrial-scale production, and are simple with cost-effective. However, they are limited to thermoplastic polymers and may require high processing temperatures. The optimization of processing parameters improves dispersion and mechanical properties (Sheng et al., 2019).

Figure 7. Creation of MXene/polymer composites through ex-situ solution blending. Reproduced with authorization from reference (Mirkhani et al., 2019). © 2019 American Chemical Society.

Ex-situ blending methods (Figure 7) are frequently utilized due to their ease in regulating the properties of polymer and MXene precursors. Leveraging their relatively modest interactions, such as van der Waals attraction, hydrogen bonding force, and electrostatic interaction, MXene/polymer composites are predominantly produced through solution mixing (Figure 7).

The MXene of interest, such as titanium carbide (Ti3C2Tx) or others, is prepared through appropriate synthesis methods. The chosen thermoplastic polymer, is compatible with the processing temperature and MXene dispersion. A twin-screw extruder or internal mixer capable of high-temperature processing and efficient mixing. Additives such as compatibilizers, plasticizers, or stabilizers may be used to improve dispersion or enhance properties.

The MXene powder is properly dried to remove any residual moisture, as moisture can affect processing and properties. The thermoplastic polymer pellets are pre-dried to remove moisture and ensure uniform processing, with any desired additives optionally incorporated into the polymer pellets. The dried MXene powder and polymer pellets are loaded into the mixing equipment in the desired ratios, with the loading ratio adjusted based on the desired properties of the nanocomposite. The mixing equipment is heated to the appropriate processing temperature, typically above the melting point of the polymer. The mixing process is started, allowing the MXene powder and polymer pellets to melt and blend thoroughly, with high shear forces generated during mixing helping to disperse MXene within the polymer matrix. After thorough mixing, the molten mixture is extruded or discharged from the mixing equipment onto a cooling conveyor or casting surface. The mixture is allowed to cool and solidify, forming the MXene-polymer nanocomposite in the desired shape (e.g., pellets, sheets, or films). Further processing steps such as pelletizing, compression molding, or injection molding may be applied to the resulting nanocomposite material depending on the intended application. The nanocomposite material is characterized to evaluate its structure, morphology, and properties, with techniques such as SEM, XRD, or mechanical testing employed.

The processing temperature should be carefully controlled to ensure proper melting of the polymer and dispersion of MXene while avoiding degradation of either component. Sufficient mixing time is essential to achieve uniform dispersion of MXene within the polymer matrix. Longer mixing times may be required for higher loading levels or less compatible polymer-MXene combinations. The incorporation of additives, such as compatibilizers or plasticizers, may improve the dispersion and compatibility of MXene within the polymer matrix. Melt blending involves high temperatures and mechanical shear forces. Proper safety precautions should be followed to prevent accidents or injuries.

Melt blending offers scalability and versatility, making it suitable for industrial-scale production of MXene-polymer nanocomposites. Adjustments to processing parameters can be made based on the specific polymer-MXene combination and intended application requirements.

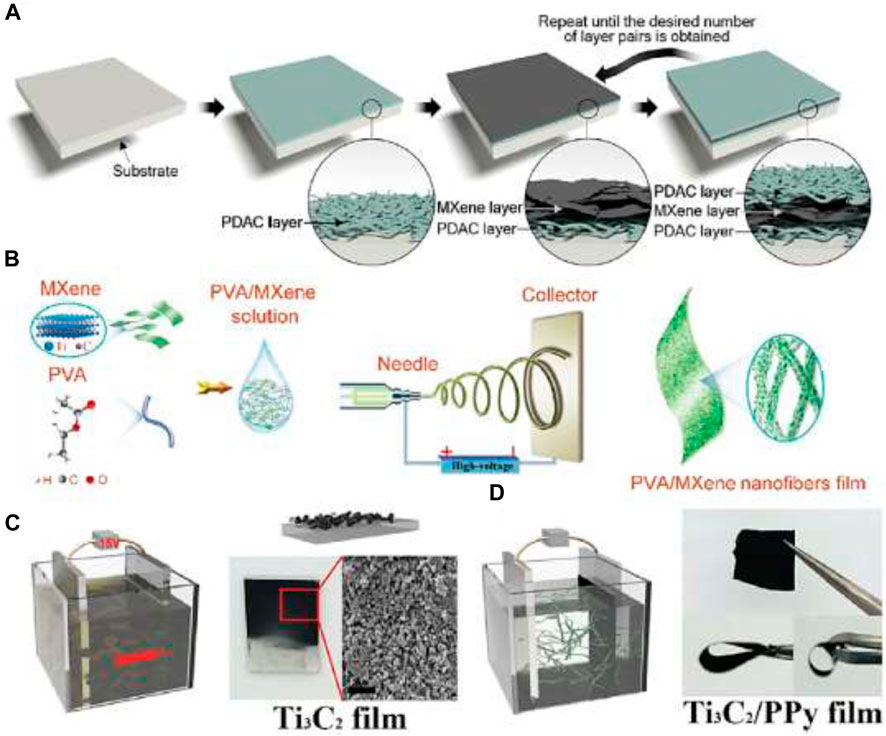

This process has precise control over layer arrangement, suitable for a variety of polymers and MXenes. They can be used for thin films and coatings. However, the process is time-consuming and is limited to specific applications due to its layer-to-layer nature. Layer-by-layer (LbL) assembly (Figure 8) is a versatile technique for fabricating MXene-polymer nanocomposites with precise control over layer thickness and composition (Chen et al., 2020).

Figure 8. (A) Schematic illustration of the synthesis of MXene/PDAC membrane by LbL assembly process. (B) Schematic illustration of the fabrication process of MXene/PVA film by electrospinning approach. (C) Schematic illustration of the electrophoretic deposition of Ti3C2 flakes. (D) Schematic illustration of the synthesis of Ti3C2/PPy membrane by electrochemical polymerization of PPy on Ti3C2 film. Panel a: Reprinted from ref (An et al., 2018) ©2016, The Authors, (B): Reprinted with permission from ref (C. Jiang et al., 2019). ©2019 Elsevier. Panels c and d: Reprinted with permission from ref (M. Zhu et al., 2016a). © 2016 John Wiley and Sons. A step-by-step guide for the LbL assembly is as.

The MXene of interest, such as titanium carbide (Ti3C2Tx) or others, is prepared through appropriate synthesis methods. The chosen polymer, typically in the form of a solution or dispersion compatible with the assembly process. Polyelectrolytes like poly (allylamine hydrochloride) (PAH) or poly (sodium 4-styrenesulfonate) (PSS) are commonly used. A solvent suitable for both MXene dispersion and polymer dissolution. Common solvents include water, ethanol, or other polar solvents. A solid substrate on which the LbL assembly will take place. Common substrates include silicon wafers, glass slides, or functionalized surfaces. Additives such as crosslinkers or stabilizers may be used to enhance film stability or modify properties.

The MXene is dispersed in the chosen solvent to create a stable MXene dispersion, with sonication or high-shear mixing possibly utilized to achieve uniform dispersion. The chosen polymer is dissolved in the solvent to generate a polymer solution or dispersion, with the polymer concentration adjustable based on desired film properties. The substrate is thoroughly cleaned to remove any contaminants or residues that may affect film formation, and optionally, the substrate surface is functionalized to promote adhesion or enhance film stability. The process is repeated by immersing the substrate in the polymer solution, allowing the polymer to adsorb onto the MXene-coated substrate surface. The substrate is rinsed with solvent to eliminate any unbound polymer molecules and stabilize the polymer layer. Deposition of MXene and polymer layers is continued alternately until the desired number of layers is achieved, with control over the sequence and thickness of layers by adjusting deposition parameters. Post-treatment steps, such as crosslinking or annealing, may be performed to enhance film stability or modify properties. The assembled MXene-polymer nanocomposite film is characterized to evaluate its structure, morphology, and properties, with techniques such as atomic force microscopy (AFM), ellipsometry, or spectroscopic methods employed.

The pH and ionic strength of the deposition solutions can influence layer deposition and film properties, so these parameters should be controlled and optimized. Parameters such as immersion time, solution concentration, and drying conditions can affect film thickness and quality and should be carefully optimized. The substrate material and surface properties can influence film adhesion, stability, and performance, so substrate selection should be based on the desired application. LbL assembly allows for precise control over film composition, enabling the incorporation of multiple materials and functionalities into the nanocomposite film.

Layer-by-layer assembly offers fine control over film thickness, composition, and functionality, making it a versatile technique for fabricating MXene-polymer nanocomposites with tailored properties for various applications. Optimization of deposition parameters and thorough characterization are essential for achieving desired film properties and performance.

They produce nanofibrous structures for enhanced properties, are suitable for a variety of polymers, and enable the fabrication of nanocomposite mats (Boys, 1887). However, they require specialized equipment and are limited to certain polymers and MXenes. Integration of electrospinning with other techniques for multifunctional nanocomposites may overcome this difficulty. Electrospinning is a versatile and widely used method for fabricating nanofibrous structures, including MXene-polymer nanocomposites (Ziabicki, 1976).

After the preparation of the MXene of interest, such as titanium carbide (Ti3C2Tx), through an appropriate synthesis method, a polymer is chosen which is typically in the form of a solution or melt suitable for electrospinning. Common polymers include polyvinyl alcohol (PVA), polyethylene oxide (PEO), or others. A solvent suitable for both MXene dispersion and polymer dissolution. Common solvents include water, dimethylformamide (DMF), or other polar solvents. A grounded collector, typically in the form of a rotating drum or flat plate, collects the electrospun fibers. A high voltage power supply capable of generating electric fields in the range of 1–30 kV. A syringe pump or similar device for controlled delivery of the polymer solution during electrospinning. A spinneret or needle with a fine tip, through which the polymer solution is extruded during electrospinning (D. Li and Xia, 2004).

The MXene is dispersed in the chosen solvent to create a stable MXene dispersion, with sonication or high-shear mixing possibly employed to achieve uniform dispersion. The chosen polymer is dissolved in the solvent to form a polymer solution, with the polymer concentration optimized for electrospinning, typically in the range of 5%–20% w/v. The electrospinning apparatus is set up in a controlled environment to prevent airflow disturbances, and the grounded collector is positioned at an appropriate distance (usually 10–20 cm) from the spinneret. The polymer solution is loaded into a syringe or reservoir connected to the spinneret, ensuring it is free of air bubbles to prevent disruption during electrospinning. A high voltage (typically in the range of 1–30 kV) is applied between the spinneret and the collector to generate an electric field, initiating the electrospinning process by dispensing the polymer solution through the spinneret at a controlled flow rate (typically in the range of 0.1–10 mL/h). The electric field induces a charge on the surface of the polymer solution droplet, leading to the formation of a Taylor cone and subsequent elongation into nanofibers. Simultaneously, the MXene dispersion is introduced into the polymer solution or applied directly onto the collector to incorporate MXene into the electrospun fibers. The electrospun fibers are collected onto the grounded collector, forming a nonwoven mat or membrane, with the rotating drum or flat plate possibly used to facilitate continuous fiber collection. Post-treatment steps, such as drying, crosslinking, or annealing, may be performed to enhance fiber stability or modify properties. The electrospun MXene-polymer nanocomposite fibers are characterized to evaluate their structure, morphology, and properties, with techniques such as SEM, transmission electron microscopy (TEM), or mechanical testing employed (Merritt et al., 2012; Keirouz et al., 2020).

The polymer concentration and solvent composition are optimized to achieve the desired solution viscosity for electrospinning. Control electrospinning parameters such as voltage, flow rate, and distance between the spinneret and collector to obtain uniform and well-aligned fibers. Uniform dispersion of MXene is ensured within the polymer solution to facilitate its incorporation into the electrospun fibers and enhance their properties. Cautions are exercised when working with high voltages and organic solvents, and follow appropriate safety protocols to prevent accidents or injuries.

Electrospinning offers precise control over fiber diameter, morphology, and composition, making it a valuable technique for fabricating MXene-polymer nanocomposite fibers with tailored properties for various applications such as filtration, tissue engineering, and sensors. Optimization of electrospinning parameters and thorough characterization are essential for achieving desired fiber properties and performance.

They allow for direct synthesis on substrates and have uniform coatings on various surfaces along with precise control over film thickness. However, they require specialized equipment and are limited to specific substrates. These days, the scalability is improved, and have control over the CVD process. Chemical vapor deposition (CVD) is a method commonly used for the synthesis of thin films or coatings of MXene-polymer nanocomposites on solid substrates (Shareef et al., 1995; Schropp et al., 2000; Hamzan et al., 2021).

The MXene of interest, such as titanium carbide (Ti3C2Tx) or others, is prepared through appropriate synthesis methods. The chosen polymer precursor, typically in the form of a vapor or gas, will react or deposit onto the substrate surface. A solid substrate onto which the MXene-polymer nanocomposite film will be deposited. Common substrates include silicon wafers, glass slides, or functionalized surfaces. A CVD reactor is equipped with the necessary components for gas flow control, temperature control, and vacuum pumping. An inert carrier gas such as nitrogen or argon, is used to transport the polymer precursor vapor to the substrate. Additives such as catalysts or dopants may be used to modify film properties or promote deposition. The substrate is thoroughly cleaned to remove any contaminants or residues that may affect film deposition, with the substrate surface optionally functionalized to promote adhesion or enhance film properties. The MXene powder is loaded onto a substrate holder inside the CVD reactor, ensuring uniform dispersion of MXene particles on the substrate surface. The polymer precursor is prepared in the desired form for CVD deposition, which may involve heating the precursor to its vaporization temperature or introducing it as a gas into the CVD reactor. The CVD reactor is purged with an inert gas (e.g., nitrogen or argon) to remove air and moisture. The polymer precursor vapor or gas is introduced into the CVD reactor at the desired flow rate, and the substrate is heated to the appropriate temperature for polymer deposition, typically in the range of 100°C–300°C. The polymer precursor reacts or deposits onto the substrate surface, forming a thin film or coating. Alternatively, MXene can be simultaneously deposited with the polymer precursor by introducing MXene vapor or gas into the CVD reactor alongside the polymer precursor. Deposition parameters such as temperature, precursor flow rate, and deposition time are controlled to achieve the desired film thickness and properties. Post-treatment steps, such as annealing or surface modification, may be performed to enhance film properties or stability. The deposited MXene-polymer nanocomposite film is characterized to evaluate its structure, morphology, and properties, with techniques such as SEM, X-ray diffraction (XRD), or spectroscopic methods employed.

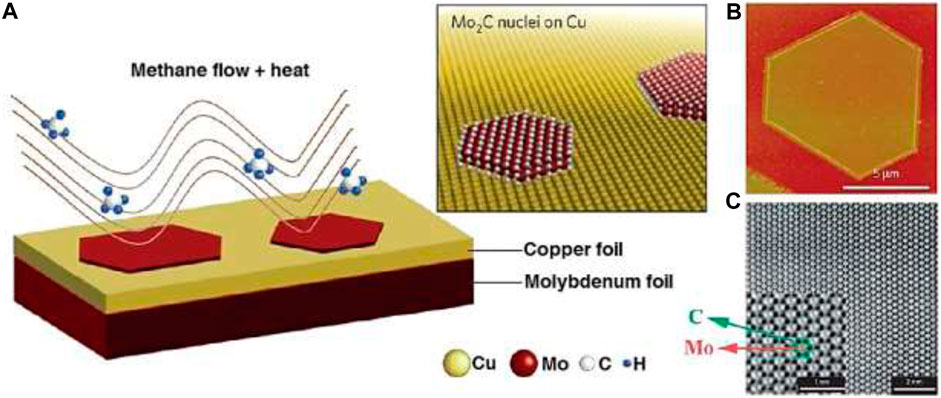

A novel method utilizing chemical vapor deposition (CVD) has been uncovered for the direct production of ultrathin MXene materials, offering a new avenue for MXene-based material fabrication (Gogotsi, 2015) (C. Xu et al., 2015; Geng et al., 2017). By employing methane as a carbon source over a Cu/Mo alloyed surface at temperatures surpassing 1085°C (Figures 9A–C) (Gogotsi, 2015) (C. Xu et al., 2015) large-area high-quality 2D ultrathin α-Mo2C crystals (−3 nm) were successfully synthesized. Control over crystal size and thickness was achieved through manipulation of experimental conditions, where growth time influenced lateral size while growth temperature affected nucleation density. The method demonstrated versatility in generating various crystal shapes, including triangles, rectangles, hexagons, octagons, nonagons, and dodecagons, all exhibiting hexagonal packing of Mo atoms. Furthermore, enabling the fabrication of ultrathin β-Mo2C nanosheets using a rapid and scalable synthesis approach involving MoO2 nanosheets as templates and Mo sources. Unlike 2D materials obtained from alternative methods, CVD-fabricated MXenes showcased fewer defects and terminations, facilitating comprehensive investigations into their intrinsic properties and domain boundaries’ effects. The exploration of bottom-up synthetic approaches is encouraged to prepare other types of monolayered MXenes with diverse functionalities, thereby enabling further investigations into their inherent electronic and optical properties (Gogotsi, 2015; Jeon et al., 2018; Sang et al., 2018)(L. Wang et al., 2016).

Figure 9. (A) The synthesis process of Mo2C. (B) Images depicting hexagonal ultra-thin Mo2C crystals. (C) STEM diagrams (P. Hu et al., 2022; Amu-Darko et al., 2024).

A polymer precursor compatible with the CVD process and suitable for deposition onto the substrate surface is chosen and optimized the substrate temperature and deposition parameters to ensure uniform film growth and adhesion. The flow rates of carrier gas and precursor gas are controlled to achieve desired deposition rates and film properties. The deposition conditions are adjusted to control the composition and stoichiometry of the deposited MXene-polymer nanocomposite film.

CVD offers precise control over film thickness, composition, and properties, making it a valuable technique for fabricating MXene-polymer nanocomposites on solid substrates. Optimization of deposition parameters and thorough characterization are essential for achieving desired film properties and performance.

It is a method of producing a single crystal under high pressure using a hot mineral water solution that is hydrothermal and producing a chemical compound that is solvothermal (Demazeau, 2008). They have a low-temperature synthesis approach that is scalable applicable to various polymers and enables large-scale production. However, the reaction conditions may affect MXene properties and require careful optimization. They are advanced by using environmentally friendly solvents (like water, limonene, ethyl acetate, ethers, esters, ionic liquids, etc.) and improved reaction control (like catalysis, optimization techniques, etc.). Hydrothermal (Byrappa and Yoshimura, 2013) and solvothermal methods are commonly used for synthesizing MXene-polymer nanocomposites in a controlled environment (Rabenau, 1985).

The MXene of interest, such as titanium carbide (Ti3C2Tx) or others, is prepared through appropriate synthesis methods. The chosen polymer precursor, is typically in the form of a solution or dispersion compatible with the hydrothermal/solvothermal conditions. Common polymers include polyvinyl alcohol (PVA), polyethylene glycol (PEG), or others. A solvent is suitable for both MXene dispersion and polymer dissolution under hydrothermal/solvothermal conditions. Common solvents include water, ethanol, or other polar solvents. A sealed autoclave or reaction vessel capable of withstanding high temperatures and pressures. A heating source capable of providing the required temperature for the hydrothermal/solvothermal reaction. Additives such as surfactants, catalysts, or stabilizers may be used to modify reaction kinetics or improve nanocomposite properties.

The MXene is dispersed in the chosen solvent to create a stable MXene dispersion, with sonication or high-shear mixing potentially employed to achieve uniform dispersion. The chosen polymer is dissolved in the solvent to form a polymer solution or dispersion, with the polymer concentration optimized for the hydrothermal/solvothermal conditions. The MXene dispersion and polymer solution are mixed in the desired ratio to obtain a homogeneous MXene-polymer mixture, ensuring thorough mixing to achieve uniform dispersion of MXene within the polymer matrix. The MXene-polymer mixture is transferred into a sealed autoclave or reaction vessel suitable for hydrothermal/solvothermal reactions, ensuring the vessel is clean and free of contaminants. The autoclave or reaction vessel is heated to the desired temperature for the hydrothermal/solvothermal reaction, typically ranging from 100°C to 250°C, depending on the polymer and MXene used. The reaction temperature is maintained for a specified duration to allow for the synthesis of the MXene-polymer nanocomposite. After the reaction is complete, the autoclave or reaction vessel is cooled to room temperature, and the MXene-polymer nanocomposite product is retrieved. The product may be in the form of a gel, powder, or precipitate, depending on the reaction conditions. Post-treatment steps, such as washing, drying, or annealing, may be performed to remove any unreacted precursors or by-products and to enhance the properties of the nanocomposite material. The synthesized MXene-polymer nanocomposite is characterized to evaluate its structure, morphology, and properties, with techniques such as SEM, XRD, or spectroscopic methods employed.

The reaction temperature, pressure, and duration to achieve the desired properties of the MXene-polymer nanocomposite are optimized. A solvent suitable (like N-methyl-2-pyrrolidone (NMP) a polar aprotic solvent that has good solubility for a wide range of polymers, including many commonly used ones such as polyvinylidene fluoride (PVDF), polyvinyl alcohol (PVA), and polyethylene oxide (PEO)) for both MXene dispersion and polymer dissolution under hydrothermal/solvothermal conditions are chosen. The additives or surfactants are incorporated to control particle size, and morphology, or to enhance the dispersion of MXene within the polymer matrix. High temperatures and pressures are handled with caution and follow appropriate safety protocols during the hydrothermal/solvothermal reaction.

This method offer controlled conditions for synthesizing MXene-polymer nanocomposites with tailored properties. Optimization of reaction parameters and thorough characterization are essential for achieving desired nanocomposite properties and performance.

Production of hydrophobic polymers in industrial and academic scales (Hohenstein and Mark, 1946) They are suitable for water-soluble polymers and have good control over particle size and distribution. However, they are limited to specific polymer types and may require additional steps for nanocomposite formation. The novel emulsion systems are developed for improved stability. Emulsion polymerization is a versatile method for preparing polymer-MXene nanocomposites in the form of latex particles dispersed in an aqueous medium (Whitby and Katz, 1933).

The MXene of interest, such as titanium carbide (Ti3C2Tx), is prepared through appropriate synthesis methods, and the monomers that are compatible with the emulsion polymerization process are selected for polymerization. Common monomers include styrene, methyl methacrylate, or butyl acrylate. An emulsifier or surfactant stabilizes the emulsion and prevents the coalescence of polymer particles. Common surfactants include sodium dodecyl sulfate (SDS), polyvinyl alcohol (PVA), or cetyltrimethylammonium bromide (CTAB). A water-soluble initiator to initiate the polymerization reaction in the aqueous phase. Common initiators include potassium persulfate (KPS), ammonium persulfate (APS), or hydrogen peroxide. Water is the continuous phase for emulsion polymerization. Optionally, a stabilizer such as polyvinyl alcohol (PVA) or polyethylene glycol (PEG) may be added to improve stability and control particle size.

The MXene is dispersed in water using mechanical agitation or sonication to obtain a stable aqueous dispersion, with the MXene concentration optimized based on the desired loading in the nanocomposite. The emulsion is prepared by mixing the MXene dispersion with the surfactant solution, with the surfactant concentration optimized to ensure the stabilization of the emulsion. The chosen monomer or monomer mixture is dissolved in water-soluble initiators to form the aqueous monomer phase, with the monomer concentration adjustable based on the desired properties of the polymer-MXene nanocomposite. The polymerization reaction is initiated by adding the monomer solution to the emulsion under stirring or agitation, with the addition performed gradually to control the particle size and nucleation rate. The reaction temperature is maintained, and stirring continues until the polymerization is complete, typically controlled below the boiling point of water. During polymerization, MXene particles become embedded within the growing polymer particles, forming a polymer-MXene nanocomposite. The surfactant molecules at the interface between water and monomer droplets stabilize the growing polymer particles, preventing coalescence. After polymerization, the nanocomposite latex can undergo post-polymerization treatments such as purification, drying, or chemical modification to remove unreacted monomers or improve their properties. The synthesized polymer-MXene nanocomposite is characterized to evaluate its structure, morphology, and properties, with techniques such as dynamic light scattering (DLS), TEM, or mechanical testing employed.

An appropriate surfactant is selected to stabilize the emulsion and control particle size during polymerization. Select monomers compatible with water-based emulsion polymerization and capable of forming stable latex particles. Water-soluble initiators are used for polymerization in the aqueous phase, ensuring efficient initiation and control of the reaction. Maintain appropriate stirring and temperature conditions throughout the polymerization process to ensure uniform particle formation and polymerization kinetics.

Emulsion polymerization offers advantages such as easy scalability, control over particle size, and compatibility with aqueous systems, making it a promising method for preparing polymer-MXene nanocomposites in latex form. Optimization of parameters and thorough characterization are essential for tailoring the properties of the nanocomposite for specific applications.

Each synthesis method has its own set of considerations, and the choice depends on the specific requirements of the application. Recent advancements often focus on improving scalability, efficiency, and control over the nanocomposite’s structure and properties. Exploration is going on innovative approaches to enhance the performance and broaden the applicability of MXene-polymer nanocomposites in diverse fields.

Techniques such as XRD and TEM are used to confirm the 2D structure and layer spacing of MXenes. X-ray photoelectron spectroscopy (XPS) and FTIR help analyze the chemical composition and functional groups on the MXene surface. Brunauer-Emmett-Teller (BET) surface area analysis is commonly used to determine the specific surface area of MXenes, providing insights into their porosity.

MXene synthesis methods are continuously evolving, with an exploration of new etchants, delamination techniques, and polymer integration strategies to enhance the properties and applications of these unique materials. The ability to customize MXene structures and incorporate them into nanocomposites opens up a wide range of possibilities for various technological advancements.

There are several fields under the biomedical application of MXene Polymer nanocomposite (George, Tandon, and Kandasubramanian, 2020; Garg and Ahmad, 2022; Parajuli et al., 2022).

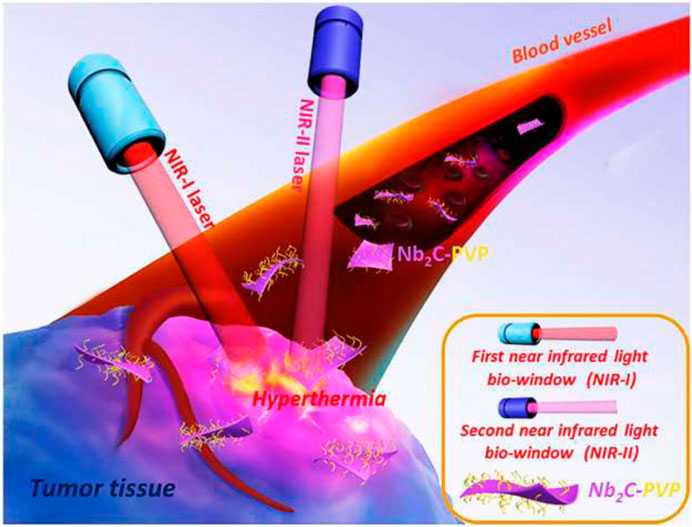

MXene-polymer nanocomposites play a significant role in drug delivery systems due to their unique properties of higher photothermal conversion and pH sensitivity, which offer advantages for enhancing therapeutic efficacy and addressing challenges associated with conventional drug delivery methods. A sketch of Nb2C/PVP used for tumor ablation by In Vivo Photothermal irradiated with NIR-I and NIR-II is shown in Figure 10. Here are some key roles of MXene-polymer nanocomposites in drug delivery systems.

Figure 10. A sketch of Nb2C/PVP used for tumor ablation by In Vivo Photothermal irradiated with NIR-I and NIR-II (Reprinted with permission from ref (Lin, Gao, et al., 2017). Copyright 2017 American Chemical Society.

MXene nanosheets provide a high surface area and abundant functional groups, allowing for efficient loading of therapeutic agents such as drugs, proteins, or nucleic acids (Sur et al., 2019). The controlled release of these agents can be achieved by modulating the interaction between the drug molecules and the nanocomposite matrix, leading to sustained or triggered release profiles (P. Zhang et al., 2019). For example: the synergistic effect developed in SP surface modified with Ti3C2 destroys the cancerous cells with the help of NIR laser (X. Han et al., 2018) as shown in Figure 11.

Incorporating MXenes into polymer matrices can improve the biocompatibility and stability of drug delivery systems. The polymer coating protects the MXene nanosheets from degradation and minimizes potential cytotoxicity, enhancing the overall biocompatibility of the nanocomposite (Zhao et al., 2021; Cui et al., 2023).

Surface functionalization of MXene-polymer nanocomposites allows for the introduction of targeting ligands such as antibodies, peptides, or aptamers. These ligands can selectively bind to specific receptors or biomarkers overexpressed on target cells, facilitating targeted drug delivery and minimizing off-target effects (Mohajer et al., 2022) (A. Liu et al., 2022). G. Liu et al. and Z. Li et al. studied MXene nanocomposites for the targeted drug delivery and found efficient for that. (Z. Li et al., 2018).

MXene-polymer nanocomposites can be engineered to respond to external stimuli such as pH, redox, temperature, light, electric, magnetic, etc. By incorporating responsive polymers or responsive MXene coatings, drug release from the nanocomposite can be triggered or modulated in a controlled manner, enabling on-demand drug delivery and localized therapy (He et al., 2024).

The pH of cancerous tissues is lower than normal (i.e. below 7.4) dealing with hydrophilic and hydrophilic interaction. (Lopes et al., 2013). In redox response, there is oxidation-reduction in extra and intracellular regions. For example: glutathione (GSH) can be the reducing agent as shown in Figure 12. (Hatakeyama, 2017). (Y. Dai, Chen, and Zhang, 2018). Some of the responsive polymers are Poly acrylic acid (PAA), polyethylene glycol (PEG), poly 2-dimethylamino ethyl methacrylate (PDMAEMA), polyethylene oxide (PEO), poly oligo ethylene methacrylate (POEGMA), etc. In electro-responsive drug release, the electrically conductive MXene by using the external electric field (Zavahir et al., 2020). Similarly, the external magnetic field plays the same role in magnetic-responsive drug release (Darroudi et al., 2023).The light-responsive molecules like photochromic compounds stimulated by light of a certain wavelength create structural changes in MXene or its surroundings for light-responsive drug release (Zavahir et al., 2020). In case of temperature-responsive drug release, MXene nanosheets into a polymer matrix with a lower critical solution temperature (LCST), the drug release can be triggered by changes in temperature above or below the LCST can be utilized (Karimi et al., 2016).

MXene-polymer nanocomposites have shown promise for theranostic applications, combining therapeutic and diagnostic functionalities within a single platform. The efficient breast cancer theranostic was achieved by tantalum carbide MXene composite (Z. Liu et al., 2018; Lin et al., 2018). Polyoxometalate as functionalizing agent for Tantalum carbide was studied by L Zong et al., 2018 for theranostic application. MXene Functionalization with imaging agents or contrast agents enables real-time monitoring of drug distribution and therapeutic response, facilitating personalized medicine and treatment optimization (Sivasankarapillai et al., 2020; Aslam et al., 2023; Nikazar, Mofidi, and Mortazavi, 2023).

The combination of MXenes with polymers can lead to synergistic therapeutic effects, where the unique properties of each component complement each other. For example, A. Liu et al., 2022, Yang et al., 2022, W Tang et al., 2019 found that MXene’s high conductivity and mechanical strength combined with the polymer’s biocompatibility and versatility can enhance the overall performance of drug delivery systems, enabling novel therapeutic strategies (A. Liu et al., 2022; Yang et al., 2022)(W. Tang et al., 2019).

MXene-polymer nanocomposites can serve as multifunctional platforms for combination therapy, allowing for the co-delivery of multiple drugs or therapeutic agents with different mechanisms of action. This approach can overcome drug resistance, improve treatment outcomes, and reduce side effects compared to single-agent therapy. Several studies and experiments have demonstrated the efficacy of MXene-polymer nanocomposites in Drug delivery systems. Wang et al. (2019) developed a pH-responsive drug delivery system based on MXene-polymer nanocomposites for targeted cancer therapy. The nanocomposites exhibited high drug loading capacity, controlled drug release behavior, and enhanced cytotoxicity against cancer cells compared to free drugs (Wang et al., 2019). In another study, Liu et al. (2021) synthesized MXene-polymer nanocomposites for the co-delivery of doxorubicin (DOX) and indocyanine green (ICG) for combined chemotherapy and photothermal therapy. The nanocomposites showed improved therapeutic efficacy and enhanced tumor inhibition in a mouse xenograft model compared to monotherapy (X. Liu et al., 2021).

In cancer treatment, therapeutics such as PLGA/Ti3C2 (Lin, Wang, et al., 2017) are employed for photothermal ablation. Additionally, Ti3C2/Al has been utilized for cancer treatment under 808 nm laser radiation (Z. Liu et al., 2018). V2C nanosheets demonstrate efficacy as photothermal agents for photothermal treatment, with applications in photoacoustic (PA) and magnetic resonance imaging (MRI) (Zada et al., 2020). Moreover, AIPH@Nb2C@mSiO2 nanocomposites have been employed for thermodynamic therapy targeting cancer cells deficient in oxygen (Xiang et al., 2019). Ti3C2-DOX complexes have been demonstrated to generate reactive oxygen species (ROS) during photodynamic therapy, effectively targeting and killing cancerous cells (K. Huang et al., 2018). Additionally, they find utility in drug delivery applications. Nb2C/polymer nanocomposites have been utilized to ablate tumors via photothermal processes, particularly in the near-infrared region (Lin, Gao, et al., 2017). Furthermore, MnOx/Ti3C2-SP and MnOx/Ta4C3-SP MXene nanocomposites have been employed for the treatment of acidic tumors (C. Dai, Chen, et al., 2017; Lin, Chen, and Shi, 2018).

Thus, MXene-polymer nanocomposites hold great promise for revolutionizing drug delivery systems by offering tailored properties, enhanced functionality, and improved therapeutic outcomes. Continued research and development in this field are expected to lead to the translation of these nanocomposites into clinically relevant applications for the treatment of various diseases.

MXene-polymer nanocomposites hold significant potential in imaging and diagnostics due to their unique properties and versatile functionalities. For example: They are used for the allocation of affected areas like tumor regions and monitoring the treatment effect by MRI. Here are some key aspects highlighting their potential in this field.

MXene nanosheets can be functionalized with imaging agents such as fluorophores, magnetic nanoparticles, or radioisotopes to enhance contrast in various imaging modalities including optical imaging, MRI, and nuclear imaging techniques (e.g., positron emission tomography (PET) or single-photon emission computed tomography (SPECT)). The integration of MXenes into polymer matrices ensures stability and biocompatibility of the contrast agents, enabling their use in vivo for non-invasive imaging (Aslam et al., 2023). Ta4C3-IONP-SP nanocomposites represent a case employed in MRI applications (Z. Liu et al., 2018) as enhanced contrast agent.

Surface modification of MXene-polymer nanocomposites with targeting ligands (e.g., antibodies, peptides, or aptamers) allows for specific binding to molecular targets or biomarkers overexpressed in diseased tissues. This targeted approach improves imaging sensitivity and specificity, enabling early detection and precise localization of pathological lesions (Kumar, Barman, and Singh, 2021).

MXene-polymer nanocomposites can be engineered to exhibit multimodal imaging capabilities by combining different imaging agents within a single platform. For example, integrating fluorescent dyes for optical imaging with magnetic nanoparticles for MRI or radionuclides for PET allows for complementary information acquisition and improved diagnostic accuracy (Z. Liu et al., 2018).

MXene-based nanocomposites can respond to external stimuli such as pH, temperature, or specific biomolecules, leading to changes in their imaging properties. C. Dai et al., 2017 used the nanocomposite in pH-guided MRI for hyperthermia treatment of tumors (C. Dai, Lin, et al., 2017). Responsive imaging agents enable dynamic monitoring of physiological processes or disease progression in real-time, providing valuable insights into treatment response and disease mechanisms (X. Han et al., 2018).

MXene-polymer nanocomposites have the potential for theranostic applications, combining diagnostic and therapeutic functionalities within a single platform. By incorporating both imaging agents and therapeutic agents, these nanocomposites enable image-guided therapy, personalized treatment planning, and monitoring of therapeutic response in real-time (Lin et al., 2018).

MXene-polymer nanocomposites exhibit excellent biocompatibility and low cytotoxicity, making them suitable for biomedical imaging applications. These nanocomposites can be used for in vitro cell imaging, in vivo molecular imaging, and bioimaging of tissues and organs, providing valuable information for disease diagnosis, prognosis, and treatment evaluation (Gomez et al., 2018).

MXene-polymer nanocomposites offer flexibility in design and functionalization, allowing for the customization of imaging properties based on specific application requirements. Tailoring the composition, size, and surface chemistry of the nanocomposites enables fine-tuning of imaging performance and optimization for different imaging modalities (Ling et al., 2014).

Some additional prominent research was made in Imaging and diagnostics. Xu et al. (2020) developed MXene-polymer nanocomposites as dual-modal contrast agents for both photoacoustic imaging (PAI) and MRI. The nanocomposites exhibited excellent imaging performance with high signal intensity and superior contrast enhancement in tumor imaging (Xu et al., 2020). Kong and Chen in 2022 reported the synthesis of MXene-polymer nanocomposites as theranostic agents for combined photothermal therapy (PTT) and photodynamic therapy (PDT) of cancer (Kong and Chen, 2022). The nanocomposites showed efficient tumor ablation and simultaneous imaging capability for guiding therapy (H. Li et al., 2021).

Biosensors are employed to identify specific elements within the human body. These devices consist of several components: a sensing element, a transducer, and a data interpreter (Prajapati and Kandasubramanian, 2019). The sensing element, typically an immobilized biomolecule like an enzyme, can detect the concentration of a target analyte in its vicinity, generating a biochemical signal. This signal is then converted into an electrical signal by a transducer and subsequently interpreted by a data interpreter. In a study by Rakhi and colleagues, they developed an enzymatic biosensor (GOx/Au/Ti3C2/Nafion/GCE) for detecting glucose (Rakhi et al., 2016). Glucose is converted into gluconolactone and hydrogen peroxide (H2O2) through the action of the enzyme glucose oxidase (GOx). The presence of glucose leads to the production of peroxide, generating a high potential indicative of glucose levels. Nafion facilitates the enzyme’s adhesion to the glassy carbon electrode (GCE) (Harper and Anderson, 2010).

In Biosensing and detection, Li et al. (2020) synthesized MXene-polymer nanocomposites for glucose biosensing applications. The nanocomposites exhibited high sensitivity, excellent selectivity, and rapid response toward glucose detection, showing promise for diabetes management and point-of-care testing (X. Li, Zhao, and Wu, 2020). Jiang et al. (2021) developed MXene-polymer nanocomposites for ultrasensitive detection of circulating tumor DNA (ctDNA) in blood samples. The nanocomposites demonstrated high specificity and sensitivity for ctDNA detection, offering potential for early cancer diagnosis and prognosis monitoring (Y. Jiang et al., 2021). The GOx/Au/Ti3C2/Nafion/GCE configuration represents an enzymatic biosensor for glucose detection (Rakhi et al., 2016).

In Tissue engineering and regenerative medicine, Zhu et al. (2020) fabricated MXene-polymer nanocomposite scaffolds for bone tissue engineering applications. The nanocomposite scaffolds exhibited excellent biocompatibility, enhanced mechanical properties, and promoted osteogenic differentiation of mesenchymal stem cells (MSCs) in vitro (J. Zhu et al., 2020). In a study by Ma et al. (2021), MXene-polymer hydrogels were developed as injectable scaffolds for cartilage repair. The nanocomposite hydrogels exhibited excellent biocompatibility, controlled drug release, and promoted chondrogenic differentiation of MSCs, showing potential for cartilage regeneration (Ma et al., 2021)

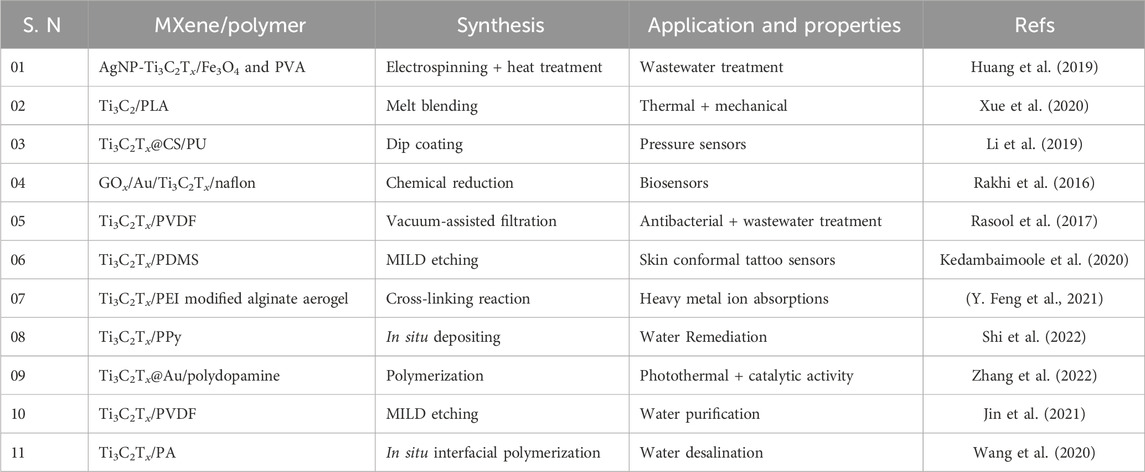

The literature demonstrates the biocompatibility of MXene-polymer nanocomposites for biomedical applications, including tissue engineering, drug delivery, and implantable medical devices. Further research is needed to fully understand the biocompatibility mechanisms and optimize the design of MXene-polymer nanocomposites for safe and effective biomedical applications. The synthesis, application, and properties of MXene-polymer nanocomposites are listed in Table 3.

Table 3. MXene–polymer composite materials for Biocompatibility and environment remedies with synthesis, application, and properties (adopted from (Parajuli et al., 2022)).