- 1Urban Water Management and Hydroinformatics Group, Department of Water Resources and Environmental Engineering, School of Civil Engineering, National Technical University of Athens, Athens, Greece

- 2KWR Water Research Institute, Nieuwegein, Netherlands

Effective waste management is crucial for sustainable industrial operations. This paper introduces a state-of-the-art digital tool designed for the circular economy. Primarily it pinpoints and quantifies symbiotic possibilities between industries with liquid waste streams, emphasising the most lucrative inter-industry connections. In practice, the tool takes in data such as waste stream volumes, material concentrations within these streams, market prices of materials, and industries’ raw material consumption rates. Utilising these, its algorithm identifies and assesses the most profitable material exchanges among the specified industries. This assessment considers the market value of materials and the costs associated with recovering those materials from liquid waste streams. One of the major challenges, the estimation of recovery costs, is addressed using an innovative Sherwood plot analysis. This analysis draws a correlation between a material’s recovery cost and its concentration within a liquid medium. The tool’s output provides a detailed list of potential transactions complemented by illustrative graphs that detail mass flows, profit margins, and environmental advantages for each industry. Collectively, these details offer insights both for individual industries and the industrial ecosystem as a whole. One of the tool’s most significant revelations is its ability to uncover potential “bridges” linking industrial waste streams to resource needs, unearthing previously unnoticed economic and ecological gains. By calculating economic and environmental benefits of “waste” reuse, this tool offers a compelling rationale for the adoption of industrial symbiosis. Ultimately, it uncovers the transformative potential of aligning industrial activities with a balance that fosters both economic growth and ecological responsibility.

1 Introduction

The constant growth of human society and economy is evidently putting an increasing stress on our natural habitat. Therefore, the need for more sustainable practices is widely accepted now by stakeholders in multiple levels (State, institutions and individuals) and organised efforts are being made. In this concept of Circular Economy—i.e., maximising the sharing, leasing, reusing, repairing, refurbishing and recycling of resources and products (European Parliament, 2023)—exists the notion of Industrial Symbiosis: “traditionally separate industries coming together in a collective approach to competitive advantage involving physical exchange of materials, energy, water, and/or by-products” (Chertow, 2000). The widespread potential and opportunity of such synergistic collaboration among industries has been identified early on, and applied successfully (with Kalundborg being the most popular example) (Chertow, 2007).

In the effort to facilitate and proliferate such practices, extensive research has been performed to “map” the existing IS landscape and identify various factors contributing to success and to failure of such endeavours. Overall, Industrial Symbiosis has a reportedly small uptake (e.g., <0.1% in European enterprises in 2019) due to technical/physical, financial, economic, regulatory, social, informational, and managerial barriers with the latter two being regarded as the most significant (Kosmol and Leyh, 2019). In this direction, a variety of ICT tools have been developed over the years, covering a wide spectrum of aspects (e.g., opportunity identification, opportunity assessment, barrier removal, commercialisation, external assessment, documentation and publication) in this “match-making” process (Grant et al., 2010). Building upon this foundation, digital tools/platforms have emerged to further facilitate this effort, evidently achieving multiple financial, social and environmental benefits (Silva et al., 2022)but eventually their application and uptake in the domain has been proven to not be successful and widespread for multiple reasons. As previous research has revealed the five predominant factors are: “a lack of commitment to sustainability [on behalf of companies], a lack of cooperation [among industries], informational barriers, technical barriers and economic barriers” (Krom et al., 2022).

In view of the current state and taking into consideration these factors, the Urban Water Management and Hydroinformatics group of NTUA’s (National Technical University of Athens) School of Civil Engineering has decided to initiate an endeavour: developing a digital suite of tools and services that will holistically cover these gaps and remove these barriers, allowing for a more fluent coordination among stakeholders that will eventually materialise Industrial Symbiosis practices. A first component of this suite is the Industrial Wastes Matchmaking tool (IWMM tool). In this publication the current state of development is presented, the existing functionality is explained and the future addition of features is discussed.

2 Scope—methodology—design

2.1 Scope

As mentioned above there exist multiple barriers that inhibit the adoption of Industrial Symbiosis among industry agents. The goal of developing the IWMM tool is to apply the expertise of our group—in water management and hydroinformatics—to the industrial sector in an effort to remove these barriers. Hence, to begin with, the tool focuses on water-matrix industrial “waste” streams. Furthermore, we acknowledge that the industrial sector is primarily profit-centric and is much more responsive to financial, short-term, direct incentives rather than long-term, holistic estimations or social/political/environmental influences and trends. For that reason, we target through the tool primarily the financial aspect, in an effort to provide quantitative profit-relevant results that are expected to have the most impact in decision making of the engaged stakeholders.

These parameters frame the operational concept of the IWMM tool: a software, provided as a service, that when given (for a set of industrial units, “agents”) A) the detailed characteristics (quantity and quality) of various water-based waste streams (“outputs”), B) the various raw material demands (“inputs”) and C) the existing market conditions (prices of the aforementioned input-output materials), it can identify synergies (input-output matches) and provide quantitative results on the profit created from these matches and transactions for all agents involved and the ecosystem cumulatively.

This kind of analysis is deemed to be valuable for multiple stakeholders in the field of Industrial Symbiosis. Some of the most apparent cases are:

• Industrial agents themselves, as it will reveal new profitable transactions that can serve as a starting point for a techno-economical analysis investment that might prove feasible and worthy.

• Organisations and institutions in the field of eco-industrial park assessment/management, as it can provide detailed results for the sum of the symbiotic transactions of the network.

• Researchers, as it can serve as a what-if scenario analysis tool that can serve in the direction of exploring thresholds, patterns, “tipping points” etc. of symbiotic networks.

• Government and policymakers, as any of the above-mentioned results could be utilised in a manner to design and instate systemic, top-down incentives and policies towards the desired direction.

2.2 Methodology—algorithm

Having identified the “high-level specifications” and the “end goal” of the tool, the computational algorithm was developed through sequential iterative cycles of ideation, addition/modification of features and internal peer reviewing. While it is still developing, a foundation of parameters has been identified, upon which the current version operates and the future development will expand on.

2.2.1 Algorithm parameters

While the selection of the variables to be included in the algorithm has been developed in tandem with the logic of the algorithm, it is deemed preferable to present them first in order to facilitate the “narrative” of the logic later on. Therefore, here is a brief mention of the variables (as organised in the user interface of the tool) that the user is requested to input (i.e., populate the database) in order to perform the simulation (their functionalities is explained in the next sub-chapter):

• “Market Materials”: the user creates an entry for each of the materials existing in the ecosystem (inputs and outputs) with its name (text value), a market price (numerical value, the price that it is commercially available) and the factors a and b (numerical values) of its Sherwood-plot recovery-cost function.

• “Industries”: the user creates an entry for each of the industrial units (agents) in the ecosystems with its name (text value), a short description (text value), the type of “personality” (“profit-only,” “self-sufficient” or “eco-friendly”), and the geographic coordinates (numerical values).

• “Raw materials”: for each of the agents defined previously, the user creates an entry for any of the materials defined in “market materials” that the agent is consuming as input. The entry contains a numerical value for the consumption of the material (unit: mass/time, e.g., tons/day).

• “Waste streams”: for each of the agents defined previously, the user creates an entry for each waste stream the agent is producing. The entry contains its the name (text value) and volumetric flow (numerical value, unit: volume/time, e.g., m3/day).

• “Waste materials”: for each of the agents and each of their respective waste streams defined previously, the user creates an entry for any of the materials defined in “market materials.” The entry contains its name (text value), concentration (numerical value, unit: mass/volume e.g., ton/m3) and a yes/no indication for the parameter “recoverable” (depending whether the material will be considered available for recovery and thus overall “participation” in the symbiotic transactions).

Upon input, this—admittedly extensive amount of—information is stored in a database organised in the corresponding tables with the required type of relationships and restrictions among them (e.g., one-to-many relationship, foreign key constraints etc.).

2.2.2 Algorithm logic

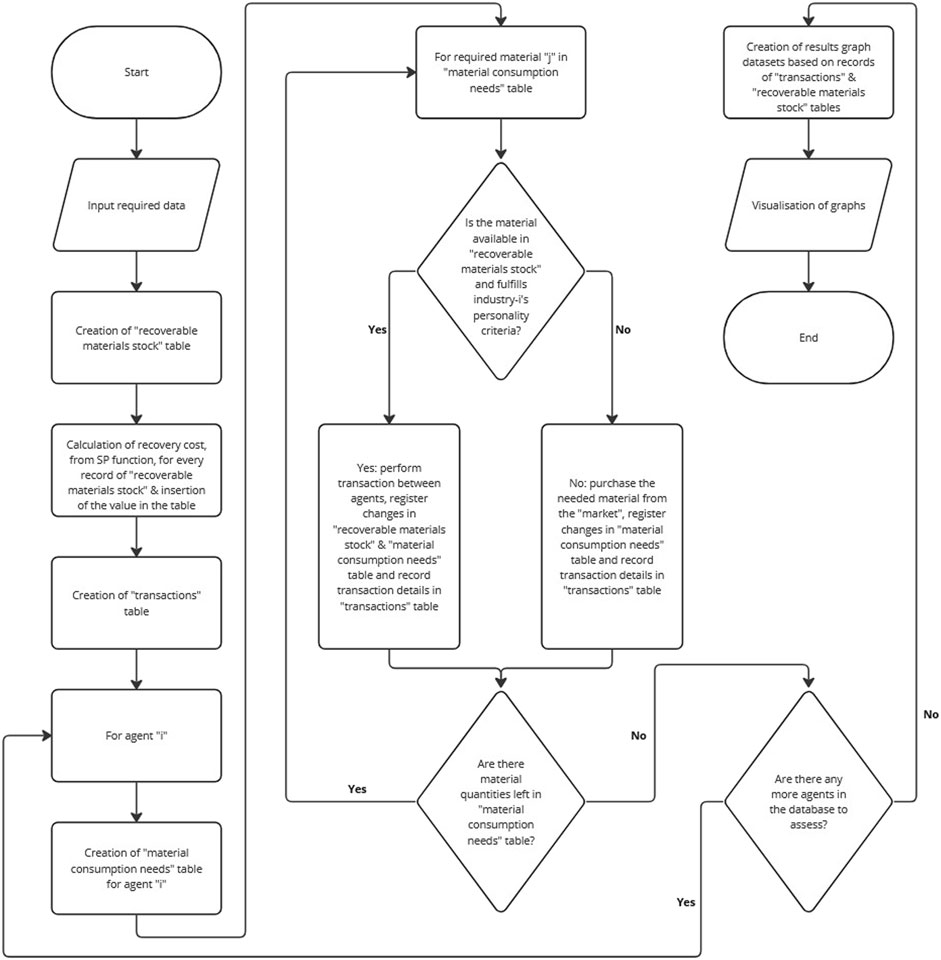

The tool utilises a simple computational algorithm logic that incorporates elements of agent-based modelling. In a nutshell the algorithm first “takes inventory” of the available materials for recovery (outputs) and the required materials consumptions (inputs) and then based on logic-rules decides whether a material need will be covered by a recoverable material or by the market. All transactions are registered in a “trade log” table and upon exhaustion of materials needed the results are calculated and presented. A high-level flow chart of the logic is presented in Figure 1.

This specific algorithm design was chosen based on an assessment between “simplicity - straightforwardness” vs. “flexibility—results.” As mentioned before, the selection of variables for data input by the user has influenced the design accordingly. To elaborate on this overall balance, a more detailed view of the algorithm is required, with emphasis on some critical design points.

2.2.2.1 Part 1—sherwood plot

As soon as the user inputs the required data, the simulation can begin. The first step is to create a table that will serve as a “stock inventory” of all the materials that can be recovered. This table has a record for every material (that was marked as “recoverable” by the user), in every waste-stream of every industry along with its total available quantity (product of “waste-stream volumetric flow” * “material concentration”) and calculated cost of recovery.

This brings us to one of the main value offerings of the IWMM tool: the utilisation of the Sherwood Plot methodology. As stated earlier (in Section 2.1), removing the information barrier, with emphasis on the financial aspect, is a key intention of the tool. With businesses responding to increased-profit incentives, the financial assessment of material-recovery from waste is a determining factor. Yet, having such business-potential, this kind of information is not openly available and thus an alternative estimator is required that is both reliable and flexible. The Sherwood Plot proved to be the most suitable approach as it depicts “the relationship between the required market price of a target material to be recovered from a waste matrix and its dilution (reverse concentration at logarithmic scale) in the latter” (Karakatsanis and Makropoulos, 2022). Beginning from a complex mathematical form it can be rendered to “the most frequent empirical form, […] the linear one” i.e., y = a*x + b where y is the recovery cost and x is the dilution. The value of Sherwood plot comes from the fact that for each assessed Value Added Compound (material of interest) the cost of recovery proves to be predominantly affected by the dilution, irrelevant from other factors (e.g., type of matrix or co-existence of other compounds in the matrix). Therefore, obtaining the a and b factors from bibliography, theoretically, the tool is able to provide a reliable cost recovery estimation for a material, regardless of industry, regardless of waste-stream.

2.2.2.2 Part 2—agent based modelling

Having a complete inventory of recoverable materials available the next step is to create the “transactions” table, essentially a trade log that as the simulation progresses any transactions executed in the ecosystem are recorded there noting the buyer, the seller (or “market”), the material (and the exact waste stream it originates from), the cost of the material’s recovery for the seller (if applicable), the transacted mass of the material and the total financial value of the trade (see below in Section 2.2.2.3). The computational part of the algorithm can now begin, selecting the first agent in the database and taking inventory for its material consumption needs (material and quantity). Then, progressing iteratively through all the materials needed for the agent currently under assessment, the algorithm juxtaposes the “recoverable materials stock” with the “material consumption needs” table and taking into consideration the “personality” defined for each agent it decides whether a symbiosis-transaction should be executed or the need will be covered by purchasing the required quantity from the market.

The addition of the “personality” parameter is an Agent Based Modelling element meant to address more effectively the inherent complexity of the IS system (Fraccascia and Yazan, 2018) flexibility and diversification that increases the “realism” of the simulation. The rationale is that symbiotic networks and their performance might be governed by general economic theories—as all markets and ecosystems—but practically develop from the individual decisions of the involved agents that can significantly deviate from the standard economic theory (e.g., a narrow definition of the “rational consumer”). Practically, the “personality” parameter is an objective function upon which the algorithm decides which transactions should be executed. Indicatively, in the current version of the tool three “personalities” have been established:

• Profit-only: The algorithm will compare the calculated recovery costs of the material (for different waste streams) with the market price of the material and aim to minimise the transaction value.

• Self-sufficient: The algorithm will first go through the “recoverable materials stock,” isolate records of the current agent and perform these transactions (i.e., internal recycling) regardless of recovery cost vs. market price comparison. If a material is not available for self-reuse, then it proceeds with a profit-only criterion.

• Eco-friendly: If the material is available in “recoverable materials stock” then the algorithm proceeds to execute the transaction, regardless of recovery cost vs. market price comparison. If it is not then and only then it will purchase it from the market.

Having this variable in place allows the user to examine how a specific setup of an industrial ecosystem (materials, needs, waste streams, market prices etc.,) can be affected solely by the variation of the decision making rationale of the participating agents. A straightforward example is how in the case of an “eco-friendly” agent, Industrial Symbiosis can result in an increase of expenses (to the contrary of its pursued financial benefits) since in this case a material will be preferred for purchase from the recoverables stock even at a higher cost than the market.

2.2.2.3 Part 3—drawing results

The algorithm repeats this process until all material needs are covered for all the agents. Each transaction is registered in the “transactions” table and upon completion it proceeds to the final step of creating datasets that will be illustrated as graphs to the user. The results are first and foremost organised in two broad categories: “Global” that refer to the cumulative results of the ecosystem under assessment and “Individual” that refer to results for each agent separately. This first categorisation is made in order to accommodate different needs of different users. The former applies to a type of user that is interested to evaluate the general economic and environmental impact IS can have (e.g., park manager, policymaker, researcher) while the latter applies to a type of user that is interested in the individual benefits IS holds for an industrial unit (e.g., plant manager, business decision-maker).

For each of these two groups the results correspond to two broad categories: mass-flows and financial flows. Also, emphasis is put not only on the results achieved after the “implementation” of IS but also on the outcome if symbiotic transactions were not performed, and the majority of graphs has a before-after style of layout. This is meant to serve as a benchmark upon which the added value of IS can be evaluated more clearly (for further details please read on to chapter 3.3.3. Simulation).

An important remark to be made refers to the evaluation of symbiotic transactions. Each needed material has a market price and—depending on the waste stream—a recovery cost. The question therefore arises: if Agent A can either buy the material from the market at price PM or from Agent B that can recover it at a lower cost PR, then at what price PT should they agree to transact? While a free-market approach could yield any PT∈(PM,PR) a simplified, yet reliable, approach was taken here concluding that PT=(PM + PR)/2 as this is deemed the logical and most fair result of a financial negotiation among the two agents (Nalebuff, 2022).

2.2.3 Algorithm technology stack

The Engine is based on an open source, fast and very secure stack of applications. Its most important layers are:

• Data Visualization layer which is based on:

○ HTML/CSS/Javascript/JQuery

○ the Apache licensed open-source JavaScript Visualization Library Echarts. The communication with the rest of the application components is done using mainly AJAX requests.

• The Application layer which consists of:

○ Python 3 on Django Web Application Framework

○ Pandas, which is a powerful and open-source Python library designed for data manipulation and analysis.

• The Data layer which consists of:

○ PostgreSQL Server v.12, a powerful and open-source relational database management system which excels in handling large volumes of data

○ REDIS server which works alongside the Database server as an application cache and quick-response database.

○ NginX is a high-performance web server responsible not only for media streaming (and generally all static content) but for load balancing of the requests ensuring optimal resource utilisation.

In order for our application to respond as quickly as possible, handle many concurrent requests—if needed, and big datasets we have transferred part of the complexity to the PostgreSQL database transactional procedures, freeing the application layer from doing rudimentary data processing jobs. On the other hand, Pandas data analysis library is responsible for most of the complex processing regarding big data frames and time series. Finally, we use Linux servers to host the application, specifically ubuntu LTS releases.

2.3 Design

Having identified the “high-level” specifications of the tool, the design that was deemed most appropriate and effective for the tool has been selected. Putting emphasis on accessibility, a software-as-a-service provision model was chosen and the tool is available online through a dedicated server (at https://iwmmt.uwmh.eu/). As with all digital tools, user-friendliness is a key factor and thus it is operated through a convenient and intuitive user interface (organised text fields and drop-down menus). In a nutshell the “user-journey” is to create an account—log in, input the relevant data, run the simulation and then browse through the results. Therefore the tool interface comprises of three tabs: Home page, Industrial Data and Simulation.

2.3.1 Home page (database summary)

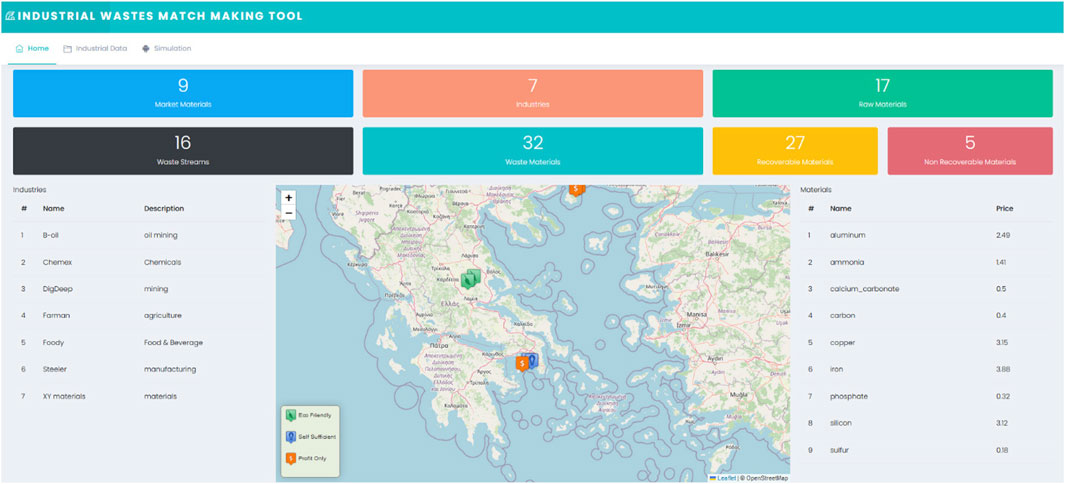

Figure 2 is an indicative view of the Home page. After the insertion of the relevant data from the user (in the next tab, “Industrial Data”), it is meant to serve as an overview-summary of the populated database. It illustrates on the top the population of some key back-end algorithm’s parameters, on the right side a list of the simulation’s materials and their defined market-prices, on the left a list of the simulation’s examined industrial units (“agents”) and on the centre a GIS visualisation of the agents’ location (see Section 2.2.1).

2.3.2 Industrial data (data input)

This is the tab that the user utilises in order to populate the database with the required data needed for the simulation to run. It has a simple text field and drop-down menu structure for insertion/selection of values and the interface follows the relationships and restrictions of the database schema. Once a record is saved then it is immediately updated in the existing summary table allowing the user to have a clear image of the entered data existing currently in the database.

2.3.3 Simulation (graph visualisations)

Upon completion of data input the user can switch to the “Simulation” tab and click on Run Now. The simulation runs and results are presented below. As mentioned in Section 2.2.2.3 Part 3—Drawing results, there exist two main tabs of results “Global” and “Individual.”

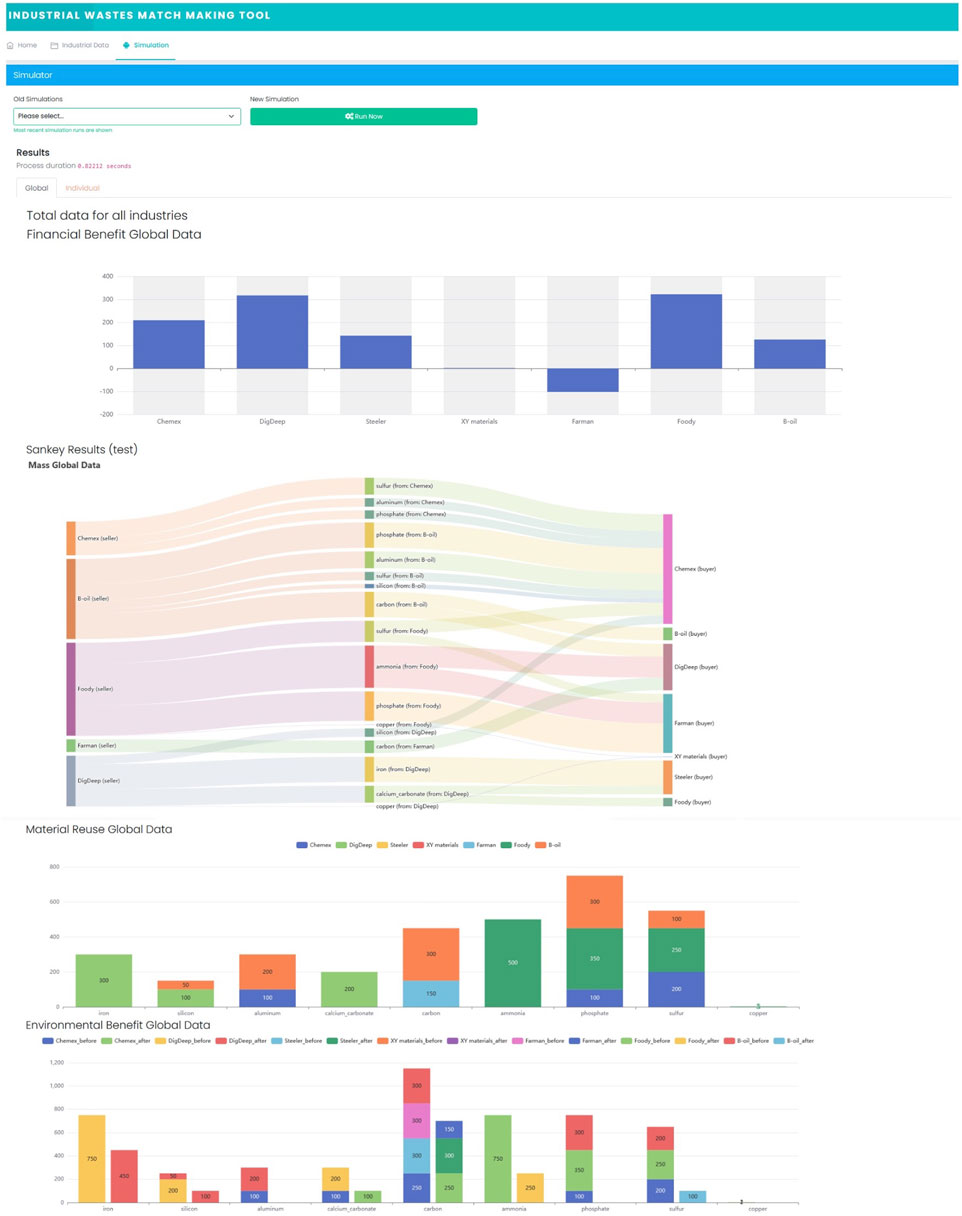

Figure 3 shows an indicative view of the “Global” tab. In sequence the presented graphs are:

• Financial Benefit Global Data: this bar chart indicates the financial benefit (y-axis: amount) of each agent (x-axis: agents) as a difference of profits (and expenses) with and without IS.

• Sankey Mass Global Data: one of the most insightful graphs, a three-tiered Sankey diagram of material mass flows. On the first tier are the “seller” agents, on the second tier are the recovered-transacted materials of each “seller” and on the third are the “buyer” agents. The thickness of the links between the nodes indicates the mass.

• Material Reuse Global Data: this stacked bar chart indicates the mass (y-axis) of every material of the ecosystem (x-axis) that has been recovered-transacted. Each material amount is broken down further to its agent source (colour axis).

• Environmental Benefit Global Data: this stacked twin-bar chart indicates the mass (y-axis) of every material of the ecosystem (x-axis) that requires waste disposal without (left bar) and with (right bar) IS. Each material amount is broken down further to its agent source (colour axis).

The “Individual” tab, shown below in Figure 4, has a similar approach. The values presented there refer only to the agent selected from the drop-down menu and are categorised quickly in two columns of graphs, the mass values on the left side and the profit (monetary) on the right.

In sequence, the presented mass and profit graph sets are:

• Individual Data (Mass and Profit): a four-tiered Sankey diagram. On the first tier is the “seller” agent currently under presentation, on the second is the waste-stream, on the third is the material recovered from the respective waste stream and on the fourth is the “buyer” agent. The thickness of the link between the nodes indicates the value.

• Sales (Mass and Profit): this stacked twin-bar chart indicates the value (y-axis) of every waste-stream the agent performs recovery upon (x-axis). Each waste-stream amount is broken down further to its materials (colour axis).

• Expenses Mass: this stacked triplet-bar chart indicates the mass (y-axis) of every material (x-axis) the current agent is purchasing to cover its consumption needs. The left bar indicates the mass purchased from other industries, the middle bar the amount that was recycled internally and the right bar the amount that was purchased from the market. Each material amount is broken down further to its origin agents/market (colour axis).

• Expenses Profit: this stacked twin-bar chart indicates the “profit” of IS through comparison of expenses (y-axis) with (left bar) and without (right bar) IS for all the purchased materials (x-axis). Each material amount is broken down further to its origin agents/market (colour axis).

• Pollution Mass: this stacked twin-bar chart indicates the mass (y-axis) of every material (x-axis) that requires waste disposal with (left bar) and without (right bar) IS. Each material amount is broken down further to its origin agents/market (colour axis).

3 Results

Overall, the tool provides an abundance of results, valuable to multiple stakeholders/occasions. On the “Global” scale it provides a very concise picture of financial performance, transaction mass flows and environmental benefits, that effectively provide the user with a much more tangible “rendering” of IS’s impact, clearly motivating towards its implementation.

Putting proportional emphasis on the “Individual” set of results—since it is the decision-making on the individual level that can eventually create a symbiotic network—similar financial, mass flow and environmental information are provided, illustrating a compelling case in favour of implementing IS. Strategic emphasis is put on the “waste stream” level as, realistically considering, any kind of intervention (e.g., addition of a material recovery apparatus) will be performed in this level. Therefore, providing a decision-maker of an industrial unit with such detailed and relevant information facilitates the implementation of the corresponding intervention.

Overall, with the dual Global x Individual approach the tool is able to provide clear and motivating pro-IS indicators to both regulators/policymakers (“global”) and private sector agents (“individual”), ultimately resulting in a two-pronged approach on the implementation of Industrial Symbiosis.

4 Discussion—future steps

The “Industrial Wastes Matchmaking Tool” is a digital tool designed to alleviate the information barrier that exists between business-as-usual and the Industrial Symbiosis paradigm, with an emphasis on financial benefits as a driver for Industrial Symbiosis. The current version and results presented here are only a milestone of a longer endeavour to create a highly usable and resourceful tool. Indicatively, some of the future steps currently under development are:

• Reduction—facilitation of data load: an import-export feature will allow for transfer of data in bulk, while the internal database will be able to suggest values (e.g., SP function’s a and b parameters).

• Reporting: an auto-generated “printable” report can facilitate the communication of the simulation results among stakeholders.

• Materials standardisation: an integration of material “library” (e.g., CAS number) will eliminate the possibility of duplicate material entries.

• Results homogenisation: the current design of the algorithm “punishes” the agents on the bottom of the list (facing an increasingly depleted “recoverable materials stock”). A homogenising function, where the list is shuffled multiple times and the results are averaged will alleviate this bias (Monte Carlo simulation).

• Expansion of symbiotic relationships: beyond materials, also energy, water and even equipment can be utilised in an IS context. Addition of these parameters to the simulation can enhance further the revealed symbiotic potential for a set of agents.

• Sensitivity analysis: allowing the simulation to run for generalised differentiations of the database (e.g., market prices increased by 5%–10%–15%) will reveal possible tipping points for the Industrial ecosystem equilibrium.

• Subsidy-penalty factors: correlation of the environmental impact to the financial aspect, through implementation of subsidy/penalty function, could also reveal possible tipping points (thus providing indicative points of reference as to what kind of policies/regulations/incentives would facilitate such a shift).

• User feedback function: capacity for the user to send feedback to the developers for purposes of troubleshooting, suggestion of features and general comments.

• Field testing: upon reaching a sufficient level of “maturity”, finding a suitable existing stakeholder scheme (e.g., industrial park with symbiotic streams) where the tool’s outcomes will be compared against the actual situation in order to initially verify the simulation results and furthermore propose further symbiotic relationships.

More generally, efforts will be focused on providing deeper levels of detail (e.g., breaking down recovery costs further to capital and operational—transportation and energy etc.) aiming to eventually reveal the “mechanics” of Industrial Symbiosis, in practical terms: to discern the set of factors and their interactions that have the most impact on whether Industrial Symbiosis is feasible/viable. In this effort certain limitations naturally exist since the tool attempts to simulate a very complex and novel market scheme that cannot be fully described in mathematical terms and therefore calculated in absolute precision. Still, any contributing factors or patterns that will be identified through the tool’s analysis are expected to provide significant support in advocating successfully for the implementation of Industrial Symbiosis and its new business paradigm.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

CM: Writing–review and editing, Supervision, Methodology, Conceptualization. N-AK: Writing–original draft, Visualization, Software, Project administration, Methodology, Investigation. CP: Writing–original draft, Visualization, Software.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This initiative has partially received funding from and developed in the context of the Horizon 2020 project ULTIMATE: indUstry water-utiLiTy symbIosis for a sMarter wATer society (Grant Agreement number: 869318).

Acknowledgments

While the author here are the core team behind the current version of this digital tool and the results produced, the overall idea has been incepted, initially explored and tentatively developed in the past, upon which progress we were able to re-launch the initiative. Therefore we would like to acknowledge the contribution of Isidora Zerva for the initial development of the concept, Kostas Eftaxias and Paraskevi Karka for their work on the first computational—visualisation algorithm and Iosif Spartalis for the further development contributions to that version.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Chertow, M. R. (2000). Industrial symbiosis: literature and taxonomy. Annu. Rev. Energy Environ. 25 (November), 313–337. doi:10.1146/annurev.energy.25.1.313

Chertow, M. R. (2007). “Uncovering” industrial symbiosis. J. Industrial Ecol. 11 (1), 11–30. doi:10.1162/jiec.2007.1110

European Parliament (2023). Circular economy: definition, importance and benefits. Available at: https://www.europarl.europa.eu/news/en/headlines/economy/20151201STO05603/circular-economy-definition-importance-and-benefits.

Fraccascia, L., and Yazan, D. M. (2018). The role of online information-sharing platforms on the performance of industrial symbiosis networks. Resour. Conservation Recycl. 136 (September), 473–485. doi:10.1016/j.resconrec.2018.03.009

Grant, G. B., Seager, T. P., Massard, G., and Nies, L. (2010). Information and communication technology for industrial symbiosis. J. industrial Ecol. 14 (5 (October), 740–753. doi:10.1111/j.1530-9290.2010.00273.x

Karakatsanis, G., and Makropoulos, C. (2022). Resource recovery and the Sherwood plot. Entropy 25 (1), 4. doi:10.3390/e25010004

Kosmol, L., and Leyh, C. (2019). ICT usage in industrial symbiosis: problem identification and study design. Proc. Fed. Conf. Comput. Sci. Inf. Syst. 18 (September), 685–692. doi:10.15439/2019F323

Krom, P., Piscicelli, L., and Frenken, K. (2022). Digital platforms for industrial symbiosis. J. Innovation Econ. Manag. 39 (June), 215–240. doi:10.3917/jie.pr1.0124

Keywords: industrial symbiosis, circular economy, sustainability, material reclamation, waste valorisation, digital tool, optimisation, Sherwood plot

Citation: Makropoulos C, Kritikos N-A and Pantazis C (2024) Matchmaking for industrial symbiosis: a digital tool for the identification, quantification and optimisation of symbiotic potential in industrial ecosystems. Front. Chem. Eng. 6:1363888. doi: 10.3389/fceng.2024.1363888

Received: 31 December 2023; Accepted: 16 May 2024;

Published: 06 June 2024.

Edited by:

Gurkan Sin, Technical University of Denmark, DenmarkReviewed by:

Peam Cheali, Technical University of Denmark, DenmarkEvina Katsou, Brunel University London, United Kingdom

Copyright © 2024 Makropoulos, Kritikos and Pantazis. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Nikolaos-Alexandros Kritikos, YWxleGtyaXRpa29zQG1haWwubnR1YS5ncg==

Christos Makropoulos

Christos Makropoulos Nikolaos-Alexandros Kritikos

Nikolaos-Alexandros Kritikos Christodoulos Pantazis1

Christodoulos Pantazis1