94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Chem. Eng., 15 February 2022

Sec. Computational Methods in Chemical Engineering

Volume 4 - 2022 | https://doi.org/10.3389/fceng.2022.828375

Most of today’s consumer electronic products such as cell phones, laptops, and tablets use pouch lithium-ion cells to make the most efficient use of space, compared to cylindrical and prismatic designs. However, eliminating the metal enclosure comes at a cost if the pouch cell swells due to gas generation and damages the product it is contained within. This paper presents various swollen battery examples in consumer products and how companies handle the issues, reviews the mechanisms of the gas generation, and offers solutions to prevent pouch cell swelling from affecting the devices.

Lithium-ion batteries have become the first choice of power for today’s portable electronics due to their relatively high specific capacity, energy density, and power density (Ren et al., 2018). These advantages allow Li-ion batteries to support long-term operation and high-current usage in products ranging from cell phones, computers to power tools and automotive applications (Aalund et al., 2021).

Commercial lithium-ion batteries come packaged in primarily four formats: coin, cylindrical, prismatic, and pouch; the first three having a hard metal casing. Coin cells are typical in small wearable consumer and medical devices such as wristwatches, calculators, and hearing aids, which require capacity levels of hundreds of milli-ampere-hours. Cylindrical cells are often used in medical instruments, e-bikes, power tools, and electric vehicles (Blomgren, 2016). Cylindrical cells have advantages associated with the ease of manufacturing, mechanical stability, and high internal pressures without deforming (Schröder et al., 2017). The major disadvantage is that the cell’s circular cross-section does not fully utilize the available space when combining cylindrical cells into packs and modules. Prismatic cells are primarily used in industrial applications, certain powertrains in hybrid and electric vehicles, and some space applications (Schröder et al., 2017). The prismatic cell uses a cubic-shaped metal can (Schröder et al., 2017) with higher packaging flexibility and space efficiency than cylindrical cells. However, the prismatic cell types are more expensive to manufacture than cylindrical cells. Pouch cells are similar to prismatic cells in shape, but instead of using a hard metal casing, pouch cells typically use polymer-coated aluminum foil casings.

Eliminating the metal casing makes pouch cells lightweight and enables them to conform to their enclosure modestly. However, pouch cells have been known to expand due to gas generation in the cell (Ellis et al., 2017; Mao et al., 2017). Swollen cells can damage the surrounding components such as electronic circuitry boards or displays. Swollen cells are also indicative of a safety risk since the volatiles are flammable and toxic if punctured.

Gas generation is a byproduct of electrochemical and chemical reactions inside the battery, which can occur when the battery is operational or in storage. The gas generation rate is dependent on chemistry, manufacturing quality, and battery management. Gas generation can be accelerated by increasing the ambient temperature, the discharge current, and by overcharging and over-discharging (Fear et al., 2018). Common gas species generated from typical lithium-ion battery composition are often toxic, e.g. CO, HF, SO2, NO2, NO, and HCl (Ellis et al., 2017; Mao et al., 2017).

This paper presents various swollen battery case studies, discusses why the gas generates, and offers solutions to prevent pouch cell swelling from affecting the devices. Section 2 reviews various swelling incidents in consumer electronics products such as phones and laptops. Section 3 discusses the gas generation mechanisms in lithium-ion batteries and the probable causes of the case studies. Section 4 presents conclusions and recommendations.

Swollen pouch cell issues have been reported on various consumer electronics products such as phones and laptops, causing the device not to operate and the trackpad, screen, or outer cases of the devices to deform, pop open, or fracture (Puls Technologies Inc, 2019; Androidcentral, 2020). Sun et al. (2021) showed that the contact pressure of the swollen cells with 278% volume increase on the surrounding components was up to 28 N/mm2. The swelling can compromise the waterproof or water-resistant level of the device (Dube, 2018). There are also safety risks such as explosion, fire, or toxic gas if the swollen pouch cell is punctured and the gas is released (Hofmann et al., 2017; An et al., 2021).

A few weeks after Apple released iPhone 8 and iPhone 8 Plus in 2017, there were complaints about iPhone 8 regarding battery swelling problems and product damage (Puls Technologies Inc, 2019). On 9 October 2017, BBC News reported six incidents of iPhone 8 plus phones “splitting apart soon after usage”. One reported iPhone 8 Plus swelling incident occurred within 5 days of purchase when charging the phone with the supplied cable and plug adapter (Jacob, 2017; Lovejoy, 2017). Two iPhone 8 Plus owners from Taiwan and Japan also shared pictures of the device burst open due to reported battery swelling (Rossignol, 2017a). In both cases, the batteries were swollen, and the resulting expansion placed pressure on the outer case and display, causing the display to pop open. Other iPhone 8 Plus owners shared pictures of their devices that had similarly burst open (Rossignol, 2017b). In all these cases, the battery inside the phone has swollen, making the phone unusable. Apple noted the problem and stated, “We are aware of it and looking into it” (BBC NEWS, 2017; Jacob, 2017). In November 2017, Apple launched iPhone X, and there were again complaints about the screen popping out and battery swelling reported on the Apple support communities (Apple, 2020a; Apple, 2020b).

Apple set up Logic Board Replacement Program in August 2018 (Apple, 2018a) and stated that a very small percentage of iPhone 8 devices contained logic boards with a manufacturing defect. Affected devices may experience unexpected restarts, a frozen screen, or will not turn on (Apple, 2018a). The program did not provide documentation on how to deal with swollen batteries in smartphones.

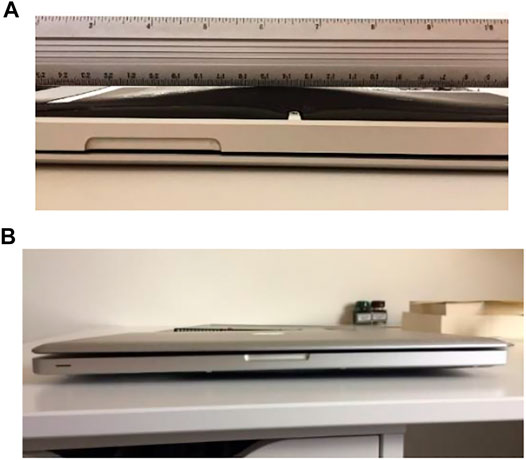

Swollen battery problems in MacBooks date back to 2010, suggesting the swollen battery issue has been a long-time widespread and unsolved problem by Apple (Apple, 2018b). For example, a customer posted on Apple Forum (Apple, 2017) that the battery in his 2011 13" MacBook Pro had swollen to the point where it broke the trackpad. Figure 1 shows photos of a MacBook Pro 2011 with swollen batteries from another customer. Figure 2 shows pictures of swollen MacBook Pro 2011 batteries.

FIGURE 1. MacBook Pro 2011 with swollen batteries (Apple, 2017). (A) Bottom view of mechanical enclosure bulging due to swelling. (B) Front facing view of mechanical enclosure.

FIGURE 2. Swollen MacBook Pro 2011 batteries (Apple, 2017). (A) Top view of swollen batteries. (B) Side view of swollen batteries.

In April 2018, Apple started a battery replacement program for some versions of the 13-inch MacBook Pro, warning consumers that the battery in these laptops may physically expand or swell, owing to a component failure. While Apple claims the MacBook Pro batteries cause no immediate safety issues, the company advised customers to check whether their laptops are affected and, if so, to contact the company to get the batteries replaced (Deleon, 2018). The battery replacement program applied to MacBook Pro models without a Touch Bar manufactured between October 2016 and October 2017 (Moon, 2018). In the 13-inch MacBook Pro battery replacement program, Apple claimed that “This is not a safety issue” (Apple, 2020c; Apple, 2020d). However, a swollen lithium-ion battery may catch on fire or explode and must be proceeded with extreme caution when removing a swollen battery from an electronic device (Hofmann et al., 2017; An et al., 2021). For the 15-inch MacBook products (Apple, 2020e), five people reported minor burn injuries, and one reported suffering from inhaling smoke (Apple, 2018b).

Apple watches also suffer from swollen battery issues, which induce watch failures. For example, Figure 3 shows photos of a swollen battery from an Apple watch, which occurred while powering on and caused the display to burst open. In January 2020, a customer posted on Apple Forum (Apple, 2020f) that the battery had swollen in his Apple Watch Series 3 and popped the screen out.

FIGURE 3. A swollen Apple Watch battery (Apple, 2020f).

In April 2018, Apple offered free-of-charge repairs for selected Apple Watch Series 2 models that cannot power on or have a swollen battery as part of a service policy (Rossignol, 2018). In some cases, Apple attributed the issue to “accidental damage” and thus refused to cover repairs under warranty (Rossignol, 2019). For example, New Jersey residents filed a class-action suit that Apple Watch batteries are swelling up and popping off or breaking the smartwatch’s screen through no user’s fault. The repair program in 2018 was limited to Apple Watch Series 2 models, but the lawsuit alleges that the problem indeed affects models from all generations (Ewdison, 2019).

Swollen pouch cell issues that resulted in the case lift-off were also observed in Google Pixel 2XL, 3, 3 XL, and 4XL series phones, often within 1–2 years of purchase (Gao, 2020; Mix, 2020; Mohan, 2020). Free replacements were offered to solve this issue; however, this was a one-time offer and not honored if the phone was out of warranty (Gao, 2020; Mix, 2020; Mohan, 2020). A Google Pixel customer reported that the replaced pouch cell swelled again (Pixel Phone Help, 2020).

Swollen battery issues also occurred to Huawei phones (p20 pro, mate 10 pro, nova 3i) (Reddit, 2020) and Samsung phones (Galaxy S20, S7, S8) (Androidcentral, 2020) within 1–2 years of purchase. These issues occurred during the charging or non-charging period. These case studies show that swollen pouch cells are general issues that concern prominent consumer electronics companies. Furthermore, the companies have done little to resolve the issues with their course of actions.

In a lithium-ion battery, lithium ions move from cathode to anode through a separator during charging and move from anode to cathode during discharging. Electrolyte acts as a medium for transporting ions between anode and cathode (Semeraro et al., 2021). Swelling mainly results from gas generation inside the battery due to various electrochemical and chemical reactions involving major battery cell components: cathode, anode, and electrolyte.

Gas generation is expected during manufacturing but should be removed before shipping. A significant amount of gas is generated during the formation cycles when the cell is initially charged and discharged under controlled environmental and operating conditions (An et al., 2016). The pouch cell package is oversized, and the excess gas is forced into a separate “bag”. After the formation, cells are degassed and resealed by cutting off the “bag” (Maiser, 2014).

Additional gas can be generated when using lithium-ion batteries because of side electrochemical reactions. Towards the end of a lithium-ion battery’s life, there is an expected level of swelling. The swelling should be accounted for in system design to allow for regular and safe device operations. However, a flawed manufacturing process, such as improper formation steps, can lead to a tremendous amount of gas generation and swelling during usage (An et al., 2016). Undesirable conditions such as elevated temperature, overcharge, and over-discharge can cause rapid gas generation (Feng et al., 2018). Nevertheless, the battery management system is intended to protect from those unwanted conditions. Figure 4 shows a fishbone diagram of all probable causes of gas generation (An et al., 2016)- (Peng et al., 2020). The mechanical damage can happen during production, shipment, and usage and lead to a leakage of the battery case.

Gas evolution starts within the first cycle during formation (Ellis et al., 2017); (Renfrew and McCloskey, 2017). The quantities and constituents of the gas produced during cycling are highly dependent on electrode material choice. Most commercial lithium-ion batteries use graphite as the negative electrode’s active material due to the ease of lithium intercalation into the spacing between graphene layers, low volume change (∼10%), and high theoretical specific capacity (372 mAh/g). During charge, the anode potential vs. Li/Li+ will decrease and go below 0.8 V. However, the organic electrolytes used in lithium-ion batteries have reduction potentials close to 0.8 V vs. Li/Li+. During the first charge cycle, the electrolyte is reduced at the anode surface, forming an SEI layer and releasing C2H4 (from EC solvent), C3H6 (from PC solvent), CO, or CO2 gases (An et al., 2016), (Teng et al., 2015).

Cells are degassed after the formation process. Once the SEI layer is formed, it should block electrons and electrolytes while having high lithium-ion permeability. Further reduction reactions of the electrolyte are prevented since the SEI layer is electronically insulated. Thus, in succeeding cycles, the gas generation rate should be significantly reduced compared to the formation cycles. During manufacturing, a high-quality formation process produces a stable SEI layer that protects the electrolyte from being reduced and will reduce gas generation in future charge-discharge cycles.

Manufacturing defects, such as contaminants within the cell, are another source responsible for gas evolution at the surface of the negative electrode. Water is one of the primary contaminants and can be present from electrolyte or insufficient electrode drying. During the SEI layer formation, the decomposition products of the LiPF6 salt and traces of water can react and generate HF, a toxic gas. The reduction reaction of moisture can take place through a single electron process: H2O +e− →0.5 H2. Bernhard et al. (Bernhard et al., 2015) found that the quantity of H2 detected was correlated with the cell’s expected water content. Additional studies found that over 80% of the H2 produced was sourced from water reduction reactions (Metzger, 2016). Another manufacturing problem is metal protrusions or burrs on the tabs and current collectors (Yao et al., 2019) and alien metal particles. Welding burrs or metal particles can penetrate the neighboring electrode and separator layers and cause internal short circuits between the anode and cathode, leading to thermal runaway, fires, and explosions.

Lithium titanium oxide (Li4Ti5O12, LTO) is an alternative active material used as the negative electrode in a lithium-ion cell. LTO electrodes have a redox potential at 1.55 V vs. Li/Li+, inside the stability window of commonly used lithium-ion battery electrolytes. There is no SEI layer formed, and thus no gas is generated from it. However, LTO-based batteries still exhibited substantial gas generation during storage (Belharouak et al., 2012). Similar to a graphite negative electrode, water contamination will result in the generation of H2 (Hoffmann et al., 2018). During elevated temperatures, HF is formed from the decomposition of LiPF6. The remainder of the gasses generated is due to reactions between the LTO electrode and the electrolyte solvent; CO2, from decarboxylation, CO from decarbonylation, and compounds produced during dehydrogenation are most common (Hoffmann et al., 2018).

At the cathode, gas can generate through electrolyte oxidation and surface contaminants. The electrolyte can experience both electrochemical oxidation and chemical oxidation with gas generation (Jung et al., 2017a). Electrochemical oxidation is dependent on the surface area of the electrode and the electrochemical potential of the cathode. For example, the gassing of NMC cathode materials at an onset potential of approximately 3.8 V is commonly attributed to the electrochemical decomposition of electrolyte, producing Li2CO3 which can deposit on the surface of NMC electrodes. Electrolyte salt degradation occurs at a cathode potential greater than 4.2 V, attributed to the hydrolysis of LiPF6 (Aiken et al., 2015).

Chemical oxidation is dependent on the presence of a reactive species during a cell’s operation. For example, NMC electrodes can release singlet oxygen from their layered structure, which initiates the electrolyte’s oxidation reaction. The CO2 generation results from the reactive oxygen released from the cathode lattice reacting with the CO generated from electrolyte oxidation (Jung et al., 2017b).

At the cell level, the gas produced from one electrode can be absorbed or consumed at the other, and reaction products diffusing between electrodes can generate more gas. An example of the interaction is transition metals from the cathode that can deposit on the anode and accelerate the SEI layer growth with gas generation. The increase in SEI layer thickness has been observed from manganese dissolution from the NMC electrode. CO2 has been observed to react with lithium at both electrodes to form carbon deposits on the electrode surface. Graphite anode can absorb CO2 generated through oxidation reactions at the cathode (Ellis et al., 2017), (Xiong et al., 2016). The consumption of gasses has been demonstrated by Xiong et al. (Xiong et al., 2016) who stored lithiated NMC electrodes in the presence and absence of a graphite electrode, and Mao et al. (2019) who cycled the NMC-graphite cells at 3–4.4 V, 30°C. To test gas consumption reactions, Ellis et al. (2017) injected various gases into pouch cells: CO2, H2, C2H4, and CO, of which CO2 was found to be the most readily consumed and was depleted after 100 h of storage. This consumption process was especially prominent in the presence of delithiated graphite electrodes, where CO2 reduction reactions form Li2C2O4 (Ellis et al., 2017). Self et al. (2015) found that the produced ethene at the graphite anode side can be depleted, forming polyethylene. Therefore, the pouch cell volume can decrease after an initial significant expansion (Mao et al., 2019).

In addition, the oxidative decomposition of the electrolyte increases with water amount within the cell. The water content supplies H+ through oxidation at the cathode and OH- through reduction reaction at the anode; both products instigate additional oxidative electrolyte decomposition at the respective electrode-electrolyte interfaces (Rowden and Garcia-Araez, 2020).

Table 1 summarized the gas species generated from different chemistries, of which CO, HF, SO2, NO2, NO, HCl are all toxic.

Post manufacturing, when a lithium-ion battery has been deployed in a device, gas generation continues with battery cycle aging and calendar aging (Zhang, 2014). The SEI layer gradually thickens during repeated charge-discharge. After the original generation of the SEI layer, with anode volume change and electrolyte diffusion, the SEI layer fracturing can occur and cause graphite exposure to the electrolyte. The gas generation rate from SEI layer growth is not as significant as the formation cycle rate. Louli et al. (Louli et al., 2017) cycled Li (NiCoAl)O2-SiO/graphite pouch cells observed a linear increase in the cell pressure at full charge, from 700 kPa initially to 1000 kPa after 1000 h’ testing time.

The gas species and generation rate also depend on the material selection and the operating conditions. During storage, Belharouak et al. (2012) found that H2 and CO2 decreased with temperature increase, whereas CO and CH4 increased with the temperature increase. Boussely et al. (2005) showed that electrolyte oxidation at the positive electrode becomes non-trivial over long storage periods for LiCoO2-based and LiNiCoAlO2-based cells at elevated temperatures and state of charge (SOC), leading to CO2 evolution. LiNiCoAlO2-based cells experienced a dramatic pressure increase initially and then stabilized, whereas LiCoO2-based cells’ internal pressure gradually increased, indicating that electrolyte oxidation depends strongly on the cathode material’s nature (Louli et al., 2017). Storage temperature is found to have a much more significant effect on the cells’ gas generation stored at 100% SOC than those stored at 0% SOC (Boussely et al., 2005). The side reaction between the electrolyte and lithium compounds, such as Li2CO3 or LiOH in the cathode, is considered the leading cause of gas evolution during storage.

A battery management system (BMS) ensures correct battery operation. The BMS may terminate the battery operation or report a warning to the user if the monitored parameters go over the operation limits to prevent batteries from over-current, over-charging, over-discharging, and overheating (Holze, 2012). Another primary function of BMS is to estimate the real-time battery states: SOC and state of health (SOH). The BMS reports on the SOC and SOH to users or indicates the end of life when the SOH falls below the user-set target threshold (Holze, 2012). BMS controls the charger to ensure proper charging of the battery (Holze, 2012). The charger can be onboard or outside. The BMS control is designed to react to the battery’s internal states and data from the sensors during charging, so these parameters are within the operating limits.

BMS does not always function correctly and has fallibility in both hardware and software; thus, over-charging, over-discharging, and overheating can occur. Over-discharging lithium-ion batteries can lead to several side reactions, including dissolution of the copper current collector and degradation of the SEI layer on the negative electrode with gas generation. Li et al. (2008) over-discharged LiCoO2 cells to 0 V and observed copper deposition on the positive electrode and gas generation, most notably CO2. Overcharging lithium-ion batteries will cause the excessive de-intercalation of lithium in the cathode, leading to a collapse of the cathode structure with heat generation and oxygen release, accelerating electrolyte oxidation and producing more gases. Ohsaki et al. (2005) overcharged LiCoO2 cells and found CO2 and CO were mainly produced on the cathode, whereas on the anode, H2 was the major component of the gases generated plus small amounts of CH4, C2H4, C2H6, CO, and CO2. The side electrochemical reactions with gas generation discussed in Section 3.1 and Section 3.2 accelerate with temperature increase. Lithium-ion batteries typically operate under 60°C. Electrolyte thermal decomposition will occur and produce gases if the BMS cannot control the battery temperature within this limit.

Gas is also generated when an external or internal short circuit occurs in a battery. External short-circuiting refers to when the battery’s positive and negative terminals are connected directly. There will be a current surge, and the BMS should cut off the battery operation. Internal short circuit means that the anode and cathode contact directly inside the battery due to internal reasons such as lithium and copper dendrite growth or external causes such as puncture, penetration, crush, or drop of the battery (Feng et al., 2018). An internal short circuit can cause an abnormal battery voltage drop and temperature increase (Feng et al., 2018); thus, the BMS should give users alarms in this kind of scenario by monitoring the battery voltage and temperature.

Pouch cell swelling is mainly due to the gas generation from electrochemical and chemical reactions inside the cell. Battery swelling can be significant enough to fracture or deform mechanical housing and electronic circuit boards, compromise the waterproof or water-resistant capability, and result in safety risks due to the flammable and toxic gas.

A review of various case studies shows that swelling battery incidents may occur at any point in a product’s life and may occur during the charging or non-charging period. However, the few recall programs neither claimed the root causes nor were sufficient to fix the numerous swollen battery incidents.

The analysis shows battery swelling issues can initiate during shipping and storage before the customer receives the device due to poor manufacturing, such as problematic formation steps and introduction of contamination. Unfortunately, at this time, there is no screening process to identify in advance those batteries that might swell due to such issues. This is made more complex when battery swelling issues occur with usage, which can also be caused by improper battery management or BMS malfunctions that allow the battery voltage, current, or temperature to exceed specified limits.

A review of the gas generation mechanisms shows that gas generation depends on the material selection, manufacturing and formation process, and operating conditions. The contamination such as water and metal debris and defects such as burrs of current collectors should be minimized during the manufacturing process. After manufacturing, the formation steps should be improved to develop a stable SEI layer at the anode and cathode sides, leading to less gas generation during the subsequent storage and usage. It is recommended that device companies qualify pouch cells in terms of thickness changes as a function of their targeted application, including at the limit of charge-discharge conditions and over the capacity fade expected in the lifetime. The space assigned for the pouch cell in the device should accommodate the maximum thickness change of the cell during the lifetime within the specified operating limit. Furthermore, the BMS should ensure that the battery temperature, current, and voltage are within safe operating limits. Finally, sensors such as strain gauges and ultrasonic may be needed to monitor battery swelling so the BMS can provide timely warnings before swollen pouch cells damage the device or result in safety issues.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The authors would like to thank the more than 150 companies and organizations that support research activities at the Center for Advanced Life Cycle Engineering (CALCE) at the University of Maryland annually, as well as the Center for Advances in Reliability and Safety (CAIRS) of Hong Kong.

Aalund, R., Diao, W., Kong, L., and Pecht, M. (2021). Understanding the Non-Collision Related Battery Safety Risks in Electric Vehicles A Case Study in Electric Vehicle Recalls and the LG Chem Battery. IEEE Access 9, 89527–89532. doi:10.1109/ACCESS.2021.3090304

Aiken, C. P., Self, J., Petibon, R., Xia, X., Paulsen, J. M., and Dahn, J. R. (2015). A Survey of In Situ Gas Evolution during High Voltage Formation in Li-Ion Pouch Cells. J. Electrochem. Soc. 162 (4), A760–A767. doi:10.1149/2.0941504jes

An, K., Tran, Y. H. T., Kwak, S., Han, J., and Song, S. W. (2021). Design of Fire‐Resistant Liquid Electrolyte Formulation for Safe and Long‐Cycled Lithium‐Ion Batteries. Adv. Funct. Mater. 31, 2106102. doi:10.1002/adfm.202106102

An, S. J., Li, J., Daniel, C., Mohanty, D., Nagpure, S., and Wood, D. L. (2016). The State of Understanding of the Lithium-Ion-Battery Graphite Solid Electrolyte Interphase (SEI) and its Relationship to Formation Cycling. Carbon 105, 52–76. doi:10.1016/j.carbon.2016.04.008

Androidcentral (2020). Available online: https://forums.androidcentral.com/ask-question/1014305-has-anyone-had-any-battery-swelling-their-samsung-galaxy-s20-plus-5g.html(Accessed August 13, 2021).

Apple (2017a). MacBook Pro Battery Has Swollen. Available online: https://discussions.apple.com/thread/7943668 (Accessed 23 March 2021).

Apple (2018a). iPhone 8 Logic Board Replacement Program. Available online: https://support.apple.com/iphone-8-logic-board-replacement-program (Accessed March 23, 2021).

Apple (2018b). Apple Recalls Macbook Pro after Reports of Fire Risk. Available online: https://www.kbaattorneys.com/blog/apple-recalls-macbook-pro-after-reports-of-fire-risk/(Accessed March 23, 2021).

Apple (2020a). iPhone X Battery Swelling. Available online: https://discussions.apple.com/thread/251641412 (Accessed March 23, 2021).

Apple (2020b). My iPhone X Battery Swollen up. Available online: https://discussions.apple.com/thread/251788656 (Accessed March 23, 2021).

Apple (2020c). 13-inch MacBook Pro (Non-touch Bar) Battery Replacement Program. Available online: https://support.apple.com/13inch-macbookpro-battery-replacement(Accessed March 23, 2021).

Apple (2020d). Is Battery Swelling Issue Not Covered as Part of Battery Recall for Mid-2015 Retina 15 Models. Available online: https://discussions.apple.com/thread/251688275(Accessed March 23, 2021).

Apple (2020e). 15-inch MacBook Pro Battery Recall Program. Available online: https://support.apple.com/en-sg/15-inch-macbook-pro-battery-recall(Accessed March 23, 2021).

Apple (2020f). Swollen Battery Apple Watch Series 3. Available online: https://discussions.apple.com/thread/251084574(Accessed March 23, 2021).

BBC NEWS (2017). Apple Investigating Swollen Batteries in iPhone 8 Plus Handsets. Available online: https://www.bbc.com/news/technology-41551596 (Accessed March 23, 2021).

Belharouak, I., Koenig, G. M., Tan, T., Yumoto, H., Ota, N., and Amine, K. (2012). Performance Degradation and Gassing of Li4Ti5O12/LiMn2O4Lithium-Ion Cells. J. Electrochem. Soc. 159 (8), A1165–A1170. doi:10.1149/2.013208jes

Bernhard, R., Metzger, M., and Gasteiger, H. A. (2015). Gas Evolution at Graphite Anodes Depending on Electrolyte Water Content and SEI Quality Studied by On-Line Electrochemical Mass Spectrometry. J. Electrochem. Soc. 162 (10), A1984–A1989. doi:10.1149/2.0191510jes

Blomgren, G. E. (2016). The Development and Future of Lithium Ion Batteries. J. Electrochem. Soc. 164 (1), A5019–A5025. doi:10.1149/2.0251701jes

Boussely, M., Biensan, P., Bonhomme, F., Blanchard, P., Herreyre, S., Nechev, K., et al. (2005). Main Aging Mechanisms in Li Ion Batteries. J. Power Sourc. 146 (1-2), 90–96.

Deleon, N. (2018). Some MacBook Pro Batteries Can Swell. Available online: https://www.consumerreports.org/laptop-computers/some-macbook-pro-batteries-can-swell-what-you-need-to-know/(Accessed March 23, 2021).

Dube, R. (2018). Why Smartphone Batteries Explode and How to Prevent it. Available online: https://www.makeuseof.com/tag/smartphone-batteries-explode-prevent/ (Accessed August 13, 2021).

Ellis, L., Allen, J., Thompson, L., Harlow, J., Stone, W., Hill, I., et al. (2017). Quantifying, Understanding and Evaluting the Effects of Gas Consumption in Lithium-Ion Cells. J. Electrochem. Soc. 164 (14), 3518–3528. doi:10.1149/2.0191714jes

Ewdison, T. (2019). Apple Watch Battery Swelling Has Finally lead to a Lawsuit. Available online: https://www.slashgear.com/apple-watch-battery-swelling-has-finally-lead-to-a-lawsuit-02571974/(Accessed March 23, 2021).

Fear, C., Juarez-Robles, D., Jeevarajan, J. A., and Mukherjee, P. P. (2018). Elucidating Copper Dissolution Phenomenon in Li-Ion Cells under Overdischarge Extremes. J. Electrochem. Soc. 165 (9), A1639–A1647. doi:10.1149/2.0671809jes

Feng, X., Zheng, S., He, X., Wang, L., Wang, Y., Ren, D., et al. (2018). Time Sequence Map for Interpreting the thermal Runaway Mechanism of Lithium-Ion Batteries with LiNixCoyMnzO2 Cathode. Front. Energ. Res. 6, 126. doi:10.3389/fenrg.2018.00126

Gao, R. (2020). Increasing Reports of Pixel 3 and Pixel 3 XL Battery Swelling Damaging Phones. Available online: https://www.androidpolice.com/2020/09/10/increasing-reports-of-pixel-3-and-pixel-3-xl-battery-swelling-damaging-phones/(Accessed August 13, 2021).

Hoffmann, J., Milien, M. S., Lucht, B. L., and Payne, M. (2018). Investigation of Gas Evolution from Li4Ti5O12 Anode for Lithium Ion Batteries. J. Electrochem. Soc. 165 (13), A3108–A3113. doi:10.1149/2.0741813jes

Hofmann, A., Uhlmann, N., Ziebert, C., Wiegand, O., Schmidt, A., and Hanemann, T. (2017). Preventing Li-Ion Cell Explosion during thermal Runaway with Reduced Pressure. Appl. Therm. Eng. 124, 539–544. doi:10.1016/j.applthermaleng.2017.06.056

Holze, R. (2012). Gianfranco Pistoia: Battery Operated Devices and Systems. J. Solid State. Electrochemistry 16 (1). doi:10.1007/s10008-011-1302-2

Jacob, K. (2017). Apple Is 'looking into' Why Some iPhone 8 Batteries Are Swelling. Available online: https://www.theverge.com/2017/10/6/16437790/iphone-8-swollen-battery-issue-apple-investigating (Accessed March 23, 2021).

Jung, R., Metzger, M., Maglia, F., Stinner, C., and Gasteiger, H. A. (2017). Chemical versus Electrochemical Electrolyte Oxidation on NMC111, NMC622, NMC811, LNMO, and Conductive Carbon. J. Phys. Chem. Lett. 8 (19), 4820–4825. doi:10.1021/acs.jpclett.7b01927

Jung, R., Metzger, M., Maglia, F., and Stinner, C. (2017). Oxygen Release and its Effect on the Cycling Stability of LiNixMnyCozO2 (NMC) Cathode Materials for Li-Ion Batteries. J. Electrochem. Soc. 164 (7), 1361–1377. doi:10.1149/2.0021707jes

Li, H.-F., Gao, J.-K., and Zhang, S.-L. (2008). Effect of Overdischarge on Swelling and Recharge Performance of Lithium Ion Cells. Chin. J. Chem. 26, 1585–1588. doi:10.1002/cjoc.200890286

Louli, A. J., Li, J., Trussler, S., Fell, C. R., and Dahn, J. R. (2017). Volume, Pressure and Thickness Evolution of Li-Ion Pouch Cells with Silicon-Composite Negative Electrodes. J. Electrochem. Soc. 164 (12), A2689–A2696. doi:10.1149/2.1691712jes

Lovejoy, B. (2017). iPhone 8 Plus Reportedly Splits Open while Charging, Another Claimed to Arrive in Same State. Available online: https://9to5mac.com/2017/09/29/iphone-8-plus-casing-split-open/ (Accessed March 23, 2021).

Maiser, E. (2014). Battery Packaging-Technology Review. AIP Conf. Proc. 1597 (1), 204–218. doi:10.1063/1.4878489

Mao, C., Ruther, R. E., Geng, L., Li, Z., Leonard, D. N., Meyer, H. M., et al. (2019). Evaluation of Gas Formation and Consumption Driven by Crossover Effect in High-Voltage Lithium-Ion Batteries with Ni-Rich NMC Cathodes. ACS Appl. Mater. Inter. 11 (46), 43235–43243. doi:10.1021/acsami.9b15916

Mao, Z., Farkhandeh, M., Pritzker, M., Fowler, M., and Chen, Z. (2017). Calendar Aging and Gas Generation in Commercial Graphite/NMC-LMO Lithium-Ion Pouch Cell. J. Electrochem. Soc. 164 (14), 2469–2483. doi:10.1149/2.0241714jes

Metzger, M. (2016). Origin of H2 Evolution in LIBs: H2O Reduction vs Electrolyte Oxidation. J. Electrochem. Soc. 163 (5), 798–809. doi:10.1149/2.1151605jes

Mix, (2020). Pixel 3 Batteries Are Swelling up. Available online: https://thenextweb.com/news/google-pixel-3-3xl-battery-swollen(Accessed August 13, 2021).

Mohan, B. (2020). Some Google Pixel 3 Phones Are Suffering from a Battery Swelling Issue. Available online: https://www.androidcentral.com/some-google-pixel-3-phones-are-suffering-battery-swelling-issues(Accessed August 13, 2021).

Moon, M. (2018). Apple Will Replace Swollen Batteries in Newer MacBook Pros. Available online: https://www.engadget.com/2018-04-21-apple-will-replace-swollen-batteries-in-newer-macbook-pros.html(Accessed March 23, 2021).

Ohsaki, T., Kishi, T., Kuboki, T., Takami, N., Shimura, N., Sato, Y., et al. (2005). Overcharge Reaction of Lithium-Ion Batteries. J. Power Sourc. 146 (1-2), 97–100. doi:10.1016/j.jpowsour.2005.03.105

Peng, Y., Yang, L., Ju, X., Liao, B., Ye, K., Li, L., et al. (2020). A Comprehensive Investigation on the thermal and Toxic Hazards of Large Format Lithium-Ion Batteries with LiFePO4 Cathode. J. Hazard. Mater. 381, 120916. doi:10.1016/j.jhazmat.2019.120916

Pixel Phone Help (2020). My Replacement Pixel 4XL Battery Is Swollen. Available online: https://support.google.com/pixelphone/thread/86005557/my-replacement-pixel-4xl-battery-is-swollen?hl=en(Accessed August 13, 2021).

Puls Technologies Inc (2019). Common iPhone 8 Problems & Solutions to Fix Them Now. Available online: https://blog.puls.com/common-iphone-8-problems-solutions (Accessed March2021 23).

Reddit Huawei (2020). Available online: https://www.reddit.com/r/Huawei(Accessed August 13, 2021).

Ren, L., Zhao, L., Hong, S., Zhao, S., Wang, H., and Zhang, L. (2018). Remaining Useful Life Prediction for Lithium-Ion Battery: A Deep Learning Approach. IEEE Access 6, 50587–50598. doi:10.1109/access.2018.2858856

Renfrew, S. E., and McCloskey, B. D. (2017). Residual Lithium Carbonate Predominantly Accounts for First Cycle CO2 and CO Outgassing of Li-Stoichiometric and Li-Rich Layered Transition-Metal Oxides. J. Am. Chem. Soc. 139, 17853–17860. doi:10.1021/jacs.7b08461

Rossignol, J. (2017). Apple Investigating Two Possible iPhone 8 Plus Battery Failures. Available online: https://www.macrumors.com/2017/10/01/apple-looking-into-iphone-8-battery-failures/ (Accessed March 23, 2021).

Rossignol, J. (2018). Apple Now Offering Free Repairs of 42mm Apple Watch Series 2 Models with Swollen Batteries. Available online: https://www.macrumors.com/2018/04/14/apple-watch-s2-swollen-battery-service-policy/(Accessed March 23, 2021).

Rossignol, J. (2019). Apple Sued Over Swollen Batteries in Apple Watches. Available online: https://www.macrumors.com/2019/04/02/apple-watch-swollen-battery-lawsuit-new-jersey/(Accessed March 23, 2021).

Rossignol, J. (2017). More Incidents Surface of iPhone 8 Plus Devices Burst Open Due to Possible Battery Failure. Available online: https://www.macrumors.com/2017/10/04/iphone-8-plus-battery-failures/ (Accessed March 23, 2021).

Rowden, B., and Garcia-Araez, N. (2020). A Review of Gas Evolution in Lithium Ion Batteries. Energ. Rep. 6, 10–18. doi:10.1016/j.egyr.2020.02.022

Schröder, R., Aydemir, M., and Seliger, G. (2017). Comparatively Assessing Different Shapes of Lithium-Ion Battery Cells. Proced. Manufacturing 8, 104–111.

Self, J., Aiken, C. P., Petibon, R., and Dahn, J. R. (2015). Survey of Gas Expansion in Li-Ion NMC Pouch Cells. J. Electrochem. Soc. 162 (6), A796–A802. doi:10.1149/2.0081506jes

Semeraro, C., Olabi, A., and Dassisti, M. (2021). “Sustainability Issues in Manufacturing and Operation of Second-Generation Flow Batteries,” in Reference Module in Materials Science and Materials Engineering. doi:10.1016/B978-0-12-815732-9.00076-0

Sun, Y., Lu, H., and Jin, Y. (2021). Experimental and Numerical Study on Mechanical Deformation Characteristics of Lithium Iron Phosphate Pouch Battery Modules under Overcharge Conditions. Energy & Fuels 35 (18), 15172–15184. doi:10.1021/acs.energyfuels.1c02308

Teng, X., Zhan, C., Bai, Y., Ma, L., Liu, Q., Wu, C., et al. (2015). In Situ analysis of Gas Generation in Lithium-Ion Batteries with Different Carbonate-Based Electrolytes. ACS Appl. Mater. Inter. 7 (41), 22751–22755. doi:10.1021/acsami.5b08399

Xiong, D., Petibon, R., Nie, M., Ma, L., Xia, J., and Dahn, J. (2016). Interactions between Positive and Negative Electrodes in Li-Ion Cells Operated at High Temperatures and High Voltage. J. Electrochem. Soc. 163 (3), 546–551. doi:10.1149/2.0951603jes

Yao, X.-Y., Saxena, S., Su, L., and Pecht, M. G. (2019). The Explosive Nature of Tab Burrs in Li-Ion Batteries. IEEE Access 7, 45978–45982. doi:10.1109/access.2019.2909018

Keywords: lithium-ion batteries, consumer products, pouch cells, gas generation, swelling

Citation: Aalund R, Endreddy B and Pecht M (2022) How Gas Generates in Pouch Cells and Affects Consumer Products. Front. Chem. Eng. 4:828375. doi: 10.3389/fceng.2022.828375

Received: 03 December 2021; Accepted: 25 January 2022;

Published: 15 February 2022.

Edited by:

Joseph Kwon, Texas A&M University, United StatesReviewed by:

Ian Johnson, Argonne National Laboratory (DOE), United StatesCopyright © 2022 Aalund, Endreddy and Pecht. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ryan Aalund, cmFhbHVuZEB1bWQuZWR1

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.