94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Chem. Eng., 30 November 2022

Sec. Sustainable Process Engineering

Volume 4 - 2022 | https://doi.org/10.3389/fceng.2022.1008680

This article is part of the Research TopicSeparations for Energy and Environmental ApplicationsView all 5 articles

Under the Paris Agreement, established by the United Nations Framework Convention on Climate Change, many countries have agreed to transition their energy sources and technologies to reduce greenhouse gas emissions to levels concordant with the 1.5°C warming goal. Lithium (Li) is critical to this transition due to its use in nuclear fusion as well as in rechargeable lithium-ion batteries used for energy storage for electric vehicles and renewable energy harvesting systems. As a result, the global demand for Li is expected to reach 5.11 Mt by 2050. At this consumption rate, the Li reserves on land are expected to be depleted by 2080. In addition to spodumene and lepidolite ores, Li is present in seawater, and salt-lake brines as dissolved Li+ ions. Li recovery from aqueous solutions such as these are a potential solution to limited terrestrial reserves. The present work reviews the advantages and challenges of a variety of technologies for Li recovery from aqueous solutions, including precipitants, solvent extractants, Li-ion sieves, Li-ion-imprinted membranes, battery-based electrochemical systems, and electro-membrane-based electrochemical systems. The techno-economic feasibility and key performance parameters of each technology, such as the Li+ capacity, selectivity, separation efficiency, recovery, regeneration, cyclical stability, thermal stability, environmental durability, product quality, extraction time, and energy consumption are highlighted when available. Excluding precipitation and solvent extraction, these technologies demonstrate a high potential for sustainable Li+ extraction from low Li+ concentration aqueous solutions or seawater. However, further research and development will be required to scale these technologies from benchtop experiments to industrial applications. The development of optimized materials and synthesis methods that improve the Li+ selectivity, separation efficiency, chemical stability, lifetime, and Li+ recovery should be prioritized. Additionally, techno-economic and life cycle analyses are needed for a more critical evaluation of these extraction technologies for large-scale Li production. Such assessments will further elucidate the climate impact, energy demand, capital costs, operational costs, productivity, potential return on investment, and other key feasibility factors. It is anticipated that this review will provide a solid foundation for future research commercialization efforts to sustainably meet the growing demand for Li as the world transitions to clean energy.

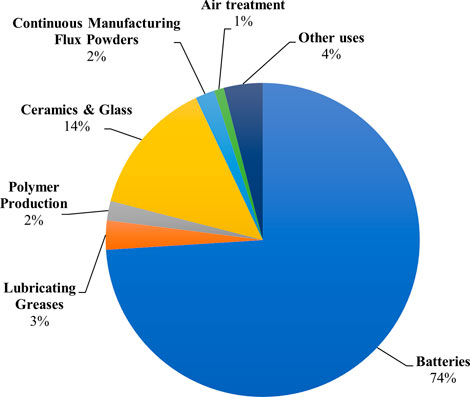

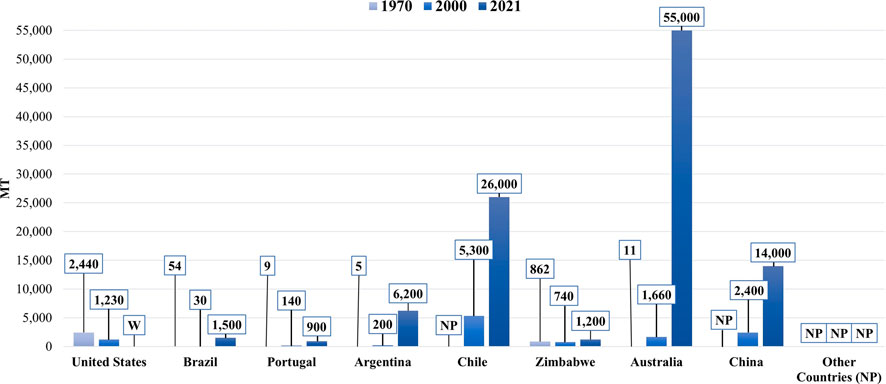

Lithium (Li) is a fundamental metal for manufacturing batteries, ceramics, glass, lubricants, and flux powders, and air treatment processes (Zhang et al., 2019)). Figure 1 shows the predominant market end uses of Li in 2021. Before the 1970s, Li was a considerably obscure mineral commodity. However, it has experienced exponential growth in production in recent years. The annual Li mine production by country in 1970, 2000, and 2021 are provided for comparison in Figure 2. Yearly global Li production has expanded from an estimated 3,700 metric tons (MT) in 1970 to over 100,000 MT in 2021, a record high (USGS, 2017; U.S Geological Survey, 2022). This growth can be attributed to Li’s crucial role in the global energy transition. The most prevalent application for Li is in rechargeable lithium-ion batteries for renewable energy storage and electric vehicles. In addition to existing use in Li-ion batteries, Li might also experience growing demand from the hydrogen fuel sector, given that it can be converted to tritium, a potential fuel source for next-generation fuel reactors.

FIGURE 1. Pie chart showing market end uses of lithium as a percentage of global consumption in 2021 (U.S Geological Survey, 2022).

FIGURE 2. A bar chart showing the annual lithium production by country in 1970, 2000, and 2021. Note that the countries labeled with “NP” reported no data that year. Additionally, the United States withheld (W) its production data in 2021 (U.S Geological Survey, 2022; Mohr et al., 2012).

In 2021, international annual electric vehicle sales more than doubled to 6.6 million cars, or 9% of the international car market. This increase in sales is almost triple the global market share in 2019 (IEA, 2022). Summarily, electric vehicles were responsible for the total net growth of global car sales in 2021 (IEA, 2022). Of the 6.6 million cars, 4.7 million (71%) were Battery Electric Vehicles (BEVs), and 1.9 million (29%) were Plug-in Hybrid Electric Vehicles (PHEVs) (Irle, 2022). The typical lithium-ion battery capacities for BEVs and PHEVs are estimated to be 25 and 9 kWh, respectively (Vikström et al., 2013). Furthermore, it is estimated that 160 g of Li can supply one kWh of battery capacity (Kushnir and Sandén, 2012). Therefore, the estimated Li requirement for a BEV and PHEV is four and 1.4 kilograms, respectively. Applying these estimations, the 4.7 million BEVs and 1.9 million PHEVs required roughly 18,800 and 2,700 MT of Li, respectively. This combined mass equates to almost 22% of global Li production in 2021. Accordingly, the global consumption of Li in 2021 was estimated to be 93,000 MT, a 22% increase from 70,000 MT in 2020 (U.S Geological Survey, 2022). By 2030, the global Li demand is expected to exceed 2 Mt, with batteries accounting for 95% of this demand (Azevedo et al., 2018; U.S Geological Survey, 2022). In response, many countries are now prioritizing the development of technologies for low-cost Li extraction to combat impending supply shortages and price hikes. Technologies that enable extraction from low Li+ concentrated aqueous solutions are the leading edge of these development efforts.

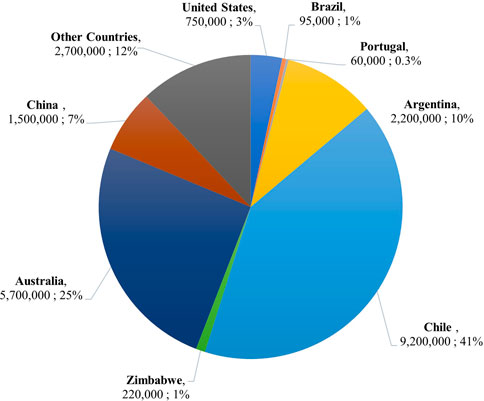

Traditionally, Li has been mined from the Li-bearing minerals lepidolite, petalite, and spodumene contained in pegmatite formations. Lepidolite (K(Li, Al)3(Al, Si, Rb)4O10(F, OH)2), contains 3.58% Li content. It is no longer a major mining ore due to its high fluorine content. Petalite (LiAlSi4O10), contains 2.09% Li content. Its high iron content and low thermal expansion rate make it ideal for glass and ceramics, but it is also used for EV and battery storage applications. Of the three minerals, spodumene (LiAl(SiO3)2), has the highest Li content at 3.73% (Vikström et al., 2013). Its treatment chain can be completed in roughly 5 days and is consistently productive (Grosjean et al., 2012). The traditional sulfuric acid method for extracting Li from spodumene ores has a percent yield between 85% and 90% and a percent recovery of 60%–70% (Ellestad and Leute, 1950; Grosjean et al., 2012; Dessemond et al., 2019). However, the pegmatite formations spodumene is contained in are challenging to mine given their hardness and occurrence in difficult-to-reach belt deposits (Grosjean et al., 2012; Kesler et al., 2012). Additionally, the treatment process requires high-energy-demanding furnaces, pit-digging machines, and rock-crushing machines. Ultimately, these machines, the dust produced from excavation, and the concentrated chemicals used for processing cause environmental damage and pose health and safety risks (Aral and Vecchio-Sadus, 2008; Grosjean et al., 2012). These drawbacks to Li recovery from terrestrial mining and the rapid depletion of Li ores have led to the innovative practice of recovering Li from salt lake brines, or Direct Lithium Extraction (DLE). As of 2021, the worldwide Li reserves from ores and brines total an estimated 22 Mt. Salt lake brines account for almost 80% of this total (Zhang et al., 2019). It is important to note that the geographical distribution of these reserves is very uneven (see Figure 3) (U.S Geological Survey, 2022). More than half of the world’s Li reserves are found in the “ABC Triangle,” a phrase coined for the South American countries of Argentina, Bolivia, and Chile (Grosjean et al., 2012). The remaining resources are concentrated in Australia (25%) and China (7%) (U.S Geological Survey, 2022).

FIGURE 3. Pie chart showing lithium reserves by country as a percentage of the total world-wide reserves in 2021 (U.S Geological Survey, 2022).

New development in DLE technologies has garnered renewed interest in seawater extraction. Although the Li+ concentration is low at 0.1–0.2 ppm, seawater contains nearly 230 Gt of Li+, making it a potentially inexhaustible extraction source (Yang et al., 2018). Additionally, seawater’s abundance eliminates many of the geopolitical concerns surrounding land-based reserves because, essentially, any country with access to the ocean has the opportunity to strengthen its Li supply chain with seawater extraction (Månberger and Johansson, 2019; Kalantzakos, 2020). While the Li+ content in salt lake brines and seawater is vast, and extraction from these resources has the potential to be more sustainable than terrestrial mining, many technological challenges must be mitigated before these resources can be considered comprehensive solutions for the impending Li shortage (Graham et al., 2021; Kelly et al., 2021; Chordia et al., 2022). The main challenges facing DLE to date are the extraction technology’s Li+ selectivity, separation efficiency, recovery, and lifetime.

This paper reviews technology used for Li+ extraction from salt lake brine and seawater, or low Li+ concentration aqueous solutions. First, brine and seawater are classified according to their content. Subsequently, key advantages and challenges of the precipitation, solvent extraction, ion sieve adsorption, ion-imprinted membrane (IIM) extraction, and electrochemical extraction technologies are detailed. The Li+ adsorption capacity, selectivity, separation efficiency, recovery, regeneration, cyclical stability, thermal stability, environmental durability, product quality, extraction time, optimal pH value, and specific energy consumption are also highlighted when provided. The adsorption capacity is the maximum amount of Li+ that can be absorbed by the technology. Selectivity is the technology’s ability to exclusively select Li+ or other desired ions over competing ions present in the solution. The separation efficiency is a measure of the quality of Li+ separation from the solution achieved by the technology. It is measured by the ratio of the Li+ concentrate removed from the solution feed stream to the initial Li+ concentration in the solution. Furthermore, the recovery is the amount or percentage of pure Li product obtained after extraction and additional treatment processes, if any. Regeneration refers to the number of times the technology can be regenerated using a treatment process without significant losses in recovery. The cyclical stability indicates the number of times a technology can be reused before there are major losses in recovery. Thermal stability indicates the operating temperature(s) at which the technology achieves optimal performance. Environmental durability refers to the number of times the technology can be reused with minimal physical degradation. The product quality is the percent purity of the Li product recovered. The extraction time is the duration required to remove Li+ and recover the Li product. The pH value is the recommended solution pH for optimal Li+ extraction and recovery. Finally, the specific energy consumption is the total energy used to produce a unit weight of Li product. The review concludes with recommendations for enhancements and future research pathways of technologies for DLE from low Li+ concentration aqueous solutions.

Brines are excessively saline solutions found in continental, geothermal, and oil field deposits. The worldwide distribution of these brine types spans continental basins (58%), geothermal brines (3%), and oil field brines (3%) (USGS, 2017). Geothermal brines are byproducts of geothermal energy production activities. These heated saline deposits can be pumped to the surface for Li+ extraction, but their complex chemistry, high salinity, and high temperature (

Both salt lakes and seawater possess complex concentrations of chlorine (Cl−), sodium (Na+), potassium (K+), magnesium (Mg2+), calcium (Ca2+), copper (Cu2+), nitrate

Salt lake brines can generally be classified into four main types based on their composition: carbonate

The evaporation, purification, and reactive crystallization, or precipitation, Li+ extraction method is credited as the first technology investigated and applied in industrial applications. The Li+ concentration of naturally occurring salt lake brines is too low for cost-effective extraction without a pre-enrichment process (Vikström et al., 2013; Flexer et al., 2018). Consequently, solar energy is used to evaporate, and therefore, concentrate the Li+ in the brine after it is pumped from the salt lake into large evaporation ponds. The optimal conditions for this process are an arid climate, consistent, unidirectional winds, low salt water permeability, and low rainfall. This evaporitic enrichment process takes several months as the brine is cycled continuously through a series of ponds that increase in salt saturation. When lithium chloride (LiCl) concentration in the evaporation pond reaches approximately 6,000 ppm, the brine is pumped to a recovery pond. The ion salts that do not spontaneously precipitate, such as boron, calcium, magnesium, and sulfate, must be removed with chemical treatments. Lime (Ca(OH)2) is added to the brine to remove the Mg2+ as magnesium hydroxide (Mg(OH)2) and remove sulfate as calcium sulfate (CaSO4) via single-replacement and acid-base neutralization reactions, respectively. The remaining brine is treated with sodium carbonate (Na2CO3) to remove residual Ca2+ as CaCO3 through a single-replacement reaction. Additionally, the brine reaches critical supersaturation after Na2CO3 is introduced, and Li2CO3 crystallization begins. The crystal nuclei begin to form and grow as crystal ions spread and deposit on the Li2CO3 nuclei surfaces. The Li2CO3 nuclei grow into precipitated particles that aggregate into larger particles (Zhao et al., 2019). The final product is a chemically stable, odorless, white powder. Typically, the initial Li2CO3 product is dissolved and re-precipitated until battery-grade purity (99.5 wt%) is reached (Flexer et al., 2018). The final product is then used as a precursor for the Li compounds utilized for the cathodes and electrodes of Li-ion batteries. However, Li2CO3 can also be converted into other industrial salts or treated to yield pure Li metal.

This Li+ extraction method is the most conventional and economical method to date, primarily due to its use of solar energy for the Li+ enrichment process. Additionally, the chemicals added for each ion salt precipitation step and the production infrastructure afford low initial investment and operation costs. However, there are significant drawbacks associated with this extraction method. While Li2CO3 extraction from brine has lower life-cycle greenhouse gas (GHG) emissions than ore mining, the initial product quality is much lower (Kelly et al., 2021). Li2CO3 produced from terrestrial extraction achieves an initial purity close to 99% wt. Conversely, additional processing is required to achieve comparable purity with conventional brine extraction, where initial product purity ranges from 50 to 80% wt (Zhang et al., 2019). Furthermore, the chemicals used for precipitation and the waste produced by this process have raised many socio-environmental concerns (Anlauf, 2016; Liu et al., 2019; Dorn et al., 2020). There is a threat of Li2CO3 and sodium carbonate leaching into the environment and contaminating the soil, air, and freshwater supply of surrounding communities (Agusdinata et al., 2018). Similarly, large amounts of waste are produced during precipitation and generally left to accumulate on the margins of the ponds. A salt lake with an annual production rate of 18,000 MT will produce approximately 2 × 107 tons of waste, which translates to a land area of 10 km2 (Flexer et al., 2018). Therefore, practical resource, waste, and land-use management strategies are of utmost priority and should be developed in tandem with Li production expansion efforts. Further investigation into the potential impacts on human health and native biodiversity is also a critical component of expansion efforts.

The economy of traditional Li extraction from low Li+ concentration aqueous solutions is highly dependent on four key factors: 1) land and climate suitability; 2) production life cycle time; 3) the brine’s natural Li+ concentration; and 4) the mass ratio of competing ions to Li+ (i.e., Mg2+/Li+ mass ratio). Producing Li from brine is an intricate process because productivity is driven by environmental factors that are impossible to control and increasingly more difficult to predict due to the disruptive influence of climate change on historical weather patterns. Consequently, a single extraction facility can experience variations in production speed and efficiency throughout the year (Perez de Solay, 2017). This production instability is especially concerning, given that 12–24 months are required to enrich the brine for Li recovery alone. Consequently, traditional Li+ extraction is uneconomical for solutions with concentrations less than 30 ppm. For reference, Salar de Atacama has one of the world’s highest Li+ concentrations (2,100 ppm) and evaporation rates (3,200 mm/year), and the Li+ enrichment process ranges from 12 to 18 months. Finally, the Mg2+/Li+ mass ratio is perhaps the most critical consideration for determining application feasibility. High amounts of Mg2+ slow the evaporation process and prevent LiCl formation, the first step to Li2CO3 production. Additionally, excessive Mg2+ causes precipitant overconsumption, further contributing to precipitation efficiency challenges and increasing operational costs. Therefore, the traditional Li+ extraction method is economically infeasible for aqueous solutions with high Mg2+/Li+ mass ratios (

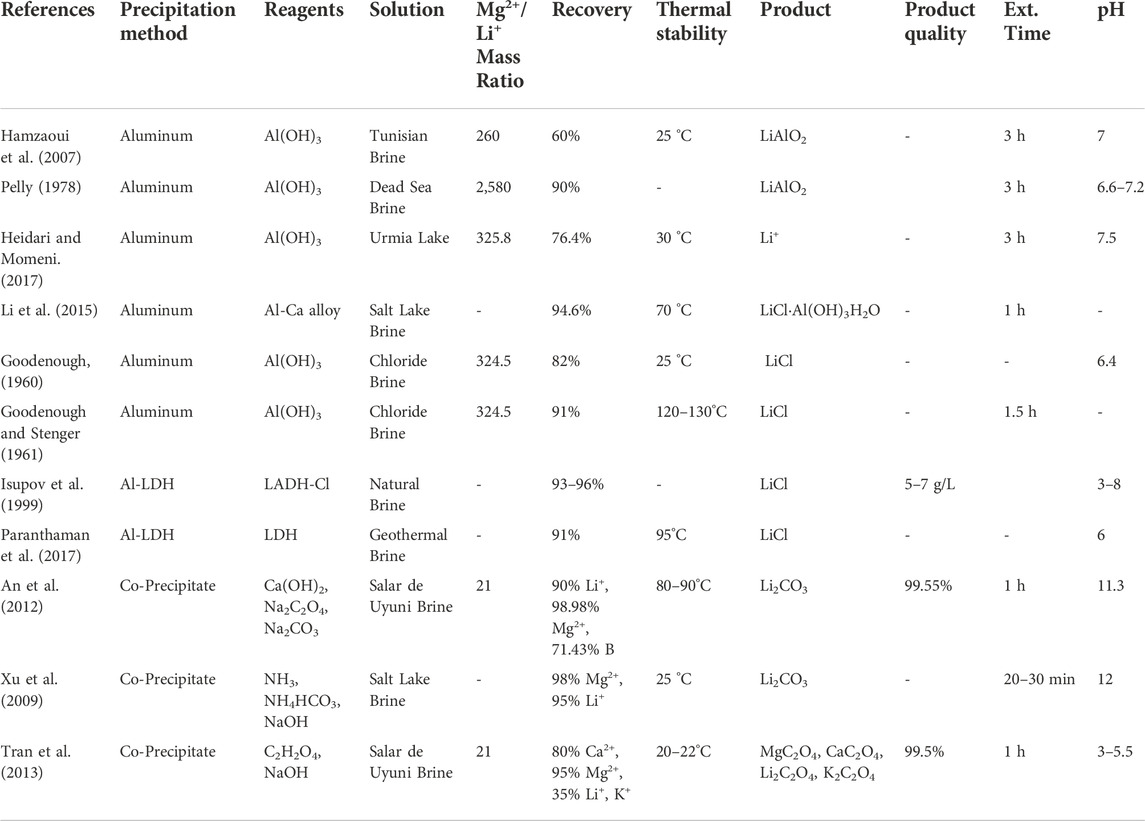

High Mg2+/Li+ precipitants continue to leverage traditional precipitation extraction’s most advantageous aspects: a solar-powered Li+ enrichment process (optional), low-cost chemical agents, and easy industrialization. Their extraction mechanism is identical: the precipitants are added to the aqueous extraction solution to generate supersaturation via chemical reactions. Once the extraction solution reaches critical supersaturation, the metal ions present (Li+, Na+, K+, Ca2+, Mg2+) can be crystallized in sequence so that the competing metal complexes are removed and a high purity Li complex is the final product. However, unlike traditional precipitants, they have effectively extracted Li+ from high Mg2+/Li+ and low Li+ concentration solutions. Additionally, their selectivity rates are comparable to or higher than the average selectivity rates achieved by traditional precipitants. The main challenges facing high Mg2+/Li+ precipitants are their sensitivity to precipitant dosage (precipitant to target ion molar ratio), pH, temperature, and very high competing ion concentrations. These factors directly impact the technology extraction efficiency, the recovery and quality of the Li products, and potential co-products. Similarly to traditional precipitants, high operational costs stemming from precipitant overconsumption, and pollution from process waste are potential challenges. Therefore, extensive experimentation is required to establish productive to optimal ranges for each precipitant performance factor and substantiate their techno-economic feasibility. Ultimately, their technological advantages combined with the opportunity to co-precipitate additional products for commercial resale indicate that high Mg2+/Li+ precipitants are promising for Li+ extraction from high Mg2+/Li+ mass ratio brines. However, further experimentation is needed to determine the feasibility of solely using these precipitants for Li extraction from seawater. To date, high Mg2+/Li+ precipitants have been paired with ion exchange technologies for seawater extraction (Um and Hirato, 2014). Table 3 provides the aqueous solution, Mg2+/Li+ mass ratio, recovery, thermal stability, products, product quality, extraction time, and optimal pH for various high Mg2+/Li+ precipitants.

TABLE 3. High Mg2+/Li+ precipitant extraction from salt lake brines, simulated brines, and seawater.

The aluminate precipitation method has demonstrated excellent performance in Li+ recovery from high Mg2+/Li+ aqueous solutions in experiments dating back to 1960 (Goodenough, 1960; Goodenough and Stenger, 1961; Kaplan, 1963; Pelly, 1978; Epstein et al., 1981; Isupov et al., 1999; Hamzaoui et al., 2007; Hamzaoui et al., 2008; Yang et al., 2013; Li et al., 2015; Heidari and Momeni, 2017; Liu et al., 2018). Epstein et al. (1981) precipitated Li+ from the dead sea as lithium aluminate (LiAlO2), used a liquid-liquid extraction technique to separate the Li+ from the Al3+. Similarly, Kaplan (1963) recovered Li+ through LiAlO2 precipitation from dead sea brine. Typically, an aluminum salt (AlCl3 ⋅ H2O) and sodium hydroxide (NaOH) are added to the salt lake brines instead of lime and sodium carbonate. The amorphous aluminum hydroxide (Al(OH)3) created by this mixture selectively precipitates Li+. Lithium aluminate precipitate (LiCl.2Al(OH)3H2O) is produced, and the Li+ in the precipitate is expulsed by manipulating the solution pH: the Li+ is released from the precipitate in acidic and alkaline conditions Zhang et al. (2019). Experimental studies with synthetic brine report that the optimal values for Al/Li, mixing time, pH, and temperature are 4.7, 3 h, 7.2, and 25°C, respectively (Hamzaoui et al., 2007; Hamzaoui et al., 2008). The highest Li percent recovery achieved with these parameters is 73%. However, the actual recovery in natural brine systems decreased to 60%. This reduction in Li recovery is attributed to brine impurities, such as boron, and variable environmental conditions (Pauwels et al., 1995). The challenges associated with this particular precipitation method are the sensitivities to Al3+/Li+ ratio, mixing time, and the solution pH at ambient temperatures.

Furthermore, Heidari and Momeni (2017) conducted experimental studies on Li recovery from Urmia lake using lithium aluminate. An aluminum salt, aluminum chloride (AlCl3⋅6H2O), and NaOH were used to co-precipitate Li+ from two Urmia Lake water samples. The first sample had a Li+ concentration of 0.038 ppm and an approximated Mg2+/Li+ mass ratio of 326. The second sample had a Li+ concentration of 0.055 ppm and an approximated Mg2+/Li+ mass ratio of 207. Therefore, both samples are high Mg2+/Li+ and low Li+ concentration aqueous solutions. The first step in the extraction process involved adding and dissolving AlCl3⋅6H2O into the water samples. Next the alkaline reagent, NaOH, was added to increase the pH and form the precipitant, Al(OH)3. The Li+ ions present in the solution were then absorbed into the Al(OH)3. Finally, the Li+ was desorbed from the solid phase using sulfuric acid (H2SO4). The maximum Li recovery from both samples occurred at a pH of 7.5. The sample with the highest Li+ concentration, 0.055 ppm, had a percent recovery of 76.4%, whereas the sample with 0.038 ppm Li+ concentration had a percent recovery of 71%. These Li percentages of recovery are comparable to those achieved by traditional precipitants from salt lakes with Li+ concentrations three to four orders of magnitude higher than the two samples tested. Also, the high Mg2+/Li+ mass ratios did not impact either sample’s Li+ adsorption or desorption process. Therefore, this technology is promising for Li+ extraction from seawater, and other brines with Li+ concentrations less than 30 ppm. The main challenges for Li+ extraction via this precipitant are the sensitivities to ambient temperature, pH, and initial Li+ concentration. Heidari and Momeni (2017) indicate Li+ adsorption is reduced when temperatures exceed 30 °C. Furthermore, the amphoteric properties of the Al(OH)3 surface groups only enhance the Li+ adsorption capacity when the pH is in the 7 to 8 range (Zymon and Kurbiel, 1986). Finally, the efficiency of the Li+ adsorption process improves with increasing Li+ concentration, as seen in the percent recovery of the two samples. This finding suggests that an Li+ pre-concentration step will be required to improve the feasibility of this precipitant for large-scale Li production from aqueous solutions with very high Mg2+/Li+ mass ratios and seawater.

Isupov et al. (1999) used a sorbent synthesized from aluminum hydroxide and the chloride of the double hydroxide of lithium and aluminum (LADH-Cl) to precipitate and extract Li+ from natural brine. The reusable sorbent demonstrated Li percent recovery ranging from 93% to 96% and an LiCl product quality of 5–7 g/l. Paranthaman et al. (2017) developed a similar lithium aluminum layered double hydroxide chloride (Al-LDH) sorbent for Li+ extraction using a three-stage, bench-scale column extraction process. The aluminum Al-LDH (Li:Al ratio 1:3) sorbent selectively precipitated LiCl from geothermal brine with an initial Li+ concentration of 360 ppm. The Mg2+/Li+ ratio of the brine is unreported. In the column extraction process three solutions, the initial brine, intermediate wash (NaCl + LiCl), and final strip solution (purely LiCl), are fed into the column extractor. From there, two computer-operated pinch valves are used to cycle the column extractor through three steps: 1) loading the lithium sorbent with the LiCl present in the brine; 2) washing the sorbent to remove any unwanted ions that are trapped; 3) a final washing of the sorbent to desorb the LiCl ions.

The Al-LDH extraction technology demonstrated an approximated percent recovery of 91% and a high selectivity of Li+ compared to competing ions Na+ and K+ at 47.87 and 212 selectivity, respectively. The only chemical agents required for this process are NaCl and LiCl, and their low cost contributes to the economy of this technology. Additionally, the load-wash-elution cycle does not produce secondary waste, an important consideration for environmental contamination and land use. Although the sorbent composition and column extraction technique could be further optimized to improve selectivity, capacity, and competing ion removal, this novel sorbent technology is a promising solution for Li extraction from aqueous solutions with high competing ion to Li+ ratios.

The high concentrations of Mg2+ present in salt lake brines and seawater have motivated investigations into the potential economic benefits of Mg and Li co-precipitation extraction from aqueous solutions. Mg and its compounds are essential to the global agricultural, insulation, automotive, food, pharmaceutical, chemical industries. The International Magnesium Association estimates global Mg production exceeds 429,000 MT annually, with steady increases attributed to the demand for Mg2+ alloys in the automobile industry (Tran et al., 2013). On average, seawater contains about 1,300 ppm of Mg2+, and the estimated global resource of Mg bearing brines and bitterns is in the billions of tonnes. Therefore, a co-extraction technology that efficiently harvests Li and Mg from these abundant aqueous resources is of high economic value.

Quintero et al. (2020) explored the use of oxalic acid (C2H2O4) for Mg2+ and Ca2+ precipitation before Li+ precipitation. The recovery of these competing divalent ions before Li+ improves the efficiency of Li+ selectivity and produces high-quality calcium oxalate (CaC2O4) and magnesium oxalate (MgC2O4). They achieved a 90% Ca2+ removal rate and a maximum yield of 88% for the solid Li+ and Mg2+ products, lithium carbonate (Li2CO3) and magnesium hydroxide (Mg(OH)2), respectively. The Ca2+ extraction yield was obtained by adding oxalic acid and sodium hydroxide (NaOH) (5 M) to the Li-enriched refined brine and then allowing a 2 h lapse at room temperature. The Oxalic Acid/Ca was added until a molar ratio of 6:1 was achieved. A NaOH/Oxalate molar ratio of 3:3:1 was used to lower the extraction solution pH into a 0–1 range. The Li2CO3/Mg(OH)2 was then co-precipitated by adding 5M NaOH and sodium carbonate (Na2CO3). The Mg2+was precipitated with NaOH, then Na2CO3 was used to precipitate the Li2CO3.

Technologies that remove and co-precipitate competing ions (Mg2+ and Ca2+) from high Mg2+/Li+ and low Li+ concentration aqueous solutions demonstrate high Li+ yield and extraction efficiency rates. Additionally, their co-production of saleable products, such as magnesium hydroxide, present a lucrative opportunity to sustainably supply the industrial demand for these co-products and Li. Overall, they present a more efficient and sustainable crystallization process than what is used in traditional precipitation extraction. The main drawback of this technology is the sensitivity to pH and the concentration of competing ions during the co-precipitation processes. If the concentration of these ions is not controlled, they become impurities that decrease the co-precipitation efficiency and quality of the co-products. More authors have explored the use of oxalic acid to remove or co-precipitate competing ions in high Mg2+/Li+ and low Li+ concentration aqueous solutions. An et al. (2012) used calcium hydroxide and sodium oxalate in a two-step precipitation process to recover

Solvent extraction, also called liquid-liquid extraction (LLE), is a method used to separate compounds according to their relative solubilities into two immiscible liquid phases, an organic phase, and an aqueous phase. An organic phase containing the solvent is added to the aqueous Li solution to form organic Li+ complexes and equilibrate coexisting metals (Na+, Mg2+, Ca2+). The Li+ complexes and some residual impurity metals are transferred to the organic phase. However, most impurity metals remain in the Li+ depleted aqueous solution, or raffinate. The organic phase containing the extracted Li+ complexes is scrubbed to remove the remaining impurities. The scrubbed organic phase is stripped, typically with an acid, to remove the Li+ in a highly concentrated strip liquor. Finally, the Li+ stripped organic phase is regenerated and recycled to the extraction stage (Bang Mo, 1984; Butt et al., 2022). Cation exchange is the driving mechanism for the extraction, scrubbing, and stripping stages, and acid-base neutralization is the driving mechanism for the organic phase regeneration stage (Shi et al., 2018). This extraction process is typically stand-alone and does not require the pre-concentration of Li+ in the aqueous solution. Additionally, solvent extraction can achieve any concentration factor up to the saturation limit compared to other DLE technologies. However, like precipitation, solvent extraction generates high volumes of harmful waste during the scrubbing and stripping stages. Additionally, the corrosive nature of the solvents and process solutions point to equipment and environmental damages under continuous operating conditions. Finally, the most significant barrier to the techno-economic feasibility of solvents for low Li+ concentration solutions is their high cost compared to present-day industrial Li+ precipitants and solvents, which are ineffective for low Li+ concentration solutions. Table 4 provides the aqueous solution, Mg2+/Li+ mass ratio, selectivity, extraction efficiency, recovery, thermal stability, regeneration, Li product, extraction time, and optimal pH value for several solvents. Note that the extraction efficiency is the percentage of the Li+ solute that moves from the brine to the extraction solution.

Several studies have investigated chelating extractants, such as crown ether (CE) and its ether derivative for Li+ extraction. Their polydentate structure encourages Li+ selectivity. Extraction using these ethers follows Pearson’s hard-soft-acid-base (HSAB) principle. The principle asserts that soft acids prefer to bond with soft bases, and hard acids prefer to bond with hard bases. The hard acids possess tiny, highly charged, non-polarizable acceptor atoms. Conversely, softer acids have larger atoms with a lower charge. Also, the bond between the hard acids and bases is dominated by electrostatic interactions, and the bonds between soft acids and bases are covalent. Applying these principles to Li+ extraction, CEs that use ether oxygens, a hard base species, as donor atoms easily bond with hard acid, alkali metal cations such as Li+ (Lowry and Richardson, 1987; Pearson, 1990). Li+ separation efficiency depends on the cavity size of the CE or the CE derivative, especially when competitive ions such as Na+ and Mg2+ are present in the extraction solution. The most Li+ selective CEs are listed in Table 5 (Bartsch et al., 1985).

While the selectivity of CEs is competitive, even for high Mg2+/Li+ ratio solutions, the commercial use of Li+ extraction using CEs has been limited due to the high costs of the ethers and ether derivatives (Hamilton, 1984; Swain, 2016). Additionally, the influence of their underlying extraction mechanisms on the base metal extraction process is not well understood (Swain, 2016). A final consideration is the severely polluting and corrosive nature of the chemical agents used in solvent extraction that ultimately reduce the lifetime of the process equipment. These factors have contributed to the delay in commercializing this solvent extraction technology. However, the development of more economical CEs could bridge this gap. Future developmental efforts should focus on the three critical factors for CE Li extractability: 1) the structure and size of the CE ring; 2) the basicity of the pendent phenolic group (PPG); 3) the geometry between the CE center and the PPG (Katayama et al., 1985).

There are two classes of acidic extractants for liquid-liquid metal extraction: organophosphorus acids and carboxylic acids. Both acids extract Li+ from aqueous solutions by cation exchange (Peppard et al., 1958). This extraction process is facilitated by increasing the aqueous solution pH. Conversely, the Li+ stripping or elution process is triggered by increasing the acidity of the aqueous stripping solution (Xie et al., 2014). To date, acidic solvents have typically been used to extract rare earth and heavy rare earth metals from aqueous solutions, with organophosphorus acids being the more conventional and efficient acid class for extraction (Safarbali et al., 2016). Their characteristically high target ion selectivity and separation efficiency have prompted investigations into their use for aqueous Li+ extraction. However, the best separation and extraction performance has been achieved by a mixture of acidic and solvating extractants (Chen and Wu, 2000). The oxygen atoms in solvating extractants enable the aqueous solution molecules to be incorporated into the Li+ coordination sphere to form an extractable solvated complex (Fuks and Majdan, 2000; Roundhill, 2001). Hano et al. (1992) demonstrated this synergy in a foundational experiment investigating Li recovery from geothermal brine using organophosphorus acid and solvating extractants. Di-2-ethylhexyl-phosphoric acid (D2EHPA) and 2-ethylhexyl-phosphoric acid 2-ethylhexyl ester (MEHPA) were the extractant agents, and tri-n-butylphosphate (TBP) or tri-n-octylphosphine-oxide (TOPO) were the solvating extractants. The geothermal brine samples used in the experiments were hot spring water collected from Yamaga and Hazama, Japan.

The Yamaga water Na+/Li+ and Mg2+/Li+ ratios are ∼301 and ∼4. The Hazama water Na+/Li+ and Mg2+/Li+ ratios are ∼184 and ∼11, respectively. The Hazama water samples are high Mg2+/Li+ and low Li+ concentration aqueous solutions. The percent of Li+ extracted from the Yamaga water samples for D2EHPA and MEHPA were 42.5% and 42.2%, respectively. The percent Li+ extraction from the Hazama water samples for D2EHPa and MEHPA were 52% and 5.2%, respectively. The TOPO additive did not affect extraction behavior. However, the TBP additive increased Li+ extraction in all cases. Li+ extraction percentages for the Yamaga water samples with additive, or D2EHPA + TBP and MEHPA + TBP, were 52.6% and 47.6%, respectively. Similarly, the extraction percentages for the D2EHPA + TBP and MEHPA + TBP Hazama water samples were 88.3% and 11.7%, respectively. D2EHPA and MEHPA demonstrated high selectivity of Li+ ions over Na+ and K+. However, Ca2+ and Mg2+ had a greater affinity for the acidic extractants and demonstrated extraction percentages greater than 91% (excluding Ca2+) from the MEHPA and MEHPA + TBP Hazama water samples. D2EHPA + TBP demonstrated the highest extraction performance overall. In a similar study, (Jang et al., 2017), used D2EHPA and TBP to recover Li+ from oilfield brine in two phases. In the first phase, 94.4% of Ca2+ and Mg2+ ions were removed by D2EHPA. In the second phase, D2EHPA and TBP recovered Li at a 41.2% extraction rate. The total amount of Li recovered was 30.8%.

The results from these experiments indicate that combining acidic extractants D2EHPA and MEHPA and neutral extractants (TBP) is ideal for Li+ extraction from aqueous solutions with minimal divalent ion (Mg2+ and Ca2+) concentrations such as the Salar de Atacama and Lake Zabuye brines. The use of these solvents for Li extraction from high Mg2+/Li+ and Na+/Li+ seawater is infeasible because Li+ is too dilute. However, these extractants could be leveraged as pre-separation agents that remove the competing divalent ions (Mg2+ and Ca2+) before an additional selectivity process is used to extract the remaining Li+ ions from solutions with exorbitant competing ion to Li+ mass ratios. Many other authors have investigated other organophosphoric extractants and TBP for aqueous Li+ extraction in recent years (Torrejos et al., 2015; Nguyen and Lee, 2018; Su et al., 2022).

Ionic Liquids (ILs) are organic compounds comprised of ions with melting points at or below room temperature (25°C). They have many advantageous solvent properties, including high thermal stability, selectivity, and separation efficiency, but marginal volatility (Mori et al., 2015; Patil et al., 2015; Rama et al., 2015). These properties have garnered the interest of researchers working to develop augmented solvents for metal ion extraction. Traditionally, conventional molecular extractants have been combined with ILs that contain fluorinated anions because their immiscible properties facilitate the formation of hydrophobic complexes with the metal ions for extraction. However, extraction with fluorinated ILs leads to hydrofluoric acid contamination, limiting the reuse of ILs for continuous extraction.

Shi et al. (2017) investigated the use of two non-fluorinated ionic liquids (ILs), tetrabutylammonium bis(2-ethylhexyl)-phosphate ([N4444][DEHP]) and tetraoctylammonium bis(2-ethlyhexyl)-phosphate ([N8888]) for aqueous Li+ extraction. These novel ILs, or functionalized ionic liquids (FILs), were prepared via ion exchange and neutralizing reactions. The Li+ extraction performance of the DEHP-type FILs was tested using a multi-metal-ion solution that contained Li+, Na+, K+, Rb+, and Cs+. Both FILs preferred the alkali metal with the smallest ionic radius and the highest surface charge density. Therefore, Li+ had the leading electrostatic interactions and formed the most stable species with the FILs’ [DEHP]− anions. Additionally, the initial Li+ stripping percentage of 90% increased with the number of stripping stages, and complete Li+ stripping occurred after four stages with minimal reduction in the FILs’ extraction efficiency. Overall, the [N4444][DEHP] FILs demonstrated higher extraction efficiencies than [N8888][DEHP] at 92% and 83%, respectively, due to the increased steric hindrance associated with longer alkyl chains. Bai et al. (2022) investigated the synergy of a phosphate-based ionic liquid ([N1888][P507]) and a neutral extractant + acidic ion compound system (TBP + FeCl3) for Li+ extraction from high Mg2+/Li+ brine. At optimal extraction parameters, 97% of the Li+ solute could be stripped from the solvent. Additionally, an initial extraction efficiency of 61% was achieved after the first extraction-stripping-extraction cycle and rose above 70% for the five remaining cycles.

[N4444][DEHP] and [N8888][DEHP] FILs show promising continuous Li extraction efficiency from aqueous solutions containing competing monovalent ions (Na+ and K+). Both FILs outperformed DEHPA, a popular acidic extractant (Shi et al., 2017). However, further investigation into the performance of these FILs in the presence of competing divalent ions such as Mg2+ is needed to determine the feasibility of extraction from brines, seawater, and any other high Mg2+/Li+, low Li+ concentration solutions. Conversely, the novel (([N1888][P507]) + TBP + FeCl3) extractant system demonstrated promising Li+ separation and extraction from high Mg2+/Li+ salt lake brine. Unfortunately, there is a potential trade-off between separation and extraction efficiency: increasing the concentration of ([N1888][P507]) increases Li+ separation efficiency but causes slight reductions in the extraction efficiency. Further experimentation with extraction solutions similar to those of salt lake brines or seawater would provide more insight into the feasibility of ILs for these applications. In recent years, more authors have studied the performance of other FILs in either salt lake brines or high Mg2+/Li+ aqueous solutions (Gao et al., 2016; Wang et al., 2018; Zante et al., 2019; Bai et al., 2020; Bai et al., 2021; Olea et al., 2022).

Ion sieve adsorbents are inorganic materials containing template ions that are introduced into an inorganic compound by redox or an ion exchange reaction. A heating process is then used to obtain the compound oxide. After the compound oxide is formed, an eluent is used to remove the target ions from their crystal positions while retaining the vacancy sites on the crystal. The resulting sieve extracts Li+ via two adsorption mechanisms: physisorption driven by electrostatic interaction and chemical adsorption via ion exchange (Xu et al., 2019). Hence, the target ions can only be obtained in these crystal sites if the ionic radii are similar to the ionic radii of the template ion. Additionally, the material tends to have a higher selectivity for ions that form the best crystal configuration. As a result, the template ions create a reliable selection effect, allowing for the adsorption of target ions even if multiple ions are present in the solution. This process is known as the “ion-sieve effect” (Weng et al., 2020).

One critical techno-economic challenge facing ion sieves is their tendency to disintegrate during adsorption/desorption cycling. This loss is caused by biofouling and the hydrochloric acid treatments used for the Li+ desorption process. Both sources of loss reduce the adsorption capacity, selectivity, and separation efficiency of the ion sieve during cycling. Consequently, operational costs are driven up because more sieve is needed to compensate for these losses, and Li-ion sieve synthesis is expensive (Hu et al., 2022). Additionally, hydrochloric acid is generally the recovery solution used for sieves and its caustic nature raises concerns for environmental pollution. A final drawback is the extraction lead time. Typically, extraction using ion sieves takes days to complete. (Chung et al., 2008; Chitrakar et al., 2014).

Despite the drawbacks, ion sieves demonstrate high Li+ adsorption, selectivity, and cycle stability. Also, the sieves can be regenerated and reused, albeit with some loss after each cycle. More importantly, the adsorption capacity is not impacted by the presence of competing ions, such as Na+, K+, Na2+, and Mg2+. The passive nature of the extraction process is conducive to low initial investment and operation costs. Lastly, in addition to superior selectivity and separation efficiency, Li-ion sieves demonstrate higher theoretical uptake capacity. This feature is particularly desirable for Li+ extraction from high Mg2+/Li+ solutions with Li+ concentrations below 30 ppm.

Manganese dioxide exists in many different crystalline structures: α-MnO2, β-MnO2, γ-MnO2, and λ-MnO2. While each structure demonstrates a strong affinity for Li+, the spinel-type hydrous manganese oxides, λ-MnO2, are the top performers (Voinov, 1982; Chitrakar et al., 2000a; Chitrakar et al., 2000b; Liu et al., 2019). This top performance is attributed to the spinel structure of the λ-MnO2 ion sieve precursor, Li+ manganese oxide (LiMn2O4). The template spinel formula is (AB2O4), where the divalent cations, A, occupy eight tetrahedral voids, the trivalent ions, B, occupy 16 octahedral voids, and the oxygen anions, O, occupy the 32 face-centered cube lattice points (Hill et al., 1979). Therefore, the ratio of A: B: O is 8: 16: 32, which can be reduced to 1: 2: 4, or the conventional spinel formula.

As it relates to spinel LiMn2O4, the Li+ cations occupy the eight tetrahedral voids, manganese (III) and manganese (IV) occupy the 16 octahedral voids, and the oxygen anions occupy the 32 face-centered cube lattice points. The manganese ions have octahedral coordination with the oxygen anions, and the MnO6 octahedra share edges that create a three-dimensional host for the Li+ guest cations. Furthermore, the Li+ tetrahedral voids are located the furthest away from the manganese octahedral voids of the interstitial tetrahedra and octahedra. Consequently, each Li+ tetrahedron face is matched with an octahedral void (Xu et al., 2016). This combination of structural features inhibits easy Li-ion exchange without changing crystalline structure during reversible Li+ intercalation. Additionally, the Mn-O framework remains stable after desorption/regeneration with an acidic treatment (Wang et al., 2008; Wang et al., 2014).

The LiMn2O4 precursor has low Li+ adsorption capacity and stability. The maximum adsorption capacities achieved from seawater and salt lake brine are 1.1 and 30.9 mg/g, respectively (Chitrakar et al., 2000b; Wang et al., 2014). However, the stoichiometric proportion between Li: Mn can be altered to increase the theoretical Li+ capacity of LMO-type LISs (Xu et al., 2016). Chitrakar et al. (2000b) used a hydrothermal method to synthesize Li1.33Mn1.67O4 and cubic Li1.67Mn1.67O4, which achieved Li+ adsorption capacities of 25 and 37 mg/g from seawater and salt lake brine, respectively. The highest recorded Li+ adsorption capacities for Li1.33Mn1.67O4 from seawater and salt lake brine are 54.7 and 63 mg/g, respectively (Zandevakili et al., 2014; Ryu et al., 2016). Additionally, the highest recorded Li+ adsorption capacities for Li1.67Mn1.67O4, from seawater and salt lake brine are 40 and 28 mg/g, respectively (Chitrakar et al., 2001; Xiao et al., 2013). Currently, Li1.67Mn1.67O4 has the highest theoretical adsorption capacity at 72.8 mg/g. However, Li1.67Mn1.67O4 requires a two-step preparation process compared to the one-step required for the other precursors. Consequently, LiMn2O4 and Li1.33Mn1.67O4 are more economical for industrial Li+ extraction applications at this time. Table 6 provides the adsorption capacity, cyclical stability, thermal stability, environmental durability, extraction time, and optimal pH of various LMO-type LISs used for Li+ extraction from salt lake brines, simulated brines, and seawater.

The main challenges facing LMO-type LISs for large-scale, industrial Li+ extraction applications are the residual impacts of the precursor acid treatments. These acid treatments reduce the LMO-type adsorbent stability, adsorption capacity, and durability and cause environmental pollution. While the acid effectively removes most of the Li+ without disrupting the precursor crystalline structure, it simultaneously causes manganese to dissolve with each successive treatment (Shen and Clearfield, 1986; Wang et al., 2009; Xiao J. L. et al., 2015; Gao et al., 2018; Weng et al., 2020). The dissolution of the Mn is attributed to the Jahn Teller effect induced by trivalent manganese (Mn3+). The octahedral MnO6 structure becomes increasingly distorted, reducing the stability, adsorbent capacity, and durability, and causing considerable water pollution (Jin et al., 2018; Weng et al., 2020). To combat this dissolution phenomenon, many authors have experimented with replacing the Mn3+ with: divalent cobalt (Co2+), nickel (Ni2+), and magnesium (Mg2+); trivalent chromium (Cr3+), aluminum (Al3+, and iron (Fe3+); and, other rare-earth ions (Malyovanyi et al., 2003; Ein-Eli et al., 2005; Eftekhari et al., 2006; Wu et al., 2007; Iqbal and Ahmad, 2008; Amaral et al., 2010; Sakunthala et al., 2010; Wu et al., 2010; Helan et al., 2011; Xu et al., 2011; Xu et al., 2016). LMO-type precursors doped with Fe3+, antimony Sb(v), and Al3+ demonstrated the highest Li+ extraction capacity with minimal Mn dissolution. However, ascertaining the optimal molar ratio between the doping ions and Mn is critical for achieving a high Li+ adsorption capacity. Further investigation is needed into improving the cyclical stability and practical ion exchange capacity of Li-Mn-O precursors for large-scale Li production.

At present, there are two classifications for LTO-type LISs: layered H2TiO3 and spinel H4Ti5O12. The structure of H2TiO3 is attributed to the layered structure of the Li2TiO3 precursor that is synthesized to create the LIS. Similarly, the spinel structure of H4Ti5O12 is derived from the spinel structure of its precursor, Li4Ti5O12. Compared to LMO-type LISs, LTO-type LISs demonstrate high adsorption capacities, with marginal Ti loss. The main advantage of these LISs is that they are more ecologically friendly because titanium ions are environmentally benign and easy to remove from liquids (Xu et al., 2016; Gopinath et al., 2020). Unlike Mn, the Ti valence ions remain stable during permeation and adsorption. Consequently, LTO-type LISs demonstrate higher theoretical adsorption capacity and better recyclability for continuous extraction (Marthi et al., 2021). Additionally, the Ti-O bonds present in Li4Ti5O12 provide anti-acidic properties: an especially compelling feature for extraction from seawater and salt lake brines. The main drawback of LTO-type LISs is that they demonstrate slower Li+ adsorption rates than LMO-type LISs (Chitrakar et al., 2014). Table 7 provides the adsorption capacity, cyclical stability, thermal stability, environmental durability, extraction time, and optimal pH of various LTO-type LISs used for Li+ extraction from salt lake brines, simulated brines, and seawater.

The crystal structure of Li2TiO3 can be represented as a cubic close packing of oxygen atoms with metal atoms placed in the octahedral voids. Li+ and Ti4+ form two layers. The first layer is solely composed of Li atoms, and the second is composed of 2/3 Ti atoms and 1/3 Li atoms. The crystal structure is formed by successive stacks of oxygen, lithium, and titanium/lithium layers (e.g., O/Li-Ti/O/Li/O) that conform to the C2/c space group symmetry (Watanabe et al., 2020). This crystal formation of Li2TiO3, also known as monoclinic β-phase Li2TiO3, achieves nearly complete Li extraction (100%) to form monoclinic H2TiO3 when treated with acid at comparatively low temperatures (700°C). Two other phases of Li2TiO3 exist, α-phase and γ-phase, but the β-phase is the most promising for aqueous Li extraction. The α-phase has lower thermal stability and will transform into β-phase when exposed to temperatures above 300°C. Alternatively, γ-phase only achieves 50% Li+ extraction (Chitrakar et al., 2014).

Chitrakar et al. (2014) investigated the Li+ ion exchange reaction of H2TiO3 in brine collected from Salar de Uyuni, Bolivia. H2TiO3 demonstrated initial adsorption of 26 mg/g within 1 h and reached equilibrium after 24 h. A Li+ adsorptive capacity of 32 mg/g was achieved, reaching equilibrium after 8 h. The high concentrations of competing monovalent (Na+ and K+) and divalent (Mg2+ and Ca2+) ions present in the brine did not impact the Li+ selectivity. Finally, after elution with an HCl solution, H2TiO3 demonstrated a Li+ adsorptive capacity of 31.4 mg/g, 98% of the initial capacity reported. Zhang et al. (2016) prepared H2TiO3 using a sol-gel process and tested its Li+ adsorption performance from LiOH and LiCl + NaOH solutions. The maximum Li+ adsorption capacities from the LiOH and LiCl + NaOH solutions were 27.4 and 24.1 mg/g, respectively. They found that alkaline pH values and higher initial Li+ concentrations yield higher adsorption capacities.

While the theoretical adsorption capacity of H2TiO3 LISs is higher than most LMO-type LISs, the practical adsorption capacity demonstrated after recovery from brine or seawater is often lower (Dai et al., 2021). Authors have explored the use of doping to potentially increase the adsorption capacity of LISs (Chitrakar et al., 2014; Wang et al., 2019; Qian et al., 2021a; Qian et al., 2021b). Dai et al. (2021) tested the adsorption performance of Al-doped H2TiO3 using a LiCl solution. A maximum adsorption capacity of 32.1 mg/g was achieved, with the adsorption capacity remaining at 29.3 mg/g after five HCl elution cycles. The undoped H2TiO3 achieved a maximum of 29.73 mg/g. Although there was no major improvement in adsorption capacity, the Al-doped H2TiO3 demonstrated favorable adsorption selectivity and solubility resistance. Additionally, the dissolution of Ti after multiple regenerations was marginal (2.53%). Further investigation into doping materials and other capacity-increasing processes is recommended to improve the feasibility of H2TiO3 LISs for Li+ extraction from high Mg2+/Li+ and low Li+ concentration aqueous solutions. The chemical stability, cyclical stability, and eco-friendliness of H2TiO3 LISs signal their potential to surpass LMO-type LISs if their adsorption capacity is significantly improved.

In the Li4Ti5O12 spinel structure, Ti atoms occupy 5/6 of the 16 days octahedral voids, Li atoms occupy the remaining 16 days octahedral voids, and oxygen atoms occupy the 32e voids (Ohzuku et al., 1995). The resulting [Li1/3Ti5/3]16dO4 framework features face shared tetrahedral and octahedral interstitial Li-ion positions in the lattice that create three-dimensional connections for Li-ion migration. In addition to creating stronger Ti-O bonds, this spinel structure enables easy migration of Li+ ions for recovery and elution with minimal Ti dissolution (Ouyang et al., 2007). Consequently, H4Ti5O12 LISs have higher Li+ capacity and greater cyclical stability than LMO-type LISs (Xu et al., 2016). Furthermore, a preliminary study of Li4Ti5O12 for Li+ recovery from Salar de Atacama brine and seawater revealed that Li4Ti5O12 has high Li+ selectivity for aqueous solutions with high concentrations of H and Na+. Consequently, Li4Ti5O12 is predicted to be one of the most promising LIS precursors for large-scale Li+ extraction from brine and seawater (Snydacker et al., 2018).

Gu et al. (2016) studied the ion exchange properties and selectivity of Li4Ti5O12 for Li recovery from a LiOH solution. Li4Ti5O12 was prepared by a solid-state reaction of Li2CO3 and TiO2 then treated with nitric acid to form the H4Ti5O12 LIS. The LISs demonstrated excellent Li+ selectivity of 145.7 ml/g, with only a moderate reduction of 5.5% after three recovery/elution cycles. Wei et al. (2020) synthesized H4Ti5O12 nanofibers (P-HTO-NF) for Li recovery from simulated brine water (Li+ 40 mg/L, Na+ 241 mg/L, K+ 443 mg/L, Mg2+ 501 mg/L, Ca2+ 535 mg/L). The P-HTO-NF demonstrated an adsorption capacity of 59.1 mg/g, which is 93% of the theoretical capacity. Adsorption equilibrium occurred within 30 min. Also, the equilibrium distribution coefficient for Li+ was two orders of magnitude higher than the coefficients of the competing ions, indicating an extraordinary Li+ selectivity. Finally, the LIS demonstrated excellent cyclical stability, with capacity remaining at 86.5% after six cycles. Similarly, Zhao B. et al. (2020) explored using H4Ti5O12 sheets in place of the traditional powder adsorbent to recover Li from Lagoco Salt Lake samples and simulated brine. While the adsorption capacity was not as competitive at 21.57 mg/g, 96.84% of the initial adsorption capacity was retained after four cycles.

H4Ti5O12 LISs have demonstrated superior Li+ selectivity, adsorption capacity, chemical stability, and cyclical stability after multiple adsorption/elution cycles from high Mg2+/Li+ and low Li+ concentration aqueous solutions. The main challenge facing the commercialization of H4Ti5O12 LISs is their novelty. Few experiments have explored the performance of this sieve in traditional powder form, and the limited studies of alternative morphologies have remained at the bench scale. Further performance testing of H4Ti5O12 LISs for recovery from high Mg2+/Li+ and low Li+ concentration aqueous solutions is needed.

Ion-imprinted membranes (IIMs) are the combined product of membrane separation and ion-imprinting techniques. Membrane separation is a highly efficient technique that utilizes pores to filter and selective permeability to separate substances in aqueous solutions (Malliga et al., 2020). These aqueous solutions are driven through the membrane by a concentration, pressure, or potential gradient. Furthermore, ion-imprinting is a bio-inspired technique that mimics the “lock and key” interaction between natural receptors and ligands (Lu et al., 2019). During the ion imprinting process, polymeric matrices are loaded with artificial ionic recognition sites complementary to the template ion’s size and shape (Ertürk and Mattiasson, 2017). Protonation is then used to remove the template ions, leaving the recognition sites open for target ion adsorption. In summary, IIMs leverage the functionality provided by both technologies and can selectively separate and detect target ions via ion-selective recognition (Lu et al., 2019). Additionally, these membranes can be modified with interlayers or imprinted with nanomaterials that prevent membrane fouling, a major challenge for all membrane extraction technologies (He et al., 2022; Sun et al., 2022). Similarly, the antifouling properties suggest that the standard feed solution pretreatment required for most membrane technologies may not be required for IIMs. Li-IIMs’ high separation efficiency, selectivity, low energy consumption, easy operation, and unique antifouling properties have prompted recent investigations into its feasibility for Li+ extraction from low Li+ aqueous solutions. Table 8 provides the selectivity, rebinding capacity, thermal stability, regeneration, cyclical stability, specific energy consumption, extraction time, and optimal pH of various IIMs used for Li+ extraction from simulated brines. Note that the rebinding capacity is the degree to which the Li-ions in the aqueous solution can bind, detach, and rebind to the IIMs Li+ recognition sites.

The most significant challenges facing the commercialization of IIMs for industrial scale, aqueous Li+ extraction are pH sensitivity, temperature dependence, extraction time, and the ratio of template ions, ligands, and functional monomers (Lu et al., 2019). The pH value is generally the determining factor for IIM ion selectivity. When the pH value is too low, protons compete with target ions for binding sites, decreasing the membrane’s adsorption capacity. Increasing the pH value can reduce this competition. Ultimately, the pH value can be adjusted to trigger Li+ adsorption/desorption and, therefore, potential membrane regeneration for continuous extraction. However, extensive experimentation is required to identify the pH values that optimize Li+ adsorption/desorption rates without destroying the IIMs ion recognition sites. The optimal pH value varies across IIM technologies. Furthermore, IIMs demonstrate enhanced adsorption capacities at higher temperatures. Consequently, passive Li+ extraction from seawater and salt brines with cooler temperatures or extraction during winter months may be economically infeasible. Similar to the pH value, additional experimentation is required to identify an extraction time that maximizes recovery without damaging the IIMs. Extended elution periods do not guarantee higher percent recovery. Finally, the ratio of templates to ligands to functional monomers dictates the number of effective binding sites on the membrane. Therefore, research that identifies the optimal ratio of templates to ligands to functional monomers, which varies according to the materials used to prepare the IIMs, is critical to adsorption capacity and overall performance. Addressing these performance challenges will significantly improve the techno-economic feasibility of Li-IIMs, especially compared to other membrane extraction technologies that are subject to fouling and require pretreated extraction solutions.

Lu et al. (2018) developed and tested High-selective Li-Ion-Imprinted Membranes (Li-IIMs) with enhanced hydrophilicity and stability for aqueous Li+ extraction. Polyether sulfone membranes (PMs) were selected for their high porosity, high-pressure resistance, and high stability. PMs have also demonstrated satisfactory performance in other ion separation experiments (Maheswari et al., 2012; Mortaheb et al., 2014). Synthetic polydopamine (PDA) layers were synthesized on the surface of the PMs to enhance interfacial adhesion for the attachment of the ion-imprinted polymers. Additionally, silicon dioxide nanoparticles (SiO2) were added to the PMs surface to enhance their hydrophilicity and stability. Finally, 12-crown-4 ether and Li+ ions were imprinted on the PMs’ surfaces to create the adsorption cavities and ion recognition sites, respectively. The Li-IIMs demonstrated high relative selectivity with coefficients of 1.85 and 2.07 for Li+/Na+ and Li+/K+, respectively. The permselectivity (separation efficiency) factors were also high, with coefficients of 7.39 and 9.86 for Na+/Li+ and K+/Li+, respectively. The rebinding (adsorption) capacity reached a maximum of 90.3% of initial binding after five cycles of adsorption/desorption with a slight decline to 88.1% after ten cycles.

While the Li-IIMs demonstrated excellent performance, experiments with aqueous solutions that more closely resemble the ionic concentration of salt lake brine and seawater should be investigated. Even salt lakes with higher Li+ concentrations, like Salar de Atacama (2,100 ppm), have Na+/Li+ and K+/Li+ ratios greater than 10:1, as compared to the 1:1 concentration used in the Lu et al. (2018) experiments. In 2021, Ding et al. (2022) developed and tested a novel high-selective ion imprinted polymer (sans membrane) for Li+ extraction lake Zabuye brine samples. The technology achieved a maximum adsorption capacity of 1.1 mg/g. While this is promising for green Li+ extraction from carbonate type, low Mg2+/Li+ brines, experiments that investigate the performance of these ion-imprinted technologies in high Mg2+/Li+ aqueous solutions are needed.

Yu et al. (2020) investigated the use of polydimethylsiloxane-polydopamine (PDMS-PDA) Li-IIMs for rapid, high-efficiency recovery of Li from seawater. A powerfully adhesive PDA layer with numerous functional groups was synthesized on the PDMS membrane surface via the self-polymerization of dopamine to improve hydrophilicity. Carboxyl groups were then grafted onto the PDA functionalized substrate per the hydrolysis of succinic anhydride. The carboxyl-modified PDMS membranes were further modified to construct ester-modified membranes. The calix [4] arene ligand and Li-ions were used to create the absorption cavities and ion recognition sites, respectively. Finally, EDTA removed the template Li-ions from the prepared Li-IIMs.

The PDMS-PDA Li-IIMs demonstrated high thermal stability, with their rebinding capacity decreasing marginally with increasing temperatures. Similarly, the modified membranes were stable in acidic and alkaline conditions. However, the pH significantly impacted rebinding capacity; a pH of 3.0 was identified as the optimal value. Furthermore, a Li+ rebinding capacity of 51 mg/g was achieved. The PDMS-PDA Li-IIMS demonstrated high relative selectivity with coefficients of 1.71, 4.56, and 3.80 for Na+/Li+, K+/Li+, and Rb+/Li+, respectively. The permselectivity factors for Na+, K+, and Rb+ were approximately 2.52, 2.8, and 3.03, respectively. Finally, the PDMS-PDA Li-IIMS showed high adsorption/desorption cycle durability. Four successive regeneration cycles were completed over 10 days, and the rebinding capacities remained almost unchanged.

PDMS-PDA Li-IIMs demonstrated excellent performance overall and appear to be a viable technology for Li+ extraction from seawater. However, similar to the High-selective Li-IIMs developed by (Lu et al., 2018), investigations with aqueous solutions that simulate the ionic concentrations in seawater are recommended. Also, the cost and specific energy consumption implications for the stirring required to elute Li+ on an industrial scale should be further explored to determine the techno-economic feasibility of this technology.

Electrochemical Li capturing systems (ELiCSs) use electricity to drive ion-separation processes for Li+ extraction. There is a proportional relationship between the total charge storage of the systems electrode and the amount of Li+ extracted from an aqueous feed solution. The basic configuration of an ELiCS consists of an external power supply, electrodes, and an aqueous electrolyte, in this case, brine or seawater (Soffer and Folman, 1972; Kim et al., 2018; Yoon et al., 2019). Electrochemical technologies are particularly interesting for extraction from high Mg2+/Li+ and low Li+ concentrations solutions because they are environmentally sustainable and have demonstrated excellent recovery capacities, scalability, cycling efficiency, reversibility, and selectivity (Hoshino, 2013a; Lee et al., 2013; Kim et al., 2015; Yoon et al., 2019; Zhang et al., 2019; Zhao et al., 2020b; Srimuk et al., 2020). Additionally, electrochemical technologies can easily integrate energy recovery techniques that utilize the salinity gradient of the aqueous feed solutions to generate energy Zhang X. et al. (2021). Their characteristic high extraction efficiency and low environmental impact suggest that ELiCSs are more techno-economically feasible for Li+ extraction from low Li+ concentration solution than precipitants or solvents. However, the main disadvantages that must be addressed are their potentially high energy consumption due to process inefficiencies and high material costs Zhang Y. et al. (2021).

ELiCSs generally belong to one of three categories: battery-based (BB), membrane enhanced battery-based (MEBB), or electro-membrane-based (EMB) (Zavahir et al., 2021). BB ELiCSs use at least one faradic electrode to capture Li+ from aqueous solutions. The faradic electrode(s) capture Li-ions via conversion reaction or intercalation over the bulk of the electrode’s materials. They have greater storage capacity, Li+ selectivity, and capacitance but slower removal rates than non-faradic (capacitive) electrodes (Patrice et al., 2014; Yoon et al., 2019). The MEBB ELiCSs augment the battery-based configuration with an anion exchange membrane (AEM) for Li recovery. In the rocking chair configuration, the AEM splits the electrochemical cell into a cathode and an anode chamber that contain one Li+ intercalating electrode each. In the redox configuration, there is one intercalating electrode and one redox couple electrode. Continuous Li recovery is achieved by swapping the positions of the Li+ “capture” and “release” electrodes. Finally, the EMB, or electrodialysis configurations, have a series of AEM and cation exchange membranes (CEM) sandwiched between two faradic electrodes. Electric potential drives the Li+ through the CEMs towards concentrating compartments (Zavahir et al., 2021). Further information about the performance, advantages, and challenges of prominent ELICSs is provided in subsequent sections.

The electrochemically switched ion exchange system (ESIX), first proposed by the Pacific Northwest National Laboratory, is a battery-based ELiCS (when employed for Li capture). In the ESIX process, an electroactive ion exchange film is deposited onto a high surface area electrode. The redox reactions that drive ion uptake and elution are directly controlled by adjusting the electric potential of the film. A cathodic potential can be applied to intercalate Li+ into the film for Li recovery from an aqueous solution. This intercalation is driven by the film’s need to maintain charge neutrality. Conversely, when an anodic potential is applied, the film is oxidized, and Li is released from the film (Sukamto et al., 1998). Essentially, the ESIX combines electrochemistry and ion exchange to provide a Li recovery process with high selectivity and reversibility. Also, the ESIX utilizes a faradic and a capacitive electrode, the combined benefits of which bridge the performance gaps in conventional battery and capacitor-based recovery systems.

Adjustments to the conventional ESIX electrode configuration must be made to circumvent the mass transport challenges associated with Li recovery from high Mg2+/Li+ and low Li+ concentration aqueous solutions. An array of smaller electrodes with higher surface areas arranged into working and counter electrode pairs can be employed for recovery instead of a large, singular electrode (Joo et al., 2020; Zavahir et al., 2021). Additionally, keeping the volume of the recovered solution low is mandatory for obtaining a high Li-concentrated final product (Joo et al., 2020; Zavahir et al., 2021). The Li+ selectivity of the ESIX depends on the selectivity of the electrode materials. Several working and counter electrode materials have been tested to identify the best candidates for Li recovery from low concentration solutions: λ-MnO2/Pt (Kanoh et al., 1991; Kanoh et al., 1993; Kim et al., 2019; Liu et al., 2019); λ-MnO2/Ag (Lee et al., 2013; Xu et al., 2018; Kim et al., 2019; Joo et al., 2020)); λ-MnO2-activated carbon (AC) (Kim et al., 2015); λ-MnO2/NiHCF (Trócoli et al., 2017); λ-MnO2/LiMn2O4 (Liu et al., 2019); LMO/Boron Doped Diamond (BDD) (Kim et al., 2018); LMO/Polypyrrole (Ppy) (Marchini et al., 2016; Missoni et al., 2016); LMO/Ppy/Al2O3 (Zhao et al., 2020c); LiFePO4/Ag (Trócoli et al., 2014); and, FePO4/NiHCF (Trócoli et al., 2015). When applied for Li recovery from simulated brine, natural brines, and multi-ion solutions, the specific energy consumption for these electrode variations ranged from 1.4 kWh/kmol to 18.5 kWh/kmol. The AC counter electrode demonstrated a high Li recovery of 14.4 mg/g for a 25 min cycle, so it is recommended for all ESIX systems (Zhao et al., 2020d; Zavahir et al., 2021). Furthermore, the λ-MnO2 and LMO working electrodes demonstrate the highest adsorption capacities at 10 mg/g and 30 mg/g, respectively. Table 9 provides the selectivity, current efficiency, regeneration, adsorption capacity, recovery, specific energy consumption, product quality and extraction time of various ESIX working/counter electrode materials used for Li+ extraction from salt lake brines, simulated brines, and wastewater. Note that the current efficiency is a measure of how efficiently the electrodes transfer the charges driving the electrochemical extraction of Li+.

A major challenge facing ESIX for industrial operation is the flushing process needed to exchange the source solution for the recovery solution. Pure water, a precious resource, is required for flushing to prevent cross-contamination of the two solutions. Consequently, this process poses a considerable threat to process efficiency and sustainability. Furthermore, this batch operation is less efficient than other continuous mode technologies, such as electrodialysis (Zavahir et al., 2021). Additionally, the reported energy consumption for ESIX can be misleading because it is typically calculated using metrics from the first cycle only, which results in underestimated projections for total energy consumption over many cycles. Finally, as mentioned previously, maintaining a low recovery solution is critical to the quality of the Li recovered. At the bench level, recovery solutions at the μ scale require around five enrichment cycles. Therefore, the solution enrichment process at the commercial level can be expected to exceed 1,000 cycles (Zavahir et al., 2021). Further investigation into the practical energy consumption and sustainability of ESIX for Li recovery from brine and seawater is needed. A special focus on the solution flushing process and finding an alternative for pure water is recommended. In this vein, Trócoli et al. (2017) have developed a promising ion-pumping process that employs a λ-MnO2/NiHCF working/counter electrodes for Li+ recovery. No chemical reactants are required, the electrodes are recyclable, and most importantly, only a small volume of water is required.

Electrodialysis (ED) is an electrochemical membrane separation process that utilizes an ion-selective membrane and an electric potential gradient for ion separation from aqueous solutions(Gurreri et al., 2020). A typical electrodialysis cell comprises an alternating series of AEMs and CEMs between a cathode and an anode (Gmar and Chagnes, 2019). In the electrodialysis process for Li+ extraction, electric force drives Li+ ions in the feed solution from the positive side of the cell (cathode) to the negative side (anode) through an ion Li+ selective membrane. As a result, Li+ is concentrated on one side of the cell. Additional treatments are required to obtain the metallic or solid Li compounds dissolved in the Li+ enriched water. Similarly to other membrane technologies, ED systems require the feed solution to be pretreated so that Ca2+, Mg2+, and other metals that cause membrane fouling can be removed prior to Li+ extraction (Wang et al., 2022). However, compared to other membrane technologies such as nanofiltration, ED systems have higher recovery rates, lower energy consumption, and higher Li+/Mg2+ separation factors (Gmar and Chagnes, 2019).

ED systems are classified according to the attributes of their ion exchange membranes (IEMs): selective electrodialysis (SED) utilizes IEMS that have high selectivity for monovalent ions; bipolar membrane electrodialysis (BMED) utilizes bipolar IEMS; and finally, ion liquid membrane electrodialysis (ILMED) which employs liquid ion membranes (Zavahir et al., 2021). While ED technologies are already used for industrial hydrometallurgical processes to recover Li from industrial brines, ore concentrates, and spent LIBs, their use for recovery from high Mg2+/Li+ and low Li+ concentration solutions has been limited (Campione et al., 2018; Gmar and Chagnes, 2019). Table 10 provides the applied voltage, selectivity, current efficiency, separation efficiency, recovery, and specific energy consumption of various ED membranes for Li+ extraction from salt lake brines, simulated brines, and seawater.

SED employs monovalent anion exchange membranes (MAEMs) and monovalent cation exchange membranes (MCEMs) to transport the monovalent anions (Cl−) and cations (Li+, Na+, and K+) through the MAEMs and MCEMS and to the anode and cathode, respectively. The divalent anions

BMED employs a bipolar membrane (BM) comprising a cation-exchange layer, an anion-exchange layer, and a hydrophilic interface layer (Huang and Xu, 2006; Li et al., 2016; Gmar and Chagnes, 2019). When an electric field is applied to the BM, the water molecules in the hydrophilic layer separate into hydrogen (H+) and hydroxide (OH−) ions. Simultaneously, anions passing through the AEM are combined with H+, and cations passing through the CEM are combined with OH−. The resulting acidic and basic solutions are enriched in corresponding recovery compartments (Mani, 1991). The acidic and basic recovery compartment streams can be treated with precipitants to produce LiOH and other valuable co-products (Bazinet et al., 1998; Jiang et al., 2014; Xue et al., 2015; Gmar and Chagnes, 2019).

Similar to SED, BMED demonstrates higher Li recovery at higher voltages. However, the ion leakage induced by higher voltages reduces Li recovery, so finding an optimum applied voltage is critical. Furthermore, BMED is very promising for Li recovery from high Mg2+/Li+ and low Li+ concentration solutions (Bunani et al., 2017b; Gmar and Chagnes, 2019). Compared to the other ED processes, it has the highest average Li+ recovery range (60%–98%), lowest average extraction time (20–120 min), and the lowest SEC range (3–19 kWh/kmol) (Bunani et al., 2017a; Bunani et al., 2017b; İpekçi et al., 2018; İpekçi et al., 2020). Also, BMED is ecologically friendly, requiring no chemical reagents for recovery (e.g., lime or sodium carbonate). The production of a basic and acidic recovery stream provides an economic opportunity to co-recover other industrial minerals, such as boron (Jiang et al., 2014; Yang et al., 2014; Hwang et al., 2016; Bunani et al., 2017a; Bunani et al., 2017b; Chen et al., 2022).

The main drawback of BMED is the sensitivity to high ion concentrations. The BM permselectivity is significantly reduced due to the Donnan exclusion phenomena wherein salt leaks through the membrane into the Li product (Tanaka, 2015; Venugopal and Dharmalingam, 2016; Pärnamäe et al., 2021). The BM’s high cost and thermal instability have also contributed to the limited use of BMED for aqueous mineral recovery. A pretreatment to reduce initial concentration is required for optimal performance. Despite its disadvantageous aspects, BMED has demonstrated higher chemical stability, mechanical stability, current efficiency, permselectivity, durability, and lower electrical resistance and voltage drop than the conventional ED processes for Li recovery. Many authors are already exploring ways to improve BMED performance, such as decreasing the AEM thickness, combining BMs with MAEMS and MCEMs, and appending catalysts layers to the BMs (Wilhelm et al., 2001; Manohar et al., 2017; Wang et al., 2017; Chen et al., 2021).