94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

EDITORIAL article

Front. Built Environ., 21 February 2025

Sec. Construction Materials

Volume 11 - 2025 | https://doi.org/10.3389/fbuil.2025.1573450

This article is part of the Research TopicSustainable Building Materials from Recycled Cement/Concrete and Recycled Industrial WastesView all 5 articles

Editorial on the Research Topic

Sustainable building materials from recycled cement/concrete and recycled industrial wastes

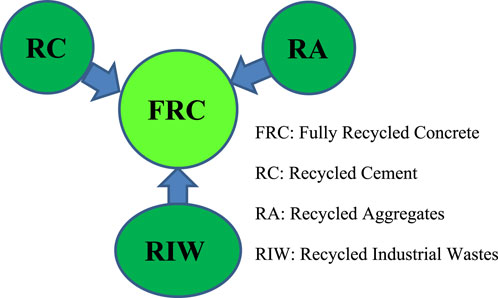

Carbon-negative cement and concrete technologies, particularly using recycled cement, recycled aggregates, and carbon curing methods for producing fully recycled concrete (Figure 1), offer a promising solution to reduce the environmental footprint of construction. This Research Topic was proposed in the context of reducing carbon emission and carbon sequestration from the Paris Agreement.

Figure 1. Fully Recycled Concrete (FRC) prepared from Recycled Cement (RC), Recycled Aggregates (RA) and Recycled Industrial Wastes (RIW).

The Research Topic contains a total of four papers and all are original contributions. Duan investigated compressive strength of fiber-reinforced recycled aggregate concrete based on optimization algorithms. Nseke et al. reported the inhibitory effect of rice husk ash on the alkali leaching and efflorescence of alkali activated granulated blast furnace slag. Samrani et al. adopted industrial wastes like fly ash and ground waste glass as cement replacement in concrete 3D-Printing as sustainable construction materials. Cardoso et al. used Sururu shell waste (Mytella falcata) as recycled aggregates in green mortar production.

Carbon-negative cement and concrete offer a promising pathway to mitigate the environmental impact of the built environment. By using recycled cement, recycled aggregates, and carbon curing techniques for fully recycled concrete, we could achieve significant reductions in both emissions and the consumption of raw materials, while also contributing to carbon sequestration.

Recycled cement, primarily obtained through the processing of demolished concrete or construction and demolition (C&D) waste, holds substantial promise in reducing the carbon footprint of concrete production. Unlike traditional cement production, which involves the calcination of limestone at high temperatures (a process that releases large amounts of CO₂), recycled cement can be produced with considerably lower energy consumption (He et al., 2019; Wang et al., 2018).

The carbon sequestration potential of recycled cement stems from the chemical interactions between recycled cementitious materials and atmospheric CO₂. Recycled cement, especially when used in conjunction with other supplementary cementitious materials (SCMs) like fly ash, slag, or silica fume, can trap and store CO₂ within the matrix. Carbonation of the calcium-silicate-hydrate (C-S-H) gel in recycled concrete leads to carbon sequestration, where CO₂ is absorbed from the atmosphere, contributing to a reduction in overall carbon emissions (Xu et al., 2023). In some cases, carbon reduction rates can be as high as 90% of CO₂ per ton of recycled cement used compared to ordinary portlandite cement.

A study by Xu et al. found that incorporating recycled cement in concrete not only reduces the demand for virgin materials but also enhances the concrete’s ability to absorb CO₂ over time, a crucial element in reducing net greenhouse gas emissions.

Recycled aggregates are another key component of carbon-negative concrete. These materials, typically sourced from demolition sites or construction waste, are a direct alternative to traditional quarried aggregates after carbonation enhancement or physical enhancement (Huang et al., 2025). The use of recycled aggregates in concrete significantly reduces the energy consumption and emissions associated with the extraction, transportation, and processing of virgin aggregates.

The use of recycled aggregates also addresses the resource depletion issue. Global demand for raw materials such as sand and gravel has skyrocketed in recent decades, resulting in unsustainable mining practices and habitat destruction. By utilizing waste concrete and recycled aggregates, the construction industry can reduce its reliance on virgin materials, helping to conserve natural resources and mitigate the environmental impact of extraction activities (Wang Y. et al., 2023; Wang et al., 2022).

Moreover, when recycled aggregates are combined with recycled cement, the carbon footprint of concrete can be significantly reduced. The reduced need for cement production results in lower emissions, while the use of recycled aggregates avoids the emissions associated with traditional aggregate production.

A transformative approach to reducing the environmental footprint of concrete is carbon curing, a method that uses carbon dioxide (CO₂) to cure concrete instead of the traditional water-based curing methods. By injecting CO₂ into freshly mixed concrete, the chemical reaction between CO₂ and the calcium compounds in the cement matrix leads to the formation of calcium carbonates, which trap CO₂ within the concrete.

For fully recycled concrete, the addition of recycled aggregates and recycled cement further enhances the potential for carbon sequestration through carbon curing. Not only does carbon curing make the concrete stronger and more durable, but it also provides an opportunity to sequester CO₂ at a significant scale. Researchers have shown that carbon curing can lead to a reduction in CO₂ emissions of up to 30% for every cubic meter of concrete produced.

A study by Wang J. et al (2023) demonstrated that using carbon dioxide curing with fully recycled concrete not only improves its compressive strength but also results in carbon sequestration, offering a carbon-negative construction material. The ability to sequester CO₂ during the curing phase of concrete production can play a pivotal role in achieving global sustainability targets.

The environmental benefits of using recycled materials in concrete go beyond carbon sequestration. The use of recycled cement and aggregates reduces the need for energy-intensive processes, such as quarrying and cement calcination, which are responsible for a significant proportion of emissions in the construction sector.

By substituting virgin cement with recycled cement and using recycled aggregates, the overall carbon footprint of concrete can be reduced by as much as 50%–60% (Xu et al., 2024). Furthermore, using these materials can contribute to reducing waste and decreasing landfill use, which is essential for sustainable construction practices. However, the durability of the materials (Xie et al., 2022) produced from these recycled materials should be a key factor for investigation before application in actual engineering projects.

YL: Validation, Visualization, Writing–original draft, Writing–review and editing. MM: Investigation, Validation, Visualization, Writing–original draft, Writing–review and editing. JW: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The authors wish to acknowledge the financial support provided by the National Natural Science Foundation of China (Grant No. 52038004).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Cardoso, A. S., Kohlman Rabbani, E. R., Silva, A. L., Mkcrgd, Sá, Monteiro, E. B., and Shakouri, M. (2024). Evaluating Sururu shell waste (Mytella falcata) as an eco-friendly recycled aggregate in mortar production. Front. Built Environ. 10:1381169. doi:10.3389/fbuil.2024.1381169

Duan, S. (2024). Compressive strength prediction of fiber-reinforced recycled aggregate concrete based on optimization algorithms. Front. Built Environ. 10:1509714. doi:10.3389/fbuil.2024.1509714

He, Z., Zhu, X., Wang, J., Mu, M., and Wang, Y. (2019). Comparison of CO2 emissions from OPC and recycled cement production. Constr. Build. Mater., 211, 965–973. doi:10.1016/j.conbuildmat.2019.03.289

Huang, R., Zhao, H., Zhong, Y., Wang, J., Xu, L., Lin, S., et al. (2025). Enhancing quality and strength of recycled coarse and fine aggregates through high-temperature and ball milling treatments: mechanisms and cost-effective solutions. J. Material Cycles Waste Manag. 22, pp 270–288. doi:10.1007/s10163-024-02109-z

Nseke, J., Kirkelund, G. M., and Sithole, T. (2024). The inhibitory influence of rice husk ash on the alkali leaching and efflorescence extents of alkali activated granulated blast furnace slag. Front. Built Environ. 10:1468703. doi:10.3389/fbuil.2024.1468703

Samrani, P., Cao, Y., Fimbres-Weihs, G., Sanjaya, E., and Abbas, A. (2024). Effect of fly ash and ground waste glass as cement replacement in concrete 3D-Printing for sustainable construction. Front. Built Environ. 10:1430174. doi:10.3389/fbuil.2024.1430174

Wang, J., Mu, M., and Liu, Y. (2018). Recycled cement. Constr. Build. Mater., 190, 1124–1132. doi:10.1016/j.conbuildmat.2018.09.181

Wang, J., Xu, L., Li, M., Wang, Y., He, H., Xiang, D., et al. (2023). Investigations on factors influencing physical properties of recycled cement and the related carbon emissions and energy consumptions. J. Clean. Prod., 414, 137715. doi:10.1016/j.jclepro.2023.137715

Wang, Y., Tang, H., Su, J., He, H., Zhao, Y., and Wang, J. (2023). Effect of sodium sulfate and gypsum on performances of expansive grouting material with aluminum as expansion agent. Constr. Build. Mater. 394 132212. doi:10.1016/j.conbuildmat.2023.132212

Wang, Y., Yu, J., Wang, J., Xiang, D., Gu, H., and Cheng, J. (2022). Effects of sodium aluminate and quicklime on the properties of CSA grouting materials. J. Build. Eng. 58 105060. doi:10.1016/j.jobe.2022.105060

Xie, J., Wang, J., Li, M., Xu, L., Xiang, D., Wang, Y., et al. (2022). Estimation of chloride diffusion coefficient from water permeability test of cementitious materials. Constr. Build. Mater. 340 127816. doi:10.1016/j.conbuildmat.2022.127816

Xu, L., Wang, J., Hu, X., Ran, B., Wu, T., Zhou, X., et al. (2024). Physical performance, durability, and carbon emissions of recycled cement concrete and fully recycled concrete. Constr. Build. Mater., 447, 138128. doi:10.1016/j.conbuildmat.2024.138128

Keywords: carbon-negative concrete, fully recycled concrete, recycled cement, recycled aggregates, recycled industrial wastes

Citation: Liu Y, Mu M and Wang J (2025) Editorial: Sustainable building materials from recycled cement/concrete and recycled industrial wastes. Front. Built Environ. 11:1573450. doi: 10.3389/fbuil.2025.1573450

Received: 09 February 2025; Accepted: 13 February 2025;

Published: 21 February 2025.

Edited and reviewed by:

Bjorn Birgisson, University of Georgia, United StatesCopyright © 2025 Liu, Mu and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Junjie Wang, Junjiewang@tsinghua.edu.cn

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.