94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Built Environ., 26 February 2025

Sec. Geotechnical Engineering

Volume 11 - 2025 | https://doi.org/10.3389/fbuil.2025.1536760

This article is part of the Research TopicThermo-hydro-chemo-mechanical applications using the fem software code_bright: a reviewView all articles

Crushed salt as backfill material in a repository for high-level nuclear waste is aimed to act as a long-term barrier. The sealing effect of crushed salt evolves with ongoing compaction and therefore reduction in porosity and permeability. For a reliable prognosis of the compaction behavior in the long-term, constitutive models are crucial that capture the experimentally observed processes and credibly extrapolate these processes outside the range they were calibrated in. Up to now there is still no constitutive model for crushed salt which is validated against all factors/processes influencing compaction and/or the whole porosity range (especially

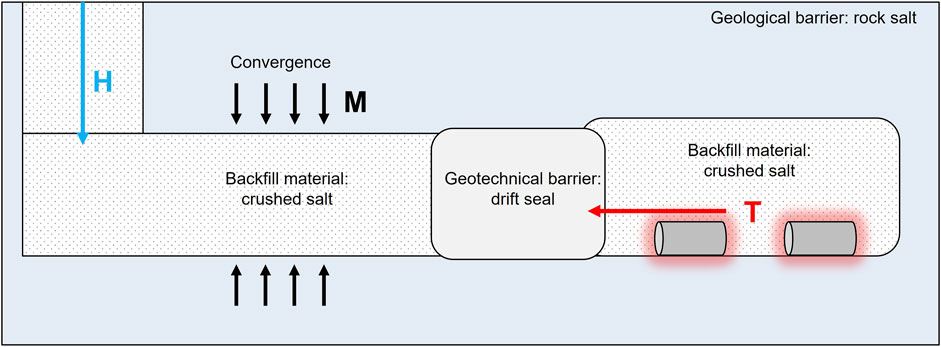

Rock salt is considered as a potential host rock formation for the deep geological disposal of high-level nuclear waste (HLW) in several countries, like Germany (Bundesgesellschaft für Endlagerung, 2020), the Netherlands (Bartol and Vuorio, 2022), and the United States (Sandia National Laboratories, 2014). The safety concept is based on a multi-barrier system comprising rock salt as the geological barrier, sealing elements and backfill as geotechnical barriers, and the waste canisters as technical barriers. Upon terminating the operational phase of the repository, the sealing function is intended to be provided by the waste matrix, waste canisters and the geotechnical barriers (Figure 1). The rock salt and the backfill material are intended to provide the sealing function in the long-term (Bertrams et al., 2020).

Figure 1. Evolution of important barriers’ sealing effectiveness in the post closure phase of a repository. The color intensity represents the degree of sealing effectiveness (Bollingerfehr et al., 2018).

Backfilling of open cavities, drifts and shafts will be realized with crushed salt. Crushed salt is not only a long-term stable and easily available material (mined-off material) but most important it guarantees a maximum compatibility with the host rock. Creep of the rock salt causes convergence of the open cavities, and, in turn, the natural compaction of crushed salt backfill with time (Figure 2). It is expected that porosity and permeability of the crushed salt backfill will decrease during compaction down to barrier properties comparable to undisturbed rock salt (porosity

Figure 2. Schematic repository for high-level nuclear waste in rock salt (modified after Friedenberg et al. (2023)).

In order to give a qualified prognosis of the long-term behavior of crushed salt as a barrier, numerical simulations are needed. The constitutive models for crushed salt need to capture the observed phenomena and credibly extrapolate the compaction process outside the range they were calibrated in. The most important metrics to predict for crushed salt in the context of a nuclear waste repository are the evolutions of porosity and permeability with time, since they are determining possible pathways for radionuclide release. The sealing effect of crushed salt against radionuclide migration evolves with decreasing porosity/permeability. Therefore, the point in time when barrier properties are reached is the most important information for long-term safety considerations. Thus, the numerical prediction of the sealing function evolution of crushed salt is crucial for the proof of the long-term safety of a repository in rock salt.

The evolution of porosity and permeability is determined by the compaction process. Crushed salt compaction is influenced by internal material properties (e.g., mineralogy, grain size distribution, initial water content), environmental conditions (e.g., temperature) and stress state (e.g., convergence rate) (Hansen et al., 2014; Kröhn et al., 2017). Therefore, several thermal-hydraulic-mechanical (THM) coupled processes must be considered when investigating the compaction behavior of crushed salt.

In the current state, uncertainties with respect to database and process understanding still remain, especially for the calibration of constitutive models and the numerical simulation of crushed salt with respect to the prognosis of its long-term behavior.

With respect to the current requirements on the long-term safety of a high-level waste repository, the understanding of the process of crushed salt compaction has some important gaps. There is no code/constitutive model available which is validated against (1) the whole porosity range for crushed salt compaction, especially for the low porosity range (

This paper presents an approach aiming at the improvement of the numerical simulation of crushed salt compaction using CODE_BRIGHT. Recent results on a model verification for the long-term compaction behavior of crushed salt will be presented. The work is performed based on experimental data generated in the international KOMPASS projects dealing with the compaction of crushed salt for safe containment (Czaikowski et al., 2020; Friedenberg et al., 2024).

The numerical simulations are performed using the finite element (FEM) code CODE_BRIGHT with the implemented mechanical constitutive model for crushed salt. The mechanical model has been used in the field of repository research for several years and is extensively tested for its performance and validated against experimental data as shown in Olivella et al. (1993), Olivella (1994), Bechthold et al. (1999), Olivella and Gens (2002) and Bechthold et al. (2004).

The model formulation is kept in terms of strain rates and composed of an additive approach (Olivella and Gens, 2002). Several deformation mechanisms account for Equation 1: linear elasticity (EL), grain rearrangement (GR), fluid assisted diffusional transfer (FADT) and dislocation creep (DC). With the combination of these four mechanisms, the relevant deformations for repository conditions are captured (Bechthold et al., 2004).

The general stress definitions are presented in the Equations 2–6. Compression is counted positive and tension is counted negative. Attention should be paid to individual definitions of deviatoric stress in the DC and the GR models.

where

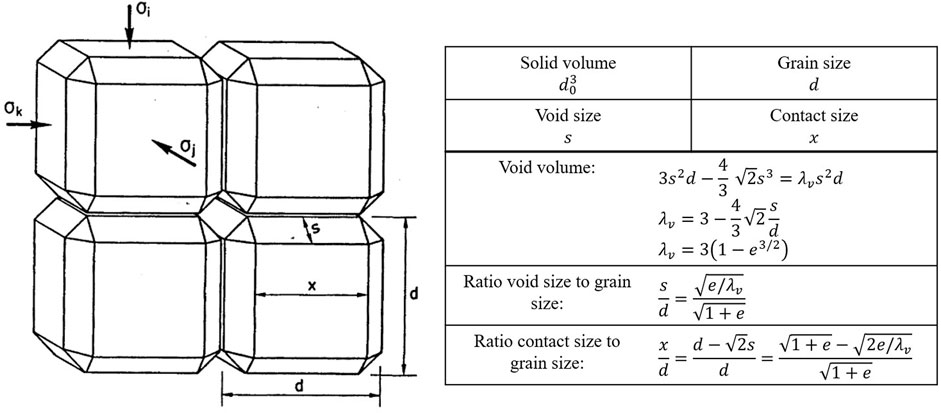

The mechanical creep models (FADT and DC) are based on microstructural observations on granular salt materials and therefore cover an idealized geometry forming a regular arrangement of polyhedrons (Olivella and Gens, 2002). Characteristic sizes are specified, and relations derived as shown in Figure 3.

Figure 3. Idealized geometry and characteristic sizes as a basis for the constitutive creep models for crushed salt in CODE_BRIGHT (modified after Olivella and Gens (2002)).

The linear elastic behavior of crushed salt is meant to play a minor role in the compaction process. However, its formulation is essential for the computational framework. The increase in stiffness with ongoing compaction is described by a generalized Hook’s law (Equation 7). Young’s modulus and Poisson’s ratio are applied as elastic constants. The isotropic linear elastic model is formulated in combination with a porosity dependent evolution of Young’s modulus (Olivella et al., 2023). By applying Equation 8, the Young’s modulus is increasing by decreasing porosity, simulating the material’s stiffness increase with ongoing compaction. The change of Young’s modulus with the change of porosity (

where

The fluid assisted diffusional transfer mechanism describes the humidity creep of crushed salt, depending on the influence of moisture and dominating in areas of low stresses and low temperatures. Dissolution of salt will take place in areas of high stress concentration; the salt will then migrates through the liquid phase and precipitates in areas of lower stress. The FADT model is based on extensive studies by Schutjens (1991), Spiers et al. (1986), Spiers et al. (1989) and Spiers and Brzesowsky (1993).

The model formulation is derived on basis of the idealized geometry (Figure 3) and the assumptions of dissolution of salt in grain contacts, diffusive flux of salt through the liquid phase driven by a chemical potential gradient and precipitation of salt in pore space. The detailed derivation of the strain rate formulation in Equation 9 is to be found in Olivella and Gens (2002). The strain rate is decomposed in a volumetric and a deviatoric part, labeled by v and d, respectively. Equation 10 and Equation 11 are called the volumetric and deviatoric viscosities, respecitvely. They compile the dependencies on temperature

where

The dislocation creep mechanism captures deformations like dislocation glide and climb. It refers to the intracrystalline mechanisms (Olivella, 1994). These mechanisms can be described by power law terms and therefore are grouped here. The model is based on the rock salt power law and combined with a geometrical derivation of a volumetric strain rate and a deviatoric strain rate formulation. It is generalized by the use of a viscoplastic approach including a flow rule and a viscosity parameter.

where

with

The term for grain rearrangement was added for simulating the irreversible processes of grain displacement during compaction taking place mainly at high porosities and under fast loads. This part is added to describe the behaviour of crushed salt as loose aggregate. In its loose state crushed salt is assumed to behave sand-like. Such material behaviour is described by a critical state approach which is based on a yield surface. Due to expansion of the yield surface, bond creation and densification of the crushed salt material is modelled. An important feature is that the hardening of the crushed salt is mainly driven by creep deformations (Equations 27–33) (Olivella and Gens, 2002). The basic equations are the following (Equations 27–33) (Olivella et al., 2023):

where

For developing a crushed salt constitutive model, it is a common approach to derive an idealized geometry and deformation mechanisms from microstructural observations (Olivella, 1994). This approach lacks some generality since grains deform in a non-regular way during the compaction and a constantly regular arrangement cannot be expected. Deformation mechanisms like dislocation creep (grain breakage, plastic deformations) and humidity creep (dissolution and precipitation) dominate under different conditions and act not uniform on a grain (Hansen et al., 2014).

The creep models in CODE_BRIGHT for FADT and DC are based on a geometry dependent formulation, expressed in terms of void ratio (Olivella, 1994). The functions

Figure 4. Auxiliary functions for DC and FADT mechanisms. v = volumetric, d = deviatoric. Modified after Olivella and Gens (2002).

Within the KOMPASS projects, benchmark calculations of long-term triaxial compaction tests on crushed salt were performed using the model implemented in CODE_BRIGHT and presented above. The reproduction of compaction was not satisfactory for both volumetric and deviatoric deformation, as well as their deformation rates (Friedenberg et al., 2023; Friedenberg and Olivella, 2024). Especially, for the creep contribution, which is the most important process in the long-term for porosity and permeability reduction, the accordance between numerical results and experimental data is weak. The example is shown in Section 4.1. Based on this work an idea for the modification of the crushed salt model in CODE_BRIGHT is developed aiming to improve the numerical simulation of crushed salt compaction.

The modification approach addresses the prescription of an idealized geometry for the creep models. To give some flexibility in the handling of the geometrical basis, it is proposed to formulate

Since the long-term compaction tests considered in the recent work of the KOMPASS projects were executed on dry crushed salt, the FADT mechanism is assumed to have no or at least a minor effect on the compaction behavior. Therefore, this modification approach focuses on the dislocation creep mechanism.

From the shape of

where

The parameters

The modification of

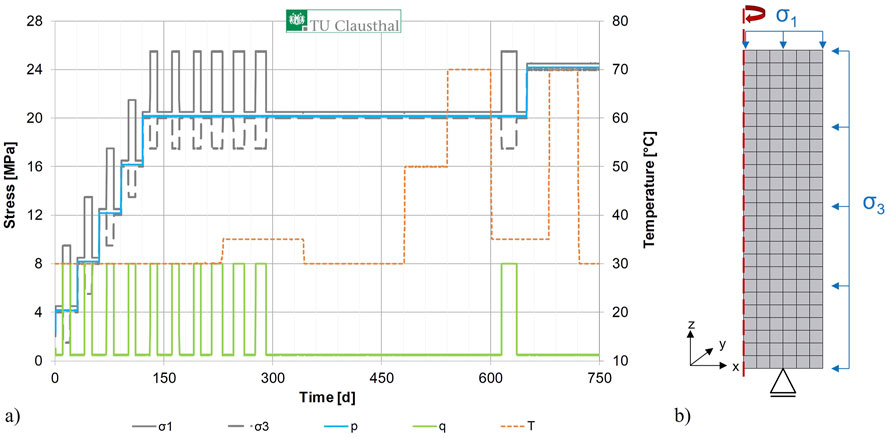

The triaxial compaction test considered here is the TUC-V2 that was executed in framework of the KOMPASS projects and comprises various level of mean stress, deviatoric load cycles and temperature changes (Friedenberg et al., 2024). The tested salt is the lately defined KOMPASS reference material (Czaikowski et al., 2020) representing a bedded Zechstein formation in the middle of Germany. The crushed salt sample had an initial water content of 0.5 w.-% and an initial porosity of 0.167. Figure 5A presents the load history lasting about 750 days and Figure 5B shows the axisymmetric numerical model.

Figure 5. Triaxial long-term compaction test TUC-V2. (A) Loading history. (B) Numerical model and grid (Friedenberg and Olivella, 2024).

In a first step, the available constitutive model is applied, and the parameters are calibrated against the experimental data. The second step includes the modification of the constitutive model and again the simulation of the long-term compaction test. The results of both simulations are compared and discussed.

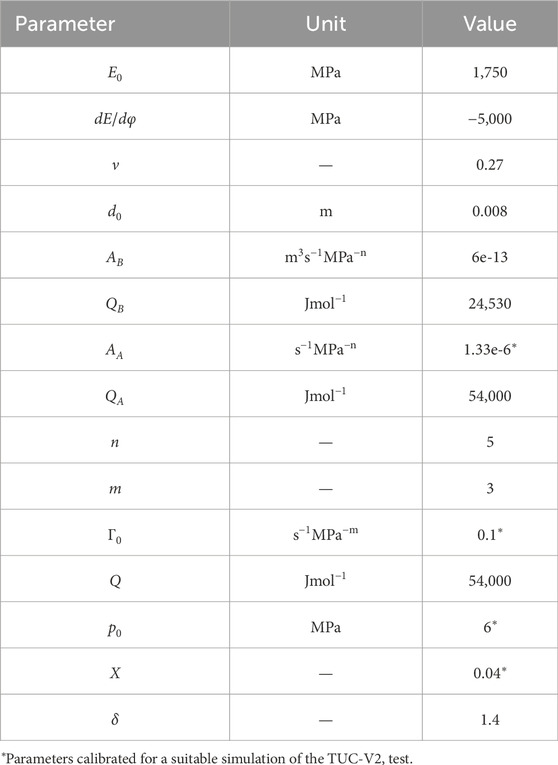

Initially, the available model was calibrated against the experimental data. The simulation was executed in a THM-coupled approach following the stress history given in Figure 5. Thermal processes are based on Fourier’s law, for the hydraulics one phase flow with a constant gas pressure of

Table 1. Parameters for the simulation of triaxial compaction test TUC-V2 (Friedenberg et al., 2024).

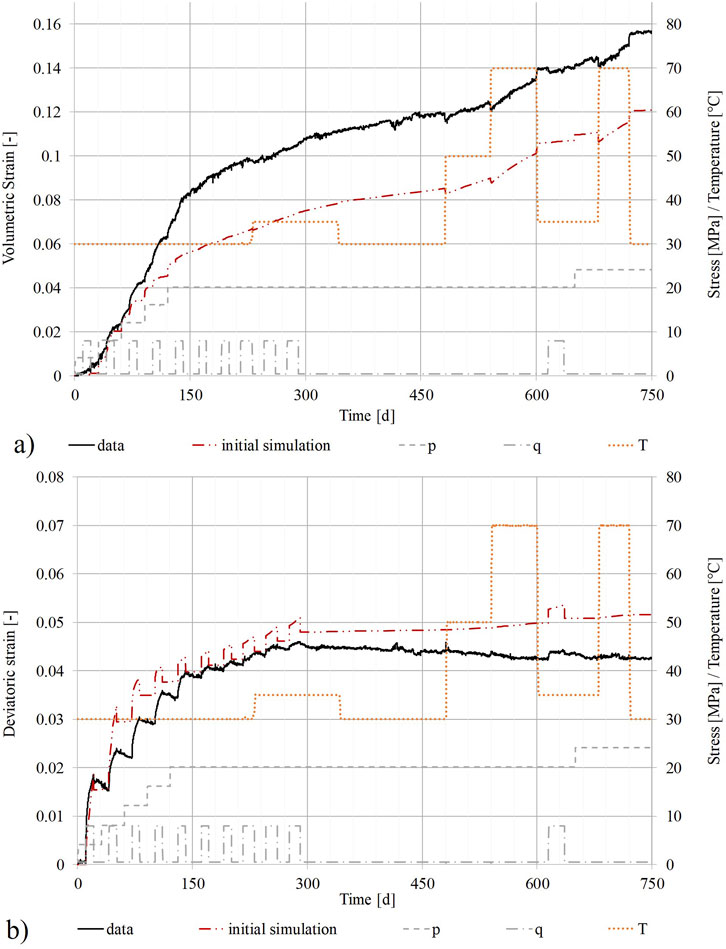

The comparison in Figure 6 shows clear differences between the experimental data and the numerical results. The volumetric compaction is strongly underestimated by the simulation, especially the compaction under the constant mean stress of 20 MPa. The final values for volumetric compaction differ by 3.5%. In contrast, the deviatoric strain is overestimated. The model response to the increase and decrease of deviatoric stress is higher compared to the experimental data. However, the final values for deviatoric strain just differ by 1%.

Figure 6. Comparison of measurements for TUC-V2 versus the initial simulation results. (A) volumetric strain. (B) deviatoric strain.

An improvement due to a broader calibration with reasonable parameter ranges could not be achieved, thus the modification approach was developed.

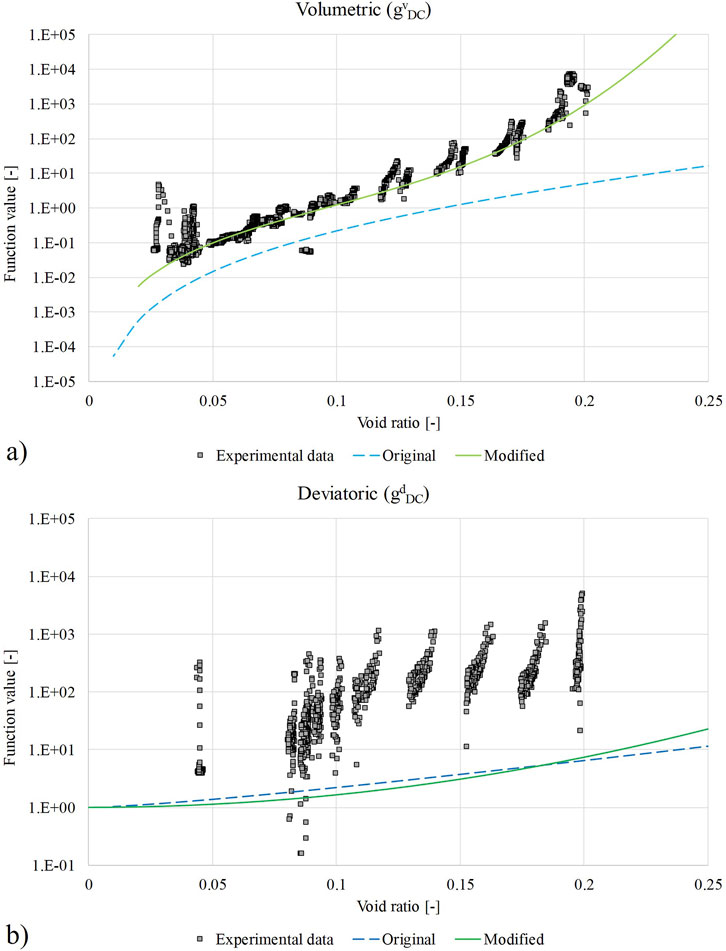

The modified approach was developed in the way that Equations 34, 35 can be calibrated against experimental data by using the experimental strain rate data transformed to be comparable with the function values of the

Figure 7. Modified and original functions and experimental data for the geometrical dependencies. (A) Volumetric function

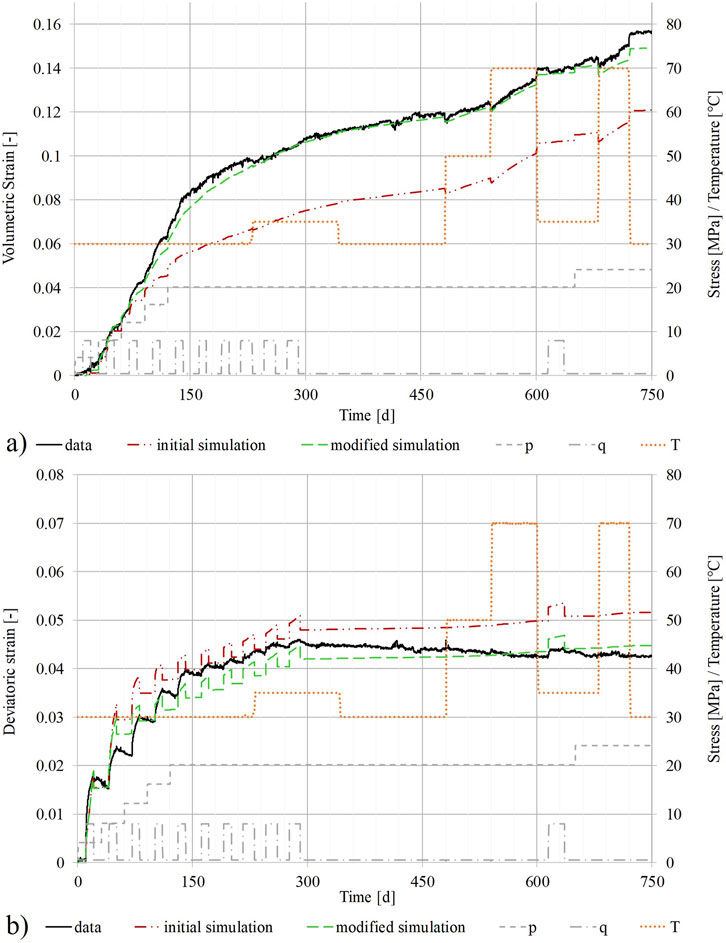

A new simulation with the modified functions and parameters as shown in Table 2 was performed. Due to the calibration of the modified function

Figure 8. Comparison of experimental data for the TUC-V2 test versus numerical results for the initial simulation and the simulation with the modified functions. (A) Volumetric strain. (B) Deviatoric strain.

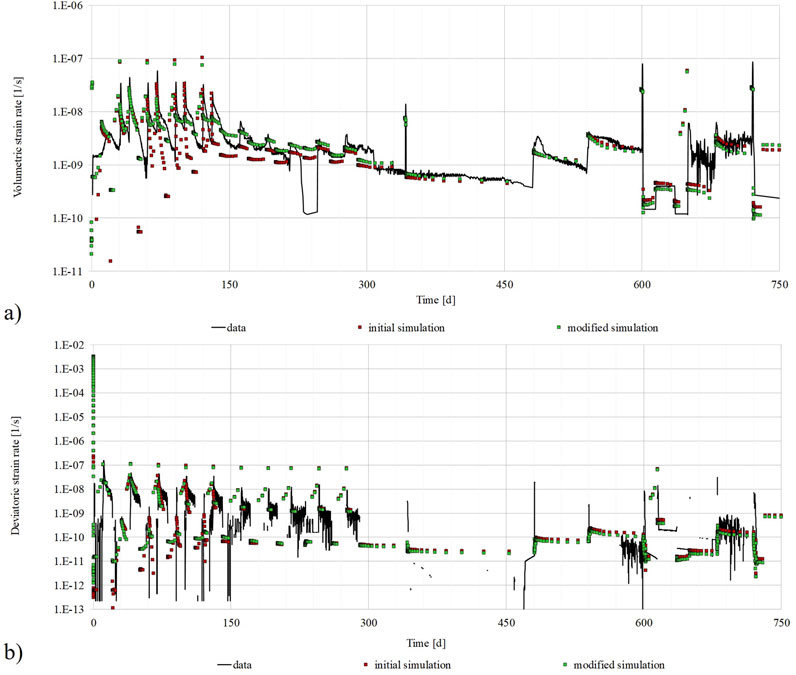

A further quantification can be realized by considering the strain rates. Figure 9A show the volumetric strain rates for both simulations, the initial and the modified, compared to the experimental data. The modified simulation shows an improved accordance for the volumetric strain rates during the rapid load changes in the beginning of the test. Up to 300 days the numerical strain rates hardly differ from each other. Figure 9B show the deviatoric strain rates. Only slight differences in the numerical results can be observed for the first 300 days, along with a higher accordance of the modified rates with the data. In both simulations, the strain rates are strongly overestimated at the start of the test. From 300 days on no significant difference between the trend of the numerical results is identifiable.

Figure 9. Comparison of experimental data for the TUC-V2 test versus numerical results for the initial simulation and the modifed simulation. (A) Volumetric strain rate, (B) Deviatoric strain rate.

In general, the results show an improvement for the simulation of crushed salt compaction by using the modified functions

The calibration for the deviatoric part provides some open questions. The experimental data for deviatoric strain shows a large scattering over the function values, leading to difficulties in the calibration process (Figure 7B). The data trend is not straight forward as it is for the volumetric strain. Reasons might be traced back to the execution of the test with short durations of deviatoric stress (10 days) and therefore a wide range of strain rates due to the rapid load changes.

For the new approach sensitivity studies are performed. First, a one-factor-at-a-time sensitivity is presented to show the influence of the newly implemented parameters c and d on deviatoric strain. Then the Morris method is applied to investigate the influence of the individual parameters a, b, c and d on volumetric and deviatoric strain. In the last step, a coupled parameter sensitivity is shown for the influence of the main parameters on volumetric strain and deviatoric strain, respectively.

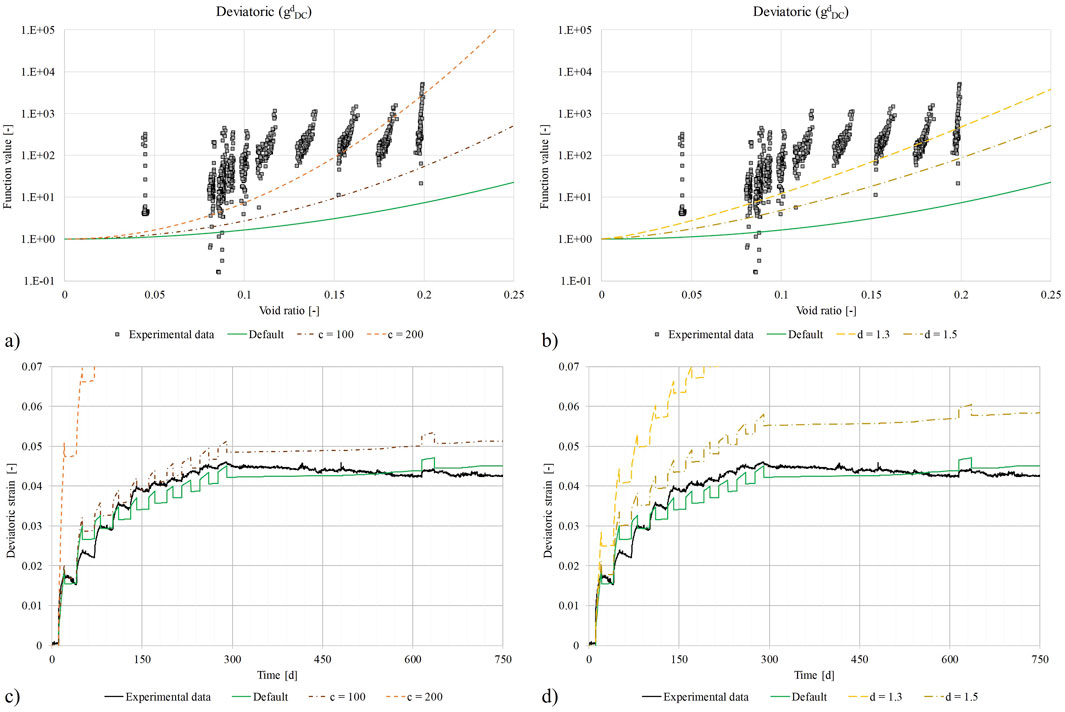

Figure 10 presents simple one-factor-at-a-time variations of

Figure 10. One-factor-at-a-time variations of the parameters

In general, the model response to changes in deviatoric stress is strongly overestimated (Figures 10C, D). In former research work, deviatoric stress and strain represented a minor part. They predominantly focused on mean stress and isotropic compaction conditions (Kröhn et al., 2017). However, in recent crushed salt projects, the need for the investigation of deviatoric stress influence on the compaction was highlighted (Friedenberg et al., 2024).

The presented simulation results indicate an overall need to focus on the simulation of deviatoric stresses with the constitutive model available in CODE_BRIGHT. The consistent strain overestimation in response to the deviatoric load changes might be a general issue but is not part of this modification approach.

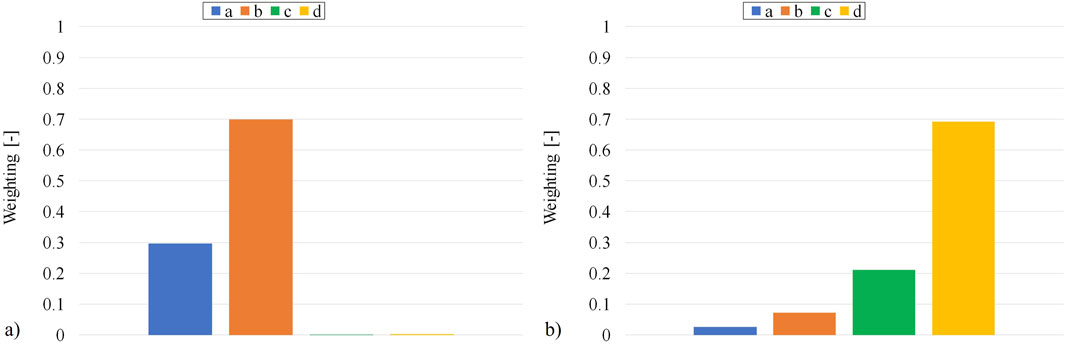

The Morris method (Morris, 1991) was used to determine which of the input parameters may have the largest effect within the simulation of the triaxial compaction test TUC-V2. The idea was to use a factor’s screening method to determine the weighted effect of changes in the parameter values. Therefore, the Morris method is based on a “one-factor-at-a-time” approach yielding the global sensitivity by performing a series of local changes at different points in a predefined parametric state-space (Saltelli et al., 2004).

The analysis was carried out by using the Julia programming language (Bezanson et al., 2017). Julia’s in-built capabilities for distributed computing were used to conduct the Morris sensitivity analysis with a simple Monte-Carlo sampling strategy on various workers in parallel. The sampling was performed within the deterministic predefined parametric state-space (

As indicators for the performance evaluation, the volumetric strain (

Figure 11. Morris sensitivity for the parameters of the modified approach. (A) Sensitivity for the volumetric strain. (B) Sensitivity for the deviatoric strain.

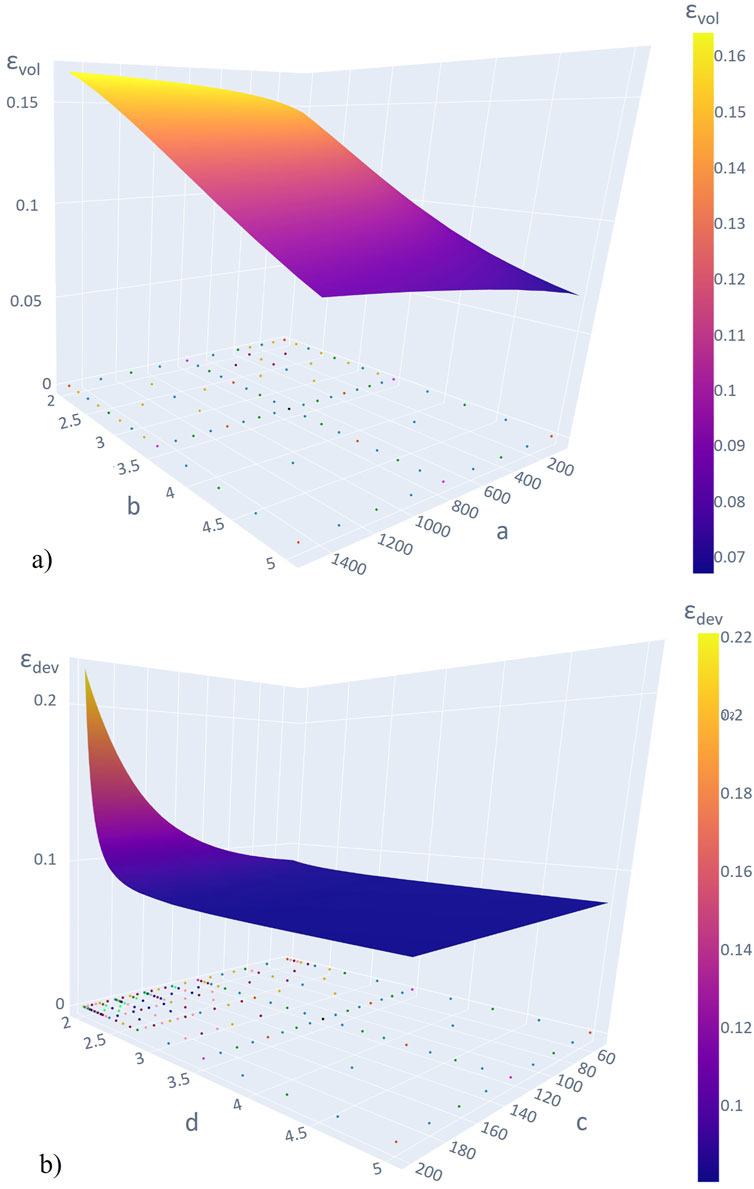

In this analysis, the influence of the main parameters on the respective output quantity is investigated. As shown in the previous section with the Morris method, the volumetric strain output is primarily influenced by the parameters

The analysis was conducted by using an adaptive sparse-grid collocation method (see, e.g., Gates and Bittens (2015)) implemented by the open-source project DistributedSparseGrids.jl (Bittens and Gates, 2023) in the Julia programming language. Hereby, a hierarchical Lagrangian basis enables the adaptive refinement of the parametric model in areas with high effect on the output quantity.

The influence on the volumetric strain for

Figure 12. Coupled parameter sensitivity. (A) Sensitivity of parameters

The response of deviatoric strain for

Table 3 presents absolute values for volumetric and deviatoric strains for the interval boundary parameter combinations.

This paper presents an approach for the modification of the dislocation creep law in CODE_BRIGHT with the aim of improving the numerical reproduction of crushed salt compaction processes. The approach addresses the stiff geometrical basis of the constitutive model and aims at a more flexible formulation. The two non-linear functions

Up to date there is no complete consensus on formulating constitutive models. The newly proposed combination of a microstructural basis with phenomenological functions shows an improvement in the numerical simulation of crushed salt compaction by simulating the triaxial long-term compaction test TUC-V2. The volumetric compaction was reproduced adequately both in the absolute values as well as in the volumetric strain rates. An enhancement in results was also achieved for the deviatoric strain and deviatoric strain rates.

Sensitivity approaches are presented to verify the new implementation. By applying the Morris method for parameter screening the sensitivities of the volumetric and deviatoric strain output to the parameters are shown. The result confirms the original idea of the modification approach and confirms the correct implementation of the parameters. Due to the coupled parameter sensitivity the evolution of the respective strain output within a defined parameter space is shown. This analysis gives an idea about the ideal parameter combination.

However, some open questions still occur. The calibration of the modified deviatoric function

All in all, the presented approach builds a basis for improving the numerical simulation of crushed salt compaction processes. These improvements will help to reduce uncertainties and will strengthen the prognosis quality for the long-term safety analysis of a repository in rock salt by predicting the barrier properties of the crushed salt.

Publicly available datasets were analyzed in this study. This data can be found here: https://www.grs.de/de/aktuelles/publikationen/grs-751.

LF: Investigation, Project Administration, Visualization, Writing–original draft, Writing–review and editing. SO: Methodology, Software, Supervision, Writing–review and editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The publication of this article is supported by the MEASURES project (FKZ 02E12214A-D) funded by the German Federal Ministry for Environment, Natural Conservation, Nuclear Safety and Consumer Protection (BMUV).

The authors would like to thank the KOMPASS family for fruitful discussions and providing the input, and Prof. Uwe Düsterloh for his support. Special thanks go to Maximilian Bittens for the supportive collaboration with the sensitivity evaluation.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The work presented in this paper received scientific support (e.g., experimental data) from the KOMPASS-II project (FKZ 02E11951A-D) and the follow-up MEASURES project (FKZ 02E12214A-D), both funded by the German Federal Ministry for Environment, Natural Conservation, Nuclear Safety and Consumer Protection (BMUV). There is no financial dependence of the work presented on the KOMPASS projects and their follow-up MEASURES.

Bartol, J., and Vuorio, M. (2022). “Disposal of radioactive waste in rock salt: long-term research programme,” in The mechanical behavior of salt X: proceedings of the 10th conference on the mechanical behvaior of salt (SaltMech X), utrecht, The Netherlands, 06 - 08 july 2022. Editors J. de Bresser, M. R. Drury, P. A. Fokker, M. Gazzani, S. Hangx, A. R. Niemeijeret al. (London: CRC Press), 236–241.

Bechthold, W., Rothfuchs, T., Poley, A., Ghoreychi, M., Heusermann, S., Gens, A., et al. (1999). Backfilling and sealing of underground repositories for radioactive waste in salt (BAMBUS project): final report. EUR Proj. Rep. - Nucl. Sci. Technol. EUR-19124-EN. Available at: http://bookshop.europa.eu/en/-pbCGNA19124/.

Bechthold, W., Smailos, E., Heusermann, S., Bollingerfehr, W., Bazargan Sabet, B., Rothfuchs, T., et al. (2004). Backfilling and sealing of underground repositories for radioactive waste in salt (BAMBUS II project): final report, Europäische Kommission. EUR Nucl. Sci. Technol. Proj. Rep. EUR-20621-EN. Available at: http://bookshop.europa.eu/en/-pbKINA20621/.

Bertrams, N., Bollingerfehr, W., Eickemeier, R., Fahland, S., Flügge, J., Frenzel, B., et al. (2020). RESUS - Grundlagen zur Bewertung eines Endlagersystems in flach lagernden Salzformationen. Ges. für Anlagen- Reakt. (GRS) gGmbH, GRS.

Bezanson, J., Edelman, A., Karpinski, S., and Shah, V. B. (2017). Julia: a fresh approach to numerical computing. SIAM Rev. 59 (1), 65–98. doi:10.1137/141000671

Bittens, M., and Gates, R. L. (2023). DistributedSparseGrids.jl: a Julia library implementing an Adaptive Sparse Grid collocation method. J. Open Source Softw. 8 (83), 5003. doi:10.21105/joss.05003

Bollingerfehr, W., Bertrams, N., Buhmann, D., Eickemeier, R., Fahland, S., Filbert, W., et al. (2018). KOSINA: concept developments for a generic repository for heat-generating waste in bedded salt formations in Germany. BGE TECHNOLOGY GmbH. Available at: https://www.bge-technology.de/fileadmin/user_upload/FuE_Berichte/KOSINA-Project_Concept-developments-for-a-generic-repository-for-heat-generating-waste-in-bedded-salt-formations.pdf.

Bundesgesellschaft für Endlagerung (2020). Sub-areas interim report pursuant to section 13 StandAG. Available at: https://www.bge.de/fileadmin/user_upload/Standortsuche/Wesentliche_Unterlagen/Zwischenbericht_Teilgebiete/Summary_Sub-areas_Interim_Report_barrierefrei.pdf (Accessed September 28, 2020).

Czaikowski, O., Friedenberg, L., Wieczorek, K., Müller-Hoeppe, N., Lerch, C., Eickemeier, R., et al. (2020). KOMPASS: compaction of crushed salt for the safe containment. Ges. für Anlagen- Reakt. (GRS) gGmbH GRS-608.

Friedenberg, L., Bartol, J., Bean, J., Beese, S., Bresser, J. H. B. de, Coulibaly, J. B., et al. (2024). KOMPASS-II, Compaction of crushed salt for safe containment—phase 2. GRS.Köln: Gesellschaft für Anlagen-und Reaktorsicherheit (GRS) gGmbH.

Friedenberg, L., and Olivella, S. (2024). “Modification in the numerical modelling of crushed salt compaction processes, ” in Department of Civil and Environmental Engineering, UPC-Barcelona Tech, CIMNE (Eds.): Workshop of CODE_BRIGHT Users, Barcelona, May 24, 2024.

Friedenberg, L., Olivella, S., and Düsterloh, U. (2023). Numerical analysis for the simulation of crushed salt compaction behavior: ARMA23-0341. 57th U.S. Rock Mechanics/Geomechanics Symposium: Atlanta.

Gates, R. L., and Bittens, M. R. (2015). A multilevel adaptive sparse grid stochastic collocation approach to the non-smooth forward propagation of uncertainty in discretized problems. doi:10.48550/arXiv.1509.01462

Hansen, F. D., Popp, T., Wieczorek, K., and Stührenberg, D. (2014). Granular salt summary: granular salt summary: reconsolidation principles and applications: fuel cycle research and development. Sandia National Laboratories. Available at: https://www.osti.gov/biblio/1164616.

Kröhn, K.-P., Stührenberg, D., Jobmann, M., Heemann, U., Czaikowski, O., Wieczorek, K., et al. (2017). Mechanical and hydraulic behaviour of compacting crushed salt backfill at low porosities: project REPOPERM - phase 2, GRS- 450. Available at: http://www.grs.de/publikation/grs-450.

Morris, M. D. (1991). Factorial sampling plans for preliminary computational experiments. Technometrics 33 (2), 161–174. doi:10.2307/1269043

Olivella, S. (1994). Nonisothermal multiphase flow of brine and gas through saline media. Barcelona: Universitat Politècnica de Catalunya. Dissertation.

Olivella, S., and Gens, A. (2002). 'A constitutive model for crushed salt. Int. J. Numer. Anal. Methods Geomechanics 26 (7), 719–746. doi:10.1002/nag.220

Olivella, S., Gens, A., Carrera, J., and Alonso, E. E. (1993). “Behaviour of porous salt aggregates. Constitutive and field equations for a coupled deformation, brine, gas and heat transport model,” in Mechanical behavior of salt: 3rd conference; ecole Polytechnique, palaiseau - France, september 14 - 16, 1993. Editor M. Ghoreychi (Clausthal-Zellerfeld: TTP Trans Tech Publ), 255–269.

Olivella, S., Vaunat, J., and Rodriguez-Dono, A. (2023). CODE_BRIGHT: user's guide (CODE_BRIGHT 2023_12)

Saltelli, A., Tarantola, S., Campolongo, F., and Ratto, M. (2004). Sensitivity analysis in practice: a guide to assessing scientific models. Eur. EUR-20859-EN. Available at: http://www.loc.gov/catdir/description/wiley041/2003021209.html.

Sandia National Laboratories (2014). Evaluation of options for permanent geological disposal of spent nuclear fuel and high-level radioactive waste: in support of a comprehensive national nuclear fuel cycle strategy. U.S. Department of Energy. Available at: https://www.energy.gov/sites/prod/files/2014/04/f15/DOE%20DispOptions%20R1%20Volume1%20Apr15.pdf.

Schutjens, P. M. T. M. (1991). Intergranular pressure solution in halite aggregates and quartz sands: An experimental investigation = Intergranulaire drukoplossing in halietaggregaten en kwartszanden. Zugl. Utrecht, Rijksuniv. Diss. 1991. Available at: https://dspace.library.uu.nl/handle/1874/238558.

Spiers, C. J., and Brzesowsky, R. H. (1993). “Densification behaviour of wet granular salt: theory versus experiment,” in Seventh symposium on salt. Editor H. Kakihana (Amsterdam: Elsevier), 83–92.

Spiers, C. J., Peach, C. J., Brzesowsky, R. H., Schutjens, P. M. T. M., Liezenberg, J. L., and Zwart, H. J. (1989). Long-term rheological and transport properties of dry and wet salt rocks: final report. Nucl. Sci. Technol. EUR-11848-EN. Available at: https://publications.europa.eu/s/cYD1.

Spiers, C. J., Urai, J. L., Lister, G. S., Boland, J. N., and Zwart, H. J. (1986). The influence of fluid-rock interaction on the rheology of salt rock: final report, Nuclear science and technology EUR 10399 EN. Available at: http://bookshop.europa.eu/en/-pbCDNA10399/.

Wieczorek, K., Düsterloh, U., Heemann, U., Lerch, C., Lüdeling, C., Müller-Hoeppe, N., et al. (2017). Reconsolidation of crushed salt backfill - review of existing experimental database and constitutive models and need for future R&D work: DAEF statement.

Keywords: crushed salt, constitutive modelling, creep, backfill material, repository research

Citation: Friedenberg L and Olivella S (2025) An approach to improve the numerical simulation of crushed salt compaction behavior. Front. Built Environ. 11:1536760. doi: 10.3389/fbuil.2025.1536760

Received: 29 November 2024; Accepted: 30 January 2025;

Published: 26 February 2025.

Edited by:

Li Li, Polytechnique Montréal, CanadaCopyright © 2025 Friedenberg and Olivella. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Larissa Friedenberg, bGFyaXNzYS5mcmllZGVuYmVyZ0BncnMuZGU=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.