- 1China Construction First Group Constitution and Development Co. LTD., Beijing, China

- 2China State Construction Engineering Corporation, Beijing, China

- 3The Key Laboratory of Urban Security and Disaster Engineering of Ministry of Education, Beijing University of Technology, Beijing, China

- 4School of Architecture and Civil Engineering, The University of Adelaide, Adelaide, SA, Australia

- 5Tianjin Renai College, Tianjin, China

Conventional pressure-type anchoring systems face challenges such as difficulty in recovery, low recovery efficiency, and insufficient durability over long-term use. Although the single-use cost of Carbon Fibre Reinforced Polymer (CFRP) strand anchors is higher than that of conventional steel strands, recovery and reuse can significantly reduce costs. Therefore, this study aims to investigate the bonded anchoring method of CFRP and proposes an innovative thermoplastic CFRP prestressed strand design that combines both anchoring strength and recoverability to address the shortcomings of existing anchoring systems. Two bonding materials, thermosetting resin and thermoplastic resin, were selected for bond strength tests under different conditions. The results indicated that epoxy resin had a bonding force of 280 kN and an anchoring efficiency of approximately 70%, making it the most suitable material. However, the anchoring efficiency still needs improvement. Based on this, an improved design scheme was proposed, which can increase anchoring efficiency to over 95%. Additionally, based on the dispersed bonding anchor system, this study explored a solution that involves adding a positioning plate at the end of the anchor strand and using epoxy resin for anchoring. The anchoring performance tests showed that the tensile strength of the CFRP strand ranged from 2.7–2.8 GPa, with an average anchoring efficiency of 100.5%, demonstrating excellent anchoring performance. Further thermoplastic recovery tests showed that when the temperature increased to 90°C, the maximum recovery force of the strand was 17.2 kN, about 4.4% of the ultimate load. When the temperature increased to 150°C, the maximum recovery force was 7.5 kN. The recovered CFRP strands were clean, with no resin residue, and had no damage, maintaining an intact structure. The proposed thermoplastic CFRP prestressed strand design demonstrates significant advantages in anchoring strength and recoverability. With the improved design, anchoring efficiency can be increased to over 95%, and the high-temperature recovery process shows good feasibility. Compared with traditional anchoring systems, CFRP strands offer higher anchoring efficiency, lower recovery force requirements, better economics, and sustainability, making them a promising solution for engineering applications.

1 Introduction

With the stable development of economic construction and substantial investment in infrastructure, especially the rapid development of the transportation industry, the number of geotechnical slope engineering projects such as highway and railway cut slopes and embankments has increased sharply. This increase has been accompanied by a growing number of geological issues, such as slope instability and landslides (Nengpan et al., 2009). Currently, slopes are mainly categorized into natural slopes that have not been excavated and artificial slopes formed after excavation. In China, engineering accidents caused by slope instability or collapse occur from time to time, making slope instability a global geological disaster issue (Zhu et al., 1989; Singh et al., 2005; Xue et al., 2023). China’s “Five Vertical and Seven Horizontal” highway network is gradually being perfected, and the construction of mountain roads is also developing progressively toward highways. Usually, the terrain in mountainous and hilly areas varies greatly, with high embankments and deep-cut sections everywhere. The issue of slope stability is gradually being exposed, and slope protection and management are receiving increasing attention (Yan et al., 2020).

Anchor support technology, as an effective way to reinforce slopes, is divided into forms, such as soil nailing walls, prestressed anchor tendons, frames with prestressed anchors, and prestressed anti-sliding piles (Cao et al., 2022; Liu et al., 2024). Among them, prestressed anchor tendons are embedded into the geotechnical layer, where the anchor segment is firmly connected to stable rock and soil through an anchoring agent. The bonding strength between the anchor segment and the surrounding rock reinforces unstable rock and soil, achieving stability (). Prestressed anchor tendon support creates a compression stress zone in the anchored layer, reinforcing the layer, enhancing its strength, improving its mechanical properties, and connecting the structure with the layer to form a working composite, effectively bearing tensile and shear forces, increasing the shear strength on potential sliding surfaces, and actively preventing slope sliding. Compared to passive support structures, it has clear advantages (Liu et al., 2022a). Additionally, prestressed anchor tendons have been widely used in slope and other protection engineering due to their simple structure, ease of installation, low cost, and wide applicability.

Conventional anchor tendons typically use steel strands as the main structural component. With the widespread application of metal anchors, the problem of slope instability caused by premature failure of anchor tendons has become increasingly prominent. Studies on numerous practical engineering cases show that steel corrosion is the main factor leading to the failure of anchoring structures, causing significant economic waste and safety issues (He et al., 2024; Liu Y. et al., 2023; Chen and Cheng, 2012).

In slope engineering, China consumes a significant number of metal anchors annually. In high slope stabilisation, the upper anchors typically serve as temporary support and are often difficult to recover post-construction, resulting in challenges such as corrosion, groundwater contamination, and obstruction of nearby underground infrastructure. Recyclable anchor technology has been developed to mitigate these issues, enabling anchors to be removed and recovered after project completion, thereby reducing subsequent construction impediments (Wang et al., 2018; Qijia and Liu, 2012). However, traditional steel recyclable anchors are hindered by their heavy weight, cumbersome transportation and installation, and susceptibility to corrosion (Gong and Jianlin, 2021; jihong, 2012; Chen et al., 2018; Wang et al., 2007; Duo et al., 2021; Yong et al., 2004; Yang et al., 2018; Liu et al., 2022b; Ruan et al., 2019; Tafsirojjaman et al., 2022; C. J. B. Structural Use of Parafil Ropes, 1987; Sayed-Ahmed and Shrive, 1998; Wang et al., 2018). As a result, recyclable anchors made from carbon fibre reinforced polymer (CFRP) have been developed as an alternative that is lighter, more durable, and more efficient (Duo et al., 2021; Yong et al., 2004; Yang et al., 2018).

FRP materials are characterized by their lightweight and high strength compared to conventional steel. Still, their mechanical properties exhibit linear elasticity without a distinct yield stage, resulting in lower strain and elongation at structural failure. Furthermore, when FRP is used as anchor rods for slope reinforcement, prestressing is required to limit initial deformation. Since the elastic modulus of FRP is generally lower than steel’s (except for CFRP), this property leads to reduced prestress losses due to shrinkage deformation after the support is completed (Gudonis et al., 2013). The advantages of FRP materials, including lightweight, high strength, corrosion resistance, fatigue resistance, and high plasticity, effectively address the challenges associated with the manufacturing and constructing traditional steel anchors. Consequently, countries in North America, Japan, and Europe have begun adopting FRP materials in slope anchors. However, current global research on FRP anchors primarily focuses on permanent anchors’ mechanical properties and design, leaving a significant gap in FRP anchor recovery (Xiang et al., 2015).

Currently, only two schemes are suitable for recovering CFRP anchors. The first method involves using CFRP materials with low shear resistance, which can be directly cut with excavation equipment during recovery. The obvious drawback of this scheme is that it does not allow for the reuse of the anchors and cannot be used for anchoring in rock slopes (Wang, 2015). The second method involves designing connectors suitable for CFRP anchors. One end connects to the CFRP anchor, and the other end connects to steel strands. This connector should withstand the ultimate pull-out force of the body. During recovery, it can use the conventional recoverable anchor form as the front end is a steel strand; however, this method has the disadvantages of being relatively complex and costly, and the connector somewhat reduces the overall structural reliability (Fang et al., 2019).

Based on the analysis of the research background and the experimental work conducted, this paper identifies a significant research gap in existing CFRP anchoring technology, particularly in balancing anchoring strength and recoverability (C. J. B. Structural Use of Parafil Ropes, 1987; Sayed-Ahmed and Shrive, 1998). Although traditional anchoring methods have achieved some success in structural applications, their complexity, cost, and reliance on construction quality have limited their widespread adoption (Fang et al., 2022; Liu Jin et al., 2023; Jin et al., 2024). CFRP’s commonly used anchoring systems include metal anchoring (mechanical clamps, bonding, and hybrid anchoring), non-metallic anchoring, and wedge-shaped bonding anchoring. The anchoring mechanism primarily relies on chemical bonding, mechanical interlocking, and interface friction to transfer stress, often employing optimized designs to achieve uniform stress distribution and reduce concentration. Load-bearing performance is closely related to the adhesive and structural design characteristics. High-efficiency anchoring systems can fully utilize the strength of CFRP. Metal anchoring systems offer high strength but are prone to corrosion, non-metallic systems are lightweight but more costly, while wedge-shaped anchoring combines reliability and stress optimization, demonstrating excellent overall performance and application potential (Li and Xian, 2018). Thermoplastic resins are commonly used as anchoring fillers due to their chain-like molecular structure, which provides excellent durability, fatigue resistance, and recyclability. Their reversible process of thermal softening and cooling hardening allows for multiple heating and cooling cycles without affecting performance while exhibiting exceptional fatigue resistance to withstand repeated mechanical stresses. Furthermore, their recyclability makes them an environmentally friendly and cost-effective material choice, widely applied in the field of high-performance composite materials (Xian et al., 2024).To address this gap, this study designs and develops a novel thermal-meltable and recoverable CFRP anchor system and conducts a series of related experiments (Yu et al., 2024-06). The scope of this research includes testing different bonding materials, evaluating anchoring performance, and analysing the recovery process. The objective is to provide a more efficient, cost-effective, and environmentally friendly CFRP anchoring solution that meets the modern engineering demands for green buildings and sustainable development (Hou et al., 2012; Ping et al., 2010; Ping et al., 2014).

2 Selection and preparation of CFRP strand materials

2.1 Pultrusion process for CFRP monofilament

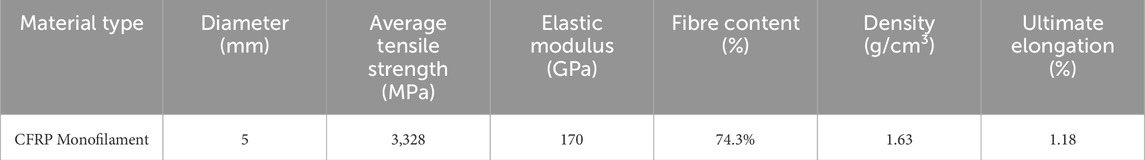

The CFRP tendons used in the test were 15.2 mm diameter CFRP strands. During fabrication, 5 mm diameter CFRP monofilaments were first produced using pultrusion. Subsequently, seven monofilaments were impregnated with resin and twisted into shape using a stranding machine, followed by curing to obtain the CFRP strands. The mechanical properties of carbon fiber bundles are shown in Table 1. The resin used in the impregnation bath is mainly divided into two categories: thermosetting resin and thermoplastic resin. Thermosetting resins, such as epoxy resin, unsaturated polyester resin, and phenolic resin, form stable three-dimensional network structures through chemical cross-linking. Their curing conditions typically include room temperature curing or heat curing at 60°C–200°C, with processes like hot pressing and vacuum infusion. In contrast, thermoplastic resins are moulded through the physical processes of heating, softening, and cooling hardening, making them suitable for rapid moulding and recyclable applications. The resin selected for this experiment is epoxy resin.

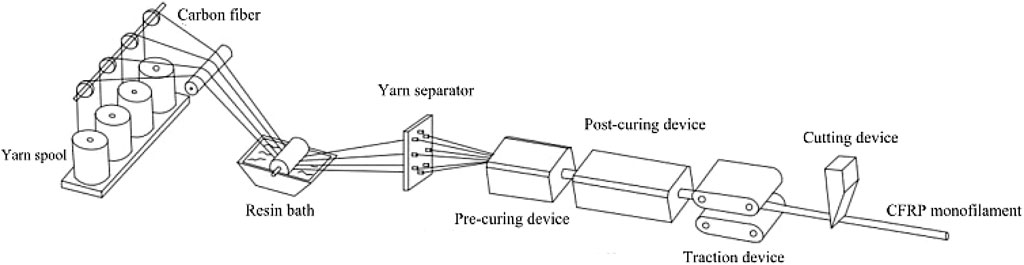

While preparing CFRP monofilaments, the carbon fibre tow is first drawn from the yarn spool and passed through the small holes of the yarn separator. It is then pulled through a resin bath filled with epoxy resin. Subsequently, the filament is procured in a procuring device, where excess resin is extruded from the surface. A traction machine gradually pulls the preliminarily shaped CFRP monofilament through the post-curing device in stages. This process includes heating, pressurizing, and shaping the filament. Finally, the prepared CFRP monofilament is wound onto spools using a winding machine, and a cutting device cuts off any excess portions. The equipment used for preparing CFRP monofilaments includes a fibre creel, a resin bath, a yarn separator, curing devices, a traction device, and a cutting device. The manufacturing process is shown in Figure 1.

2.2 Stranding process of CFRP strands

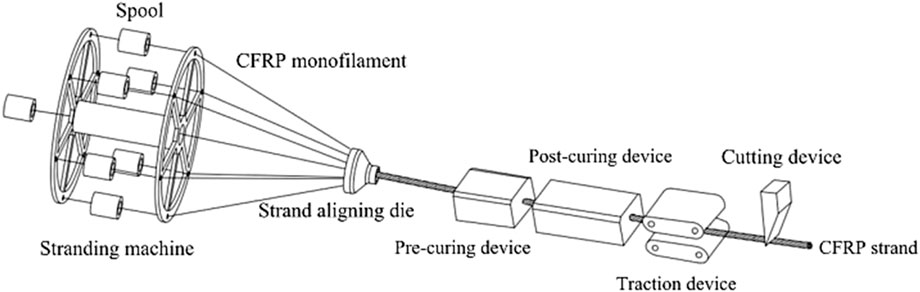

The process of preparing CFRP strands begins with pultrusion to obtain CFRP monofilaments primarily composed of axial fibres. These monofilaments are then wound onto spools. The spools are placed on the cantilever of a stranding machine, and the CFRP monofilaments are threaded through small holes in the stranding machine. At the strand aligning die, the monofilaments are twisted together to form a strand.

Next, the strand passes through a procuring device, where it is impregnated with a silicone solution and subjected to high-temperature performance. Under the action of a traction machine, the strand slowly passes through the post-curing device to obtain the final CFRP strand, which is then cut to appropriate lengths.

The equipment used for preparing CFRP strands includes spools, a stranding machine, a strand aligning die, a procuring device, a post-curing device, a traction device, and a cutting device. The physical and mechanical properties of the CFRP monofilaments are listed in Table 2, and the equipment used for strand preparation is shown in Figure 2.

3 Selection and performance testing of adhesive media materials

3.1 Material selection

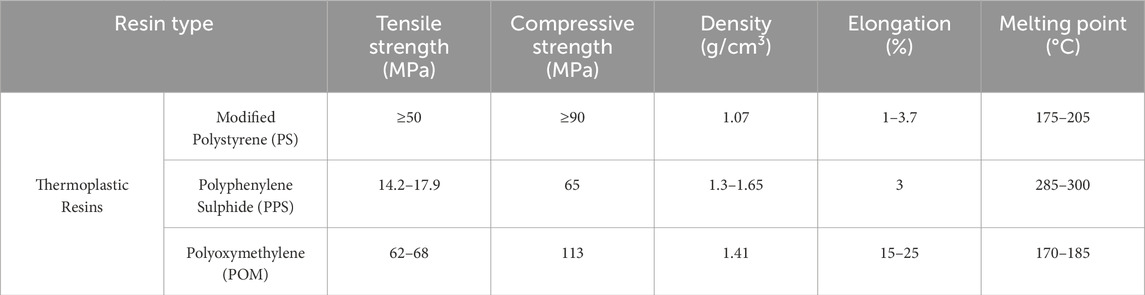

Resins used in engineering are divided into thermosetting and thermoplastic resins based on their reformation behaviour after curing (Liu et al., 2022b; Ruan et al., 2019). Thermoplastic resins soften when heated and harden when cooled. They can undergo multiple heating and cooling cycles during the reformation process while retaining their original properties without undergoing chemical reactions. Common thermoplastic resins include polypropylene (PP), polyethylene (PE), polyamide (PA), polyphenylene sulphide (PPS), and polyetherimide (PEI). Their physical and mechanical properties are shown in Table 3.

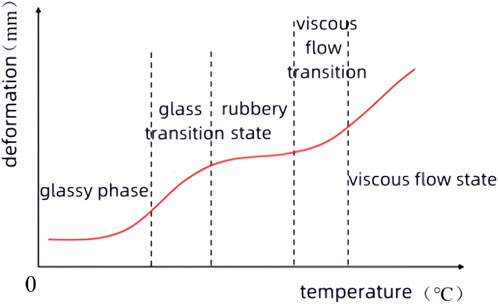

The resin used for hot melt anchor adhesive must meet at least one of the following conditions: the resin itself should be thermoplastic, becoming molten when heated to facilitate separation between structures; or the resin, while not thermoplastic, should be highly sensitive to temperature changes after curing, with high temperatures causing the resin to transition to a rubbery state, significantly reducing structural strength, as illustrated in Figure 3. In addition to these basic conditions, the resin should also have good mechanical properties and excellent interfacial performance with carbon fibre.

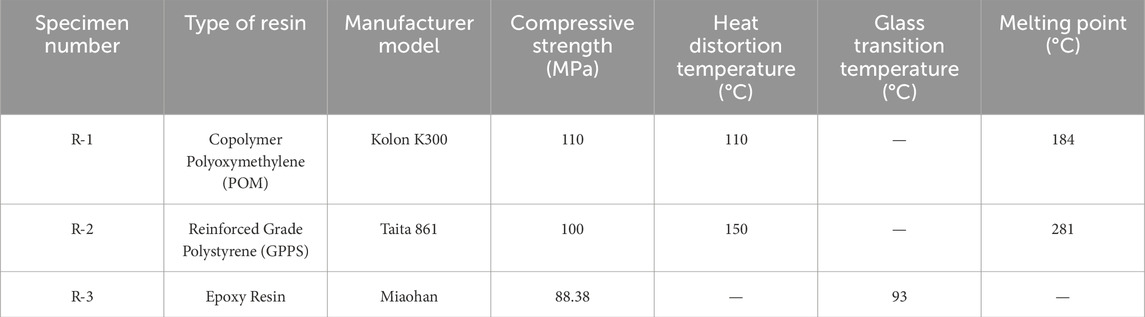

In summary, this paper selected two thermoplastic resins with high compressive strength and good fluidity, as well as an epoxy resin impregnation adhesive with good interfacial properties. Specific parameters are shown in Table 4.

3.2 Specimen preparation

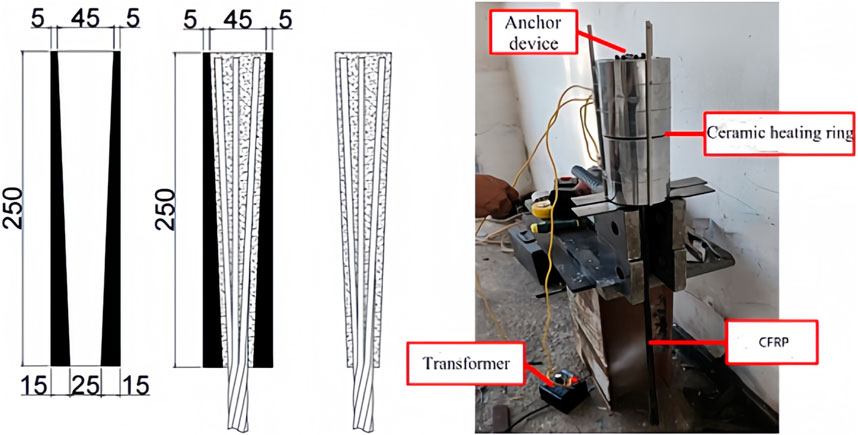

The preparation for CFRP specimens uses conical anchor grips, with structural dimensions shown in Figure 4. For the epoxy resin specimen R-3, the preparation begins by positioning the separated strands of the CFRP cable in the anchor grip at an angle of 5°. Then, epoxy resin is mixed in a 1:2 (Hardener: Resin) ratio and poured into the inner conical tube of the anchor grip. It is cured at room temperature for 48 h.

For the preparation of thermoplastic resin specimens, the resin pellets are first processed into approximately 200 mesh resin powder using a heating and curing method. The two thermoplastic resin powders are then poured, and the cable is fixed similarly. The resin powder is slowly poured along the inner wall of the anchor grip.

The heating device used is a ceramic heating ring, with a length of 300mm, slightly longer than the total length of the anchor grip. The anchor grip filled with powder is placed into the heating ring and continuously heated to melt the thermoplastic resin inside the anchor grip. The temperature is monitored and recorded periodically, and new powder is added if needed. Finally, the specimen is removed and solidified. A tension test is then performed to measure the anchorage bond strength. The dimensions of the anchor grip and heating device are shown in Figure 4.

3.3 Bonding force test

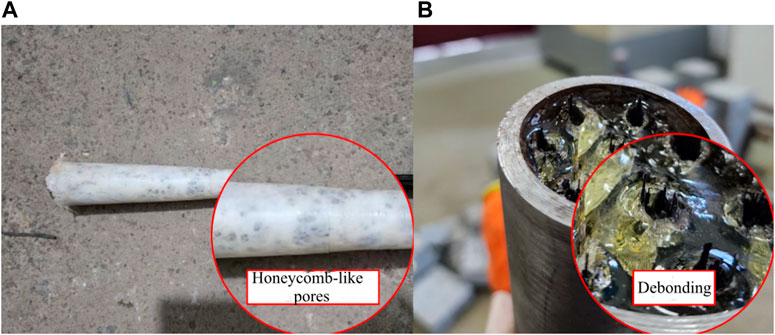

While preparing specimen R-1 using the heating method, severe foaming of Polyoxymethylene was observed during the heating process, resulting in numerous honeycomb-like pores inside the specimen. Tests showed that its bonding force was only about 40 kN. The presence of numerous pores significantly affected the compressive strength of the POM resin, and the failure mode of the specimen was the crushing of the resin, as shown in Figure 5A. Due to the lack of equipment for pressure injection moulding or pultrusion to directly prepare CFRP profiles in the laboratory, POM is not considered a bonding medium.

For specimen R-2, prepared using the heating method, General Purpose Polystyrene exhibited good fluidity when heated to around 280°C. As the GPPS powder in the sleeve continued to melt and sink to the bottom, the material was continuously added until the entire sleeve was filled. After cooling, tests showed that the bonding force of specimen R-2 reached approximately 100 kN. This was mainly because the thermoplastic GPPS had low viscosity and debonded from the strands during tensile testing, with an anchorage efficiency of about 30%, as shown in Figure 5B.

Compared to thermoplastic resins, the epoxy resin exhibited better performance, with the bonding force of specimen R-3 reaching 280 kN and an anchorage efficiency of about 70%. However, the specimen still experienced slippage failure. Due to the low bond strength of specimen R-2 prepared with thermoplastic resin, epoxy resin was selected as the main bonding medium for the hot melt anchor. Based on this, an improved design was proposed to achieve an anchorage efficiency of over 95%.

4 Bonded anchorage performance test of CFRP strands

4.1 Anchorage design

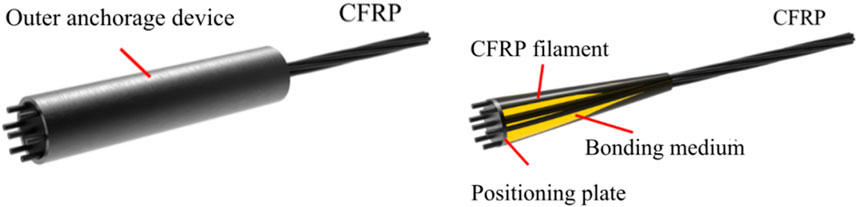

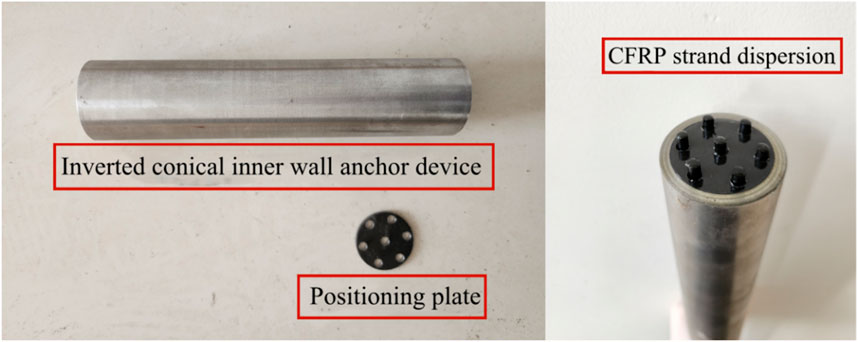

A positioning plate is added to the end of the CFRP anchor cable and filled with epoxy resin for anchorage based on the dispersed bonded anchorage system (Tafsirojjaman et al., 2022). The positioning plate is embedded in the open end of one side of the anchor device. During fabrication, the strands are first fixed to the positioning plate and then placed into the inverted conical inner groove of the outer anchor device, and epoxy resin is poured in, as shown in Figure 6. This anchorage system allows for the dispersion of the CFRP strands at the anchorage end, reducing the anchorage length and improving anchorage efficiency, fully utilising the high tensile strength of CFRP, as shown in Figure 7.

The strands themselves are treated with a sandblasting process, with the ends of the strands (300 mm on both sides) being sandblasted, thus effectively enhancing the interface strength between the strands and the adhesive. Additionally, this bonded anchorage system can be heated at the ends during recovery; once the resin softens, the anchor device and the CFRP anchor cable can be separated. This allows for the recovery of both the CFRP anchor cable and the anchor device, thus achieving economic and environmental benefits.

4.2 Anchorage performance test

The test selected three CFRP strands with a total length of 1,100 mm. The specimen dimensions and test methods followed the relevant provisions for tensile testing of reinforcements in ASTM (2006). The anchorage length at both ends was 250 mm, and the free length was 600 mm. Before the test, the ends of the strands were fanned out and sandblasted. A new bonded anchor was used to anchor both ends, and the specimens were cured at room temperature for 48 h before the tension test.

The tension test was conducted using a Long Bridge Centre MTS-1000 universal testing machine. The loading rate was set to 2 mm/min as recommended by the standard, and the applied load and its corresponding displacement were recorded. Three specimens were tested, namely, C-1, C-2 and C-3. The overall dimensions of the specimens are shown in Figure 8.

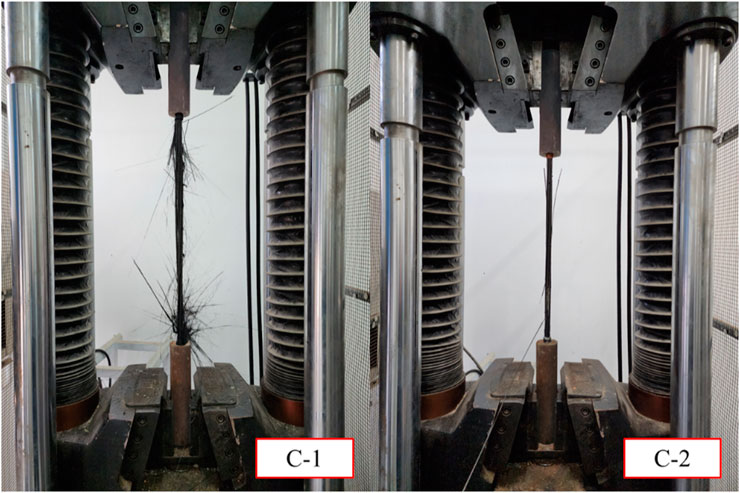

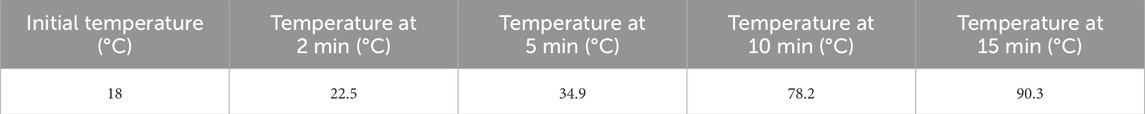

During the tension test of CFRP strands, as the tensile stress increased, partial detachment of the resin occurred at the connection between the anchorage segment and the free segment. This was followed by slight cracking sounds, and some fibres on the surface of the strands broke, ultimately leading to specimen failure.

The failure modes of the specimens in the test can be categorised into two types. The first type occurs when the anchorage system fails to reliably anchor the CFRP strands, resulting in the strands being pulled out once the tensile force reaches a certain value. The second type occurs when the anchorage system reliably anchors the CFRP strands, leading to an explosive failure in the free segment of the strands. The failure of the specimen is shown in Figure 9. The first failure mode primarily reflects the anchorage system’s inadequacy rather than the performance of the CFRP strands. Since the anchorage system fails to fix the strands securely, the specimen does not reach its theoretical ultimate strength, making it impossible to reflect the material’s mechanical properties accurately. The second failure mode, on the other hand, due to the reliability of the anchorage system, can accurately represent the performance of the CFRP strands. Throughout the test, the force-displacement curve exhibited a linear increase, instantly dropping to zero at the point of failure.

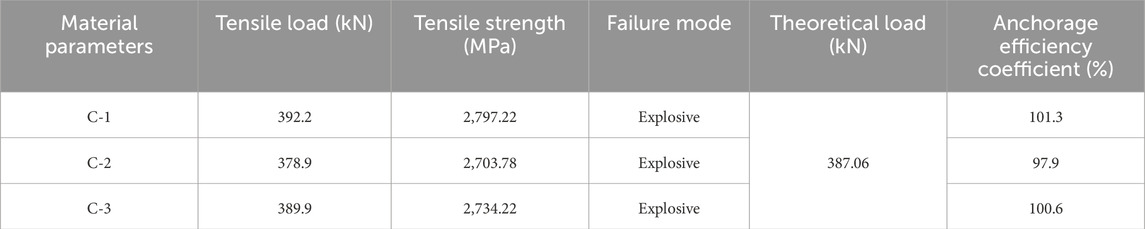

The bonded anchorage system used in the test exhibited excellent anchorage performance for CFRP strands. However, the CFRP strands experienced explosive failure in the free segment. Table 5 shows detailed data from the bonded anchorage test.

Table 5 shows that the tensile strength of the CFRP strands ranged between 2,700 and 2,800 MPa. The average anchorage efficiency of the anchorage device was 100.5%, demonstrating a significant anchorage performance. The average tensile load is 387 MPa, with a standard deviation of 5.66. The average tensile strength is 2,745.74 MPa, with a standard deviation of 38.57. The average anchorage efficiency coefficient is 99.93%, with a standard deviation of 1.39%.

5 Hot melt recycling test and analysis

5.1 Design of hot melt recyclable anchor cable

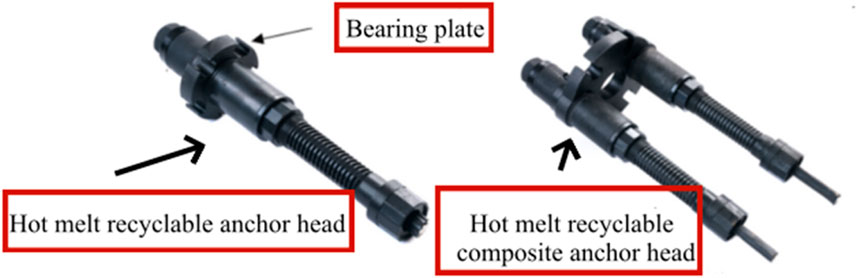

Currently, recyclable anchor cables primarily use end-dissolution methods. The end-dissolution recyclable anchor cable uses electrical, electromagnetic, or chemical agents to heat or induce a chemical reaction within a self-unlocking anchorage device. This process melts the anchor tendons, separates them from the clips, or dissolves the anchor tendons, allowing them to be pulled out and recycled, as shown in Figure 10. In China, Suzhou Nenggong Jichu is a leading example of the end dissolution recyclable anchor cable. Their self-unlocking anchorage device contains a high strength and high hardness hot melt material. In its working state, the anchor cable and the clips securely clamp the anchor tendon. The hot melt material includes a heating ring. The heating ring is electrified during the tendon removal process, causing the hot melt material to melt. This separation allows the clips and the anchor tendon to disengage, enabling the anchor tendon to be pulled out and recycled.

The primary characteristic of existing hot melt recyclable anchor cables is that the inside anchorage still relies on annular clips for anchoring, with the hot melt material only serving as a filler to provide pressure. This makes them unsuitable for materials with weak shear strength, such as CFRP. Therefore, this paper designs and develops a hot melt recyclable anchor cable that completely relies on bonded anchorage.

For convenience in testing, the anchor head was simplified by reducing the bearing plate, wires, and other accessories, retaining only the main structure related to recycling. The simplified hot melt recyclable anchor cable is shown in Figure 11.

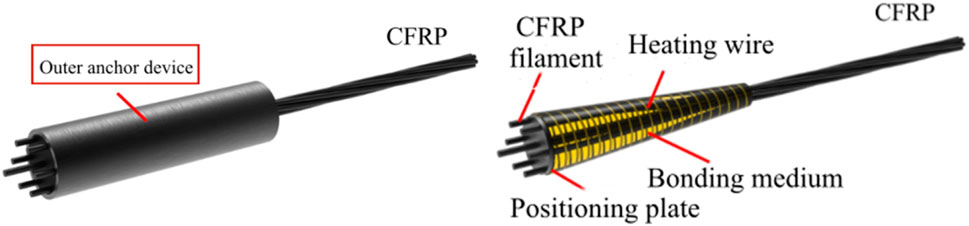

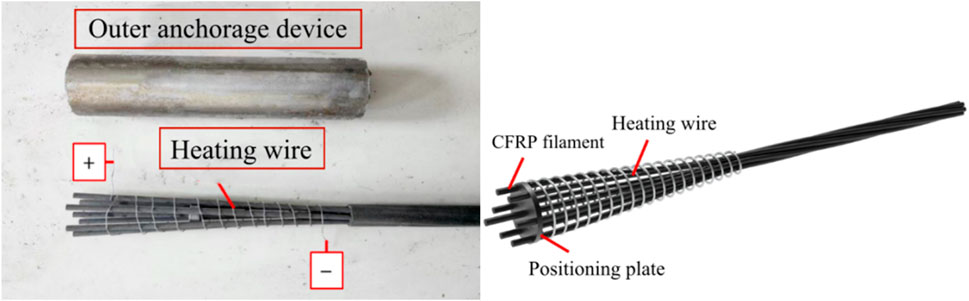

The anchor cables used in the experiment consist of three parts: the outer anchor device, the positioning plate, and the heating wire. The inner wall of the outer anchor device is inverted and conical in shape. The CFRP strands are evenly dispersed and fixed inside the anchor device through the positioning plate. The positioning plate has seven through holes with a diameter of 5.1 mm, slightly larger than the diameter of the CFRP filament. The outer diameter of the positioning plate is close to the inner diameter of the outer anchor device, allowing it to be securely positioned at the top of the anchor device.

The heating wire used is a 0.2 mm nickel-chromium wire with a resistance of 4 Ω per meter. It is spirally wound around the CFRP strands, with both ends leaving 50 mm for connecting the positive and negative terminals of the power supply, insulated with electrical tape. The winding method of the heating wire is shown in Figure 12.

5.2 Heating rate

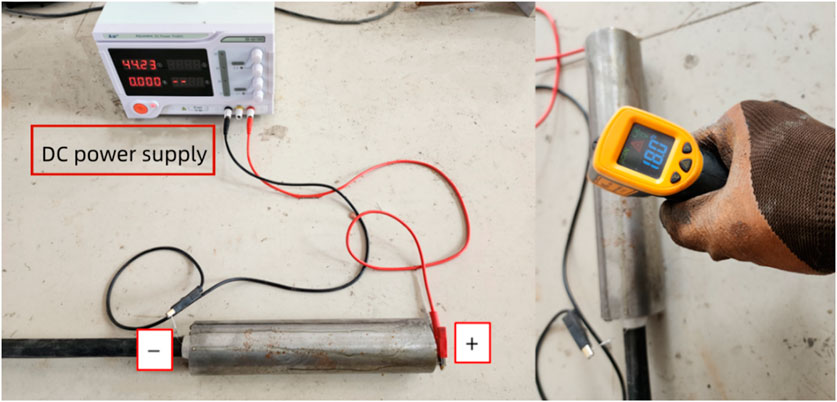

In the hot melt recyclable anchor cable scheme, heating efficiency is a crucial indicator for measuring the recovery efficiency of the hot melt recyclable anchor cable. This experiment used a 600 W DC power supply with a maximum current of 10 A and a maximum voltage of 60 V. The purpose of using the 600 W DC power supply is to precisely control the temperature changes by passing current through the hot melt recyclable anchor cable, utilizing the resistance heating principle. This heating method ensures the stability of the temperature and the controllability of the heating process. In actual engineering projects, using a 600 W DC power supply for heating is primarily employed to accurately heat the resin in the hot melt recyclable anchor cable, thereby enabling the recovery and reuse of thermoplastic materials. Therefore, the experiment utilized constant current control, maintaining a constant current of 8 A and a voltage of approximately 22 V during testing. The temperature changes were recorded promptly during heating to determine the optimal current range. The heating test equipment and measurement method are shown in Figure 13.

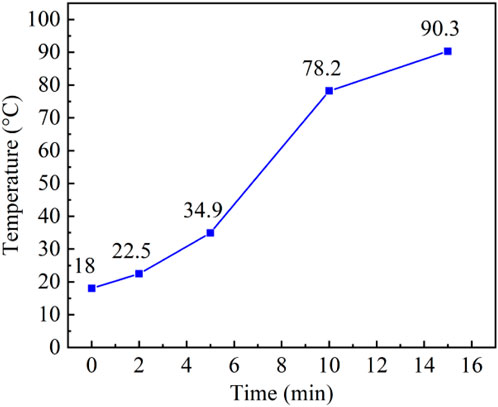

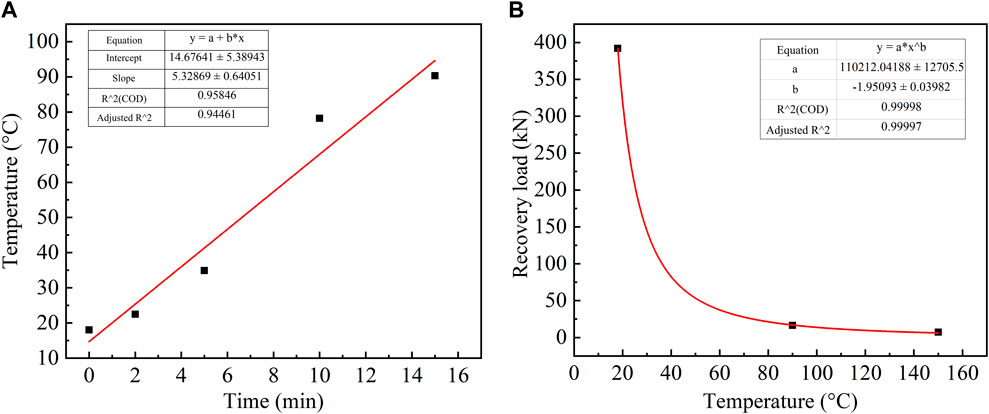

Based on the experimental results, the heating rate curve for the hot melt recyclable anchor cable was plotted, as shown in Figure 14. The time-temperature curve can be divided into three stages. The initial stage (below 35°C) is when the heating wire is not fully preheated, and the heating rate increases slowly over time. The middle stage (35°C–80°C) is when the heating rate significantly accelerates as the temperature increases. The final stage (above 80°C) is when the temperature reaches around 80°C, and the heating rate noticeably slows down, approaching the initial heating rate. The specific experimental data are shown in Figure 14 and Table 6.

5.3 Hot melt recycling efficiency

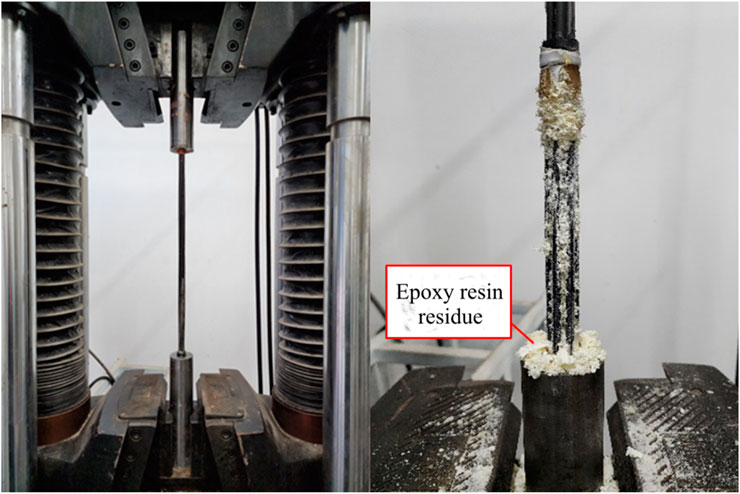

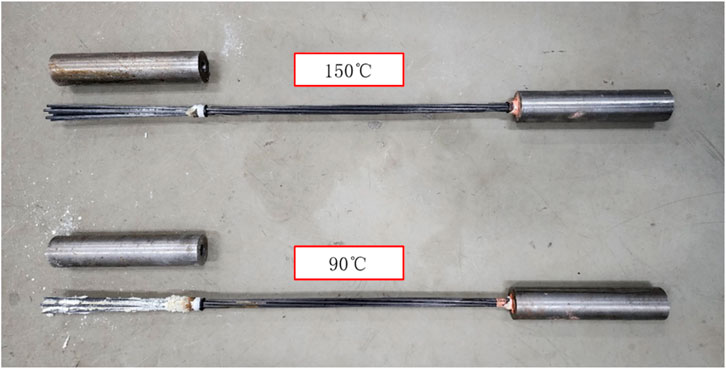

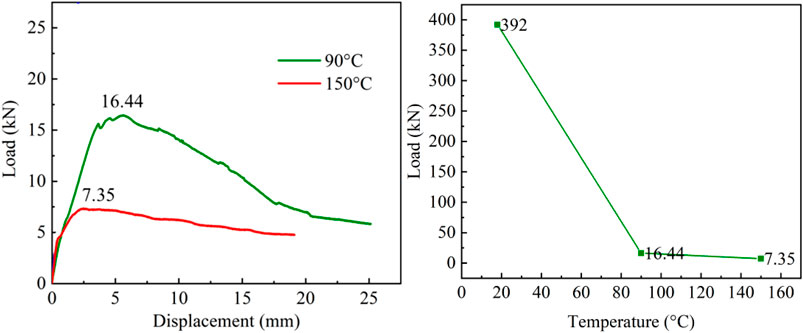

The hot melt recycling experiment for the CFRP anchor cable did not involve embedding a heating wire inside the cable to ensure the safety of the experimenters. Instead, an indirect heating method was used. Since epoxy resin is a thermosetting resin that forms a stable three-dimensional network structure after curing, its glass transition temperature typically ranges from 80°C to 150°C . At temperatures of 50°C–60°C, epoxy resin remains in its glassy state, exhibiting high strength and rigidity, and does not soften. Therefore, no tests were conducted at 50°C–60°C. One end of the CFRP anchor cable was directly placed in a constant temperature drying oven, with the temperature set to 90°C and 150°C. The samples were heated for 20 min to ensure the resin was thoroughly heated. Immediately after heating, the specimens were removed and subjected to tensile performance testing using an MTS-1000 universal testing machine. The experimental setup and the behaviour of the specimen observed during the test are illustrated in Figure 15.

The experiment observed that the force-displacement curves of each group of specimens initially rose briefly and then slowly declined. The strands slipped, accompanied by powdery resin residue being extruded from the end of the sleeve. At this point, the resin was in a rubbery state, feeling elastic. After the CFRP strands were pulled out, the resin cooled, solidified and hardened.

Figure 16 shows the recovery condition of the specimens at the two temperatures. The specimens heated to 90°C had more residual resin on the surface, while those heated to 150°C had their surface resin wholly stripped off.

The recovery efficiency of both groups of hot melt anchor cables met expectations. When the temperature reaches 90°C, immediately remove the specimen and perform a tensile test using the MTS-1000 universal testing machine. The test results show that the anchor cable’s recovery force was only 17.2 kN, approximately 4.4% of the ultimate load, as shown in Figure 17. Even after the resin cooled, it could not provide additional tensile strength.

When the temperature increased to 150°C, the specimen’s maximum recovery force was 7.5 kN, and the recovered strands had clean surfaces without any residual resin. Additionally, both groups of recovered CFRP strands showed no damage, maintaining structural integrity and being reusable.

5.4 Power on recovery time

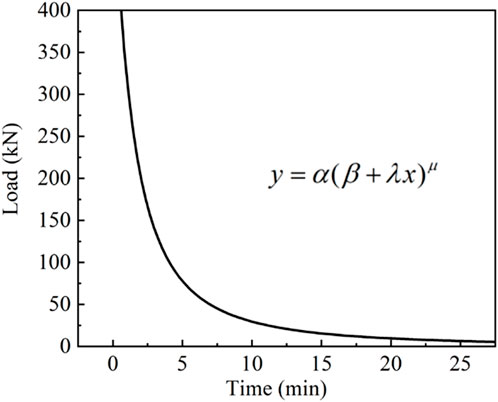

When determining the construction plan for thermoplastic anchor cables, it is essential first to establish the relationship between power on time and recovery load to identify the most efficient recovery method and formulate corresponding standards. Therefore, this paper uses a linear function to fit the time-temperature curve and an exponential function to fit the temperature-load curve. The formulas obtained from these two fits are then combined to derive the time-recovery load curve for CFRP recoverable anchor cables. The specific results of the two fits are shown in Figure 18.

The fitted curves were examined, and the R-squared value for the time-temperature curve fitting result is 0.944, while the R-squared value for the temperature-recovery load curve fitting result is 0.999. Both fitting results meet the accuracy requirements. The fitted Equations 1, 2 are shown below:

Where: K is Temperature at the anchor cable end; T is Power on time; F is Recovery load.

By combining the fitted Equations 1, 2, the relationship between the power on heating time and the recovery load for the anchor cable is obtained. The time recovery load curve is shown in Figure 19.

The thermoplastic CFRP anchor cable recovery model is obtained by combining the equations, as shown in Equation 3. This model provides a reference for construction design.

Where: T is Power on time; F is Recovery load.

6 Conclusion

In this study, a hot melt recyclable CFRP prestressed anchor cable was developed and designed based on bonded anchorage devices. This system combines anchorage strength and recyclability, fully utilizing the high tensile strength characteristics of CFRP tendons. The study involved bond strength tests, anchorage performance tests, and hot melt recycling tests. The specific conclusions are as follows:

i. Epoxy resin, compared to thermoplastic resins, exhibits superior performance and practical value. The study evaluated hot melt bonding media, selecting Polyoxymethylene (POM), GPPS, and epoxy resin for comparison. The experiments confirmed their feasibility as bonding media in hot melt anchor devices. The results showed that POM exhibited severe foaming during the heating process, resulting in numerous honeycomb-like pores inside the specimens. GPPS demonstrated good fluidity at around 280°C, but due to its low viscosity, it deboned from the strands during tensile testing, achieving only 30% anchorage efficiency. In contrast, epoxy resin achieved approximately 70% anchorage efficiency, indicating that epoxy resin has the best overall performance as a hot melt bonding medium.

ii. Based on bond strength tests, the bonded anchorage device was improved to enhance the anchorage efficiency of CFRP strands. The new bonded anchor added a positioning plate at the end of the CFRP anchor cable and filled it with epoxy resin for anchorage. Results indicated that during the tension test, as the tensile stress increased, resin at the connection between the anchorage segment and the free segment partially detached, followed by slight cracking sounds and the breaking of some fibres on the surface of the strands, ultimately leading to specimen failure. The force-displacement curve remained linear throughout the test and dropped to zero instantly upon failure.

iii. The bonded anchorage system used in the anchorage performance test showed excellent performance for CFRP strands. At the ultimate load, the CFRP strands in the free segment experienced explosive failure.

iv. The anchorage performance test results showed that the tensile strength of the bonded anchor was concentrated between 278 and 292 kN, with an average anchorage efficiency of 100.5%, demonstrating excellent anchorage performance.

v. This study developed a fully bonded hot melt recyclable anchor cable for materials with weak shear strength like CFRP. The results confirmed that electrical heating can effectively separate the anchor device from the CFRP strands when the resin reaches its glass transition temperature. Experimental results showed that after 10 min of electrical heating, only 4% of the ultimate load (≤20 kN) was needed to recover the anchor cable. The recovered CFRP strands were undamaged, structurally intact, and reusable.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

YZ: Conceptualization, Investigation, Methodology, Writing–original draft. SX: Conceptualization, Writing–review and editing, Investigation, Methodology, Visualization. XF: Writing–review and editing, Data curation, Formal Analysis, Validation. WL: Formal Analysis, Writing–review and editing, Methodology. SG: Writing–review and editing, Investigation, Resources. RJ: Writing–review and editing, Data curation, Formal Analysis, Validation. TT: Writing–review and editing, Conceptualization, Funding acquisition, Supervision.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

Authors YZ, XF, and WL were employed by China Construction First Group Constitution and Development Co. LTD. Author YZ was employed by China State Construction Engineering Corporation.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

ASTM (2006). Standard test method for tensile properties of fiber reinforced polymer matrix composite bars.

Cao, J., Bai, S., and Qin, W. (2022). Research progress on the preparation and properties of carbon fiber reinforced thermoplastic composites. J. Compos. Mater., 1–15.

Chen, C., and Cheng, X. (2012). Time-dependent reliability analysis of double-slide block slope anchorage system. Rock Soil Mech. 33 (01), 197–203.

Chen, G., Chen, T., Chen, Y., Huang, R., and Liu, M. (2018). A new method of predicting the prestress variations in anchored cables with excavation unloading destruction. Eng. Geol. 241, 109–120. doi:10.1016/j.enggeo.2018.05.015

C. J. B. Structural Use of Parafil Ropes (1987). Constr. Build. Mater. 1 (1). doi:10.1016/0950-0618(87)90053-5

Duo, Y., Liu, X., Liu, Y., Tafsirojjaman, T., and Sabbrojjaman, M. (2021). Environmental impact on the durability of FRP reinforcing bars. J. Build. Eng. 43, 102909. doi:10.1016/j.jobe.2021.102909

Fang, Z., Lixin, F., and Fang, Y. (2022). Experimental study on the mechanical properties of bonded CFRP reinforcement anchoring system under impact. Acta Mater. Compos. Sin. 39 (11), 5287–5299. doi:10.13801/j.cnki.fhclxb.20220811.001

Fang, Y., Fang, Z., Jiang, R., Xiang, Y., and Huang, D. (2019). Transverse static and low-velocity impact behavior of CFRP wires under pretension. J. Compos. Constr. 23 (5). doi:10.1061/(asce)cc.1943-5614.0000970

Gong, X., and Jianlin, Y. (2021). Development and prospect of recyclable anchor rod technology. J. Civ. Eng. 54 (10), 90–96.

Gudonis, T., Timinskas, E., Gribniak, V., Kaklauskas, G., Arnautov, A. K., and Tamulėnas, V. (2013). FRP reinforcement for concrete structures: state-of-the-art review of application and design. Eng. Struct. Technol. 5 (4), 147–158. doi:10.3846/2029882x.2014.889274

He, Z., Jiang, G., and Feng, H. (2024). Dynamic response characteristics of pile-wall-anchor composite support for slope under earthquake. Rock Soil Mech. (07), 1–14. doi:10.16285/j.rsm.2018.1242

Hou, S., Shizhong, Q., and Ping, Z. (2012). Fatigue test study of bonded anchors with carbon fiber strands. China J. Highw. Transp. 25 (03), 100–106.

jihong, H. (2012). Research on fully recyclable foundation pit retaining system (RESS). Chin. J. Geotechnical Eng. 34 (S1), 287–291.

Jin, W., Jiayuan, H., and Qi, W. (2024). Experimental study on the interface performance of carbon fiber cloth-clay brick masonry under sulfate dry-wet environment. J. Jilin Univ. Eng. Technol. Ed. 54 (05), 1368–1376. doi:10.13229/j.cnki.jdxbgxb.20230002

Li, C., and Xian, G. (2018). Novel wedge-shaped bond anchorage system for pultruded CFRP plates. Mater. Struct. 51, 162. doi:10.1617/s11527-018-1293-x

Liu, H., Ka, T. A., Su, N., Zhu, Y., Guan, S., Long, J., et al. (2024). Experimental study of dimensional effects on tensile strength of GFRP bars. Buildings 14 (5), 1205. doi:10.3390/buildings14051205

Liu, J., Song, B, and Du, X. (2023b). Modified method for shear bearing capacity calculation of FRP reinforced concrete deep flexural members. J. Build. Struct. 44 (12), 170–182. doi:10.14006/j.jzjgxb.2022.0616

Liu, Y., Xie, J. Z., Tafsirojjaman, T., Yue, Q. R., Tan, C., and Che, G. J. (2022b). CFRP lamella stay-cable and its force measurement based on microwave radar. Case Stud. Constr. Mater. 16, e00824. doi:10.1016/j.cscm.2021.e00824

Liu, Y., Zhang, H. T., Tafsirojjaman, T., Dogar, A. U. R., AlAjarmeh, O., Yue, Q. R., et al. (2022a). A novel technique to improve the compressive strength and ductility of glass fiber reinforced polymer (GFRP) composite bars. Constr. Build. Mater. 326, 126782. doi:10.1016/j.conbuildmat.2022.126782

Liu, Y., Zhang, H. T., Tafsirojjaman, T., Dogar, A. U. R., Yue, Q. R., and Manalo, A. (2023a). Compressive behaviour and prediction model for short and slender FRP-confined GFRP bars. Constr. Build. Mater. 376, 131059. doi:10.1016/j.conbuildmat.2023.131059

Nengpan, J., Jianjun, Z., and Hui, D. (2009). Evaluation of stability and optimization of support design for highway high slopes. Chin. J. Rock Mech. Eng. 28 (06), 1152–1161. doi:10.3321/j.issn:1000-6915.2009.06.009

Ping, Z., Shizhong, Q., and Hou, S. (2010). Parameter test study of clip-type anchors with carbon fiber reinforcement. J. Southwest Jiaot. Univ. 45 (04), 514–520.

Ping, Z., Yong, D., and Hou, S. (2014). Theoretical and experimental study on a new type of carbon fiber strand anchoring system. China J. Highw. Transp. 27 (12), 80–87.

Qijia, Z., and Liu, Z. (2012). Technical research and application of recyclable anchors in foundation pit support engineering. Chin. J. Geotechnical Eng. 34 (S1), 480–483.

Ruan, F., Shi, J., and Xu, Z. (2019). Research progress on recycling and reuse of carbon fiber reinforced resin matrix composites. J. Text. Res. 40 (06), 153–158.

Sayed-Ahmed, E. Y., and Shrive, N. G. (1998). A new steel anchorage system for post-tensioning applications using carbon fibre reinforced plastic tendons. Can. J. Civ. Eng. 25 (1), 113–127. doi:10.1139/cjce-25-1-113

Singh, V. K., Singh, J. K., and Kumar, A. (2005). Geotechnical study for optimizing the slope design of a deep open-pit mine, India. Bull. Eng. Geol. Environ. 64 (3), 301–306. doi:10.1007/s10064-004-0259-0

Tafsirojjaman, T., Dogar, A. U. R., Liu, Y., Manalo, A., and Thambiratnam, D. P. (2022). Performance and design of steel structures reinforced with FRP composites: a state-of-the-art review. Eng. Fail. Anal. 138, 106371.

Wang, C. (2015). Experimental study on the transverse load performance of carbon fiber cables and their anchorage systems. China: Hunan University.

Wang, Y., Wang, Y., and Hongyang, X. (2007). Computing of the anchor by the method of three-dimension point-radiate infinite elements. J. China Univ. Geosciences 18 (2), 185–190. doi:10.1016/s1002-0705(07)60036-3

Wang, Z., Wang, Q., and Ma, S. (2018). A method for calculating ultimate pullout force of recoverable under-reamed prestressed anchor cable. Rock Soil Mech. 39 (S2), 202–208. doi:10.16285/j.rsm.2018.1242

Xian, G., Zhou, P., Bai, Y., Wang, J., Dong, S., et al. (2024). Design, preparation and mechanical properties of novel glass fiber reinforced polypropylene bending bars. Constr. Build. Mater. 429, 136455. doi:10.1016/j.conbuildmat.2024.136455

Xiang, Y., Fang, Z., and Wang, C. (2015). Experimental study on the impact resistance performance of carbon fiber cables and their anchorage systems. J. Civ. Eng. 48 (12), 82–90.

Xue, S., Li, X., Liu, Y., Smith, S. T., Dogar, A. U. R., Li, X., et al. (2023). A novel winding–wedge anchorage for CFRP straps: conceptual design and performance evaluation. Case Stud. Constr. Mater. 19, e02636. doi:10.1016/j.cscm.2023.e02636

Yan, Z., Liu, C., and Zhe, L. (2020). Experimental study on seismic response of anchorage of bedding rock slope with weak layer. Chin. J. Geotechnical Eng. 42 (12), 2180–2188. doi:10.11779/CJGE202012003

Yang, W., Jun, F., and Jiayao, L. (2018). Research progress on FRP anchors in geotechnical anchorage. J. Eng. Geol. 26 (03), 776–784.

Yong, Y., Jia, X., and Fuyou, Y. (2004). Feasibility study on GFRP rock bolts. J. Highw. Transp. Res. Dev. 21 (9), 13–15.

Yu, Li, Kuihua, M., and Xue, Li (2024). Long-term performance of composite anchors with CFRP reinforcement under various bonding media. China J. Highw. Transp. 1-14.

Keywords: carbon fibre reinforced polymer (CFRP), strand, anchor cable, thermal-meltable anchoring, recovery

Citation: Zuo Y, Xu S, Fan X, Liu W, Guan S, Jia R and Tafsirojjaman T (2025) Study on the application of thermal-meltable recovery of CFRP strand anchors. Front. Built Environ. 10:1500415. doi: 10.3389/fbuil.2024.1500415

Received: 23 September 2024; Accepted: 12 December 2024;

Published: 14 January 2025.

Edited by:

Yucheng Zhong, Wuhan University of Technology, ChinaReviewed by:

Jun He, Changsha University of Science and Technology, ChinaChenggao Li, Harbin Institute of Technology, China

Copyright © 2025 Zuo, Xu, Fan, Liu, Guan, Jia and Tafsirojjaman. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: T. Tafsirojjaman, dGFmc2lyb2pqYW1hbkBhZGVsYWlkZS5lZHUuYXU=

Yize Zuo1,2

Yize Zuo1,2 Ruixin Jia

Ruixin Jia T. Tafsirojjaman

T. Tafsirojjaman