- 1College of Environmental Science and Engineering, Ocean University of China, Qingdao, Shandong, China

- 2Tianjin Survey and Design Institute for Water Transport Engineering, M.O.T., Tianjin, China

- 3Research Institute for National Defense Engineering of Academy of Military Sciences, Beijing, China

- 4School of Sciences, Qingdao University of Technological, Qingdao, China

Sedimentary processes often produce natural and blown calcareous sands that are deposited in inclined and layered formations. These calcareous sands frequently exist in a complex stress state with rotating principal stress axes that result in intricate mechanical properties. To investigate the mechanical behaviors of calcareous sands with inclined sedimentary surfaces, we developed a device to prepare hollow cylindrical specimens from artificially crushed calcareous sands. By combining this device with a hollow cylindrical torsional shear apparatus, undrained monotonic loading and pure principal stress rotation tests were conducted to investigate the static and dynamic properties of the inherently anisotropic calcareous sands. The results indicate that the shear dilatancy property is related to the principal stress direction; the shear dilatancy of calcareous sand decreases as the direction of the principal stress increases, and the peak stress ratio decreases with increasing principal stress direction and increases with increasing deposition direction. In the precyclic loading period, increases in the deposition direction led to increases in the stabilities of the specimens and decreases in excess pore pressure accumulation, which further affect the dynamic shear modulus and damping ratio of the calcareous sand. In the late stage of cyclic loading, the inherent anisotropies of the specimens are destroyed, so that the excess pressure and hysteresis loop characteristics start to converge.

1 Introduction

Calcareous sand is widely distributed near coral reefs and is an important material used in island geotechnical engineering constructions. Site investigations have shown that natural calcareous sand is sedimented in accordance with the local seafloor topography. The sedimentation features along with horizontal, monoclinal, diapiric, and other complex geological structures are affected by the characteristics of the marine environment, such as winds, waves, and tides. Although this type of stratified sediment is common, very few studies are available in literature regarding the effects of various phenomena on the mechanical characteristics of calcareous sands, which have resulted in problems with ocean engineering constructions and exploitation of marine resources.

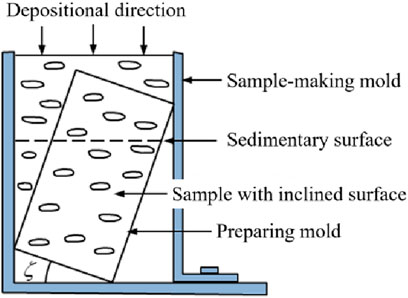

There are many feasible methods available for coring and cutting along different directions with regard to specimen preparations of stratified rocks and clays as they possess self-stabilizing abilities (Deng et al., 2018). Figure 1 illustrates the typical coring orientations of inclined specimens, in which the angle values are determined on the basis of the deposition surface and end face; these allow subsequent study of the effects of the sedimentation direction on the mechanical properties of the material. Diyuan et al. (2012) found that the triaxial compressive strengths of transversely laminated rock specimens were higher than those of longitudinally laminated rock specimens under identical circumferential pressure conditions. Ghazvinian et al. (2013) studied the shear characteristics of greenschists with different bedding angles under different loading directions through the oblique shear test; they found that the shear strength and failure mechanism of the specimen were affected by the laminar inclination angle and loading direction. Jia et al. (2013) conducted simple shear and triaxial tests and concluded that the strength of the layered shale first decreased and then increased with increase in the bedding plane dip angle. Deng et al. (2018) studied the bedding effects of sandstones on their mechanical characteristics and failure models; they concluded that the bedding angle of the sandstone dominates its strength, apparent cohesion, internal friction angle, and failure model. Yuan and Yang (1996) and Salager et al. (2013) studied the mechanical behaviors of clay for depositional dips of 0°, 45°, and 90°. Their results show that specimens with 0° depositional dip exhibit great stretchability, specimens with 90° depositional dip have higher stiffness values, and specimens with 45° depositional dip have the lowest strengths. Wichtmann and Triantafyllidis (2018) analyzed the effects of the stratification planes on the mechanical behaviors of kaolin clays and noted that specimens that are cut horizontally have greater dilatancies and higher strengths.

Figure 1. Diagram showing the cutting directions of the inclined specimens (Deng et al., 2018).

The sand specimens in the laboratory tests were mostly made from remolded samples as they cannot stabilize by themselves owing to low cohesion. The common methods used to prepare the sand specimens can be categorized as follows: vibration, compaction, ramming, and sand rain (Ministry of Housing and Urban Rural Development of the People’s Republic of China). The sand rain method used to prepare the sand specimens depends mainly on the gravity of the sand particles, which further influences the horizontal depositional surface. To prepare sand specimens with inclined depositional surfaces, the preparation mold was placed inside a specimen-making mold to achieve a specific angle ζ (Figure 2). Thereafter, the sand particles were sprinkled over the specimen-making mold in accordance with the guidelines of the sand rain method. Thus, sand specimens with inclined depositional angles of ζ were obtained. Guo (2008), Tong et al. (2014), and Afzali-Nejad et al. (2018) obtained different internal friction angles and dilatancy angles against the dip angles through direct shearing tests on the sand specimens with inclined depositional angles. Based on a series of laboratory triaxial tests on sand specimens with inclined depositional angles, various researchers (Lam and Tatsuoka, 1988; Tang et al., 2021; Zamanian et al., 2020, 2021) found that sand has significant anisotropy and that its shear strength tends to decrease with increase in ζ. Rodriguez and Lade (2013) performed true triaxial tests on sand specimens with inclined depositional angles and showed that the inclined angles and intermediate principal stress parameter have significant effects on the deformation and strength characteristics of anisotropic sands.

Only the effects of the depositional direction on the behavior of sand were accounted for in the aforementioned studies, while the loading direction was maintained constant during testing. However, it has been widely reported in literature that marine environmental loads, such as wave loads and earthquakes, result in obvious rotation of the principal stress axis (Zhu et al., 2020; Zamanian and Jafarzadeh, 2020; Chaudhary et al., 2002). This has significant effects on the mechanical characteristics of geotechnical materials, such as their strength, deformation, and pore pressure (Tong et al., 2021; Zdravković and Jardine, 2001; Sivathayalan and Vaid, 2011). Accordingly, a new testing method must be developed to study the mechanical behaviors of inclined sedimentary sands under the principal stress rotation. To address this gap, we developed a specimen preparation method for hollow cylindrical tests of sand samples with inclined sedimentary surfaces based on the principle of the hollow cylindrical torsional shear instrument; accordingly, reshaped calcareous sand specimens can be prepared in the laboratory for monotonic and cyclic loading tests of samples with inclined sedimentary surfaces. The main feature of this method is that it enables study of the static and dynamic mechanical behaviors of calcareous sands with inclined sedimentary surfaces even when the stress loading direction changes.

2 Hollow cylindrical torsional shear apparatus

2.1 Introduction of the instrument

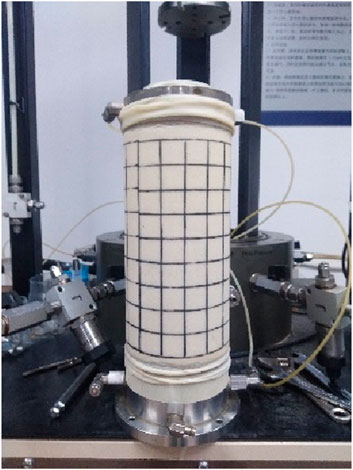

The hollow cylindrical torsional shear apparatus (HCA) is an ideal instrument for studying the soil mechanical behaviors under the principal stress rotation condition and is especially appropriate for the static and quasistatic cases. The apparatus used in this study is the GDS HCA, as shown in Figure 3, which includes the pressure chamber, axial torsional loading control system, external pressure controller, internal pressure controller, back pressure controller, and data control and collection system. The apparatus can exert a maximum axial force of 10 kN with an accuracy of 0.01 kN, has a measuring range of axial displacements between −20 mm and 60 mm with an accuracy of 0.001 mm, apply a maximum torque of 100 Nm with an accuracy of 0.1 Nm, and has an unlimited torsion angle with an accuracy of 0.1°.

2.2 Loading laws

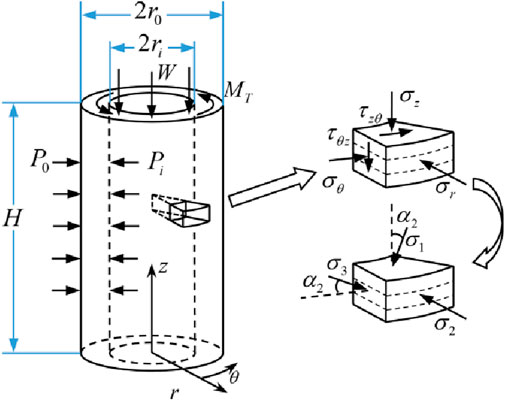

The HCA system was used to prepare the sand specimen with the stress state shown in Figure 4 by exerting an axial load W, a torsional load MT, an internal pressure

3 Preparation of the soil specimen

3.1 Principle of specimen preparation

The resultant forces on the sand particles determine the casting and deposition directions during sand rain preparation. The gravitational force causes the sand particles to fall vertically to form a horizontal sedimentary surface that is always parallel to the secondary principal stress direction; this means that the stress state of the specimen rotates only around the secondary principal stress axis. With reference to the methods used to prepare the rock and clay specimens, rotation of the stress state around the secondary principal stress axis can be realized using specimens with directional deposition surfaces. To better analyze the obtained data, the slope angle of the specimen’s sedimentary surface must be independent of the stress rotational angle. Considering that the radial stress direction is fixed during the loading of the hollow cylindrical torsional shear test, a viable method would be to prepare a sand specimen with an inclined sedimentary surface first and then ensure that the stress rotates about the radial direction using the torsional shearing apparatus. Thus, we can control the stress direction from two aspects, i.e., the specimen and the stress.

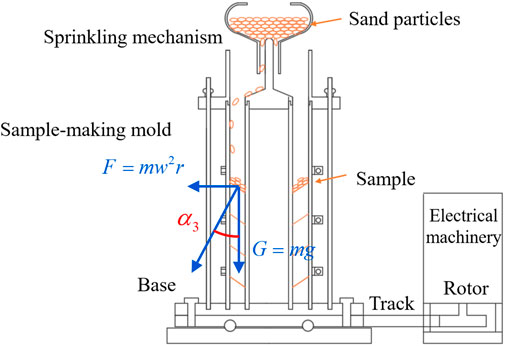

To prepare sand specimens with specific sedimentary surfaces, it is necessary to control the resultant forces of the particles along the radial oblique inward or outward direction during specimen preparation. Considering that gravity is an objective force in the downward direction, an inclined resultant force can be obtained by exerting a horizontal force on the sand particles. Moreover, the centrifugal force has a horizontal, controllable, and radially symmetric nature. Accordingly, we developed a special specimen preparation system capable of producing sand specimens with specific inclined sedimentary surfaces by rotating the hollow cylindrical specimen-making mold at high speeds to generate centrifugal forces (Dong et al., 2022).

3.2 Method for preparing the sand specimen

As shown in Figure 5, the sand particles are subjected to the vertical gravitational force G and horizontal centrifugal force F during sprinkling:

where m is the mass, g is the gravitational acceleration, r is the rotating radius, and ω is the angular velocity. Then, the intersection angle

where ω is governed as

Considering that

the rotational speed is obtained as

where

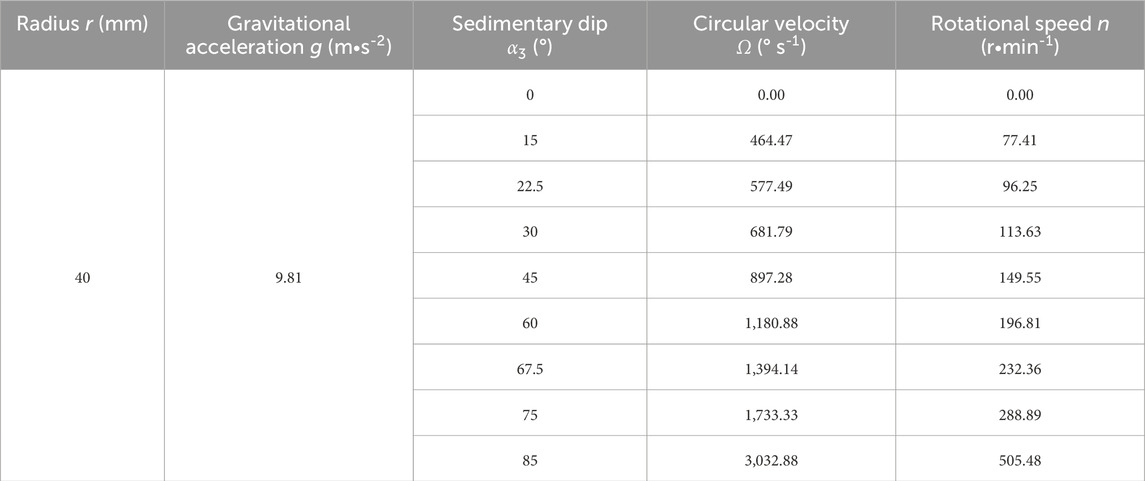

The relationship between rotational speed and inclination angle α3 can be determined by Equations 1–6. Among them, the average radius r = 40 mm (inner and outer radii of the specimen are 30 mm and 50 mm, respectively) is used to calculate the rotational speed for convenience. Table 1 shows the parameters for the inclined specimen. It is seen that the sedimentary dip increases linearly with the rotational speed. For n = 0 r/min,

3.3 Effectiveness and reproducibility of sample preparation

To verify the effectiveness and reproducibility of the sampling method in this paper, a series of mixed samples of quicklime and colored sand were prepared. Figure 6 shows some cross sections of samples with a deposition direction of

4 Testing method and results

4.1 Testing method

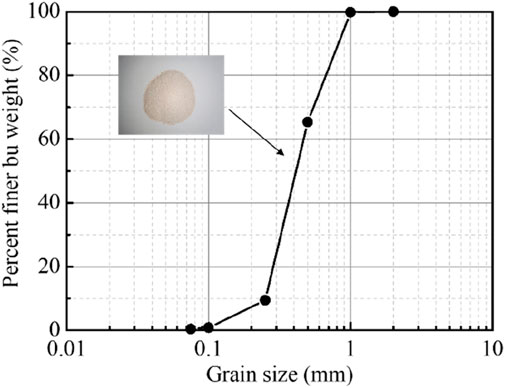

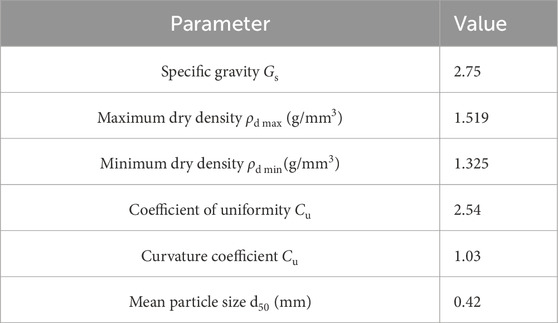

The calcareous sand used in this study was sourced from the Philippines and was crushed artificially. The particle grading curve of the artificially crushed calcareous sand (ACCS) is shown in Figure 7, which indicates that the particle sizes of the crushed sand are relatively uniform between 0.1 mm and 1 mm. The basic physical properties of the ACCS were measured and are shown in Table 2. The specific gravity of the sand was 2.75, and the maximum and minimum dry densities were 1.519 and 1.325 g/mm3 that allowed the maximum and minimum pore ratios to be calculated as 1.08 and 0.81, respectively. Moreover, the ACCS has a coefficient of uniformity of 2.54, curvature coefficient of 1.03, and mean particle size of 0.42.

Because of the friable nature of calcareous sand, it is necessary that the new sampling method considers the problem of particle crushing during the sampling process. In fact, crushing of calcareous sand particles requires a critical crushing pressure that is greater than the particle strength of the sample itself. During the sample preparation process, only centrifugal and gravitational forces act on the calcareous sand particles, that is, there is no strong load during the sample preparation process. Moreover, particle breakage was not observed during the entire sample preparation process, so the particle crushing problem can be ignored. The prepared specimen of ACCS is shown in Figure 8. The vibration method was used to control the relative density

Saturation and consolidation were started immediately after installing the sample in the pressure chamber. The first step in the saturation process is to pass carbon dioxide (CO2) through the specimen and then through the airless water to replace any air in the specimen. Thus, the sand reached full saturation at an effective pressure of 20 kPa and a back pressure of 200 kPa. The tested Skempton B parameters were all greater than 0.95. Next, the specimens were consolidated to an effective stress of 50 kPa and monotonic loading tests were performed using isotropic consolidation. However, the pure principal stress rotation test requires the bias stress q to be loaded to a certain value before anisotropic consolidation is carried out under the condition of this q certain value.

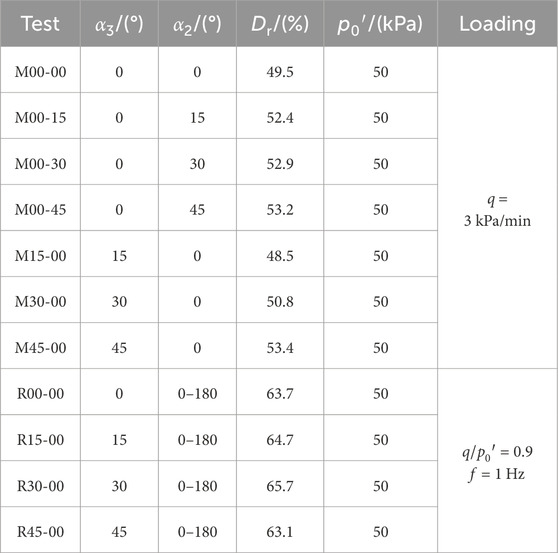

Considering that inclined calcareous sands are usually under the influences of buildings or wave loads, two stress paths are designed in this paper, namely monotonic loading and pure principal stress rotation. Both these tests were performed under undrained conditions, and all tests were conducted at an effective confining pressure of

4.2 Monotonic loading test results

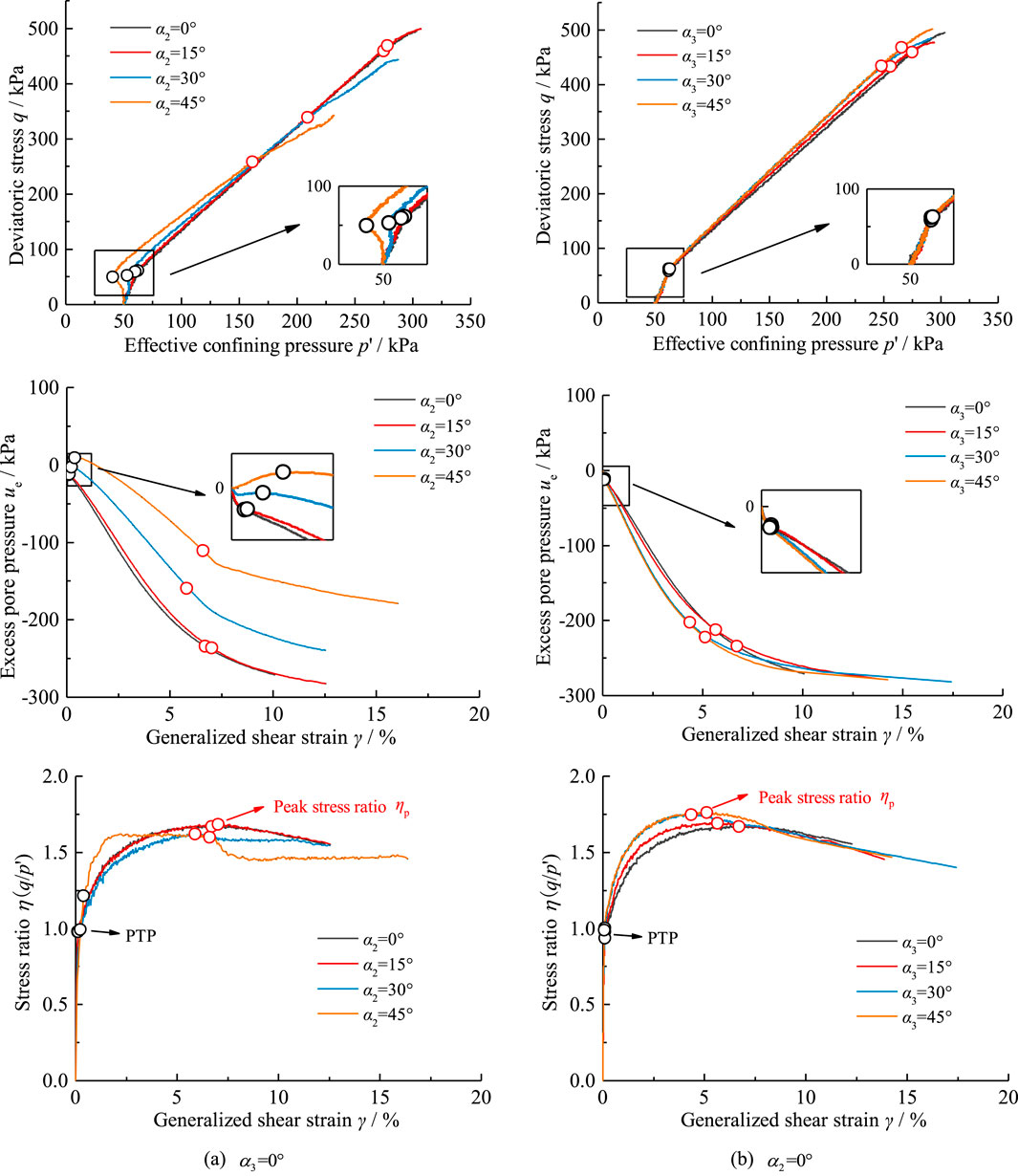

Figure 9 shows the monotonic responses of calcareous sand for various principal stress directions

Figure 9. The monotonic loading test results of specimens with different stress directions α2=0-45° and deposition directions α3=0-45°.

In most cases, the stress ratio

A comprehensive comparison of the test results reveals that the strain of the calcareous sand specimen develops at an accelerated rate after phase transformation. In addition to strain development, the pore pressure dissipates rapidly, but there are differences in the pore pressure dissipation rates under different principal stress directions

4.3 Pure principal stress rotation test results

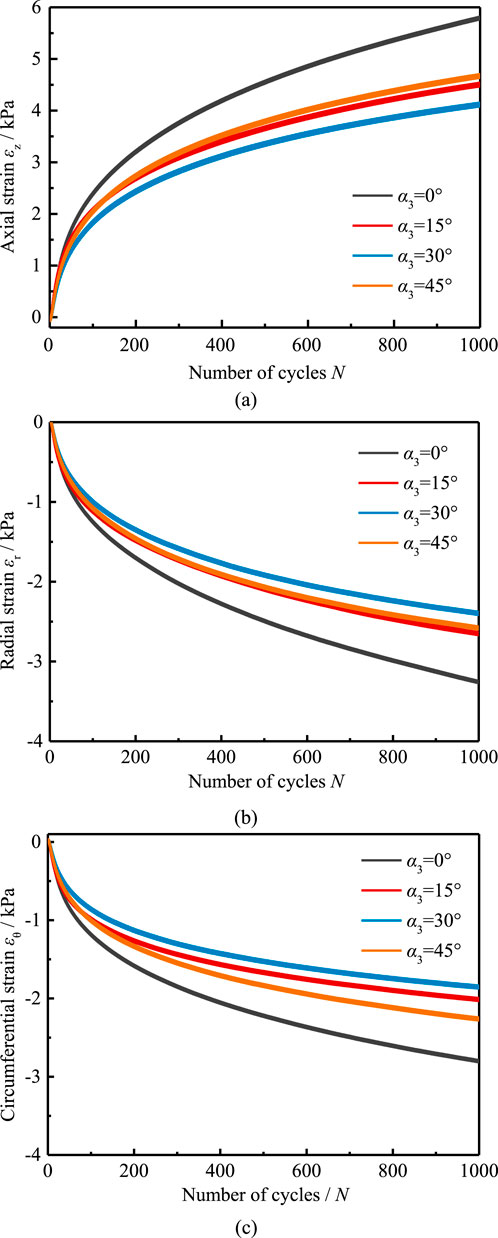

A series of undrained pure principal stress rotation tests were conducted on calcareous sand specimens with deposition directions

Figure 10. Strain components of specimens with different deposition directions α3=0-45°.10 (A): Axial strain εz.10 (B):Radial strain εr.10 (C): Circumferential strain εθ.

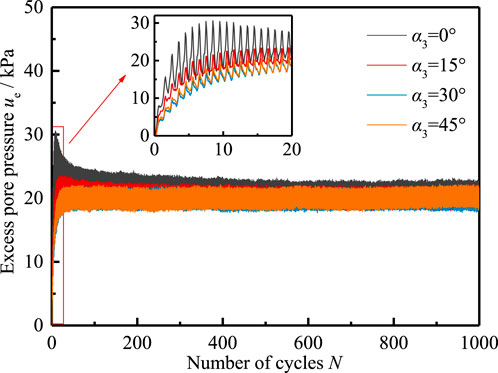

Figure 11 shows the development pattern of the excess pore pressure

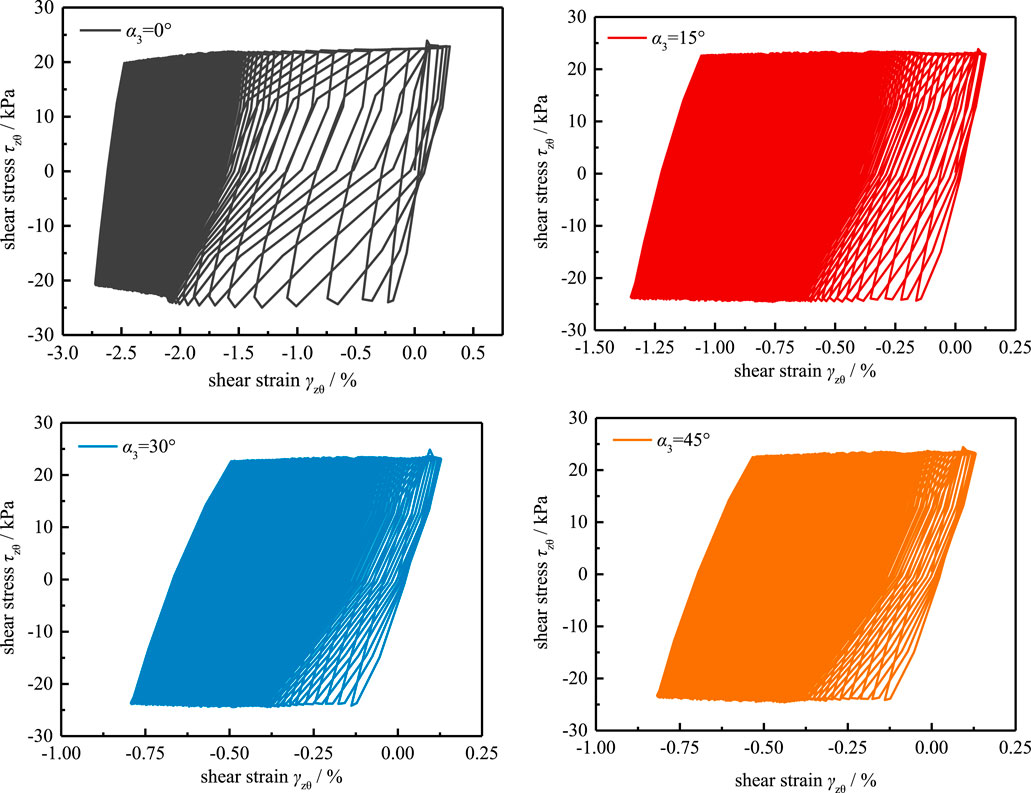

Figure 12 presents the shear stress–strain relationship for different

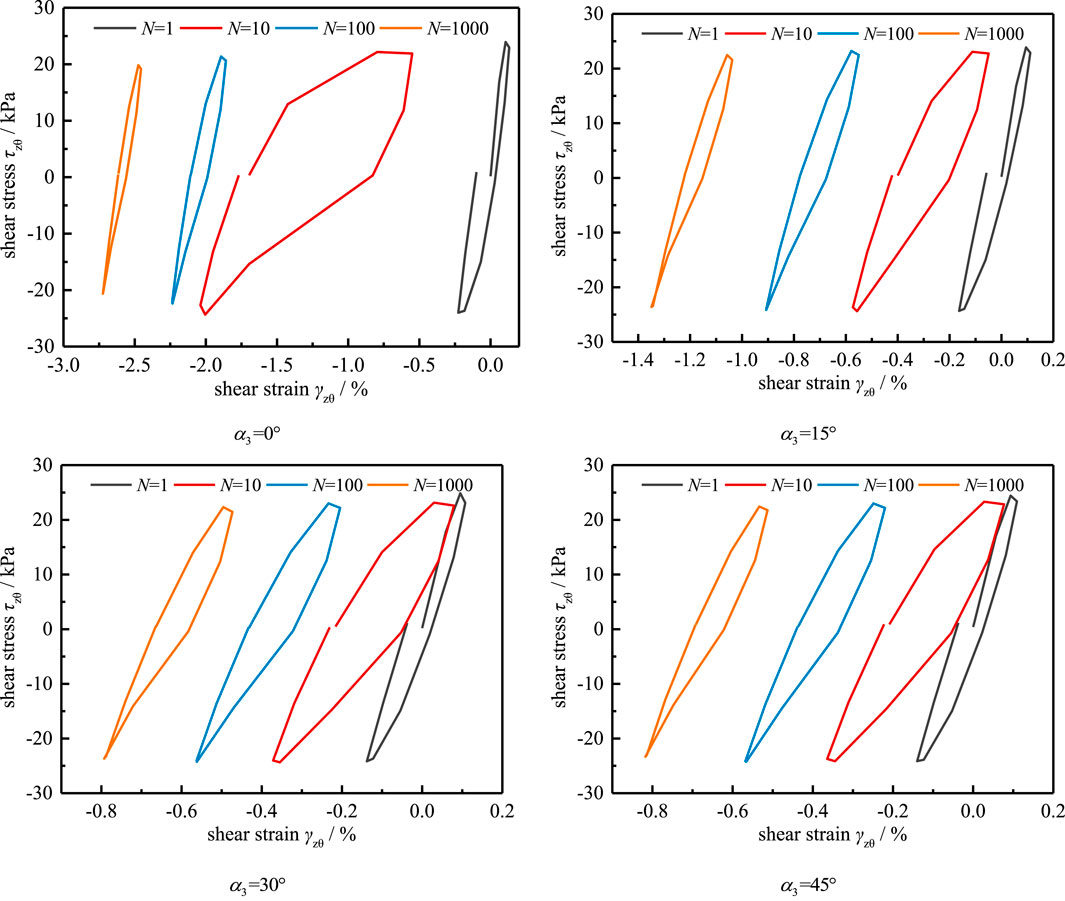

To better observe the effects of the number of cycles and

As mentioned above, under larger CSR values (0.9), the calcareous sand strains develop rapidly in the precyclic phase, inducing excess pore pressure accumulation, which further affects the dynamic shear modulus and damping ratio. Owing to anisotropic consolidation, the calcareous sand enters the plastic creep state and stabilization of the dynamic properties in the later stages of the experiment. The deposition direction

5 Conclusion

Based on the proposed method of preparing sand specimens and the principle of the specimen loading equipment, a new device was developed to prepare hollow cylindrical specimens of inclined sand. Hollow cylindrical calcareous sand specimens with rotating sedimentary surfaces about the radial orientation were prepared by controlling the direction of the resultant forces of particles in the sand rain method. The relationship between the centrifugal and gravitational forces was derived to quantitatively control the deposition direction of the hollow cylindrical specimen. The inclined sedimentary dip of the sand specimen can be quantitatively controlled through the rotational speed of the equipment, which lays the foundation for the corresponding tests.

Monotonic shear tests were carried out on the calcareous sand specimens under different principal stress directions

Data availability statement

The original contributions presented in the study are included in the article/supplementary material; further inquiries can be directed to the corresponding author.

Author contributions

YA: writing–original draft and writing–review and editing. HL: writing–review and editing. TD: writing–review and editing. CL: writing–review and editing. MZ: writing–review and editing.

Funding

The authors declare that financial support was received for the research, authorship, and/or publication of this article. This research was financially supported by the project funded by China Postdoctoral Science Foundation (no. BX2021115) and National Natural Science Foundation of China (no. 51909268).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Afzali-Nejad, A., Ali, L., and Farhadi, B. (2018). Role of soil inherent anisotropy in peak friction and maximum dilation angles of four sand-geosynthetic interfaces. Geotext. Geomembranes 46 (6), 869–881. doi:10.1016/j.geotexmem.2018.08.003

Chaudhary, S. K., Kuwano, J., Hashimoto, S., Hayano, Y., and Nakamurai, Y. (2002). Effects of initial fabric and shearing direction on cyclic deformation characteristics of sand. Solis Found. 42 (1), 147–157. doi:10.3208/sandf.42.147

Deng, H., Wang, W., Jianlin, L., Zhang, Y., Zhang, X., et al. (2018). Experimental study on anisotropic characteristics of bedded sandstone. Chin. J. Rock Mech. Eng. 37 (1), 112–120. (in Chinese). doi:10.13722/j.cnki.jrme.2017.1205

Diyuan, L., Wong, N., Liu, G., and Zhang, X. (2012). Influence of water content and anisotropy on the strength and deformability of low porosity meta-sedimentary rocks under triaxial compression. Eng. Geol. 126, 46–66. doi:10.1016/j.enggeo.2011.12.009

Dong, T., Liu, C., Fang, Y., Wang, Y., An, Y., et al. (2022). Preparation method of hollow cylindrical specimen of inclined sedimentary sand. Chin. J. Geotechnical Eng. S2, 3551–3558. doi:10.13722/j.cnki.jrme.2022.0102

Dong, T., Zheng, Y., Liang, K., Mei, Z., et al. (2017). Control and realization of generalized stress paths in HCA test. Chin. J. Geotechnical Eng. 39 (S1), 106–110. (in Chinese).

Ghazvinian, A., Vaneghi, R. G., Hadei, M. R., and Azinfar, M. (2013). Shear behavior of inherently anisotropic rocks. Int. J. Rock Mech. Min. Sci. 61, 96–110. doi:10.1016/j.ijrmms.2013.01.009

Guo, P. (2008). Modified direct shear test for anisotropic strength of sand. J. Geotechnical Geoenvironmental Eng. 134 (9), 1311–1318. doi:10.1061/(asce)1090-0241(2008)134:9(1311)

Jia, C., Chen, J., Guo, Y., Yang, C., Wang, L., et al. (2013). Research on mechanical behaviors and failure modes of layer shale. Rock Soil Mech. 34 (S2), 57–61. (in Chinese). doi:10.16285/j.rsm.2013.s2.006

Lam, W.-K., and Tatsuoka, F. (1988). Effects of initial anisotropic fabric and σ2 on strength and deformation characteristics of sand. Soils Found. 28 (1), 89–106. doi:10.3208/sandf1972.28.89

Liu, F., Yu, M., Yin, J., Zhou, C., et al. (2005). Stress control in hollow cylindrical torsional specimen for study of double shear unified strength. Chin. J. Rock Mech. Eng. 24, 2463–2467. (in Chinese). doi:10.1360/biodiv.050084

Ministry of Housing and Urban Rural Development of the People's Republic of China. Standard for geotechnical test methods (GB/T 50123-2019). Beijing: China Planning Press. (in Chinese).

Rodriguez, N. M., and Lade, P. V. (2013). True triaxial tests on cross-anisotropic deposits of fine Nevada sand. Int. J. Geomechanics 13 (6), 779–793. doi:10.1061/(ASCE)GM.1943-5622.0000282

Salager, S., François, B., Nuth, M., and Laloui, L. (2013). Constitutive analysis of the mechanical anisotropy of Opalinus Clay. Acta Geotech. 8, 137–154. doi:10.1007/s11440-012-0187-2

Sivathayalan, S., and Vaid, Y. P. (2011). Influence of generalized initial state and principal stress rotation on the undrained response of sands. Can. Geotechnical J. 39 (1), 63–76. doi:10.1139/t01-078

Tang, Z., Luo, Q., Feng, C., and Zhu, S. (2021). Experimental investigation of the influence of bedding planes on the mechanical characteristics of saturated sand. Bull. Eng. Geol. Environ. 80, 641–651. doi:10.1007/s10064-020-01924-6

Tong, D., Zheng, Y., Liang, K., and Liu, C. (2021). Shear strength and shear bands of anisotropic sand. Acta Geotech. 17, 2841–2853. doi:10.1007/s11440-021-01372-w

Tong, Z., Fu, P., Zhou, S., and Dafalias, Y. F. (2014). Experimental investigation of shear strength of sands with inherent fabric anisotropy. Acta Geotech. 9 (2), 257–275. doi:10.1007/s11440-014-0303-6

Wichtmann, T., and Triantafyllidis, T. (2018). Monotonic and cyclic tests on kaolin: a database for the development, calibration and verification of constitutive models for cohesive soils with focus to cyclic loading. Acta Geotech. 13, 1103–1128. doi:10.1007/s11440-017-0588-3

Yang, S., Zhou, J., and Gong, X. (2006). Analysis on ability of HCA to imitate cyclic principal stress rotation under constant confining pressure. Chin. J. Geotechnical Eng. 28 (3), 281–287. (in Chinese).

Yuan, J., and Yang, X. (1996). Experimental study on anisotropic characteristic of shanghai soft clay. Dam Observation Geotechnical Test. 20 (2), 10–14. (in Chinese).

Zamanian, M., and Jafarzadeh, F. (2020). Experimental study of stress anisotropy and noncoaxiality of dense sand subjected to monotonic and cyclic loading. Transp. Geotech. 23, 100331. doi:10.1016/j.trgeo.2020.100331

Zamanian, M., Mollaei-Alamouti, V., and Payan, M. (2020). Directional strength and stiffness characteristics of inherently anisotropic sand: the influence of deposition inclination. Soil Dyn. Earthq. Eng. 137, 106304. doi:10.1016/j.soildyn.2020.106304

Zamanian, M., Payan, M., Memarian, S., and Senetakis, K. (2021). Impact of bedding plane direction and type of plastic microparticles on stiffness of inherently anisotropic gap-graded soils: index, wave propagation and micromechanical-based interpretations. Soil Dyn. Earthq. Eng. 150, 106924. doi:10.1016/j.soildyn.2021.106924

Zdravković, L., and Jardine, R. J. (2001). The effect on anisotropy of rotating the principal stress axes during consolidation. Geotechnique 51 (1), 69–83. doi:10.1680/geot.51.1.69.39359

Keywords: calcareous sand, inclined sedimentary surface, anisotropy, laboratory test, static and dynamic mechanical behavior, s

Citation: An Y, Liu H, Dong T, Liu C and Zhang M (2024) Laboratory evaluation of calcareous sand specimens with inclined sedimentary surfaces. Front. Built Environ. 10:1447428. doi: 10.3389/fbuil.2024.1447428

Received: 11 June 2024; Accepted: 29 October 2024;

Published: 27 November 2024.

Edited by:

Yong Tan, Tongji University, ChinaCopyright © 2024 An, Liu, Dong, Liu and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hongjun Liu, aG9uZ2p1bkBvdWMuZWR1LmNu

Yongning An

Yongning An Hongjun Liu1*

Hongjun Liu1*