- 1Wood Science and Engineering, Oregon State University, Corvallis, OR, United States

- 2Dipartimento di Ingegneria Civile, Ambientale e Meccanica, University of Trento, Trento, Italy

The urgent need to reduce carbon emissions in the construction sector has driven the exploration of circular economy practices in the built environment. Nevertheless, the implementation of circular economy principles in projects remains limited. This research contributes to bridging this gap by introducing a project proposal that establishes a typology of modular systems designed for easy assembly, disassembly, and reuse. Specifically, the proposal focuses on load-bearing wood furniture modules (FMs) as an intermediate solution between planar and volumetric modules. These FMs expand the structural wall’s volume, facilitating the integration of services, storage, and appliances. This addresses scenarios where swift building deployment is required. The proposed modular dimension enhances transportation efficiency compared to volumetric solutions and simplifies construction by eliminating the need for temporary stabilization, as seen in planar systems. Standardization and “separability” of each component within the FM allows for easy integration and maintenance. Special attention is paid to the timber connection systems within and between FMs facilitating easy assembly, and disassembly for future reuse. The adaptability of the FM concept is demonstrated through versatile compositions and layouts, facilitating space reconfiguration. While the technical feasibility of the FM-based system is demonstrated, further research is needed to address regional and cultural variations and customize the system to different contexts. The study emphasizes the potential of FMs as a solution for buildings aligned with circular economy principles and highlights the importance of continued research and development in this field.

1 Introduction

According to UNEP (2021), building operations and construction accounted for 37% of energy-related CO2 emissions in 2020, with 11,7 gigatons of CO2, 27% from operational emissions–direct and indirect–and 10% from construction activities. Circular economy (CE) practices in the built environment are some of the strategies explored by policymakers and academia, thus providing alternatives to current linear economic models (“take-make-use-dispose” or, in a life cycle assessment perspective, cradle-to-grave models) (Eberhardt et al., 2022).

Circular economy is an approach based on narrowing, slowing, and closing material flows (Eberhardt et al., 2022). In the latter process, materials are reused or recycled, so that the loop between post-use and production is closed (cradle-to-cradle, Braungart and McDonough, 2003). Design strategies for slowing resource flows aim to extend and intensify a product utilization period (Bocken et al., 2016). Narrowing resource flows are approaches to increasing resource efficiency, therefore using less resources per product.

Timber is widely endorsed as a promising building material to serve CE purposes, given its relatively low environmental impact during production (i.e., from cradle to gate) (Bergman et al., 2014), and the suitability of close-loop strategies based on wood waste recycling and/or reuse, as shown by CINARK’s Construction Material Pyramid (CINARK and Vandkunsten Architects, 2019).

To further contribute to transitioning the wood construction industry to circular economy, several slow-loop design approaches can be implemented, namely,: (a) design for ease of maintenance and repair, (b) design for adaptability/flexibility, (c) design for standardization and compatibility, and (d) design for easy assembly and disassembly (Bocken et al., 2016; Ahn et al., 2022). These strategies address two different, complementary aspects of a product’s life extension: material durability (i.e., ability to meet a designed performance over time), and design flexibility (i.e., ability to meet evolving performance criteria) (Hamida et al., 2022). One of the key advantages of slow-loop models applied to wood construction is the possibility to lock carbon into constructed buildings for a longer time and without the need for additional inputs for regeneration.

Modular construction has been identified as an enabler of circular buildings (Minunno et al., 2020). The Circular Construction Evaluation Framework (CCEF) proposed by Dams et al., 2021 allocates high scores to prefabricated modular units assembled with dry, accessible, and reversible connections. Bertram et al., 2019 describe different scales of modular construction, from individual elements, to panels, volumetric units and complete structures. They also identify increasing levels of complexity of modular construction from largely structural, to partial and full integration of functions and fixtures (Bertram et al., 2019). The CCEF assigns high scores to increasing scales of modularity. However, large scale, volumetric modules may lead to increased emissions during transportation, compared to flat-pack, compact shipping alternatives, and increased costs (Bertram et al., 2019). Additionally, the CCEF considers high complexity and full integration of systems in modular construction as potential limiting factors to circularity. This is due to the fact that integration of systems with differing life expectancies (the so-called shearing layers - site, structure, skin, services and stuff-described by Brand, 1994) may hinder disassembly and adaptability (Dams et al., 2021).

Prefabrication and modular construction have emerged as promising solutions to meet the critical need for affordable housing, especially in contexts where swift transportation and rapid deployment are essential, such as in remote communities (Roscetti et al., 2022) and post-disaster recovery situations (Ghannad et al., 2020). In such situations, the possibility to relocate and reuse the building or its parts brings significant benefits.

The objective of the research presented in this paper is to develop a typology of modular systems that can foster circular construction investigating novel opportunities for intermediate modular scales (i.e., between panels and volumetric units) and complexity (i.e., integrated functions with separable shearing layers), particularly targeting this market segment. The development of a design proposal and possible building layouts are presented, with the intention of showing the building system potential and proposing new research paths for circular, modular construction.

2 Background

2.1 Circular economy and related design approaches

Bocken et al. (2016) describe alternative, and potentially complementary, circular design strategies, underpinned by narrowing, closing, and slowing resources loops. Narrowing loops involve optimization of resources, for instance by preferring renewable, local resources, materials that require less energy during production and transportation, underutilized resources, or waste material. Closing resource loops involve either designing for a technological cycle (for instance, by remanufacturing, or recycling) or for a biological cycle (for instance by composting uncontaminated, biodegradable materials). Design for slowing resource loops entails either designing long-life products (i.e., design for attachment and trust, design for liability and durability) or extending a product life (i.e., ease of maintenance and repair, upgradability and adaptability, standardization and compatibility). As noted by Bocken et al. (2016), “design for dis- and reassembly” fits both closing and slowing loop criteria. In fact, by ensuring that products and parts can be separated and reassembled easily, it is possible to more easily access and repair damaged parts, rearrange parts, and eventually separate materials that will enter different cycles.

The International Organization for Standardization (ISO) published in 2020 the first version of a standard providing guidelines for the design of disassembly and adaptability (ISO 20887:2020). Ease of access to components and services, independence of each component, simplicity and standardization of the parts, avoidance of unnecessary finishes and safety of disassembly are relevant disassembly principles listed by the ISO 20887 standard.

Similar concepts, considering the product’s life cycle in the design phase, originated in manufacturing and transferred to the building industry. The “Design for Manufacture and Assembly” (DfMA) emphasizes simplicity, high-quality design, and details to minimize time, costs, skills, materials, components, techniques, and energy (Guy and Ciarimboli, 2008; Open System Lab, 2019), when integrated with “Design for Maintenance and Disassembly” criteria (DfMAMD), embraces both slowing and closing loop strategies.

High-quality design incorporates construction tolerances for component flexibility and durability during assembly/disassembly (Guy and Ciarimboli, 2008; Open System Lab, 2019). Accessible connections aid maintenance and deconstruction (Guy and Ciarimboli, 2008), while error prevention is crucial during installation (Open System Lab, 2019).

DfMAMD principles relate to the concept of shearing layers by Duffy, further developed by Brand (1994) (Knaack et al., 2012). The classification includes Site, Structure, Skin (building enclosure), Space plan, Services, and Stuff (furniture) based on service life. DfMAMD emphasizes independence of shearing layers for easier repair or replacement without disrupting other systems. Independent shearing layers enhance building adaptability (Guy and Ciarimboli, 2008; Open System Lab, 2019). Best practices include consolidating service systems in core units (Guy and Ciarimboli, 2008; Open System Lab, 2019).

Standardization and some levels of customizations are potentially competing criteria (Guy and Ciarimboli, 2008; Open System Lab, 2019). Interoperable materials, off-the-shelf products, and compatible systems enhance a building system’s versatility. Customization within pre-set solutions promotes customer satisfaction, designing for “attachment and trust” in functional and emotional durability.

Eberhardt et al. (2022) assessed circular design strategies, identifying assembly/disassembly, material selection/substitution, adaptability/flexibility, and modularity as the most cited. Fifteen studies in their review of 34 papers recommend prioritizing local, renewable, durable, reusable, recyclable, certified, and non-toxic materials (Eberhardt et al., 2022). Wood, although theoretically meeting these criteria, may have some limitations in recyclability due to potential presence of preservatives, coatings, paints, and adhesives.

Crucial to reusability is the absence or minimal presence of damage and a performance level comparable to the original. Depending on the age of the material and the load history, consideration of the reusability of salvaged structural timber may need to account for potential decreases in mechanical properties due to load duration, as noted by Cavalli et al. (2016), and for time-dependent deformations, such as creep. Various studies have assessed the appropriateness of different timber connection systems for easy disassembly. Pozzi (2019) examined the disassembly potential of timber connections, considering favorable factors like prefabrication level and reduced connection and structural system complexity. The research concluded that plug-in bracket connectors were most suitable for reuse. A comprehensive review by Ottenhaus et al. (2023) concluded that for enabling reuse, connections should remain within the elastic domain, tolerances should be accounted for, and designs should allow for simple load paths.

2.2 Examples of wood prefabrication in western history

Prefabrication enables DfMAMD (Shang et al., 2019), with modularity being a widely cited construction method in circular economy literature (Eberhardt et al., 2022). Timber prefabrication arose from colonialism’s demand for quick construction in remote areas (Smith, 2010). “Design for assembly” was crucial, utilizing pre-cut members, panelized infills, and heavy timber framing. 1800s iron advancements and dowel-type connections simplified assembly, as seen in Australia’s Manning Portable Colonial Cottage for Emigrants in 1830 (Smith, 2010).

In the early 20th century, standardized timber construction processes in the USA, along with the need for quickly deployable systems that could be easily self-assembled, led to the creation of flat-packed, mail-ordered kits like Aladdin and Sears Modern homes. These kits provided pre-cut lumber for balloon-framed houses (Smith, 2010).

Acute housing shortages spurred the development of fully prefabricated wood-based panel housing in several countries with a tradition of wooden dwellings. Notable examples include the Plattenhäuser produced by Deutsche Werkstätten in Dresden, Germany, in 1921 during the hyperinflation period (Wilk, 2017). During the Great Depression of the 1930s, the Forest Products Laboratory (FPL) in the USA conducted research into prefabrication. This research led to the development of a model house utilizing wall, ceiling, or floor box girder panels measuring 4 × 8 feet (1.22 × 2.44 m). These panels were constructed from 3-ply sheets glued to internal lumber elements and filled with insulation (Wilk, 2017).

Although the FPL’s model house did not embody the conventional style of American housing, which contributed to its limited adoption in the country, the industrial, minimalist aesthetic of plywood still attracted modernist architects. Richard Neutra incorporated exposed plywood for exterior cladding, interior paneling, and flooring in several projects commissioned by the Evans Plywood Company in 1940. The system was intended for fully demountable and “transport-proof” houses, with panels attached to a timber frame using aluminum-clad joints designed for easy disassembly (Wilk, 2017). In 1942, Gropius and Wachsmann proposed the General Panel System, an example of “design for assembly and disassembly,” based on prefabricated panels with timber posts, insulating boards, and plywood enclosures. However, the system lacked standardization and compatibility, using a non-standard module size and costly proprietary connections (Smith, 2010; Imperiale, 2012).

Standardization and compatibility are vital for a building system’s longevity, allowing for adaptability and upgradability over time (Bocken et al., 2016). Design and construction quality also impact a system’s physical and emotional durability (Haug 2018). Mass-produced wooden mobile homes in the USA exemplify the pitfalls of excessive standardization and subpar construction. Though intended to meet housing demands, these homes resulted in low-value solutions with shortened lifespans, thereby contributing to the negative perception of prefabrication in the country (Smith, 2010).

The advancement of new materials aligns with the progress of prefabrication systems. Multi-functional panelized products have emerged to replace conventional wall construction methods, consolidating various functional layers. For instance, structural insulating panel (SIP) systems (Amran et al., 2020) combine both structural and insulation functions. Cemesto, used extensively across the United States during the mid-20th century, including in iconic projects such as the Eames’ houses (Ballester et al., 2023), featured a laminated bagasse fiberboard bonded on one or both sides to asbestos-cement sheets using a waterproof, highly vapor-resistant bituminous adhesive. These panels were affixed to a supporting framing, providing sheathing, building paper, insulation, and lath and plaster functionalities in a single product (Ballester et al., 2023). One of the biggest limitations of these multifunctional systems is that impossibility of decoupling shearing layers for maintenance and upgrading.

All the examples provided are founded on 2D prefabrication, with a growing adoption of panelized systems, facilitated by the advancements in engineered wood products. Timber volumetric prefabrication emerged in Central Europe by the early 1970s, initially limited to single-story applications and temporary construction. One example is the Holtmann system, which featured 3 × 3 m (and multiples) modules using a glulam skeleton filled with wood framing (Huss et al., 2019). The development of multistory timber room modules began in the 1990s, using timber frames and light framing. Since the early 2000s, this has included engineered wood panels such as CLT (Huss et al., 2019).

Huss et al. (2019) classify room modules into load-transferring and inserted modules. A hybrid solution involves room modules with mounted ceiling slabs. The most common example of an inserted module is the sanitary module, which is placed on a supporting floor. The construction strategy for these types of modules focuses on concentrating volumetric prefabrication in areas extensively equipped with services, while limiting prefabrication to planar or linear elements for the structural components. Huss et al. (2019) highlighted the high potential of combining planar and three-dimensional elements to create new, more effective types of prefabrication.

The scale of room modules typically ranges from a service cell to a complete flat, and can extend to the combination of several open modules to create larger spaces. In all cases of volumetric modular construction, the interior space is defined within the modules themselves, determining the spatial organization based on module composition and arrangement.

Although less common, there are noteworthy examples of furniture modules, such as Shigeru Ban’s Furniture Houses (McQuaid, 2003). Furniture House 1, built in 1995, featured lightweight wooden FM types: a 90 × 70 × 240 cm closet and a 90 × 45 × 240 cm bookshelf. Ban used different materials in subsequent projects: Nine-Square Grid House (1997) with hybrid plywood-steel, China Furniture House (2002) with laminated bamboo, and Sagaponac House (2004) with improved plywood. The Nine-square Grid House utilized steel studs for a 10.4 m span floor, creating adaptable spaces with sliding doors. In all these cases, the FMs are used in single-story single-family houses (McQuaid, 2003).

This brief overview of timber prefabrication precedents highlights several key elements for success: adherence to standardized solutions for compatibility across multiple products, use of durable materials and quality standards for long-lasting systems and buildings, and sufficient flexibility and customizability to adapt to different contexts and user needs. Additionally, combining smaller, specialized, open, volumetric modules with simpler planar elements is seen as a promising approach to achieving both flexibility and optimization. Only a handful of the analyzed precedents were designed for easy disassembly and reuse, and in those cases, the connection system played a crucial role.

In the context of a circular economy, implementing modular solutions with extended physical and functional life cycles helps slow resource loops. Additionally, adopting strategies for easy disassembly and reuse of prefabricated parts at the end of a building’s life closes resource loops, reducing waste and the environmental impact associated with the production of new materials and components.

This design research contributes to the discourse on wood prefabrication and circular economy for low-rise fast deployable buildings by leveraging intermediate volumetric, open modules in combination with planar structural elements. It explores the creation of flexible full-height units that serve as both structural and functional, space-defining elements, promoting slow and close resource loops in construction.

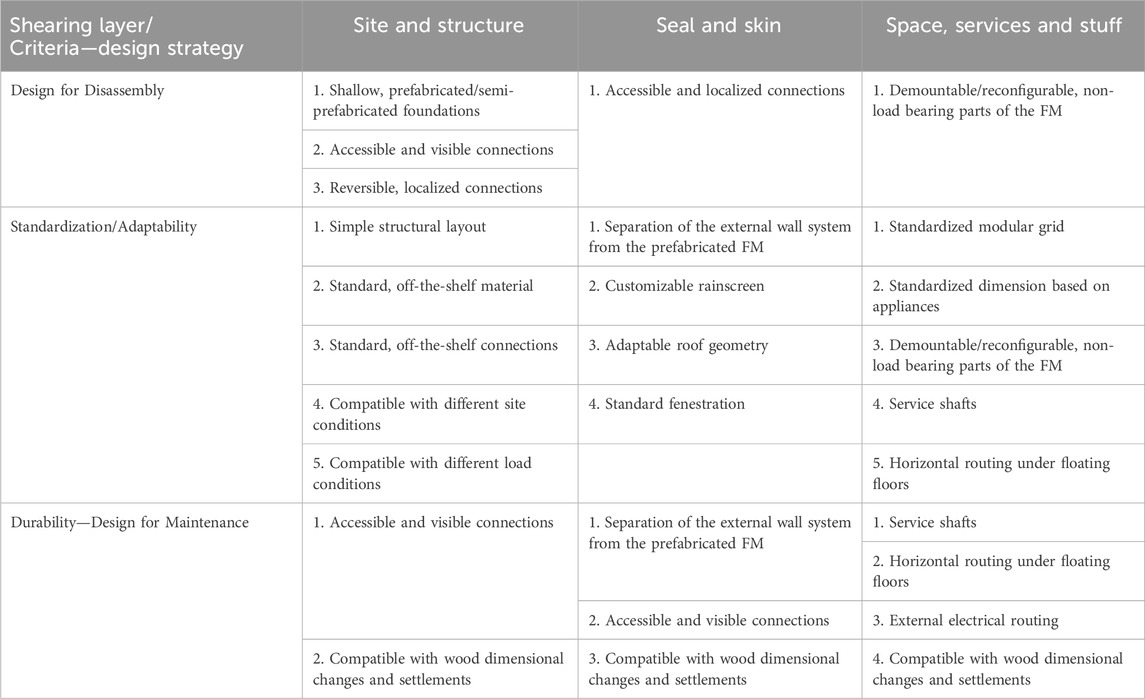

3 The methodology: implemented design criteria

The following sections describe the criteria used to design the proposed solution for self-standing, load bearing, reusable and flexible wood furniture modules. The project focuses on the potential of integrating multiple shearing layers within a wood furniture module while enabling the decoupling of shearing layers under different life expectancies. This approach ensures functional and physical longevity of the building. Table 1 provides a synthesis of the main design strategies proposed, based on the reviewed circular economy design criteria.

3.1 Site and structure

As a prerequisite, the FM solution should adapt to site conditions, including varying geotechnical parameters and the nature and magnitude of external forces. Design loads are determined based on worst-case scenarios, particularly for wind and seismic actions, due to the lightweight nature of the system.

The proposed FMs are designed to act as load-bearing structures for both vertical and lateral forces, and to be used in combination with other wood-based structural systems for the floors. The FMs are designed to receive and transfer the loads of other stacked modules in low-rise buildings. The lateral force resisting system follows seismic design principles, ensuring simplicity, uniformity, and bidirectional resistance (Follesa et al., 2018).

Prefabricated or semi-prefabricated foundations are preferred for ease of installation and compatibility. Shallow foundations (Pujadas-Gispert et al., 2018), such as concrete plinths or screw foundations connected by steel beams, are viable options, considering soil impact and site recovery. Overturning prevention measures are taken for shallow concrete blocks. Foundations keep wood materials elevated from the ground to minimize moisture intrusion (DIN 68800-2, 2022).

Connections between stacked FMs and adjacent FMs, as well as with other structural systems, must effectively transfer design loads and enable easy disassembly and module reuse. To achieve this, it is important to minimize joints and use accessible and visible connections.

Carpentry joints, commonly used in furniture making and timber construction, offer flexibility and may facilitate disassembly for repair, maintenance, and reuse. However, in structural applications, carpentry joints require additional mechanical reinforcements to prevent unintended disconnections under different loading conditions, including earthquakes and strong winds. Additionally, changes in wood moisture can lead to swelling, shrinking, or deformation over time, reducing or preventing the reversibility of carpentry joints.

Modern connections employ metal dowel-type connections with fasteners such as nails, bolts, dowels, screws, or specialized metal connectors like toothed plates, ring plates, metal brackets, and angle brackets. Bolts offer a higher level of reversibility. While nails and screws have lower reversibility, disassembly is still possible, particularly if the connection has not experienced significant stress. Structural elements can be reused by employing new fasteners and inserting them in areas that do not overlap with the previous connections. Screws are also used with specialized connectors for gravity load transfer. This family of connection systems consists of two parts pre-installed on the timber elements which are then connected on site by sliding or clamping the two parts together, like in the case of concealed hooks. These systems allow for high deconstructability if each connection component remains in place during disassembly.

Stiff and high-strength adhesive-type connectors and glued-in steel rods, although creating rigid connections, lack reversibility and limit recyclability.

This study explores mechanical connections within FMs and between FMs and other structural components, considering different geometrical configurations. These configurations include parallel side by side, parallel stacked, and orthogonal at an angle. Reversibility is prioritized, focusing on punctual, localized connectors between stacked and adjacent modules, and linear two-part sliding/clamping connections between modules and the other structural elements of the gravity load bearing system.

3.2 Seal and skin

The building skin’s opaque components consist of various layers that control heat, air, and moisture flow between the interior and exterior. Prefabricated facade modules often span multiple floors. Proper detailing and installation are crucial for maintaining control layer continuity at horizontal and vertical joints between modules. “Wet sealing” strategies, as implemented in projects like Brock Commons, ensure joint tightness (Gasparri and Aitchison, 2019). Gasparri and Aitchison (2019) proposed a “unitised timber envelope” that replicates curtain wall technology, utilizing an integrated aluminium frame with rubber gaskets and pressure equalization to prevent air and water infiltration.

The solution proposed in this paper separates the external wall system from the prefabricated FM to enable flexibility, adaptability to various climate zones, and ease of maintenance and refurbishment. The rainscreen is designed as an independent component and can be connected to FMs when they form part of the external wall. Joints in the exterior wall are insulated and sealed during on-site assembly.

Standardized windows and doors are incorporated to address fenestration, enhancing design flexibility and compatibility with different products. The choice of roof geometry and roofing system is influenced by the context and climate, requiring adaptability to accommodate various roof geometries (e.g., flat, and pitched roofs with different slopes) and a range of roof assembly layups and materials.

3.3 Space, services and stuff

The proposed FM system utilizes the space between the modules, allowing for specific functions and spatial configuration without constraints.

The dimensions of the FMs accommodate standard furniture components, including kitchen cabinets, appliances, bathroom fixtures, wardrobes, and libraries, integrating various functions into the housing units. Service shafts accommodate the routing of service pipes and cables between vertically stacked modules, providing easy access for mechanical, electrical and plumbing (MEP) systems repair and replacement. Details consider wood shrinkage and differential material movement at MEP lines and shaft wall connections. Horizontal routing within a storey is mainly resolved in the floor plane using a floating floor. Electrical conduit is exposed on the walls of the furniture modules, and switches and power sockets are mounted externally instead of being routed within the walls for greater flexibility.

To enhance adaptability of the spaces to changing needs and functions, FM systems are designed with a certain level of demountability and reconfigurability, allowing for the removal and rearrangement of non-critical elements while leaving important structural elements in place.

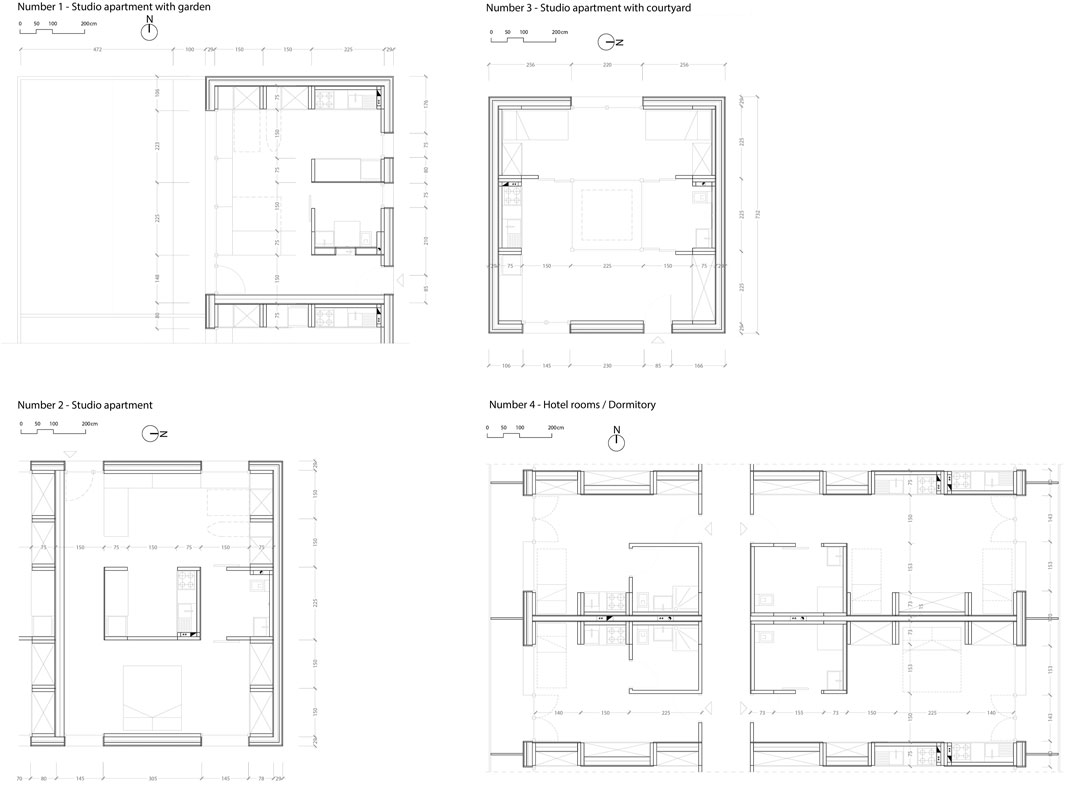

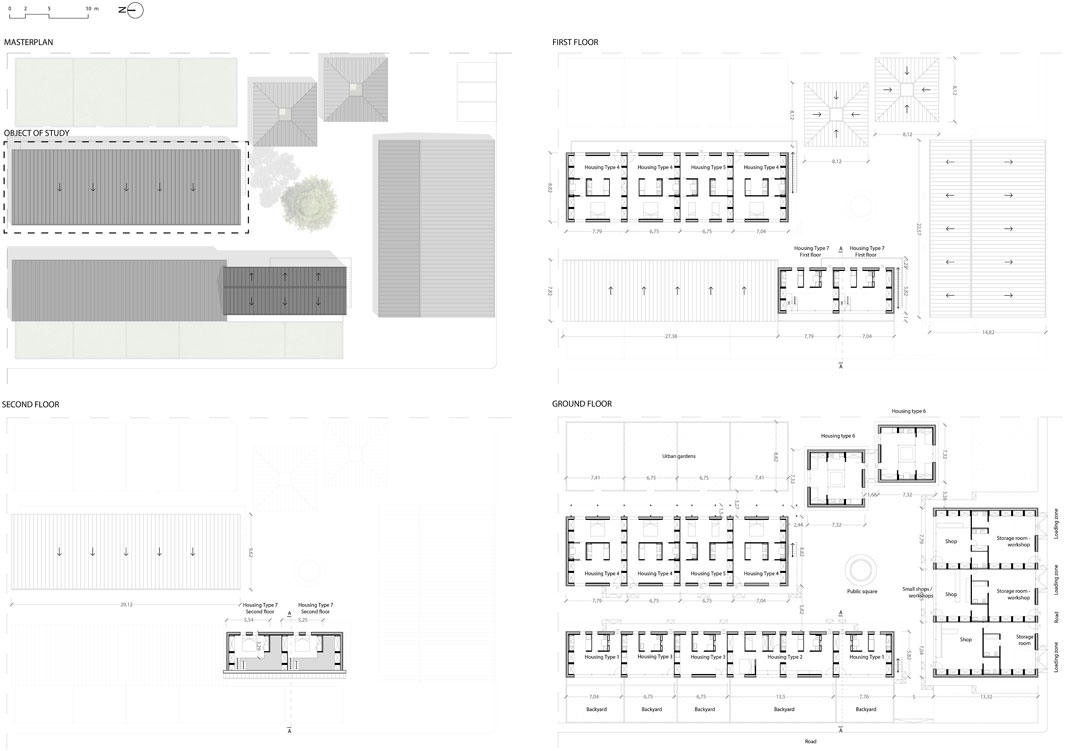

The FMs offer versatility and adaptability to various housing types and layouts, including single-family houses, townhouses, duplexes, and multi-unit residential buildings. In multi-unit buildings, flats can be arranged along a central corridor or external arcade.

The system’s flexibility is achieved through a standardized grid used for all building types. Within this grid, core areas containing functions like bathrooms and kitchens are organized alongside open spaces that can accommodate living rooms and bedrooms. Different combinations of core and open spaces allow for multiple compositions.

4 The project

This proposal focuses on the development of individual FMs, their utilization within residential units, and the arrangement of these units in a settlement proposal. These sections encompass both architectural design and structural analysis.

4.1 Design of the furniture modules

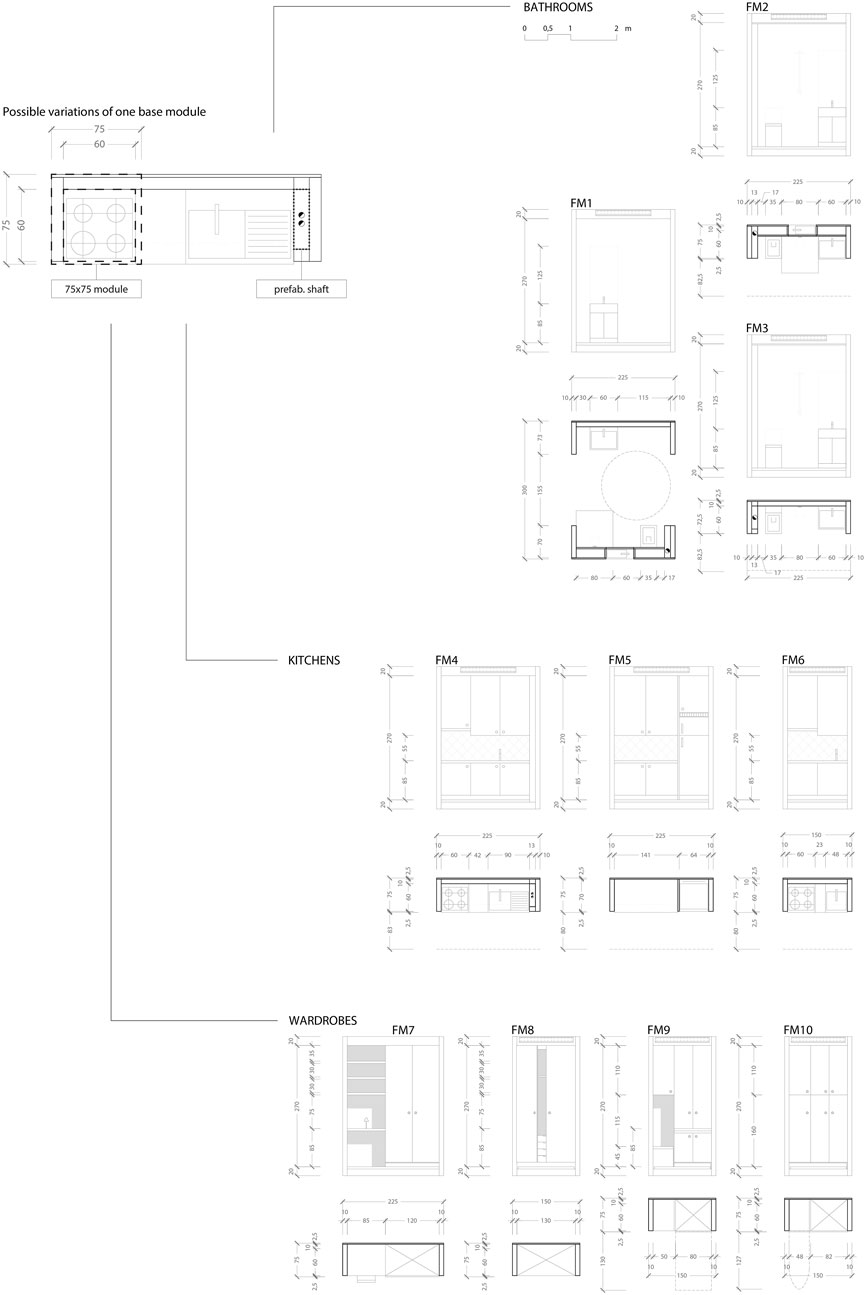

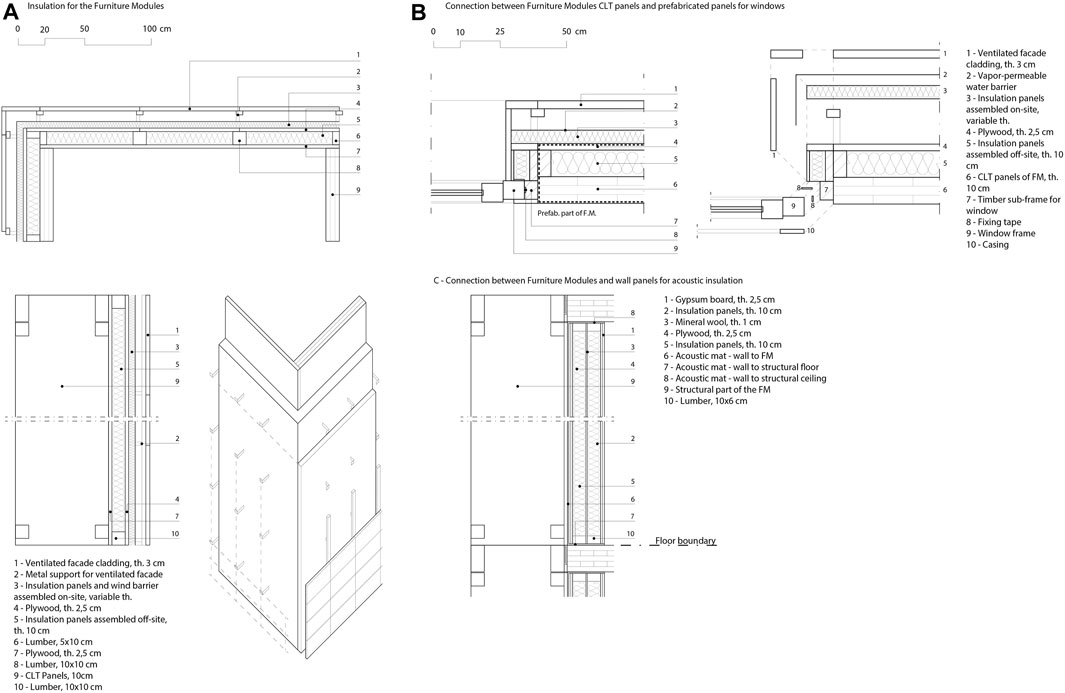

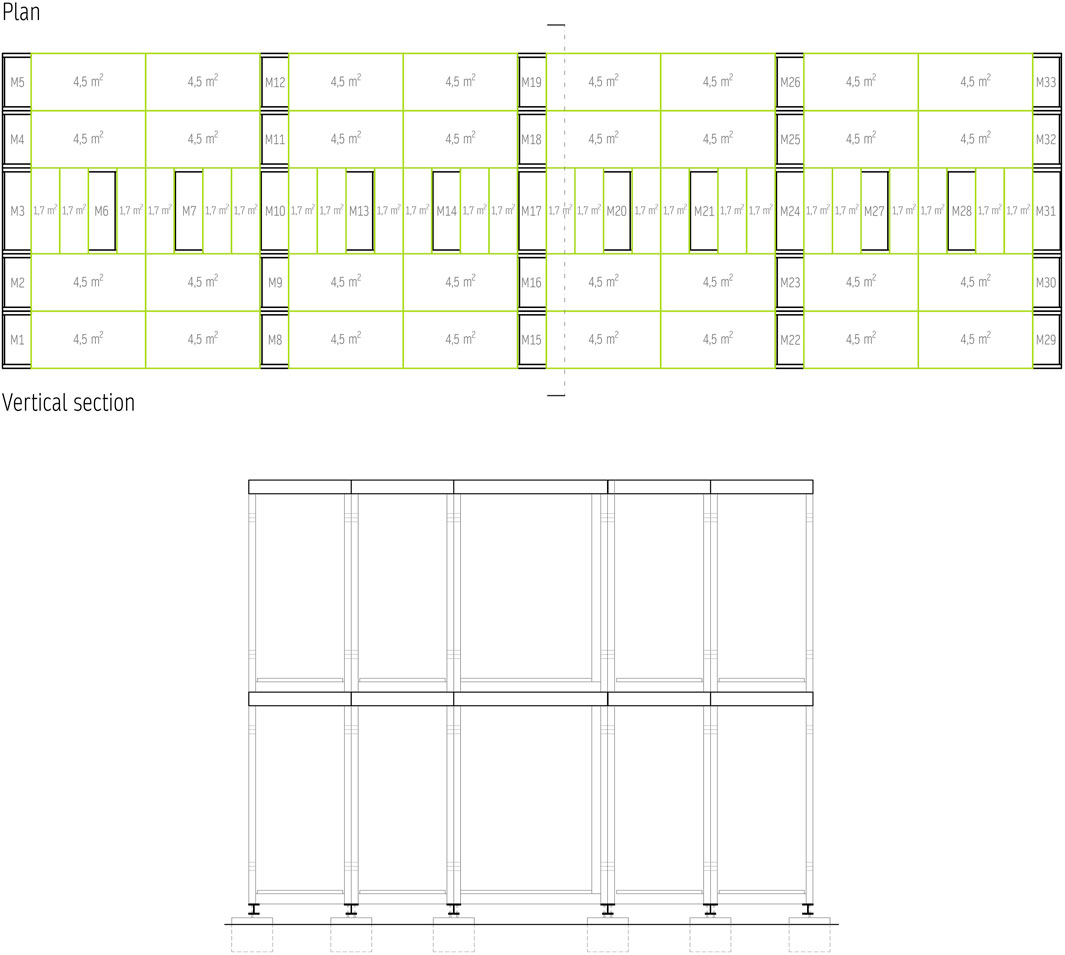

DfMA emphasizes the use of standardized components, and this proposal follows this principle. The basic modular unit consists of three standard wood products, which are selected based on their functional and structural roles: thick panels for vertical upright supports, thin panels for shelves and bracing, and linear elements for horizontal framing In this paper, the emphasis is placed on a specific solution that utilizes cross-laminated timber (CLT) for the upright panels, plywood for shelves and bracing panels, and lumber for framing elements (Figure 1).

The dimensions of the base module take into consideration standard sizes for most wood-based sheet materials, which are manufactured in 300 mm increments, as well as the typical sizes of furniture and appliances, which are usually multiples of 600 mm (Canepa, 2017). Additionally, the dimensions are designed to accommodate structural and service components. A 750 × 750 mm base dimension was chosen to accommodate both furniture and service components, while utilizing halves of 1,500 mm wide sheets. To account for tolerances, the design includes a 15 mm gap for connecting with the floor panels. Along the perimeter, the intermodular connections allow for adjustment to dimensional variations.

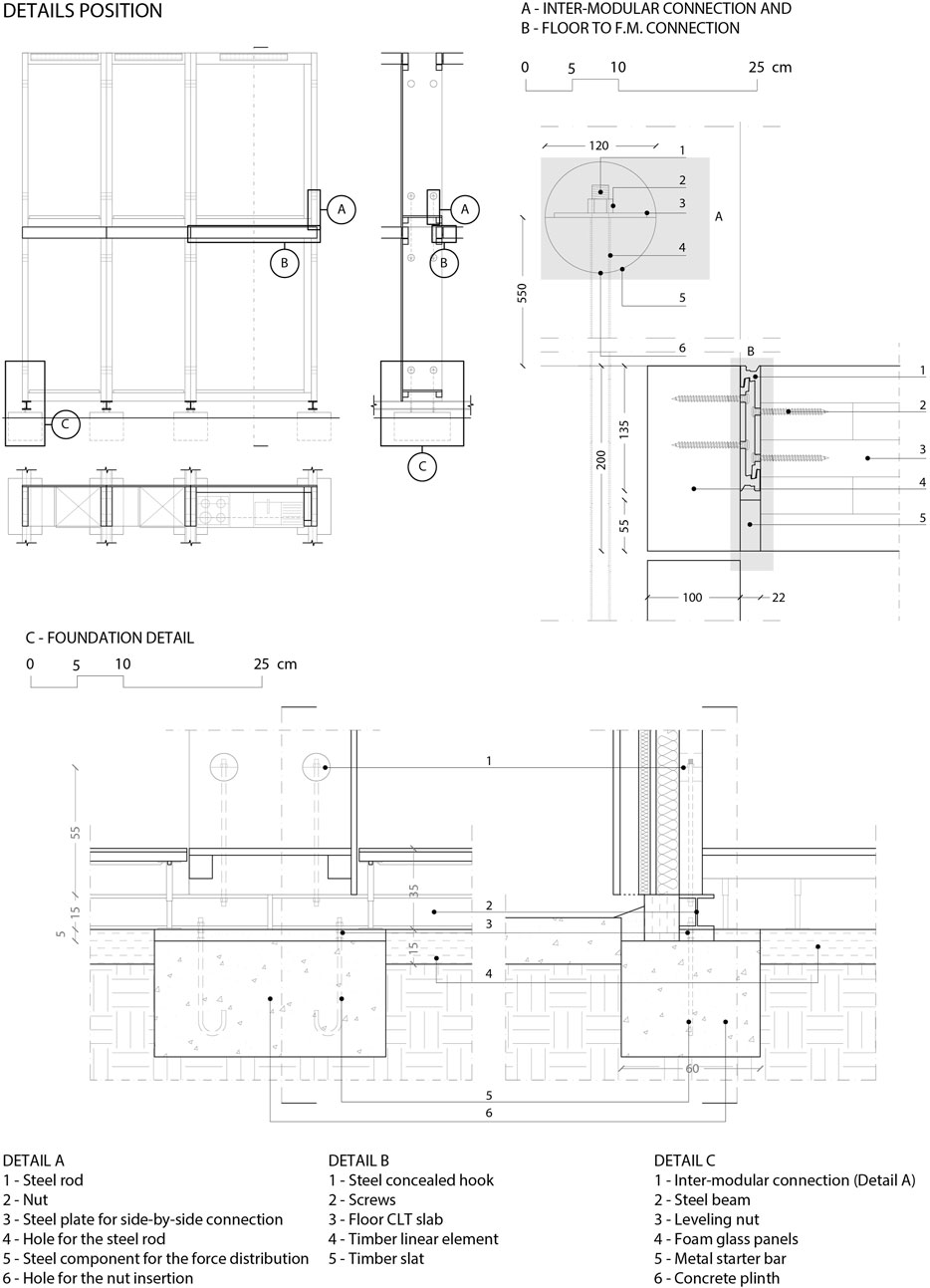

Considering the types of elements involved, the necessary intra-modular connections consist of butt connections between thick panels and linear elements, resolved with reversible clamping connection, (detail A in Figure 1), and butt connections between thick panels and thin panels, utilizing nails (detail B in Figure 1). Furthermore, intermodular connections between FM units encompass stacking connections (detail C in Figure 1) and side-by-side connections (detail D in Figure 1).

Steel threaded rod connections inserted in pre-drilled holes in the CLT panels and tightened with nuts are employed for stacking FM units on different floors (Figure 1 Detail D, and Figure 2 Detail A), ensuring alignment and accommodating tolerances. Rounded panel slots expedite assembly. In high seismicity contexts, the connection system can be adapted with post-tensioning and hyperelastic elastomeric bearings (Asgari et al., 2021) or steel springs (Gesh et al., 2023) to prevent tension losses over time. Similar steel threaded rod connections are used to secure the FM to the foundation (Figure 2- Detail C). For horizontal connections between FMs on the same floor, a steel plate tightened with a nut is used (Figure 1- Detail B). The connection accommodates assembly tolerances, including a 3 mm total diameter tolerance for the timber element holes. For seismic events or horizontal loads, a 7 mm tolerance allows for sliding between FMs.

Concealed hooks are pre-assembled on FMs and CLT floor panels, enabling immediate floor installation after FM positioning (Figure 2- Detail B). This streamlines the construction process, but also enables disassembly for future reuse of the FMs as well as of the CLT floor panels. For pitched roofs, a ridge beam is placed on top of the upright panels and secured using steel threaded rods through the intermodular connection.

The FMs in this study are categorized based on the number of squares they occupy (FM2 for two squares, FM3 for three squares) (Figure 3). The designed FMs can accommodate various types of furniture and services, depending on the intended function. Figure 3 showcases examples of the studied FMs, including three kitchen types, two bathrooms, one accessible bathroom, and four closets. These furniture modules encompass a range of options adopted for housing solutions.

The FMs are designed with transportation convenience in mind. The dimensions are influenced by the ability to transport them on a standard European truck. An FM3 module has a width of 2.25 m, fitting within the standard truck width. The modules also have a height of 3.1 m, allowing for transportation of 3 or 4 modules. With a length of 13.5 m, the modules maximize truck capacity and ensure efficient transportation.

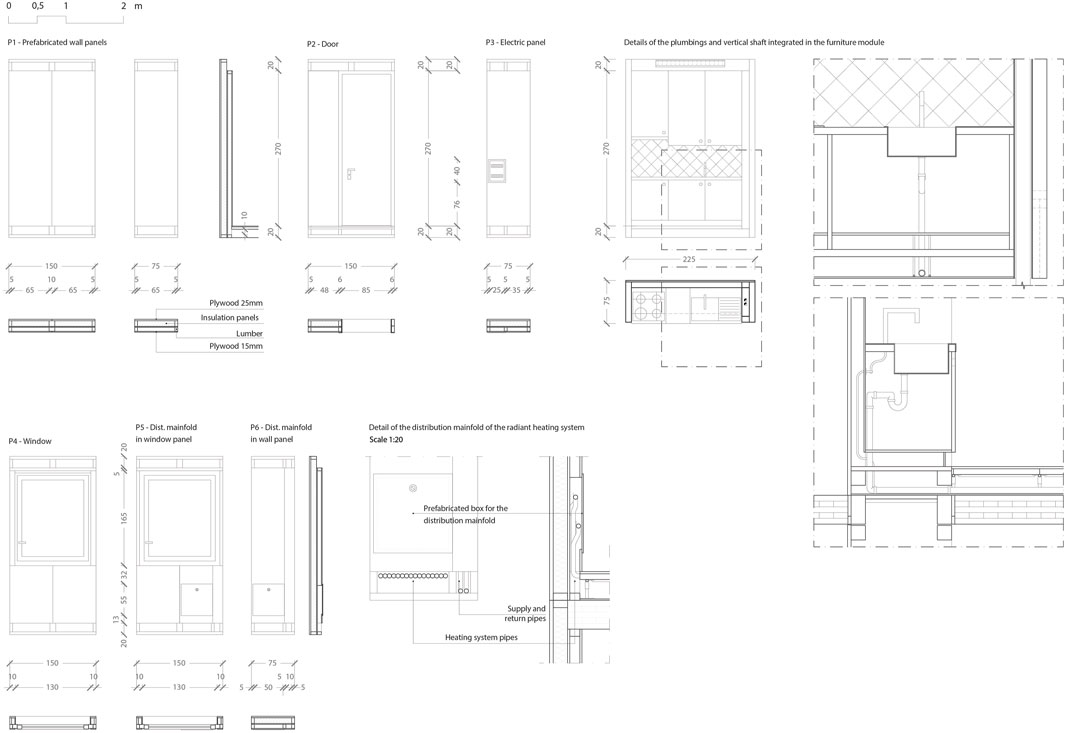

The design considers the spatial requirements of other systems to ensure accessibility, independence between shearing layers and enhance reversibility. The intra-modular connections are placed 55 cm away from the ends for accessibility. Floor connections are accessed from the bottom, while thick panel connections are accessed from inside the module. Thin interior panels remain visible, allowing easy access for maintenance and replacement. Additionally, the upwind lumber placed on the base is elevated by 5 cm to allow the passage of plumbing and electrical systems underneath. Moreover, the FMs designed for bathrooms are specifically engineered to accommodate plumbing and electrical shafts, enabling them to pass through the entire height, from floor to floor. Prefab service components integrate control cabinet, thermostat, and distribution manifold in furniture modules for radiant heating. Plumbing and electrical connections are housed in accessible shafts for maintenance. Visible wiring enhances accessibility during maintenance. Detailed illustrations with the additional non-structural prefabricated elements to accommodate services can be found in Figure 4.

Figure 5A shows FM units making the external walls. In this case, a vapor-permeable water barrier and a primary layer of mineral fiber insulation are pre-installed off-site. The rainscreen can be then completed on site, incorporating a secondary thermal insulation layer to meet various thermal performance requirements. This approach provides a high degree of adaptability to various contexts within a standardized system. Additionally, decoupling the external parts of the rainscreen from the FM allows for easier management of shearing layers with different life expectancies. Figure 5B illustrates the window connection to an external wall module. Figure 5C depicts details for fire and acoustic separation between stacked modules and between two adjacent apartments. In the latter scenario, a prefabricated inter-module wall, meeting the necessary sound transmission class and fire resistance rating, is utilized. This wall, along with additional panels shown in Figure 4 for accommodating services, forms part of the non-structural kit-of-parts, facilitating customization of the basic module.

4.2 Housing and settlement proposal

The research aims to demonstrate the feasibility and versatility of the proposed FM concept and architecture plans. This is achieved by studying housing solutions for different users and designing a small housing development. The design proposals align with the circular economy criteria of “Design for attachment and trust” and the principle of designing long-life products, which are often overlooked in prefabrication.

The 75 by 75 cm grid of the FM system is also applied to the building designs. Within the proposed grid, specific “core” areas are designated for concentrated functions such as bathrooms and kitchens, while “open space” areas are designed to accommodate living rooms and bedrooms. This allows flexibility in accommodating different housing typologies. By manipulating the arrangement of these core and open spaces, a diverse array of compositions can be created, providing versatility and adaptability in the design. The arrangement of the housing solutions is derived from three main spatial combinations.

The first combination features a side core adjacent to an open space. This design provides access to windows for functions in the side core while ensuring privacy. It is well-suited for duplexes or small studio apartments where separation between the bedroom and living room is unnecessary.

The second combination involves a central core with open spaces on both sides. Although functions in this configuration do not have window access, natural light can reach the living rooms and bedrooms. It is suitable for small flats, and by extending the open spaces on the sides, it can accommodate small shops and workshops.

The third combination introduces a “rail” system where functions are positioned on the sides, creating an open central space. This building typology prioritizes access to natural light.

Examples of different floor layouts, employing the side core and open space, central core and open spaces on the sides, and rail system, can be observed in Figure 6.

Figure 7 presents seven housing solutions, including a small flat for one person, a flat for three people, a small flat accessible to people with disabilities, two options for a flat for two people, a proposal for a courtyard house for two people, and a duplex for two people.

4.3 Structural analysis

This section examines the viability of the proposed structural system, which utilizes FMs, and provides support through a structural analysis of an exemplary 2-story residential building (Figure 8). Given the limited dimensions of the building, and its structural simplicity, the standards allow a simplified linear static analysis (EN, 1998-1, 2004).

The structural analysis is conducted in accordance with European Standards, specifically EN 1995-1-1:2004 A2, 2014; EN 1998-1, 2004. The FM system is designed to withstand both gravity loads and lateral loads. Due to the advantageous ratio between the self-weight and strength of wood, the design is primarily governed by horizontal actions. The analysis considers worst-case wind and seismic load scenarios. For this purpose, two specific locations in Italy were selected to verify the design under high-demand conditions: Trieste and Ferla. Details of the structural analysis are reported in (Supplementary Appendix SA).

The design loads were determined using the EN 1991-1-1 standard, Italian NDP (Nationally Determined Parameters), and the relevant European Technical Assessment (ETA) documents for the building products.

For the seismic and wind actions, the resulting horizontal forces were distributed based on a linear static analysis, considering a 2-floor model with weak floor bands, which behaves like a simple 1 degree of freedom oscillator. The adopted combinations for seismic actions follow the life safety limit state (LLS), and for wind loads ULS (EN, 1991-1, 2002).

Results of the structural analysis show that the seismic horizontal action necessitated varying dimensions for the inter-modular connection and the thickness of the panels. In Trieste, it is feasible to utilize 100 mm-thick panels for the upright panel and a diameter of 120 mm for the inter-modular connection, employing an M18 8.8 steel rod. However, in Ferla, due to the higher seismic demand, it is necessary to increase the thickness of the panels to 158 mm and the diameter of the steel rods to 130 mm, employing an M24 8.8.

5 Conclusion

The research presented in this paper aimed to develop a typology of modular systems for rapidly deployable buildings that foster circular construction and explore opportunities for intermediate modular scales. The main objective was to propose a building system suitable for low-rise multi-story construction, based on load-bearing furniture modules (FMs) adhering to circular economy principles.

The research demonstrates the technical feasibility of the proposed FM-based building system, showcasing its potential for integrating vertical load bearing systems with other shearing layers, while allowing flexibility and maintenance of each of them.

The proposed solution aligns with circular economy principles by narrowing, slowing and closing resource loops. These three goals are achieved, respectively by optimizing materials, extending the service life of the construction, and enabling deconstruction and reuse of the modules at the end of the building’s service life. Resources optimization is achieved by combining different strategies: 1. Utilizing prefabrication and dimensioning FM to use halves of standard panel sizes allows for waste reduction 2. The FM design allows reducing the overall quantity of materials required by providing efficient use of space 3. Finally, the free-standing nature of the FMs eliminates the need for temporary work, and, with the easily assembled connections, reduces on-site skills, time, and costs.

Multiple strategies have been implemented to prolong the service life of the building and its components: 1) The FM system integrates easily accessible connections and replaceable parts, ensuring simplified maintenance and long-term durability; 2) Maintenance provisions encompass all shearing layers, including the structure, seal, skin, and services; 3) The system’s extended functionality is achieved through the versatility of compositions and layouts and its adaptability, allowing for space reconfiguration; 4) The furniture modules are based on dimensions that easily accommodate most furniture sizes, enabling the integration of standardized products into the project and facilitating replacement at the end of their service life.

Finally, the system is designed with a closed loop approach in mind. The FM design prioritizes ease of assembly and disassembly. The connections between adjacent and stacked FMs, as well as those between FMs and floor panels, are fully reversible. This design allows for the reuse of FMs at the end of the building’s service life. While the FMs can be reused without modifications for the same type of application, minimal adaptations will be required to add or remove non-structural components to assign the basic module a new function in a different building.

Considering the site-specific aspects, the research emphasizes the potential to design light, removable foundations, enabling the restoration of the land to its previous state. The research demonstrates the technical feasibility of adapting FM-based buildings to various contexts, including different environmental conditions and acting loads. The flexibility of the FM concept in adapting to local contexts is evident in the ability to use varying thicknesses for the upright panels. This adaptability is made possible by the 75 × 75 cm base module, which provides an additional 15 cm of space within each FM to accommodate the structural components. However, it should be noted that the FM design primarily aligns with European and North American standards. Further research is needed to develop FMs suitable for other regions and to customize the system according to different cultural contexts, which may influence aspects such as grid dimensions and product choices. Additionally, normative contexts and related design requirements should be considered in the adaptation process.

The proposed kit-of-parts encompasses non-structural components designed to address diverse needs, such as accommodating services or providing acoustic and fire separation. Further customization might be necessary to align with specific occupancy requirements and local standards. To further improve the kit, future exploration could focus on incorporating customizable prefabricated elements for the exterior skin. While the research has primarily focused on housing typologies, the inclusion of small shop designs in the master plan illustrates the versatility of FMs for various uses. This indicates the potential for expanding the application of FMs to address different housing types and destinations. While the proposed system is demonstrated within a specific locale in an open lot, its potential applicability in alternative contexts such as interstitial plots or high-density zones appears promising. However, further demonstration is required to confirm its viability in these settings. Future research should explore the boundaries of the proposed FM design and develop additional modules to cater to diverse requirements.

Another avenue worth exploring in future research is the integration of FMs within other construction systems or even existing buildings, thereby broadening the horizons for hybrid wood construction and adaptive reuse.

To enhance the integration of fabrication and design, future research can investigate design-driven parametric systems that incorporate FMs and evaluate their suitability compared to other available building systems. This would facilitate the development of optimized FM designs for specific contexts.

While the research has successfully addressed the technical feasibility of FMs, other aspects that require further investigation include the economic feasibility of implementing such a system, social and cultural acceptance, and environmental benefits over multiple life cycles.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

MR: Writing–review and editing, Writing–original draft, Validation, Supervision, Methodology. AD: Writing–review and editing, Visualization, Investigation, Formal Analysis, Conceptualization. MP: Writing–review and editing, Validation, Supervision, Methodology.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. Partial financial support was provided by the research project framework ReLUIS-DPC 2024-2026 (Italian University Network of Seismic Engineering Laboratories and Italian Civil Protection Agency).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fbuil.2024.1405500/full#supplementary-material

References

Ahn, N., Dodoo, A., Riggio, M., Muszynski, L., Schimleck, L., and Puettmann, M. (2022). Circular economy in mass timber construction: state-of-the-art, gaps and pressing research needs. J. Build. Eng. 53, 104562. doi:10.1016/j.jobe.2022.104562

Amran, Y. M., El-Zeadani, M., Lee, Y. H., Lee, Y. Y., Murali, G., and Feduik, R. (2020). Design innovation, efficiency and applications of structural insulated panels: a review. Structures 27, 1358–1379. doi:10.1016/j.istruc.2020.07.044

Asgari, H., Tannert, T., Ebadi, M. M., Loss, C., and Popovski, M. (2021). Hyperelastic hold-down solution for CLT shear walls. Constr. Build. Mater. 289, 123173. doi:10.1016/j.conbuildmat.2021.123173

Ballester, C. B., Matarese, L., and McCoy, C. (2023). Eames house conservation project. Cemesto panel investigations phase 1. Research report. Los Angeles, CA, USA: The Getty Conservation Institute.

Bergman, R., Puettmann, M., Taylor, A., and Skog, K. E. (2014). The carbon impacts of wood products. For. Prod. J. 64 (7-8), 220–231. doi:10.13073/fpj-d-14-00047

Bertram, N., Fuchs, S., Mischke, J., Palter, R., Strube, G., and Woetzel, J. (2019). Modular construction: from projects to products. McKinsey and Company: Capital Projects and Infrastructure, 1–34.

Bocken, N. M., De Pauw, I., Bakker, C., and Van der Grinten, B. (2016). Product design and business model strategies for a circular economy. J. Industrial Prod. Eng. 33 (5), 308–320. doi:10.1080/21681015.2016.1172124

Braungart, M., and McDonough, W. (2003). Cradle to cradle: remaking the way we make things. 1 ed. North Point Pr.

Canepa, S. (2017). Space for cooking in housing architecture. J. Civ. Eng. Archit. 11, 1038–1059. doi:10.17265/1934-7359/2017.11.006

Cavalli, A., Cibecchini, D., Togni, M., and Sousa, H. S. (2016). A review on the mechanical properties of aged wood and salvaged timber. Constr. Build. Mater. 114, 681–687. doi:10.1016/j.conbuildmat.2016.04.001

CINARK, and Vandkunsten Architects (2019). The construction material Pyramid. Available at: https://www.materialepyramiden.dk/ (Accessed May 11, 2022).

Dams, B., Maskell, D., Shea, A., Allen, S., Driesser, M., Kretschmann, T., et al. (2021). A circular construction evaluation framework to promote designing for disassembly and adaptability. J. Clean. Prod. 316, 128122. doi:10.1016/j.jclepro.2021.128122

DIN 68800-2 (2002). Wood preservation - Part 2: preventive constructional measures in buildings. Berlin, DE: DIN German Institute for Standardisation Deutsches Institut für Normung.

Eberhardt, L. C., Birkved, M., and Birgisdottir, H. (2022). Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 18 (2), 93–113. doi:10.1080/17452007.2020.1781588

EN 1991-1-1 (2002). Eurocode 1: actions on structures - Part 1-1: General actions - densities, self-weight, imposed loads for buildings. Geneva, CH: European Standard, European Committee for standardization.

EN 1995-1-1:2004 A2 (2014). Eurocode 5: design of timber structures - Part 1-1: General - Common rules and rules for buildings. Geneva, CH: European Standard, European Committee for standardization, CEN.

EN 1998-1 (2004). Eurocode 8: design of structures for earthquake resistance - Part 1: General rules, seismic actions and rules for buildings. Geneva, CH: European Standard, European Committee for standardization, CEN.

Follesa, M., Fragiacomo, M., Casagrande, D., Tomasi, R., Piazza, M., Vassallo, D., et al. (2018). The new provisions for the seismic design of timber buildings in Europe. Eng. Struct. 168, 736–747. doi:10.1016/j.engstruct.2018.04.090

Gasparri, E., and Aitchison, M. (2019). Unitised timber envelopes. A novel approach to the design of prefabricated mass timber envelopes for multi-storey buildings. J. Build. Eng. 26, 100898. doi:10.1016/j.jobe.2019.100898

Gesh, J., Baas, E. J., Longman, R., Riggio, M., Barbosa, A. R., Muszynski, L., et al. (2023). Effects of variable climate conditions on the behavior of post-tensioned mass timber wall panels. Oslo, Norway: World Conference on Timber Engineering, 17-23 June 2023.

Ghannad, P., Lee, Y. C., and Choi, J. O. (2020). Feasibility and implications of the modular construction approach for rapid post-disaster recovery. Int. J. Industrialized Constr. 1 (1), 64–75. doi:10.29173/ijic220

Guy, B., and Ciarimboli, N. (2008). Design for disassembly in the built environment. Philadelphia, PA: Hamer center for community design.

Haug, A. (2018). Defining ‘resilient design’ in the context of consumer products. Des. J. 21 (1), 15–36. doi:10.1080/14606925.2018.1395265

Huss, W., Kaufmann, M., and Merz, K. (2019). Building in timber. Munich, Germany: Room Modules. Detail.

Imperiale, A. (2012). “An American wartime dream: the packaged house system of Konrad Wachsmann and Walter Gropius,” in Proceedings 2012 ACSA fall conference, 27-29th september 2012.ISO 20887; sustainability in buildings and Civil engineering works—design for disassembly and adaptability—principles, requirements and guidance (Geneva, Switzerland: ISO), 35.

Knaack, U., Chung-Klatte, S., and Hasselbach, R. (2012). Prefabricated systems: principles of construction. Berlin, Boston: Birkhäuser. doi:10.1515/9783034611404

Open System Lab (2019). The DfMA housing manual: an introduction to the principles of design for manufacture and assembly (DfMA) for homes by open system Lab. Version 1.1. Available at: https://docs.google.com/document/d/1OiLXP7QJ2h4wMbdmypQByAi_fso7zWjLSdg8Lf4KvaY/edit?usp=sharing (Accessed May 11, 2022).

Ottenhaus, L. M., Yan, Z., Brandner, R., Leardini, P., Fink, G., and Jockwer, R. (2023). Design for adaptability, disassembly and reuse–A review of reversible timber connection systems. Constr. Build. Mater. 400, 132823. doi:10.1016/j.conbuildmat.2023.132823

Pozzi, L. E. (2019). Design for disassembly with structural timber connections—analysis and assessment of different connection systems used in engineered timber building structures to maximise demountability and reuse of the elements; faculty of architecture and the built environment. Delft, Netherlands: Delft University of Technology, 24.

Pujadas-Gispert, E., Sanjuan-Delmás, D., and Josa, A. (2018). Environmental analysis of building shallow foundations: the influence of prefabrication, typology, and structural design codes. J. Clean. Prod. 186, 407–417. doi:10.1016/j.jclepro.2018.03.105

Roscetti, D., Atkins, A., and Lacroix, D. (2022). “Prefabrication and modular construction—a potential solution to affordable and temporary housing in ontario?,” in Canadian society of Civil engineering annual conference (Cham: Springer Nature Switzerland), 497–511.

Shang, G., Ruoyu, J., and Weisheng, L. (2019). Design for manufacture and assembly in construction: a review. Building Research and Information. doi:10.1080/09613218.2019.1660608

Keywords: circular economy, design for reuse, timber furniture modules, load-bearing furniture, prefabrication

Citation: Riggio M, Dalle Vedove A and Piazza M (2024) Load-bearing furniture modules for fast deployable and reusable systems. Front. Built Environ. 10:1405500. doi: 10.3389/fbuil.2024.1405500

Received: 23 March 2024; Accepted: 13 June 2024;

Published: 17 July 2024.

Edited by:

Arianna Brambilla, The University of Sydney, AustraliaReviewed by:

Jorge Branco, University of Minho, PortugalHans-Christian Wilhelm, Curtin University, Australia

Copyright © 2024 Riggio, Dalle Vedove and Piazza. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mariapaola Riggio, bWFyaWFwYW9sYS5yaWdnaW9Ab3JlZ29uc3RhdGUuZWR1

Mariapaola Riggio

Mariapaola Riggio Alberto Dalle Vedove2

Alberto Dalle Vedove2