- 1Faculty of Technology Management and Business, Department of Construction Management University Tun Hussein Onn Malaysia (UTHM) Parit Raja, Batu Pahat, Malaysia

- 2Faculty of Civil Engineering and Built Environment, University Tun Hussein Onn Malaysia (UTHM) Parit Raja, Batu Pahat, Malaysia

- 3Department of Civil, Environmental and Natural Resources Engineering, Luleå University of Technology, Luleå, Sweden

- 4Department of Civil Engineering, School of Engineering, Monash University Malaysia, Selangor, Malaysia

- 5Faculty of Technology Management and Business, Department of Technology Management Universiti Tun Hussein Onn Malaysia (UTHM) Parit Raja, Batu Pahat, Malaysia

- 6Faculty of Engineering, Department of Civil Engineering, Universiti Putra Malaysia, Serdang, Malaysia

The construction industry, a pivotal business sector facilitating physical infrastructure and equipment provision, holds a significant indirect influence on diverse industries. This study investigates the role of supply chain management in enhancing sustainable construction practices within the Algerian construction industry. The research delves into the relationship between traditional supply chain management and sustainable construction, employing a quantitative approach. Data collection involved a survey comprising 61 items, utilizing a five-point Likert scale, gathered through an online survey method targeting managers, supervisors, executives, and suppliers in the Algerian construction industry. With 237 participants from construction companies in Algeria, the study utilized Smart PLS for data analysis, confirming a positive relationship between traditional supply chain management and sustainable construction through partial least squares (PLS) path analysis. The findings provide valuable insights for future stakeholders, guiding employers, designers, manufacturers, contractors, and suppliers to enhance supply chain management practices for sustainable construction in Algeria. Consequently, this study offers significant results with practical and theoretical implications, contributing to the integration of sustainable supply chain management in Algerian construction. In summary, the research addresses the relationship challenges between traditional supply chain management and sustainable construction practices in Algeria.

1 Introduction

The Algerian government has demonstrated a growing commitment to environmental protection by establishing institutions and legislation, encouraging companies to integrate ecological considerations into their actions (Trirat et al., 2017). The construction industry in Algeria has experienced notable growth across different markets, project types, and construction activities, providing critical insights into industry trends, challenges, and opportunities (Nikjow et al., 2021). As Aroua et al. (2010) asserts, the construction sector in developing countries like Algeria plays a pivotal role in the planning, design, construction, maintenance, and eventual dismantling of structures essential for economic activities. To realize socioeconomic benefits and reduce energy consumption, Algeria should prioritize investments in sustainable construction and passive housing (Trirat et al., 2017). The urgency of environmental concerns aligns with both local and international efforts towards sustainability—a contemporary theme that necessitates proactive preparation. Despite facing challenges, the Algerian construction industry has exhibited positive growth in the reporting period from 2012 to 2016, emphasizing the importance of continued focus on sustainable practices for future development.

The intricate relationship between construction and economic growth encompasses a spectrum of influences. Infrastructure, as highlighted by Razzaq et al. (2021), not only directly impacts production and consumption but also engenders numerous direct and indirect externalities. Moreover, it serves as a substantial source of expenditure, concurrently creating additional avenues for employment. Extensive research, exemplified by Livingston and Myers (2010), underscores the pivotal role of infrastructure in significantly affecting production, income, employment, international trade, and overall quality of life. The expansion of infrastructure extends beyond economic realms, manifesting positive effects on public health by reducing stress and curbing crime rates. In the broader context, infrastructure emerges as a linchpin in the integration of regional economies, as elucidated by Menhas et al. (2019). A robust and efficient infrastructure stands as a cornerstone for socio-economic development and regional growth. Adopting a dynamic perspective, transportation infrastructure emerges as a regional public good capable of reshaping production factors within and between countries, thereby fostering heightened productivity and accelerated growth.

This study is dedicated to establishing a conducive environment within the Algerian construction industry, fostering collaboration between the public and private sectors. The primary objective is to cultivate authentic construction businesses where stakeholders within the framework of Traditional Supply Chain Management (TSCM) align themselves to generate innovative ideas. These ideas, in turn, contribute to the creation of value, thereby enhancing competitiveness within the construction industry. The research outcomes not only unveil numerous opportunities but also pave the way for further investigation into SCM practices in Algeria. For organizations seeking to elevate their performance in design, manufacturing, distribution, and procurement, the adoption of SSCM is advocated. The study underscores the imperative for these entities to embrace sustainable construction practices, aligning with the vision of creating a lasting impact. As highlighted by Salhi and Messaoudi (2021), the construction industry in Algeria necessitates a paradigm shift in its supply chain management system to embrace sustainability in construction. Consequently, this study provides a strategic roadmap for future stakeholder’s employers, designers, manufacturers, contractors, and suppliers to harness the potential of Traditional Supply Chain Management for the cause of sustainable construction in Algeria. This may impact sustainable development drivers which are Economic, Social and Environment.

Limited research has delved into the intricate causative relationship between economic growth and construction investment within developing nations, yielding varied empirical findings on causality. Several studies posit that the construction industry plays a pivotal role in steering economic growth, forging tight interconnections with other sectors of the economy. Notably, housing expansion correlates with heightened employment and income opportunities, along with the facilitation of goods and housing services. The paramount objective of the construction sector lies in the provision of physical infrastructure, a vital cornerstone for addressing multifaceted challenges encompassing social networks, health, environment, development, and the broader economy (Harrison et al., 2010). Supply Chain Management (SCM) traditionally centers on production, provision, and distribution aspects. This conventional paradigm entails an integrated manufacturing process wherein suppliers furnish raw materials or semi-finished goods to manufacturers, subsequently culminating in final product assembly (Ellram and Murfield, 2019). The traditional supply chain encompasses a linear progression involving a supplier, manufacturer, wholesaler, retailer, and end customer (Belvedere & Grando., 2017). The imperative of broadening the conventional supply chain lies in encompassing the intermediate stages and potential environmental ramifications of all products (Shee et al., 2018).

2 Literature review

Sustainable construction involves the application of methods and technologies that enhance resource efficiency while minimizing negative environmental effects across the entire life cycle of buildings, spanning from the extraction of raw materials to the removal and disposal of components (Ngwepe & Aigbavboa, 2015). While construction activities inherently have some environmental impacts, sustainable construction aims to mitigate these impacts to a certain extent. In the 1990s, management scientists began exploring corporate environmental practices and advocated for a more comprehensive and responsible approach to supply chain management (Siracusa et al., 2014).

The term “supply chain management” (SCM) was introduced in the 1980s to underscore the integration of crucial business processes between end users and original suppliers (Salam and Khan, 2018). SCM encompasses the planning, execution, and effective oversight of supply chain operations, encompassing the acquisition of raw materials, inventory management, and the movement and storage of finished products from origin to consumption. However, construction activities frequently lead to substantial and irreversible environmental consequences, including natural resource depletion, pollution, and elevated energy consumption throughout the entire supply chain from the procurement of building materials to the end consumers (Kibert, 2016).

The notion of sustainable construction has garnered increasing attention in response to the growing imperative for environmental awareness. It is universally recognized as a fundamental principle in the realm of sustainable building, demanding careful examination of environmental variables (Ngwepe and Aigbavboa, 2015). In Algeria, since the 1980s, the government has exhibited a growing commitment to environmental preservation, instituting entities and regulations to incentivize companies to incorporate ecological considerations through the implementation of environmental actions (Trirat et al., 2017). The foundation of supply chain management lies in the optimal distribution of roles, activities, responsibilities, and authority among supply chain participants to secure and optimize the entire supply chain process (Tian, 2017). The focus should be on identifying the most effective and efficient methods for the entire supply chain to meet the final customer’s demands and ensure smooth operations.

In the realm of academia, the conventional approach to traditional supply chain management primarily centers on the production, provision, and distribution facets. It encompasses a cohesive manufacturing process wherein the supplier furnishes raw materials or partially completed goods to the manufacturer, who subsequently integrates them to produce the final products (Ellram and Murfield, 2019). However, in the initial stages of design, traditional supply chain management often overlooks the comprehensive analysis of various components (Belvedere and Grando, 2017). The extended supply chain typically comprises a supplier, manufacturer, wholesaler, retailer, and customer, intending to consider the environmental impacts of all products throughout their lifecycle (Shee et al., 2018). By extending the traditional supply chain, the focus expands beyond the immediate stages of production and distribution to encompass the entire lifecycle of the products. This holistic approach enables a comprehensive assessment of the environmental effects associated with the production, use, and disposal of the products involved in the supply chain. After the product’s lifecycle ends, any usable components are directly sent to the retailer, while non-usable parts are either recycled or disposed of. This study will develop an effective supply chain management framework to improve the current supply chain towards the sustainable construction industry in Algeria.

2.1 Sustainable construction

In the business context, sustainability refers to the ongoing value creation for both shareholders and stakeholders. A crucial aspect of sustainable value is that companies that serve society and the environment ultimately serve their clients and shareholders more effectively (Khan et al., 2017). Sustainable development, as discussed in the book “Conceptual Sustainability: Business Opportunities,” helps companies extend their lifespan, enhance the planet’s wellbeing, preserve the biosphere, support living beings, and protect and improve society (Khan et al., 2017). It entails the ability to preserve present and future resources, address challenges, maintain wellbeing, foster human participation, and uphold personal freedom. Sustainability necessitates that companies consider the social and environmental impact of their activities and daily operations (Epstein et al., 2018). Sustainable development has become a pressing global issue, encompassing concerns at both national and international levels in the contemporary world. (Elliott, 2012). The central theme of sustainability revolves around the tension between the increasing needs of the population and the degradation of Earth’s resources and environment.

2.2 Traditional supply chain management in the Algerian construction industry

The elements driving traditional SCM in the construction industry in Algeria encompass design, manufacturing, distribution, and purchasing. The definition of these drivers may vary depending on the researcher, particularly when incorporating environmental considerations into supply chain management (SCM). Incorporating various elements such as product design, material sourcing and selection, manufacturing processes, and post-utilization product management, this integration is comprehensive in its scope (Dekkers et al., 2013).

2.2.1 Drivers of supply chain management

The concept of “supply chain” or “logistics network” refers to a comprehensive system involving organizations, individuals, technologies, activities, information, and resources, all working together to facilitate the movement of products or services from suppliers to customers (Kain and Verma, 2018). Another definition characterizes the supply chain as a network of organizations engaged in various processes and activities, both upstream and downstream, intending to create value through end-user products and services (Salam and Khan, 2018). However, achieving success in sustainable development often poses significant challenges (Alwan et al., 2017). This success should encompass information exchange at multiple levels, including the systemic level where unsustainable building practices impact the biosphere, as well as strategic guidance and actionable steps in gradually adopting sustainable practices within the building sector.

2.2.1.1 Design

The initial phase of the product life cycle is the design stage. So, designers should use as many environmentally friendly product components as possible to reduce harm to the environment (Tischner and Charter, 2017). Organizations ought to engage in the creation of technologically advanced and environmentally friendly products to contribute to sustainable development (Baidoc and Bacali, 2017). The design is missing an energy management strategy that balances the demand for equitable energy consumption with the demand to reduce the cost of production to achieve sustainability (Silva et al., 2020).

2.2.1.2 Manufacturing

Sustainability is imperative, and manufacturing firms neglecting to incorporate sustainability into their strategic framework risk tarnishing their reputations and forfeiting significant business prospects (Montabon et al., 2016). The current manufacturing companies’ weaknesses are undoubtedly insufficient t o promote sustainable products (Almeida et al., 2017). From a manufacturing perspective, sustainability should be seen as the next logical step in the historic trend from manual, large-scale and flexible production to small-batch production. Either way, keep costs down by eliminating inefficiencies, waste and change. Braccini and Margherita (2018) stated that, as more and more external social and environmental factors enter the company’s bottom line, sustainable manufacturing has grown to identify and manage unforeseen production costs. Progressive companies are beginning to recognize that the field of sustainability offers opportunities to increase value beyond operational efficiency and risk management (Parida et al., 2019).

2.2.1.3 Distribution

The company asserts that, despite being a certified carbon-neutral organization, it has successfully achieved reduced energy consumption and emissions in its transportation operations (Silva et al., 2020). It should be noted that a considerable proportion of a company’s carbon footprint arises from its transportation and logistics activities, suggesting a lack of environmental awareness by not considering sustainable practices as a competitive advantage (Hammes et al., 2020). According to Adeitan et al. (2019), the distribution process in supply chains often faces challenges that result in deviations from planned schedules. These challenges include delays in delivering essential materials, incorrect and faulty shipments, large batch sizes, prolonged storage periods, involvement of multiple subcontractors and suppliers, insufficient training of contractors, suppliers, subcontractors, and workers, as well as inadequate supply chain management practices. These issues highlight the need for improvements in the distribution process to ensure smoother operations and more effective supply chain management.

2.2.1.4 Purchasing

In the broader context outlined, purchasing organizations are confronted with the additional responsibility of effectively managing sustainability aspects and risks within their supply chains (Xiao et al., 2019). In the realm of Procurement and Supply Management (PSM), the extent of sustainability management can be characterized as the amalgamation of environmental, social, ethical, and economic aspects in the administration of external resources. This holistic approach seeks to guarantee the procurement of goods, services, capabilities, and knowledge essential for an organization’s fundamental and auxiliary operations while considering the wellbeing of both the organization and society at large, along with the overall economy. By adopting this approach, the aim is to generate value that transcends the organization’s interests and extends to encompass societal and economic benefits (Miemczyk et al., 2012). Purchasing organizations will face even greater challenges shortly due to factors such as resource scarcity, stakeholder expectations, and increasing regulatory requirements. The authors highlighted that to implement sustainable sourcing practices, PSM should possess the necessary capabilities to manage stakeholders effectively. This suggests that collaboration and communication with stakeholders are crucial for achieving sustainability objectives in purchasing and supply management.

2.3 Sustainable supply chain management

The illustration of sustainable supply chain management is the integration of sustainable development principles with supply chain management practices. It recognizes that sustainable development encompasses environmental, social, and economic dimensions, all of which are essential for human progress. Within the realm of supply chain management, sustainable development principles influence corporate strategies and behaviours, aiming to create a more sustainable and responsible approach to sourcing, production, distribution, and consumption. By incorporating sustainability considerations into supply chain decision-making, organizations can strive for long-term environmental stewardship, social responsibility, and economic viability. There has been a significant increase in interest in SCM in recent years (Dadhich et al., 2015). In his work, Das (2018) defines SCM as a strategic and transparent integration aiming to accomplish the social, environmental, and economic goals of an organization by revamping, skilfully synchronizing critical inter-organizational business procedures to elevate the overall economic prosperity of both the individual company and its supply network.

Research on logistics social responsibility (LSR) has explored various processes such as procurement, transportation, packaging, storage, and reverse logistics. These studies have identified six main thematic areas of LSR: the environment, ethics, diversity, working conditions, human rights, and security. In addition, investigations into sustainable supply chain practices, specifically environmental procurement, have revealed linkages between conventional procurement activities and environmental management. It is important to emphasize that sustainable transport refers to transportation that fulfils mobility requirements while concurrently fostering the preservation and enhancement of human health, ecosystems, economic development, and social equity for both current and future generations (Dadhich et al., 2015).

2.3.1 Outcomes of sustainable supply chain management in the construction industry

According to Choi et al. (2012), environmental performance can be improved through business interactions based on proximity, and establishing relationships with suppliers can facilitate the introduction and development of innovative environmental technologies. Collaborative efforts involving employees from both customers and suppliers, as well as agreements for joint research and development, can enhance environmental performance. Regarding supply chain performance, the short-term objective primarily revolves around increasing productivity, reducing inventory levels, and minimizing cycle times. Conversely, the long-term goal is to enhance market share and profitability for all participants in the supply chain. Financial indicators are used as a tool to compare and evaluate an organization’s performance. With escalating global competition from a supply chain perspective, supply chain efficiency has become a crucial source of sustainable advantages across various industries (Liu et al., 2018).

As a result, supply chain management serves a twofold purpose by improving the operational efficiency of individual businesses and contributing to the overall efficiency of the entire supply chain. (Kwamega et al., 2018). A study by Ji et al. (2016) suggested that environmental design should consider both the product’s function and the minimization of its environmental impact throughout its life cycle. Consequently, the design phase presents an opportunity to develop an effective product that is both cost-effective and environmentally sustainable. Purchasing practices need to consider the potential higher costs of materials and the limited availability of qualified suppliers due to the demand for specialized materials and components. It is essential to navigate these challenges to ensure the procurement of environmentally friendly products (or products with a reduced environmental footprint) while considering the associated costs and supplier availability. To find environmental solutions, manufacturers and suppliers need to improve their relationships and collaboration.

2.3.2 Challenges facing SSCM in the Algerian construction industry

SSCM is still relatively new to most companies in many industries (innovative) SSCM provides an appropriate approach to improving the performance of the construction industry as it will help reduce the fragmentation of industry relationships. The main Challenges to implementing SSCM can be identified as.

2.3.2.1 Technology

To implement SCM, the industry must adapt and keep up with the latest trends and technologies. A deficiency exists in novel technologies, materials, and procedures, with company’s generally demonstrating reluctance to respond to inquiries focused on enhancing environmental performance. Construction companies are particularly known for lacking both the quantity and technical knowledge of human resources required to pursue environmental management (Shao et al.,.2021). Some concerns simplifying administrative and legislative burdens for companies may result in lower environmental standards, with ongoing fears of overlapping and contradictory legislation.

2.3.2.2 Finance

The primary obstacle to executing SSCM practices within high cost involved. This is attributed to the fact that domestic consumers are not willing to spend more money on eco-friendly products. Although domestic consumers are not necessarily unaware of sustainability, they tend to select the least expensive option when presented with products that have similar performance. The investment cost of adopting practices, such as environmental management systems, remains high due to a lack of customer awareness and pressure regarding SSCM. Consequently, manufacturers are more inclined to adopt practices as they do not negatively impact profits (Salhi and Messaoudi, 2021)

The Algerian government has prioritized property development as part of its spending initiatives. Recognizing the significance of providing affordable housing to a growing population, the government has committed €58bn in funding to construct 1.6 million new homes by 2019, aiming to address the current housing shortage. Considering the 650,000 units that were still under construction in 2014 as part of the previous 5-year plan, the total number of housing units required by the end of 2019 would exceed 2.2 million (Tabet and Kahf, 2018).

2.3.2.3 Knowledge

Companies promoting environmentally friendly systems in the professional industry face exposure to less sustainable alternatives. There are barriers to reducing waste and increasing profits. The limited use of environmental management systems is attributed to ignorance and lack of awareness regarding wellbeing. Technology is intended to bring environmental benefits. In the construction sector, environmental issues are increasingly important, and companies must prioritize the efficient use of energy and resources to establish an environmentally responsible supply chain (Nidumolu et al., 2009).

Outsourcing the monitoring and measurement of suppliers’ environmental performance is a complex process. The Algerian construction industry lacks sufficient monitoring and measurement systems for assessing suppliers’ environmental activities. Due to the absence of guidelines and laws on environmental management, the industry lacks clarity on what aspects to measure and how to measure them. It is crucial to protect environmental suppliers. Moreover, the issue of outsourcing new knowledge and working with suppliers in the context of technical data protection has been identified as problematic (Zirpoli and Becker, 2011).

2.3.2.4 Recycling

Algeria faces a deficiency, which is a key challenge to overcome that conflict. This situation often fluctuates, and the implementation of e-waste reverse logistics is sporadic in accordance with the National Solid Waste Directive. Nevertheless, major companies have already established collection points for products that are no longer in use in Algeria (Eddine and Salah, 2012).

2.4 Relationship between traditional SCM and sustainable construction

Organizations are progressively prioritizing the development of technologically advanced and environmentally friendly products to attain sustainability in their product offerings (Kostova, 2019). An integrated manufacturing process involves suppliers providing raw materials or partially processed goods to manufacturers, who then assemble them into final products. Subsequently, these finished goods are dispatched to wholesalers and retailers that ultimately deliver to customers, encompassing all the parties involved, including suppliers, manufacturers, distributors, wholesalers, retailers, and customers, both directly and indirectly. This comprehensive process involves the seamless integration of physical distribution, information flow, and financial transactions (Currie et al., 2020). Within the domain of purchasing and supply management, an exploration of the factors influencing the integration of environmental and social considerations in supply chain management reveals a significant impact on a firm’s external supply base (Schulze and Bals, 2018). As expectations regarding sustainability performance and sustainable supply chain management continue to rise, the role and responsibilities of the purchasing department transform. In this context, the explicit knowledge held by buyers concerning international labor standards or environmental benchmarks like ISO 14001 is pivotal (Schulze and Bals, 2018).

Traditional Supply Chain Management can play an important role in architecture. It provides general guidelines for analyzing, redesigning, and coordinating the entire supply chain of the building and continuous improvement, solving basic problems, and controlling short-sighted supply chains. Because the results of the traditional supply chain management apply in Algeria, these are not defecting without the most important defects. The complexity of the design is based on the wishes of the customer, the change of the customer’s wishes, the discussion of the lengthy change process and the interaction with other participants during the presentation and the design. Logistics: large quantities, improper packaging, bad weather or political circumstances, long shelf life. Problems occur in the local community due to quality or security issues. Unresolved quality and technical issues that delay the completion of work delays. Supplier and procurement interface: inaccurate data, unfulfilled technical specifications, other changes, lack of coordination between suppliers, cooperation and commitment, inferior materials, and components. Ike et al. (2018) found that waste management practices are not yet fully implemented, as they are not closely related to existing legislation on waste management, treatment, and disposal.

The term “supply chain” denotes the critical stage through which building materials traverse before seamlessly integrating into a project’s permanent structure. Existing literature and empirical evidence from prior studies underscore the pivotal role of supply chain dynamics within the construction sector in Algeria, shedding light on its potential benefits. However, it becomes evident that certain sustainable supply chain practices, which have demonstrated compelling environmental advantages in developed nations through their commitment to eco-friendly production, are yet to be fully embraced. Consequently, this research aims to discern and elucidate the correlation between the conventional drivers of traditional supply chain management, namely, design, manufacturing, distribution, and purchasing, and the prospects for sustainable construction practices in the Algerian context.

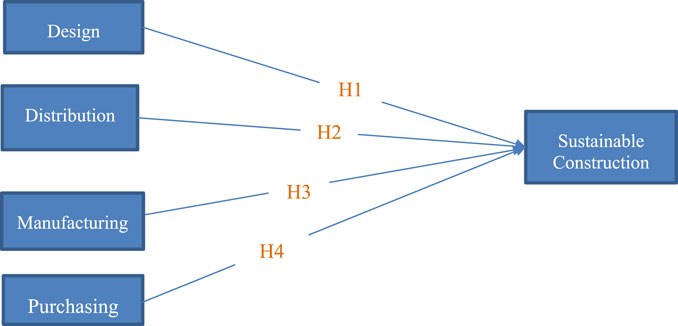

2.5 Conceptual framework

The final conceptual framework of this research is shown in Figure 1 below. The evaluation of this model and approval of the multiple relationships between traditional supply chain management and sustainable construction have been achieved in the empirical part of this study through a survey of Algerian construction industry stakeholders. The model fit of the conceptual framework is examined using quantitative methods.

The present study utilizes the depicted conceptual framework to illustrate the interconnection among the variables investigated. The Independent Variables investigated in this research pertain to traditional supply chain management practices, while the Dependent Variable focuses on sustainable construction. The objective of this research is to enhance the construction industry in Algeria, specifically focusing on the implementation of Sustainable Construction principles in terms of economic, social, and environmental aspects. The study aims to identify strategies and practices that promote sustainability within the construction sector, considering economic viability, social wellbeing, and environmental preservation. By addressing these dimensions, the research aims to contribute to the overall improvement of the construction industry in Algeria towards a more sustainable future. The emerging proposal of the knowledge gap led to the formulation of the research framework as an area of further study. A questionnaire is a tool for gathering information that describes, compares, or interprets the knowledge, attitudes, and/or socio-demographic characteristics of a target audience.

3 Methodology

This research adopts a quantitative methodology, employing a questionnaire survey to assess the comprehension of sustainable supply chain management within the construction industry among key stakeholders in Algiers, the capital city of Algeria. The primary aim of the survey is to scrutinize the perceptions of respondents concerning the sustainability practices in the Algerian construction sector. Focusing specifically on Algiers’ construction landscape, the study targets individuals holding pivotal roles such as Managers, Supervisors, Suppliers, Executives, and researchers/academic institutions. This diverse selection reflects the significance of enriching the construction industry in the region through varied perspectives. In order to ensure the research’s validity and delineate the research problem, a preliminary investigation was diligently conducted. The survey was distributed both online and in hard-copy format, capturing data from respondents affiliated with organizations and companies involved in conventional supply chain practices within the Algerian construction domain. The study’s demographic scope encompasses contractors and industry experts in Algiers, spanning managerial, supervisory, and academic roles.

A modified questionnaire survey was used, and experts were consulted to identify and address any issues with the survey questions. Pre-testing of the questionnaire involved obtaining feedback from professionals in the same field. These professionals were asked to focus on aspects such as wording, comprehension difficulties, and data collection variables, and to highlight any major concerns or suggestions. The pre-test was carried out with the participation of five professional lecturers from the faculties of construction management, as well as experienced engineers with expertise relevant to the study area in the Algiers construction industry. The feedback obtained from the pre-test was instrumental in refining the language and format of specific survey questions. A pilot study was carried out before the precise data collection. In this study, the questionnaire was distributed to 50 participants of public and private clients, contractors and consultants, and 46 questionnaires were returned. There were no changes required to the questionnaire.

The research necessitated a sample size determination involving 350 respondents, following the methodology outlined by Krejcie and Morgan (1970), and this methodology found support in the work of Rahi (2017), given the total population size of 4,076 within the Algiers construction industry. Employing both online and hard-copy formats, the survey utilized a mixed distribution method to enhance participation. Ultimately, the final sample size, totalling 237 participants, adhered to the guidelines set by Krejcie and Morgan (1970) and was endorsed by Rahi (2017), taking into careful consideration the size of the population under study. The survey, targeting stakeholders of construction companies in Algiers, Algeria’s capital, collected data through the distribution of 350 questionnaires. The participants, including Managers, Supervisors, Suppliers, and Executives, were strategically chosen as representatives of key stakeholders in the Algerian construction industry. Respondents were tasked with rating their evaluations on a five-point scale, aligning with the categories outlined by Zikmund et al. (2013) and Ajayi and Oyedele (2018), where 1 indicated “Strongly Disagree,” 2 indicated “Disagree,” 3 indicated “Neither Agree nor Disagree,” 4 indicated “Agree,” and 5 indicated “Strongly Agree.”

4 Results and findings

4.1 Respondents rate

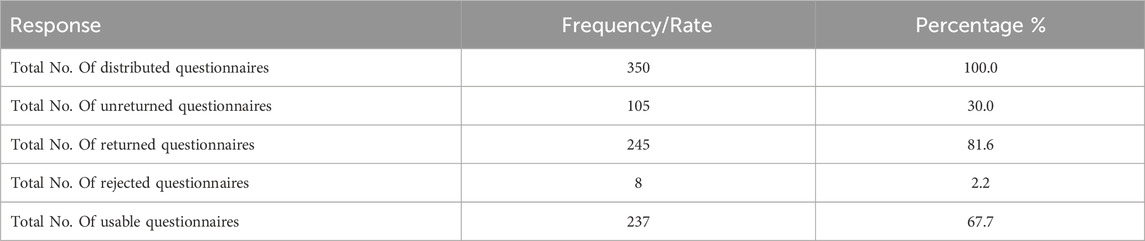

Among the 237 questionnaires received from the construction companies involved in this research. The collected questionnaires for unusable questionnaires (either blank or partially completed only) were examined, and 8 of the questionnaires were excluded from the analysis. With 237 useful returns and questionnaires out of 350, the response rate was 67.7%. The response rate is demonstrated in Table 1.

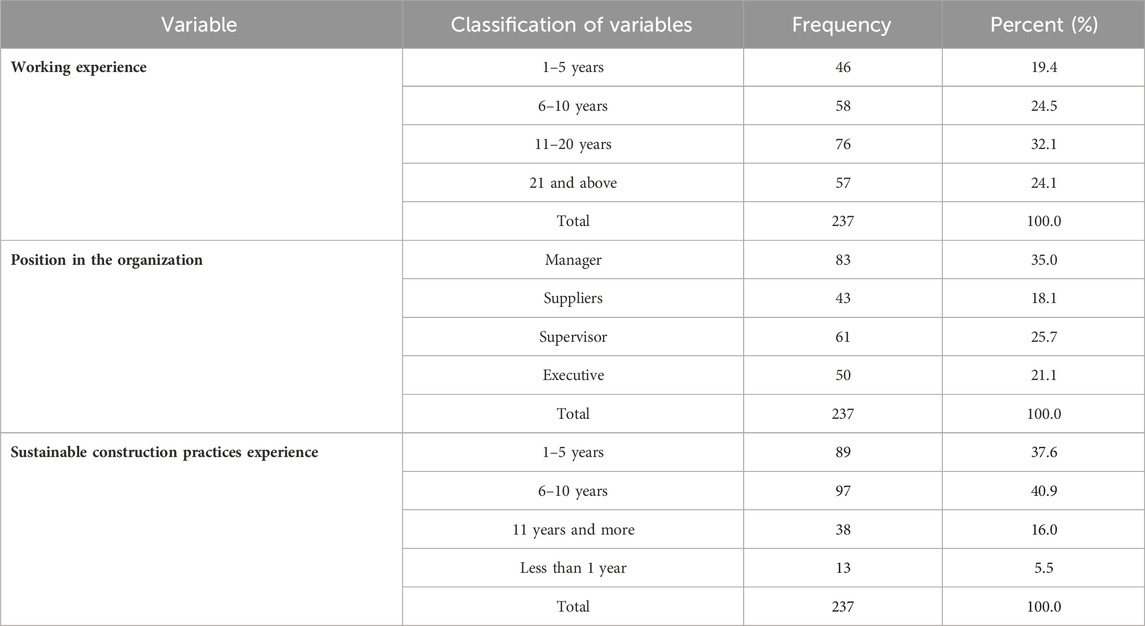

4.2 Respondents profile

The frequency distribution and the percentage of respondents are presented and discussed based on the respondents’ demographic characteristics. Table 2 demonstrates the survey participants’ characteristics. The analysis unit includes organization. Demographic information includes position, working experience, Years of working experience, Designation, and Employment status, as shown in Table 2.

The essence of structures in the social sciences shows a variety of scales and metrics that can contribute to positive or negative skewness (Pallant, 2010). Feurer et al. (2015) contended that the cutoff value between +3 and −3 is still acceptable. As for the kurtosis values, Alotaibi. (2014) claimed that the acceptable range is from +3 to −3. Normality can be verified by calculating the skewness and Kurtosis ratings in SPSS as shown in Table 3.

4.3 Model assessment

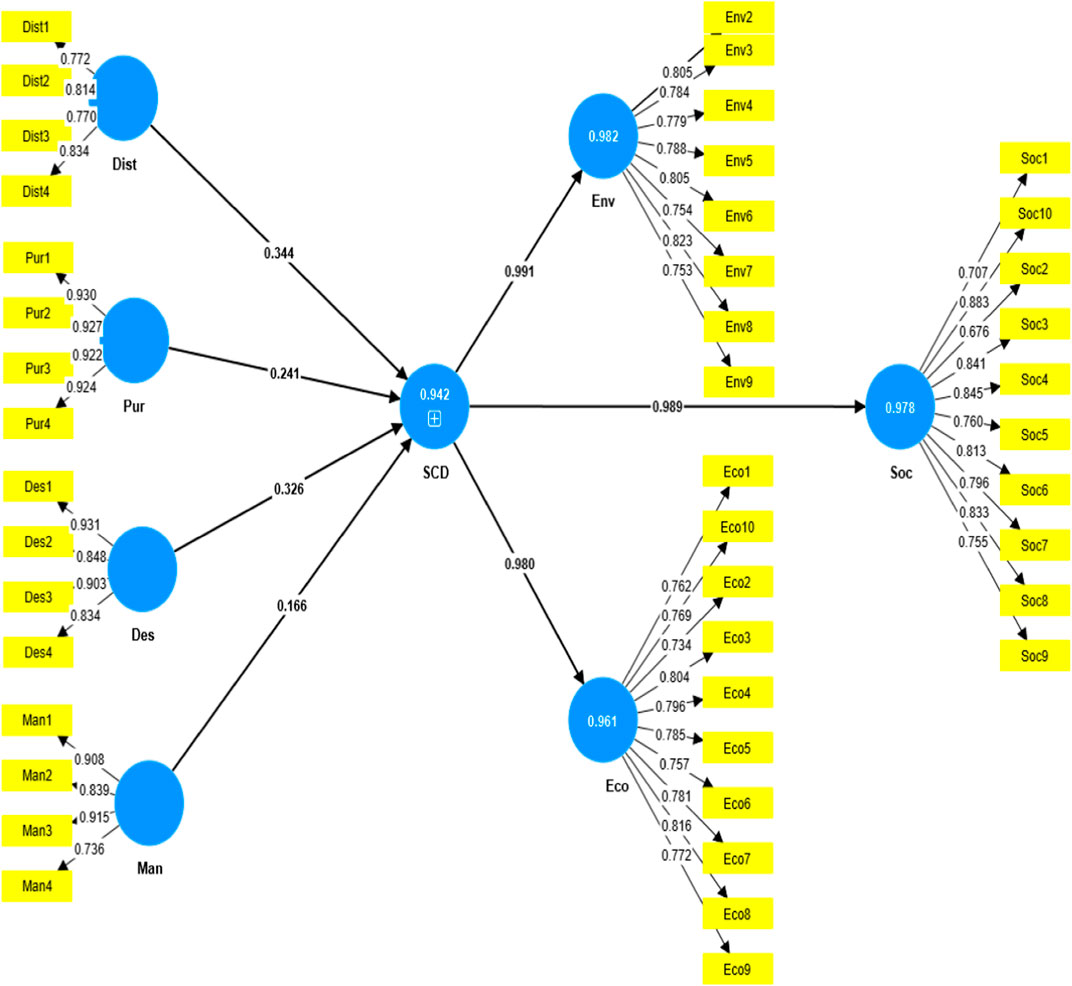

The measurement validity test is applied to the entire first-order construct that is the subject of their reflective model. Design, Distribution, Manufacturing, and Purchasing, as well as Environment, Economic, and Social, are reflective variables within the first-order construct.

4.3.1 Convergent validity—factor loading (outer loading)

Loadings gauge the interchangeability of items within the same construct, with higher loadings indicating greater consistency among the items. Hair et al. (2014) proposed a standard threshold of 0.70 for factor loadings, indicating that loadings surpassing this criterion demonstrate stronger consistency in measuring the construct. In line with this criterion, all factor loadings in the current study were found to be above the recommended threshold of 0.70, ranging from 0.707 to 0.931, as shown in Table 4.

4.3.2 Convergent validity—composite reliability

The composite reliability (CR) is a distinct technique for assessing reliability. To determine whether the build indicators adequately represent the latent variable, it is recommended that the CR value exceeds 0.70. In this study, all of the CR values surpassed the suggested threshold of 0.70, ranging from 0.875 to 0.944, as presented in Table 4.

4.3.3 Convergent validity—average variance extracted

The average percentage of variance (AVE) is a statistical measure that quantifies the average amount of variation captured by the observed variables within a latent construct. A higher AVE indicates that the latent variable explains a larger proportion of the variation in its predictors. According to Henseler and Sarstedt. (2013), the recommended standard value for AVE is above 0.50. This means that the latent variable should account for more than half of the variance in its predictors on average. Meeting this threshold indicates a satisfactory level of explanatory power and reliability for the construct, as shown in Table 4.

4.3.4 Discriminant validity

Discriminant validity, as determined by empirical criteria, assesses the distinctiveness of a construct from other constructs. It examines the associations between measures of potentially incompatible structures to measure distinct definitions (Hair et al., 2014). It aims to determine how closely constructs within a product, for example, are related to each other compared to another construct. Discriminant validity is confirmed when the square root of the AVE is higher than the correlation between variables within each pair, as shown in Table 4.

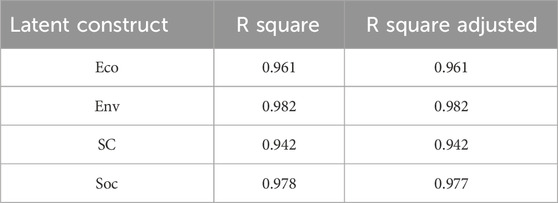

4.3.5 Coefficient of determination R2

The coefficient of determination known as R2, plays a crucial role in assessing the structural model in partial Least Squares Structural Equation Modeling PLS-SEM. It measures the extent to which the variation in the endogenous variables can be explained by the exogenous variable(s). The reliability of the structural model relies on the R2 values, which demonstrate the ability of the exogenous variables to account for the endogenous variables. In this study, all R2 values met Chin’s (1998) criteria, as indicated in Table 5.

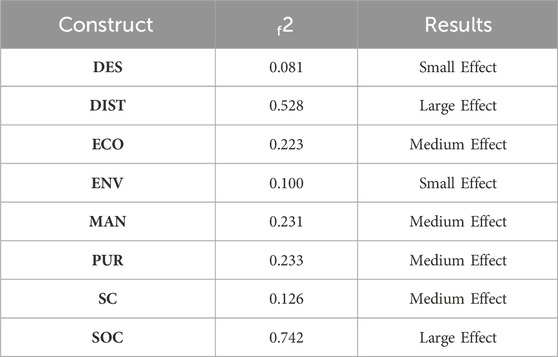

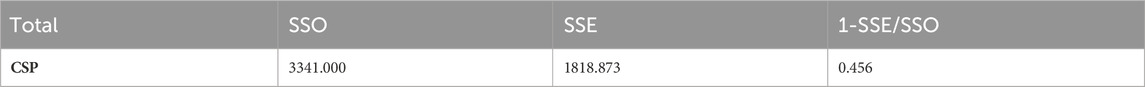

4.3.6 The effect size (f2)

The computation of the effect size (f2) involves meticulous analysis of the observed alterations in R2, a methodology meticulously delineated by Hair et al. (2017). According to Table 6, the effect size of DES, DIST, ECO, ENV, MAN, PUR and SOC on SC were small, large, medium, small, medium, medium and large. Subsequently, the discourse shifts towards the realm of predictive relevance, denoting the structural model’s efficacy in forecasting increased relevance for each indicator of the endogenous variable. As articulated earlier, the PLS-SEM approach harmonizes seamlessly with the current investigation when the cross-validity redundancy value in Table 7 (Q2) surpasses zero, aligning with the insights provided by Sarstedt and Cheah, (2019). This strategic integration of methodological principles ensures a robust and comprehensive analytical framework within the academic ambit.

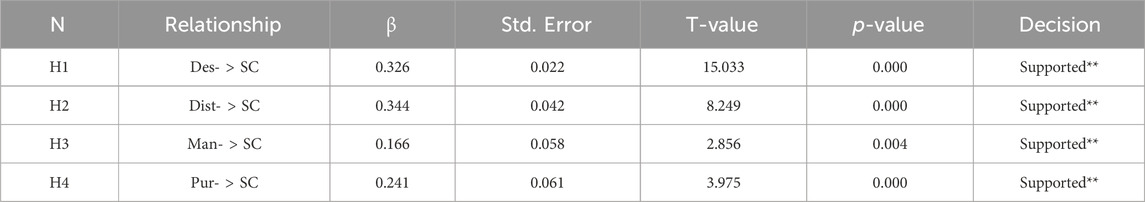

4.3.7 Hypotheses testing path coefficient

The final step is testing the structural model involves examining the study hypotheses by calculating the path coefficients. To investigate the hypothesized relationships, the method of bootstrapping was employed. Bootstrapping is particularly useful in PLS-SEM because it allows for estimating the normality of the data. Unlike other statistical techniques, PLS-SEM does not rely on assumptions about the underlying distribution of the data. Instead, it is distribution-free, which makes nonparametric bootstrapping a suitable approach for assessing the accuracy of the PLS estimates.

This study’s measuring model was put to the test in accordance with the SEM literature’s recommendations (Hair et al., 2017). The results, as predicted by Fornell and Bookstein (1982), meant that all values were higher off-diagonal. As a result, the discriminant validity test was able to satisfactorily demonstrate the validity of the measurements. Figure 2 shows the final exact and true measurement model created with Smart-PLS Version 3.2.7.

After assessing the measurement model’s reliability and validity, the structural model is assessed. As proposed by Ramayah et al. (2018), Hair et al. (2017), and Hair et al. (2017), six separate tests were used to assess the inner model (2019). Lateral collinearity, coefficient of determination (R2), impact size (f2), predictive relevance (Q2), and direction coefficient are the various measures.

5 Hypotheses analysis and discussion

The response rate achieved was 67.7%, with 237 complete and usable survey tools returned by the respondents. Out of the 237 questionnaires received from the construction companies, the collected questionnaires were carefully examined to identify any unusable ones. In total, 8 questionnaires were excluded from the analysis due to being either blank or partially completed. The final dataset used for analysis included 237 profitable returns and questionnaires out of the initially distributed 350, resulting in a response rate of 67.7%. The data from 237 surveys was imported into SPSS 24, where it was thoroughly reviewed for missing tests. According to the comprehensive data results, eight questionnaires had missing responses from the returned questionnaires. Because of the sensitivity of Smart PLS, addressing missing data before completing the analysis is crucial. They have data missing for ring (2–9) items, which was between (2 percent and 10%) but below the 30% cutoff. Because the missing data values were discovered to be missing in a completely random manner, the mean replacement approach was used (Pallant, 2010; Hair et al., 2017).

In this study, the examination of reflective construct item loadings revealed that the minimum acceptable threshold for determining the close-off value is 0.70, as suggested by Hair et al. (2014). It is important to note that both the composite reliability (CR) and average variance extracted (AVE) should surpass the recommended thresholds of 0.70 and 0.50, respectively. This is in line with Fornell and Larcker’s (1981) viewpoint that Cronbach’s alpha is a measure of convergent validity. These reliability and validity criteria serve as benchmarks to ensure the robustness and consistency of the measurement model in capturing the constructs under investigation. Hair et al. (2014) corroborate (Considine et al.,2005) stance on CR’s reliability, arguing that, unlike Cronbach’s alpha, CR has a stronger relation to internal consistency. The full summary of validity calculation is provided in Table 4 with the essential values of the thresholds taken into account.

In line with this, our findings indicate positive relationships between Des, Dist, and Pur with SC (β = 0.319, p < 0.000; β = 0.284, p < 0.000; β = 0.104, p < 0.043), providing support for hypotheses H1, H2, and H4. These results suggest that Des, Dist, and Pur have a positive impact on SC. However, our study did not find support for hypothesis H3 (β = 0.051, p < 0.158), indicating that Dist, Man, and Pur do not significantly contribute to sustainable development. Consequently, organizations seeking to enhance their supply chain should focus on improving design, manufacturing, distribution, and purchasing indicators.

The study’s main objective was to investigate the traditional supply chain management (TSCM) and sustainable construction (SC) in the Algerian construction industry. Design, manufacturing, distribution, and purchasing are the four dimensions of traditional supply chain management (TSCM) used in this analysis. The findings showed that the TSCM dimensions (design, manufacturing, distribution, and purchasing) explained 95% of the sustainable construction (R2 = 0.952).

Further, to find out the main objective of this study, four hypotheses were developed. According to Table 8 the first hypothesis was developed to examine the significant relationship between design and sustainable construction (Hypothesis 1). The result revealed that design relates to the sustainable construction (β = 0.319, t = 14.277, p > 0.000). The second hypothesis was developed to examine the insignificant relationship between manufacturing and sustainable construction (Hypothesis 2). The result indicated that manufacturing relates to the sustainable construction (β = 0.051, t = 1.414, p > 0.158). The third hypothesis stated that there is a significant relationship between distribution and sustainable construction (Hypothesis 3). The result also indicated that distribution relates to sustainable construction (β = 0.284, t = 7.361, p > 0.00). The fourth hypothesis states that there is a significant relationship between purchasing and sustainable construction (Hypothesis 4). The result also indicated that purchasing relates to sustainable construction (β = 0.104, t = 2.028, p > 0.043). Based on the empirical tests conducted in the previous chapter, it was clear that only three hypotheses (H1, H3, and H4) from the four dimensions of TSCM showed significant effects on sustainable construction. On the contrary, only one dimension (H2) failed to predict sustainable construction.

In addition to consumer pressure, industries are currently under pressure to implement environmental policies due to government legislation and global competition. As a result, businesses are compelled to adopt sustainable practices in order to boost their environmental rather than economic efficiency. The Sustainable Supply Chain Management (SSCM) scheme guarantees environmentally friendly activities in conventional supply chains. Developing-country industries, such as Algeria’s, are under pressure from a variety of sources to implement SC in traditional SCM. As a result, it was shown in this analysis that only one of the four dimensions of TSCM, manufacturing, is insignificantly linked to sustainable building.

It eventually becomes economically viable, long-term, and socially appropriate (Chowdhury et al., 2019). Even though SSCM alleviates environmental problems by providing economic benefits to organizations (Chowdhury et al., 2019), the theory of SSCM is largely ignored in the construction sector when it comes to waste reduction. According to previous reports, developed countries have made substantial improvements in SSCM compared to developing countries. Even though there is an insignificant relationship between the SSCM and the SC, it has been discovered to date. Despite the increasing concern about environmental sustainability, there has been little improvement in Bangladesh’s construction industry in terms of SSCM practices (Chowdhury et al., 2019). According to Testa and Irlado (2010), there is a connection between implementing SSCM practices and improving an organization’s credibility and brand image. Sustainable supply chain management (SSCM) has emerged as an industry’s antidote to sustainability.

This study employed a comprehensive analysis of existing literature and survey outcomes to elucidate responses to the research inquiries and unveil significant findings. The survey results strongly indicate that TSCM, when integrated with robust relationships, manifests a positive impact on sustainability. Consequently, organizations adopting TSCM not only prioritize financial outcomes but also demonstrate a commitment to cultural and environmental responsibilities. The preliminary findings underscore a promising trajectory for future investigations into the mechanisms and rationales behind organizations fortifying TSCM practices to secure a competitive edge in the contemporary market. This research, conducted within the Algerian context, aspires to contribute substantially to the current body of literature and significantly bolster the construction sector. The overarching goal is to enhance the industry’s performance, thereby positively influencing the Algerian economy as a whole.

6 Limitation of the study

This study bears certain limitations that warrant consideration for future research endeavors. Primarily, the exclusive participation of respondents from a single country might restrict the generalizability of findings, given the potential influence of regulatory environments, national culture, and institutional backgrounds on TSCM efficiency. Replicating this study in diverse geographical contexts could enrich this relatively under-explored domain, offering fresh insights and augmenting the existing knowledge base. Incorporating qualitative or multilevel research designs alongside quantitative analysis, possibly integrating exploratory techniques like in-depth interviewing, may further enhance the comprehensiveness and depth of future investigations in this field. Employing a mixed-method approach, which combines quantitative and qualitative methodologies, remains an unexplored avenue that could strengthen future studies in this area.

7 Conclusion

Sustainable development has evolved into a multifaceted concept, extending beyond mere economic stability to encompass environmental impact, resource utilization, and social implications. This research underscores sustainable construction as a vehicle for disseminating environmental principles among workers. The study conducted in Algeria is poised to enrich existing literature and significantly uplift the country’s construction sector. By examining the interface between these domains, this research aimed to offer valuable insights to researchers and practitioners, potentially advancing both the construction industry and the Algerian economy.

The study’s primary objective was to deepen understanding of supply chain management’s significance in construction, revealing a significant positive relationship between independent and dependent variables. It emphasizes the necessity of integrating Sustainable Supply Chain Management (SSCM) for construction industry enhancements. Recognizing the importance of sustainable attention for industry improvement, this research yields substantial managerial and theoretical implications for integrating TSCM toward sustainable construction practices. This study significantly contributes by demonstrating how integrating TSCM positively impacts sustainability in the Algerian construction sector, highlighting its cultural, environmental, and financial aspects. It underscores the pivotal role of sustainable supply chain management integration in advancing construction practices and fostering economic growth within Algeria.

8 Recommendations

Based on the results of this research, the following recommendations are presented for Algerian construction industries interested in diminishing their environmental footprint and improving their sustainable construction.

a) Make certain that top executives support environmental initiatives. For example, top executives must integrate environmental issues into the company’s vision and mission, as well as include the environment in long and short-term priorities and ensure that agreed-upon practices are properly enforced and monitored.

b) Concentrate on management strategies, such as recruiting staff, to raise employee awareness and knowledge about the environment. Rewarding workers through benefits and compensations should all be included in the recruiting process, as this would lead to greater loyalty and devotion to the new culture.

c) By identifying the principles, standards, initiatives, and laws, the construction industry must incorporate environmental concerns into all facets of its operations. Adopting an ISO 14001 will also help you monitor your long-term results.

Data availability statement

The datasets presented in this article are not readily available because The data that support the findings of this study are available on request from the author. The data are not publicly available due to privacy. Requests to access the datasets should be directed to AH, YWhtZWQuaGFyb3VhY2hlMTdAZ21haWwuY29t.

Author contributions

AH: Writing original draft, format analysis. MA: Writing, review and editing. YG: Conceptualization, Methodology, project administration. AA-S: Data curation. AM: Validation. All authors contributed to the article and approved the submitted version.

Acknowledgments

The authors would like to extend their heartfelt appreciation to the University Tun Hussein Onn Malaysia and the Faculty of Technology Management and Business for granting the opportunity to pursue PhD studies. The academic environment provided by the university has been invaluable in shaping research and enhancing knowledge in construction management. Also grateful to the stakeholders of the construction industry in Algeria for their support and collaboration. We are committed to utilizing the knowledge and experiences gained during my PhD journey to contribute to the advancement of our field.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ajayi, S. O., and Oyedele, L. O. (2018). Critical design factors for minimising waste in construction projects: A structural equation modelling approach. Resources, Conservat. Recycl 137 (May), 302–313.

Aroua, A., Berndt, H., Bitter, J. N., Gopin, M., Hussain, A., Kartas, M., et al. (2010). Transforming conflicts with religious dimensions: methodologies and practical experiences. In CCDP Conference Report. Zürich: Center for Security Studies (CSS).

Adeitan, D. A., Aigbavboa, C. O., Emem-Obong Agbenyeku, E., and Bamisaye, O. S. (2019). “Industry 4.0 and construction supply chain management,” in Creative construction conference 2019 (Hungary: Budapest University of Technology and Economics), 368–375.

Almeida, C. M., Agostinho, F., Huisingh, D., and Giannetti, B. F. (2017). Cleaner Production towards a sustainable transition. J. Clean. Prod. 142, 1–7. doi:10.1016/j.jclepro.2015.06.081

Alotaibi, F. M. S. (2014). Impact on quality culture of total quality management practices factors. Int. J. Bus. Econ. Dev. (IJBED) 2, 3. doi:10.3844/ajassp.2013.638.645

Alwan, Z., Jones, P., and Holgate, P. (2017). Strategic sustainable development in the UK construction industry, through the framework for strategic sustainable development, using Building Information Modelling. J. Clean. Prod. 140, 349–358. doi:10.1016/j.jclepro.2015.12.085

Baidoc, D., and Bacali, L. (2017). Impact of innovation on sustainable development of organizations. Rev. Appl. Socio-Economic Res. 14 (2), 5–18.

Belvedere, V., and Grando, A. (2017). Sustainable operations and supply chain management. John Wiley & Sons.

Braccini, A. M., and Margherita, E. G. (2018). Exploring organizational sustainability of industry 4.0 under the triple bottom line: the case of a manufacturing company. Sustainability 11 (1), 36. doi:10.3390/su11010036

Choi, T. M., Lo, C. K., Wong, C. W., Yee, R. W., and Ho, H. P. Y. (2012). A Five-R analysis for sustainable fashion supply chain management in Hong Kong: a case analysis. J. Fash. Market. Manage.: Internat. J.

Chowdhury, T., Zealand, N., Adafin, J., Albert, M., Zealand, N., Wilkinson, S., et al. (2019). Review of digital technologies to improve productivity of New Zealand construction industry. 24, 569–587.

Considine, J., Botti, M., and Thomas, S. (2005). Design, format, validity and reliability of multiple choice questions for use in nursing research and education. Collegian 12 (1), 19–24. doi:10.1016/s1322-7696(08)60478-3

Currie, B. A., French, A. D., and Ülkü, M. A. (2020). “Sustainability, big data, and consumer behavior: a supply chain framework,” in Big data analytics in supply chain management (Beca Raton, FL: CRC Press), 109–132. doi:10.1201/9780367816384

Dadhich, P., Genovese, A., Kumar, N., and Acquaye, A. (2015). Developing sustainable supply chains in the UK construction industry: a case study. Int. J. Prod. Econ. 164, 271–284. doi:10.1016/j.ijpe.2014.12.012

Das, D. (2018). The impact of sustainable supply chain management practices on firm performance: lessons from Indian organizations. J. Clean. Prod. 203, 179–196. doi:10.1016/j.jclepro.2018.08.250

Dekkers, R., Chang, C. M., and Kreutzfeldt, J. (2013). The interface between “product design and engineering” and manufacturing: a review of the literature and empirical evidence. Int. J. Prod. Econ. 144 (1), 316–333. doi:10.1016/j.ijpe.2013.02.020

Eddine, B. T., and Salah, M. M. (2012). Solid waste as a renewable source of energy: current and future possibility in Algeria. Internat. J. Energy Environ. Engineer. 3, 1-12.

Ellram, L. M., and Murfield, M. L. U. (2019). Supply chain management in industrial marketing–Relationships matter. Ind. Mark. Manag. 79, 36–45. doi:10.1016/j.indmarman.2019.03.007

Epstein, M. J., Elkington, J., and Herman, B. (2018). Making sustainability work: best practices in managing and measuring corporate social, environmental and economic impacts. London: Routledge. doi:10.4324/9781351280129

Feurer, M., Klein, A., Eggensperger, K., Springenberg, J., Blum, M., Hutter, F., et al. (2015). Efficient and robust automated machine learning,” in Advances in neural information processing systems (Spinger) (Germany: University of Freiburg).

Fornell, C., and Bookstein, F. L. (1982). Two structural equation models: LISREL and PLS applied to consumer exit-voice theory. J. Mark. Res. 19 (4), 440–452. doi:10.1177/002224378201900406

Fornell, C., and Larcker, D. F. (1981). Structural equation models with unobservable variables and measurement error: algebra and statistics. J. Mark. Res. 18, 382–388. doi:10.1177/002224378101800313

Hair, F., Gabriel, M. L., and Patel, V. K. (2014). Amos covariance-based structural equation modeling (Cb-Sem): guidelines on its application as a marketing research tool. REMark Rev. Bras. Marketing 13, 2.

Hair, J., Hollingsworth, C. L., Randolph, A. B., and Chong, A. Y. L. (2017). An updated and expanded assessment of PLS-SEM in information systems research. Alabama, USA: Industrial management & data systems.

Hammes, G., De Souza, E. D., Rodriguez, C. M. T., Millan, R. H. R., and Herazo, J. C. M. (2020). Evaluation of the reverse logistics performance in civil construction. J. Clean. Prod. 248, 119212. doi:10.1016/j.jclepro.2019.119212

Harrison, C., Eckman, B., Hamilton, R., Hartswick, P., Kalagnanam, J., Paraszczak, J., et al. (2010). Foundations for smarter cities. IBM J. Res. Develop. 54 (4), 1–16.

Henseler, J., and Sarstedt, M. (2013). Goodness-of-fit indices for partial least squares path modeling. Comput. Stat. 28 (2), 565–580. doi:10.1007/s00180-012-0317-1

Ike, C. C., Ezeibe, C. C., Anijiofor, S. C., and Daud, N. N. (2018). Solid waste management in Nigeria: problems, prospects, and policies. J. Solid Waste Technol. Manage. 44 (2), 163-172.

Ji, X., Wu, J., and Zhu, Q. (2016). Eco-design of transportation in sustainable supply chain management: a DEA-like method. Transp. Res. Part D Transp. Environ. 48, 451–459. doi:10.1016/j.trd.2015.08.007

Kain, R., and Verma, A. (2018). Logistics management in supply chain – an overview. Mater. today Proc. 5 (2), 3811–3816. doi:10.1016/j.matpr.2017.11.634

Kibert, C. J. (2016). Sustainable construction: green building design and delivery. John Wiley & Sons.

Kostova, I. (2019). Eco-labels as a commitment to responsible production practices. Econ. Altern. 2, 251–262.

Krejcie, R. V., and Morgan, D. W. (1970). Determining sample size for research activities. Educational and psychological measurement, 30 (3), 607-610.

Kwamega, M., Li, D., and Abrokwah, E. (2018). Supply chain management practices and agribusiness firms’ performance: mediating role of supply chain integration. South Afr. J. Bus. Manag. 49 (1), 1–11. doi:10.4102/sajbm.v49i1.317

Livingston, M., and Myers, D. (2010). Contributions of watercourse-associated greenways to green infrastructure: a comparison between two case studies in Arizona and Maryland, USA. In Proceedings of the Fábos Conference on Landscape and Greenway Planning 3, 1, 34.

Menhas, R., Mahmood, S., Tanchangya, P., Safdar, M. N., and Hussain, S. (2019). Sustainable development under Belt and Road Initiative: a case study of China-Pakistan economic corridor’s socio-economic impact on Pakistan. Sustainability 11 (21), 6143. doi:10.3390/su11216143

Miemczyk, J., Johnsen, T. E., and Macquet, M. (2012). Sustainable purchasing and supply management: a structured literature review of definitions and measures at the dyad, chain and network levels. Supply Chain Manag. Int. J. 17, 478–496. doi:10.1108/13598541211258564

Montabon, F., Pagell, M., and Wu, Z. (2016). Making sustainability sustainable. J. Supply Chain Manag. 52 (2), 11–27. doi:10.1111/jscm.12103

Ngwepe, L., and Aigbavboa, C. (2015). A theoretical review of building life cycle stages and their related environmental impacts. South Africa: Ex Libris, a Clarivate Company.

Nidumolu, R., Prahalad, C. K., and Rangaswami, M. R. (2009). Why sustainability is now the key driver of innovation. Harv. Bus. Rev. 87 (9), 56–64.

Nikjow, M. A., Liang, L., Qi, X., and Sepasgozar, S. (2021). Engineering procurement construction in the context of belt and road infrastructure projects in West Asia: a SWOT analysis. J. Risk Finan. Manag. 14 (3), 92. doi:10.3390/jrfm14030092

Liu, J., Feng, Y., Zhu, Q., and Sarkis, J. (2018). Green supply chain management and the circular economy. Internat. J. Phys. Distribut. Logist. Manage.

Parida, V., Sjödin, D., and Reim, W. (2019). Reviewing literature on digitalization, business model innovation, and sustainable industry: past achievements and future promises. Sustainability 11 (2), 391. doi:10.3390/su11020391

Rahi, S. (2017). Research design and methods: a systematic review of research paradigms, sampling issues and instruments development. Internat. J. Econom. Manage. Sci 6 (2).

Ramayah, T. J. F. H., Cheah, J., Chuah, F., Ting, H., and Memon, M. A. (2018). Partial least squares structural equation modeling (PLS-SEM) using smartPLS 3.0. An updated guide and practical guide to statistical analysis. Kuala Lumpur. Malaysia: Spinger.

Razzaq, A., Nawaz, A., Noman, S. M., and Khan, S. A. R. (2021). Nexus between green logistic operations and triple bottom line: evidence from infrastructure-led Chinese outward foreign direct investment in Belt and Road host countries. Environmen Sci. Pollut. Res. 28 (37), 51022–51045.

Salam, M. A., and Khan, S. A. (2018). Achieving supply chain excellence through supplier management: a case study of fast moving consumer goods. Benchmarking Int. J. 25, 4084–4102. doi:10.1108/bij-02-2018-0042

Salhi, R., and Messaoudi, K. (2021). The effects of delays in Algerian construction projects: an empirical study. Civ. Environ. Eng. Rep. 31 (2), 218–254. doi:10.2478/ceer-2021-0027

Sarstedt, M., and Cheah, J. H. (2019). Partial least squares structural equation modeling using SmartPLS: a software review. J. Market. Analy. 7 (3), 196–202.

Schulze, H., and Bals, L. (2018). Implementing sustainable supply chain management: a literature review on required purchasing and supply management competencies. Soc. Environ. Dimensions Organ. Supply Chains 11, 171–194. doi:10.1007/978-3-319-59587-0_11

Shao, X. F., Liu, W., Li, Y., Chaudhry, H. R., and Yue, X. G. (2021). Multistage implementation framework for smart supply chain management under industry 4.0. Technol. Forecast. Soc. Change 162, 120354. doi:10.1016/j.techfore.2020.120354

Shee, H., Miah, S. J., Fairfield, L., and Pujawan, N. (2018). The impact of cloud-enabled process integration on supply chain performance and firm sustainability: the moderating role of top management. Supply Chain Manag. Int. J. 23, 500–517. doi:10.1108/scm-09-2017-0309

Silva, B. N., Khan, M., and Han, K. (2020). Futuristic sustainable energy management in smart environments: a review of peak load shaving and demand response strategies, challenges, and opportunities. Sustainability 12 (14), 5561. doi:10.3390/su12145561

Siracusa, V., Ingrao, C., Giudice, A. L., Mbohwa, C., and Dalla Rosa, M. (2014). Environmental assessment of a multilayer polymer bag for food packaging and preservation: an LCA approach. Food Res. Int. 62, 151–161. doi:10.1016/j.foodres.2014.02.010

Tabet, I., and Kahf, M. (2018). Design of Islamic financial certificates for housing development in Algeria. Intellectual Discourse.

Testa, F., and Iraldo, F. (2010). Shadows and lights of GSCM (Green Supply Chain Management): determinants and effects of these practices based on a multi- national study. J. Clean. Product. 18 (10-11), 953–962.

Tian, F. (2017). “A supply chain traceability system for food safety based on HACCP, blockchain & Internet of Things,” in 2017 International Conference on Service Systems and Service Management, Dalian, 16-18 June 2017 (IEEE), 1–6.

Tischner, U., and Charter, M. (2017). “Sustainable product design,” in Sustainable solutions (Routledge) (London, UK: Routledge), 118–138.

Trirat, T., Brahamia, K., and Benselhoub, A. (2017). The issues of the implementation of an environmental management system ISO 14001 in the Algerian companies. Stud. Univ. Vasile Goldis Ser. Stiintele Vietii (Life Sci. Ser. 27 (4).

Xiao, C., Wilhelm, M., van der Vaart, T., and Van Donk, D. P. (2019). Inside the buying firm: exploring responses to paradoxical tensions in sustainable supply chain management. J. Supply Chain Manag. 55 (1), 3–20. doi:10.1111/jscm.12170

Zikmund, W. G., Babin, B. J., Carr, J. C., and Griffin, M. (2013). Business Research Methods (8th ed.). United States of America: South-Western, Cengage Learning. Business Research Methods. Cengage Learning.

Keywords: sustainable construction, supply chain management, Algerian construction industry, sustainability, environmental

Citation: Harouache A, Abkar MMA, Gamil Y, Al-Shameri ASA and Gabir AAM (2024) Influence of supply chain management on the sustainable construction industry in Algeria. Front. Built Environ. 10:1233266. doi: 10.3389/fbuil.2024.1233266

Received: 01 June 2023; Accepted: 08 January 2024;

Published: 01 February 2024.

Edited by:

Zhen Chen, University of Strathclyde, United KingdomReviewed by:

Salman Riazi Mehdi Riazi, University of Science Malaysia (USM), MalaysiaRichard Jimoh, Federal University of Technology Minna, Nigeria

Copyright © 2024 Harouache, Abkar, Gamil, Al-Shameri and Gabir. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yaser Gamil, eWFzZXIuZ2FtaWxAbHR1LnNl

Ahmed Harouache

Ahmed Harouache Mahdi Mohammed Abdullah Abkar

Mahdi Mohammed Abdullah Abkar Yaser Gamil

Yaser Gamil Ahmed Saleh Ahmed Al-Shameri5

Ahmed Saleh Ahmed Al-Shameri5 Adham Ahmed Mohammed Gabir

Adham Ahmed Mohammed Gabir