95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Built Environ. , 26 September 2023

Sec. Construction Management

Volume 9 - 2023 | https://doi.org/10.3389/fbuil.2023.1232195

This article is part of the Research Topic Rising Stars in Built Environment View all 10 articles

Mahdi Mohammed Abdullah Abkar1

Mahdi Mohammed Abdullah Abkar1 Riduan Yunus1

Riduan Yunus1 Ahmed Saleh Ahmed Saif Al-Shameri2

Ahmed Saleh Ahmed Saif Al-Shameri2 Ahmed Harouache2

Ahmed Harouache2 Yaser Gamil3,4*

Yaser Gamil3,4*Automation technology in the construction industry is the use of advanced tools, devices, and processes that reduce manual labor and enhance efficiency in various construction activities. Automation technology can minimize waste, optimize resource utilization, and reduce the environmental impact of construction processes. This study aims to examine the relationship between automation technology adoptions (ATAs) utilizing reduce, reuse, and recycle (3R), building information modeling (BIM), industrialized building systems (IBSs), green building index (GBI), and Internet of Things (IoT) practices toward construction site performance (CSP) to measure their influences on material waste mitigation measures at Johor construction sites. To achieve these goals, five hypotheses were developed to explore the association between ATA and CSP. Data were gathered utilizing an online survey. The participants were contractors and expert practitioners in the Johor construction industry, including architects, project managers, and academicians/researchers. A total of 257 valid responses were used to investigate the assumptions. The partial least squares structural equation modeling (PLS-SEM) procedure was used. The findings revealed that ATA utilizing 3R, BIM, IBS, GBI, and IoT as material mitigation measures positively enhances CSP.

Technological advancements in the construction industry offer practical solutions for improving overall efficiency. These technologies serve as tools to enhance productivity throughout the construction life cycle, connecting productivity, cost, and technology to drive economic innovation and growth for the industry’s development (Chowdhury et al., 2019). According to Edwards (2020), evidence suggests that incorporating new technology into construction site practices consistently leads to reducing material waste. Furthermore, the emergence of technologies for material management at the construction site has the potential to reduce the costs connected with waste and missing objects at construction sites (Ibrahim et al., 2021; Shi and Xu, 2021). As a result, the Internet of Things (IoT) tends to increase the quality of construction firms (Ghosh et al., 2019). Smart gadgets improve stakeholder involvement by allowing them to offer project perspectives. According to Louis and Dunston (2018) and Dallasega (2018), using technology in the construction sector offers a solution for satisfying client expectations, improving execution monitoring, efficient control, quality, cost, and time savings. In addition, real-time data analytics are now accessible, and their use has grown to enable fast decisions (Gamil et al., 2020). The performance of a construction site is measured by the performance of project attributes and functionalities (Nguyen, 2016). Lut and Takki (2019) and Mahmud et al., 2018 stated that IoT technology devices are incorporated into many types of equipment, and connected sensors can monitor workers at the site and record progress for further analysis. Concrete waste accounts for approximately 88% of construction waste, and other sources include waste generated from power generation, markets, commercial enterprises, institutions, landscaping, and street sweeping (Bakchan and Faust, 2019). The current waste management approaches in Johor, a Malaysian state, need to be reconsidered because some waste is being illegally dumped in Johor (Chang & Kumar, 2021). Significant problems have arisen in construction site management practices, specifically in the areas of management and administration, technical and engineering, and site communication. These problems are attributed to communication failures between professional teams and contractors. The combination of these failures, along with a shortage of skilled labor and the presence of inaccurate information, leads to inadequate planning, ineffective plant and material management, and conflicts among the parties involved (Oyenuga and Bhamidimarri, 2015). The strategy of reduce, reuse, and recycle (3R) principles, emphasized in the 10th Malaysia Plan (TMP), provides a foundation for construction waste management (CWM) and regulations. Implementing the 3R approach has proven to be a significant concern, aiming to reduce material waste at construction sites and promote rapid recycling and maximum reuse of resources (Boon et al., 2019; Wahi et al., 2016). Additionally, the management of material waste on construction sites has a substantial impact on project costs and the environment, emphasizing the need for contractors to innovate and propose new methods for waste reduction (Mohammed et al., 2020).

The utilization of industrialized building systems (IBSs) in construction sites has shown a potential to enhance performance in terms of quality, safety, cost-effectiveness, productivity, and material waste reduction (Mohsen et al., 2021). However, the low adoption and uptake of IBSs in Malaysia’s construction industry are major challenges, exacerbated by the industry’s reliance on foreign workers who may lack the awareness, technical skills, knowledge, and experience required for IBS implementation in Malaysian construction sites (Nawi et al., 2015). Automation through IBSs has been identified as an effective approach to improve Malaysia’s construction performance, enhance productivity, and ensure the effectiveness of building projects. Furthermore, the utilization of building information modeling (BIM) technology in conjunction with IBSs has been recognized as a way to achieve a desirable level of project quality, reduce the likelihood of unanticipated problems, and enhance construction management by facilitating effective communication and information sharing among stakeholders (Sio Kah and Ming Qin, 2021). The integration of BIM technology into construction processes and its connection with stakeholders, including facility management, can support the creation of a comprehensive database (Olawumi and Chan, 2019). Furthermore, the incorporation of BIM technology into CWM is in its initial phases and necessitates further research and comprehension (Basheer et al., 2021).

Various studies have highlighted the potential of BIM technology to increase construction productivity, lower project costs, reduce project duration, and improve material tracking, delivery, planning, and monitoring (Doumbouya et al., 2016; Khanzadi et al., 2018; Al-ashmori et al., 2020; Manzoor et al., 2021; Sio Kah and Ming Qin, 2021). Implementing smart and innovative technologies, including BIM, along with other material management technologies, has the potential to enhance productivity and output in the construction industry (Rahim, et al., 2017; Olawumi and Chan, 2019). Despite the potential benefits of automation technologies such as IBSs and BIM in the construction industry, their adoption has been slow due to various challenges and barriers. Resistance from workers and management, lack of standardized protocols, high initial costs, and the need for extensive training and re-skilling programs are among the complexities involved in adopting technology automation in construction sites (Hatoum and Nassereddine, 2020; Yap, 2022). According to Rahim et al. (2017), the management of construction waste in developing nations is poorly defined, resulting in harmful environmental consequences.

The adoption of technologies like the green building index (GBI) can play a crucial role in mitigating construction waste and promoting environmentally conscious practices in the industry (Manoharan et al., 2020). The construction industry faces significant challenges in effectively managing construction waste, which has detrimental environmental and economic impacts. The GBI has been proposed as a solution to mitigate construction waste, but green technology is still in its infancy stage in Malaysia because many parties are unwilling to use it for construction projects (Jaffar et al., 2022). The adoption of the GBI as a technology to address construction waste remains limited, and there is a need to explore the factors influencing its adoption and the potential benefits it can offer.

According to Ibrahim et al. (2021), traditional methods of material tracking and monitoring in construction sites often rely on manual processes, leading to errors, delays, and increased waste. The study highlights the potential of IoT technologies to revolutionize material management practices in the construction industry. By leveraging IoT devices and sensors, real-time tracking, monitoring, and inventory management of construction materials can be achieved, leading to improved efficiency, reduced waste, and enhanced project performance. According to a study conducted by Yap (2022), the construction industry has been slow to adopt automation technologies due to various factors, including resistance from workers and management. Despite the potential benefits of technology automation in the construction industry, the resistance to its adoption remains a significant challenge, limiting its widespread implementation. In addition to challenges and barriers to the adoption of automation technologies, Hatoum & Nassereddine (2020) highlighted the complexities involved in adopting technology automation in construction sites. The review revealed multiple challenges and barriers, including resistance from workers, lack of standardized protocols, high initial costs, and the need for extensive training and re-skilling programs.

Therefore, this study aims to empirically test and investigate the automation technology adoption (ATA) utilizing the 3R approach, BIM, IBSs, the GBI, and the IoT for material waste mitigation measures and improvements in construction site performance (CSP). The absence of automation technology can also lead to delays in construction schedules that could increase costs and result in the accumulation of more waste on the site. This can occur because manual construction methods are often slower and require more labor and resources, which can lead to inefficiencies and an increased likelihood of errors. Overall, incorporating these strategies could create a framework that could address material waste mitigation measures and enhance performance on construction sites.

Low-waste technologies (LWTs) are not new in the construction industry; they are regarded as an essential strategy in construction waste management (CWM). The construction sector consumes up to 40% of all raw materials mined from the lithosphere and accounts for nearly 50% of worldwide carbon emissions (Bonoli et al., 2021). The use of LWTs in the construction phase helps to optimize the consumption of resources, resulting in waste reduction, widely acknowledged as a significant factor in the reduction of global environmental consequences. These technologies, sometimes known as soft technologies, assist the project managers by enhancing the operations and work performance during building projects and reducing the creation of construction waste (Martínez-Rojas et al., 2016). These LWTs enhance coordination, cooperation, and data interchange among the parties engaged in the building process, encompassing data sharing, device performance, and archiving (Zhang and Ng, 2012; Martínez-Rojas et al., 2016). For instance, BIM is a widely used information system in construction, engineering, and technology. It has a large-scale dataset with many resources. In addition, it may be connected to the project’s timetable, allowing better planning to ensure just-in-time delivery of supplies, machinery, and manpower (Won and Cheng, 2017).

IBSs have been characterized as a collection of interconnected components that facilitate a building to target specifications. An IBS may also contain numerous technological and managerial techniques for manufacturing and assembling these components (Mundher et al., 2022). According to Abedi et al. (2011) and Jaffar and Lee (2020), an IBS is a building approach that results from human innovation and investment for the conceptualizing and development of an ideal construction plan based on the firm’s resources. The adoption of technology for the construction industry is challenging for digital technologies such as the Internet of Things (IoT), which combines storing data for the location and environment and project parameters in a cloud-based BIM platform (Mohammed et al., 2022b). The construction management information may be collected and visualized in real-time to facilitate IoT applications for use by real-time supervision, control, protection, collaboration, supply management, and safety and monitoring staff.

A systematic approach based on specific criteria was adopted to conduct a comprehensive review of previous studies. First, a comprehensive search strategy was developed to identify relevant scholarly articles and publications from reputable databases such as Google Scholar and Science Direct. The review focused on articles published within the last 5 years to ensure the inclusion of recent advancements and up-to-date findings. The main terms and keywords employed for the literature review encompassed automation technology adoption, reduce, reuse, and recycle (3R), building information modeling (BIM), industry building systems (IBSs), green building index (GBI), and Internet of Things (IoT) in construction. These terms were specifically chosen to explore the role of these technologies and approaches in mitigating material waste at construction sites.

The construction business needs effective construction organization, efficient construction procedures, and novel building methods to compete well in the 21st century when globalization, market competition, and technology are all improving (Folkesson and Lönnroos, 2018). As a consequence, a technology adoption may be used to enhance the improvement plans at each step of the construction phase and to manage the distribution of resources and staff efficiently. According to construction industry research conducted by Hussaini and Abdul Majid (2015), technology adoptions for construction can reduce negative influences and improve construction productivity and efficiency, minimize the quantity of waste, and achieve project goals by obtaining good value for the money spent while considering project constraints. Automation is a term that focuses on the application of computer-controlled processes and mechanization concepts. It involves the application of the latest automation technologies, which may perform unfinished, undesirable, or unsafe human construction tasks in construction (Xu and Lu, 2018). According to Umar, Shafiq and Isa (2018), approximately 41% of Malaysian construction waste from residential buildings is produced from the construction of high-rise buildings, while terraces and bungalows represented 51% and 8% of total waste, respectively. Most of these projects were built in the states of Selangor (25%) and Johor Bahru (15%), while the remaining percentage was allocated across 12 states in Malaysia; 60% of the sites were located in densely populated areas. It is well known that several sources impact environmental pollution, and emissions from buildings are considered one of the major factors that contribute to increasing atmospheric pollution. Construction generates a large amount of waste, including waste from site preparation for new construction, site clearance, renovation, or excavation. The method for quantifying waste mitigation measures on Malaysian construction sites was adjusted to accommodate data limitations. Previous studies had assessed contractor performance using Construction Industry Development Board (CIDB) grades (Umar et al., 2018).

The concept of “reduce, reuse, and recycle” is known as “the 3Rs” and represents one of the ways that solid waste can be addressed. Compared to recycling, waste reduction is a more challenging choice. Nevertheless, the first step in the solid waste management hierarchy is a reduction of waste in the construction sector (Saleh, 2018). Nasaruddin et al. (2008) and Umar et al. (2018) stated that waste management in Malaysia, namely, disposal and sorting, comprises an essential component of the administration of the local government. However, the ever-increasing volume of waste material leads to emergent dumping; an illegally large amount of this waste is produced during the construction of significant infrastructure projects. In addition, commercial construction and housing development projects are now being undertaken in Malaysia that cause a significant impact on the environment (Nasaruddin et al., 2008). It is an essential and fundamental waste management concept to coordinate these three reduction techniques throughout the demolition, design, and building stages. Materials like structural steel, wooden shutters, and doors may all be reused in a structure for many purposes; this is what is meant by the term “reuse” (Park and Tucker, 2017). Of the four waste management technologies, waste recycling stands out as the most favored among local practitioners. They have consistently chosen this method due to its various benefits, such as reducing waste in construction. However, the implementation of waste recycling requires extensive planning across different stages of the project. Kazerooni Sadi et al. (2012) also highlight that waste recycling is a standard approach for material management.

As was previously noted, the implementation of BIM, a cutting-edge technology, must be coordinated throughout the planning and design stage. Musa et al. (2018) stated that construction is an imperative feature of BIM that creates an object-oriented record composed of intelligent objects that show the project in 3D dimensions. Although the adoption of BIM may overcome some concerns, it is one of the possible answers to future issues. It can make the industry more efficient, effective, adaptable, and inventive while raising construction productivity to support economic development (Musa et al., 2018). In addition, the implementation of Malaysia’s Construction 4.0 Strategic Plan (2021–2025) by CIDB Malaysia acknowledges the Fourth Industrialization (IR 4.0) and details how the country’s construction industry can adapt to an adaptively moving business world through the intelligent application of digital innovation (Hadzaman, 2022). Furthermore, Arif et al. (2021) stated that the integration and implementation of the BIM technology approach in the construction sector have a significant impact on professionals and management abilities. The researchers added that the integration of BIM as modern technology in the construction industry is seen as essential for the growth of construction industry sectors in Malaysia.

IBS is a term that represents the construction industry-based materials management and protection systems. Malaysia’s building sector has significantly benefited from IBS implementations that drastically reduce waste. Construction in factories often uses industrialized building materials, as advocated by IBSs. The need for costly and time-consuming imported labor may be reduced by using this strategy (Nawi et al., 2015). The classifications provided by CIDB have sometimes been misused in place of systems with limitations to the construction industry, and IBS is interpreted as a method or process for constructing buildings more quickly, with less labor, while meeting quality requirements.

Datuk Ahmad Asri Abdul Hamid, the Chief Executive, reported a notable rise in IBS implementation within government projects, reaching 84 percent in 2021, up from 79.5 percent in 2020. Concurrently, there has been a substantial increase in IBS adoption in private projects, surging to 60 percent in 2021, compared to a prior rate of 41 percent in 2020 (Bernama, 2023). However, it has been agreed that industrializing the building sector is a worldwide process, not a local or national one. There is a need for a system of categorization and naming that takes into account international viewpoints and norms. Prefabricated components, off-site construction, contemporary building techniques, off-site assembly, off-site fabrication, and pre-assembly all fall under the “off-site” umbrella; thus, their definitions and classifications must be verified (Anuar et al., 2011).

The implementation of green principles as a mitigation measure for project management is significant for cost savings to be achieved over time and to the quality project life cycle. GBI has improved the environment in many ways, can protect the natural environment, promote a healthy life, and reduce the negative impact on the environment. Critical green building management practices positively affect the environment and support the economy (Aghili, 2018).

Similarly, environmental protection through sustainable projects can reduce project operating costs, increase the value of buildings, and increase return on investment (Vyas et al., 2019). In recent years, the ideology of environmentally sustainable development and the new paradigm of “sustainable development” have become widespread in the Malaysian construction industry. To raise the construction sector’s awareness of the importance of viable development, the Malaysian government has introduced the 11th Malaysia Plan. A new construction plan known as the “Construction Industry Transformation Plan” (CITP) was produced in 2016 by CIDB. One of the primary objectives of the CITP is to incorporate environmental sustainability further into the construction process (CITP, 2017).

IoT can integrate data and reduce manual interaction, resulting in clarity, accuracy, effectiveness, and financial value, among other advantages in the development, such as cloud-based digital collaboration and mobility via BIM, drone monitoring and simulation, real-time sense platforms, and 3D printing (Lokshina, Greguš and Thomas, 2019). Current construction industry developments are geared toward utilizing innovative technology to boost efficiency and the planning process; this approach is known as smart construction (Al Neyadi, 2019; Gbadamosi et al., 2019). IoT in the construction industry may provide information about digital payments, management teams, financial advisors, and planners (Basheer et al., 2021). IoT in construction helps to record machinery and workers’ time, enhancing construction productivity (Wang et al., 2020).

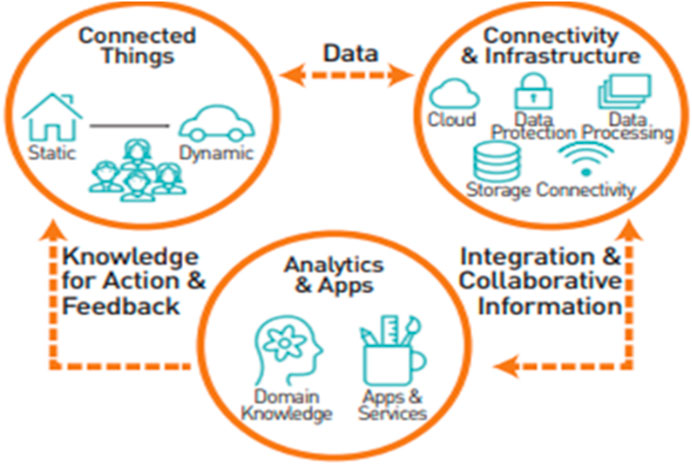

According to the Malaysian National IoT report, IoT is a convergence with intelligent devices that can generate information data through the sensors and store the knowledge and information in its system and device storage MIMOS Berhad (2015). This is an advantage because data increase productivity by enhancing the quality of the construction industry, as shown in Figure 1. Three main components are connected: the first is dynamic and static entities with embedded sensors, the second is infrastructure connectivity, and the third and most important is the analytics application.

FIGURE 1. Connectivity of IoT sensors and storage (MIMOS Berhad, 2015).

Figure 2 depicts the model of this paper. Five main hypotheses are formulated to achieve the objectives of the papers presented as follows:

H1: There is a significant relationship between automation technology adoptions (ATAs) of reduce, reuse and recycle (3R) and construction site performance (CSP).

H2: There is a significant relationship between automation technology adoptions (ATAs) of building information modeling (BIM) and construction site performance (CSP).

H3: There is a significant relationship between automation technology adoptions (ATAs) of industrialized building systems (IBS) and construction site performance (CSP).

H4: There is a significant relationship between automation technology adoptions (ATAs) of the green building index (GBI) and construction site performance (CSP).

H5: There is a significant relationship between automation technology adoptions (ATAs) of the Internet of Things (IoT) and construction site performance (CSP).

This research used a quantitative method approach to gathering data through a questionnaire survey with leading members of the construction industry in the state of Johor who understood the concept of waste reduction and mitigation measures in the construction industry. This survey investigates the respondents’ evaluations of mitigation measures in the construction industry and the use of technologies and material management adoptions for waste reduction. This study was conducted with members of the Johor construction industry. Respondents were selected based on their positions as directors, engineers, architects, project managers, quantity surveyors, developers, local authorities/government agencies, and researchers at academic institutions

A preliminary investigation was conducted to validate the study and establish the problem statement. The survey was administered online and in hard-copy format. The researcher collected data from six respondents from different organizations involved in solid waste management, recycling, and construction management in Johor and other states of Malaysia. The exploratory research was useful in validating the necessity for the present study, which concentrates on the employment of automation technology adoption utilizing 3R, BIM, IBS, GBI, and IoT. In this study, the population is the contractors and expert practitioners in the Johor construction industry, including architects, project managers, and academicians/researchers. The modified questionnaire survey was undertaken with experts to identify any issues with the survey questions. One way to conduct questionnaire pre-testing is by requesting the opinion of professionals from the same field. During the screening process, the professionals are asked to focus on the wording, difficulties, gathering variables, and notice the major issues they encountered. The procedure administered a pre-test with five professional lecturers from the faculties of construction engineering and civil engineering, as well as some engineers who had experience handling these concerns in the study area in the Johor construction industry. The feedback gathered from the pre-test is typically helpful in exploring how to alter the language and format of specific inquiries.

A pilot study was carried out before the main data collection. In this study, 40 surveys were given to the participants, such as lecturers, academics, and construction parties in the Johor construction industry. The researcher collected a total of 33, of which 30 were valid; three contained missing parts.

In this study, the population is the contractors and expertise practitioners in the Johor construction industry such as architects, project managers, and academicians/researchers (CIDB, 2016). The maximum number of respondents required for this research is 365 respondents, as determined by Krejcie and Morgan (1970) and granted by Rahi (2017) based on the sample size calculation for a population of 7,481 people working in the Johor construction industries. The questionnaire was administered online using the Google website and emails. A total of 257 valid responses were collected, representing a response rate of 70%. The evaluation was a five-point scale: 1 = strongly disagree, 2 = disagree, 3 = neither agree nor disagree, 4 = agree, and 5 = strongly agree (Zikmund et al., 2013; Ajayi and Oyedele, 2018).

The questionnaire used in this study was adapted from previous studies. First, items of the ATA3R practice were adapted from the previous studies conducted by Seow et al. (2018), Kanimoli et al. (2020), Asadi & Kone, (2018), Shan et al. (2015), Azman and Yaacob (2017), Howlader (2020), and Mohammed et al. (2022a). The measurement of ATABIM utilization was adapted from previous studies conducted by Liu et al. (2016), Acquah et al. (2018), and Tam et al. (2021). Measurement items ATAIBS technology as an off-site construction method for environmentally friendly development and its ability to enhance construction performance in the current research were adapted from Algburi and Faieza (2018), Turkyilmaz et al. (2019), and Azira et al. (2020). The fourth section of the questionnaire addressed the GBI as an automation technology to enhance environmental measures on the construction site. The measurement items for this construct were adapted from Marhani and Muksain (2018) and Manzoor et al. (2021). IoT was the fifth construct, and its measurement items were adapted from Shan et al. (2015), Dallasega (2018), Mao et al. (2019), Perrier et al. (2020), Ibrahim et al. (2021), and Dilakshan et al. (2021).

Advanced statistical tools, Statistical Package for Social Sciences SPSS 25.0 and partial least squares structural equation (PLS-SEM) using SmartPLS version 3.7.9, were used to evaluate the obtained data (Sarstedt et al., 2019). The inferential approach was used to assess the conceptual framework study for the hypotheses, using PLS-SEM to evaluate the characteristics of respondents.

The constraints issues investigated in this research were believed to motivate the use of ATA in construction sites as material waste mitigation measures as these segments enhance CSP. This study aimed to explore the five hypotheses. The primary focus of this section is to discuss the outcomes of testing the hypotheses based on the prior investigations and explore the possible mechanisms for the findings. The topic focuses on the presence of ATA and CSP techniques in the Johor construction industry, the effects of material waste mitigation measures on construction site performance, and the significance of ATA as a contributing element for construction site performance using PLS-SEM.

The pilot study was carried out to improve uniformity, structure, and requirements of the questionnaire. It is possible to use a pilot study as an aid for a more extensive investigation or to look at specific areas of a study to evaluate whether chosen processes would be completed as expected. Cronbach’s alpha was determined using SPSS v25.

Table 1 shows the Cronbach’s alpha values for the pilot test. The obtained values were 0.826 for ATACSP, 0.832 for ATA3R, 0.776 for ATABIM, 0.740 for ATAIB, 0.615 for ATAGBI, and 0.729 for ATAIoT. Table 1 also presents the mean values of constructs in the pilot study and the analysis of normality through skewness and kurtosis. The results indicate that all variables in the questionnaire have achieved univariate normality. Kurtosis has an absolute value within 0.217 and 2.305, and the maximum skewness values are between −0.634 and 1.34. Most writers agree that the data set is normal if the skewness and kurtosis fall within the proper range (i.e., −3.0 to +3.0, representing the suggested threshold of ± 3) (Hamdollah and Baghaei, 2016). Therefore, the results indicate univariate normality in the dataset.

Evaluating the reliability of the survey’s variables indicates a better consistency for questionnaire fields and the overall mean of the questionnaire. Cronbach’s alpha has a typical range of 0.0–1.0, with higher values representing more consistency. Table 2 illustrates the Cronbach’s alpha values for all variables, demonstrating reliability and validity across all the items (Ajayi and Oyedele, 2018).

The respondents were categorized according to the position, organization, type of project, cost of the project, education level, and working experience. Table 3 outlines the demographics of respondents in this study.

Most respondents were engineers (105, 38%) and directors (78, 28%). Many respondents were academicians (28, 10.4%), project managers (26, 9.6%), and architects (20, 7.4%). Respondents included quantity surveyors (6, 2.2%) and individuals categorized as “others” (7, 2.6%). Most respondents worked at designer/consultant firms (88, 32.6%) and contractors (73, 27%). Most respondents (123, 45.6%) are involved in projects that cost less than one million. Other respondents are involved in projects that cost from one million to more than twenty million. More than one-third of respondents (123, 45.6) have working experience that ranges from 0 to 5 years; some respondents have 6–10 years (55, 17.8%) and 11–15 years (48, 10.7%) of working experience. Finally, a few respondents (15, 5.6%) have working experience that is more than 20 years.

The questionnaire results are summarized by adopting the 5-point Likert scale, whereby 5 points indicate a strong agreement, and a score of 1 indicates a strong disagreement (Louis and Dunston, 2018). Table 4 presents the results.

Statistics in Table 4 showed that ATAIBS obtained a higher mean value than the remaining five variables (3.92), followed by ATAIoT with (3.90), while ATA3R was third (3.72). CSP has a mean value of 3.71, and ATABIM has a mean value of 3.69. ATAGBI obtained a mean value of 3.68. These statistics show that the mean scores are higher than the possible average, indicating respondents generally agreed with the questionnaire’s statements.

This study analyzed and reported PLS-SEM results using a two-stage procedure (Henseler et al., 2009). To assess the PLS-SEM overview, Henseler and Sarstedt (2013) recommend using the goodness-of-fit (GoF) index rather than choosing a nonparametric evaluation method based on bootstrapping and blindfolding (Hair et al., 2014). Many researchers now use a two-stage process to evaluate PLS-SEM pathway model results.

Figure 3 presents the output data of the measurement model obtained from the determination of R-value and the factor loading, using SmartPLS 3.3.9, in accordance with the recommendations by Henseler et al. (2016). In this research, bootstrapping was applied to assess the direct effect, as recommended by Hair and Sarstedt (2019). Researchers are advised to implement a bootstrapping test using the sampling distribution of the direct association (Hair et al., 2014). As shown in Figure 4, the output data obtained the probability (p) values, signifying the significance of the associations.

The term “convergent validity” (CV) refers to the extent to which items reflect the desired latent components and their relationship to other measures of the same constructs (Usakli and Kucukergin, 2018). The accuracy of CV is determined by assessing each variable among the average variance extracted (AVE), composite reliability (CR), and the loading for each item (Hair et al., 2014; Sarstedt and Cheah, 2019). Chin (2010) proposed that to achieve adequate CV, the AVE of each variable must be 0.50 or higher, while the threshold for composite dependability is 0.70. Table 5 displays the AVE values, which range from 0.66 to 0.765. As a result, it can be concluded that CV has been established for each construct in this research because each item amply reflects the latent components.

Table 5 shows that the Cronbach alpha for all variables is larger than 0.70. This means that all variables in the present investigation are consistent (Wan and gtmmad, 2013). Furthermore, all variables have strong reliability, and their AVEs are higher than threshold values (>0.5), supporting the measurement model’s reliability (Bido and Da Silva, 2019). Therefore, the overall reliability of the latent variables used in this study has internal consistency values ranging from 0.853 to 0.934 for the components of the study, which is satisfactory because they are all above the minimum threshold of 0.70.

Discriminant validity (DV) describes how much one latent notion varies from another (Ab Hamid et al., 2017). AVE is used in this research to assess the discriminant validity, as proposed by Usakli and Kucukergin (2018). This was accomplished by comparing the latent variable correlations to the AVE square roots (Mohd Hilmi and Kasim, 2017). As illustrated in Table 6, the significant values of each of the AVE items along the diagonal lines are greater than the corresponding values in both columns and rows, confirming discriminant validity (Fornell and Larcker, 1981).

Likewise, as Ab Hamid et al., 2017 indicated, DV might be verified by evaluating the indicator loading values compared to the cross-loadings for the others; the intended indicator loadings should be more significant than the corresponding diagonal of the others. Based on Table 6, all indicator loadings (shown in bold) loaded beyond the threshold value of 0.5 and higher levels, as suggested by Wong (2013) and Sarstedt and Cheah (2019).

The structural model is evaluated when the model is completed (Henseler, Hubona and Ray, 2016). The t-values in the present study are the results of bootstrapping (with 5,000 sample rounds for 257 instances/observes), as advised by Hair and Sarstedt (2019).

According to Table 7, the f2 values of the effects of ATA3R, ATABIM, ATAGBI, ATAIBS, and ATAIoT on CSP were small, small, medium, medium, and small, respectively, according to Hair and Sarstedt (2019). The results also indicated that the R2 obtained in this study was 0.687. This value suggests a high level of explanation for the variance in CSP, demonstrating its “substantial” value, as it exceeds the threshold of 0.67 (Nitzl et al., 2016). The effect size (f2) is calculated from the observed changes of R2, as guided by Hair and Sarstedt (2019). However, the following part goes into predictive relevance, which refers to the structural model’s capacity to predict more relevance within each endogenous variable indicator. As stated previously, it is a candidate for the PLS-SEM approach if the value of cross-validity redundancy in Table 8 (Q2) is larger than zero (Sarstedt et al., 2019).

Based on the bootstrapping technique that explains the empirical association of variables, the hypothesis is accepted at a p-value of 0.01 and 0.05 (Hair and Sarstedt, 2019). Therefore, all of the direct hypotheses of this study were supported because they obtained values that are less than 0.01, as illustrated in Table 9.

This paper examines ATA as a coherent set of CSP strategies that influence measures for mitigating material waste. The finding suggests a significant positive association between ATA utilization of the 3R approach and CSP. The results demonstrate that ATA utilizing the 3R approach has a significant impact on CSP. This result is given in Table 9 as (β = 0.250, t = 3.440, p < 0.001). Similarly, Mohammed et al. (2020) stated that management of material waste on site has a considerable influence on project costs while also having a positive impact on the environment; the conclusion suggested that contractors should be encouraged to innovate and propose a new method to reduce waste in the construction site. Mundher et al. (2022) stated that the 3R strategy had a significant influence on construction waste, in particular, steel waste. Azman and Yaacob (2017) defined 3R practice in construction sites as the responsibilities that all parties involved in the site must consider as important actions to follow during the construction workplace.

The results confirm that the relationship between ATABIM and CSP is significant, with the result shown in Table 9 (β = 0.158, t = 2.605, and p < 0.009). The finding indicated a significant positive relationship, as proposed in the hypothesis, which indicates that BIM technology has a significant and positive influence on the material mitigation approach in the Johor construction sites. Similarly, research by Tanko and Zakka (2022) declared that “Johor and Selangor states had a significant population presence with high construction output due to a variety of factors including location, administrative, and the results of utilizing BIM-based site showed a significant impact for material waste minimization.” Another finding by Sio Kah and Ming Qin (2021) states that it is possible for BIM technology to carry out tasks that enable construction partners to achieve a desirable level of project quality and reduce the likelihood of unanticipated problems during construction, such as delay, additional costs, ineffective construction management, and misunderstandings between the parties involved. The finding was validated by contractors, project managers, engineers, architects, and quantity surveyors in Johor and Selangor in the indicators of site conditions, planning, and material waste minimization in construction sites.

The results demonstrate that ATAGBI significantly affects CSP. The result supports the hypothesis as a positive relationship exists between ATAGBI and CSP; the result is shown in Table 9 (β = 0.271, t = 2.762, and p < 0.006). The outcome showed a strong and substantial correlation between ATAGBI practices and construction sites. Several empirical investigations have demonstrated that the GBI, as an indicator of innovativeness in construction, has a favorable effect on construction sites. One example is the need for construction organizations to prioritize green innovation to improve the quality of construction projects, for sustainability considerations, and to strengthen their market position (Rizqa, 2016; Aghili, 2018; Algburi and Faieza, 2018; Ali, 2018; Vyas, Jha and Rajhans, 2019).

ATAIBS technology, as a material mitigation measure on a construction site, was a major component of this research, and IBS technology across the construction industry has yielded many beneficial effects on CSP. To that aim, the third research objective was to assess the effects of ATAIBS on CSP. The findings reveal that ATAIBS has a significant effect. The result confirms that the relationship between ATAIBS and CSP is significant. The result is shown in Table 9, presented as (β = 0.283, t = 4.292, and p < 0.000), which indicates a significant positive relationship, as contained in the hypothesis. This finding reinforced that IBS technology has a significant and positive influence on the material mitigation approach in the Johor construction sites. The present research revealed a strong and significant relationship between IBS technology practices and material management approaches. These findings are consistent with those published by Ayisy and Ghazalli (2021), Nawi et al. (2019), Thomas Tarang et al., 2022, and Soon Ern et al. (2017). In terms of automation in construction, recent findings by Azira et al. (2020) and Kamaruddin et al. (2018) indicated that automation through IBS in construction is effectively influencing Malaysia’s construction performance and that automation in construction is a modern technology that could be employed to improve the efficiency and performance of all construction projects.

The fifth relationship in this paper was established to examine the association between ATAIoT and CSP in the practice of material waste mitigation at the construction sites; the result is shown in Table 9 (β = 0.202, t = 3.087, and p < 0.002). The result supports the hypothesis that a significant positive relationship exists between ATAIoT and CSP. The finding indicated the importance of the IoT for construction sites as a material waste mitigation measure in Johor construction sites. These results are supported by findings that indicated that IoT technology used for construction can enhance material supply chain efficiency at the construction site (Gbadamosi et al., 2019; Maru and Raval, 2020; Perrier et al., 2020; Basheer et al., 2021). Providing an integrative approach regarding IoT adoption within construction firms is supported by these studies. Other important findings by Lin et al. (2019) and Sidani et al. (2021) showed that IoT contributes positively to environmental protection, and it can decrease energy consumption and carbon emissions while also eliminating material wastage to obtain the highest performance.

The evaluation of the survey variables with high reliability, as indicated by Cronbach’s alpha values in Table 2, demonstrates the consistency and accuracy of the questionnaire items, ensuring reliability and validity in measuring the constructs. The analysis of the data reveals that the study attracted a diverse range of respondents representing various sectors of the construction industry, including engineers, directors, academicians, project managers, architects, and quantity surveyors. The descriptive statistics from Table 4 indicate that ATAIBSs had the highest mean value (3.92) among the variables studied, followed by ATAIoT (3.82) and ATA3R (3.72). The mean scores for CSP (3.71), GBI (3.68), and ATABIM (3.69) were also above the average.

The averages of the results (AVE) were calculated, and the CR of each latent was calculated through the analysis of constructed variables. The cross-loadings matrix was also investigated to validate the conceptual model. As a result, this research was able to evaluate the latent variables that were depicted in its conceptual model using a robust PLS-SEM method. This increases reliability and simplifies the process for researchers to obtain accurate and trustworthy information about material management toward site performance in the context of material mitigation measures sourced from appropriate participants. The measurements utilized in this research for the various variables were adopted from various sources. Additionally, similar investigations were carried out in various contexts in the reviewed literature about questionnaire adoption; consequently, it is essential to demonstrate the reliability and validity of these scales. This was comprehensively performed in this research through the use of different measurements described in the CV sections.

As a result, this research was able to evaluate the latent variables that were depicted in its conceptual model using a robust PLS-SEM method. In conclusion, the findings of this study provide solid evidence of the significant positive relationships between technology adoption strategies and CSP, with a focus on material waste mitigation.

The adoption of ATA strategies can lead to improved construction performance, waste reduction, and sustainability. These findings emphasize the importance of integrating innovative technologies and practices in the construction industry to enhance overall performance and contribute to a more sustainable built environment. Additionally, to assess the strength of the association between the adoption of automation technology and CSP, the superiority of this approach over others was taken into account. Therefore, the findings of the present research demonstrate the successful utilization of Malaysian professional contractors’ expertise in the fields of technology and management. This is achieved through their endorsement of research parameters and techniques like 3R, BIM, IBS, GBI, and IoT to aid in material mitigation measures at construction sites. Consequently, it is crucial to prioritize technological innovation aligned with material mitigation measures to effectively address material waste reduction. As a result, Johor construction firms can consider automation technology as a key factor in determining strategies for reducing material waste, thereby addressing economic and environmental concerns and improving construction site practices. The utilization of a quantitative research approach enables the collection of objective and measurable data on the adoption of automation technology as a material mitigation measure in Johor construction sites. This quantitative analysis provides a solid foundation for drawing statistical inferences and establishing a deeper understanding of the relationships between variables in the context of automation adoption and material waste mitigation toward CSP. This consideration is especially important, given that the variables in this research are measured reflectively.

This research has attempted to expand the body of knowledge concerning material management adoption by examining the relationship between automation technology adoption employing 3R, BIM, IBS, GBI, and IoT with CSP. The findings of this study contribute important theoretical concepts along with certain limitations; it has effectively answered the study questions and fulfilled the stated objectives. The present study used the literature and a survey to acquire credible answers to the study’s research questions and findings. Based on the survey results, it can be concluded that ATA3R, ATABIM, ATAIBS, ATAGBI, and ATAIoT techniques are interconnected and have solid relationships that have a positive impact on material mitigation measures toward construction site performance.

Overall, the findings of this research point to many engaging directions for further studies. The construction industry should incorporate the combination of ATA and CSP techniques to maintain its competitive advantage. The findings of this study, which was conducted in the context of Johor construction sites, add to the current literature and considerably enhance the producers of material management aspects and CSP. Most importantly, the study findings will help corporations develop construction technology and innovative products and improve the growth of the Malaysian construction sector in general. As a result, the innovative capabilities of material management and CSP could be considered for future research concerning automation technology in construction performance.

This study has several limitations that should be acknowledged. First, the research was conducted in a specific context, focusing on Johor construction sites. The findings may be influenced by the unique characteristics and practices of this region, limiting the generalizability of the results to other locations. This research is restricted to the Johor construction sector and does not compare the data analysis with other Malaysian states. Future research should consider conducting similar studies in different regions to provide a broader understanding of automation technology adoption as material waste mitigation measures. Although these factors were found to be significant concerning CSP, other variables not considered in the present study might also be important. Finally, the research could explore additional dimensions and interactions between automation technology adoption, material management practices, and CSP to provide a more comprehensive analysis.

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to restrictions as their containing information could compromise the privacy of research participants. Requests to access the datasets should be directed to MA, bWFoZGkubW9oYW1tZWQzNEBnbWFpbC5jb20=.

MA and RY jointly conceived the presented idea, devised the methodology, and developed the main conceptual ideas, proof outline, and theory. They were responsible for performing the computations and overseeing the progress of this work. RY provided supervision and guidance throughout the research process. AA-S and AH reviewed the manuscript and methods employed in this study. YG verified the results and contributed to the manuscript editing. The final manuscript was the result of collaborative discussions among all authors, who actively contributed to the refinement of the findings and the overall content. All authors contributed to the article and approved the submitted version.

The authors express their deepest gratitude to the participants from the Johor construction industries for their invaluable contributions, active participation, and valuable insights, which greatly contributed to the success of this research. They also extend sincere appreciation to the Ministry of Higher Education and Scientific Research Yemen for their ultimate support in ensuring the successful completion of the research. The authors acknowledge the support of Universiti Tun Hussein Onn Malaysia (UTHM) for providing the necessary resources and an academic environment that facilitated the study’s progress.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Ab Hamid, M. R., Sami, W., and Mohmad Sidek, M. H. (2017). Discriminant validity assessment: use of fornell & larcker criterion versus HTMT criterion. J. Phys. Conf. Ser. 890 (1), 012163–012165. doi:10.1088/1742-6596/890/1/012163

Abedi, M., Fathi, M. S., Mirasa, A. K., Technology, A., Campus, I., and Lumpur, K. (2011). Establishment and development of ibs in malaysia. Sustain. Build. Infrastructure Syst. Our Future Today 405.

Acquah, R., Eyiah, A. K., and Oteng, D. (2018). Acceptance of building information modelling: a survey of professionals in the construction industry in Ghana. J. Inf. Technol. Constr. 23, 75–91.

Aghili, N. (2018). Green building management practices model for Malaysian green building. Skudai, Malaysia: Universiti Teknologi Malaysia. doi:10.1017/CBO9781107415324.004

Ajayi, S. O., and Oyedele, L. O. (2018). Critical design factors for minimising waste in construction projects: a structural equation modelling approach. Resour. Conservation Recycl. 137, 302–313. doi:10.1016/j.resconrec.2018.06.005

Al Neyadi, A. (2019). Sustainable and digital strategies for enhancing United Arab Emirates construction industry competitiveness. Available from: http://oatd.org/oatd/record?record=handle%5C:2436%5C%2F622670&q=digital construction.

Al-ashmori, Y. Y., Othman, I., Rahmawati, Y., Amran, Y. H. M., Sabah, S. A., Rafindadi, A. D., et al. (2020). BIM benefits and its influence on the BIM implementation in Malaysia. Ain Shams Eng. J. 11, 1013–1019. doi:10.1016/j.asej.2020.02.002

Algburi, S. M., and Faieza, A. A. (2018). Review of green building index in Malaysia; existing work and challenges. Int. J. Appl. Eng. Res. 11 (5), 3160–3167.

Ali, A. (2018). Development of a framework for sustainable construction waste management. A case study of three major Libyan cities.

Ali, M. M., Abas, N. H., Affandi, H. M., and Abas, N. A. (2018). Factors impeding the industrialized building system (IBS) implementation of building construction in Malaysia. Int. J. Eng. Technol. 7 (4), 2209–2212. doi:10.14419/ijet.v7i4.17863

Anuar, K., Kamar, M., and Hamid, Z. A. (2011). Industrialised building system (IBS): the issue of definition and classification. Int. J. Emerg. Sci. 1, 120–132.

Arif, N. K., Hasmori, M. F., Deraman, R., Yasin, M. N., and Mohd Yassin, M. A. (2021). Readiness of Malaysian small and medium enterprises construction companies for building information modelling implementation. IOP Conf. Ser. Mater. Sci. Eng. 1200 (1), 012027. doi:10.1088/1757-899x/1200/1/012027

Asadi, S., and Kone, V. (2018). Evaluation of reducing waste materials in construction projects using ranking analysis. Int. J. Civ. Eng. Technol. 9, 831–838.

Ayisy, M., and Ghazalli, M. (2021). “Industrial revolution 4.0: impact of automation and robotics in ibs towards occupational safety, employee satisfaction and productivity,” in Proceeding of the 8th International Conference on Management and Muamalah, 485–496.

Azira, S., Rahim, A., Amir, M., Hashim, S., and Shen, W. S. (2020). A potential study of automation system in industrialised building system (IBS) i n enhancing Malaysian construction industry ’ s performance. INTI J. 2020.

Azman, N., and Yaacob, N. A. (2017). Construction contractor’s perception on effective 3R implementation for solid waste reduction in Perak.

Bakchan, A., and Faust, K. M. (2019). Construction waste generation estimates of institutional building projects: leveraging waste hauling tickets. Waste Manag. 87, 301–312. doi:10.1016/j.wasman.2019.02.024

Bernama (2023). IBS growing steadily in Malaysia for the last 15 years. StratsTimes, Available at: https://shorturl.at/jrCLY.

Basheer, A., Altohami, A., Haron, N. A., Hizami, A., Alias, A., and Law, T. H. (2021). Investigating approaches of integrating BIM, IoT, and facility management for renovating existing buildings: a review. Sustainability 13, 3930. doi:10.3390/su13073930

Bido, D. de S., and Da Silva, D. (2019). SmartPLS 3: especificação, estimação, avaliação e relato. Adm. Ensino Pesqui. 20 (2), 488–536. doi:10.13058/raep.2019.v20n2.1545

Boon, C., Den Hartog, D. N., and Lepak, D. P. (2019). A systematic review of human resource management systems and their measuremen. Journal of management 45 (6), 2498–2537.

Bonoli, A., Zanni, S., and Serrano-Bernardo, F. (2021). Sustainability in building and construction within the framework of circular cities and european new green deal. The contribution of concrete recycling. Sustainability 13 (4), 2139–2216. doi:10.3390/su13042139

Chang, T. W., and Kumar, D. (2021). Overview of environmental management practice for construction in Malaysia. Civ. Sustain. Urban Eng. 1 (1), 15–25. doi:10.53623/csue.v1i1.33

Chin, W. W. (2010). “How to write up and report PLS analyses,” in Handbook of partial Least squares. Editors V. V. Esposito, W. W. Chin, J. Henseler, and H. Wang, 655–690.

Chowdhury, T., Zealand, N., Adafin, J., Albert, M., Zealand, N., Wilkinson, S., et al. (2019). Review of digital technologies to improve productivity of New Zealand construction industry. J. Inf. Technol. Constr. 24, 569–587. doi:10.36680/j.itcon.2019.032

CIDB, C. I. D. B. (2016). Construction industry development board,for Malaysia contractors by registration and construction idustries statics.

Dallasega, P. (2018). Industry 4. 0 fostering construction supply chain management: lessons learned from engineer-to-order suppliers. IEEE Eng. Manag. Rev. 46 (3), 49–55. doi:10.1109/EMR.2018.2861389

Dilakshan, S., Rathnasinghe, A. P., and Seneviratne, L. D. I. P. (2021). Potential of internet of things (Iot) in the construction industry. World Construction Symposium, 445–457. doi:10.31705/WCS.2021.39

Doumbouya, L., Gao, G., and Guan, C. (2016). Adoption of the building information modeling (BIM) for construction project effectiveness: the review of BIM benefits. Am. J. Civ. Eng. Archit. 4 (3), 74–79. doi:10.12691/ajcea-4-3-1

Edwards, D. J. (2020). Patterns and trends in internet of things (IoT) research: Future applications in the construction industry. doi:10.1108/ECAM-04-2020-0271

Folkesson, P., and Lönnroos, R. (2018). Construction automation: assessment of state of the art and future possibilities, 55.

Fornell, C., and Larcker, D. F. (1981). Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 18 (1), 39–50. doi:10.2307/3151312

Gamil, Y., A. Abdullah, M., Abd Rahman, I., and Asad, M. M. (2020). Internet of things in construction industry revolution 4.0: recent trends and challenges in the Malaysian context. J. Eng. Des. Technol. 18 (5), 1091–1102. doi:10.1108/JEDT-06-2019-0164

Gbadamosi, A., Mahamadu, A., and Olawale, O. A. (2019). The role of internet of things in delivering smart construction the role of internet of things in delivering smart construction.

Ghosh, A., Hosseini, M. R., Edwards, D., Kassem, M., and Matteo-Garcia, M. (2019). “Use cases for the internet of things (IoT) in the construction sector: lessons from leading industries. CIB W78 2019,” in Proceedings of 36th CIB (International Council for Research and Innovation in Building and Construction) W78 2019 Conference, 1–8.

Hadzaman, N. A. H. (2022). Study on quality efficiency for bim-based construction projects. Int. J. Acad. Res. Bus. Soc. Sci. 12 (9), 355–364. doi:10.6007/ijarbss/v12-i9/14637

Hair, J. F., and Sarstedt, M. (2019). Factors versus composites: guidelines for choosing the right structural equation modeling method. Proj. Manag. J. 50 (6), 619–624. doi:10.1177/8756972819882132

Hair, J. F., Sarstedt, M., Hopkins, L., and Kuppelwieser, V. G. (2014). Partial least squares structural equation modeling (PLS-SEM) an emerging tool in business research. Eur. Bus. Rev. 26 (2), 106–121. doi:10.1108/ebr-10-2013-0128

Hamdollah, R., and Baghaei, P. (2016). Partial least squares structural equation modeling with R. Pract. Assess. Res. Eval. 21 (1), 1–16. doi:10.1108/ebr-10-2013-0128

Hatoum, M. B., and Nassereddine, H. (2020). “Developing a framework for the implementation of robotics in construction enterprises,” in EG-ICE 2020 workshop on intelligent computing in engineering, proceedings, 453–462.

Henseler, J., Hubona, G., and Ray, P. A. (2016). Using PLS path modeling in new technology research: updated guidelines. Industrial Manag. Data Syst. 116 (1), 2–20. doi:10.1108/IMDS-09-2015-0382

Henseler, J., Ringle, C. M., and Sinkovics, R. R. (2009). “The use of partial least squares path modeling in international marketing,” in New challenges to international marketing (Bingley: Emerald Group Publishing Limited), 277–319.

Henseler, J., and Sarstedt, M. (2013). Goodness-of-fit indices for partial least squares path modeling. Comput. Stat. 28 (2), 565–580. doi:10.1007/s00180-012-0317-1

Howlader, S. (2020). “Factors affecting the construction productivity in the context of khulna city of Bangladesh,” in Proceedings of the 5th international conference on civil engineering for sustainable development, khulna, Bangladesh, 7–9.

Hussaini, I. U., and Abdul Majid, N. H. (2015). Energy development in Nigeria and the need for strategic energy efficiency practice scheme for the residential building sector. Management of Environmental Quality: An International Journal 26 (1), 21–36.

Ibrahim, F. S. B., Esa, M. B., and Rahman, R. A. (2021). The adoption of IOT in the Malaysian construction industry: Towards the adoption of IOT in the Malaysian construction industry. doi:10.30880/ijscet.2021.12.01.006

Jaffar, N., Affendi, N. I. N., Mohammad Ali, I., Ishak, N., and Jaafar, A. S. (2022). Barriers of green building technology adoption in Malaysia: contractors’ perspective. Int. J. Acad. Res. Bus. Soc. Sci. 12 (8), 1552–1560. doi:10.6007/ijarbss/v12-i8/14490

Jaffar, Y., and Lee, C. K. (2020). Factors influencing industrialized building system (IBS) project performance: a systematic review. J. Gov. Integr. 3 (2), 64–81. doi:10.15282/jgi.3.2.2020.5311

Kamaruddin, S. S., Mohammad, M. F., Mahbub, R., and Ahmad, K. (2018). The mechanisation and automation of the IBS construction approach in Malaysia. Asian J. Environment-Behaviour Stud. 3 (10), 167–177. doi:10.21834/aje-bs.v3i10.324

Kanimoli, A., Adeleke, A. Q., and Taiwo, T. T. (2020). Organizational structure influence on construction waste management among penang Malaysian construction industry: an approach via partial least square structural equation modeling. J. Bus. Manag. Econ. Res. 4 (1), 56–73. doi:10.29226/tr1001.2020.183

Kazerooni Sadi, M. A., Abdullah, A., Sajoudi, M. N., Bin Mustaffa Kamal, M. F., Torshizi, F., and Taherkhani, R. (2012). Reduce, reuse, recycle and recovery in sustainable construction waste management. Adv. Mater. Res. 446–449, 937–944. doi:10.4028/www.scientific.net/AMR.446-449.937

Khanzadi, M., Sheikhkhoshkar, M., and Banihashemi, S. (2018). BIM applications toward key performance indicators of construction projects in Iran. Int. J. Constr. Manag. 20, 305–320. doi:10.1080/15623599.2018.1484852

Krejcie, R. V., and Morgan, D. W. (1970). Determining sample size for research activities. Educational and psychological measurement 30 (3), 607–610.

Lin, S., Shen, B., Yong, S., Angelo, M., Promentilla, B., Yatim, P., et al. (2019). Prioritization of sustainability indicators for promoting the circular economy: the case of developing countries. Renew. Sustain. Energy Rev. 111, 314–331. doi:10.1016/j.rser.2019.05.001

Liu, S., Xie, B., Tivendal, L., and Liu, C. (2016). Critical barriers to BIM implementation in the AEC industry. Int. J. Mark. Stud. 7, 162. doi:10.5539/ijms.v7n6p162

Lokshina, V., Greguš, M., and Thomas, W. L. (2019). Application of integrated building information modeling, IoT and blockchain technologies in system design of a smart building. Procedia Comput. Sci. 160, 497–502. doi:10.1016/j.procs.2019.11.058

Louis, J., and Dunston, P. S. (2018). Integrating IoT into operational workflows for real-time and automated decision-making in repetitive construction operations. Automation Constr. 94, 317–327. doi:10.1016/j.autcon.2018.07.005

Lut, L. T. Y., and Takki, H. (2019). Utilization and adoption of Internet of Things in construction industry: Comparative case study in Finland and Sweden.

Mahmud, S. H., Assan, L., and Islam, R. (2018). Potentials of internet of things (IoT) in malaysian construction industry. Ann. Emerg. Technol. Comput. (AETiC) 2, 44–52. Print ISSN, 2516-0281. doi:10.33166/aetic.2018.04.004

Manoharan, E., Othman, N., Mohammad, R., Chelliapan, S., and Tobi, S. U. M. (2020). Integrated approach as sustainable environmental technique for managing construction waste: a review. J. Environ. Treat. Tech. 8 (2), 560–566.

Manzoor, B., Othman, I., Gardezi, S. S. S., and Harirchian, E. (2021). Strategies for adopting building information modeling (BIM), 1–14.

Mao, C., Shen, Q., Asce, M., Pan, W., and Ye, K. (2019). Major barriers to off-site construction: the developer ’ s perspective in China. J. Manag. Eng. 31. doi:10.1061/(ASCE)ME.1943-5479.0000246

Marhani, M. A., and Muksain, M. A. S. (2018). GBI assessment checklist: level of awareness of the contractors in the Malaysian construction industry. IOP Conf. Ser. Earth Environ. Sci. 117 (1), 012024. doi:10.1088/1755-1315/117/1/012024

Martínez-Rojas, M., Marín, N., and Vila, M. A. (2016). The role of information technologies to address data handling in construction project management. J. Comput. Civ. Eng. 30 (4), 1–20. doi:10.1061/(asce)cp.1943-5487.0000538

Maru, R. V., and Raval, A. (2020). Feasibility study of internet of things (IoT) in construction industry.

MIMOS Berhad (2015). “National internet of things (IoT) strategic Roadmap,Technology park Malaysia,” in MIMOS Berhad, 1–18.

Mohammed, B. H., Sallehuddin, H., Yadegaridehkordi, E., Safie Mohd Satar, N., Hussain, A. H. B., and Abdelghanymohamed, S. (2022a). Nexus between building information modeling and internet of things in the construction industries. Appl. Sci. 12 (20), 10629. doi:10.3390/app122010629

Mohammed, M., Shafiq, N., Elmansoury, A., Al-mekhlafi, A. A., Rached, E. F., Zawawi, N. A., et al. (2022b). Modeling of 3R (reduce, reuse and recycle) for sustainable construction waste reduction: a partial least squares structural equation modeling (PLS-SEM). Sustainability 13, 10660. doi:10.3390/su131910660

Mohammed, M., Shafiq, N., Abdallah, N. A. W., Ayoub, M., and Haruna, A. (2020). A review on achieving sustainable construction waste management through application of 3R (reduction, reuse, recycling): a lifecycle approach. IOP Conf. Ser. Earth Environ. Sci. 476 (1), 012010. doi:10.1088/1755-1315/476/1/012010

Mohd Hilmi, I. A. R., and Kasim, N. (2017). Conceptual model for systematic construction waste management. MATEC Web Conf. 87, 01008. doi:10.1051/matecconf/20178701008

Mohsen, A., Alawag, M., Alaloul, W. S., Liew, M. S., Al-bared, M. A. M., Amila, N., et al. (2021). The implementation of the industrialized building system in the Malaysian construction industry a comprehensive review. Springer Singapore.

MundherAli Tighnavard Balasbaneh, A. A., and Farid, G. (2022). Evaluation of 3rs concept for sustainable steel waste disposal: control strategy. Malays. J. Civ. Eng. 34 (1), 11–17. doi:10.11113/mjce.v34.17545

Musa, S., Marshall-Ponting, A., Nifa, F. A. A., and Shahron, S. A. (2018). “Building information modeling (BIM) in Malaysian construction industry: benefits and future challenges,” in AIP Conference Proceedings, 2016.

Nasaruddin, F. H. M., Ramli, N. H. M., and Ravana, S. D. (2008). E-construction waste exchange in Malaysia: a preliminary study. Proc. - Int. Symposium Inf. Technol. 2008, ITSim 3, 1–7. doi:10.1109/ITSIM.2008.4631883

Nawi, M. N. M., Azman, M. N. A., Baluch, N., Kamar, K. A. M., and Abd Hamid, D. Z. (2015). Study on the use of industrialised building system in Malaysian private construction projects. ARPN J. Eng. Appl. Sci. 10 (17), 7368–7374.

Nawi, M. N. M., Nasir, N. M., Azman, M. N. A., Jumintono, , and Khairudin, M. (2019). Investigating factors of delay in IBS construction project: manufacturer perspectives. J. Eng. Sci. Technol. 14, 59–66. Special Issue on ICEES2018.

Nguyen, H. T. (2016). Integration of BIM and IoT to improve the building performance for occupants’ perspective, 84. Available from: https://www.researchgate.net/publication/310481201.

Nitzl, C., Roldan, J. L., and Cepeda, G. (2016). Mediation analysis in partial least squares path modeling: helping researchers discuss more sophisticated models. Industrial Manag. Data Syst. 116 (9), 1849–1864. doi:10.1108/IMDS-07-2015-0302

Olawumi, T. O., and Chan, D. W. M. (2019). Critical success factors for implementing building information modeling and sustainability practices in construction projects: a delphi survey, 1–16.

Oyenuga, A., and Bhamidimarri, R. (2015). Sustainable approach to managing construction and demolition waste: an opportunity or a new challenge. Int. J. Innovative Res. Sci. Eng. Technol. 4 (11), 10368–10378. doi:10.15680/ijirset.2015.0411007

Park, J., and Tucker, R. (2017). Overcoming barriers to the reuse of construction waste material in Australia: a review of the literature. Int. J. Constr. Manag. 17 (3), 228–237. doi:10.1080/15623599.2016.1192248

Perrier, N., Bled, A., Bourgault, M., Cousin, N., Danjou, C., Pellerin, R., et al. (2020). Construction 4.0: a survey of research trends. J. Inf. Technol. Constr. (ITcon) 25 (24), 416–437. doi:10.36680/j.itcon.2020.024

Rahi, S. (2017). Research design and methods: a systematic review of research paradigms, sampling issues and instruments development. Int. J. Econ. Manag. Sci. 06 (02). doi:10.4172/2162-6359.1000403

Rahim, M. H. I. A., Kasim, N., Mohamed, I., Zainal, R., Sarpin, N., and Saikah, M. (2017). “Construction waste generation in Malaysia construction industry: illegal dumping activities,” in IOP conference series: Materials science and engineering (IOP Publishing), 271, 012040.

Rizqa, E. Y. (2016). Promoting green building by investigating sustainability concepts in building projects with regard to economic, environment, social, and technical goals. doi:10.1115/1.2710245

Saleh, A. A. (2018). Solid waste management in Shah Alam city residential area. J. Sustain. Sci. Manag. 13 (1), 211–227.

Sarstedt, M., and Cheah, J. H. (2019). Partial least squares structural equation modeling using SmartPLS: a software review. J. Mark. Anal. 7 (3), 196–202. doi:10.1057/s41270-019-00058-3

Sarstedt, M., Ringle, C. M., Cheah, J. H., Ting, H., Moisescu, O. I., and Radomir, L. (2019). Structural model robustness checks in PLS-SEM. Tour. Econ. 26, 531–554. doi:10.1177/1354816618823921

Seow, T. W., Tan, L. W., and Ng, L. S. (2018). Constraints to 3R construction waste reduction among contractors in Penang. IOP Conf. Ser. Earth Environ. Sci. 140 (1), 012103. doi:10.1088/1755-1315/140/1/012103

Shan, N. L., Chen, G. K., and Wai, T. L. (2015). Construction contractors ’ perception on effective 3R implementation for solid waste reduction. Int. J. Conceptions Manag. Soc. Sci. 3, 52–57.

Shi, Y., and Xu, J. (2021). BIM-based information system for econo-enviro-friendly end-of-life disposal of construction and demolition waste. Automation Constr. 125, 103611. doi:10.1016/j.autcon.2021.103611

Sidani, A., Duarte, J., Baptista, J. S., Vaz, M., Poças, J., and Soeiro, A. (2021). BIM-based sensors technologies implemented in the construction site: protocol for a systematic review: (Protocol). Int. J. Occup. Environ. Saf. 5, 25–31. doi:10.24840/2184-0954_005.001_0003

Sio Kah, K., and Ming Qin, H. (2021). Barriers of applying building information modelling (BIM) according to BIM ISO. 2022, 2600–7320. Available from: https://intijournal.intimal.edu.my.

Soon Ern, P. A., Kasim, N., Nasid Masrom, M. A., and Kai Chen, G. (2017). Overcoming ICT barriers in IBS management process in Malaysia construction industry. MATEC Web Conf. 103, 03007–03010. doi:10.1051/matecconf/201710303007

Tam, N. V., Diep, T. N., Toan, N. Q., Le, N., and Quy, D. (2021). Factors affecting adoption of building information modeling in construction projects: a case of vietnam. Cogent Bus. Manag. 8 (1), 1918848.

Tanko, B. L., Zakka, W. P., and Heng, W. N. (2022). BIM in the Malaysian construction industry: a scientometric review and case study. Eng. Constr. Archit. Manag. doi:10.1108/ECAM-04-2021-0324

Thomas Tarang, V. A., Mohammad, M. F., Nizam Akbar, A. R., and Mohamed, M. R. (2022). Pertinent internal and external issues in industrialised building system (IBS) construction business in Malaysia. Built Environ. J. 19 (1), 32. doi:10.24191/bej.v19i1.15990

Turkyilmaz, A., Guney, M., Karaca, F., Bagdatkyzy, Z., Sandybayeva, A., and Sirenova, G. (2019). A comprehensive construction and demolition waste management model using PESTEL and 3R for construction companies operating in central Asia. Sustain. Switz. 11 (6), 1593. doi:10.3390/su11061593

Umar, U. A., Shafiq, N., and Isa, M. H. (2018). Investigation of construction wastes generated in the Malaysian residential sector. Waste Manag. Res. 36 (12), 1157–1165. doi:10.1177/0734242X18790359

Usakli, A., and Kucukergin, K. G. (2018). Using partial least squares structural equation modeling in hospitality and tourism: do researchers follow practical guidelines? Int. J. Contemp. Hosp. Manag. 30, 3462–3512. doi:10.1108/IJCHM-11-2017-0753

Vyas, G. S., Jha, K. N., and Rajhans, N. R. (2019). Identifying and evaluating green building attributes by environment, social, and economic pillars of sustainability. Civ. Eng. Environ. Syst. 36, 133–148. doi:10.1080/10286608.2019.1672164

Wan, M., and gtmmad, A. B. W. A. (2013). PLS-CB-with-cover-page-v2. Int. J. Eng. Sci. Innovative Technol. (IJESIT) 2 (5), 198–205.

Wang, M., Wang, C. C., Sepasgozar, S., and Zlatanova, S. (2020). A systematic review of digital technology adoption. Buildings 2020 (10), 1–29.

Wahi, N., Joseph, C., Tawie, R., and Ikau, R. (2016). Critical review on construction waste control practices: legislative and waste management perspective. Procedia-Social and Behavioral Sciences 224, 276–283.

Won, J., and Cheng, J. C. P. (2017). Identifying potential opportunities of building information modeling for construction and demolition waste management and minimization. Automation Constr. 79, 3–18. doi:10.1016/j.autcon.2017.02.002

Wong, K. K. K.-K. (2013). Partial least squares structural equation modeling (PLS-SEM) techniques using SmartPLS. Mark. Bull. 24.

Xu, J., and Lu, W. (2018). “Smart construction from head to toe: a closed-loop lifecycle management system based on IoT,” in Construction research congress, 157–168.

Yap, J. B. H., Lam, C. G. Y., Skitmore, M., and Talebian, N. (2022). Barriers to the adoption of new safety technologies in construction: a developing country context. J. Civ. Eng. Manag. 28 (2), 120–133. doi:10.3846/jcem.2022.16014

Zhang, P., and Ng, F. F. (2012). Attitude toward knowledge sharing in construction teams Peihua. Industrial Manag. Data Syst.

Keywords: automation technology, material waste mitigation, construction site performance, construction waste management (CWM), Johor construction sites

Citation: Abkar MMA, Yunus R, Al-Shameri ASAS, Harouache A and Gamil Y (2023) An empirical investigation of automation technology as material waste mitigation measure at Johor construction sites. Front. Built Environ. 9:1232195. doi: 10.3389/fbuil.2023.1232195

Received: 31 May 2023; Accepted: 04 September 2023;

Published: 26 September 2023.

Edited by:

Panrawee Rungskunroch, University of California, Berkeley, United StatesReviewed by:

Domenico Camassa, Politecnico di Bari, ItalyCopyright © 2023 Abkar, Yunus, Al-Shameri, Harouache and Gamil. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yaser Gamil, eWFzZXIuZ2FtaWxAbHR1LnNl

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.