- 1School of Civil Engineering, Xi’an Shiyou University, Xi’an, China

- 2No. 6 Oil Production Plant of Changqing Oilfield Branch of PetroChina, Xi’an, China

- 3School of Mechanical Engineering, Xi’an Shiyou University, Xi’an, China

As the exploitation of oil and gas field becomes more difficulty nowadays, severe casing deformation may occur if anti-extrusion strength of casing decreases to a certain degree and this brings large economic loss and severe safety problems. As an annular sheath between casing and formation, creep of oil well cement paste is one of the most important factors in deciding abnormal casing deformation and wellbore integrity. To figure out the mechanism on how to reduce the creep value of oil well cement paste, effect of different additives, e.g., retarder, glass fibre reinforcement and CSA expansive agent on the creep value of oil well cement are investigated in this study. It can be found out that retarder plays a negative role in reducing the creep deformation and creep value of cement with 1, 2, 3% retarder is 2.39%, 7.85%, and 15.02% higher than that without retarder at 12 h. Results from heat flow indicates that retarder may play an important role in prolonging the early induction period of hydration and reducing the hydration rate in the middle and later stages. On the contrary, Glass fibre shows a positive effect in reducing the creep value of oil well cement paste and creep value reaches with 0.2%, 0.4%, 0.6%, and 0.8% is 1.27%, 6.61%, 9.82%, and 12.60% lower than that without fibre addition at 72 h. This is because high porosity between and around fibers based on a microstructure observation may lead to a more continuous and uniform stress field between cement paste, and consequently reduce the creep value of cement paste. It can also be found out that CSA cement is considerably effective in limiting creep deformation of oil well cement paste at early ages. There is also an acceleration effect on the heat flow of oil well cement in both induction and acceleration periods and the corresponding maximum heat flow is 7.3%, 9.0%, and 11.2% higher than the reference cement with no CSA addition. The results obtained in this study are aimed to provide theoretical basis for the wellbore integrity and improvement of oil and gas recovery.

Introduction

Casing is a special oil pipe used in oil drilling process and it plays a very important role in the production process. The performance of casing is a decisive factor governing successful exploitation of oil and gas (Li et al., 2020). However, with the increasing difficulty of oil and gas field exploitation and complexity of downhole conditions, severe casing deformation may occur if anti-extrusion strength of casing decreases to a certain degree, which will significantly affect the economic benefits of resource development of oil and gas (Lin et al., 2017; Mohammed et al., 2019). In terms of intrinsic reasons, casing deformation may result from geological and/or engineering factors, e.g., non-uniform load, extremely high temperature, initial casing defects and so on (Lu et al., 2021). Among these factors, according to the wellbore structure, creep parameters of the surrounding rock and cement are the most important factors that need more attentions. Within it, creep deformation of the surrounding rock has been widely investigated by many researchers (Zhai et al., 2015; Brandao et al., 2017). However, creep deformation of cement has not been fully characterized in the published literature, therefore it needs to be investigated before reasons for casing deformation can be understood comprehensively.

Cementing is an important construction process in petroleum engineering and it is one of the most important drilling processes deciding the sealing and integrity of oil and gas well (Jafariesfad et al., 2017). The main function of cement sheath is to seal between the formation and casing, prevent cross flow of underground fluid into layers, improve the stress state of casing and extend service life of casing (Kumar et al., 2022). Various theories and calculation methods have been put forward to predict the creep property of concrete used as construction materials (Li and Yao, 2001; Bazant et al., 2004; Stierwalt and Hamilton, 2005; Garas et al., 2009; Fathifazl et al., 2011), but the results are not applicable to oil well cement paste due to their difference in raw materials, chemical compositions, internal microstructure and both physical and chemical properties.

Class G cement is the commonly used oil well cement at present. As the downhole conditions are becoming more and more complex, perforation, acid fracturing and other construction processes would be applied during the exploitation process. These processes may introduce large dynamic loadings upon cement sheath, therefore conventional cement sheath is more vulnerable to crack. If the cracks within cement initiate and propagate to great extent, radioactive crack may generate within cement. This would lead to the crossflow channel of downhole formation fluid, causing a series of severe development problems, e.g., casing damage, leakage of underground natural gas and toxic gas, etc. (Yan et al., 2020; Su et al., 2022). Therefore, oil well cement with great ductility, small creep and high strength is of great importance in improving casing integrity as well as efficiency of oil exploitation.

Due to the special working condition of oil well cement, cement slurry should has enough pumping time under the condition of high temperature and pressure at the bottom of the well (Bassioni and Ali, 2013; Kupwade-Patil et al., 2019). Sodium triphosphate retarder is an important additive in oil well cement, which can adjust the thickening time of cement (Dai et al., 2022). In literature, researches on retarder additive mainly concentrate on its molecular structure optimization design, but its effect on the creep properties of oil well cement has not been fully understood.

Hydrated cement paste is a brittle material with low tensile strength and inferior resistance to crack propagation. Previous studies showed that its toughness would be improved by the addition of fiber reinforcements (Brandt, 2008; Song et al., 2019). Fibres can not only limit the crack expansion but can also withstand the external loads mutually with cement. Microstructural studies have shown that fibres are randomly displayed in the cement matrix and act as bridging effect, which can efficiently disperse and transfer stresses (Ferreira and Branco, 2007; Orlowsky and Raupach, 2008; Song et al., 2015). Glass fibre is a common reinforcement used in cement and previous studies on glass fibre reinforced cement (GRC) mainly concentrates on cement matrix modification to improve the durability of the composite materials, but there is a lack of study on the effect of glass fibre on the creep value of cementitious materials.

In order to solve the volume shrinkage of conventional cement, researchers have developed a series of oil well cement expansion agents such as MgO, gypsum lattice expansion agent and sulphoaluminate (CSA) expansion agent (Mo et al., 2010; Moradpour et al., 2013; Corinaldesi et al., 2015). Among them, CSA cement demonstrates great potential in improving the shrinkage properties of oil well cement (Chen et al., 2012; Hargis et al., 2019; Mark et al., 2021), furthermore it is also beneficial for improving strength development of cement (Wang and Song, 2021). However, the effect of CSA expansion agent on the creep properties of oil well cement remains unknown and this needs further investigation.

In the present study, oil well cements with the addition of different additives (e.g., retarders, glass fibres, expansive agent) are investigated to illustrate their influence on the creep property of hydrated oil well cement. This is considerably necessary before casing deformation and damage can be understood, prevented and solved.

Experimental materials and methods

Materials

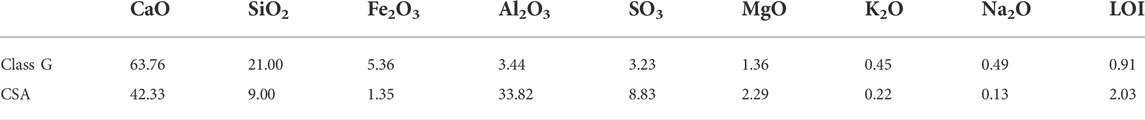

Class G oil well cement was used in this study. To improve the workability of cement slurry, 0.5% dispersant and 2% water loss reducer were added in the mix. Besides this, sodium triphosphate retarder (1.0%, 2.0%, 3.0%), glass fiber reinforcement (0.2%, 0.4%, 0.6%, 0.8%) and CSA expansive agent (5%, 10%, 15%) were added respectively in the mix. Chemical composition of class G oil well cement and CSA cement is present in Table 1. A water to cement ratio of 0.33 is applied in the mix design and specimen size was 150 mm × 50 mm × 50 mm heat flow tests and 100 mm × 100 mm × 400 mm for creep tests.

Experimental work

Creep tests were carried out on a double-shaft creep test rig with 80 mm steel probes embedded on both sides, and a dial gauge was used to measure the deformation. Each group of specimens was equipped with a corresponding auxiliary shrinkage specimen, because the deformation

In the present study, CSA expansive agent is added to compensate the autogenous shrinkage of cement. Hydration of CSA expansive agent will initiate intensively soon once contact with water and generate dominant heat flow compared to the pure cement. During this process large amounts of needle-shape is generated, which is beneficial to improve the autogenous shrinkage of cement and therefore may reduce its creep value. Therefore, investigation on the heat flow of cement is of great importance in predicting the creep value. In this study, multi-channel isothermal calorimeter (model TAM Air, TA Instruments) was applied to investigate the heat flow of oil well cement. A stress ratio of 0.33 (0.33 times of flexural strength) is applied in the test and the specific isothermal temperature is 20

SEM was carried out by JEOL JSM-5800LV in this study and secondary electron imaging mode was selected in order to characterize the micro-morphology of fractured surfaces on oil well cement reinforced by glass fibre. Before testing, the samples were carbon coated to increase the electricity conductivity of hydrated cement paste. The detailed setting of acceleration voltage is 15 Kev, working distance is 10 mm and spot size is 25 nm.

Analysis of experimental results

Effect of retarders on the creep deformation of cement

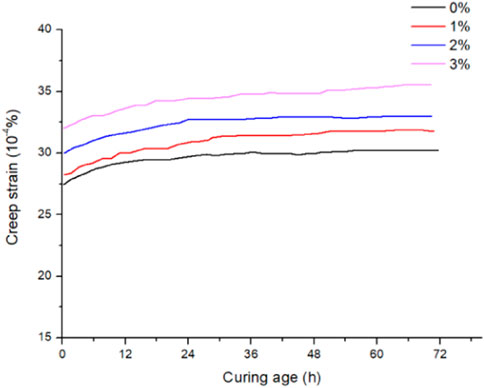

The effect of retarder content on the creep deformation of oil well cement is shown in Figure 1. It can be observed that creep deformation increases with elevated retarder content. The overall creep value exhibits a rapid increase in the first 12 h. At 12 h, creep strain of oil well cement with 1%, 2%, 3% retarder addition is 30

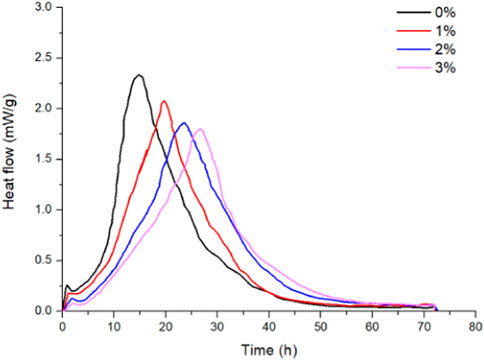

In order to analyze the intrinsic hydration mechanism relating to the changes in creep values caused by different retarder contents, heat flow from cement hydration is investigated and the result is present in Figure 2. It can be seen that there is an obvious temperature peak in induction period at about 5 h with the addition of retarder, and the second exothermic peak at about 15 h–30 h exhibits a broader and wider range of time as content of retarder increases, compared to that without retarder content. More importantly, corresponding times for the second exothermic peak shows a tendency of delay as retarder content increases. The maximum heat flow value occurs at 19.63, 23.54, and 26.72 h, respectively for the specimen with 1%, 2%, and 3% addition of retarder, which are greatly postponed compared with 15.51 h for the reference sample without retarder addition. At the same time, the heat flow peaks of the sodium triphosphate-doped samples occurred at about 18 h was lower than that of the blank samples. The main peak reaches 2.08, 1.86, and 1.80 mW/g, respectively for the specimen with 1%, 2%, and 3% retarder addition, which are 9.96%, 19.48%, and 22.08% lower than that for the reference sample with no retarder addition. Therefore the results show that retarder may play an important role in restraining the hydration process of cement, prolonging the early induction period of hydration and reducing the hydration rate in the middle and later stages. This is consistent with the previous researches (Tan et al., 2015; Zhang et al., 2022). Research by Zhang (Zhang et al., 2022) showed that the intensity of the hydration exothermic peak decreased as the dosage of retarder increase, this was because the retarder would precipitate with calcium ions and the deposit would accumulate on the surface of cement grain, which may influence dissolution of cement grain and consequently hinder the formation of hydration products.

Effect of glass fibres on the creep deformation of cement

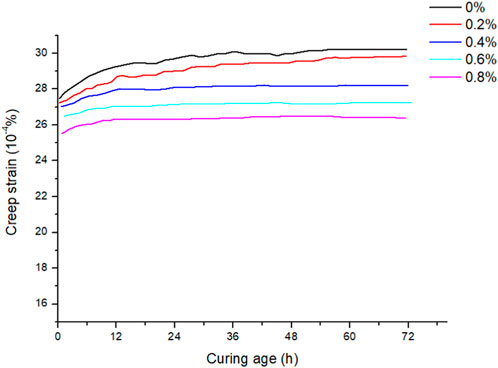

The effect of glass fiber on the creep deformation of oil well cement paste is shown Figure 3. It can be observed that creep value demonstrates great reduction as glass fiber content increase. In detail, creep strain of cement paste reduces to a value of 29.8

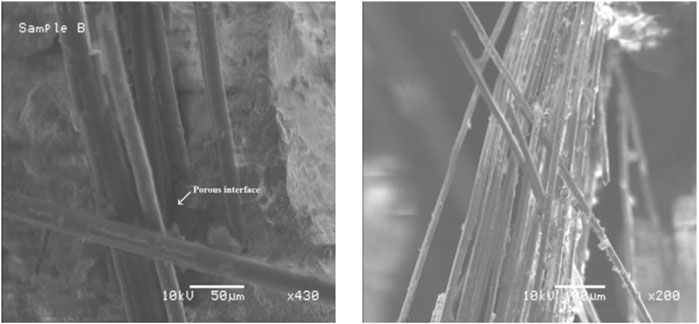

In order to understand the microstructural reasons underlying decreasing creep deformation as shown in Figure 3, microstructure between and around glass fibres are also characterized in this study as shown in Figure 4. It can be observed that fibres are randomly dispersed in the cement matrix, which may act as a bridge to carry parts of the imposed loading system. The more fiber is added, the wider the scope of overlap, and thus the creep deformation of the cement paste can be controlled to a certain extent, causing reduction of the creep value. Furthermore, it can be seen that there is still flexible space between fibres, which is beneficial to distribute and transverse loading system. At the same time, interfacial area between cement and fibre are highly porous, when the micro-cracks arrive at the transition zone, stress can be dispersed and transferred along the porosity, therefore further development and transmission of cracks can be limited and corresponding creep value of cement paste can be controlled. This is in agreement with the previous study (Brandt, 2008; Song et al., 2015; Song et al., 2019).

Effect of expansive agent on the creep deformation of cement

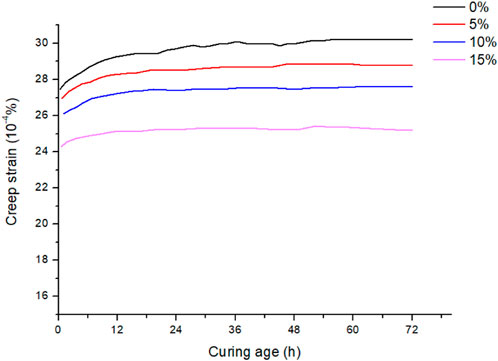

To investigate the effect of CSA expansive agent on the creep value of hydrated oil well cement, CSA cement with a content of 5%, 10%, 15% are added to replace cementitious materials and the corresponding results are demonstrated in Figure 5. It can be found out that CSA cement is considerably effective in limiting creep deformation of hydrated oil well cement at early ages. At the same time, creep reduction rate increases as the content of CSA cement increases and lowest creep value can be obtained in the cement with the addition of 15% CSA. Until 72 h, the corresponding creep strain reaches 28.9

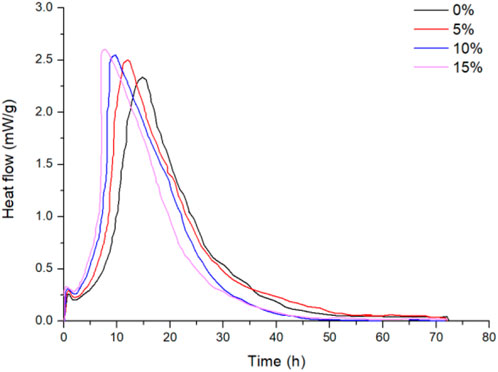

The heat flow of oil well cement with 5%, 10%, 15% CSA addition up to 72 h is illustrated in Figure 6. A dormant period can be observed in the induction period in first 8 h in all the investigated specimens and the hydration heat rate over time is increased by an increased incorporating dosage of CSA cement. This is consistent with the previous research by Qin (Qin et al., 2018) indicating that the increased heat rate at this stage could be attributed to high contents of sulfates and Ye’elimite in CSA cement. A subsequent strong exothermic peak between about 8 and 15 h indicates an acceleration period in the hydration process, and the strong peak occurs earlier as CSA contents increases. In detail, it takes place at 11.92, 9.56, and 8.09 h, respectively for cement with 5%, 10%, and 15% CSA addition, both of which shifts to an earlier date compared to 14.76 h for the reference sample with no CSA addition. Similar results were obtained in previous studies (Saoût et al., 2013; Qin et al., 2018).

At the same time, it is also clear that CSA plays a significantly important role in affecting the heat flow of oil well cement at early ages. In general, the maximum heat flow reaches to 2.50, 2.54, and 2.59 mW/g for the cement with 5%, 10%, and 15% CSA addition, which is 7.3%, 9.0%, and 11.2% higher than the reference cement with a corresponding value of 2.33 mW/g. This phenomenon is indicative of an acceleration effect of CSA addition on the acceleration period in the heat flow development of oil well cement at early ages. The results can be explained that hydration of calcium sulfoaluminate initiates more rapidly and intensively in the first 48 h than traditional Portland cement, and the hydration is an exothermic reaction and releases large proportions of hydration heat flow, therefore addition of CSA in the oil well cement can lead to advanced larger exothermic heat flow.

Conclusion

It can be concluded that creep deformation of oil well cement paste increases with elevated retarder content, it reaches 30

Glass fibre shows a positive effect in reducing the creep value of oil well cement paste and the creep strain reaches 29.8

It can also be concluded that CSA cement is considerably effective in limiting the creep deformation of oil well cement paste at early ages. The creep value of cement with 5%, 10%, and 15% CSA cement addition is 4.65%, 8.59%, and 16.61% lower than that for the specimen without CSA addition. Results from heat flow indicates an acceleration effect of CSA addition on the acceleration period in the heat flow of oil well cement at early ages, the corresponding maximum heat flow is 7.3%, 9.0%, and 11.2% higher than the reference cement with no CSA addition.

Data availability statement

The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number(s) can be found in the article/supplementary material.

Author contributions

YG and YZ contributed to conception and design of the study. YG and YZ organized the database. YG performed the statistical analysis and YZ carried out parts of the experimental work. All authors contributed to manuscript revision, read, and approved the submitted version.

Funding

This project was funded by the National Natural Science Foundation of China (No. 51974246), Basic Research Program of Natural Science in Shaanxi Province (No. 2021JQ-605 and 2021KJXX-40), State Key Laboratories of Silicate Materials for Architectures, Wuhan University of Technology in China (SYSJJ2019-17).

Conflict of interest

Author YG was employed by the company No. 6 Oil Production Plant of Changqing Oilfield Branch of PetroChina.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bassioni, G., and Ali, M. M. (2013). The effect of counterion in lignosulfonates as oil-well cement retarders. Adv. Cem. Res. 25 (5), 245–253. doi:10.1680/adcr.12.00016

Bazant, Z. P., Cusatis, C., and Cedolin, L. (2004). Temperature effect on concrete creep modeled by microprestress-solidification theory. J. Eng. Mech. 130 (6), 691–699. doi:10.1061/(asce)0733-9399(2004)130:6(691)

Brandao, N. B., Roehl, D., Silva, F. D., and Rosas e Silva, R. (2017). The impact of cement slurry aging creep on the construction process of oil wells. J. Petroleum Sci. Eng. 157, 422–429. doi:10.1016/j.petrol.2017.07.051

Brandt, A. M. (2008). Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 86 (1-3), 3–9. doi:10.1016/j.compstruct.2008.03.006

Chen, I. A., Hargis, C. W., and Juenger, M. C. F. (2012). Understanding expansion in calcium sulfoaluminate–belite cements. Cem. Concr. Res. 42 (1), 51–60. doi:10.1016/j.cemconres.2011.07.010

Corinaldesi, V., Nardinocchi, A., and Donnini, J. (2015). The influence of expansive agent on the performance of fibre reinforced cement-based composites. Constr. Build. Mater. 91, 171–179. doi:10.1016/j.conbuildmat.2015.05.002

Dai, X. D., Aydin, S., Yardimci, M. Y., and De Schutter, G. (2022). Early structural build-up, setting behavior, reaction kinetics and microstructure of sodium silicate-activated slag mixtures with different retarder chemicals. Cem. Concr. Res. 159, 106872. doi:10.1016/j.cemconres.2022.106872

Fathifazl, G., Razaqpur, A. G., Isgor, O. B., Abbas, A., Fournier, B., and Foo, S. (2011). Creep and drying shrinkage characteristics of concrete produced with coarse recycled concrete aggregate. Cem. Concr. Compos. 33 (10), 1026–1037. doi:10.1016/j.cemconcomp.2011.08.004

Ferreira, J. G., and Branco, F. A. (2007). Structural application of GRC in telecommunication towers. Constr. Build. Mater. 21 (1), 19–28. doi:10.1016/j.conbuildmat.2005.08.003

Garas, V. Y., Kahn, L. F., and Kurtis, K. E. (2009). Short-term tensile creep and shrinkage of ultra-high performance concrete. Cem. Concr. Compos. 31 (3), 147–152. doi:10.1016/j.cemconcomp.2009.01.002

Hargis, C. W., Lothenbach, B., Muller, C. J., and Winnefeld, F. (2019). Further insights into calcium sulfoaluminate cement expansion. Adv. Cem. Res. 31 (4), 160–177. doi:10.1680/jadcr.18.00124

Jafariesfad, N., Geiker, M. R., Gong, Y., Skalle, P., Zhang, Z., and He, J. (2017). Cement sheath modification using nanomaterials for long-term zonal isolation of oil wells: Review. J. Petroleum Sci. Eng. 156, 662–672. doi:10.1016/j.petrol.2017.06.047

Kumar, S., Bera, A., and Shah, S. N. (2022). Potential applications of nanomaterials in oil and gas well cementing: Current status, challenges and prospects. J. Petroleum Sci. Eng. 213, 110395. doi:10.1016/j.petrol.2022.110395

Kupwade-Patil, K., Boul, P. J., Rasner, D. K., Everett, S. M., Proffen, T., Page, K., et al. (2019). Retarder effect on hydrating oil well cements investigated using in situ neutron/X-ray pair distribution function analysis. Cem. Concr. Res. 126, 105920. doi:10.1016/j.cemconres.2019.105920

Li, H., Li, Z. H., Gao, Li, Yu, H., Jiang, Z., He, L., et al. (2020). Casing deformation mechanisms of horizontal wells in Weirong shale gas field during multistage hydraulic fracturing. J. Nat. Gas Sci. Eng. 84, 103646. doi:10.1016/j.jngse.2020.103646

Li, J. Y., and Yao, Y. (2001). A study on creep and drying shrinkage of high performance concrete. Cem. Concr. Res. 31 (8), 1203–1206. doi:10.1016/s0008-8846(01)00539-7

Lin, T. J., Yu, H., Lian, Z. H., and Sun, B. (2017). Casing failure mechanism during volume fracturing: A case study of shale gas well. Adv. Mech. Eng. 9 (8), 168781401771718–168781401771719. doi:10.1177/1687814017717182

Lu, Q., Liu, Z., Guo, J. C., He, L., Li, Y., Zeng, J., et al. (2021). Hydraulic fracturing induced casing shear deformation and a prediction model of casing deformation. Petroleum Explor. Dev. 48 (2), 460–468. doi:10.1016/s1876-3804(21)60037-x

Mark, M., Winnefeld, F., Lothenbach, B., Dolenec, S., et al. (2021). The influence of calcium sulfate content on the hydration of belite-calcium sulfoaluminate cements with different clinker phase compositions. Mat. Struct. 54 (6), 212. doi:10.1617/s11527-021-01811-w

Mo, L. W., Deng, M., and Tang, M. S. (2010). Effects of calcination condition on expansion property of MgO-type expansive agent used in cement-based materials. Cem. Concr. Res. 40 (3), 437–446. doi:10.1016/j.cemconres.2009.09.025

Mohammed, A. I., Oyeneyin, B., Atchison, B., and Njuguna, J. (2019). Casing structural integrity and failure modes in a range of well types - a review. J. Nat. Gas Sci. Eng. 68, 102898. doi:10.1016/j.jngse.2019.05.011

Moradpour, R., Taheri-Nassj, E., Parhizkar, T., and Ghodsian, M. (2013). The effects of nanoscale expansive agents on the mechanical properties of non-shrink cement-based composites: The influence of nano-MgO addition. Compos. Part B Eng. 55, 193–202. doi:10.1016/j.compositesb.2013.06.033

Orlowsky, J., and Raupach, M. (2008). Durability model for AR-glass fibres in textile reinforced concrete. Mat. Struct. 41 (7), 1225–1233. doi:10.1617/s11527-007-9321-2

Qin, L., Gao, X. J., and Zhang, A. L. (2018). Potential application of Portland cement-calcium sulfoaluminate cement blends to avoid early age frost damage. Constr. Build. Mater. 190, 363–372. doi:10.1016/j.conbuildmat.2018.09.136

Saoût, L. G., Lothenbach, B., Hori, A., Higuchi, T., and Winnefeld, F. (2013). Hydration of Portland cement with additions of calcium sulfoaluminates. Cem. Concr. Res. 43, 81–94. doi:10.1016/j.cemconres.2012.10.011

Song, M., Purnell, P., and Richardson, I. (2015). Microstructure of interface between fibre and matrix in 10-year aged GRC modified by calcium sulfoaluminate cement. Cem. Concr. Res. 76, 20–26. doi:10.1016/j.cemconres.2015.05.011

Song, M., Wu, K., and Dou, Y. (2019). Durability of GFRC modified by calcium sulfoaluminate cement under elevated curing temperatures. Adv. Mater. Sci. Eng. 2019, 1–6. doi:10.1155/2019/2915684

Stierwalt, D. D., and Hamilton, H. R. (2005). Creep of concrete masonry walls strengthened with FRP composites. Constr. Build. Mat. 19 (3), 181–187. doi:10.1016/j.conbuildmat.2004.07.001

Su, D. H., Wu, X. N., Li, Z. Y., Huang, S., Li, J., Sun, J., et al. (2022). Theoretical analysis of the micro annulus of an oil-well cement sheath formed via cooling under acid-fracturing conditions. Process. (Basel). 10 (5), 966. doi:10.3390/pr10050966

Tan, H. B., Huang, J., Ma, B. G., and Li, X. (2015). Effect of superplasticiser and sodium tripolyphosphate on fluidity of cement paste. Mag. Concr. Res. 66 (23), 1194–1200. doi:10.1680/macr.14.00091

Wang, C. L., and Song, M. M. (2021). Influence of water-cement ratio and type of mixing water on the early hydration performance of calcium sulphoaluminate (CSA) cement. Adv. Mater. Sci. Eng. 2021, 1–10. doi:10.1155/2021/5557763

Yan, Y., Guan, Z. C., Yan, W. J., and Wang, H. (2020). Mechanical response and damage mechanism of cement sheath during perforation in oil and gas well. J. Pet. Sci. Eng. 188, 106924. doi:10.1016/j.petrol.2020.106924

Zhai, X. P., Lou, Y. S., Cao, Y. F., et al. (2015). Influences of stratum stiffness and relaxation time of creep layers on external squeeze pressure of casing. Acta Pet. Sin. 36 (10), 1299–1304. doi:10.7623/syxb201510013

Keywords: oil well cement, creeping, retarder, glass fibre, CSA cement

Citation: Song M, Gao Y and Zhang Y (2022) Influence of different additives on the creep property of oil well cement. Front. Built Environ. 8:1063229. doi: 10.3389/fbuil.2022.1063229

Received: 06 October 2022; Accepted: 31 October 2022;

Published: 11 November 2022.

Edited by:

Zhenming Li, Delft University of Technology, NetherlandsReviewed by:

Tianshi Lu, Southwest Petroleum University, ChinaXuhui Liang, Delft University of Technology, Netherlands

Copyright © 2022 Song, Gao and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Meimei Song, bW1zb25nQHhzeXUuZWR1LmNu

Meimei Song

Meimei Song Yang Gao2

Yang Gao2