- 1Université Grenoble Alpes, CEA, LETI-DTIS (Département des Technologies pour l’Innovation en Santé), Grenoble, France

- 2Université Paris-Saclay, CEA, JACOB-SEPIA, Fontenay-aux-Roses, France

Implantable and wearable bioelectronic systems are arising growing interest in the medical field. Linking the microelectronic (electronic conductivity) and biological (ionic conductivity) worlds, the biocompatible conductive materials at the electrode/tissue interface are key components in these systems. We herein focus more particularly on resorbable bioelectronic systems, which can safely degrade in the biological environment once they have completed their purpose, namely, stimulating or sensing biological activity in the tissues. Resorbable conductive materials are also explored in the fields of tissue engineering and 3D cell culture. After a short description of polymer-based substrates and scaffolds, and resorbable electrical conductors, we review how they can be combined to design resorbable conductive materials. Although these materials are still emerging, various medical and biomedical applications are already taking shape that can profoundly modify post-operative and wound healing follow-up. Future challenges and perspectives in the field are proposed.

1 Introduction

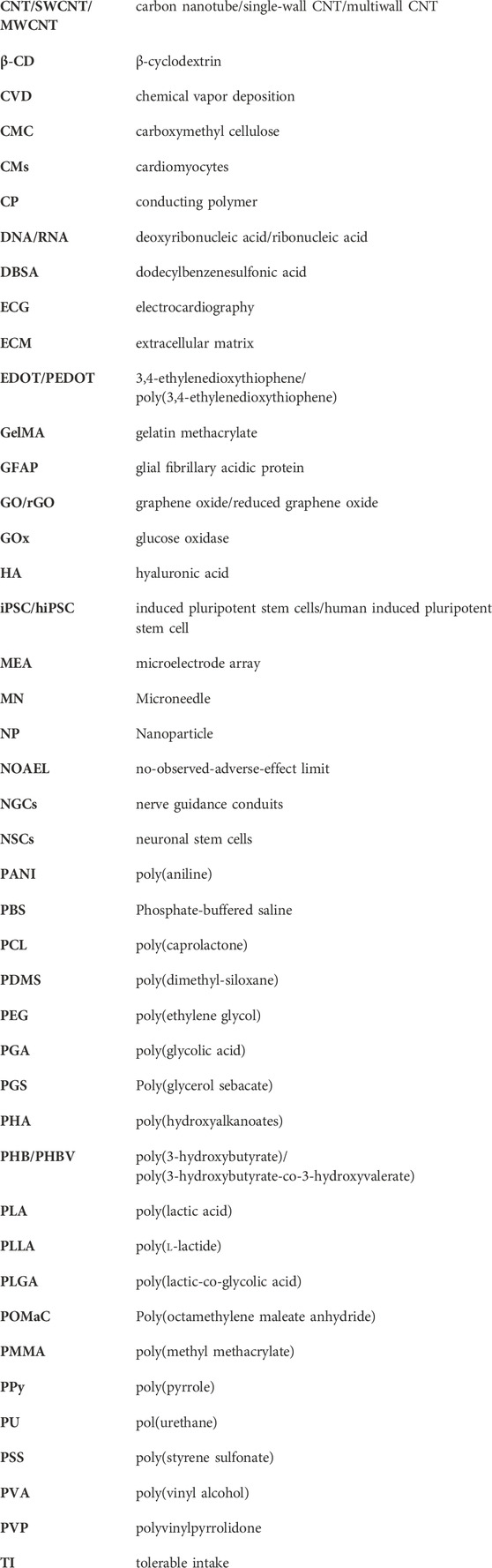

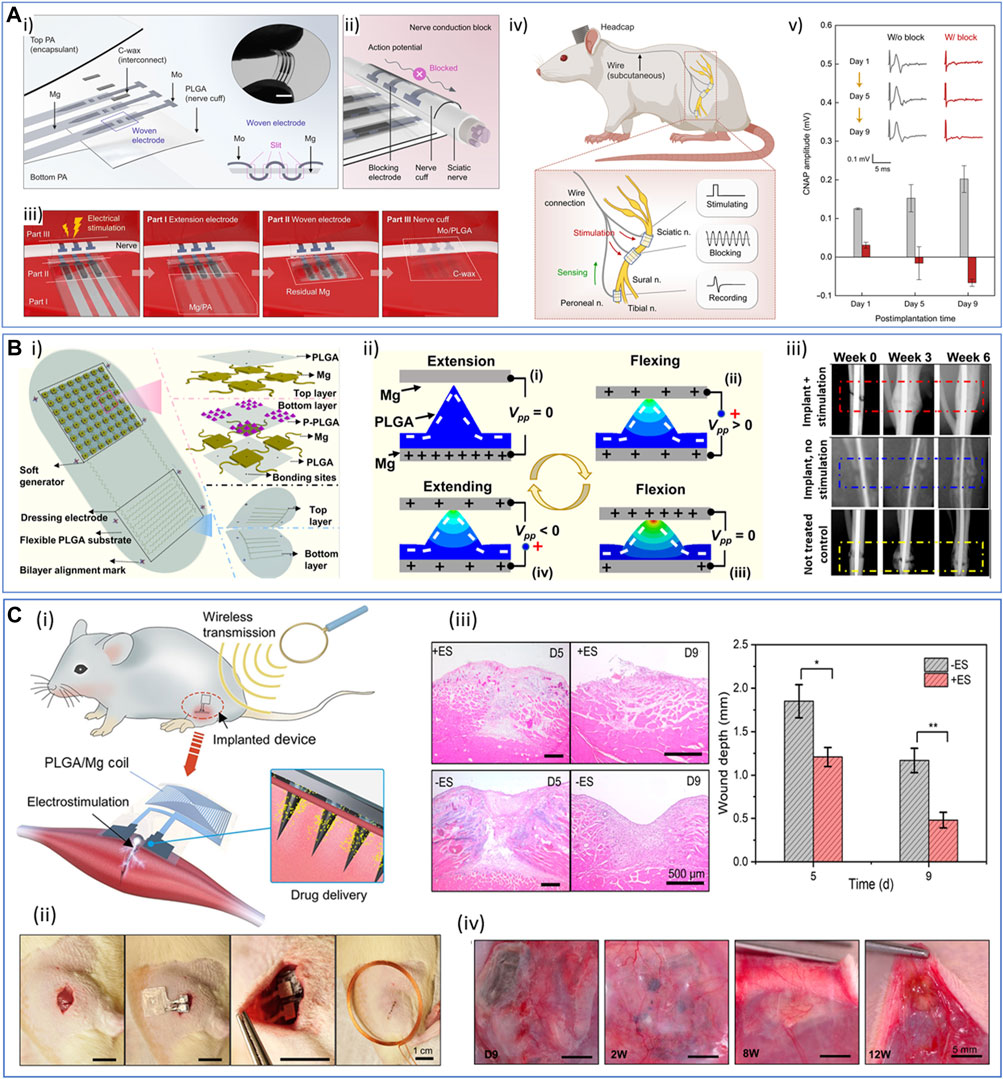

The current landscape of electronic systems in the medical field is diverse, encompassing wearable and implantable devices tailored to various applications, such as drug delivery, occasional or continuous monitoring, or stimulation. These systems primarily rely on traditional materials like metals, semiconductors, and plastics and conventional processes such as patterning and lithography from the realm of microelectronics. In recent years, much effort has been dedicated to conferring these systems with mechanical properties more suitable for in vivo use, for instance, with the employment of thinned structures, and the development of processes compatible with flexible and stretchable substrates such as elastomers (Palma et al., 2022; Veletić et al., 2022). However, the large majority of presently used medical bioelectronic systems display a fundamental difference with living tissues: they are not resorbable, meaning they are not composed of materials that progressively dissolve in the body or onto the skin, without inducing toxicity or immunogenicity. Long-term implants are required for a set of medical applications that are presently addressed (e.g., cardiac and neural implants such as deep brain stimulation implants for Parkinson’s disease or vagus nerve stimulation devices), or for which it would be highly desirable to prolong the device lifetime (e.g., continuous glucose monitoring sensors, drug delivery pumps, etc.). However, innovative applications could emerge with the advent of resorbable, wearable, or implanted medical bioelectronic systems (Figure 1). Resorbable bioelectronics can be used for the design of microelectrode arrays for transient neuromodulation (brain, spinal cord, and peripheral nerve), on-skin sensors, and heart, skin, muscle, or bone stimulation to promote healing. More prospectively, resorbable sensors can be dedicated to post-surgical follow-up to alert on infection risks or ensure the success of a graft (tissue anastomosis). Resorbable conductive materials are also intensively sought for tissue engineering, in particular in the case of electro-responsive organs such as the heart, nerves, or skin, and for demanding in vitro applications, particularly in the field of 3D cell culture models (Guo et al., 2018; Park et al., 2022b; Tringides et al., 2022).

FIGURE 1. Examples of applications in the field of medical devices requiring the use of resorbable conductive materials. Bioelectronic systems: brain: reproduced with permission, Copyright 2019, John Wiley and Sons (Xu K. et al., 2019). Heart: adapted with permission, Copyright 2023, the Authors, published by Science Advances (Chen et al., 2023). Skin: reproduced with permission, Copyright 2019, John Wiley and Sons (Wang Q. et al., 2019). Bone: adapted with permission, Copyright 2021, the Authors, published by PNAS (Yao et al., 2021). Muscle: adapted with permission from Huang et al. (2022), Copyright 2022, the American Chemical Society. Peripheral nerve: Copyright 2022, the Authors, published by Science Advances (Lee et al., 2022). Tissue engineering substitutes: Heart: adapted from Xu Y. et al. (2019), Copyright 2019, John Wiley and Sons. Skin: adapted with permission from Huang et al. (2018), Copyright 2018, the American Chemical Society. Spinal cord: adapted from Chen et al. (2022), Copyright 2022, Springer Nature. Bone: reproduced from eSilva et al. (2021), Copyright 2021, Springer Nature. Peripheral nerve: reproduced with permission, Copyright 2020, John Wiley and Sons (Park et al., 2020), created with BioRender.com.

It is noteworthy that material resorbability in the body or onto the skin is more demanding than biodegradability, which may also encompass degradation in the natural environment under a more general definition. In the body, biodegradable materials degrade in smaller fragments that can eventually diffuse from their implantation site but not necessarily be eliminated. Contrarily, resorbable materials are totally eliminated from the body. These are materials that degrade into safe, smaller components when exposed to physiologically relevant conditions like biological fluids and enzymes. These resulting components and by-products are subsequently removed from the body via either metabolic processes or excretion (Eglin et al., 2008; Grosjean et al., 2023). Material resorbability can occur through different mechanisms, i.e., chemical and enzymatic degradations. The main chemical degradation processes occur through the hydrolysis of the polymer backbone bonds. Notably, the kinetics of degradation of commonly used synthetic polyesters such as poly(lactic acid) (PLA), poly(lactic-co-glycolic acid) (PLGA), and poly(hydroxyalkanoates) (PHA) can be controlled by their molecular composition, polymer molecular weight, and crystallinity (Bano et al., 2018). Natural polymers such as collagen, gelatin, and hyaluronic acid are primarily degraded by proteolytic and glycolytic enzymes.

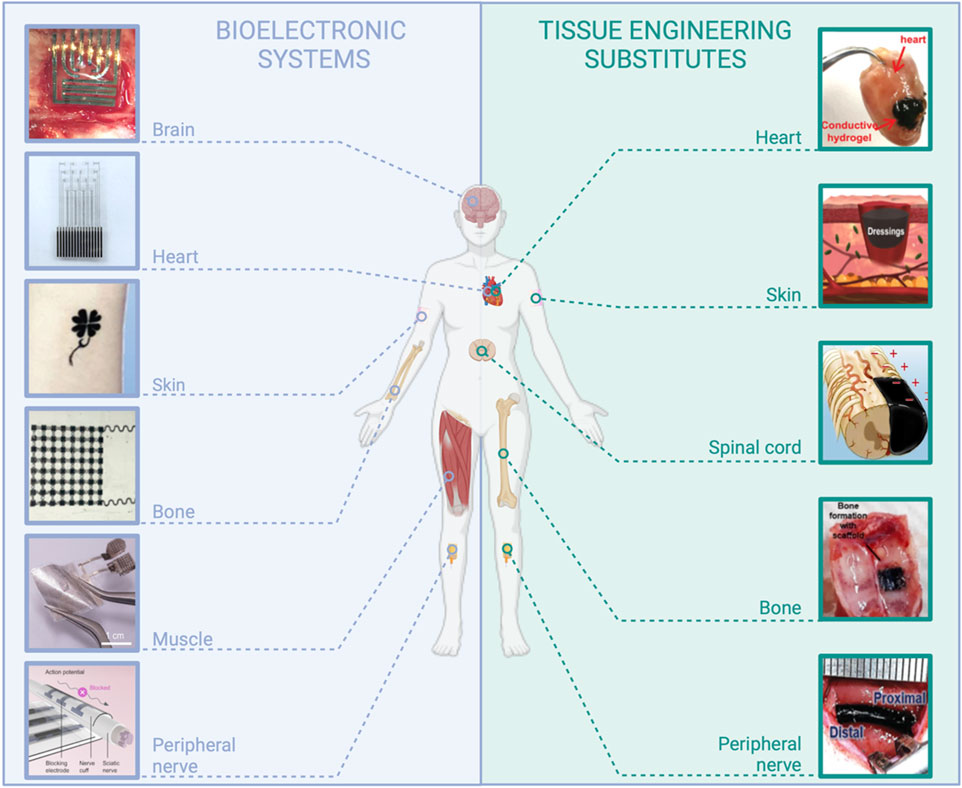

In addition to biocompatibility, materials employed in designing medical devices must fulfill additional requirements due to their intimate interaction with tissues. Indeed, these tissues can display a wide range of mechanical properties. First, bones, tendons, and nerves can be considered very hard and poorly stretchable tissues, with mechanical stiffness quantified by Young’s modulus in the decreasing order of 12 GPa (Keller et al., 1990), 550 MPa (O’Brien et al., 2010), and 580 kPa (Borschel et al., 2003), respectively. They exhibit high elastic moduli, similar to those of plastic materials (Figure 2). The skin is both relatively tough and stretchable (0.5–1 MPa elastic modulus) (Li et al., 2012), whereas very soft tissues like the brain display very high viscoelastic properties (elastic modulus G′ below 10 kPa, elastic-to-viscous moduli ratio G″/G′ > 0.5) (Hall et al., 2021; Tringides et al., 2022). In any case, tissue mechanical properties are quite different from those of rigid metal, plastics, or elastomers, classically employed in electronic devices (Figure 2) (Sunwoo et al., 2021). Such a mechanical mismatch between these materials and tissues at the intimate cellular level can be responsible for undesired effects, ranging from progressive material encapsulation by tissues, therefore inhibiting the correct functioning of the device, to acute inflammatory reaction and pain (Rivnay et al., 2017; Sunwoo et al., 2020). Another remarkable difference between tissues and materials such as metals, semiconductors, and elastomers presently used in bioelectronics consists in their morphological structure. While tissues display a macroporous/microporous structure, most of these synthetic materials are shaped as solid bulk or thin continuous layers without either no or poor porosity. Very importantly, many tissues are intimately exposed to biological fluids like interstitial fluid and blood, even sometimes with shear flow as in the cardiac and circulatory systems, and many of them, in particular soft tissues, are continuously bathed in these fluids making them an integral part of the tissue itself (Figure 2). By comparison, metals, semiconductors, and synthetic elastomers do not comprise water. For tissue engineering applications, material water content is an important hallmark to allow the necessary perfusion of nutrients, oxygen, and biological cues. In these perspectives, hydrogels—3D cross-linked polymer networks that can absorb large quantities of water—are interesting to explore. Their mechanical properties can be tuned across a wide range of Young’s modulus and viscoelasticity to design scaffolds with mechanical properties similar to those of the different types of tissues, from bone to brain (Figure 2) (Yuk et al., 2022). However, they are not intrinsically electronic conductors (though they can be ionic conductors), and consequently, they cannot be used as such to design electrically conductive materials for medical applications that require moderate to high electronic conductivity (103–105 S cm−1). Therefore, for all the above reasons, it is clear that beyond resorbability, bioelectronics and tissue engineering applications can advantageously benefit from the use of innovative conductive materials that better display the fundamental characteristics of tissues, i.e., hydrogel-based materials.

FIGURE 2. Quantification and comparison of the mechanical modulus (Pascal, Pa), viscoelasticity (loss modulus/storage modulus, G″/G′), and water content (percentage of weight) of tissues with those of materials classically employed in bioelectronic devices and tissue engineering (i.e., metals, plastic, elastomers, and hydrogels). Data taken from literature. Mechanical modulus: brain (Hall et al., 2021), heart (Jacot et al., 2010), spinal cord (Karimi et al., 2017), nerve (Rosso et al., 2019), skin (Kalra et al., 2016), bone (Morgan et al., 2018), and materials classically employed in bioelectronic devices and tissue engineering (Tringides et al., 2022). Viscoelasticity: adapted from Tringides et al. (2022). Water content: bone (Surowiec et al., 2022), nerve (Anand et al., 1988), spinal cord (Mbori et al., 2016), skin (Téllez-Soto et al., 2021), heart (Eitel et al., 2011), and brain (Gottschalk et al., 2021). Created with Octave (software version 8.2.0) and adapted on BioRender.com.

Passive (i.e., non-conductive) resorbable polymer-based medical devices have been extensively developed for the short-term or prolonged delivery of active ingredients. These drug-delivery implants are mainly based on synthetic polyesters like PLA, PLGA, poly(caprolactone) (PCL), and PHA that are sometimes also referred to as “bioplastics” (Bano et al., 2018) or on resorbable biopolymer-based hydrogels. Though bioplastics and biopolymer-based hydrogels are both resorbable, these materials differ markedly by their mechanical and swelling properties (“tough” and quite hydrophobic materials for bioplastics and “soft” and wet materials for hydrogels). Resorbable synthetic polyesters, such as PLA, PLGA, and PHA, are interesting because they can act as insulating supports or passivation layers in bioelectronic systems, taking advantage of their rather hydrophobic properties. First resorbable elastomers have also been recently reported (Turner et al., 2022). Hydrogels, from their side, are by definition highly hydrophilic materials and not suitable to act as insulating substrates in the design of bioelectronic systems, but they can be combined with conductive moieties to obtain suitable interfaces (for instance, electrodes) with the tissues or for the development of 3D cell cultures or organoids (Caliari et al., 2016; Kozlowski et al., 2021). Silk fibroin is a resorbable natural polymer combining the interesting features of both bioplastics (i.e., mechanical properties) and hydrogels (i.e., porous biopolymer scaffold).

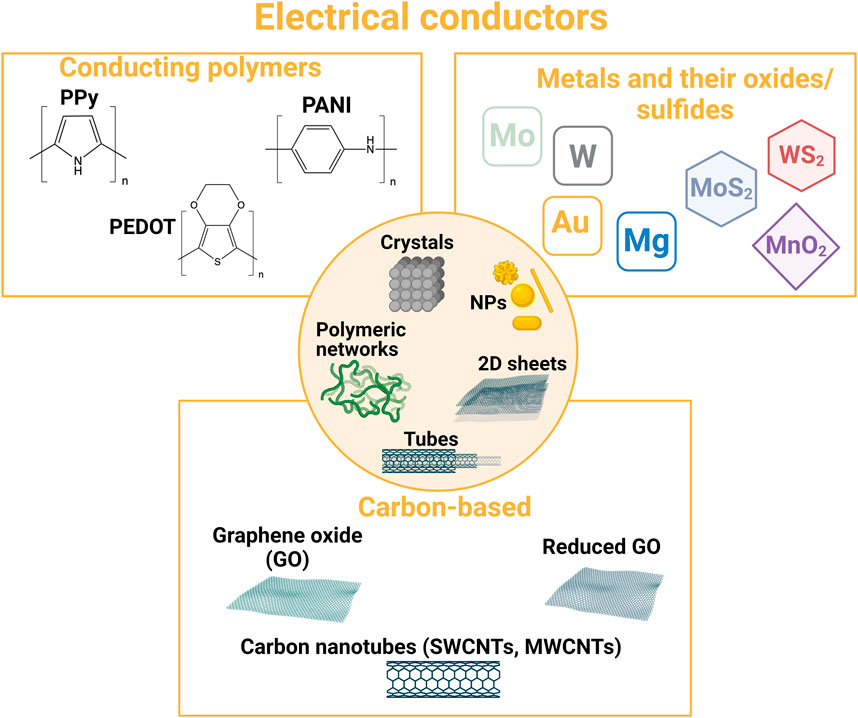

Concerning electrical conductors, the interest in conducting polymers such as poly(pyrrole) (PPy), poly(aniline) (PANI), and poly(3,4-ethylenedioxythiophene) (PEDOT) to optimize system/tissue bioelectronic interface was underlined several times due to both their ionic and electronic conductivity (Chen et al., 2021; Han et al., 2022). Indeed, Sansinena et al. (1997) and Kim et al. (2000) first pointed out the interest in such conductive materials, used in conjunction with hydrogels, for the design of artificial muscles exhibiting interesting actuation capabilities. However, other conductive materials of high interest are largely employed in bioelectronics and tissue engineering applications, especially when it is necessary to achieve high material conductivities. There exist a few biocompatible and resorbable metals such as molybdenum, tungsten, and iron. Two-dimensional (2D) transition-metal chalcogenides (e.g., MoS2 sheets) and carbon-based structures and fillers like carbon nanotubes (CNTs) and graphene derivatives are also commonly employed materials.

In this review, we will describe how resorbable substrates and scaffolds such as elastomers, synthetic polyesters, and biopolymer-based hydrogels can be combined with a variety of electrical conductors like metals, micro- and macro-structured fillers, and conducting polymers, to lead to resorbable conductive materials with a wide range of mechanical properties. Some reviews have already discussed related subjects, such as conductive hydrogels (Rogers et al., 2020; Xu et al., 2020; Chen et al., 2021; Xu et al., 2021; Gao et al., 2022; Zhu et al., 2023a), conducive materials for neural interfaces (Fattahi et al., 2014), and conductive materials for tissue engineering (Min et al., 2018; Mostafavi et al., 2020; Rogers et al., 2020; Zhao et al., 2022b; Gao et al., 2022). However, we herein focus specifically on conductive materials that exhibit resorbability, a topic that has received comparatively less attention, especially for bioelectronic systems. As discussed earlier, the resorbability of conductive materials holds significant relevance for both the fields of bioelectronic devices and tissue engineering. It is worth noting that there is a noticeable gap in the existing literature concerning a comprehensive work that effectively merges the domains of soft bioelectronic systems that interact with living tissues and tissue engineering. This review aims to bridge the gap between these two distinct yet interconnected fields, which both rely on similar polymer and electrical components, as well as process methodologies, especially when it comes to resorbable conductive materials. Thus, we aim to provide readers with a review and thorough analysis of various approaches within the context of bioresorbable materials, allowing for an in-depth exploration of specific challenges and opportunities, encompassing both bioelectronics and tissue engineering applications. Special emphasis will also be placed on resorbable hydrogel-based materials. As highlighted earlier, these materials exhibit exceptional properties for replicating the characteristics of living tissues, making them a natural choice for tissue engineering applications. Furthermore, our extensive literature review has unveiled that the utilization of resorbable hydrogels represents a smart and emerging approach to the design of resorbable bioelectronic devices. While this review encompasses resorbable conductive materials and their applications in a broader sense, we will particularly emphasize the role of hydrogel-based systems in this context. Note that although these are closely related domains, we will not review here electronic textiles and refer the reader to other publications in that field (Kim et al., 2019; Alhashmi Alamer et al., 2022; Gong et al., 2022; Zhang et al., 2022; Wei et al., 2023).

Following the examination of various resorbable substrates and scaffolds, we will review the selection of electrical conductors that present resorbability. Subsequently, we will describe the different processes that can be used to combine them into resorbable conductive materials. These processes can impact the resorbability, conductivity, and mechanical properties of the resultant resorbable devices. These innovative resorbable conductive materials have broad applications, such as the development of novel transient bioelectronic systems for monitoring and stimulation, which will not require retrieval surgery after they have served their purpose. Additionally, they hold promise for on-skin electronic applications, 3D cell culture, and tissue engineering, particularly in the context of electro-sensitive organs like the heart, nerves, brain, and skin. They are therefore expected to address emerging applications in the biomedical field.

2 Selecting components for the design of resorbable conductive hydrogels

Resorbable conductive materials rely on the combination of a 2D substrate or a 3D scaffold and an electrical conductor. In this section, we will give a short overview of these materials.

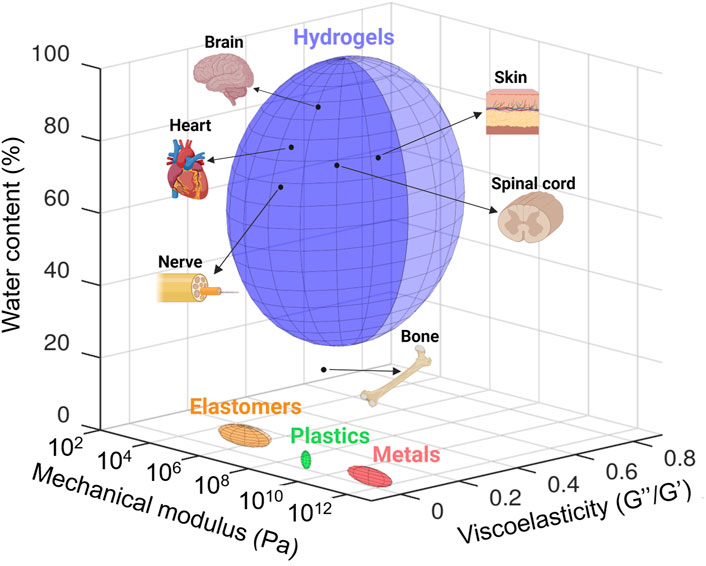

2.1 Substrates and scaffolds

The different resorbable materials that can be employed as 2D substrates or 3D scaffolds (Figure 3) do not display similar mechanical properties (Young’s modulus and viscoelasticity), the same hydrophobic/hydrophilic properties, or degradation kinetics and mechanisms (Figure 2) (Tringides et al., 2022). Since it is desirable to select a material whose mechanical properties match as much as possible those of the tissue that it is in contact with to limit discomfort and inflammation, the different types of substrates and scaffolds are used for different applications. Classical substrates for the design of wearable or implantable bioelectronic systems are mainly based on elastomers, such as silicone rubber or poly(urethane)-based films. These materials exhibit high chemical stability and can withstand very large strain rates. Therefore, they are particularly well-suited for seamlessly integrating with tissue movements, such as stretching, bending, and torsion, in particular for their application in skin electronics. They are also good candidates for applications involving tubing or highly flexible structures, such as cuff electrodes. However, the design of resorbable elastomers is still an emerging field (Turner et al., 2022). Therefore, bioplastics such as resorbable polyesters have driven much attention, especially considering that some of them, such as PLGA, PLA, and PHAs, are already approved implant materials by regulatory agencies (the Food and Drug Administration and European Medical Agency) (Nair et al., 2007; Ulery et al., 2011; Bano, 2018; Lu et al., 2023a). Elastomers and bioplastics are mainly employed as 2D thin-film substrates that are assembled with electrical conductors to design multilayer electronic systems. When aiming to create more viscoelastic 3D scaffolds, for instance, for 3D cell culture or tissue engineering applications, biopolymer-based hydrogels are more appropriate. From its natural origin, silk can display both hydrogel resorbability and eventual swellability and bioplastic-like mechanical properties. It is therefore a particularly relevant polymer to use as a resorbable substrate and packaging material in bioelectronics.

FIGURE 3. Overview of main materials employed for the construction of resorbable substrates and scaffolds at the interface with tissues.

2.1.1 Resorbable elastomers

Recent advancements in the design, synthesis, and medical uses of resorbable elastomers, mainly polyurethanes (PUs), poly(glycerol sebacate), and poly(diol citrate) (Figure 3), have been recently reviewed (Turner et al., 2022). Polyurethanes are a large class of copolymers where at least two organic monomers react to create a carbamate bond. Typically, PUs are produced by the reaction between a diisocyanate and polyol. A judicious choice of reactants makes it possible to confer degradability to the polymer, for instance, by selecting degradable monomers comprising an ester bond (Christenson et al., 2007). PUs are interesting in medical applications for their biocompatibility, the versatility of their chemical structure, and their high stretchability. The addition of poly(urethane) cross-links in an already resorbable bioplastic material can also confer it with elastomeric properties while maintaining its resorbability (Sharma et al., 2018). For instance, Sharma et al. designed a resorbable elastomeric stent based on a network of poly(glycolide-co-caprolactone) chains cross-linked with short polyurethane segments. The material, initially resorbable and stretchable, but without any deformation reversibility, displayed elastomeric behavior after PU cross-linking.

Poly(glycerol sebacate) (PGS) elastomers are polyesters obtained by the polycondensation of FDA-approved glycerol and sebacic acid. Due to their high biocompatibility, elastomeric properties, and biodegradability, PGS elastomers constitute materials of choice for medical applications (Rai et al., 2012). They have been used mainly in tissue engineering, in particular for neural and cardiac tissues, and wound healing. More recently, PGS elastomers have been combined with different conductive materials for the design of smart textiles that include pressure, strain, and temperature sensors (Vogt et al., 2021). Poly(diol citrate) elastomers are also polyesters derived from the condensation of citric acid with polyols during thermal treatment, with potential for tissue engineering applications. Poly(octamethylene maleate (anhydride)) (POMaC) has been combined with PGS to package resorbable strain and pressure sensors made of PLA and magnesium (Boutry et al., 2018). The resorbable device was intended to follow up tendon repair and self-degrade after its service to avoid second retrieval surgery.

Most of the resorbable elastomers described above are not yet commercial, which has limited their use in resorbable medical devices to proof-of-concept studies until now. However, a variety of chemical structures are possible to tune their mechanical and degradation properties. Depending on the materials, compression moduli, tensile strength, and elongation at break have been reported to range from 0.025 to 400 MPa, 0.2 to 2,500 MPa, and 10% to 2,500%, respectively (Turner et al., 2022). These materials typically degrade in a few weeks in water (Turner et al., 2022), due to the hydrolysis of ester bonds in saline media, accelerated in a basic medium, and by the action of endogenous esterases. Resorbable elastomers can also be combined with other materials such as bioplastics (PLA, PLGA, PCL, etc.) to obtain copolymers with intermediate mechanical or degradation properties. Elastomers do not possess the viscoelastic properties of soft tissues (Figure 2). However, they are particularly interesting in interfacing with highly stretchable tissues, such as skin, and are extensively used in the field of wearable bioelectronic systems and “skin electronics” (e-skin) (Park et al., 2022a; Gong et al., 2022; Liu et al., 2023a). Their mechanical toughness makes them also interesting when in contact with moderately “hard” tissues, like the tendons and heart. Therefore, it can be foreseen that resorbable elastomers will attract more and more interest in the coming years.

2.1.2 Synthetic polyesters and other polymers

Thanks to their biocompatibility and well-controlled structure-tunable degradability, synthetic aliphatic polyesters have been extensively developed in medical devices since the 1970s. In particular, they have been used as surgical sutures, drug delivery systems, and tissue-engineering scaffolds. Most employed materials include PLA, poly(glycolic acid) (PGA), PLGA, PCL, and PHA (Figure 3). Because these materials generally display thermoplastic properties and can also serve as alternatives to petro-sourced polymers in other applications such as packaging, they have also been described as “bioplastics” (Bano et al., 2018; Jiang et al., 2022).

PLA is obtained by the poly(condensation) of lactic acid, which can interestingly be obtained by the bacterial fermentation of carbohydrates or synthetically. The L-lactide isomer is naturally produced and leads to PLLA (poly(L-lactide)). PLLA is quite a hydrophobic and slow-degrading crystalline polymer, with a glass transition temperature of 60°C–65°C and melting temperature of 175°C (Nair et al., 2007). It displays a relatively high tensile strength (0.01–5 GPa) (Eglin et al., 2008; Ulery et al., 2011) and a high modulus, with resorption kinetics up to 5 years (Ulery et al., 2011), making it suitable for use in surgical sutures. To increase its kinetics of resorbability, the two isomers, D and L, can be combined to obtain amorphous PLA with less mechanical strength and a lifetime of 12–16 months (Nair et al., 2007). Lactic acid can also be combined with glycolic acid to obtain PLGA. PLGA polymers are extensively used in medical applications since they can be processed with a wide range of different shapes: micro-structured films (Abu Ammar et al., 2021), porous scaffolds (Pan et al., 2012), microspheres and nanoparticles (Lu et al., 2023a), and microfibers (Chor et al., 2020). They can be used for drug delivery and tissue engineering applications or as surgical sutures or substrates for bioelectronics. Indeed, by modulating not only the L/G monomer ratio but also the polymer molecular mass and ending groups, it is possible to fine-tune the thermal, mechanical, and degradation properties of PLGA to make them match with the targeted application (Bano et al., 2018; Lu et al., 2023a). Contrary to PLA and PGA, PLGA are amorphous polymers when the L/G ratio is between 1/3 and 3, with fast kinetics of hydrolysis degradation up to 1–2 months for the 1/1 copolymer (Ulery et al., 2011). PGA is less hydrophobic and resistant against hydrolysis than PLA, but still crystalline and with a high melting temperature (>200°C), as well as displaying very high tensile strength (0.3–0.9 GPa) (Eglin et al., 2008; Ulery et al., 2011), which has made it a relevant material for surgical sutures and tissue engineering.

Poly(caprolactone) (PCL) is a hydrophobic semi-crystalline polymer that is interesting for its low glass transition (−54°C) and melting (approximately 60°C) temperatures, and its high elongation (300%–4,700%) and tensile strength (20–40 MPa) at break (Eglin et al., 2008; Ulery et al., 2011). It displays a very long degradation time (2–4 years). Because of its high permeability, it is mainly used in drug delivery systems and tissue engineering (Bano et al., 2018). PCL is also extensively used in combination with PLLA, PLA, and PLGA.

Poly(hydroxyalkanoates) (PHAs) are a family of polyesters produced by bacterial fermentation or algal bioproduction and presenting a very wide variety of structures and properties. To date, PHAs used in the biomedical field are mainly poly(3-hydroxybutyrate) (PHB) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBHV) (Singh et al., 2019; Tebaldi et al., 2019; Ansari et al., 2021). Their biocompatibility, non-immunogenicity, and non-carcinogenic properties have been regularly pointed out. Their mechanical properties can be tuned to match those of very soft (skin) to very hard (bone) tissues. Their kinetics of degradation can be tuned from weeks to several years, for short- or long-term drug delivery or implant use. Present biomedical applications of PHA include resorbable surgical sutures (muscle and skin regeneration) (Piarali et al., 2020), cardiovascular stents, bone and cartilage implants, or nerve repair conduits. In addition to tissue engineering applications, their use as drug delivery systems has also been explored (Koller, 2018; Singh et al., 2019; Tebaldi et al., 2019; Piarali et al., 2020; Ansari et al., 2021).

Bioplastics have been extensively used in resorbable bioelectronic applications, mainly as substrate films, eventually conformable and stretchable, but they can also be processed as fibers. For instance, electrospun PLA or PCL fibers coated with poly(aniline) or gold nanoparticles, eventually assembled in mats, have been used in cardiac tissue engineering (Fleischer et al., 2014; Wang et al., 2017a) and PCL fibers embedded with graphene and carbon nanotubes for nerve reconstruction (Sun et al., 2021). If bioplastics present tunable thermal and mechanical properties, as well as kinetics of resorbability, they remain rather hydrophobic materials. They can be combined with more hydrophilic polymer segments such as poly(ethylene glycol) (PEG), poly(vinyl alcohol) (PVA), and polyvinylpyrrolidone (PVP) to create copolymers. PEG, PVA, and PVP are synthetic polymers that can form after chain cross-linking hydrogels, i.e. 3D cross-linked polymer networks that can encapsulate large quantities of water. Because of their important swelling in aqueous buffers and biological fluids, hydrogels constitute ionic conductive materials when wet (Chen et al., 2021). As such, hydrogels also constitute materials of choice to mimic the tissue extracellular matrix (ECM). PEG, PVA, and PVP polymers are resorbable in the sense that they can be excreted through urine when their molecular mass is not too high (Yamaoka et al., 1994; Jensen et al., 2016; Kurakula et al., 2020). However, pure cross-linked PEG networks could present limited resorbability and potential safety concerns (Ulery et al., 2011). PVP and PVA are highly soluble in water and, therefore, are rather used as formulation aids but not often as scaffolds by themselves. If not cross-linked, they dissolve very quickly in water.

2.1.3 Natural polymers

Natural polymers comprise mainly polysaccharides and protein-derived macromolecules.

Polysaccharides have aroused large interest due to their high availability, biocompatibility, variety of structures, and chemical and biological properties that they offer (Yang et al., 2022). In particular, hyaluronic acid (HA) is a highly relevant material for bioelectronics because it is an endogenous glycosaminoglycan of the extracellular matrix (ECM), which is widely available today as it is being produced by controlled bacterial fermentation, is easily processable (high water solubility and functional groups amenable to chemical modification on the polymer backbone), and is already being used in numerous biomedical applications (Knopf-Marques et al., 2016; Kobayashi et al., 2020; Vasvani et al., 2020). HA contributes to maintaining homeostasis and promotes cell migration, adhesion, and differentiation and as such has long been used in drug delivery systems and tissue engineering, in particular when in contact with the brain tissue (Miyata et al., 2017). HA is fully resorbable, with a degradation rate of a few hours to days (according to the body location) when not cross-linked. Other polysaccharides of interest for medical applications are chitosan which presents mucoadhesive properties (Dash et al., 2011), cellulosics (Aghazadeh et al., 2022), and alginate (Zhang et al., 2023). Though they display high biocompatibility and are degradable, only a few of their derivatives, such as oxidized cellulose and oxidized alginate, appear resorbable. Nevertheless, a few alginate-based materials will be described below since they were largely used to develop and illustrate innovative concepts, particularly in the field of dynamic hydrogels (Tringides et al., 2021; Tringides et al., 2023).

Another class of natural polymers is protein-derived macromolecules, such as collagen and its gelatin derivative, fibrin, elastin, elastin-like polypeptides, and silk fibroin. Similar to HA, collagen, fibrin, and elastin are endogenous components of the ECM. This confers to these materials mechanical properties that are very close to that of native tissues and a high biocompatibility although they can also elicit an immune response (Ulery et al., 2011). However, their supply can be limited by their extraction from animal sources and their cost (Wang et al., 2023). Mainly, silk has been explored for the design of resorbable bioelectronic systems, while collagen and gelatin have been used to design conductive hydrogels for tissue engineering.

Silk is a natural material produced by a variety of arthropods; the one extracted from the cocoons of Bombyx mori has been used for centuries and is still the most exploited due to its extraction by simple processes (Ullah et al., 2019). After processing, the major components, silk sericin and silk fibroin, are obtained. Fibroin, a structural protein composed of 18 amino acids, is constituted of crystalline β-sheets that self-assemble through intramolecular and intermolecular interactions (such as H-bonds, van der Waals, and hydrophobic interactions) and of hydrophilic and amorphous random coil domains. Playing with processing conditions that can tune the rearrangement and the ratio of the crystalline and amorphous domains, silk fibroin can be processed as nanofibers, microfibers (that can be converted to yarns and textiles), films, aerogels/cryogels, and hydrogels (Wang et al., 2019a). Its protein nature confers the material with high biocompatibility and programmable degradability and opens the possibility to further genetically engineer the protein (e.g., insert elastin-like sequences to improve elasticity for instance) to match the desired properties (Wang et al., 2021). The proteolytic degradation of silk fibroin films by enzymes such as chymotrypsin, actinase, and carboxylase can be accelerated by reducing the protein β-sheet content through the presence of chaotropic agents or the drying process (Cao et al., 2009; Chatterjee et al., 2019; Ullah et al., 2019). Because of its high biocompatibility and processability, the absence of adverse immune reaction, its resorbability, and outstanding mechanical toughness, silk fibroin has been employed for centuries in biomedical applications, for instance, as surgical sutures, besides its use in the textile industry.

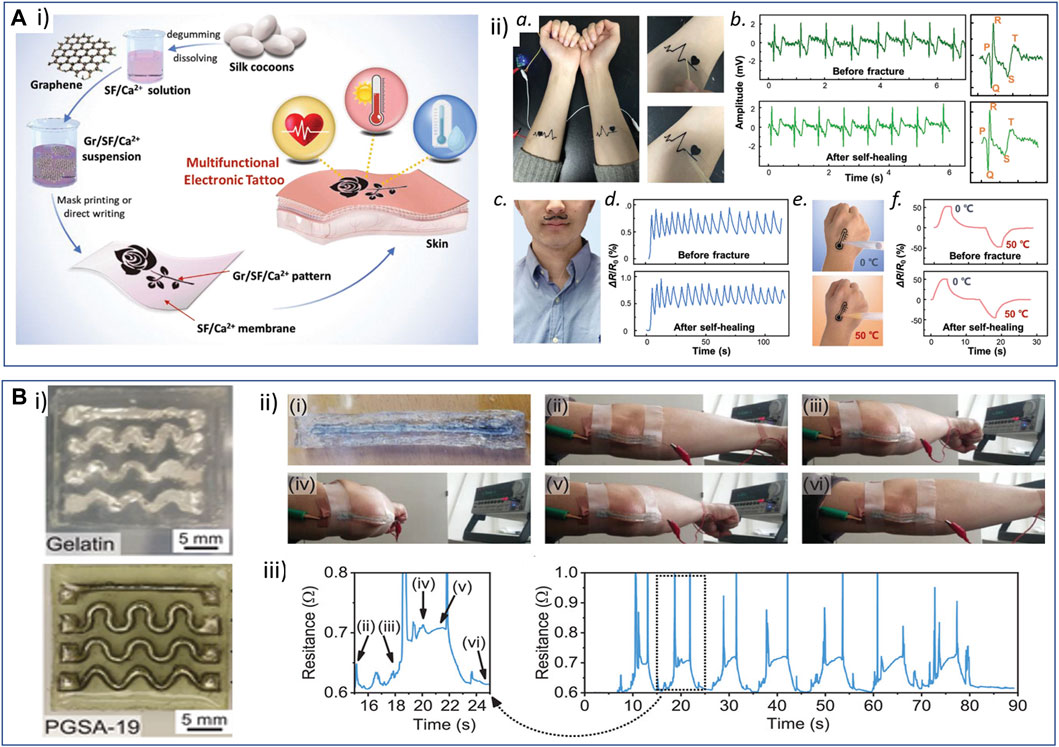

Silk films were identified as early as the late 2000s as resorbable substrates of high interest for the design of soft electronics, particularly in the group of Rogers (Kim et al., 2009; Kim et al., 2010; Hwang et al., 2012; Tao et al., 2014). Transient electrode microarrays were designed by transfer printing very thin silicon patterns onto a casted 5- to 15-µm-thick silk fibroin film (Kim et al., 2009; Kim et al., 2010; Hwang et al., 2012). The very soft material showed high conformability to adapt to brain morphology and resorbability in water of approximately 1 h. Silk was also combined with resorbable magnesium [Mg (conductive) and MgO (insulating)] materials to develop a resorbable implanted system for the on-demand delivery of antibiotics to treat infected surgical wounds (Tao et al., 2014). The high Young’s modulus (5–12 GPa) and low stretchability (20%) of silk fibroin films were modulated by Chen et al. (2018a) in order to obtain stretchable films suitable for on-skin electronics. The authors studied the plasticization of a fibroin film through the addition of CaCl2 and ambient hydration, guided by molecular dynamics simulations of the rearrangement of β-sheets and coil domains into the film structure. After patterned vacuum deposition of gold, electrodes were obtained onto a wrinkled highly stretchable (>400%) film (Young’s modulus 0.1–2 MPa), and the device was tested for skin interfacial impedance measurement.

Silk fibroin can also be used to design resorbable conductive inks. Graphene derivatives and silk fibroin are particularly interesting to combine thanks to hydrogen bonds that can be reversibly created between the two materials (Wang et al., 2021). For instance, Dorishetty et al. (2022) studied the formulation, microstructure, and biocompatibility of a set of extrusion printable silk/graphene inks with different rGO content. An increase in the rGO concentration was shown to decrease the obtained material pore size while increasing its mechanical resistance. A PEDOT-based conductive printable ink was also developed by the addition of photosensitive sericin in an aqueous dispersion of PEDOT:PSS (Pal et al., 2016) (Figure 5). Silk sericin was modified with photosensitive methacrylate groups and mixed with PEDOT:PSS conductive ink. The photosensitive conductive resin was then spin-coated onto the fibroin substrate and UV-exposed through a photomask to create micropatterns after development in water.

The above examples demonstrate the high versatility and processability of silk that make it a real asset in the design of resorbable conductive materials. Similar to bioplastics, silk displays programmable structure-related degradability and mechanical properties and can moreover form optically transparent films for optoelectronic applications. As a natural polymer, silk is also a highly biocompatible and sustainable material, processable in water, and amenable to chemical modifications that can improve its interaction with conductive materials or tissue adhesion.

We have highlighted in this section the wide range of substrates/scaffolds that can be used to design resorbable materials. In the next section, we will focus on the electrical conductors.

2.2 Electrical conductors

Different conductive components can be employed to design resorbable materials for healthcare applications (Figure 4). Metals and semiconductors are the electrical conductors that are usually employed in microelectronics. Therefore, when resorbable, they have been used to design resorbable bioelectronic systems dedicated to wearable or in vivo sensing or stimulation. To address tissue engineering applications and design 3D medical devices, such materials are employed in micro- or nanoparticle forms. Other micro- and nanostructures can also be used, and transition-metal dichalcogenides and carbon-based fillers (carbon nanotubes and graphene derivatives) are very popular in the field, either for the design of bioelectronic systems or tissue engineering. Conducting polymers are also very relevant materials for the bioelectronic system/tissue interface, either for the design of wearable bioelectronic systems or tissue engineering. Their strengths are their mixed ionic/electronic behavior and their polymeric nature, making them both a structuring and conductive material.

FIGURE 4. Overview of typical resorbable electrical conductors used in the design of bioresorbable conductive materials.

2.2.1 Metals and semiconductors

Classically employed materials for designing conductive patterns in microelectronics are semiconductors or metals. Several are biocompatible (platinum, gold, titanium nitride, silicon, etc.), while some are resorbable (molybdenum, magnesium, tungsten, iron, silicon, germanium, and zinc/zinc oxide) (Chatterjee et al., 2019). Their resorbability is mainly accounted for by the formation of metal hydroxides or oxides that are dissolvable in biofluids. The kinetics of bioresorption of resorbable metals can vary over different orders of magnitude, from 1.7 µm/day at pH 7 at 37°C for Mg to 7 nm/day for Mo (Chatterjee et al., 2019). Silicon hydrolysis depends not only on pH, temperature, and ionic concentration but also on its crystalline form (Hwang et al., 2012). Although these materials are inherently hard in bulk, they can be deposited on a flexible substrate in thin layers, of the order of a hundred nanometers, or can be thinned after deposit to obtain flexible bioelectronic systems. Metals and semiconductors can also be shaped into nanostructures such as nanotubes or nanowires to increase the contact surface with tissues (Duan et al., 2012; Robinson et al., 2012). Combining resorbable polymer substrates and metals, different research groups have started developing resorbable electronic systems since the late 2000s. For instance, the group of Rogers has extensively developed the electronic on-silk concept (Kim et al., 2009; Kim et al., 2010; Hwang et al., 2012; Tao et al., 2014). Huang et al. (2014a) developed a fully printed circuit board using poly(ethylene oxide) and carboxymethyl cellulose as substrate materials combined with magnesium stacks and a paste comprising tungsten microparticles for electrical connections. Still, resorbable polyester substrates such as PLGA films are presently the most employed.

The high interest of semiconductors and metals is their high intrinsic conductivity. However, it could be complicated to combine them in bulk with highly porous and hydrophilic materials such as hydrogels. Choi et al. (2020) described the possibility of combining hydrogels with a liquid metal, an eutectic alloy of 75% gallium and 25% indium (mass ratio). Though the biocompatibility of liquid metal Galinstan, an eutectic mixture of 68% Ga, 22% In, and 10% Sn (mass ratio), has been assessed (Foremny et al., 2021), the use of such materials still remains questionable from the biocompatibility and resorbability points of view. Another possibility to combine metals and other conductive materials to resorbable scaffolds is their use as micro- or nanostructures.

2.2.2 Conductive nanostructures

A large variety of inorganic conductive micro- and nanostructures are available to design conductive materials (Figure 4). Micro- and nanostructures include semiconductor or metallic flakes, nanowires or nanorods, 2D materials like transition metal dichalcogenides (MoS2 and WS2), Xenes (e.g., black phosphorous), MXenes (2D carbides or nitrides), transition metal oxides (e.g., MnO2 and MoO3), and carbon-based structures, such as carbon nanotubes and graphene-based materials. The increased surface/volume ratio facilitates and fastens the material resorption in the body, when possible. We will shortly focus below on the few structures that have been highlighted in literature and for which more solid resorption data exist. Numerous other conductive micro- and nanomaterials are presently under development and could be acknowledged in the near future as suitable for the design of resorbable bioelectronics (Choi et al., 2019).

Concerning metallic nanostructures, because of biocompatibility issues, copper and silver are ruled out for most biomedical applications (Han et al., 2022). The in vivo safety of platinum nanoparticles (Pt NPs) has also been questioned (Czubacka et al., 2019; Gutiérrez de la Rosa et al., 2022). As a highly stable metal in biological fluids, Pt NPs require a very long time for dissolution-based resorption but can possibly be eliminated by urinary excretion. Because of their high biocompatibility and processability, gold nanoparticles, nanocages, nanorods, and nanowires are extensively studied in tissue engineering applications (Yadid et al., 2019), especially cardiac engineering (Saghebasl et al., 2022). However, they are not bioresorbable, even if very recently, small gold-polymer nanostructures (90 nm size, 4.5% w/w gold) were found to be excretable (Cassano et al., 2019), 4–22 nm-diameter gold nanostructures were also found to be degraded and metabolized by cells by similar pathways than gold ions, but into biopersistent products (Balfourier et al., 2020).

Two-dimensional transition-metal dichalcogenides, such as molybdenum disulfide (MoS2) sheets, are very attractive thanks to their 2D electrical conductivity and optical transparency in the visible range that can be used advantageously in optoelectronic systems (Choi et al., 2019). The resorbability of MoS2-isolated crystals and large-area polycrystalline films in representative fluids and cranial environments was studied (Chen et al., 2018b). The polycrystalline MoS2 monolayer (grain size ∼200 nm) dissolved in approximately 2 months in PBS solution at 37°C, and the CVD-grown monolayer inserted in implantable device prototypes was dissolved completely in 1 month. Such implantable bioelectronic systems can be used to monitor pressure, strain, and temperature (Chen et al., 2018b), as well as serve as an image sensor array when implanted in the eye, thanks to their photoabsorption and photocurrent generation performances (Choi et al., 2017).

Pristine graphene is also a 2D material of high interest for bioelectronic applications (Choi et al., 2019). Because of the thickness of individual layers (a few angstroms), graphene can be soft and flexible, yet strain-resistant and optically transparent. Based on a hexagonal honeycomb lattice of carbon atoms, graphene is also biocompatible and can be functionalized easily for better interactions with tissues or other materials though its impact on the immune system is being questioned (Ban G et al., 2023). Endogenous peroxidases such as human myeloperoxidase can degrade graphene in the form of a single or a few layers, in tens of hours to days (Ma et al., 2020). However, pristine graphene is quite hydrophobic and hence poorly compatible with hydrogels (Chen et al., 2021). Graphene oxide (GO), more hydrophilic and dispersible in water, displays poor conductivity because of the damaged conductive network due to the oxidation of the graphene structure. Therefore, reduced graphene oxide (rGO), for which the graphene structure has been partially restored, constitutes a good compromise between conductivity and limited hydrophobicity and is preferred for biomedical applications (Chen et al., 2021). The kinetics of degradation of GO and rGO is related to the oxygen atom content of the structures, and therefore they resorb in the body with faster kinetics than pristine graphene (Ma et al., 2020).

Carbon nanotubes (CNTs) also constitute a hexagonal lattice of carbon atoms rolled up into a tube of 0.5–2 nm diameter for single-walled carbon nanotubes (SWCNTs), with several SWCNTs in a tube-in-tube structure for multi-walled carbon nanotubes (MWCNTs). Like graphene, their carbon atoms can be oxidized and functionalized to confer additional functionalities and hydrophilicity. For instance, Liu et al. (2011) studied in vitro the influence of carbon nanotube surface chemistry (carboxylic acids, amines, and alcohols) on neuron network organization, offering cells a high variety of adhesion orientation and sites. They have been particularly explored in wearable sensor applications (Gandhi et al., 2020; Palumbo et al., 2022) and nerve constructs for tissue engineering (Salehi et al., 2018; Manousiouthakis et al., 2022). Though resorbable, thanks to their degradation by peroxidases (Ma et al., 2020), their biocompatibility is questionable (Mishra et al., 2018). It seems to mostly depend on their synthesis and purification process, as well as their aspect ratio.

2.2.3 Conducting polymers

Electronic conducting polymers (CPs) such as poly(pyrrole) (PPy), polyaniline (PANI), poly(thiophene) (PTh), and poly(3,4-ethylenedioxythiophene) (PEDOT) are a class of polymers that possess π-conjugated structures, enabling electron delocalization along their backbone (Guo et al., 2020). Given the aromaticity of the polymer structure, the overlapping of π-orbitals results in a conductive pathway obtained by freely moving delocalized π-electrons (Nezakati et al., 2018). In their pristine state, CPs behave as semiconductor materials exhibiting weak conductivity compared to classical semiconductors. When oxidized (0.25–0.33 charge per monomeric unit) through electrochemical treatments or oxidation/reduction chemical reactions, they gain high electronic conductivity. This (electro)-oxidation process is accompanied by the introduction in the CP films of counter anions that maintain their electroneutrality. Such an ion exchange property is generally referred to as a doping process correlatively to inorganic semiconductors, the counter anions being referred to as the dopant species (Namsheer et al., 2021). As such, conducting polymers are a category of organic materials characterized by distinctive electrical and electrochemical performances. They combine the advantages of a wide range of electrical conductivity (10−5–105 S cm−1) like carbon- or metal-based electrical conductors and of structure tunability, flexibility, and relatively low cost, like polymers. They also feature both ionic (such as tissues) and electronic (such as bioelectronic systems) conductivities, making them ideal interface materials for bioelectronic applications (Fattahi et al., 2014; Onorato et al., 2019; Gao et al., 2022). CP coatings on metallic electrodes can significantly enhance the electrical properties at the interface of tissues as compared to bare electrodes, especially decreasing electrical impedance and increasing charge transfer capacity (Ludwig et al., 2006; Richardson-Burns et al., 2007; Khodagholy et al., 2015). For instance, conducting polymer microstructures (microcups) were obtained by the electrochemical deposition of conducting polymers (PEDOT, PPy) onto the surface of PLLA/PLGA sacrificial microspheres (Antensteiner et al., 2017a; Khorrami et al., 2017). These microstructures deposited on the surface of a metallic electrode enhanced the surface roughness of the CP films by over 90% through the control of both deposition time and applied electrical voltage. The impedance of PPy-modified electrodes was found to decrease by up to 88% in comparison to bare electrodes (Antensteiner et al., 2017b). These neural electrodes improved the cellular response of neurons during chronic stimulation and recording (Antensteiner et al., 2017a; Khorrami et al., 2017). Thanks to these unique combined properties, as well as their ease of preparation and biocompatibility, conducting polymers have attracted significant attention for a wide range of biomedical applications such as the development of (bio)-sensors, actuators, drug delivery systems, and tissue engineering scaffolds. Due to their availability and physiologically relevant electrical conductivity upon intrinsic or external doping, PPy, PANI, PEDOT, and their derivatives, are the most widely used CPs for bio-interfacing applications.

Poly(pyrrole) (PPy) is a heterocyclic polymer that can be easily synthetized in different solvents (such as water) and polymerized via chemical or electrochemical routes of pyrrole oxidation (Mao et al., 2018). Due to its high biocompatibility, ease of preparation, and good conductivity in physiological conditions, it has been widely used at the interface between bioelectronic systems and cells or tissues, for both recording and stimulation purposes (Liu et al., 2023b). Notably, PPy is a suitable substrate in the modulation of different cellular activities (such as cell attachment and proliferation) and possesses excellent biocompatibility in vivo (Huang et al., 2014b). Furthermore, it can be easily chemically modified to allow the conjugation of bioactive molecules such as proteins and enzymes (e.g., glucose oxidase and antibodies), short peptides with specific “recognition sequences” (providing binding sites for cells), nucleic acids, DNA/RNA, or growth factors (which allow the immobilization of cytokines). These bioactive molecules can act as PPy dopants, improving material conductivity and/or further promoting material–tissue integration. Nevertheless, additional polymer modifications are required to overcome issues with water solubility, mechanical rigidity, and poor processability, which significantly limits its use as a standalone material. In addition, PPy is very sensitive to over-oxidation in the presence of radical oxygen species present in biological media or generated by local inflammatory processes (Palmisano et al., 1995). Despite its considerable biocompatibility, at its pristine state, PPy is also poorly degradable. Bioerodible forms of PPy can be prepared via electrochemical polymerization of beta-substituted pyrrole monomers containing hydrolyzable side groups (Zelikin et al., 2002) or by PPy integration in biodegradable polymers, such as PLA or PCL (Boutry et al., 2012).

Polyaniline (PANI) is a phenylene-based polymer offering several advantages in biomedical applications, such as high thermal and environmental stability, high conductivity values (101–102 S cm−1), and inexpensive and easy synthesis processes (Solazzo et al., 2019). It can be synthesized via electrochemical processes, or chemical oxidation of aniline monomer, typically in the presence of ammonium persulfate as the oxidizing agent. Fine control over synthesis conditions, such as pH, the presence of acids, and the choice of solvents and oxidizing levels, greatly influence the physical and electrical properties of the obtained PANI polymers that can be under different forms (i.e., leucoemeraldine, emeraldine, and pernigraniline) that differ by the oxidation level of the backbone (Tran et al., 2022). PANI generally offers several advantages for biomedical applications, such as high thermal and environmental stability, antibacterial properties, inexpensive and easy synthesis processes, and excellent charge transport due to the doping/de-doping process (Beygisangchin et al., 2021). Another major advantage of PANI is its good solubility in a few selected organic solvents, as well as in water, thereby largely improving material processability. Nevertheless, the biocompatibility of both pristine PANI and its derivatives is still controversial. Several studies have reported high in vitro cytotoxicity and chronic inflammation episodes after cell/tissue contact (Wang et al., 1999; Borriello et al., 2011; Zhang et al., 2019), despite a plethora of studies having reported good in vitro and in vivo compatibility of PANI oligomers (pentamers and tetramers) when employed in subcutaneous films or biomimetic sensors for short-term use (Humpolicek et al., 2012; Guo et al., 2018; Pyarasani et al., 2019). Furthermore, similar to the other conducting polymers, PANI used as a standalone material is also non-degradable. As well as for PPy applications, in recent years, numerous studies have focused on combining PANI with other biodegradable synthetic or natural polymers to develop blends or composite systems (Rai et al., 2022). Despite this, in vivo studies assessing the resorbability of PANI-based materials or their long-term presence in the body (eventually in degraded form) have not been extensively carried out.

Poly(3,4-ethylenedioxythiophene) (PEDOT), a thiophene derivative of the less stable and less biocompatible pristine poly(thiophene), is one of the most widely studied CPs in bioelectronics and tissue engineering applications due to its improved chemical and environmental stability and biocompatibility compared to PPy and PANI (Tropp et al., 2021). PEDOT is generally synthetized in the presence of a dopant, typically polystyrene sulfonate (PSS), which plays the role of the counter anion of the positively charged PEDOT (more conductive than the pristine form) and improves polymer solubility and conductivity (Gueye et al., 2020). Although poly(styrene sulfonate) (PSS) is the most widely studied PEDOT dopant to design soft flexible conductive materials for bioelectronics, PSS lacks biocompatibility and degradability (Kayser et al., 2019). Several biomolecules have therefore been investigated to obtain resorbable PEDOT:biomolecule inks to be used for the design of transient implantable electronic devices (Boehler et al., 2019; Leprince et al., 2023a). PEDOT is generally obtained via three polymerization routes: i) oxidative chemical polymerization of EDOT-based monomers using various oxidants, yielding a suspension of PEDOT (or PEDOT:dopant) particles (ink) (Nie et al., 2021; Leprince et al., 2023a), ii) electrochemical polymerization of an EDOT-based monomer onto a conductive substrate in a three-electrode setup yielding a PEDOT coating or a film, and iii) using transition-metal-mediated coupling (Nie et al., 2021). When not electrochemically synthetized onto a substrate or as a self-standing film, PEDOT can be formulated to be further coated, casted, or printed by different processes (spin-coating, dip-coating, spray coating, screen printing, inkjet printing, doctor blading, roll-to-roll printing, etc.). The relative ease of PEDOT (or PEDOT/dopant) processing and the possibility to design it as resorbable using biomolecule-based dopants have led to the widespread use of PEDOT in the development of modified electrodes for tissue interface (Wang et al., 2019b) and tissue engineering applications (Bhat et al., 2021).

Despite CPs promising bioelectrical characteristics and ease of processability, the same intrinsic structure enabling conductivity is also characterized by strong bond dissociation energies, imparting the materials with excessive rigidity and poor degradability, limiting their application as biointerfaces with tissues (Liu et al., 2023b). CPs’ conjugated backbones are indeed hardly cleavable in physiological conditions, unless for small molecular mass, resulting in a poor to null degradation and metabolization in the body. Furthermore, several classical dopants, such as PSS for PEDOT, are not cleavable in the physiological condition as well, further hindering CPs' in vivo employability. Replacing PSS by potentially (bio)degradable molecules, such as alginate (Puiggalí-Jou et al., 2020; Yang et al., 2020), heparin (Xu et al., 2019b), or hyaluronic acid (Guo et al., 2018; Leprince et al., 2023a) is a widely known strategy to increase PEDOT:dopant biocompatibility and degradability, preserving the inherent conductivity of the polymer (Guo et al., 2013). Interestingly, such biopolymer-based dopants can also be used to design the conductive substrate/scaffold part of the conductive material. If resorbable and associated with CP oligomers, resorbable conductive hydrogels can be obtained with high interest in bioelectronics and tissue engineering. A second reported strategy is the integration of cleavable chemical motifs in the CPs' backbone, which allows their partial or complete degradation into smaller products (monomer or oligomer fragments) that can be processed through different physiological mechanisms, such as phagocytosis, metabolization, bioabsorption, or excretion (Feig et al., 2018). Disintegrable organic semiconductors can also be obtained by utilizing degradable or reversible dynamic covalent linkages, for instance, based on Schiff base chemistry, within each conducting polymer repeat unit (Tropp et al., 2021). The use of hydrolyzable linkages within a CP monomer leads to a degradable conducting polymer backbone that affords the design of high-performance transient and biocompatible semiconductors (Lei et al., 2017). In conclusion, extensive and rigorous studies on the mid- and long-term use of CP-based materials in transient implantable devices are still required to solve the pending questions of device biocompatibility and electroconductive stability over time. However, such materials display high structural versatility and offer large possibilities and interest in bioelectronic applications, especially on-skin electronics and tissue engineering.

Only a limited number of electrical conductors inherently exhibit full bioresorbability such as resorbable metals, semiconductors, and MoS2 sheets. However, the functionalization of others (such as graphene, carbon nanotubes, and their derivatives) through the application of organic coatings or the combination of conductive oligomers with bioresorbable polymers has paved the way for enhancing these materials' biocompatibility and resorbability. Consequently, strategies that amalgamate structuring scaffolds with electrical conductors play a pivotal role in achieving resorbable conductive materials.

3 Combining structuring scaffolds and electrical conductors

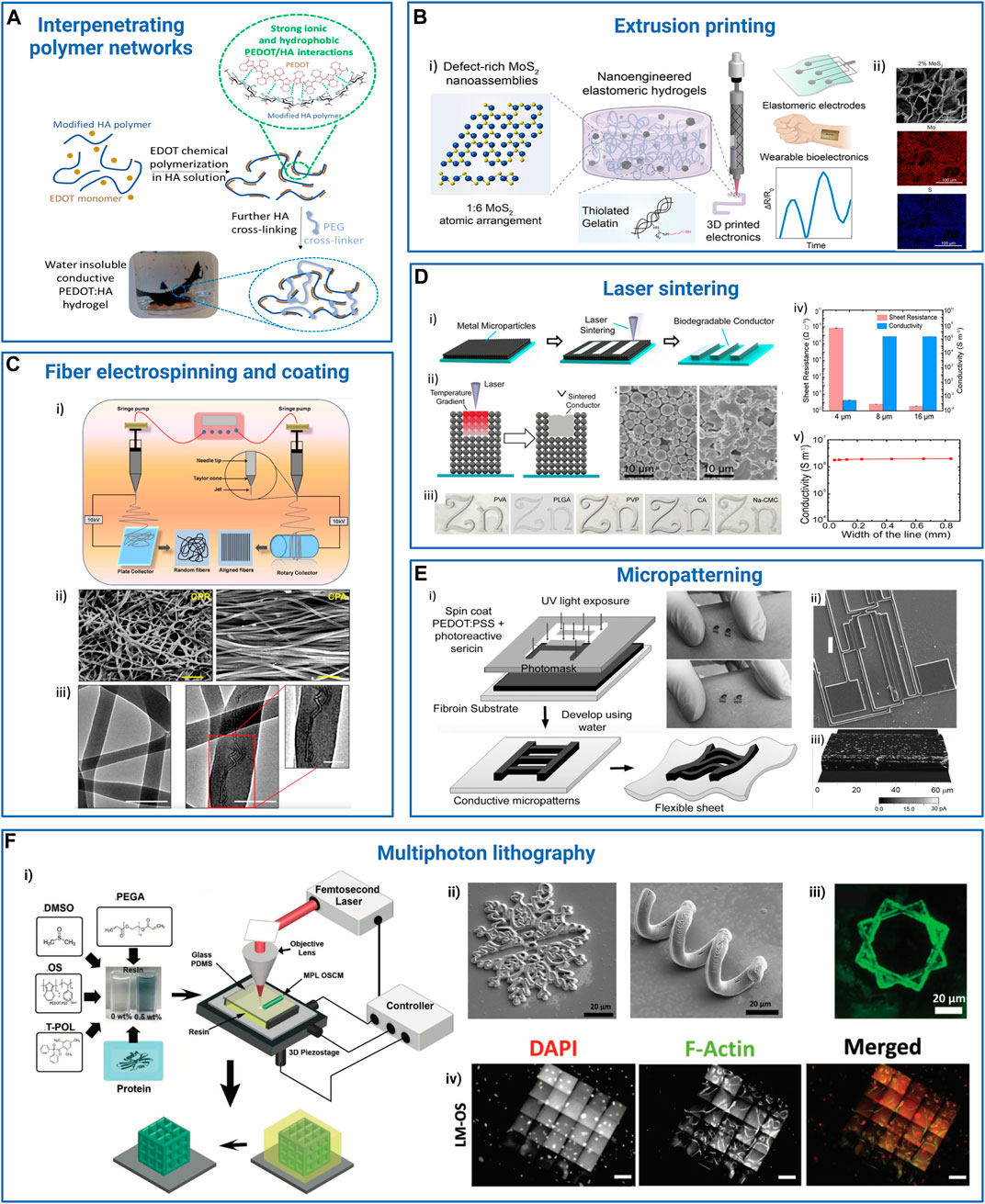

Based on the large variety of existing chemical structures for both resorbable substrates/scaffolds and electrical conductors, there exist different possibilities to combine them to obtain conductive materials for their use in bioelectronics or tissue engineering. We propose below an insight into the most popular processes encountered in the bibliography. Some of them are illustrated in Figure 5.

FIGURE 5. Examples of processes and strategies used to obtain resorbable conductive materials for their application in bioelectronics. (A) Interpenetrating networks of scaffolding and conducting polymers: conducting polymer PEDOT is chemically synthetized in a solution of modified hyaluronic acid (HA) polymer. The PEDOT:HA ink can be further photo-cross-linked to achieve non-water soluble resorbable conductive hydrogels (Leprince et al., 2023b). Adapted with permission from Leprince et al. (2023a), Copyright 2023, Elsevier, and Leprince et al. (2023b), Copyright 2023, the Royal Society of Chemistry. (B) Extrusion printing: (i) a bioprintable conductive ink is obtained by mixing thiolated gelatin and defect-rich MoS2 nano-assemblies. This ink can be further extrusion-printed as a stand-alone material to design wearable sensors. ii) Scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) images of a transverse cross-section of the hydrogel: gelatin scaffold (top), molybdenum (Mo, middle), and sulfur (S, bottom). Scale bar: 100 µm. Reprinted with permission from Deo et al. (2022), Copyright 2022, the American Chemical Society. (C) Fiber electrospinning and coating: electrospun PCL-collagen fibers coaxially reinforced with MWCNTs. i) Electrospinning parameters were modulated to deposit random or parallel fibers. ii) SEM images of the random (CPR, left) and aligned (CPA, right) MWCNT-reinforced fiber scaffolds. Scale bar: 1 μm. iii) TEM images of scaffolds without (left) and with (right) MWCNT fibers. Scale bar: 200 nm, inset: 100 nm. Adapted with permission from Ghosh et al. (2020), Copyright 2020, the American Chemical Society. (D) Laser sintering: laser sintering process to integrate zinc or iron microparticle inks into hydrogels (i). The microparticle ink (black) was spin-coated onto the hydrogel substrate (blue), and the device was washed in the appropriate solvent after laser sintering to reveal the pattern. ii) Scheme illustrating the sintering process. Scale bar: 10 μm. iii) Examples of Zn patterns obtained on different polymer substrates [PVA, PLGA, PVP, cellulose acetate (CA), and sodium carboxymethyl cellulose (Na-CMC)]. iv and v) Resistance and conductivity of Zn line patterns with different thicknesses (iv) and widths (v) onto PVA substrate. Adapted with permission from Feng et al. (2019), Copyright 2019, the American Chemical Society. (E) Photolithography micro-patterning: i) scheme depicting the microfabrication of silk sericin/PEDOT:PSS patterns onto a silk fibroin substrate. ii) SEM image of a complex resorbable device (ii, scale bar: 100 µm). iii) Conductive AFM image of a 50-μm-thick ink line deposited on a glass surface. Reproduced with permission, Copyright 2015, John Wiley and Sons (Pal et al., 2016). (F) Multiphoton lithography: i) schematics illustrating the composition of the organic semiconductor (OS) resin, featuring PEDOT:PSS, photoinitiator (3-(trimethoxysilyl)propyl methacrylate), dimethyl sulfoxide (DMSO), laminin, glucose oxidase, and the experimental setup for multiphoton lithography, resulting in the formation of 3D OS composite microstructures (OSCM) upon resin removal (depicted in yellow). ii) SEM images showcasing diverse conductive and bioactive complex microstructures. Scale bar: 20 μm. iii) Fluorescent microscopy images depicting laminin-incorporated OS (LM-OS) microstructures in green. Scale bar: 20 μm. iv) Epifluorescence microscopy images showing endothelial cells on LM-OS microstructures after 48 h of culture, stained with DAPI (red, indicating cell nuclei) and phalloidin (green, representing F-actin). Scale bar: 100 µm. Reproduced with permission, Copyright 2022, John Wiley and Sons (Dadras-Toussi et al., 2022). Created with BioRender.com.

3.1 Blending structuring scaffolds/substrates and electrical conductors

Blending is the easiest way to combine synthetic or natural polymer-based substrates/scaffolds with electrical conductors such as metallic or semiconducting nanoparticles, nanorods or nanowires, carbon-based conductive fillers, and conducting polymers. We provide below general examples of blended resorbable conductive materials, preceding a brief section concerning polymer cross-linking that can be used to ensure material infusibility in tissues in contact with biological fluids and place specific enphasis on conducting polymer/hydrogel interpenetrated polymer networks.

3.1.1 Blended resorbable conductive materials

Blending has been used to design several parts of resorbable bioelectronic systems.

Biodegradable conductive pastes were developed by blending tungsten micro-/nanoparticles with natural waxes (issued from bee, soy, myrtle, or candelilla) (Won et al., 2018; Kim et al., 2023a). These hydrophobic pastes, which degrade within days to weeks, can be used to interconnect different electronic components of resorbable bioelectronic systems (Won et al., 2018; Choi et al., 2021).

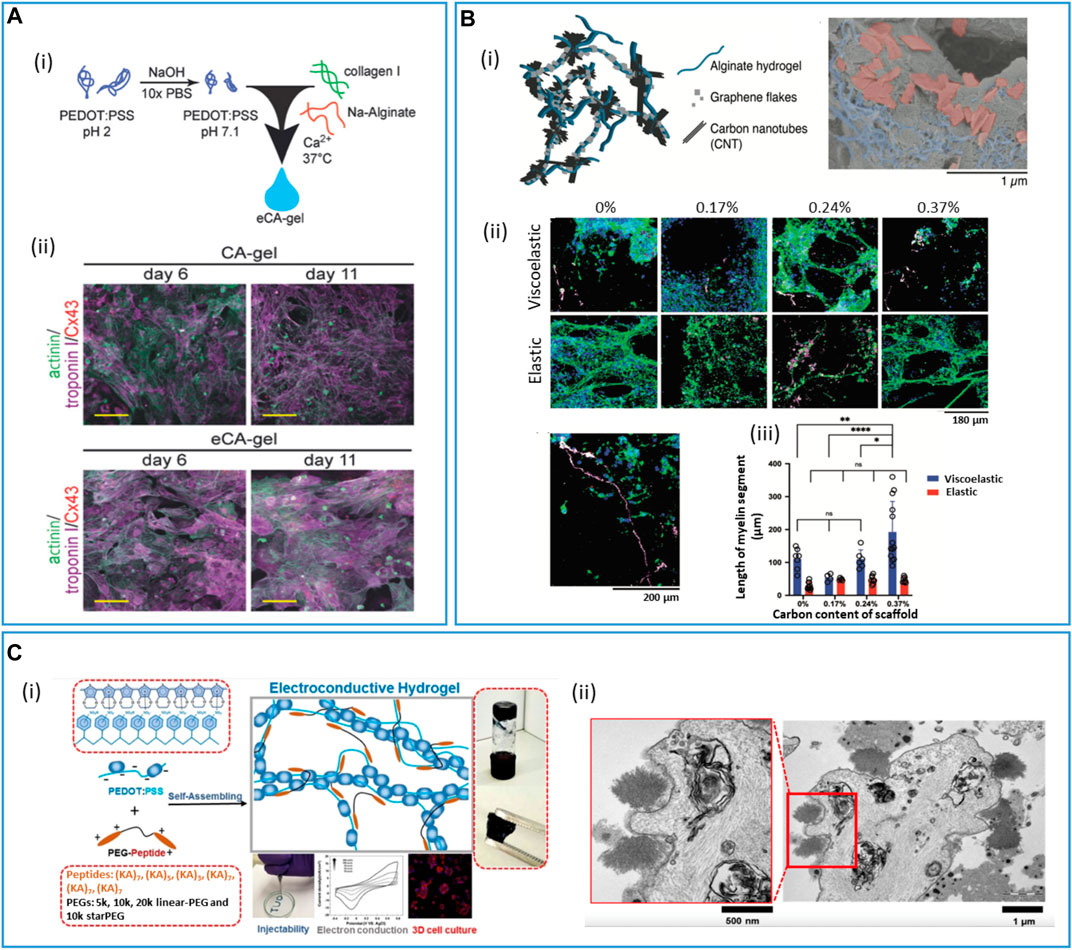

Resorbable PVA films filled with iron nanoparticles and MWCNT were used to design biodegradable tactile sensors (Karmakar et al., 2022). Wang et al. (2019c) designed a resorbable strain sensor based on a dynamic network of PVA, borate, and GO particles partially reduced during dopamine oxidative self-polymerization. The PVA-PDA-rGO material displayed self-healing features, and the rGO filler acted both as a mechanical stiffener and electrically conductive particles. rGO was also combined with PCL, PU, PEG, gelatin methacrylate (GelMA), collagen, and chitosan for cardiac (Saghebasl et al., 2022) or neural (Manousiouthakis et al., 2022) tissue engineering. Tringides et al. (2021) blended alginate hydrogels with both graphene flakes and carbon nanotubes prior to gelation and freeze drying to obtain macroporous materials. They thoroughly studied the impact of the two types of materials on the structure and conductivity of the obtained conductive hydrogels. They showed that graphene flakes were integrated into the walls of the porous materials, whereas CNT acted as interconnects through the pores, to achieve conductivities as high as 35 S m–1. The conductive alginate hydrogel (100 µm thick) could then be encapsulated between two thin layers (15 µm) of a resorbable viscoelastic elastomer in which openings could be performed with a CO2 laser and to design a resorbable electrode array for the heart or brain electrical recording or stimulation.

In tissue engineering applications, blending conductive fillers or conducting polymers into resorbable hydrogels is the usual method to obtain conductive ECM-like scaffolds. For instance, AuNPs have been integrated with different polymer-based scaffolds (alginate, chitosan, PCL/gelatin, etc.) and shown to improve the mechanical and electrical properties of the matrices and tissue regeneration from stem cells. PEDOT:PSS was mixed with collagen and (3-glycidoxypropyl)trimethoxysilane as a cross-linker to design 3D conductive scaffolds that can be used to measure impedance and monitor cell growth (Inal et al., 2017). In nerve tissue reconstruction, 2D graphene materials have often been combined with carbon nanotubes as polyester or hydrogel fillers (Gupta et al., 2019; Sun et al., 2021; Huang et al., 2023). The objective is to optimize the material conductivity by ensuring the percolation of the conductive domains, while minimizing the impact of these additives on the scaffold biocompatibility and/or mechanical properties.

Nano- and microparticles and 2D materials are interesting to blend with a polymer matrix to obtain resorbable devices for different reasons. Their size and dimensionality make them soft and suitable to be combined with flexible substrates to match the curvilinear shape of the human body and fasten and ease their resorption. In addition to their electrical properties, they can also confer the materials with additional functional properties, such as optical transparency, when at low concentration or present as a thin layer. The increased surface-to-volume ratio can also increase electric signal sensitivity to the adsorption of molecules or biomolecules. Therefore, the use of such materials is a real asset to design resorbable optoelectronic systems and sensors or biosensors. However, we have to consider that the presence of fillers generally modifies the material’s toughness and stretchability (most of the time, the material becomes harder), which can impact its interaction with tissues.

It is also noteworthy that it is necessary to achieve high payloads of electrical conductors within the polymer matrix to ensure high material conductivity, especially when dry materials, i.e., elastomer- or bioplastic-based substrates are concerned. Indeed, in that case, the electrical conductors have to percolate into the by-nature insulating matrix to ensure material conductivity. In this perspective, the blending strategy is particularly interesting to combine electrical conductors and hydrogels. The ionic conductivity of hydrogels and their porous structure potentially facilitating the percolation of electronic conductors, could offer advantages to achieve conductive materials with moderate electrical conductivities.

When synthetic or natural polymers are used as substrates/scaffolds, it is sometimes required that the polymer chains are cross-linked so that the material is resorbable in the mid to long term but remains infusible when in contact with biological fluids during its use. This is particularly true for hydrophilic polymer networks that are hydrogels. Polymer cross-linking strategies will be detailed in the following sections.

3.1.2 Polymer cross-linking

Cross-linking by physical bonds like H-bonding and hydrophobic interactions, or chemical bonds, in particular covalent bonds, can be achieved through thermal, mechanical, or chemical treatments. A variety of functional groups natively present on synthetic or natural polymers can be exploited for chemical cross-linking, such as alcohols (-OH), thiols (-SH), carboxylic acids (-COOH), and amines (-NH2). Other chemical functions (such as alkenes, alkynes, acrylates, methacrylates, azides, hydrazides, hydroxyamines, etc.) can be introduced, notably to further use click chemistry-based cross-linking strategies that can be performed in water and limit the formation of potentially toxic by-products (Hu et al., 2019; Chiulan et al., 2021; Battigelli et al., 2022; Mueller et al., 2022). Popular chemical cross-linking reactions include Michael additions, Diels–Alder reactions, azide–alkyne cycloadditions, thiol-ene photo-reaction, or photo-initiated methacrylate polymerization. By the modulation of the nature of the polymer, polymer and cross-linker concentrations, and eventually the number of chemical groups per polymer chain (degree of substitution), the crosslink density and hence the porosity and the mechanical and swelling properties of obtained materials can be fine-tuned.

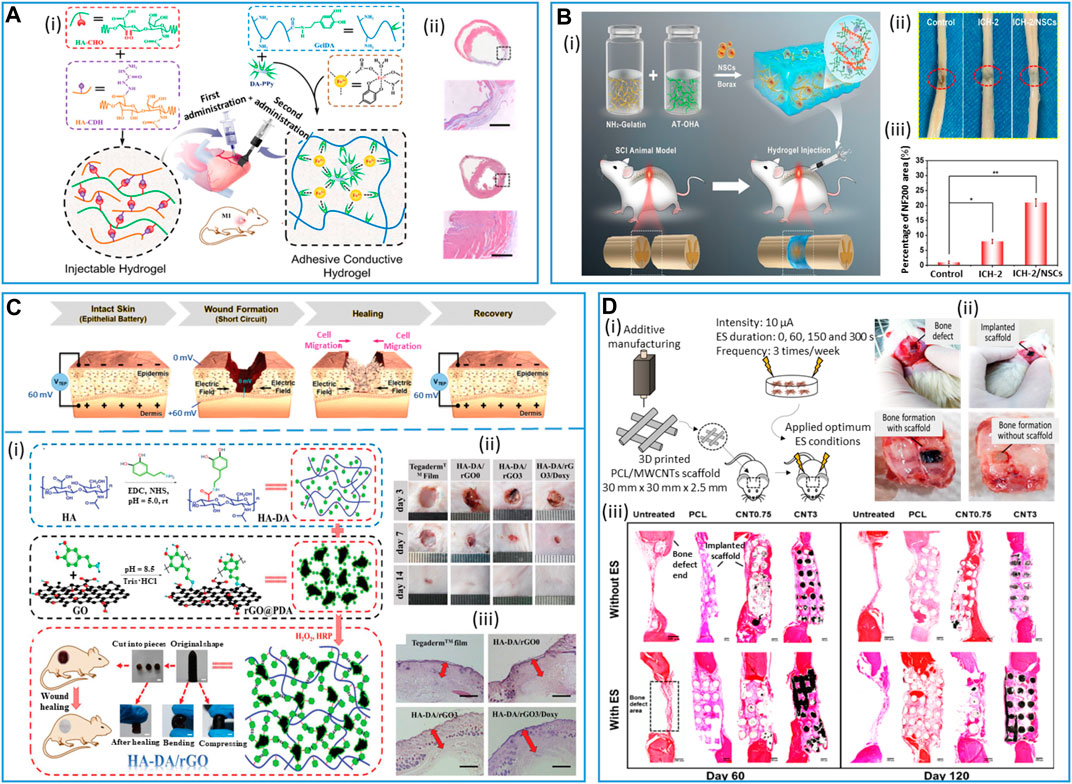

More recently, the limitations of purely elastic polymer networks (i.e., cross-linked with static covalent bonds) were underlined, especially in the field of tissue engineering (Chaudhuri et al., 2015; Chaudhuri et al., 2016; Yang et al., 2016; Morgan et al., 2022). Dynamic polymeric networks, especially hydrogels, were described that can offer self-healing behavior, and dynamicity and stress relaxation properties that exist in tissues (Elosegui-Artola, 2021). Dynamic hydrogels are also intensively explored in the field of wearable bioelectronic systems as outstanding reversible adhesives to interface electronics and skin. Hydrogel/tissue interface interactions can rely on electrostatic or hydrophobic interactions, topological adhesion, and irreversible or reversible (i.e., dynamic) covalent bonding (Cong et al., 2022). In particular, bioinspired approaches such as those based on catechol chemistry (mussel-inspired) allow the establishment of stable and high-strength adhesive interfaces using easy polymer modification by functional moieties such as catechol, dopamine, or tannic acid (Zhang et al., 2020). The conductive version of these adhesive hydrogels is of greatest interest as ideal electrode interfaces between electronic systems and tissues. Other typical dynamic linkages are boronic esters, disulfide bonds, and hydrazine and oxime bonds (Zhu et al., 2023b; Grosjean et al., 2023). In particular, hydrogels obtained by mixing fast equilibrium hydrazide cross-links (Keq ≈ 103–104 L mol–1) and slow equilibrium oxime cross-links (Keq ≈ 106–108 L mol–1) have aroused high interest in tissue engineering (Morgan et al., 2022). They can be easily obtained by mixing an aldehyde or a methyl-ketone–modified polysaccharide with a mixture of bis(hydrazine) and bis(oxyamine) cross-linkers, whose ratio can be tuned to obtain a series of hydrogels with a range of elastic and viscoelastic properties (Su et al., 2010; Koivusalo et al., 2019; Baker et al., 2021; Morgan et al., 2022).

Taking advantage of the polymeric structure of both conducting polymers such as PANI, PPy, and PEDOT and hydrogels, the above-described crosslinking strategies can be pushed further to interpenetrate the two polymeric networks (Rogers et al., 2020; Xu et al., 2020; Chen et al., 2021; Xu et al., 2021; Gao et al., 2022; Zhu et al., 2023a).

3.1.3 Interpenetrated networks of conducting polymers and hydrogels

Conducting polymer hydrogels have garnered particular interest because it is possible to uniquely play with the polymer nature of both the CP and hydrogel scaffold to end with original molecular designs where the two networks are interpenetrated. Integrating CPs within the hydrogel matrix allows the generation of conductive hydrogels that combine the tissue–biomimetic characteristics of hydrogels, such as soft mechanical properties and high swelling ratio, minimizing mismatch at the interface with biological tissues, with the peculiar conductivity of CPs (Liu et al., 2023b).

CP/hydrogel interpenetrated networks (IPNs) can be obtained by different strategies (Xu et al., 2020; Liu et al., 2023b). In a one-step strategy, the conductive monomer and the scaffold precursors are mixed, then the in situ redox polymerization of the conductive monomer (for instance, EDOT) is conducted simultaneously to the reticulation/gelation of the polymer matrix. For instance, a PEDOT:alginate hydrogel to support the 3D culture of brown adipose-derived stem cells was obtained by mixing in one pot EDOT, alginate, ammonium persulfate (as EDOT oxidant), and adipic acid dihydrazide (as alginate cross-linker) (Yang et al., 2020). However, the one-step strategy requires that the scaffold precursors and the conductive monomer react simultaneously, or with orthogonal chemistries. In a two-step strategy, the conductive monomer is mixed within the already cross-linked scaffold and then oxidized chemically or electrochemically to obtain the conducting polymer intertwined within the scaffold matrix. EDOT was chemically polymerized in the presence of a chitosan/gelatin cross-linked scaffold for neural tissue engineering (Wang et al., 2017b). Despite that relatively high conductivity was obtained (0.17 S/cm), the authors first swelled the hydrogel for 3 h in ammonium persulfate buffer, before immersing it in an EDOT/hexane solution to perform EDOT polymerization, probably in order to avoid EDOT polymerization that only occurs at the hydrogel interface. Alternatively, scaffold precursors are dispersed in a conducting polymer dispersion (for instance, a PEDOT:PSS ink), and then polymerized or reticulated. A conductive PEDOT:PSS/silk fibroin/tannic acid adhesive hydrogel that could serve as a skin/electrode interface was developed, where the PEDOT:PSS ink was mixed with silk fibroin before polymer cross-linking using Ca2+ and tannic acid (Luo et al., 2020). Interestingly, Ca2+ can form complexes with PSS, establishing strong interactions between the fibroin and PEDOT:PSS networks. This results in highly stretchable (≈300–400%, up to 32,000% for specific formulations) and adhesive materials, with a conductivity of 3 S/cm.

PSS can also be replaced by another biopolymer-based resorbable dopant, whose cross-linking can lead to the hydrogel scaffold, avoiding dilution of the PEDOT conducting moiety into the material. Our group developed a specific biodegradable hyaluronic-based dopant of PEDOT in order to achieve a PEDOT:HA ink with good conductivity (1.6 ± 0.2 S/cm) in comparison to similar PEDOT:biomolecule inks described in the literature (below 0.1 S/cm) (Leprince et al., 2023a). The introduction of both sulfonic acid and aromatic aminophenylboronic groups on the HA polymer backbone to mimic the PSS structure was shown to enhance ink conductivity above the additive effect, by providing, at the same time, charge carrier mobility and intra-/inter-chain charge transport through PEDOT/aminophenylboronic π-stacking interactions (Figure 5). The HA dopant was further functionalized to introduce alkene moieties that could photo-crosslink with a PEG-bis(thiol) linker to obtain a resorbable PEDOT:HA conductive ink. This ink was inkjetted on a flexible PLGA substrate in order to design a bioelectronic system that could resorb within 2 months in physiological conditions (Leprince et al., 2023b).

IPN conductive hydrogels are characterized by good biocompatibility, easy processing, and high processability (Zhu et al., 2023a). Contrary to a blend of carbon/metallic particles that are island-type distributed into the polymer matrix, the CP chains can come into contact with each other, forming a 3D interconnected conducting network, for electron transporting with relatively low resistance (Yao et al., 2017; Onorato et al., 2019). As a consequence, electronic conductivity in bulk electronically conductive hydrogels not only depends on the intrinsic CP electronic conductivity but also, and more particularly, on the inter-chain connectivity of the CPs and therefore on their spatial arrangement and concentration in the 3D matrix (Li et al., 2017; Xu et al., 2018). Still, limitations of such materials can come from the poor degradability of CPs, unless they are used in their oligomer form. However, the tunability of conductive hydrogel structures and properties make them a real asset in the field of bioelectronics.

The resorbable conductive materials obtained by the blending of scaffolds/substrates and electrical conductors are generally used without significant modification in tissue engineering applications. For these applications, they are applied onto the wound/skin, or implanted into the tissue through surgical intervention or injection. However, resorbable conductive materials can also be shaped into fibers. Another possibility is to combine them with specific patterns of the electrical conductor onto the resorbable 2D substrate to obtain wearable or implanted bioelectronic systems.

3.2 Fabricating composite resorbable conductive micro- and nanofibers

Two main strategies have been described to obtain nano- or microfibers of resorbable conductive material (Wei et al., 2023).