95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Bioeng. Biotechnol. , 08 January 2024

Sec. Biosensors and Biomolecular Electronics

Volume 11 - 2023 | https://doi.org/10.3389/fbioe.2023.1331968

This article is part of the Research Topic Next Generation Bioanalysis by Microfluidics-Integrated Methods, Devices, and Systems View all 6 articles

The ability to manipulate and focus particles within microscale fluidic environments is crucial to advancing biological, chemical, and medical research. Precise and high-throughput particle focusing is an essential prerequisite for various applications, including cell counting, biomolecular detection, sample sorting, and enhancement of biosensor functionalities. Active and sheath-assisted focusing techniques offer accuracy but necessitate the introduction of external energy fields or additional sheath flows. In contrast, passive focusing methods exploit the inherent fluid dynamics in achieving high-throughput focusing without external actuation. This review analyzes the latest developments in strategies of sheathless inertial focusing, emphasizing inertial and elasto-inertial microfluidic focusing techniques from the channel structure classifications. These methodologies will serve as pivotal benchmarks for the broader application of microfluidic focusing technologies in biological sample manipulation. Then, prospects for future development are also predicted. This paper will assist in the understanding of the design of microfluidic particle focusing devices.

Microfluidics allows precise manipulation of droplets, cells, and bacteria on a micro-scale (Whitesides, 2006). Compared with traditional micro-scale systems, microfluidics has cost-saving advantages, low energy consumption, and high efficiency (Nagrath et al., 2007). Microfluidics promises to be a revolutionary technology in biomedicine and clinical diagnostics due to the ability to precisely manipulate less volume of fluid. In recent years, microfluidics has been developed for many applications, such as focusing (Xuan et al., 2010), separation (Hettiarachchi et al., 2023), and trapping (Nilsson et al., 2009). Microfluidics has been widely used in chemical, biological, environmental, and other fields. Among these applications, particle focusing refers to aligning and arranging dispersed particles into ordered single or multiple trains in microfluidics, which is often a prerequisite step for downstream processing, such as enrichment, detection, separation, and manipulation of target particles, benefiting from the powerful and automatic arranging function (Zhang et al., 2020).

Classified according to the principle of manipulation, there are mainly three kinds of focusing methods relating to microfluidics: active, sheath-assisted, and passive focusing methods. Active methods rely on external forces such as acoustic (Rufo et al., 2022), magnetic (Liu et al., 2023), and optical (Yang et al., 2022) forces to control particle motion to achieve the goal of arranging particles into one or multiple ordered trains. Active focusing has higher flexibility and control accuracy. However, the additional external energy field requires sophisticated control systems and increases the complexity of microfluidic devices (Zhu and Wang, 2017). Often, the particle fluid is required to maintain a low flow rate to ensure that particles can be subjected to sufficient external force to move to the focusing equilibrium position, making it difficult to achieve high throughput.

Sheath-assisted focusing uses additional sheath flows to pinch particle flow into a narrow single train (Mao et al., 2007). Sheath-assisted focusing can achieve high throughput, but introducing an external fluid requires additional geometrical microchannels and micro-pumps for sheath inputs, which reduces the integration of microfluidic devices (Chiu et al., 2013). Among passive focusing techniques, inertial focusing utilizes the inertia of fluid (Zhang et al., 2016), viscoelasticity of non-Newtonian medium (Zhang et al., 2016; Lu et al., 2017), or micro-vortex induced by channel structure (Jiang et al., 2021) to control the transverse position of particles to achieve the focusing effect. The integration and footprint of microfluidic devices are effectively improved (Lim et al., 2014). When used in cell focusing, it can attenuate cell damage caused by the external fluid or force. This focusing method can achieve continuous, high-throughput, and label-free particle manipulation. The elasto-inertial focusing principle is generally distinguished due to the different fluid mediums. Among sheathless inertial focusing methods, the inertial focusing technique is generally 2D focusing, i.e., particles are arranged in a single train only in a 2D plane. To achieve 3D focusing, some measures can be taken, such as combining with different morphologies or changing channel structure; however, elasto-inertial focusing can achieve 3D focusing.

There are some scientific literature works with reviews of inertial microfluidics (Amini et al., 2014; Shi, 2023), non-Newtonian microfluidics (Yuan et al., 2018), sheath-assisted focusing (Lu et al., 2016), secondary flow in inertial microfluidics (Zhao et al., 2020), sub-micrometer particle focusing (Zhang et al., 2020), channel innovations for inertial microfluidics (Tang et al., 2020), passive microfluidic separation and sorting (Bayareh, 2020), passive microfluidic driving method (Narayanamurthy et al., 2020), and inertial microfluidic separation (Xu et al., 2021). This review summarizes polymeric particles’ sheathless inertial focusing in microfluidic devices. We clarified the focusing mechanism from theoretical analysis, simulation, and experimental perspectives. This review promises to provide insights into particle focusing and into the related biomedical applications.

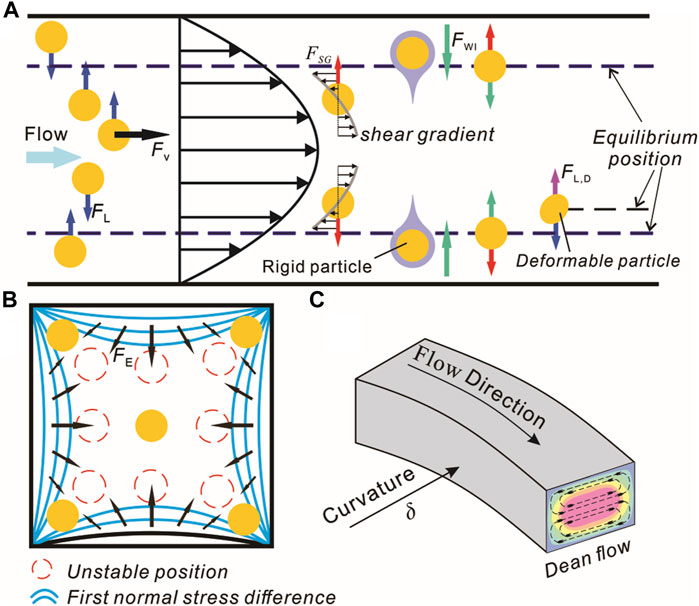

Inertial microfluidics relies on the intrinsic properties of fluids to achieve particle focusing. The forces related to the inertial effect are lift force induced by particle rotation (Magnus force, FΩ) (Rubinow and Keller, 1961), lift force induced by slip and shear motion of a particle (Saffman force, FS) (Saffman, 1965), lift force induced by the channel wall (FWI) (Zeng et al., 2005), and lift force induced by the shear gradient due to the curvature of the fluid velocity profile (FSG) (Matas et al., 2004). In most cases, Magnus and Saffman forces are usually neglected for being much smaller than FWI and FSG. The Dean effect and viscoelastic effect will induce Dean drag force (FD) and elastic force (FE) in the microchannel, respectively. The forces can independently or synthetically affect the trajectory and equilibrium of particles to achieve different focusing states.

When the inertia of the fluid exists, the neutral buoyant particle will be subjected to the net inertial lift FL. FL is the joint force of FWI and FSG. The role of FWI is to drive particles away from walls, and that of FSG is to drive particles near the channel center to the walls. Under the action of joint force FL, particles will be stable at the equilibrium position between the channel center and the wall (Figure 1A). The expression of the FL is given by (Di Carlo, 2009)

where ρf is the fluid density, Um is the maximum velocity of flow, a is the particle diameter, and DH is the hydraulic diameter of the channel. For rectangular channels, DH = 2wh/(w + h), where w and h are the channel width and height, respectively. fL is the lift coefficient, which depends on the channel’s Reynolds number Rc and particle position xc in a microchannel. The lift coefficient can be estimated via direct numerical simulation (Mashhadian and Shamloo, 2019), explicit formula (Su et al., 2023) or machine learning (Su et al., 2021).

FIGURE 1. Schematic of hydrodynamic forces in microfluidics. (A) Inertial forces in a straight microchannel. (B) Elastic force distribution in a square cross-section microchannel. (C) Dean flow within a curved microchannel.

The channel’s Reynolds number Rc and the particle’s Reynolds number (Rp) are the dimensionless numbers related to the inertial effect. Rc describes the relationship between the inertial force and the viscous force. Rp introduces the ratio of particle diameter to channel hydraulic diameter.

where μ is the dynamic viscosity of the flow.

When the fluid medium changes from viscous to viscoelastic or Newtonian to non-Newtonian, the elastic force on particles should be considered (Feng et al., 2022). In pressure-driven viscoelastic flows, the first normal stress (N1 = σxx-σyy) and the second normal stress (N2 = σyy-σzz) will affect particle migration in the fluid. σxx, σyy, and σzz are normal stresses exerted in the flow and are directed toward the flow, velocity gradient, and vorticity direction, respectively. N2 is often negligible in the diluted viscoelastic solution for being much smaller than N1 (Pathak et al., 2004). The elastic force (Figure 1B) due to the non-uniform distribution of N1 acting on particles is (Leshansky et al., 2007)

where CeL is the elastic lift coefficient and ηp is the polymeric contribution to the solution viscosity.

The dimensionless Weissenberg number Wi (Rodd et al., 2005; Rodd et al., 2007) is usually used to describe the viscoelasticity of a fluid and is defined as

where

When flowing through a curved microchannel with a parabolic velocity distribution and flow inertia, two vortexes with opposite rotational directions perpendicular to the flow direction are generated, known as Dean secondary flows (Figure 1C). The intensity of the Dean flow can be expressed with the Dean number (Zhao et al., 2020):

where δ is the curvature of the curved channel, and the Dean drag force acting on a particle can be expressed as

The magnitude and direction are determined by the distribution of Dean flow in the cross-section. The velocity of the Dean secondary flow can be estimated with

In a uniform Stokes fluid, the viscous drag force on a rigid particle due to the difference between the particle and fluid velocity is (Yuan et al., 2018)

where Uf and Up represent the velocity of the fluid and particle, respectively; the direction of the viscous drag force is along the mainstream (Figure 1A).

Unlike rigid particles, the shape change of the deformable particles will induce additional lift force. The dimensionless numbers used to define the relative deformation of droplets are Weber number (

In inertial microfluidics, particles’ focusing behavior must satisfy the confinement ratio and force ratio principles. These principles ensure that the particles are subjected to sufficient forces in the microfluidic channel to achieve equilibrium. In inertial focusing, a better-focusing effect can be achieved by meeting the requirements of confinement ratio a/DH>0.07 (Kuntaegowdanahalli et al., 2009). By ensuring this condition, particles can have sufficient inertial force for migration to the equilibrium position. In elasto-inertial microfluidics, it has been proven that focusing can be realized under a/DH<0.04 (Young Kim et al., 2012; Lee et al., 2013) by using the spiral channel with extended length in a quite small footprint or a smaller channel size relative to the particle diameter with adequate elasticity.

The relative balance of forces on a particle determines the motion behavior in inertial focusing. In a curved channel, the focusing effect will be affected by the ratio of FL/FD (Bhagat et al., 2008; Kuntaegowdanahalli et al., 2009). The ratio of FL/FD can be scaled as

where fL scales with Rcn and n < 0. Rf needs to meet the following requirements when designing a curved microfluidic device for particle focusing (Amini et al., 2014). When FD is much larger than FL, the inertial lift force can be neglected, and particles will rotate with Dean flow. When FD and FL are equal in magnitude, particle focusing will be achieved, and the equilibrium position can be controlled by adjusting the intensity of Dean flow (i.e., changing the curvature or flow rate). When FD is much less than FL, the effect of particle focusing will be the same as inertial focusing in a straight channel.

In a non-Newtonian fluid medium, the elastic number El, which describes the elastic to inertial force ratio, will determine the focusing process. The expression of El is

El ≈ 0 means that the elastic force can be negligible, and El ≥ 1 means that the inertial force can be negligible. El is determined by the channel cross-section size and the characteristics of the fluid medium (Nam et al., 2012). When the fluid viscosity remains constant, El will be independent of the flow rate (Amini et al., 2014). The dynamic balance between forces can describe the particle-focusing mechanism. Equations 1-10 helps explain the mechanism and design of inertial microfluidic focusing chips.

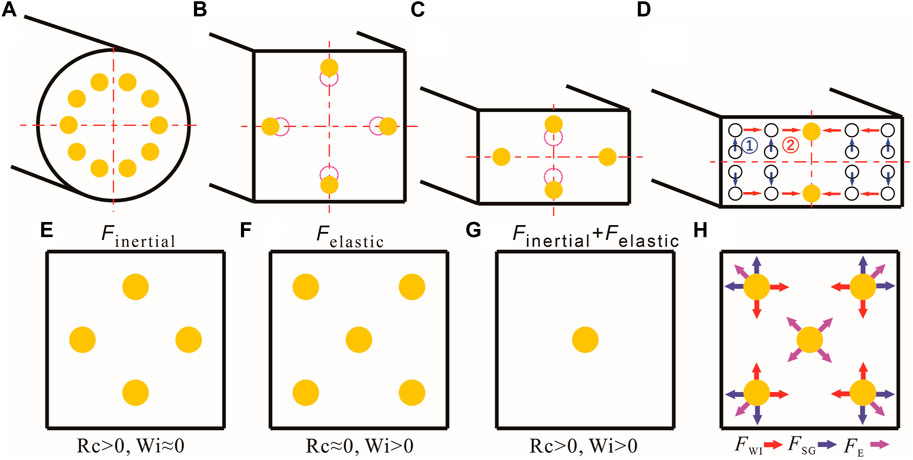

The inertial focusing method is widely used, independent of the external force field and other sophisticated auxiliary devices. Inertial focusing refers to controlling the lateral migration of particles by employing fluid inertia and eventually arranging particles into one or multiple trains. In 1961, Segré-Silberberg discovered that in a cylindrical pipe (∼1 cm in diameter), the neutral buoyant particles flowing in a laminar flow distribute equitably at the outlet from 0.6 times pipe radius to the center of the pipe (Figure 2A) (Segré and Silberberg, 1961). This effect is due to the inertial migration caused by the inertial lift force acting on the particles. Since then, the research field of particle inertial focusing has been pioneered. Inertial focusing was first applied to microfluidic applications in 2007 (Di Carlo et al., 2007). When introducing viscoelastic fluid into a circular microchannel, the randomly distributed particles focus on the central lines and disperse as the flow rate increases due to the high FSG directed to the wall and the obvious shear-thinning effect (Seo et al., 2014). This section reviews inertial focusing in microfluidic devices from the channel configuration aspects.

FIGURE 2. Inertial focusing of particles in the cross section. (A) In a circular cross-section pipeline, particles focus on 0.6 R (R is the pipe radius) at the exit. (B) Focusing position in a square channel (AR = 1); the dotted line represents the initial focus position, and the solid line represents the equilibrium position after the particle Reynolds number increases. (C) Equilibrium position in rectangular cross-section channels (AR < 1): as the Reynolds number increases, the equilibrium position changes from 2 to 4. (D) A two-stage migration model explaining inertial focusing mechanisms in a straight microchannel (Zhou and Papautsky, 2013). (E–H) Elasto-inertial focusing mechanisms in a square microchannel.

Straight microchannels have been widely used in microfluidic applications for their simple structure and easy manufacturing. Among straight microchannels, the most frequently used are square [AR = 1 (aspect ratio = channel height/width) and rectangular cross-section channels (AR ≠ 1)]. In a rectangular channel, the net lift FL balancing Stokes drag force shifts the particle to equilibrium. When Rp << 1, the viscous interaction of the fluid and particles dominates particle motion. Under this condition, particles are subjected to the dominant surface drag and move to follow fluid streamlines. As Rp increases to 1, inertial forces dominate, and lateral migration across fluid streamlines becomes obvious (Di Carlo et al., 2007), forming a focusing phenomenon. In a square channel, the randomly distributed particles focus on four equilibrium positions along the center of each channel wall (Figure 2B) and then move toward the wall as Rp increases due to the strengthening of FSG (Di Carlo et al., 2007).

The focusing properties in the straight microchannel can be affected by aspect ratio, cross-section morphology, particle confinement ratio, and flow rate. In the rectangular channel (AR ≠ 1), due to the blunted velocity profile along the wider surface, particles focus on two equilibrium positions along the center of the longer surface (Ciftlik et al., 2013). Notably, with an increase in the flow rate, the two unstable equilibrium positions along the short-channel side reappear, with FWI becoming less dominant than FSG, and the equilibrium positions recover from two to four (Figure 2C). The detailed inertial focusing principle in the straight microchannel was explained through a two-stage focusing model (Figure 2D) (Zhou and Papautsky, 2013). In a low-AR rectangular microchannel, particles move to an equilibrium position where FWI and FSG are balanced. Then, particles near the wall move toward the wall-centered equilibrium position under the rotation-induced force FΩ. Particles moving to the first-stage equilibrium usually take less time than those moving to the second stage. The model can also explain the principle of inertial focusing under different cross-section microchannels.

The negligible elastic effect in viscoelastic fluids can affect and regulate particle migration behavior. The particle-focusing process depends on the rheological properties of fluids and the first principal stress difference (Caserta et al., 2011; Bai et al., 2023). The shear viscosity of viscoelastic fluids is generally divided into the constant viscosity region and the shear-thinning region. Particle focusing usually occurs in the constant viscosity region. The elasto-inertial focusing concept was first proposed by Yang et al. (2011) to illustrate 3D focusing in a straight square channel. When particles flow in a viscoelastic fluid with finite inertia, the particle focusing becomes intriguing, and single-train focusing will be achieved under the inertial and elastic effects.

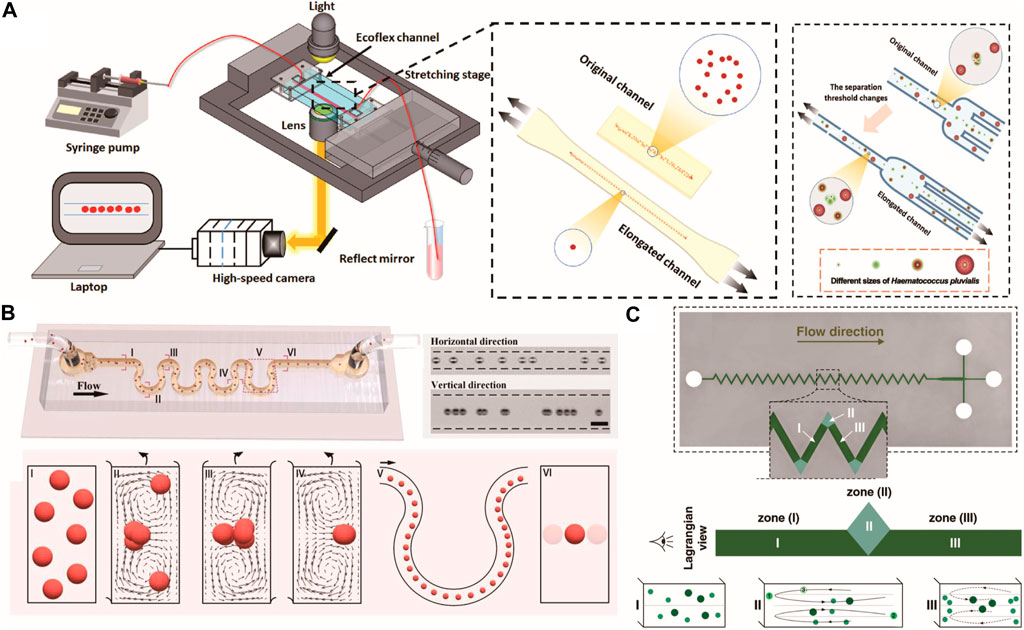

In a square microchannel with a viscoelastic fluid, randomly distributed particles focus on four equilibrium positions near each center of the channel wall due to the inertial effect only (Re > 0 and Wi = 0) (Figure 2E) (Zhou and Papautsky, 2020). When subjected to elastic forces only (Re ≈ 0 and Wi > 0), particles focus on five equilibrium positions, with four near the corner and one at the central line (Figure 2F) (Yang et al., 2011; Liu et al., 2015). When elastic and inertial effects exist simultaneously (Re > 0 and Wi > 0), under a moderate El number, 3D focusing with high precision can be achieved at the centerline (Figure 2G) (Yang et al., 2011; Del Giudice et al., 2013). In viscoelastic microfluidics, the 3D single-train focusing can only be achieved with the synergistic effects of inertia and elasticity (Figure 2H). The equilibrium position at the corner caused by elasticity can be easily destroyed by inertial force. In contrast, the equilibrium position at the central line is maintained with elastic force (Yang et al., 2011). The dimensionless numbers related to elasto-inertial focusing are elasticity number (El), Reynolds number (Rc), and Weissenberg number (Wi), among which Wi is the most adequate one for evaluating the focusing efficiency (Song et al., 2016). In a low AR channel, the difference in first principal stress is more evident along the height direction than the width direction. The larger elastic force drives particles to the centerline of width. The lateral migration is mainly determined by inertial force because of the weakened elastic effect near the narrow surface (Won Seo et al., 2014). Multiple focusing trains were observed in low AR channels (Yang et al., 2017). In a square channel, by increasing the corner angle, the equilibrium position at the corner can also be reduced, and a more accurate single-train focusing can be obtained (Raoufi et al., 2019). Jia et al. (2023) developed a size-tunable elasto-inertial separation microfluidic system using an ultra-stretchable channel (Figure 3A). Channel stretching alters the local flow velocity distribution and strongly regulates particle focusing.

FIGURE 3. Particle focusing regulation in inertial microfluidics. (A) Ultra stretchable microfluidic platform for enhancing particle focusing in the straight microchannel (Jia et al., 2023). Copyright 2023, American Chemical Society. (B) 3D single-line inertial focusing in the high aspect ratio serpentine microchannel (Ni et al., 2022). Copyright 2023, American Chemical Society. (C) Particle focusing in the zigzag serpentine microchannel. Reproduced from Razavi Bazaz et al. (2022) with permission from the Royal Society of Chemistry.

Inertial focusing in a straight microchannel is usually more suitable for larger micron-sized particles. Sub-micron particles (0.1–1 μm) generally require longer channel length or smaller cross-section (FL ∼ DH−2) (Bhagat et al., 2009; Zhou and Papautsky, 2013) for the net lift force scales with particle diameter FL ∼ a4 (Guan et al., 2013), increasing manufacturing and detection complexity.

With viscoelastic fluids, particles with a diameter down to 200 nm can be focused remarkably (Leshansky et al., 2007). The focusing behavior of the submicron particles is determined by elastic force, inertial force, and Brownian motion force (Young Kim et al., 2012). Effective focusing of particles of diameter less than 100 nm can be achieved using oscillatory viscoelastic microfluidics, eliminating the need for long microchannels (Mutlu et al., 2018; Asghari et al., 2019).

Elasto-inertial focusing can also be used for deformable particles, which are subjected to additional lift induced by the channel wall due to deformation. The focusing method can be applied to particle separation due to different equilibrium positions and deformability (Yang et al., 2012). In addition to the widely used PEO and PVP viscoelastic solutions, other solutions are also used as viscoelastic fluids. Lim et al. (2014) reported extremely high-throughput focusing (Q = 50 ml/min and Re ∼10,000) in the hyaluronic acid (HA) solution with an epoxy microchannel, which demonstrated the highest flow rate yet achieved. Kim and Kim (2016) investigated the particle focusing process in a diluted λ-DNA solution. The throughput can be enhanced significantly due to the long relaxation time of DNA and high elasticity.

For straight channels with different cross-section shapes, particles will have dissimilar focusing effects for diverse velocity gradient profiles compared to a rectangular cross-section. By processing the master die with micro-milling and 3D-printing methods, various cross-sections, such as trapezoidal, triangular, and semi-circular, can be manufactured. Under the asymmetric axial velocity profile, the equilibrium positions will be derived to the long trapezoidal side between the centerline and the bottom when the trapezoidal cross-section is used. The focusing equilibrium will change as the angle of the slanted wall increases. This focusing method can also be applied to filtration of larger particles (Moloudi et al., 2018). Compared to a trapezoid cross-section, the triangular cross section makes realizing a single-streamline focusing near the channel apexeasier, especially with a low AR channel (with a 120° apex angle, AR = 0.4) (Mukherjee et al., 2019). The number of equilibrium positions will increase as the apex angle reduces. In a semicircular cross-section microchannel, particles are focused near the top and bottom of the centerline, and the position changes are unobvious with Rp altered (Kim et al., 2016). Kim U. et al. (2022) compared and investigated the particle behavior in rhombic and equilateral hexagonal cross-section microchannels with different flow rates and particle sizes, and this microfluidic device with non-rectangular microchannels can be used for bioparticle sorting.

Straight channels have the limitations of slow lateral migration, considerable resistance, and multiple equilibrium positions. Secondary flow (perpendicular to the main flow) within a curved channel will overcome these problems (Tang et al., 2020). Meanwhile, curved channels can effectively reduce the length needed for focusing, accelerate the focusing process, reduce focusing positions, and improve the integration of microfluidic devices (Wang and Dandy, 2017). This section reviewed the sheathless inertial particle focusing techniques from channel aspects: serpentine, spiral, and other curved channels.

Di Carlo et al. (2007) first studied the particle-focusing process in a serpentine channel. Introducing a symmetric or asymmetric curvature can reduce the four equilibrium positions in a straight, square channel to one or two, depending on the flow rate. This focusing mechanism can be applied for particle separation and filtration based on the different equilibrium positions (Di Carlo et al., 2008; Wang et al., 2018).

When used for submicron-sized particle focusing, smaller channel sizes and larger flow rates are required to ensure adequate lateral migration force. Wang and Dandy (2017) manufactured an asymmetric serpentine channel with the thermoset polyester (TPE) casting method and demonstrated single-stream focusing of submicron particles through a controllable flow rate. TPE has an elastic modulus that is 1,000 greater than that of polydimethylsiloxane (PDMS), with a favorable stiffness ratio of 1:10, which is suitable for microfluidic applications requiring high load-bearing pressure. This focusing method pushes the inertial focusing particle range down to the sub-micrometer level and can be applied for micron particle separation from the micro-nanoparticle mixture (Wang and Dandy, 2017).

Paiè et al. (2017) manufactured 3D microfluidic loops with femtosecond laser irradiation followed by chemical etching. The use of 3D loops produces a strong Dean flow with low resistance, which can be used for compact parallelization of multiple focusing. Zhou et al. (2018) adopted a series of reversed wavy channel structures generating periodically reversed Dean flow perpendicular to direction of the main flow to focus particles. As the Rc increases, the alternation in the Dean flow direction in the serpentine channel produces special hydrodynamic effects to focus particles. Ni et al. (2022) developed high aspect ratio asymmetric serpentine (HARAS) microchannels for single-line inertial focusing of particles and cells at the 3D center of the channel and observed size-independent and positionally controllable focusing phenomena over a wide range of flow rates (Figure 3B).

For symmetric serpentine microchannels, Zhang et al. (2019) systematically studied the effects of viscosity, flow conditions, particle size, and cross-section dimensions on focusing effects. Focusing patterns can be classified as two-train focusing, single-train focusing, and defocusing, which depend on the different focusing parameters. A parametric map of

Yuan et al. (2019) studied the distribution of particles and cells in viscoelastic fluids, where inertia becomes dominant and destroys the focusing of particles above a certain flow rate. Instead of using a syringe pump, Shamloo and Mashhadian (2018) performed the simulation by using a centrifugal platform to drive fluid. The focusing behavior of particles is a combination of Dean drag force, inertial lift force, and centrifugal force. The channel length required for focusing is related to particle density and channel corner angles to the driving method. Removing pumps from centrifugal platforms provides an efficient integration for microfluidic devices. Zhang et al. (2014) adopted a low AR right-angled transitional serpentine microchannel based on the Dean drag and centrifugal force to focus particles. The inertial lift force is weakened due to the blunted velocity profile along the direction of the wider surface. The number of focusing trains is related to the particle size and channel Reynolds number. Single-train focusing can be achieved at the center of the long surface at a moderate Reynolds number. Amani et al. (2022) studied the inertial focusing behavior in the divergent serpentine microchannel, which showed an excellent performance compared to the convergent geometry in focusing (Razavi Bazaz et al., 2022; Ebrahimi et al., 2023) and developed a zigzag microfluidics channel that demonstrated superior separation and purity efficiency due to the sudden channel cross-section expansion at the corners compared to other serpentine microchannels, and the threshold of the particle-confinement ratio decreased to 0.04 (Figure 3C).

In serpentine microchannels, particle focusing accuracy can be regulated by channel expansion or the introduction of micro-obstructions. Lu et al. (2020) proposed a microfluidic chip introducing periodic micro-square contractions to the serpentine channel, which provides a strategy for developing high-precision inertial sorting. The transition region shrank to the sub-micron scale, and the separation of 6.0 and 5.5 μm particles with a higher recovery ratio was achieved (Lu et al., 2020). Cha et al. found that embedding asymmetric obstacle microstructures in a symmetric serpentine flow channel adjusts inertial focusing and reduces the equilibrium position. The asymmetric concave obstacle destroys the symmetry of the original inertial focusing position, which leads to unilateral focusing (Cha et al., 2022; Cha et al., 2023b).

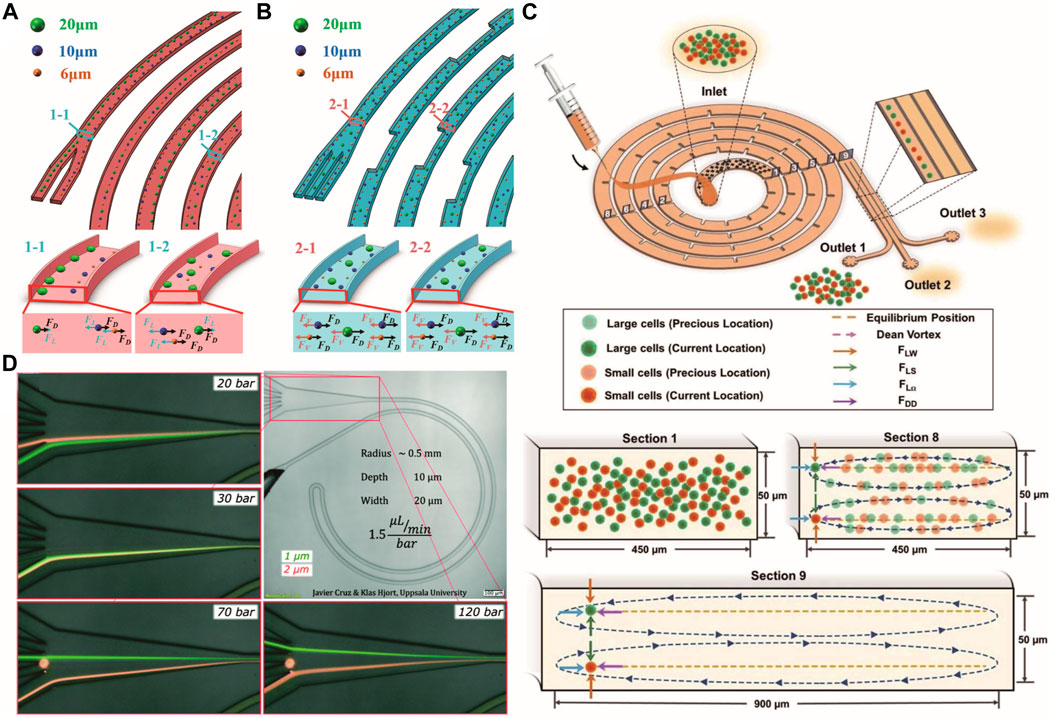

Archimedes spiral is commonly used in microfluidic applications, benefiting from the compact structure and additional Dean drag force. With the increasing Dean number, the focusing process can accelerate, and particles can find the transverse stable position more quickly. Particles of different sizes have different FL/FD values and will focus on the position near the inner wall according to size (Kuntaegowdanahalli et al., 2009). A spiral microchannel with increasing width and curvature can provide an additional secondary flow field for focusing. The particle will focus on two equilibrium positions along the height direction near the inner wall (Russom et al., 2009). Martel and Toner (2012) studied the focusing effect in spiral channels of different aspect ratios. As AR decreases, FL along the wide surface decreases due to the blunted velocity profile, and the focusing process will be dominated by FD, which means that the equilibrium position can be obtained by regulating the flow rate. Jeon presented a mass-producible, clogging-free plastic spiral inertial microfluidic system, a material conversion from PDMS to harder plastics that will be crucial in realizing the vision of high-throughput industrial applications of inertial microfluidics (Jeon et al., 2022).

Establishing the corresponding model relates to the range of flow rate change and the focusing position, which will help elucidate the mechanism of the focusing process. Xiang et al. used a five-stage model to illustrate the focusing mechanism of the changing flow rate (Xiang et al., 2013b; Xiang et al., 2013a). As the flow rate increases, focusing patterns will change as follows: in the case of a low flow rate with non-negligible inertia and weakened Dean effect, particles focus along the center of the upper and lower wider surface. As the flow rate increases, the transversal motion will be dominated by FL, and particles will move toward the inner wall. The equilibrium position will be stable on the inner wall. Then, FD exceeds FL, and the equilibrium position moves toward the outer wall. Ultimately, defocusing and mixing effects were formed due to the faster strengthening of the Dean effect (Kuntaegowdanahalli et al., 2009). Xiang et al. (2015) investigated the migration dynamics of particles with different confinement ratios and summarized it with three modes: non-focusing, rough focusing, and distinct focusing. The work provides an insightful understanding of the focusing dynamics of particles.

Guan et al. (2013) investigated the particle focusing process in a trapezoidal cross-section spiral microchannel. Strong Dean flow will be generated near the wider sidewall, which speeds up the trapping of particles toward the narrow side and accelerates the focusing process (Guan et al., 2013). Zhu et al. (2021) presented a polymer-film inertial microfluidic jigsaw sorter with trapezoidal spiral channels by accurately assembling polymer-film jigsaws of different thicknesses, which brings advantages to the flexible design of inertial microfluidics. The Dean effect can be controlled and enhanced by increasing the slant angle. The acceleration of Dean flow intensity can also be realized by introducing micro-obstacles into the spiral microchannel, as reported by Shen et al. (2017). The focusing performance will be improved, and the focusing process will speed up. The manufactured device can be promising for the application of high-throughput microfluidics systems. However, the introduced micro-obstacles will increase the flow resistance and require higher bonding strength for microfluidic chips. Accurate single-train focusing can also be obtained in spiral microfluidics by adopting an appropriate channel contraction (Gou et al., 2020) or arranging obstacles (Cha et al., 2023a). Introducing asymmetric periodic expansion structures in the spiral channel produces a stable additional vortex-induced lift force, combined with Dean drag force, effectively enhancing the focusing process (Gou et al., 2020) (Figures 4A, B). Inertial microfluidic chip design usually requires flow rate optimization, which increases the development cycle. By introducing a series of microstructures in a dimension-confined ultra-low aspect ratio spiral microchannel, Zhao et al. (2022) demonstrated flow-rate and particle-size insensitive inertial focusing of 15.5-μm particles and tumor cells, which will be promising for cytometry application (Figure 4C).

FIGURE 4. Particle focusing in the spiral microchannel. Comparison of the particle motions in the normal (A,B) Periodic expansion spiral channel (Gou et al., 2020). Copyright 2020, American Chemical Society. (C) Inertial focusing in the dimension-confined ultra-low aspect ratio spiral microchannel (Zhao et al., 2022). (D) Inertial focusing of submicron particles. Reproduced from Cruz et al. (2019) with permission from the Royal Society of Chemistry.

In a spiral microchannel with viscoelastic fluid, the equilibrium positions are determined by the ratio of FD to FE, which is proportional to a2. Unlike the principle of inertial focusing, larger particles are focused close to the outer wall due to the existence of FD and FE (Kumar et al., 2021). This focusing mechanism can be used for a/DH < 0.04, which makes up for the deficiency of inertial focusing. Xiang et al. (2016b) systematically studied the mechanism of elasto-inertial focusing in a spiral microchannel with different flow rates, aspect ratios, and curvatures. A six-stage model was proposed to explain the mechanism under different flow rates. The equilibrium position of particles is more sensitive to the flow rate change (Xiang et al., 2016b). Gao et al. (2023) systematically investigated particle elasto-inertial migration in spiral channels, which helped improve the understanding of the underlying mechanisms. When the fluid changes from water to PEO and then to PVP, the elasticity increases, and particles focus on the centerline due to excessive elastic force, which overweighs the inertial lift and Dean drag force (Xiang et al., 2016a). As the concentration of viscoelastic decreases, the position of the focusing equilibrium moves toward the outer wall under the combined influence of FE, FD, and FL (Xiang et al., 2018).

In curved channels, inertial lift forces determine the focusing of particles, and the Dean flow is responsible for modifying the focusing equilibrium positions. Under different Dean number conditions, lateral migration of particles to stable and unstable states will be caused. Increasing the radius of curvature or decreasing the hydraulic diameter will improve the single-train focusing. Gossett and Di Carlo (2009) investigated the effect of the degree of asymmetry on the particle-focusing process. With increased asymmetry, particles can quickly focus on a single train at lower Rc. Martel and Toner (2013) decoupled the effects of Rc and De on the inertial focusing behavior and concluded that the focusing mechanism is more complex than an explanation of force balance (FL/FD). The equilibrium position of three particle sizes under critical parameters such as Rc, confinement ratio, and curvature ratio was analyzed. Increasing curvature not only increases Dean drag force but also changes shear gradient lift force through redistribution of the velocity profile, which leads to a new vertical equilibrium position of particles (Martel and Toner, 2013). The detailed results can provide a guide for designing curved microfluidics channels.

By reducing the cross-section size to 20 × 10 μm2, Cruz et al. (2019) demonstrated single-line inertial focusing of spherical particles as small as 0.5 μm in a curved microchannel and extended it to bacterial sorting (Figure 4D). They explained the equilibrium and migration mechanisms through numerical simulations and experimental studies. High-aspect-ratio curved microchannels can achieve a single-focus position near the inner center, largely independent of the flow rate and separation at the submicron scale. In curved triangular channels, the inertial focusing could be easily tuned to achieve a single stream, which enables finding the best design for a specific application with less time and effort (Kim et al., 2022). More detailed viscoelastic microfluidic focusing within curved microchannels can be found in Feng et al. (2022). Table 1 lists particle focusing in microfluidics with Newton fluid, and detailed parameters are provided.

Micro-vortex refers to the emergence of a vortex in a fluid that can provide a helpful transversal drag force for particle migration. The vortex can be generated by gradually adjusting the cross-section area along the flow direction, the topological expansion or contraction of the straight channel, or the arrangement of micro-obstacles in a channel. There are usually two types of micro-vortexes: vertical vortex, perpendicular to the flow direction, and horizontal vortex, parallel to the flow direction. The balance between the drag force induced by the vortex and the inertial lift force can explain the focusing mechanism.

Choi and Park (2007) investigated the particle focusing process in microfluidics with slanted obstacles. The arrangement of slanted rectangular obstacles with a fixed angle in the microchannel can induce a vertical vortex, and the focusing operation can be achieved under the different fluid pressure distributions compared to a straight rectangular microchannel. The focusing method has a great relationship with particle size and relates slightly to the flow rate (Choi and Park, 2007). The particle-focusing process can also be achieved under the action of a vertical vortex in a microfluidic chip bonded by two PDMS microchannels with slanted obstacles of exponentially increased width (Choi and Park, 2008). The proposed focusing method is suitable for larger particles and is more efficient with longer channels. Hsu et al. (2008) studied the focusing performance in microfluidics channels with the arrangement of herringbone grooves at the top of the microchannel. The focusing effect is related to channel height, channel size, groove numbers, and the ratio of groove height to channel height. By arranging herringbone grooves, particles can have a definite transverse focusing position. Chung et al. (2013b) studied the particle focusing process in microfluidic channels with the arrangement of cylindrical microstructures in the microchannel. The four equilibrium positions can be reduced to one by the vertical vortex induced by micro-obstacles, and precise focusing of a single train can be realized. Introducing micro-obstacles will result in high flow resistance, which may limit the focusing throughput and cause blockage.

When groove arrays are introduced in microchannels, a transverse pressure gradient will be generated for enhancing particle focusing. A stepped groove microchannel structure (with 30 pairs of steps) can also induce a vertical vortex (Chung et al., 2013a). The two equilibrium positions in the low AR rectangular channel will be gradually reduced to one due to the vertical vortex induced by the step structure in a microchannel. In stepped microfluidics, focusing performance is mainly determined by the step numbers and particle concentration. When the step groove is inclined to the straight channel, channel width will be the key element that affects focusing performance (Song and Choi, 2013). Particles focusing on high throughput (1.1 mL/min) can be realized by adopting a straight microchannel with inclined arc-shaped steps on the top side of the microchannel, as reported by Zhao et al. (2017). Zhang et al. (2013) developed a resource-saving and efficient numerical computational model and analyzed the focusing mechanism of 1–9.9 μm particles in a double-layered grooved microchannel, which provides a reliable method for predicting particle motion (Zhang et al., 2022). With the proposed numerical model, they conducted geometrical and dimensional optimization for double-layered grooved microchannels; with optimized microchannel structures, microparticles with diameter less than 1 μm can be focused (Zhang et al., 2013).

In a straight channel with an expansion–contraction cavity, a horizontal vortex at the topological cavity region and a vertical vortex downstream of the cavity will be generated due to great inertia in the fluid (Lee et al., 2011). Park et al. (2009) investigated focusing behavior in straight microchannels with topological rectangular expansion on both sides. The focusing process can be achieved by benefiting from the micro-vortex induced by channel structure and inertial lift force in the narrow pinched channel. The focusing state changes with flow rate increase: defocusing, focusing on two trains, defocusing, single-train focusing, and defocusing. Zhang et al. (2013) studied the focusing behavior in a straight microchannel with a unilateral triangular topology. The focusing efficiency is determined by particle size, and larger particles are easier to focus. According to the flow rate, the different focusing states can apply to particle focusing, separation, and trapping in microfluidic devices (Zhang et al., 2013).

For viscoelastic fluids, the streamline bends at the expansion area in the expansion–contraction channel, and the generated additional hoop stress pushes particles to the centerline (Cha et al., 2014; Jiang et al., 2021). The focusing method can improve the efficiency and throughput of elasto-inertial focusing. Yuan et al. studied the focusing behavior in straight viscoelastic microfluidics channels with a unilateral triangular topology. Combining the fluid’s elasticity, inertia, and Dean effect can achieve high-quality particle focusing. Non-Newtonian fluids are more suitable to focus particles than Newtonian fluids (Yuan et al., 2015; Yuan et al., 2017). Zhou and Papautsky (2020) summarized the progress and challenges of viscoelastic microfluidics. Recent reviews can provide more details on inertial microfluidics in contraction–expansion microchannels (Jiang et al., 2021).

Table 2 lists various particle-focusing phenomena with non-Newtonian fluid in microfluidic devices.

Multi-staged microfluidics, which typically combine multiple inertial technologies, are emerging technologies that offer better performance in terms of stability, versatility, and convenience. By combining microchannels of different focusing characteristics, the equilibrium position of particles can be controlled in multiple stages, and 3D focusing of a single train with high precision and efficiency can be achieved. Oakey et al. (2010) investigated focusing behavior in microfluidics with a straight, rectangular, and asymmetric serpentine channel. Through the synergistic effect between the multiple channel structures, the two or four roughly focused trains in straight microchannels, depending on AR, can be reduced to one after flow in a curved channel. The focusing behavior in the staged microfluidic device is mainly determined by the flow rate. Because the staged channel is connected in series, the focusing effect will be affected by the order of the channels. Staged microfluidics is a promising technology for high-throughput analysis and flow cytometry.

Zhang et al. (2018) designed a single-layer microfluidic chip that combined a periodic high-AR straight rectangular microchannel with semicircular microchannels. With the introduction of a semicircular channel, the two equilibrium positions at the top and bottom centerlines of the wide surface in rectangular channels will be reduced to one due to the stirring effect of Dean flow, and the stirring effect will be suppressed with rectangular channels. High-throughput 3D focusing can be realized with a simple channel structure (Zhang et al., 2018). Wang et al. (2015) reported high-efficiency focusing in a two-stage straight rectangular channel. The flow direction of particles is controlled by changing the hydrodynamic resistance and properly defining the channels’ length at a Y-shaped outlet in the second stage. Particle solution flows into rectangular microchannels with different aspect ratios in sequence. Particles will be focused on two central lines at the first stage with low AR. Then, the two equilibrium positions will shift to a single line at the high-AR stage. The proposed device used the advantages of being rectangular with different AR, which offers a convenient design for microfluidic focusing. The disadvantage may be that the device needs a long channel, which may increase the footprint. The two-staged rectangular cross-section microfluidics can also be used for particle separation due to the equilibrium position difference according to the particle size (Zhou et al., 2013). Adjusting cross-sectional shapes can be favorable for particle manipulation. Due to the size-dependent characteristics, the current focusing methods can also be applied to particle separation (Kim et al., 2018).

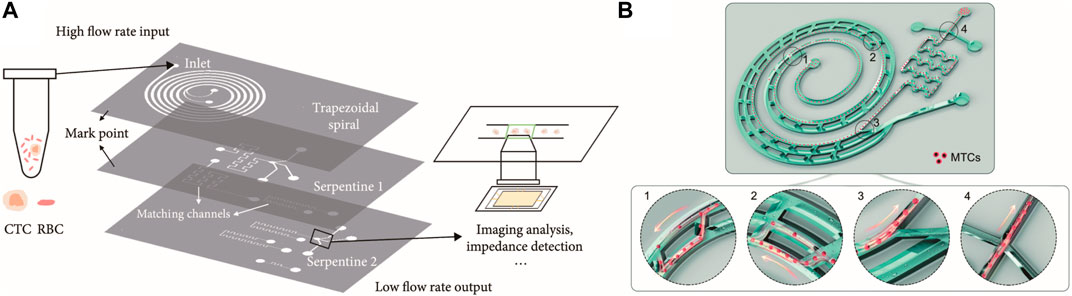

Kim et al. (2016) reported a novel three-staged inertial focusing device that includes rectangular, triangular, and semicircular cross-section microchannels. The focusing process can be controlled according to the difference in the flow velocity profile in different cross-sections, and an efficient single-train focusing process can be achieved (Kim et al., 2016). Xu et al. (2022) proposed a 3D-stacked multistage inertial microfluidic chip cascading spiral channel with a trapezoidal cross-section and symmetrical square serpentine channels, which can achieve higher throughput in the separation and enrichment of CTCs (Figure 5A). Xiang described a low-cost multiplexed inertial microfluidic tumor cell concentrator by adopting a serial cascading asymmetric serpentine channel with the spiral channel, which will be readily integrated with other on-chip cell sorters to enhance the analysis (Xiang and Ni, 2022) (Figure 5B). More details on multi-stage microfluidics with coupled multiphysics fields can be found in Xu et al. (2021).

FIGURE 5. Particle focusing in the multi-staged microchannel. (A) 3D-stacked multistage inertial microfluidics with the trapezoidal spiral channel at the top, serpentine channel in the middle, and serpentine channel at the bottom for cell sorting (Xu et al., 2022). (B) Multistage inertial microfluidics for malignant tumor cell concentrators. Reproduced from Xiang and Ni (2022) with permission from the Royal Society of Chemistry.

This paper reviews the working principles and channel structures of existing sheathless inertial microfluidic techniques applied to particle focusing. Inertial microfluidics, as a method of cellular sample pre-processing, offers several advantages over conventional methods by reducing the size of the necessary equipment and simplifying the complex protocols. It paves the way for a more accessible, rapid, and cost-effective way of handling biological samples, catalyzing advancements in research and clinical settings. Sheathless inertial microfluidics focusing has found various applications in the biological sciences due to its ability to precisely manipulate cells and particles in a label-free and high-throughput manner. The main applications are as follows:

Microfluidic cytometer: flow cytometry is widely used in life sciences and clinical diagnostics to characterize and analyze cells. Conventional flow cytometry uses attached probes’ scattering properties or fluorescence intensity to detect cells. Traditional flow cytometers are bulky and mechanically complex, requiring specialists to operate the equipment (Yang et al., 2018). Microfluidic cytometry has a much lower reagent/sample volume consumption and cost than conventional flow cytometry. Conventional microfluidic flow cytometers, which focus the sample stream into a narrow stream employing a surrounding sheath flow, can minimize the possibility of two or more particles simultaneously entering the optical interrogation region. Inertial microfluidics offers more freedom in multiplexing, automation, and parallelization than traditional technologies, thus adding more functionality to cell preparation, analysis, and manipulation (Yan and Yuan, 2021). With inertial microfluidics, 3D flow focusing and alignment in microfluidic channels can be achieved with a simple design, offering the potential to develop new flow cytometry systems with superior performance (Zhou et al., 2023). Microflow cytometry will become one of the most powerful technologies for rapidly analyzing cells and particles.

Cell sorting and enrichment: sorting and enrichment of target cells is a prerequisite for many biomedical applications, such as cancer detection and drug screening. Downstream analysis can be significantly simplified with sorting and enrichment. As a passive method with high manipulation efficiency, inertial microfluidics outperforms other techniques in isolating or concentrating rare cells from large background cell populations (Tang et al., 2020). Depending on the differences in inertial lift and drag forces on the particles, the equilibrium position of biological samples of different sizes within the microfluidic channel varies, and the use of inertial microfluidics such as spiral, serpentine, and constricted–expansion channels allows for the high-throughput and high-efficiency enrichment of biological samples, such as CTCs (Jeon et al., 2022; Xu et al., 2022), sperms (Feng et al., 2021), bacteria (Lu et al., 2021), and blood cells (Xiang and Ni, 2015).

Pre-processing steps for further sorting and detection: Enrichment of target cells before downstream analysis is an essential pre-processing step in many biomedical and clinical assays. Additional sheath flow is often required to focus the sample for more precisely isolating and detecting individual cells. The introduction of the sheath flow requires a sophisticated syringe pump to control the flow and keep it stable. Benefiting from the unique advantages of inertial microfluidics focusing, such as high-precision alignment and high-throughput characteristics, makes it a pre-processing step for higher precision sorting and detection. For example, inertial focusing can be used for high-precision active acoustofluidic separation (Wu et al., 2018; Peng et al., 2023). The development of integrated and efficient sorting chips can be more easily achieved by upstream inertial focusing. Inertial-focusing microfluidics for integrated cell detection has emerged as a promising trend for reducing cross-contamination and enabling single-cell unlabeled analysis (Zhou et al., 2021).

Based on a review of the existing literature, we present some prospects for sheathless inertial microfluidics focusing:

Designing an inertial microfluidic chip to achieve a specific application requires optimizing the flow rate for optimal device performance. Recently, flow-rate-insensitive spiral inertial microfluidic chips have been developed for CTC sorting applications, reducing the dependence of the device on the flow rate (Zhao et al., 2022). In the future, the development of inertial focusing microfluidic devices independent of flow rate, particle size, and other characteristics to extend applications and reduce the development cycle will be required.

At high flow rate inputs, higher pressures are typically provided. Deformation of commonly used PDMS channels causes changes in the flow profile, so implementing inertial microfluidic focusing using stiffer polymer materials will show advantages in terms of device performance and high-volume fabrication.

To enhance the integration of microfluidic chips and improve the purity and efficiency of cell separation, it is essential to combine inertial microfluidics with active separation technologies, such as coupling with multiple physical fields like acoustics, optics, and electrics. However, inertial microfluidics typically operate at high flow rates, so the flow rate mismatch with active technologies needs to be addressed. A more efficient pre-processing of biological samples can be achieved by accommodating both the high throughput of passive methods and the high precision of active methods.

In the future, with the deepening of related research, we hope that sheathless inertial microfluidic focusing can be integrated into biological sample sampling, separation, and detection and can be efficiently and practically used in POCT health monitoring.

TP: conceptualization, formal analysis, funding acquisition, resources, writing–original draft, and writing–review and editing. JQ: formal analysis, validation, writing–original draft, and writing–review and editing. SY: formal analysis, investigation, resources, writing–original draft, and writing–review and editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research is financially supported by the China Postdoctoral Science Foundation (Grant No. 2023M734087).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Amani, A., Shamloo, A., Vatani, P., and Ebrahimi, S. (2022). Particles focusing and separation by a novel inertial microfluidic device: divergent serpentine microchannel. Ind. Eng. Chem. Res. 61, 14324–14333. doi:10.1021/acs.iecr.2c02451

Amini, H., Lee, W., and Di Carlo, D. (2014). Inertial microfluidic physics. Lab. Chip 14, 2739–2761. doi:10.1039/c4lc00128a

Asghari, M., Cao, X., Mateescu, B., van Leeuwen, D., Stavrakis, S., and DeMello, A. (2019). Oscillatory viscoelastic microfluidics for efficient focusing and separation of nanoscale species. bioRxiv. doi:10.1101/668301

Bai, J.-J., Zhang, X., Wei, X., Wang, Y., Du, C., Wang, Z.-J., et al. (2023). Dean-flow-coupled elasto-inertial focusing accelerates exosome purification to facilitate single vesicle profiling. Anal. Chem. 95, 2523–2531. doi:10.1021/acs.analchem.2c04898

Bayareh, M. (2020). An updated review on particle separation in passive microfluidic devices. Chem. Eng. Process. - Process Intensif. 153, 107984. doi:10.1016/j.cep.2020.107984

Bhagat, A. A. S., Kuntaegowdanahalli, S. S., and Papautsky, I. (2008). Continuous particle separation in spiral microchannels using dean flows and differential migration. Lab. Chip 8, 1906–1914. doi:10.1039/b807107a

Bhagat, A. A. S., Kuntaegowdanahalli, S. S., and Papautsky, I. (2009). Inertial microfluidics for continuous particle filtration and extraction. Microfluid. Nanofluidics 7, 217–226. doi:10.1007/s10404-008-0377-2

Caserta, S., D’Avino, G., Greco, F., Guido, S., and Maffettone, P. L. (2011). Migration of a sphere in a viscoelastic fluid under planar shear flow: experiments and numerical predictions. Soft Matter 7, 1100–1106. doi:10.1039/c0sm00640h

Cha, H., Amiri, H. A., Moshafi, S., Karimi, A., Nikkhah, A., Chen, X., et al. (2023a). Effects of obstacles on inertial focusing and separation in sinusoidal channels: an experimental and numerical study. Chem. Eng. Sci. 276, 118826. doi:10.1016/j.ces.2023.118826

Cha, H., Dai, Y., Hansen, H. H. W. B., Ouyang, L., Chen, X., Kang, X., et al. (2023b). Asymmetrical obstacles enable unilateral inertial focusing and separation in sinusoidal microchannel. Cyborg Bionic Syst. 4, 0036. doi:10.34133/cbsystems.0036

Cha, H., Fallahi, H., Dai, Y., Yadav, S., Hettiarachchi, S., McNamee, A., et al. (2022). Tuning particle inertial separation in sinusoidal channels by embedding periodic obstacle microstructures. Lab. Chip 22, 2789–2800. doi:10.1039/D2LC00197G

Cha, S., Kang, K., You, J. B., Im, S. G., Kim, Y., and Kim, J. M. (2014). Hoop stress-assisted three-dimensional particle focusing under viscoelastic flow. Rheol. Acta 53, 927–933. doi:10.1007/s00397-014-0808-9

Chiu, Y. J., Cho, S. H., Mei, Z., Lien, V., Wu, T. F., and Lo, Y. H. (2013). Universally applicable three-dimensional hydrodynamic microfluidic flow focusing. Lab. Chip 13, 1803. doi:10.1039/c3lc41202d

Choi, S., and Park, J. K. (2007). Continuous hydrophoretic separation and sizing of microparticles using slanted obstacles in a microchannel. Lab. Chip 7, 890–897. doi:10.1039/b701227f

Choi, S., and Park, J. K. (2008). Sheathless hydrophoretic particle focusing in a microchannel with exponentially increasing obstacle arrays. Anal. Chem. 80, 3035–3039. doi:10.1021/ac8001319

Chung, A. J., Gossett, D. R., and Di Carlo, D. (2013a). Three dimensional, sheathless, and high-throughput microparticle inertial focusing through geometry-induced secondary flows. Small 9, 685–690. doi:10.1002/smll.201202413

Chung, A. J., Pulido, D., Oka, J. C., Amini, H., Masaeli, M., and Di Carlo, D. (2013b). Microstructure-induced helical vortices allow single-stream and long-term inertial focusing. Lab. Chip 13, 2942–2949. doi:10.1039/c3lc41227j

Ciftlik, A. T., Ettori, M., and Gijs, M. A. M. (2013). High throughput-per-footprint inertial focusing. Small 9, 2764–2773. doi:10.1002/smll.201201770

Cruz, J., Graells, T., Walldén, M., and Hjort, K. (2019). Inertial focusing with sub-micron resolution for separation of bacteria. Lab. Chip 19, 1257–1266. doi:10.1039/C9LC00080A

Del Giudice, F., Romeo, G., D’Avino, G., Greco, F., Netti, P. A., and Maffettone, P. L. (2013). Particle alignment in a viscoelastic liquid flowing in a square-shaped microchannel. Lab. Chip 13, 4263–4271. doi:10.1039/c3lc50679g

Di Carlo, D., Edd, J. F., Irimia, D., Tompkins, R. G., and Toner, M. (2008). Equilibrium separation and filtration of particles using differential inertial focusing. Anal. Chem. 80, 2204–2211. doi:10.1021/ac702283m

Di Carlo, D., Irimia, D., Tompkins, R. G., and Toner, M. (2007). Continuous inertial focusing, ordering, and separation of particles in microchannels. Proc. Natl. Acad. Sci. 104, 18892–18897. doi:10.1073/pnas.0704958104

Ebrahimi, S., Alishiri, M., Shamloo, A., Pishbin, E., Hemmati, P., Seifi, S., et al. (2023). Optimizing the design of a serpentine microchannel based on particles focusing and separation: a numerical study with experimental validation. Sensors Actuators A Phys. 358, 114432. doi:10.1016/j.sna.2023.114432

Fan, L. L., Han, Y., He, X. K., Zhao, L., and Zhe, J. (2014). High-throughput, single-stream microparticle focusing using a microchannel with asymmetric sharp corners. Microfluid. Nanofluidics 17, 639–646. doi:10.1007/s10404-014-1344-8

Feng, H., Jafek, A., Samuel, R., Hotaling, J., Jenkins, T. G., Aston, K. I., et al. (2021). High efficiency rare sperm separation from biopsy samples in an inertial focusing device. Analyst 146, 3368–3377. doi:10.1039/D1AN00480H

Feng, H., Jafek, A. R., Wang, B., Brady, H., Magda, J. J., and Gale, B. K. (2022). Viscoelastic particle focusing and separation in a spiral channel. Micromachines 13, 361. doi:10.3390/mi13030361

Gao, H., Zhou, J., Naderi, M. M., Peng, Z., and Papautsky, I. (2023). Evolution of focused streams for viscoelastic flow in spiral microchannels. Microsystems Nanoeng. 9, 73. doi:10.1038/s41378-023-00520-4

Gossett, D. R., and Di Carlo, D. (2009). Particle focusing mechanisms in curving confined flows. Anal. Chem. 81, 8459–8465. doi:10.1021/ac901306y

Gou, Y., Zhang, S., Sun, C., Wang, P., You, Z., Yalikun, Y., et al. (2020). Sheathless inertial focusing chip combining a spiral channel with periodic expansion structures for efficient and stable particle sorting. Anal. Chem. 92, 1833–1841. doi:10.1021/acs.analchem.9b03692

Guan, G., Wu, L., Bhagat, A. A., Li, Z., Chen, P. C. Y., Chao, S., et al. (2013). Spiral microchannel with rectangular and trapezoidal cross-sections for size based particle separation. Sci. Rep. 3, 1475. doi:10.1038/srep01475

Hettiarachchi, S., Cha, H., Ouyang, L., Mudugamuwa, A., An, H., Kijanka, G., et al. (2023). Recent microfluidic advances in submicron to nanoparticle manipulation and separation. Lab. Chip 23, 982–1010. doi:10.1039/D2LC00793B

Hsu, C. H., Di Carlo, D., Chen, C., Irimia, D., and Toner, M. (2008). Microvortex for focusing, guiding and sorting of particles. Lab. Chip 8, 2128–2134. doi:10.1039/b813434k

Hur, S. C., Henderson-Maclennan, N. K., McCabe, E. R. B., and Di Carlo, D. (2011). Deformability-based cell classification and enrichment using inertial microfluidics. Lab. Chip 11, 912–920. doi:10.1039/c0lc00595a

Jeon, H., Kwon, T., Yoon, J., and Han, J. (2022). Engineering a deformation-free plastic spiral inertial microfluidic system for CHO cell clarification in biomanufacturing. Lab. Chip 22, 272–285. doi:10.1039/D1LC00995H

Jia, Z., Wu, J., Wu, X., Yuan, Q., Chan, Y., Liu, B., et al. (2023). Size-tunable elasto-inertial sorting of <i>Haematococcus pluvialis</i> in the ultrastretchable microchannel. Anal. Chem. 95, 13338–13345. doi:10.1021/acs.analchem.3c02648

Jiang, D., Ni, C., Tang, W., Huang, D., and Xiang, N. (2021). Inertial microfluidics in contraction–expansion microchannels: a review. Biomicrofluidics 15, 041501. doi:10.1063/5.0058732

Kim, B., and Kim, J. M. (2016). Elasto-inertial particle focusing under the viscoelastic flow of DNA solution in a square channel. Biomicrofluidics 10, 024111. doi:10.1063/1.4944628

Kim, J., Choi, Y., and Lee, W. (2022a). Alteration of inertial focusing positions in triangular channels using flexible PDMS microfluidics. BioChip J. 16, 342–350. doi:10.1007/s13206-022-00062-3

Kim, J., Lee, J., Wu, C., Nam, S., Di Carlo, D., and Lee, W. (2016). Inertial focusing in non-rectangular cross-section microchannels and manipulation of accessible focusing positions. Lab. Chip 16, 992–1001. doi:10.1039/C5LC01100K

Kim, J. A., Lee, J. R., Je, T. J., Jeon, E. C., and Lee, W. (2018). Size-dependent inertial focusing position shift and particle separations in triangular microchannels. Anal. Chem. 90, 1827–1835. doi:10.1021/acs.analchem.7b03851

Kim, U., Kwon, J.-Y., Kim, T., and Cho, Y. (2022b). Particle focusing in a straight microchannel with non-rectangular cross-section. Micromachines 13, 151. doi:10.3390/mi13020151

Kumar, T., Ramachandraiah, H., Iyengar, S. N., Banerjee, I., Mårtensson, G., and Russom, A. (2021). High throughput viscoelastic particle focusing and separation in spiral microchannels. Sci. Rep. 11, 8467. doi:10.1038/s41598-021-88047-4

Kuntaegowdanahalli, S. S., Bhagat, A. A. S., Kumar, G., and Papautsky, I. (2009). Inertial microfluidics for continuous particle separation in spiral microchannels. Lab. Chip 9, 2973. doi:10.1039/b908271a

Lee, D. J., Brenner, H., Youn, J. R., and Song, Y. S. (2013). Multiplex particle focusing via hydrodynamic force in Viscoelastic Fluids. Sci. Rep. 3, 3258–3310. doi:10.1038/srep03258

Lee, M. G., Choi, S., Kim, H.-J., Lim, H. K., Kim, J.-H., Huh, N., et al. (2011). Inertial blood plasma separation in a contraction–expansion array microchannel. Appl. Phys. Lett. 98, 253702. doi:10.1063/1.3601745

Leshansky, A. M., Bransky, A., Korin, N., and Dinnar, U. (2007). Tunable nonlinear viscoelastic “focusing” in a microfluidic device. Phys. Rev. Lett. 98, 234501. doi:10.1103/PhysRevLett.98.234501

Lim, E. J., Ober, T. J., Edd, J. F., Desai, S. P., Neal, D., Bong, K. W., et al. (2014). Inertio-elastic focusing of bioparticles in microchannels at high throughput. Nat. Commun. 5, 4120. doi:10.1038/ncomms5120

Liu, C., Ding, B., Xue, C., Tian, Y., Hu, G., and Sun, J. (2016). Sheathless focusing and separation of diverse nanoparticles in viscoelastic solutions with minimized shear thinning. Anal. Chem. 88, 12547–12553. doi:10.1021/acs.analchem.6b04564

Liu, C., Xue, C., Chen, X., Shan, L., Tian, Y., and Hu, G. (2015). Size-based separation of particles and cells utilizing viscoelastic effects in straight microchannels. Anal. Chem. 87, 6041–6048. doi:10.1021/acs.analchem.5b00516

Liu, Y., Shen, H., Yang, X., Kang, S., Cai, L., Tian, T., et al. (2023). Recent progress in microfluidic biosensors with different driving forces. Trac. Trends Anal. Chem. 158, 116894. doi:10.1016/j.trac.2022.116894

Lu, M., Ozcelik, A., Grigsby, C. L., Zhao, Y., Guo, F., Leong, K. W., et al. (2016). Microfluidic hydrodynamic focusing for synthesis of nanomaterials. Nano Today 11, 778–792. doi:10.1016/j.nantod.2016.10.006

Lu, X., Chow, J. J. M., Koo, S. H., Jiang, B., Tan, T. Y., Yang, D., et al. (2021). Sheathless and high-throughput elasto-inertial bacterial sorting for enhancing molecular diagnosis of bloodstream infection. Lab. Chip 21, 2163–2177. doi:10.1039/D1LC00085C

Lu, X., Chow, J. J. M., Koo, S. H., Tan, T. Y., Jiang, B., and Ai, Y. (2020). Enhanced molecular diagnosis of bloodstream Candida infection with size-based inertial sorting at submicron resolution. Anal. Chem. 92, 15579–15586. doi:10.1021/acs.analchem.0c03718

Lu, X., Liu, C., Hu, G., and Xuan, X. (2017). Particle manipulations in non-Newtonian microfluidics: a review. J. Colloid Interface Sci. 500, 182–201. doi:10.1016/j.jcis.2017.04.019

Mao, X., Waldeisen, J. R., and Huang, T. J. (2007). “Microfluidic drifting” - implementing three-dimensional hydrodynamic focusing with a single-layer planar microfluidic device. Lab. Chip 7, 1260–1262. doi:10.1039/b711155j

Martel, J. M., and Toner, M. (2012). Inertial focusing dynamics in spiral microchannels. Phys. Fluids 24, 032001. doi:10.1063/1.3681228

Martel, J. M., and Toner, M. (2013). Particle focusing in curved microfluidic channels. Sci. Rep. 3, 3340. doi:10.1038/srep03340

Masaeli, M., Sollier, E., Amini, H., Mao, W., Camacho, K., Doshi, N., et al. (2012). Continuous inertial focusing and separation of particles by shape. Phys. Rev. X 2, 031017–31113. doi:10.1103/PhysRevX.2.031017

Mashhadian, A., and Shamloo, A. (2019). Inertial microfluidics: a method for fast prediction of focusing pattern of particles in the cross section of the channel. Anal. Chim. Acta 1083, 137–149. doi:10.1016/j.aca.2019.06.057

Matas, J., Morris, J., and Guazzelli, E. (2004). Lateral forces on a sphere. Oil Gas. Sci. Technol. 59, 59–70. doi:10.2516/ogst:2004006

Moloudi, R., Oh, S., Yang, C., Ebrahimi Warkiani, M., and Naing, M. W. (2018). Inertial particle focusing dynamics in a trapezoidal straight microchannel: application to particle filtration. Microfluid. Nanofluidics 22, 33–14. doi:10.1007/s10404-018-2045-5

Mukherjee, P., Wang, X., Zhou, J., and Papautsky, I. (2019). Single stream inertial focusing in low aspect-ratio triangular microchannels. Lab. Chip 19, 147–157. doi:10.1039/c8lc00973b

Mutlu, B. R., Edd, J. F., and Toner, M. (2018). Oscillatory inertial focusing in infinite microchannels. Proc. Natl. Acad. Sci. 115, 7682–7687. doi:10.1073/pnas.1721420115

Nagrath, S., Sequist, L. V., Maheswaran, S., Bell, D. W., Irimia, D., Ulkus, L., et al. (2007). Isolation of rare circulating tumour cells in cancer patients by microchip technology. Nature 450, 1235–1239. doi:10.1038/nature06385

Nam, J., Lim, H., Kim, D., Jung, H., and Shin, S. (2012). Continuous separation of microparticles in a microfluidic channel via the elasto-inertial effect of non-Newtonian fluid. Lab. Chip 12, 1347–1354. doi:10.1039/c2lc21304d

Narayanamurthy, V., Jeroish, Z. E., Bhuvaneshwari, K. S., Bayat, P., Premkumar, R., Samsuri, F., et al. (2020). Advances in passively driven microfluidics and lab-on-chip devices: a comprehensive literature review and patent analysis. RSC Adv. 10, 11652–11680. doi:10.1039/D0RA00263A

Ni, C., Zhou, Z., Zhu, Z., Jiang, D., and Xiang, N. (2022). Controllable size-independent three-dimensional inertial focusing in high-aspect-ratio asymmetric serpentine microchannels. Anal. Chem. 94, 15639–15647. doi:10.1021/acs.analchem.2c02361

Nilsson, J., Evander, M., Hammarström, B., and Laurell, T. (2009). Review of cell and particle trapping in microfluidic systems. Anal. Chim. Acta 649, 141–157. doi:10.1016/j.aca.2009.07.017

Oakey, J., Applegate, R. W., Arellano, E., Carlo, D., Graves, S. W., and Toner, M. (2010). Particle focusing in staged inertial microfluidic devices for flow cytometry. Anal. Chem. 82, 3862–3867. doi:10.1021/ac100387b

Ookawara, S., Higashi, R., Street, D., and Ogawa, K. (2004). Feasibility study on concentration of slurry and classification of contained particles by microchannel. Chem. Eng. J. 101, 171–178. doi:10.1016/j.cej.2003.11.008

Özbey, A., Karimzadehkhouei, M., Akgönül, S., Gozuacik, D., and Koşar, A. (2016). Inertial focusing of microparticles in curvilinear microchannels. Sci. Rep. 6, 38809–38811. doi:10.1038/srep38809

Paiè, P., Bragheri, F., Di Carlo, D., and Osellame, R. (2017). Particle focusing by 3D inertial microfluidics. Microsystems Nanoeng. 3, 17027–17028. doi:10.1038/micronano.2017.27

Park, J. S., Song, S. H., and Jung, H. (2009). Continuous focusing of microparticles using inertial lift force and vorticity via multi-orifice microfluidic channels. Lab. Chip 9, 939–948. doi:10.1039/b813952k

Pathak, J. A., Ross, D., and Migler, K. B. (2004). Elastic flow instability, curved streamlines, and mixing in microfluidic flows. Phys. Fluids 16, 4028–4034. doi:10.1063/1.1792011

Peng, T., Qiang, J., and Yuan, S. (2023). Investigation on a cascaded inertial and acoustic microfluidic device for sheathless and label-free separation of circulating tumor cells. Phys. Fluids 35. doi:10.1063/5.0160391

Raoufi, M. A., Mashhadian, A., Niazmand, H., Asadnia, M., Razmjou, A., and Warkiani, M. E. (2019). Experimental and numerical study of elasto-inertial focusing in straight channels. Biomicrofluidics 13, 034103. doi:10.1063/1.5093345

Razavi Bazaz, S., Mihandust, A., Salomon, R., Joushani, H. A. N., Li, W., Amiri, H., et al. (2022). Zigzag microchannel for rigid inertial separation and enrichment (Z-RISE) of cells and particles. Lab. Chip 22, 4093–4109. doi:10.1039/D2LC00290F

Reece, A. E., and Oakeya, J. (2016). Long-range forces affecting equilibrium inertial focusing behavior in straight high aspect ratio microfluidic channels. Phys. Fluids 28, 043303. doi:10.1063/1.4946829

Rodd, L. E., Cooper-White, J. J., Boger, D. V., and McKinley, G. H. (2007). Role of the elasticity number in the entry flow of dilute polymer solutions in micro-fabricated contraction geometries. J. Nonnewt. Fluid Mech. 143, 170–191. doi:10.1016/j.jnnfm.2007.02.006

Rodd, L. E., Scott, T. P., Boger, D. V., Cooper-White, J. J., and McKinley, G. H. (2005). The inertio-elastic planar entry flow of low-viscosity elastic fluids in micro-fabricated geometries. J. Nonnewt. Fluid Mech. 129, 1–22. doi:10.1016/j.jnnfm.2005.04.006

Rubinow, S. I., and Keller, J. B. (1961). The transverse force on a spinning sphere moving in a viscous fluid. J. Fluid Mech. 11, 447. doi:10.1017/S0022112061000640

Rufo, J., Cai, F., Friend, J., Wiklund, M., and Huang, T. J. (2022). Acoustofluidics for biomedical applications. Nat. Rev. Methods Prim. 2, 30. doi:10.1038/s43586-022-00109-7

Russom, A., Gupta, A. K., Nagrath, S., Carlo, D., and Toner, M. (2009). Differential inertial focusing of particles in curved low-aspect-ratio microchannels. New J. Phys. 11, 075025. doi:10.1088/1367-2630/11/7/075025

Saffman, P. G. (1965). The lift on a small sphere in a slow shear flow. J. Fluid Mech. 22, 385–400. doi:10.1017/S0022112065000824

Segré, G., and Silberberg, A. (1961). Radial particle displacements in Poiseuille flow of suspensions. Nature 189, 209–210. doi:10.1038/189209a0

Seo, K. W., Byeon, H. J., Huh, H. K., and Lee, S. J. (2014). Particle migration and single-line particle focusing in microscale pipe flow of viscoelastic fluids. RSC Adv. 4, 3512–3520. doi:10.1039/c3ra43522a

Shamloo, A., and Mashhadian, A. (2018). Inertial particle focusing in serpentine channels on a centrifugal platform. Phys. Fluids 30, 2621. doi:10.1063/1.5002621

Shen, S., Tian, C., Li, T., Xu, J., Chen, S. W., Tu, Q., et al. (2017). Spiral microchannel with ordered micro-obstacles for continuous and highly-efficient particle separation. Lab. Chip 17, 3578–3591. doi:10.1039/c7lc00691h

Shi, R. (2023). Numerical simulation of inertial microfluidics: a review. Eng. Appl. Comput. Fluid Mech. 17. doi:10.1080/19942060.2023.2177350

Song, H. Y., Lee, S. H., Salehiyan, R., and Hyun, K. (2016). Relationship between particle focusing and dimensionless numbers in elasto-inertial focusing. Rheol. Acta 55, 889–900. doi:10.1007/s00397-016-0962-3

Song, S., and Choi, S. (2013). Design rules for size-based cell sorting and sheathless cell focusing by hydrophoresis. J. Chromatogr. A 1302, 191–196. doi:10.1016/j.chroma.2013.06.030

Stan, C. A., Ellerbee, A. K., Guglielmini, L., Stone, H. A., and Whitesides, G. M. (2013). The magnitude of lift forces acting on drops and bubbles in liquids flowing inside microchannels. Lab. Chip 13, 365–376. doi:10.1039/C2LC41035D

Su, J., Chen, X., Zhu, Y., and Hu, G. (2021). Machine learning assisted fast prediction of inertial lift in microchannels. Lab. Chip 21, 2544–2556. doi:10.1039/D1LC00225B

Su, J., Zheng, X., and Hu, G. (2023). New explicit formula for inertial lift in confined flows. Phys. Fluids 35. doi:10.1063/5.0168474

Tang, W., Zhu, S., Jiang, D., Zhu, L., Yang, J., and Xiang, N. (2020). Channel innovations for inertial microfluidics. Lab. Chip 20, 3485–3502. doi:10.1039/D0LC00714E

Wang, C., Sun, S., Chen, Y., Cheng, Z., Li, Y., Jia, L., et al. (2018). Inertial particle focusing and spacing control in microfluidic devices. Microfluid. Nanofluidics 22, 25. doi:10.1007/s10404-018-2035-7

Wang, L., and Dandy, D. S. (2017). High-throughput inertial focusing of micrometer- and sub-micrometer-sized particles separation. Adv. Sci. 4, 1700153. doi:10.1002/advs.201700153

Wang, X., Zandi, M., Ho, C. C., Kaval, N., and Papautsky, I. (2015). Single stream inertial focusing in a straight microchannel. Lab. Chip 15, 1812–1821. doi:10.1039/c4lc01462f

Whitesides, G. M. (2006). The origins and the future of microfluidics. Nature 442, 368–373. doi:10.1038/nature05058

Won Seo, K., Ran Ha, Y., and Joon Lee, S. (2014). Vertical focusing and cell ordering in a microchannel via viscoelasticity: applications for cell monitoring using a digital holographic microscopy. Appl. Phys. Lett. 104, 213702. doi:10.1063/1.4880615

Wu, M., Chen, K., Yang, S., Wang, Z., Huang, P.-H., Mai, J., et al. (2018). High-throughput cell focusing and separation via acoustofluidic tweezers. Lab. Chip 18, 3003–3010. doi:10.1039/C8LC00434J

Xiang, N., Chen, K., Sun, D., Wang, S., Yi, H., and Ni, Z. (2013a). Quantitative characterization of the focusing process and dynamic behavior of differently sized microparticles in a spiral microchannel. Microfluid. Nanofluidics 14, 89–99. doi:10.1007/s10404-012-1025-4

Xiang, N., Dai, Q., and Ni, Z. (2016a). Multi-train elasto-inertial particle focusing in straight microfluidic channels. Appl. Phys. Lett. 109, 134101. doi:10.1063/1.4963294

Xiang, N., and Ni, Z. (2015). High-throughput blood cell focusing and plasma isolation using spiral inertial microfluidic devices. Biomed. Microdevices 17, 110. doi:10.1007/s10544-015-0018-y

Xiang, N., and Ni, Z. (2022). High-throughput concentration of rare malignant tumor cells from large-volume effusions by multistage inertial microfluidics. Lab. Chip 22, 757–767. doi:10.1039/D1LC00944C

Xiang, N., Ni, Z., and Yi, H. (2018). Concentration-controlled particle focusing in spiral elasto-inertial microfluidic devices. Electrophoresis 39, 417–424. doi:10.1002/elps.201700150

Xiang, N., Shi, Z., Tang, W., Huang, D., Zhang, X., and Ni, Z. (2015). Improved understanding of particle migration modes in spiral inertial microfluidic devices. RSC Adv. 5, 77264–77273. doi:10.1039/c5ra13292d

Xiang, N., Yi, H., Chen, K., Sun, D., Jiang, D., Dai, Q., et al. (2013b). High-throughput inertial particle focusing in a curved microchannel: insights into the flow-rate regulation mechanism and process model. Biomicrofluidics 7, 44116–44210. doi:10.1063/1.4818445

Xiang, N., Zhang, X., Dai, Q., Cheng, J., Chen, K., and Ni, Z. (2016b). Fundamentals of elasto-inertial particle focusing in curved microfluidic channels. Lab. Chip 16, 2626–2635. doi:10.1039/c6lc00376a

Xu, X., Huang, X., Sun, J., Chen, J., Wu, G., Yao, Y., et al. (2022). 3D-Stacked multistage inertial microfluidic chip for high-throughput enrichment of circulating tumor cells. Cyborg Bionic Syst. 2022, 9829287. doi:10.34133/2022/9829287

Xu, X., Huang, X., Sun, J., Wang, R., Yao, J., Han, W., et al. (2021). Recent progress of inertial microfluidic-based cell separation. Analyst 146, 7070–7086. doi:10.1039/D1AN01160J

Xuan, X., Zhu, J., and Church, C. (2010). Particle focusing in microfluidic devices. Microfluid. Nanofluidics 9, 1–16. doi:10.1007/s10404-010-0602-7

Yan, S., and Yuan, D. (2021). Continuous microfluidic 3D focusing enabling microflow cytometry for single-cell analysis. Talanta 221, 121401. doi:10.1016/j.talanta.2020.121401

Yang, R.-J., Fu, L.-M., and Hou, H.-H. (2018). Review and perspectives on microfluidic flow cytometers. Sensors Actuators B Chem. 266, 26–45. doi:10.1016/j.snb.2018.03.091

Yang, S., Kim, J. Y., Lee, S. J., Lee, S. S., and Kim, J. M. (2011). Sheathless elasto-inertial particle focusing and continuous separation in a straight rectangular microchannel. Lab. Chip 11, 266–273. doi:10.1039/c0lc00102c

Yang, S., Lee, S. S., Ahn, S. W., Kang, K., Shim, W., Lee, G., et al. (2012). Deformability-selective particle entrainment and separation in a rectangular microchannel using medium viscoelasticity. Soft Matter 8, 5011–5019. doi:10.1039/c2sm07469a