94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

EDITORIAL article

Front. Bioeng. Biotechnol. , 05 April 2023

Sec. Industrial Biotechnology

Volume 11 - 2023 | https://doi.org/10.3389/fbioe.2023.1181822

This article is part of the Research Topic The Value of Microbial Bioreactors To Meet Challenges In The Circular Bioeconomy View all 8 articles

Editorial on the Research Topic

“The value of microbial bioreactors to meet challenges in the circular bioeconomy”

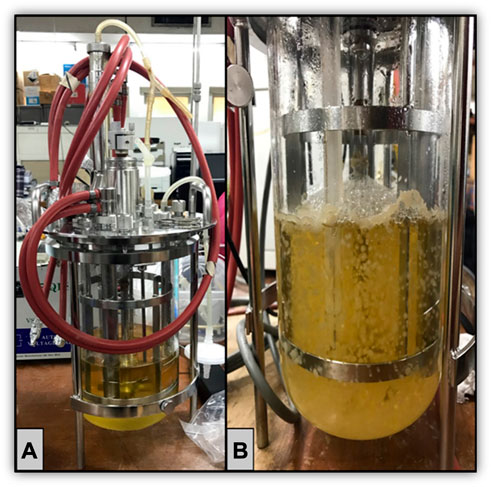

The use of microbial bioreactors has harnessed immense attention to support many of the United Nation’s Sustainable Development Goals where this innovative platform provides crucial insights into unlocking a diversity of solutions to society ranging from fundamental research to hydrocarbon purification (Ghosh et al., 2023) and living lab demonstrations (O’Neill et al., 2022). Bioreactor-based solutions have desirable qualities such as safety compliance, scalability, non-toxicity, proven culture-based processes, and ease of operation (Rowan and Galanakis, 2020). There has been a growing interest in the progress of bioreactors to improve supply chains, enabling circularity (the bioeconomy) and food sustainability, along with the potential of using bio-based properties from food and waste products, which is aligned with the “One-Health” concept and digitalization (O’Neill et al., 2022; Rowan et al., 2022). The creative use of bioreactors can also be exploited as a novel toolbox approach for informing and modeling the potential impact of climate change variance on aquatic ecosystems, including testing new green innovation aligned with biodiversity (O’Neill et al., 2022). In recent years, researchers have adopted bioreactor-based cultivation methods to utilize microbial biomass for social advantages (O’Neill et al., 2022). Overall, the manuscripts presented in this Research Topic provided significant paradigms for the usage of bioreactors (Figure 1), which will benefit academia, bioreactor manufacturers, cultivation technologists, small–mid-sized enterprises (SMEs), and factory technicians.

FIGURE 1. Large-scale microbial biomass production in a stirred-tank bioreactor 2-L (Sartorius Biostat A plus). (A) Without inoculation. (B) With microbial inoculum.

In this report, Abdullah et al. (2022) proved that both exo-β-glucan and endo-β-glucan can be extracted from the Malaysian mushroom Ganoderma lucidum using a 10-L industrial bioreactor crude-biomass. Both β-glucans showed a high inhibitory effect in the alpha-glucosidase enzyme test which mimics a clinically approved inhibitor (acarbose) for postprandial hyperglycemia regulation, which is an essential component in diabetic treatment. Prior to human clinical trials, these compounds were proved to be non-toxic in zebrafish embryotoxicity assay, as the zebrafish have a similar genetic structure to humans. Surprisingly, these G. lucidum β-glucans reduced blood glucose levels and blocked hyperglycemia in induced diabetic adult zebrafish. This idea provides an economical way for antidiabetic drug production using a scalable bioreactor.

A biodegradable plastic called poly (3-hydroxybutyrate) (PHB) was produced in a high-scale bioreactor and extracted successfully using a green solvent 1,3-dioxolane (Wongmoon & Napathorn, 2022). Such a green solvent is currently used in paint manufacturing as an alternative for xylene and toluene and in the polymer business as a copolymerizing agent. This novel idea provides an alternative to the biodegradable PHA production which suffers from the high cost of raw materials, high toxicity, and the use of flammable and hazardous organic solvents during biomass extraction.

Another green extraction in the form of microwave-assisted hydrolysis on cassava pulp biomass waste for bioplastic (PHB) was performed by another research team (Prasetsilp et al., 2023). Such a technique offers better radiation input and time and temperature control than alkaline and enzymatic treatments. The utilization of cassava pulp is considered the second-generation biorefineries since it is a biomass waste and a non-edible crop. This study proved that a combination of direct hydrolysis and saccharification processes was efficient using the levulinic acid-tolerant, glucose- and fructose-utilizing bacterium Cupriavidus necator.

The first attempt to create continuous pilot-scale biological industrial residual process brine (RPB) was successfully operated for more than 210 days (Mainka et al., 2022). Degradation rates for organic pollutants employing halophilic bacteria were close to 100%, and the process was robust in the face of variations in the RBP stream’s composition. Pilot-scale bioreactor experiments demonstrated degradation efficiencies comparable to those shown in laboratory bioreactor works. The present study underscores the potential of exploiting an alternative and sustainable bioprocess for treating residual process brine that harnesses natural microbial diversity in an industrial context.

Crude glycerol is a by-product from the biodiesel industry that has been extensively studied for potential valorization. One way is to utilize the crude glycerol as a carbon source for microbial growth such as the recombinant Komagataella phaffii (Pichia pastoris) (Bernat-Camps et al., 2023). This research proved the ability of microorganisms to convert raw substrates into small molecules and proteins in a shake-flask cultivation process, using an engineered organism; pseudo-starving conditions were achieved by employing the feed technology FeedBeads® that slowly release a defined amount of glycerol over time. This work contributes to enlarge the Pichia toolbox by providing more alternatives for the efficient production of different kinds of proteins. This process can promote the transition toward the circular bioeconomy, thus significantly decreasing our carbon footprint.

The timely approaches depicted in this Research Topic offer exciting examples, highlighting the creative use of bioreactors in terms of design, application, and products that can help unlock opportunities for the circular bioeconomy and the New Green Deal. The application of microbial bioreactors is evolving especially for non-cultivation purposes, such as enzymatic hydrolysis and plant cells. The value of microbial bioreactors will gain momentum in the coming years, supporting sustaining and disruptive innovation to be enabled by digital transformation.

WW-M, ZI, and NR wrote the editorial draft with feedback from the remaining editors incorporated into the final submission.

ZI would like to thank the Ministry of Higher Education (MOHE) under the Fundamental Research Grant Scheme (FRGS: FP062-2022) (FRGS/1/2022/STG01/UM/02/2) for this editorial task. NR would like to thank the MSCA RISE ICHTHYS Project (No. 872217).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abdullah, N. R., Mohd Nasir, M. H., Azizan, N. H., Wan-Mohtar, W. A. A. Q. I., and Sharif, F. (2022). Bioreactor-grown exo-and endo-β-glucan from Malaysian Ganoderma lucidum: An in vitro and in vivo study for potential antidiabetic treatment. Front. Bioeng. Biotechnol. 10, 960320. doi:10.3389/fbioe.2022.960320

Bernat-Camps, N., Ebner, K., Schusterbauer, V., Fischer, J. E., Nieto-Taype, M. A., Valero, F., et al. (2023). Enabling growth-decoupled Komagataella phaffii recombinant protein production based on the methanol-free PDH promoter. Front. Bioeng. Biotechnol. 11. doi:10.3389/fbioe.2023.1130583

Ghosh, S., Rusyn, I., Dmytruk, O. V., Dmytruk, V., Onyeaka, H., Gryzenhout, M., et al. (2023). Filamentous fungi for sustainable remediation of pharmaceutical compounds, heavy metal and oil hydrocarbons. Front. Bioeng. Biotechnol. 11, 1106973. doi:10.3389/fbioe.2023.1106973

Mainka, T., Herwig, C., and Pflügl, S. (2022). Reducing organic load from industrial residual process brine with a novel halophilic mixed culture: Scale-up and long-term piloting of an integrated bioprocess. Front. Bioeng. Biotechnol. 10, 896576. doi:10.3389/fbioe.2022.896576

O'Neill, E. A., McKeon-Bennett, M., and Rowan, N. J. (2022). Peatland-based innovation can potentially support and enable the sustainable development goals of the United Nations: Case study from the Republic of Ireland. Case Stud. Chem. Environ. Eng. 6, 100251. doi:10.1016/j.cscee.2022.100251

Prasetsilp, P., Pattaragulwanit, K., Kim, B. S., and Napathorn, S. C. (2023). Microwave-assisted cassava pulp hydrolysis as food waste biorefinery for biodegradable polyhydroxybutyrate production. Front. Bioeng. Biotechnol. 11, 1131053. doi:10.3389/fbioe.2023.1131053

Rowan, N. J., and Galankis, C. M. (2020). Unlocking challenges and opportunites presented by COVID-19 pandemic for cross-cutting disruption in agri-food and green deal innovations: Quo Vadis? Sci. Total Environ. 748, 141362. doi:10.1016/j.scitotenv.2020.141362

Rowan, N. J., Murray, N., Qiao, Y., O'Neill, E. O., Clifford, E., Barcelo, D., et al. (2022). Digital transformation of peatland eco-innovations (‘Paludiculture’): Enabling a paradigm shift towards the real-time sustainable production of ‘green-friendly’ products and services. Sci. Total Environ. 838, 156328. doi:10.1016/j.scitotenv.2022.156328

Keywords: bioreactor, biomass, fermentation, sustainability, bioeconomy, UN Sustainable Development Goals

Citation: Wan-Mohtar WAAQI, Ilham Z and Rowan NJ (2023) Editorial: “The value of microbial bioreactors to meet challenges in the circular bioeconomy”. Front. Bioeng. Biotechnol. 11:1181822. doi: 10.3389/fbioe.2023.1181822

Received: 07 March 2023; Accepted: 24 March 2023;

Published: 05 April 2023.

Edited and reviewed by:

Georg M. Guebitz, University of Natural Resources and Life Sciences Vienna, AustriaCopyright © 2023 Wan-Mohtar, Ilham and Rowan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Wan Abd Al Qadr Imad Wan-Mohtar, cWFkeXJAdW0uZWR1Lm15; Zul Ilham, aWxoYW1AdW0uZWR1Lm15; Neil J. Rowan, TmVpbC5Sb3dhbkB0dXMuaWU=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.