94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Bioeng. Biotechnol. , 20 December 2019

Sec. Synthetic Biology

Volume 7 - 2019 | https://doi.org/10.3389/fbioe.2019.00420

This article is part of the Research Topic Heterologous Protein Expression and Production Platforms: The How, Now and Wow of It View all 6 articles

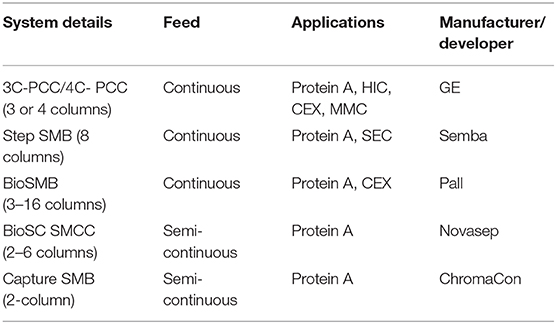

Infectious diseases, along with cancers, are among the main causes of death among humans worldwide. The production of therapeutic proteins for treating diseases at large scale for millions of individuals is one of the essential needs of mankind. Recent progress in the area of recombinant DNA technologies has paved the way to producing recombinant proteins that can be used as therapeutics, vaccines, and diagnostic reagents. Recombinant proteins for these applications are mainly produced using prokaryotic and eukaryotic expression host systems such as mammalian cells, bacteria, yeast, insect cells, and transgenic plants at laboratory scale as well as in large-scale settings. The development of efficient bioprocessing strategies is crucial for industrial production of recombinant proteins of therapeutic and prophylactic importance. Recently, advances have been made in the various areas of bioprocessing and are being utilized to develop effective processes for producing recombinant proteins. These include the use of high-throughput devices for effective bioprocess optimization and of disposable systems, continuous upstream processing, continuous chromatography, integrated continuous bioprocessing, Quality by Design, and process analytical technologies to achieve quality product with higher yield. This review summarizes recent developments in the bioprocessing of recombinant proteins, including in various expression systems, bioprocess development, and the upstream and downstream processing of recombinant proteins.

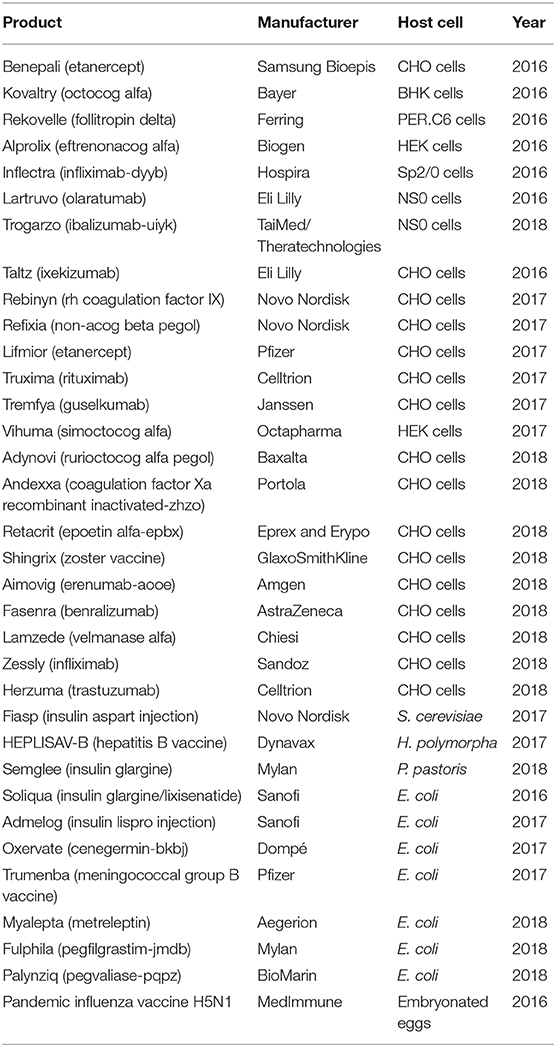

Biopharmaceuticals are the main drugs developed in the pharma sector. Market demand has instigated the development of various protein expression hosts and bioprocessing technologies. The products approved from 2014 to mid-2018 include 68 monoclonal antibodies (mAbs), 23 hormones, 16 clotting factors, nine enzymes, and seven vaccines (Walsh, 2018). Advancements in the area of recombinant protein production have changed the previous trend, making the yield much higher and the cost much lower, thus allowing the production of such proteins on an industrial scale and opening the door for the treatment of multiple diseases and disorders. With the help of recombinant protein technology, expression of recombinant protein-based biopharmaceuticals has been achieved using bacteria, mammalian cells, yeast, insect cells, transgenic plants, and transgenic animals (Huang et al., 2012; Ahmad et al., 2014; Merlin et al., 2014; Gupta S. K. et al., 2019; Owczarek et al., 2019). Escherichia coli offers a fast growth rate with high product yield. Yeast systems (Saccharomyces cerevisiae and Pichia pastoris) provide post-translational modifications (PTMs). Mammalian cell lines have been used for the majority of the approved recombinant therapeutics. In the past 3–4 years, 62 of the 71 new biopharmaceutical active ingredients in the market were recombinant proteins, and of those, 52 (84%) were from mammalian cells, one from a transgenic system, five from E. coli, and four from S. cerevisiae (Walsh, 2018). A list of some recently approved recombinant biopharmaceuticals is given in Table 1.

Table 1. Some examples of recently approved biopharmaceuticals with their expression host systems and manufacturers/developers (Walsh, 2018).

After successful cell line development and clone selection, small-scale cultures using microtiter plates, test tubes, tissue culture flasks, and shake flasks are generally used for screening of recombinant protein expression. Various cultivation parameters, such as media composition, pH, agitation, aeration, temperature, cell density, the concentration of inducers, induction time, and feeding strategies affect the protein expression level depending upon expression systems (Gronemeyer et al., 2014; Tripathi, 2016). Thus, it is essential to evaluate each of the cultivation conditions for the expression of every recombinant protein and the development of effective bioprocesses. Recently, high-throughput process development (HTPD) techniques have become available and have been effectively utilized for process optimization in a cost-effective manner (Baumann and Hubbuch, 2017). Single-use upstream and downstream processing techniques have also been used for recombinant proteins to minimize the production cost and process time (Langer and Rader, 2014). After successful process development, large-scale production is carried out using bioreactor systems to fulfill the demand for biopharmaceuticals. Batch, fed-batch, and continuous or perfusion culture are used for bulk production of recombinant proteins. Continuous bioprocessing has also emerged as a novel technique and has been used in both upstream and downstream process development as well as in manufacturing for therapeutic proteins (Subramanian, 2018). The implementation of Quality by Design (QbD) and process analytical technologies (PAT) tools has improved biopharmaceutical production strategies (Kornecki and Strube, 2018; Shekhawat et al., 2019). The framework of bioprocess modeling and control also offers robust control solutions and is advantageous for optimal bioprocess design (Baumann and Hubbuch, 2017). Integrated continuous bioprocessing has also been developed recently; this allows smaller facilities and equipment footprints and facilitates rapid process development and process scale up (Godawat et al., 2015; Zydney, 2015). New developments in manufacturing processes are bringing benefits in terms of cost of production, manufacturing flexibility, and quality of the end product. The present review describes the various host systems, bioprocess development, and recent trends in bioprocessing for the production of recombinant protein-based biopharmaceuticals.

A variety of expression hosts are used for the recombinant proteins, including bacteria, mammalian cells, yeast, insect cells, transgenic animals, and transgenic plants (McKenzie and Abbott, 2018; Owczarek et al., 2019; Puetz and Wurm, 2019). Manufacturing of recombinant therapeutic proteins of high quality is crucial for their use in humans. Protein glycosylation is an important characteristic and plays a crucial role in the efficacy, serum half-life, and antigenicity of a recombinant biopharmaceutical. Expression host systems such as mammalian, yeast, and insect systems are genetically engineered to produce a human-like glycan pattern in a recombinant product to avoid side effects. Recent approaches utilized for the modification of the glycan pattern of recombinant proteins include the selection of a proper expression host, glycoengineering, and upstream process optimization to control protein glycosylation. The cell culture, biochemical, and physical process parameters are also responsible for achieving the desired glycoform of a recombinant therapeutic protein. Therefore, these parameters need to be taken into consideration carefully during the production of such glycoproteins (Gupta and Shukla, 2018). The reproducibility of the glycosylation pattern of a cell line is important to ensure product quality (Zhu, 2012). Therapeutic protein-induced antidrug antibodies can alter drug pharmacokinetics and pharmacodynamics, leading to impaired efficacy and occasionally, serious safety issues. Therapeutic protein immunogenicity risk assessment, with attention to assays and in vivo models, has been described as a way to mitigate this risk in a recent study (Tourdot and Hickling, 2019). The use of gene knockout/knockdown and overexpression to develop meaningful approaches to improve the PTMs of biopharmaceuticals in different production platforms and their applicability were well-described in a recent study (Amann et al., 2019). Recent developments in metabolic engineering also include the use of gene-editing tools for successful clone and product development. Innovations in cell engineering, including the use of RNAi, ribozyme engineering, and CRISPR-Cas-based techniques, have been applied in pursuit of better strategies for antibody production (Dangi et al., 2018). Gene-editing tools like CRISPR/Cas9, zinc finger nucleases (ZFNs), transcription activator-like effector nucleases (TALENs), and recombinase-mediated cassette exchange (RMCE) are being utilized for efficient gene editing (Lalonde and Durocher, 2017; Heffner et al., 2018). Genetic manipulation utilizing three major tools (CRISPR/Cas9, ZFNs, and TALENs) and associated advances have been described, with a focus on the use of CRISPR/Cas9 for the “multiplexing gene-editing approach” for genetic manipulation of yeast and CHO cells, which finally leads to rapid product development with consistency, improved product yield, quality, and affordability (Gupta and Shukla, 2017a).

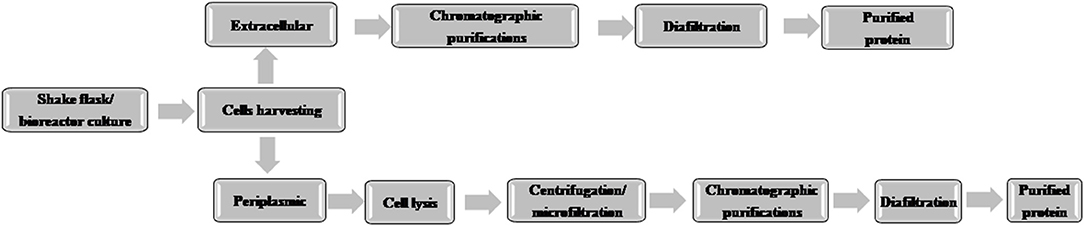

A bacterial expression host system, generally E. coli, is the preferable host for recombinant proteins due to its low cost, well-known biochemistry and genetics, rapid growth, and good productivity (Baeshen et al., 2015; Gupta and Shukla, 2016). Some disadvantages of this system include a lack of proper post-translational modifications (PTMs), inclusion body (IB) formation, codon bias, and endotoxin issues. Some techniques such as the addition of fusion tags (Liu M. et al., 2019) to the gene sequence, cofactor supplementation, and co-expression of the protein with molecular or chemical chaperones can avoid IB formation (Gupta S. K. et al., 2019) and improve soluble expression (Malekian et al., 2019). Different tags such as Fh8, SUMO, His, TRX, and MBP at the N- or C-terminal enhance protein solubility and also help in affinity purification (Paraskevopoulou and Falcone, 2018). Inducing protein expression by lowering the temperature after induction of culture leads to soluble protein. This strategy also increases protein stability and proper folding. Further, novel promoters and glycoengineering E. coli cells also lead to increased expression of a recombinant protein (Gupta and Shukla, 2016). However, the production of recombinant proteins in IBs has some advantages such as low product degradation by host cell proteases. Despite the various advantages of this system, a lack of PTM machinery results in a cumbersome purification process (Mamat et al., 2015). PTMs (glycosylation, disulfide bond formation, phosphorylation, or proteolytic processing) are involved in folding processes, stability, and biological activity (Ferrer-Miralles et al., 2009). E. coli has been modified for PTM for the production of recombinant proteins. An E. coli host has also been engineered to produce glycosylated antibodies (Wacker et al., 2002; Valderrama-Rincon et al., 2012; Gupta and Shukla, 2016). E. coli has been engineered to allow simple glycosylation of proteins by transferring the N-glycosylation system of Campylobacter jejuni into it. However, further studies are required to establish it for the industrial production of commercial therapeutic proteins (Gupta and Shukla, 2017c). The expression of genes with rare codons (e.g., those found in the human genome) often results in low expression and triggers premature termination of the synthesis of a protein molecule (Owczarek et al., 2019). The presence of rare codons can be addressed by using codon optimization or host modification. Codon optimization increases the expression of recombinant protein by many folds (Rosano and Ceccarelli, 2014; Gupta S. K. et al., 2019; Rosano et al., 2019). A redox environment and foldases [e.g., disulfide isomerases (Dsb proteins) and peptidyl-prolyl isomerases (PPIase)] are necessary to form the correct disulfide bond in the periplasm (Gupta and Shukla, 2017b). The incorporation of appropriate signal sequences for protein expression in periplasm or in the extracellular space aids correct protein folding and also minimum proteolytic degradation (Gupta and Shukla, 2016). The endotoxin problem can be solved by using a purification process to increase the safety of bacterially derived therapeutics (Mamat et al., 2015). SHuffle, an E. coli strain, was developed to correctly fold disulfide-bonded proteins in its cytoplasm (Lobstein et al., 2012) and was successfully used for biologically active IgG production (Robinson et al., 2015). The T7-phage polymerase, which is commonly utilized for protein expression, also results in decreased protein expression after 3–5 subsequent generations and subcultures. The novel promoter T7C p/p system can enhance recombinant protein production significantly as well as facilitating economical purification (Kesik-Brodacka et al., 2012). A specific pNEW vector has been developed using a cumate gene with a synthetic operator and the repressor protein cymR for the constitutive expression of the desired gene. This vector led to enhanced expression in comparison with a pET-based expression system (Choi et al., 2010).

MoCloFlex, a new modular cloning system for flexible de novo part/plasmid assembly, has been developed, and it has been revealed that it can be used to plan, build, and isolate a custom plasmid within 24 h. This leads to reduced costs and time consumption (Klein et al., 2019). In one study, it was reported that the E. coli “TatExpress” strain resulted in the delivery of 5.4 g/l of human growth hormone to the periplasm by the Tat pathway using fed-batch fermentation. The protein was shown to be homogeneous, disulfide-bonded, and active. Further studies are required to evaluate the full potential of this system, and especially to explore its capability for the export of more complex proteins (Guerrero Montero et al., 2019). In another study, it was shown that the use of diverse carbon and nitrogen sources and acetate metabolism knockout strains can redirect E. coli carbon fluxes to different pathways and resulted in a 5-fold increase in protein production (Lozano Terol et al., 2019).

Small antibody fragments such as single-chain variable fragments (scFvs) and antibody fragments (Fabs) do not need glycosylation. Therefore, these fragments have been successfully produced in E. coli. These antibody fragments show better tissue penetration and are less immunogenic to the human body in comparison to the full antibody. Recently, ESETEC secretion technology (Wacker Biotech) has been developed to secrete recombinant products into the culture broth during fermentation and resulted in a high yield of Fab (exceeding 4.0 g/l) and of scFv (up to 3.5 g/l) (Gupta and Shukla, 2017b). In another study, it was shown that the optimization of antibody fragment production was accompanied by the alleviation of stress production in the periplasm of E. coli. Thus, the monitoring of stress responses could be used to facilitate enhanced recombinant protein production yields (Baumgarten et al., 2018). Overexpression of membrane protein in E. coli may lead to toxicity and low yields of the active protein product. Snijder and Hakulinen (2016) described the challenges associated with overexpression of α-helical membrane proteins and different approaches to overcoming these challenges as well as a detailed protocol to express and screen membrane proteins using a His-specific fluorescent probe and fluorescent size-exclusion chromatography. Strategies for the production of soluble recombinant proteins using E. coli were described in another study (Gurramkonda et al., 2018). The latest advances in recombinant protein expression in E. coli were also described recently (Rosano et al., 2019).

CRISPR/Cas9 has been used to successfully carry out the chromosomal integration of large DNA into E. coli and was also able to integrate functional genes in diverse E. coli strains (Chung et al., 2017). In a recent study, it was also reported that CRISPR-Cas9-assisted native end-joining editing offered a simple strategy for efficient genetic engineering in E. coli (Huang et al., 2019). The existing obstacles to CRISPR-based editing in bacteria and guidelines to help achieve and enhance editing in bacteria were also described in a recent review (Vento et al., 2019). Deletion of the D-alanyl-D-alanine carboxypeptidase gene dacC has resulted in enhanced extracellular protein production in E. coli (Hu et al., 2019). Alkaline phosphatase (phoA) promoter and the heat-stable enterotoxin II (STII) leader sequence have also facilitated extracellular production in E. coli for the manufacture of Fab fragments (Luo et al., 2019). It was established that the post-translational targeting of single-chain variable antibody fragment (scFv) BL1 enabled its efficient production in the periplasm due to a favorable adaptation of the E. coli proteome (Ytterberg et al., 2019). It was also revealed that by combining signal peptide and production rate screening, enhanced recombinant protein yields were obtained in the E. coli periplasm (Karyolaimos et al., 2019). One study established scale-up of a type I secretion system in E. coli using a defined mineral medium, paving the way for industrial application (Ihling et al., 2019). The industrially important strain engineering strategies utilized to increase both the quantity and quality of therapeutic products were discussed in another study (Castiñeiras et al., 2018). Another study described the use of hierarchical-Beneficial Regulatory Targeting (h-BeReTa) employing a genome-scale metabolic model and transcriptional regulatory network (TRN) to identify the relevant TR targets for strain improvement (Koduru et al., 2018). Translating heterologous proteins places a major burden on host cells, consuming expression resources and leading to slower cell growth and productivity. In a recent study, a standard cell lysate-based assay was used to quantify the burden of expressing a protein-coding sequence and provided a parameter for predicting the burden synthetic gene expression places on E. coli. These lysate measurements can be utilized with a computational model of translation to predict the in vivo burden placed on growing E. coli cells for many proteins of different functions and lengths (Borkowski et al., 2018). Although a lot of work has been done on strain improvement, further technological development is still required.

Among all approved recombinant protein-based biopharmaceuticals, the mammalian cells dominate the other recombinant protein-expression systems (Owczarek et al., 2019). Mammalian cells have the capacity to express large and complex recombinant proteins. The introduction of the gene and selection of the clone in this system is time-consuming in comparison to microbial systems. The major steps during cell-line development include selection of an expression host, vectors, and transfection, as well as cell-line selection. High-throughput devices such as CLonePix (Thermo) and FACS (BD and Beckman) are now utilized for the development of the cell line and its screening. The major criteria for clone selection after extensive screening include a high level of protein expression with the desired PTM and genetic stability. Other features, viz. cell growth pattern, stable, and consistent production, cultivation in serum-free medium as a suspension culture, scalability in the bioreactor, adaptive performances, and product quality attributes, are also considered during clone development and selection (Gupta and Shukla, 2017c; Gupta et al., 2017). The methodologies of cell-line selection that exist for the isolation of high-producing clones and the techniques that can be utilized to predict, at a smaller scale, the performance of clones at large, industrially-relevant scales have been described in detail (Priola et al., 2016). A paper by Mauro (2018) discussed codon optimization for therapeutic protein production in mammalian cells, including potential risks and considerations.

CHO, NS0, and Sp2/0 are the main cell lines used for the expression of recombinant biopharmaceuticals. A recent survey revealed that CHO cell-based systems contribute 84% (57 of the 68 mAb products) of approved biopharmaceuticals and that the remaining antibodies are expressed in either NS0 cells (nine products) or Sp2/0 cells (two products) (Walsh, 2018). PTM is present in mammalian cell lines; however, their glycosylation pattern is different from human-type glycosylation. HEK293, HKB11, PER.C6, HeLa, and CAP cells (all human cells lines) are being also studied for protein expression (Bandaranayake and Almo, 2014; Dumont et al., 2016; Dyson, 2016; Hu et al., 2018; Gupta S. K. et al., 2019; Hunter et al., 2019). A human cell line enhances the expression of proteins with human-like PTMs. Fully glycosylated recombinant connective tissue growth factor CCN2 protein was successfully expressed using HeLa cells (Nishida et al., 2017). However, the cultivation of these cells on a commercial scale is still in the development phase. The other disadvantages of this system include contamination with animal viruses. It is difficult to formulate a culture medium for a cell line, as it requires various components such as growth factors, amino acids, reducing agents, and vitamins. CHO cells have different lineages: CHO-K1, CHO-S, CHO-DG44, and CHO-DXB11.

In a study by Reinhart et al. (2019), host cell-specific differences among CHO-K1, CHO-S, and CHO-DG44 were examined in mAb expression in batch, fed-batch, and semi-continuous perfusion cultures, revealing CHO cell line-specific preferences for mAb production. The quality attributes of mAb were also affected by the host cell line and media. It has also been established that cell engineering helps to avoid ammonium and lactate accumulation and improves cell growth (Kim and Lee, 2007). The cell line is optimized by codon optimization and various other approaches (Zhu, 2012). Further, glycoengineering is employed to produce the desired glycoform of a protein for its improved efficacy and to achieve a good-quality product (Lalonde and Durocher, 2017; Wang et al., 2017; Heffner et al., 2018). Glycoengineering strategies reduce the fucosylation or increase the sialylation of the therapeutic product. This strategy will be beneficial to industry in the future, enhancing product quality and bioactivity (Lalonde and Durocher, 2017). Tejwani et al. (2018) described in detail the advances in genetic manipulation, modeling, and glycan and glycoprotein analysis that together will present new approaches for glycoengineering of CHO cells with required or enhanced glycosylation capabilities. The types of mammalian cells used for the production of recombinant therapeutic proteins, their glycosylation potential, and the resultant impact on glycoprotein characteristics were discussed. Further, a comparison has been made between the glycosylation patterns of four recombinant glycoproteins (IgG, coagulation factor VII, erythropoietin, and alpha-1 antitrypsin) produced using different mammalian cell lines to establish the influence of mammalian host cell line on glycosylation (Goh and Ng, 2018). Strategies to increase recombinant protein expression by modulating and designing transcription factors and with advancements in synthetic biology have also been discussed (Gutiérrez-González et al., 2019). Conventional and emerging technologies for the expression of recombinant multi-protein complexes in mammalian expression systems were summarized in a review (Baser and van den Heuvel, 2016). The evolution of culture media, nutrient composition and formulation needs, optimization strategies, consistency and scalability of powder and liquid media preparation for industrial applications, and key recent advances driving progress in CHO cell culture medium design and development have been described (Ritacco et al., 2018). The major technological advancements along with the areas of application of CHO cell line development and engineering were discussed by Hong et al. (2018a). The effects of media and clonal variation on lactate shift were studied for CHO cell culture, and it was shown that the clone exhibiting lactate shift produced less lactate in the exponential phase but 2-fold higher non-toxic alanine, thus leading to a better culture environment (Hong et al., 2018b). Comparative multi-omics analysis in another study indicated some physiological variations between CHO cells grown in the same media. The protein processing abilities and the N- and O-glycosylation profiles also differed significantly across the host cell lines, suggested the necessity of choosing host cells in a rational manner for cell-line development on the basis of the recombinant protein being produced (Lakshmanan et al., 2019). A simple technique was also developed to screen multiple CHO cell clones for cell growth rate and protein production (Beketova et al., 2019). Additionally, a multi-omics study was carried out on the impact of cysteine feed level on cell viability and IgG 1 mAb production in 5 l bioreactors using CHO cells so as to obtain an in-depth understanding of the CHO cell biology (Ali et al., 2019). In a recent study, CHO cells were engineered with synthetic genetic circuits to tune the N-glycosylation of a stably expressed IgG (Chang et al., 2019).

Recent developments in metabolic engineering also include the use of knock-in (KI) and knock-out (KO) gene-editing tools for successful clone and product development. Gene-editing tools such as CRISPR/Cas9 have been successfully applied to attain better product quality for mammalian expression systems. In a recent study, C1s protease was inactivated using CRISPR/Cas9 for the production of recombinant HIV envelope protein gp120 in CHO cells (Li S. W. et al., 2019). CRISPR/Cas9-mediated site-specific integration was also used as an efficient and reliable tool for establishing recombinant stable HEK293 cell lines for biopharmaceuticals production (Yang H. et al., 2019). Through CRISPR/Cas9 gene editing, HEK293 cells were enabled to achieve antibiotic-free media bioprocessing. Further selective media and genetic optimization is required in order to increase productivity for its potential industrial use (Román et al., 2019). In another study, Anxa2- and Ctsd-knockout CHO cell lines were established by CRISPR/Cas9 and resulted in complete removal of the corresponding host cell protein (HCP) in cell lysates without affecting growth and viability for recombinant protein production (Fukuda et al., 2019). It was also reported that the CRISPR/Cas9-mediated knockout of microRNA-744 improved the antibody titer of CHO production cell lines (Raab et al., 2019). Among gene-editing tools, CRISPR/Cas9 and RMCE technologies will contribute most to the advancement of glycoprotein production in the near future.

Yeasts are good choices as expression hosts for recombinant proteins due to their rapid growth, easy genetic manipulation, cost-effective growth medium requirements, available complete genome sequences, and ability to provide PTMs (Fletcher et al., 2016; Vieira Gomes et al., 2018; Baghban et al., 2019; Huertas and Michán, 2019). Codon bias and extracellular expressions occur with the recombinant proteins expressed using this system. P. pastoris and S. cerevisiae are the most commonly used expression host systems for recombinant biopharmaceutical production. S. cerevisiae is well-established for the commercial production of therapeutics for human use. Several gene targets, most of which are involved in the trafficking and secretory pathways, that could enhance protein production by S. cerevisiae to the gram per liter level have been identified. It was also found that intracellular retention of recombinant proteins can be considerably reduced by engineering the endosome-to-Golgi trafficking (Huang et al., 2018). The development of a synthetic biology toolkit and how those tools have been applied in the areas of drug production and screening were described in detail by Chen et al. (2018). Due to overexpression of recombinant protein, there is intracellular accumulation, leading to reduced product titers. The hypermannosylation of proteins leads to faster blood clearance when used as therapeutics. This issue has been solved by knocking out the mannosyltransferase gene (Gupta and Shukla, 2017c). The GlycoSwitch® platform has been developed and used for the production of glycosylated proteins. In it, the hypermannosylation gene (OCH1) of yeast is removed, and glycosyltransferase and glycosidase genes are introduced to produce the desired glycosylated protein (Laukens et al., 2015). However, the main issue with the above platform is the low yield of the glycosylated protein, which limits its commercial use.

Pichia pastoris (a.k.a. Komagataella phaffi or K. pastori) is another choice of host for heterologous protein expression due to its ability to secret properly folded and functional proteins, provide reduced protein glycosylation, and achieve high cell densities (Looser et al., 2015; Juturu and Wu, 2018; Yang and Zhang, 2018; Werten et al., 2019). However, the N-linked glycosylation patterns of this system are different in higher eukaryotes. Yeasts were genetically engineered to perform humanlike N-glycosylation (Nielsen, 2013). A study by Liu et al. (2018) reported an expressing platform and strain engineering and production processes using yeasts for antibody production, and it was concluded that the homogeneous mAb production opened a window for glycoengineering. The disadvantage of the P. pastoris system is the proteolytic degradation or truncation of the product, causing reduced yield, and loss of biological activity. Various strategies have been used to overcome this problem, including addition of casamino acids, yeast peptone, and protease inhibitors, optimization of induction times, reduction of pH and temperature during fermentation, and the use of alternative carbon sources (Sinha et al., 2005; Zhang et al., 2007). The establishment of systems metabolic engineering in P. pastoris was described in a review (Schwarzhans et al., 2017).

Overexpression of recombinant protein often leads to severe burden on the physiology of yeast and triggers cellular stress. Yu et al. (2017) identified novel factors to enhance recombinant protein production in multi-copy K. phaffii based on transcriptomic analysis of overexpression effects. In another study, a data-driven approach was used to analyze the secretory production of a human insulin analog precursor (IAP) in S. cerevisiae during prolonged cultivation (80 generations) in glucose-limited aerobic chemostat cultures. Due to long-term adaptation, a metabolic remodeling of the IAP-expressing strain was observed, leading to decreased cellular expression potential for the secretory production of IAP (Kazemi Seresht et al., 2013). In order to evaluate the potential metabolic burden that cellulase expression imposed on the yeast metabolism, two recombinant strains of S. cerevisiae employing two different expression strategies, namely plasmid-borne, and chromosomally expressed, were studied in comparison to a reference strain. Supplementation of the growth medium with amino acids significantly improved culture growth and enzyme production but only partially minimized the physiological effects and metabolic burden of cellulase expression (Van Rensburg et al., 2012). In another study, the problem of low secretion titers of heterologous cellulases by S. cerevisiae was overcome by individually over-expressing two native S. cerevisiae genes, PSE1 and SOD1. This overproduction of SOD1 and PSE1 genes could increase cellulase production more than 3-fold. The study demonstrated that the strain engineering can greatly improve cellulase secretion in S. cerevisiae (Kroukamp et al., 2013). Recently, a heterologous cellulase system was studied in S. cerevisiae, where two native S. cerevisiae genes related to yeast stress tolerance (YHB1 and SET5) were overexpressed, and their effects on the heterologous secretion of Talaromyces emersonii cel7A cellobiohydrolase were investigated. The recombinant strains overexpressing either YHB1 or SET5 demonstrated improved tolerance to osmotic and heat stress as well as improved heterologous secretion (Lamour et al., 2019). The applications of systems biology in P. pastoris range from an increased understanding of cell physiology to improving recombinant protein expression have been described (Zahrl et al., 2017). A study by Liu W. et al. (2019a) provided information on methanol metabolism during the expression of P-glycoprotein from the P. pastoris MutS strain and suggested an expression procedure for hard-to-express proteins from P. pastoris.

A novel system was reported for fast and easy expression of recombinant proteins in S. cerevisiae and P. pastoris. In S. cerevisiae, the gene needs only the transformation of yeast cells with an unpurified PCR product carrying the gene to be expressed, and in P. pastoris, it needs only the isolation of the plasmid generated in S. cerevisiae and its transformation into this second yeast, thus making this system suitable for HTP studies (González et al., 2018). A new, stable, autonomously replicating P. pastoris plasmid vector containing the full-length chromosome 2 centromeric DNA sequence was constructed that exhibits high stability for plasmid retention, facilitating genetic manipulation. This vector has the ability to speed up cloning and HTP screening in P. pastoris, accelerating metabolic and genome engineering and high-level protein expression in this organism (Nakamura et al., 2018). New developments related to the P. pastoris expression system including hosts, vectors, glycosylation pattern, and fermentation technology, as well as strain engineering using CRISPR/Cas9 technology to produce human-like glycoproteins, and protease deficient strains have been described (Baghban et al., 2018). Advances in engineering tools for P. pastoris including genome editing technologies for gene disruption, deletion, and editing, new chassis strains for facilitated expression of complex proteins, and innovative technologies for balanced co-expression of multiple proteins have also been described (Fischer and Glieder, 2019).

CRISPR/Cas9 was successfully applied for yeast engineering to integrate a site-specific gene or to knock out certain unwanted genes for improved recombinant biopharmaceutics production (Stovicek et al., 2015, 2017; Raschmanová et al., 2018). The recombination machinery in P. pastoris is less effective as compared to S. cerevisiae, where efficient homologous recombination naturally facilitates genetic modifications. CRISPR/Cas9 technologies for P. pastoris have been established and used for gene disruption studies, to introduce multiplexed gene deletions, and to test the targeted integration of homologous DNA cassettes. This system allowed rapid, marker-less genome engineering in P. pastoris, enabling unprecedented strain and metabolic engineering applications (Weninger et al., 2016). The CRISPR/Cas9-mediated integration of markerless donor cassettes at efficiencies approaching 100% using a P. pastoris ku70 deletion strain was successfully demonstrated, and it was reported that the CRSIPR-Cas9 tools can be used to modify existing expression strains and provide an opportunity for markerless whole-genome modification studies in P. pastoris (Weninger et al., 2018). CRISPR-Cas9 was also used to develop a one-step multiloci gene integration method without the requirement of selective markers. This method can be used for pathway assembly of complicated pharmaceuticals expressed in P. pastoris (Liu Q. et al., 2019). The key factors that can enhance recombinant protein production in P. pastoris were well-described recently, and it was reported that up to 120 g DCW per liter of culture can be achieved using a chemically defined medium (García-Ortega et al., 2019). In a recent study, eight wild-type eukaryotic micro-organisms (including yeast, filamentous fungi, and mammalian cells) were evaluated to assess growth rates in industry-relevant media, adaptability for genome editing, and product quality. This study showed that multiple organisms may be suitable for recombinant protein production with appropriate engineering and development and highlighted the advantages of yeast for rapid genome engineering and development cycles (Jiang H. et al., 2019).

Recombinant protein-based therapeutics, including mAbs, vaccines, hormones, enzymes, and growth factors have been expressed using transgenic animals. Transgenic animals possess a transgene coding a recombinant protein that is integrated into their genome, and they are capable of passing it on to their offspring. Nowadays, the ways of sourcing proteins include milk from transgenic mammals and eggs from transgenic chickens (Moura et al., 2011; Maksimenko et al., 2013; Owczarek et al., 2019). The natural secretion of recombinant proteins occurs in this system and provides the correct PTMs. However, it is ethically questionable to produce transgenic animals. Zoonotic pathogens may be present in the protein preparations obtained from the transgenic animals (Wang et al., 2013; Bertolini et al., 2016). One study proposed potential strategies to help overcome inefficiencies in transgenic methodologies for cattle to enable the use of transgenic cattle as bioreactors for protein production in milk for industry (Monzani et al., 2016). Shepelev et al. (2018) discussed technologies for generating transgenic animals including targeted genome-editing technologies, with emphasis on the creation of animals that produce recombinant proteins in milk.

Transgenic plants have the ability to enhance recombinant biopharmaceutical production. This system has several advantages, viz. low cost, safety (low risk of contamination with animal pathogens), easy scale-up, stability, presence of metabolites, and ability to produce N-glycosylated proteins (Fahad et al., 2015; Yao et al., 2015; Łojewska et al., 2016; Lomonossoff and D'Aoust, 2016; Park and Wi, 2016; Xu et al., 2016; Buyel et al., 2017; Dirisala et al., 2017; Owczarek et al., 2019). Plant-based biologics have expanded to include cancer immunotherapy agents (Chen et al., 2016; Hefferon, 2017). Certain crucial factors should be considered to enhance the yield and quality of plant-produced biopharmaceuticals, namely the host plants, expression cassettes, subcellular localization, PTMs, and protein extraction and purification methodologies. DNA technology and genetic transformation methodologies have also involved to a great extent, with substantial improvements. Intensive glycoengineering study has been carried out to reduce the immunogenicity of the recombinant proteins produced in plants (Moustafa et al., 2016). The disadvantages of this system include pesticides, herbicides, and toxic plant metabolite contamination of the product. The other challenges associated with this system are control of the transgene expression level and the complex purification process. Plant cell cultures, plant tissue-based systems, and the construction of transgenic plants are mainly utilized for the production of recombinant proteins. The transgene is generally introduced into the plant cells using bacterial infection (agroinfection) or viral infection or via direct approaches such as biolistic bombardment or the PEG-mediated technique. One major advantage of these expression systems is the expression of recombinant protein in the desired cell compartment or plant organ. Human therapeutic proteins produced in plants often exhibit a plantlike rather than a humanlike glycosylation pattern. Glycoengineering is being used to solve this issue (Fischer et al., 2018; Owczarek et al., 2019). Rozov and Deineko (2019) discussed in detail the classical strategies for optimizing the synthesis of recombinant proteins and also new approaches, including gene-editing tools associated with the insertion of target genes in euchromatin genome regions.

Transgenic plants that have been used as a source of edible vaccines include rice, bananas, peas, potatoes, lettuce, and corn. A level of 100 mg/l (e.g., antibodies) or even up to 247 mg/l (e.g., α1-antitrypsin) was achieved in transgenic rice cell culture using genetic engineering (Loh et al., 2017; Owczarek et al., 2019). Human recombinant β-glucocerebrosidase (taliglucerase alfa-approved by FDA in 2012) enzyme was produced on a large scale in carrot (Daucus carota) cell culture (ProCellEx™) for the treatment of Gaucher disease (Tekoah et al., 2015; Moustafa et al., 2016). The world's first plant-derived IgA mAb that recognizes the surface antigen I/II of Streptococcus mutans (CaroRxTM-an anti-S. mutans produced in tobacco), the predominant cause dental caries, has been licensed in Europe and is used to prevent tooth decay (Larrick et al., 2001; Loh et al., 2017). Biopharmaceuticals produced in plants are at various stages of clinical trials or market implementation (Yao et al., 2015; Park and Wi, 2016; Dirisala et al., 2017; Owczarek et al., 2019). Examples are HAI-05 (Influenza Vaccine) [for Influenza A virus H5N1; host plant, tobacco (N. tabacum); status, phase II], Insulin (SBS-1000) [for diabetes; host plant, safflower (Carthamus tinctorius), status, phase III], ZMApp (monoclonal antibody cocktail) [for Ebola virus; host plant, tobacco (N. benthamiana); status, phase II], and Human growth hormone [for deficiency treatments; host plant, barley seed (H. vulgare); status, commercialization] (Owczarek et al., 2019). Human growth hormone was the first recombinant protein produced in transgenic tobacco (Barta et al., 1986; Yao et al., 2015; Loh et al., 2017).

Combined treatment of the mannosidase inhibitors kifunensine (KIF) and swainsonine (SWA) in transgenic rice cell culture media can be an effective method of producing recombinant human acid α-glucosidase (rhGAA) displaying dominantly high-mannose glycans such as Man7GlcNAc2, Man8GlcNAc2, and Man9GlcNAc2 (Man7/8/9) glycoforms without genetic manipulation of glycosylation (Choi et al., 2018). In a recent study, knockout of a green fluorescent protein (gfp) reporter gene in Arabidopsis cell culture was carried out, and it was concluded that the CRISPR/Cas9 system can be utilized for introducing site-specific mutations into the genome of cultured suspension cells of Arabidopsis (Permyakova et al., 2019). A new plant system based on carnivorous plants was established and showed the ability of biomimetic approaches to lead to an original production of recombinant proteins. However, the protein yields were low and did not qualify these plants for an industrial platform (Miguel et al., 2019). Recent advances in mAbs production using plant-based systems such as transgenic plants, tissue and cell cultures, and transient expression systems were described recently (Donini and Marusic, 2019). The current status of recombinant biopharmaceutical proteins generated using plant-based systems was well-documented elsewhere (Owczarek et al., 2019). A commercial-scale biotherapeutics manufacturing facility for plant-made pharmaceuticals was described by Holtz et al. (2015). Various approaches for plant-based production of recombinant proteins and recent progress in the development of plant-made therapeutics and biologics for the prevention and treatment of human diseases have also been described (Loh et al., 2017). A recent study (Rozov et al., 2018) described the similarities and differences between N- and O-glycosylation in plant and mammalian cells, as well as the effect of plant glycans on the activity, pharmacokinetics, immunity, and intensity of biosynthesis of pharmaceutical proteins. It also looked at current strategies of glycoengineering of plant expression systems to obtain fully humanized proteins for pharmaceutical application. Developments and computational tools for vaccine and antibody production in plants were also discussed recently (Dubey et al., 2018). Critical analysis of the commercial potential of plants for the production of recombinant proteins was also reported in a recent study. This study discussed the strengths of plant expression systems for specific applications, but mainly addressed the problems that must be overcome before plants can compete with conventional systems, to enable the commercial use of plants for the production of valuable proteins (Schillberg et al., 2019).

Insect cell expression host systems are also used for the expression of various recombinant proteins (Contreras-Gómez et al., 2014; Felberbaum, 2015; Kost and Kemp, 2016). The baculovirus expression vector system (BEVS) is used for the production of recombinant proteins in insect cells. The insect cells are grown to the desired cell density and then infected with a recombinant baculovirus containing the gene of interest (Owczarek et al., 2019). The glycosylation pattern in this system is comparable to, but not similar to, that of a mammalian expression system. Insect cells are not able to carry out N-glycosylation, but this issue can be solved by introducing mammalian glycosyltransferases into insect cells or by the co-expression of these enzymes together with the gene of interest in baculoviruses (Le et al., 2018). The most common cell line used for the baculovirus expression system is Sf9 (Van Oers et al., 2018; Yee et al., 2018; Ghasemi et al., 2019). In addition to Sf9 cells, S2, Sf21, Tn-368, and High-Five™ cells are also used for the expression of recombinant proteins (Contreras-Gómez et al., 2014; Felberbaum, 2015). MultiBac, an advanced baculovirus/insect cell system, has been developed and used to produce multiprotein complexes with many hitherto-inaccessible subunits for academic and industrial research and development (Sari et al., 2016; Gupta K. et al., 2019). The creation of Bac-2-the-Future, a 2nd-generation Tn7-based system, was reported, and it was demonstrated that the new system is compatible with multiple cloning methodologies and resulted in equal or better titer and protein productivity relative to the currently available systems (Mehalko and Esposito, 2016). It was also reported that a vankyrin-enhanced technology improved the baculovirus expression vector system. This study found that cell lysis could be delayed and that recombinant protein yields could be increased by using cell lines constitutively expressing vankyrin or vankyrin-encoding baculovirus vectors (Steele et al., 2017). SmartBac, a new baculovirus system, was developed for large protein complex production (Zhai et al., 2019). The FlexiBAC protein expression system was also developed for the production of both cytosolic proteins and secreted proteins that require proteolytic maturation. The design of FlexiBAC and its expansive complementary shuttle vector system enabled a reduction in cloning steps and simplification of baculovirus production (Lemaitre et al., 2019). The main methods and elements playing a role in the BEVS for protein production have been discussed in a review (Martínez-Solís et al., 2019). Many insect cell lines utilized for protein expression were found also to be persistently infected with adventitious viruses. New insect cell lines lacking adventitious viruses have been isolated for use as improved research tools and safer biological manufacturing platforms. Adventitious viruses found in insect cell lines, affected cell lines, and new virus-free cell lines were well-described in a recent review (Geisler and Jarvis, 2018).

Another study described two methods for production and purification of filovirus glycoproteins in insect and mammalian cell lines and suggested that the difficulties encountered by the authors in the purification of the proteins would facilitate other researchers to produce and purify filovirus glycoproteins rapidly (Clarke et al., 2017). The baculovirus-produced N-Terminal Pfs230 domain was also studied as a biological active transmission-blocking vaccine candidate to accelerate malaria parasite elimination (Lee et al., 2017). A baculovirus expression system was also used for the development of a combined genetic engineering vaccine for Porcine Circovirus type 2 and Mycoplasma hyopneumoniae (Tao et al., 2019). In one study, Hantaan virus-like particles were successfully produced by co-expressing Hantaan virus nucleocapsid (N) protein and glycoproteins (Gn and Gc) in Sf9 cells for vaccine studies, and it was shown that the purified VLPs provided protection from virus challenge in mice (Dai et al., 2019).

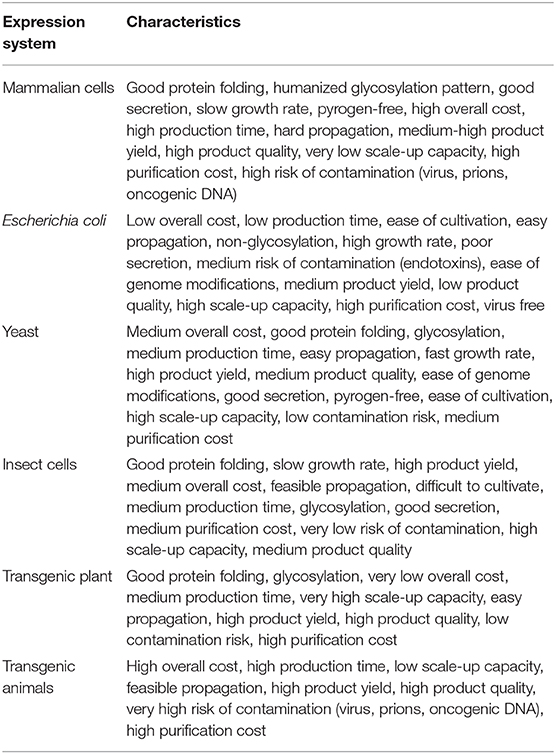

In a study by Mabashi-Asazuma and Jarvis (2017), various insect U6 promoters were used to construct CRISPR-Cas9 vectors, and their usefulness for site-specific genome editing in sf9 and High five cells was evaluated. This study demonstrated the use of CRISPR-Cas9 for editing an endogenous insect cell gene and altering protein glycosylation in the baculovirus-insect cell system. The successful demonstration of CRISPR in Sf9 points to a new and exciting direction for virus-less engineering of insect cells. CRISPR is expected to instigate a rapid expansion of engineering approaches to achieve enhanced expression of multiple genes in insect cells. These current and expected future developments in engineering insect cells for enhanced expression of humanized proteins are dissolving perceived disadvantages to bring about the upcoming age of the use of insect cells for the development and manufacturing of therapeutic proteins (Yee et al., 2018). Pazmiño-Ibarra et al. (2019) reported the use of a CRISPR/Cas9 system for the engineering of baculovirus to improve its performance as a protein expression vector. This study showed that the delivery of Cas9-single guide RNA ribonucleoprotein (RNP) complex with or without a DNA repair template into Sf21 insect cells through lipofection might be efficient for producing knockouts as well as knock-ins in the baculovirus (Pazmiño-Ibarra et al., 2019). A comparison of the characteristics of various expression systems used for recombinant proteins is given in Table 2.

Table 2. Characteristics of different expression host systems used for production of recombinant biopharmaceuticals (Demain and Vaishnav, 2009; Houdebine, 2009; Berlec and Štrukelj, 2013; Rosano and Ceccarelli, 2014; Ghag et al., 2016; Tripathi and Shrivastava, 2018; Vieira Gomes et al., 2018; Owczarek et al., 2019).

Innovation in bioprocessing is driven by the need for time for successful cost-effective production as well as to fulfill the demand for biopharmaceuticals. The final aim of bioprocess development is large-scale production of biopharmaceuticals. Commercial-scale process optimization is generally costly, so it is preferred to optimize processes at a small scale using laboratory bioreactors. Infectious diseases are increasing in prevalence day by day across the world, so there will be a huge demand for biopharmaceuticals. Novel concepts are being used at various stages of upstream bioprocessing, such as cell line selection and development, screening and selection of clones, optimization of media, optimization of feed, and process optimization (Shukla and Thömmes, 2010; Gronemeyer et al., 2014; Gupta and Shukla, 2017c; Gagliardi et al., 2019). During the cell development process, the selection of host cells and expression vectors and of transfection and selection methods is critical for high productivity and defined product quality (Gronemeyer et al., 2014). Process development starts with identifying cells that express the desired protein, and the identified cells are used for small scale (test tube, shake flask) and bioreactor culture to evaluate cell growth and protein production levels.

The development of an effective medium composition that includes all the essential nutrients necessary for higher cell growth and protein productivity is very important. Various commercially available cell-specific media are also used for the production of recombinant proteins. Cultivation media were previously developed using the traditional “one factor at a time” (OFAT) approach. This is essential to optimize culture medium components for every cell line individually because of cell line diversity, the medium constituents, and their interactions, processes, and metabolic pathways (Gronemeyer et al., 2014; Tripathi and Shrivastava, 2018; Gupta S. K. et al., 2019).

The batch, fed-batch, and continuous or perfusion modes of cultivation are used for the production of recombinant protein-based biopharmaceuticals (Jozala et al., 2016; Gupta and Shukla, 2017c; Tripathi and Shrivastava, 2018). In a batch mode of cultivation, all essential nutrients are provided in the initial base medium. In a fed-batch process, nutrients are fed during cultivation. In perfusion culture, the medium is circulated through a growing culture to allow simultaneous waste removal and nutrient supply (Agbogbo et al., 2019). In a continuous or chemostat bioreactor culture, feed containing essential nutrients is fed in and product containing culture is recovered continuously. If the desired rate of dilution is less than the growth rate of cells, this growth needs to be controlled using a turbidostat or chemostat culture. However, if the rate of dilution is more than the growth rate of cells, cells need to be returned back to the bioreactor (Peebo and Neubauer, 2018; Rahimi et al., 2019).

In a study by Hou et al. (2019), it was reported that the phosphorylation and hydroxylation level of an Fc-fusion protein could be reduced by nutrient optimization in a CHO fed-batch process. The application of fed-batch MTPs for HTP screening of E. coli clones (32 strains) was also established (Keil et al., 2019). Batch and exponential-fed-batch cultures were designed to evaluate the effect of the specific growth rate (μ) and resulted in recombinant glycoprotein AcrA glycosylation and a maximum specific synthesis rate at μmax (Caillava et al., 2019). Another study evaluating continuous and fed-batch modes of cultivation for recombinant protein in P. pastoris revealed that at the highest μ levels and volumetric and specific productivities in the continuous mode were roughly 1.5 and 3 times greater than in the fed-batch mode (de Macedo Robert et al., 2019). The use of bioreactor technology for sustainable production of plant cell-derived products was described elsewhere (Werner et al., 2018).

For the production of therapeutic mAbs using mammalian cells, a perfusion culture is the preferred choice, because this mode decreases the residence time of the mAbs in the bioreactor. In perfusion culture, cell retention devices (tangential flow filtration, spin filters, and alternating tangential flow filtration systems) are very important for recovering culture medium containing the desired product from the bioreactor. The development and optimization of the perfusion process focuses on the transfection process, feeding strategy, cultivation time, and perfusion rate (Gronemeyer et al., 2014). In a recent study, a novel, alternative intensified cell culture perfusion process resulted in a 2-fold volumetric productivity enhancement as compared to a commercially ready, optimized fed-batch process (Gagnon et al., 2019). In another study, a single-use fluidic components-based perfusion bioreactor system was developed and enabled the implementation of active environmental control (Bournonville et al., 2019). In a study by Bertrand et al. (2019), the impact of perfusion cultivation on the intracellular physiological state of a CHO cell line was investigated, revealing decreased mAb productivity as well as a transition phase for metabolites and product quality before reaching steady-state conditions. For viral vaccine production using anchorage-dependent cells (e.g., Vero cells), microcarriers are necessary in the bioreactor. The microcarriers also provide protection to the cells from excessive shear (Hu et al., 2011; Merten, 2015).

Bioreactor type and process control are also important factors to consider for successful process optimization and effective process development (Butler and Meneses-Acosta, 2012). The bioreactors used for biopharmaceuticals production include stirred tank bioreactors, airlift bioreactors, bubble column bioreactors, hollow fiber bioreactors, and fixed bed and fluidized bed bioreactors (Warnock and Al-Rubeai, 2006; Jain and Kumar, 2008; Vermasvuori and Hurme, 2011; Rivas-Interián et al., 2019). Membrane bioreactors are also available commercially (miniPERM bioreactor from Vivascience and CELLine from Integra Biosciences) and are utilized for small-scale production of mAbs (Dewar et al., 2005).

The various operating parameters [temperature, pH, agitation, aeration, dissolved oxygen (DO), CO2, and hydrodynamic shear] used for bioreactor cultivation also need optimization to achieve enhanced productivity for recombinant biopharmaceuticals using different protein expression host systems. The successful development and optimization of a bioprocess also takes into account temperature shifts and gas exchange during cultivation. The optimization of all of the above-described parameters results in high cell densities and enhanced specific and volumetric productivities with better product quality. Successful process optimization strategies have resulted in an increase in product yield from 50 mg/l to 5–20 g/l for mAbs (Gronemeyer et al., 2014). In a recent study, it was also established that aeration and shear stress were critical process parameters for the production of oncolytic measles virus using Vero cells (Grein et al., 2019). In a recent review, the methodology and devices used for oxygen uptake rate determination were well-described (Martínez-Monge et al., 2019).

Upstream process development also includes scale-up of a fermentation process to ensure a similar product yield with quality at large scale as is produced at small scale. Thorough knowledge of bioreactor parameters at various scales helps the successful scale-up of robust production processes. The important parameters for scale-up, which are critical to efficient cell growth, viability, and protein production, include mixing, oxygen transfer, heat-transfer characteristics, and shear forces (Werner, 2013). The most commonly used criterion for scale-up is to keep one or more parameters similar between different scales. Such parameters include constant agitation power input (power/volume), constant oxygen transfer coefficient, constant mixing time, constant agitation impeller tip speed, constant heat transfer rate (heat/volume), constant gas volumetric flow rate (vvm), and constant gas superficial velocity (m/s) (Junker, 2004; Schmidt, 2005; Garcia-Ochoa and Gomez, 2009; Xu et al., 2017). Linear scale-up parameters include temperature, pH, pressure, DO, airflow rate, and nutrient concentrations. In general, oxygen transfer rates (OTRs) decrease as fermentor scales increase (Yang, 2010). The challenge to meet temperature control requirements may be due to the limited cooling capacity of a large bioreactor. Pressure may also be adjusted as a strategy or tool to improve gas transfer at larger scales where a high agitation rate is difficult to reach (Islam et al., 2008; Lee, 2009; Meagher et al., 2011; Zawada et al., 2011; Ruiz et al., 2013). It was also reported that understanding the genetic heterogeneity will inform metabolic engineering and synthetic biology approaches to reduce the emergence of non-producer mutants in scaled-up fermentations and increase product quality and yield (Rugbjerg and Sommer, 2019). Ultimately, successful scale-up is determined to have been achieved when comparable process performance endpoints such as cell growth, cell viability, protein production (i.e., titer), and product quality are achieved.

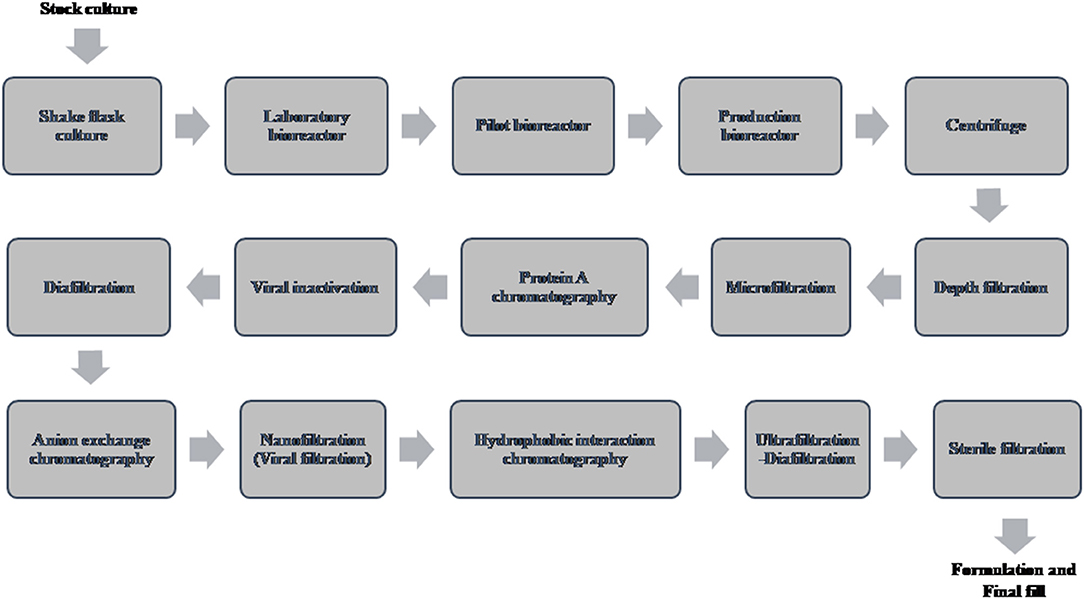

A typical flow chart for the large-scale production of mAb using mammalian cells is shown in Figure 1. The upstream process includes inoculation of working cell stock into small-scale shake flask cultures followed by laboratory-scale and pilot-scale bioreactors and final cultivation into a production bioreactor. The downstream manufacturing process includes cell harvesting (using centrifugation and depth filtration), microfiltration, Protein A chromatography, viral inactivation, diafiltration, anion exchange chromatography (AEX), viral filtration, hydrophobic interaction (HI) or cation exchange chromatography (CEX), diafiltration, sterile filtration, and formulation.

Figure 1. Flow chart of the production of therapeutic monoclonal antibody using mammalian cell culture.

Recent innovation in the upstream processing has resulted in cost-effective, high yield, and speedy production of recombinant protein-based biopharmaceuticals. The innovative technologies used for successful upstream process developments include high-throughput (HTP) technologies, single-use devices, statistical optimization of media and environmental parameters, QbD, PAT, and continuous upstream processing.

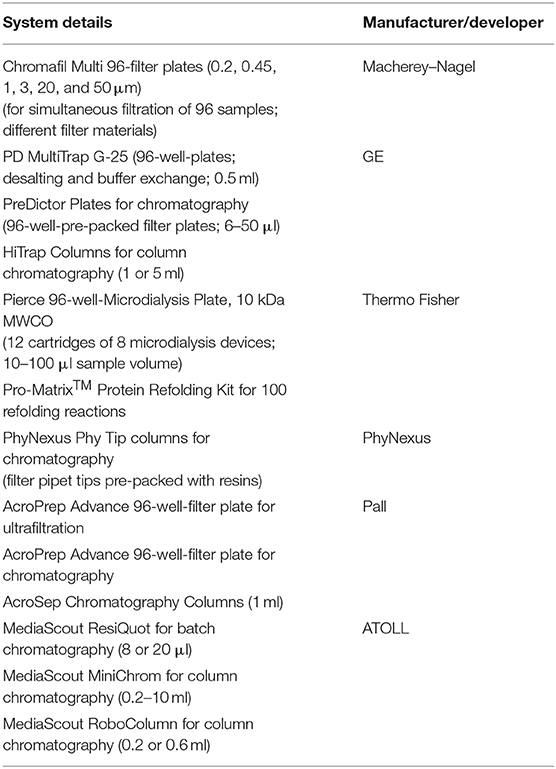

High-throughput devices (HTPDs) have been developed for upstream process development such as multi-well-plates and mini-bioreactors. Using these HTPDs, it is now very easy to do all the screening experiments including optimization of processes to save time and cost before proceeding to scale up the production of recombinant proteins. Examples of high-throughput systems are miniature shaken vessel/wells or microtiter plates (MTPs), bubble column or microplate-based mini-bioreactors, and stirred mini-tank bioreactors. Batch and fed-batch process optimization have been established and improved using HTPD. Process optimization for perfusion cell culture is needed for successful continuous bioprocessing. For this reason, the equipment developers and manufacturers have a motivation to develop suitable HTP perfusion microbioreactors for perfusion process optimization studies (Fisher et al., 2018). Cultivations in standard 96-well-microtiter plates represent the optimal system for miniaturization (Duetz, 2007; Baumann and Hubbuch, 2017). MTPs were successfully used for recombinant protein process development (Long et al., 2014; Chung et al., 2018; Fink et al., 2019; Keil et al., 2019).

A 10–15 ml microscale bioreactor (ambr) (Sartorius) with a fully automated robotic workstation and feeding and sampling was used for mAbs production from CHO cells. BioLector (m2p-labs) cultivation plates [with an optical bottom and optical sensors (for pH and oxygen transfer rates)] have become available and have been used for recombinant proteins. In one study, a continuous perfusion microbioreactor system (1-ml working volume) was developed and demonstrated to have a perfusion rate of 1 ml/h (Mozdzierz et al., 2015; Fisher et al., 2018). The ambr 250 was successfully demonstrated as a representative scale-down model for two mAbs commercial processes at scales of >10,000 l (Manahan et al., 2019). A polymer-based controlled-release fed-batch microtiter plate (48-well-plate) with on-line monitoring capabilities was also studied with E. coli for screenings and initial process development (Habicher et al., 2019a). In a study by Fink et al. (2019), 32 production clones were characterized in carbon-limited microbioreactor cultivations (BioLector), with production yields of 0–7.4 mg Fab per gram of cell dry mass. The use of polymer-based controlled-release fed-batch microtiter plates during preculture was theoretically studied and tested with an E. coli clone bank containing 32 strains (Keil et al., 2019). The suitability of an automated small-scale bioreactor (ambr 15 with 48 wells) as a small-scale model was confirmed using a perfusion process (Janoschek et al., 2019). In another study, it was reported that an automated microbioreactor system (ambr15) can be utilized to scale down the perfusion process using cell sedimentation (as the cell retention method). It was observed that this model under-predicted cell line productivity but accurately predicted product quality attributes, including glycosylation profiles, from cultures carried out in 1 l and 1,000 l working-volume bioreactors. The microbioreactor system allowed an 80-fold decrease in culture media requirements and halved the daily operator time, resulting in an approximately 2.5-fold cost reduction compared to a similar bench-scale experimental setup (Kreye et al., 2019). The impact of the bioreactor scale (10 ml ambr as the scale-down model and a 300 l pilot scale) on intracellular micro-heterogeneities in a CHO cell line producing mAbs in fed-batch mode was studied by Bertrand et al. (2018), revealing that the enzymatic activity was affected by the varying environmental conditions, leading to an observed time-dependent variation. In another study, FeedER (feedback-regulated enzyme-based slow-release system) exponential fed-batch for microscale cultivations was developed that enabled 48 fed-batch experiments to be run in parallel in an automated and miniaturized manner. This can significantly accelerate the bioprocess scale-up from lab scale to industrial scale. Future work will focus on the application of this system for different feeding modes, e.g., constant feed rates or different slow-release systems (Jansen et al., 2019). In another study, a fully automated microbial cultivation platform (capable of performing up to 32 fed-batch cultivations simultaneously) was developed, and it was reported that the initial performance (with respect to different expression systems and process conditions) of this platform was comparable to 5 l cultivations. Thus, fully automated HTP cultivation (with automated centralized data storage) considerably speed up the identification of the optimal expression systems and process conditions, offering the potential for automated early-stage bioprocess development (Janzen et al., 2019). A systematic analysis of HTP scale-down models (ambr®250, 250 ml) was carried out for 500 or 2,000 l single-use bioreactors to produce a mAb using vvm (volume of gas per volume of liquid per minute) as the scale-up criterion. This study reported that scale-down using a similar vvm as the criterion was feasible for reproducing large-scale gas transfer characteristics (Zhang et al., 2019).

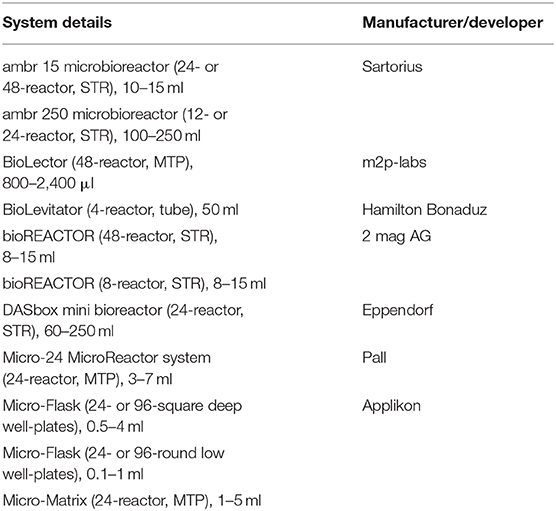

In another study, hydrodynamic conditions, and mass transfer in miniaturized bubble column (MBC) bioreactors were investigated using E. coli. The gas hold-up and volumetric mass transfer coefficient (KLa) in MBCs were found up to ten times greater than those in the larger bubble columns and comparable to the stirred tank bioreactors (Khanchezar et al., 2019). A membrane-based fed-batch shake flask with a Respiration activity monitoring system (RAMOS) device was also used to study the effect of substrate-limited fed-batch conditions (Habicher et al., 2019b). A mini-chemostat (MC) system (16 reactors with 40 ml working volume) was developed to characterize yeast physiology, and it was shown that the MC system provided the same environmental conditions as the DASGIP® parallel bioreactor system (Eppendorf) (Bergenholm et al., 2019). In a recent review, a systematic approach toward scale-down model (SDM) development in ambr 15 systems was described, and it was suggested that ambr SDMs are suitable for future regulatory submissions (Sandner et al., 2018). In a study by Vit et al. (2019), the efficiency of a microfluidic cell cultivation device and its applicability for rapid screening of multiple parameters was also established. A list of some HTP devices is given in Table 3.

Table 3. List of some HTPD systems used for upstream process development (Baumann and Hubbuch, 2017).

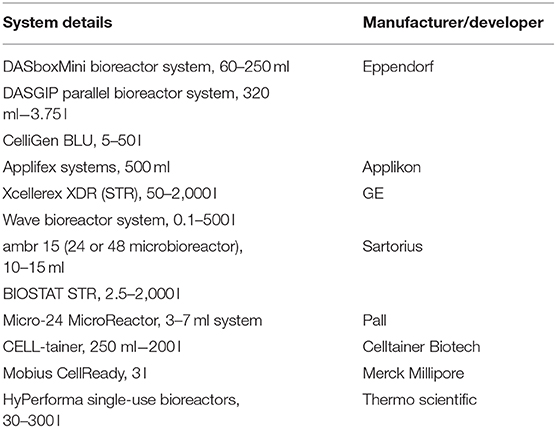

Recent progress in single-use (SU) cultivation systems, including single-use probes/sensors and fluidics components, has led to rapid developments of upstream processing. The implementation of single-use upstream processing devices resulted in less capital and operating costs with greater flexibility (Boedeker et al., 2017). A study on integrated continuous processing reported that cost savings of about 30% can be achieved using disposable technologies with respect to stainless steel (SS) batch process (Jacquemart et al., 2016; Hummel et al., 2018; Somasundaram et al., 2018). The different varieties of single-use disposable cultivation systems include wave, orbital shaken (OS), stirred tank (ST), and pneumatically mixed bioreactors (Shukla and Gottschalk, 2013; Raven et al., 2015; Challener, 2017; Ghasemi et al., 2019). There is very low risk of contamination with these systems, as cleaning and sterilization are not needed. A list of some single-use systems is given in Table 4.

Table 4. List of some single-use systems used for upstream process development (Gupta S. K. et al., 2019).

A wave bioreactor system (GE) has been developed that consists of a Cellbag (made of polymers) placed on a rocker unit equipped with controllers for pH, DO, temperature, and pressure. This design improves the mixing of the cultivation media and mass transfer (Ghasemi et al., 2019). Some disadvantages associated with a bag-based bioreactor are the risk of leaching from the plastic bag to the product and decreased process performance due to binding of media constituents with plastic (Shukla and Gottschalk, 2013; Gupta and Shukla, 2017c). Disposable Wave bioreactors up to a 500 l scale, disposable ST bioreactors up to a 2,000 l scale (Xcellerex XDR 2000; GE), and orbitally shaken (OS) bioreactors (with a cylindrical or square-shaped vessel) up to a 2,500 l scale (De Jesus and Wurm, 2011) are available and are used for cultivations. The single-use Biostat B (1 l and 5 l bioreactors) and single-use ST bioreactor (Mobius 3 l) are also available and are utilized in process development (Gupta S. K. et al., 2019). The operating cost is high at large scale due to frequent purchasing of new bags. Single-use cultivation systems are also utilized to prepare inoculum for large-scale cultivations (Mahajan et al., 2010).

In one study, scale-up was carried out in a 200 l disposable OS bioreactor with BY-2 cells (Tobacco) for the production of the human mAb M12 and resulted in 300–387 g/l cell fresh weights with ~20 mg/l M12 (Raven et al., 2015). In another study, a Wave bioreactor at the 2 l scale was used to cultivate Sf9 cells and infected/non-infected BTI-TN-5B1-4 cells to estimate the specific oxygen uptake rates. Using these results, active soluble human papillomavirus (HPV) 16L1 protein expression was scaled up to 10 l and 50 l cell bags, resulting in a 10% decrease in volumetric protein expression (Ghasemi et al., 2019).

Single-use bioreactor (microcarrier-based) culture is a good option for viral vectors and viral vaccines. A microcarrier bead-to-bead expansion and transfer process was established for HEK293T cells and Vero cells and scaled up to 50–200 l using XDR-50 and XDR-200 bioreactors, resulting in 3.3 × 106 cells/ml in the XDR-200 bioreactor with Vero cells (Yang J. et al., 2019).

In order to minimize experimental effort in upstream process development, the Design of Experiments (DoE) approach has also been applied to investigate the various process parameters in recombinant protein production (Papaneophytou and Kontopidis, 2012; Hanke and Ottens, 2014; Shekhawat et al., 2019). Statistical experiments using various DoE approaches, such as full factorial design, fractional factorial design, Taguchi orthogonal arrays, and the response surface methodology (RSM), were used for the optimization of media to enhance protein yield because various components are present in media that interact with each other. In DOE, various process parameters can be changed in a set of experimental trials, and a small number of experiments are enough to decide the effect of the various parameters and to select the most important ones (Papaneophytou and Kontopidis, 2014; Kumar et al., 2019; Shekhawat et al., 2019). In one study, RSM was applied to develop a defined medium to enhance human interferon gamma production (Unni et al., 2019). Using DoE, the signal peptide was selected and optimal growth conditions were established for recombinant antibody fragment production in the periplasm of E. coli (Kasli et al., 2019).

The concepts of Quality by Design (QbD) with high-throughput devices or Design of Experiments have also been studied for upstream process development. QbD is a manufacturing principle in which product quality is integrated into the manufacturing process. The QbD method has been implemented for the process development and analytical characterization of recombinant proteins, including mAbs (Pathak et al., 2014; Yu et al., 2014; Kumar et al., 2019; Narayanan et al., 2019a; Shekhawat et al., 2019). Using the QbD approach, the effect of various media components and process parameters in Fab production was studied, resulting in a 5-fold enhancement of the target protein titer as compared to the basal medium, thus demonstrating the efficacy of QbD (Kumar et al., 2019).

Effective process optimization requires real-time monitoring of different process parameters. PAT is the process of ensuring that final product quality meets specifications by designing, analyzing, and controlling manufacturing through periodic and/or continuous measurement of critical quality and performance attributes. Critical quality attributes (CQAs) are properties that ensure the desired product quality by meeting defined criteria. Process parameters that affect CQA are called critical process parameters and need to be observed or controlled to ensure that the process leads to the desired quality. There is a need for innovation in sensor technology, its configuration, and its robustness so that PAT can be implemented for the advancement of continuous cultures (Fisher et al., 2018). The development of process analytical tools for analysis of the performance of perfusion bioreactor cultures has made significant contributions in terms of regulatory issues regarding the manufacturing of proteins (Somasundaram et al., 2018). The PAT tools based on spectrometry, which are used for on-line (integrated into the bioreactor system, i.e., lying outside the bioreactor, requiring an automatic sampling interface to the bioreactor that enables a sample to be drawn and delivered to the analyzer for bioreactor content analysis), at-line (manual sampling and analysis), and in-line (directly connected to the bioreactor) monitoring of samples, are near-infrared (NIR), fluorescence, IR, and Raman (Esmonde-White et al., 2017; Fisher et al., 2018). Raman spectroscopy has the ability to monitor structural/chemical changes in proteins. Glycoform patterns such as sialylation were directly observed on-line as a quality attribute criterion. Further development will be required to improve sensor design for easy integration into continuous bioprocessing systems (Fisher et al., 2018).

In a study by Kornecki and Strube (2018), in-situ turbidity and ex-situ Raman spectroscopy measurements were combined with an offline macroscopic Monod kinetic model in order to predict substrate concentrations in CHO cultivations in bioreactors. In another study, high-throughput MALDI mass spectrometry based on a microarray technology was used to observe N-glycopeptides of IgG1 produced in a perfusion cell culture (Hajduk et al., 2019). Different approaches for the determination of critical timepoints for product stability in an E. coli IB bioprocess were studied, and an empirical value was found that can be utilized as a process analytical tool (Slouka et al., 2019). An on-line method to control and manipulate glucose was studied and was validated to produce various recombinant therapeutic proteins across cell lines with different glucose consumption demands; it was then successfully demonstrated on micro (15 ml)-, laboratory (7 l)-, and pilot (50 l)-scale systems (Goldrick et al., 2018). For a P. pastoris fermentation to produce human interferon alpha 2b, a PAT platform was developed to monitor and control μ using capacitance (ΔC) during the induction phase (Katla et al., 2019). A novel approach based on the PAT initiative was also developed for on-line estimation of μ using in-situ dielectric spectroscopy (Li M. et al., 2019). The PAT framework was also used during the production of Lethal Toxin-Neutralizing Factor (LTNF) by E. coli, which was controlled by a decoupled input-output linearizing controller (DIOLC) (Dalal et al., 2019). LC-MS metabolomics at three bioreactor scales (10 l, 100 l, and 1,000 l) were utilized to gain insight into the basal metabolic states of the CHO cell culture during fed-batch, and this was demonstrated as a useful technique to obtain physiological information on the cell culture state during a bioprocess, regardless of scale (Vodopivec et al., 2019).

It remains a challenge to set up a universal mechanistic model for processes dealing with mammalian cells because of the lack of full knowledge of metabolic networks and reaction pathways. A hybrid semi-parametric model containing mechanistic and machine-learning methodologies has emerged as a potential tool for bioprocess development (Pinto J. et al., 2019). In one study, a mathematical model to describe polio virus production in batch bioreactors was developed and was able to accurately describe its production by Vero cells (Jiang Y. et al., 2019). The combination of mechanistic growth models with a parallel mini-bioreactor system for E. coli strain screening was studied to select the most robust strains with a scale-down approach for bioprocess scale-up (Anane et al., 2019). A hybrid model was studied using a 3.5 l fed-batch process for therapeutic protein production and was found to have a better capability to predict the time evolution of various process variables in comparison to statistical models (Narayanan et al., 2019b). A simple techno-economic model for mAbs production was also studied that can be used for any production platform (Mir-Artigues et al., 2019). Various other modeling approaches to optimize bioprocesses have also been studied (Gangadharan et al., 2019; Grilo and Mantalaris, 2019). A three-dimensional computational fluid dynamics (CFD) model was established for the analysis of the influence of baffle structure on the flow field in orbitally shaken bioreactors (OSRs), and it was proposed that the shear stress was gentle for mammalian cell growth (Zhu et al., 2019a). Further, a three-dimensional CFD model for hollow OSRs was established and validated, and it was verified that the hollow cylinder wall could improve the mixing efficiency (Zhu et al., 2019b). CFD simulations were also applied to analyze and compare microfluidic single-cell trapping and cultivation devices (Ho et al., 2019). In a study by Li et al. (2019), a scale-down model representing a 4,000-l culture process was established for foot and mouth disease vaccine production, and computational fluid dynamics (CFD) simulation was also used to study hydrodynamic environments inside the bioreactors.