- Mining Institute of the Ural Branch of the Russian Academy of Sciences, Perm, Russia

In recent years, there has been a notable integration of artificial intelligence (AI) technologies into mine ventilation systems. A mine ventilation network presents a complex system with numerous interconnected processes, some of which pose challenges for deterministic simulation methods. The utilization of machine learning techniques and evolutionary algorithms offers a promising avenue to address these complexities, resulting in enhanced monitoring and control of air parameter distribution within the ventilation network. These methods facilitate the timely identification of resistance faults and enable prompt calculation of ventilation parameters during emergency scenarios, such as underground explosions and fires. Furthermore, evolutionary algorithms play a crucial role in the advancement of methods for visual analysis of ventilation systems. However, it is essential to acknowledge that the current utilization of AI technologies in mine ventilation is limited and does not encompass the full spectrum of challenging-to-formalize problems. Promising areas for AI application include analyzing changes in air distribution caused by unaccounted thermal draft and gas pressure, as well as developing novel approaches for calculating shock losses. Moreover, the application of AI technologies in optimizing large-scale mine ventilation networks remains an unresolved issue. Addressing these challenges holds significant potential for enhancing safety and efficiency in mine ventilation systems.

1 Introduction

The ventilation system is an important element for the trouble-free operation of a mine and is often described as the respiratory system (Liu et al., 2022a) or the lifeblood of a mine (McPherson, 2012). Its task is to continuously supply fresh air to all underground working areas to dilute and remove various harmful impurities such as gas and dust, while also providing comfortable microclimatic conditions determined by air velocity, temperature, and relative humidity. The need to organize an effective ventilation system in mines is reinforced by specific requirements in regulatory documents of many countries (Semin et al., 2020).

The consumption of mineral resources is constantly growing, accompanied by a continual increase in mining capacity. Mines are expanding and branching out, with underground mining being carried out using increasingly high-performance equipment (Jia et al., 2020). The amount of harmful emissions released during mining operations is increasing, and the task of delivering the required amount of air to working areas is becoming more challenging for mining enterprises (Shriwas and Pritchard, 2020).

Complex mine ventilation network analysis relies heavily on analytical tools and software systems. Improving ventilation necessitates numerical simulation to manage airflows and pollutants (Yi et al., 2022). Yet, mine ventilation networks are intricate, with numerous degrees of freedom (Liu et al., 2022a). Constructing mathematical models for such networks proves challenging due to substantial input data errors from field measurements and unpredictable aerodynamic factors. This compels engineers and scientists to seek novel approaches to ventilation issues.

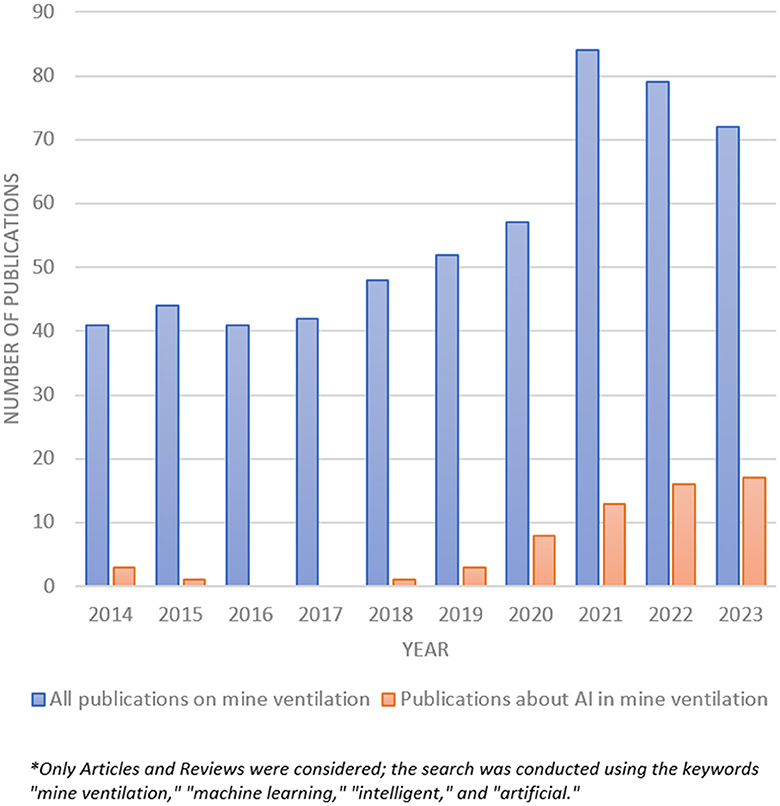

Artificial intelligence (AI) has emerged as one such approach, offering the capability to discern hidden patterns, adapt to changing conditions, and provide forecasts amidst uncertainty. Consequently, AI is increasingly applied to mine ventilation tasks, as evidenced by our bibliometric analysis of publications in the past decade (see Figure 1), based on Scopus database.

Figure 1. Time dynamics of the number of publications on mine ventilation in the period from 2014 to 2023.

Figure 1 illustrates that the proportion of publications discussing the application of AI within the total articles on mine ventilation has notably increased over the past four years, surpassing 20% by the end of 2023. Deep learning emerged as one of the frequently cited keywords in a cluster analysis of bibliographic works on mine ventilation spanning the past decade, as reported by Xue et al. (2024).

The utilization of AI in addressing mine ventilation challenges was examined in a review article by Hati (2021). The authors delineated various strategies for enhancing the energy efficiency of mine ventilation systems, explored the selection of components, and methods for intelligent prediction of airflow and contaminant concentrations. While the review provided a brief overview of AI technologies, including their general classification and advantages and disadvantages, it lacked an analysis of specific mine ventilation problems where AI has been effectively applied. Furthermore, there was no classification of AI technologies based on different areas of mine ventilation problems. We attribute this partly to the timing of the review, which predates a significant portion of AI-focused publications in mine ventilation, as indicated in Figure 1.

Another literature review by Shriwas and Pritchard (2020) addressed an essential application of AI technologies in mine ventilation monitoring and control. While the review did not directly focus on AI, it explored the concept of the Industrial Internet of Things (IIoT), emphasizing the need for long-term storage and advanced analysis of monitoring data to detect hidden trends and potential emergencies (Zhou et al., 2017).

Considering the aforementioned points and the rapid increase in the number of articles on AI in mine ventilation, an urgent task is to conduct a comprehensive literature review of AI technologies concerning mine ventilation issues. This review, while concise due to the current limited number of publications on AI in mine ventilation, aims to delineate the primary directions of AI implementation in mine ventilation and identify promising areas for AI application. We have identified four broad categories of mine ventilation problems that are currently being addressed using AI technologies. Subsequently, we discuss each application area sequentially, culminating in a comprehensive discussion of published research on mine ventilation utilizing AI.

2 Application areas of AI technologies

2.1 Mine ventilation monitoring systems

One of the main questions facing a mining engineer is how, based on the readings of individual measurements of air flows and air pressures in a real mine airway, to reconstruct a comprehensive depiction of the air flow distribution in a mathematical model. If the mine has a relatively small number of airways, then this can be achieved by measuring the air flow (Q) and pressure drop (ΔP) in almost every working, and subsequently calculating the resistance of each airway using the Equation (1) (Liu et al., 2022a):

However, for extensive ventilation networks with hundreds or thousands of branches, obtaining a complete picture of air flow distribution becomes challenging. This necessitates reconstructing air flow distribution in mines based on data from a limited number of manual or automatic measurements.

Liu et al. (2022b) studied optimal sensor placement for monitoring air distribution in mines, suggesting that equipping < 30% of tunnels with air velocity sensors ensures accurate air flow reconstruction if there are over 200 mine airways. Gao et al. (2018) employed a modified genetic algorithm (GA) to solve the inverse air distribution problem, determining mine airway resistance from air flow and pressure measurements. Liu (2023) used a GA-optimized neural network algorithm to assess mine ventilation system safety. Cao et al. (2024) applied deep reinforcement learning (DRL) to adjust mine airway resistances dynamically, showing smaller errors compared to other algorithms. This was demonstrated in a ventilation network with 153 branches. Ventilation resistance coefficient inversion has been explored by other researchers without AI (Li et al., 2019; Wu et al., 2024), but we omit these studies here.

Reconstructing air distribution in mines based on air velocity measurements is part of an intelligent mine monitoring system, considering mines within the IoT framework as cyber-physical systems. Kychkin and Nikolaev (2020) outlined four subsystems: physical objects, IoT network and computing infrastructure, digital twin, and human-machine interface. Jo and Khan (2018) proposed an IoT system for air quality monitoring, integrating pollutant assessment and forecasting features using an ANN model. Liu et al. (2020) integrated GIS and a transient ventilation network model to support real-time decision-making, envisioning an intelligent mine ventilation system.

Mining airway resistance is influenced by both well-formalized geometric parameters of the airway (such as cross-sectional area S, perimeter P, and length L) and poorly formalized parameters (including lining type and related parameters). The latter factor is typically implicitly considered in the air resistance coefficient α, from which R is derived:

In some cases, instead of α, other similar coefficients are used in the Equation (2) (McPherson, 2012; Amiri et al., 2020).

Determining α for mine airways with complex linings poses challenges, prompting researchers to turn to AI solutions. Zhao and Chen (2022) demonstrated SVM's effectiveness in modeling ventilation resistance coefficients based on mine airway geometry and lining parameters. For more intricate linings, Song et al. (2021) suggested using the PSO-SVM algorithm, known for its high accuracy, as a methodological guide.

Mine airway resistances change over time due to various factors (Skopintseva and Balovtsev, 2020). Such random changes in resistance are called resistance faults (Wang et al., 2023). These changes, whether short-term or gradual, can disrupt air distribution, posing risks of impurity buildup. Locating resistance faults is challenging and leads to active research in AI-based solutions.

Liu et al. (2022a, 2023) proposed resistance fault diagnostic models based on K-nearest neighbor (KNN), multilayer perceptron (MLP), SVM, and decision tree (DT). The authors showed high accuracy of these models in simulation and field studies. Wang et al. (2022) introduced an multi-label k-nearest neighbor (ML-KNN) model for rapid resistance failure identification in extensive ventilation networks. Subsequent work by Wang et al. (2023) presented a more sophisticated supervised learning model, combining DT, MLP, and ranking SVM, showcasing improved performance on complex networks. Zhao and Chen (2022) developed a fault scope library incorporating air volume and resistance relationships for diagnosing fault locations using SVM.

Cheng et al. (2014) and Cheng (2016) addressed a broader issue concerning reliability allocation in mine ventilation system design. The authors employed fuzzy mathematics and a Monte Carlo simulation approach to develop a model for scientifically allocating reliability practices.

2.2 Graphical analysis of ventilation networks

With the expansion and branching of mine ventilation networks, their graphical analysis also becomes more complex. The Ventilation Network Feature Graph (also known as a Q-H graph) offers a novel approach to directly and quantitatively represent the condition of a ventilation system and serves as an effective tool for studying complex ventilation networks (Xu and Tien, 1993). However, constructing such a graph requires a non-trivial analysis of the relationships between the elements of the ventilation network. For this reason, Jia et al. (2020) utilized GA to construct graphs that visually depict the main characteristics of the ventilation network, including air flows and pressure losses.

Initially, the Q-H plotting method faced challenges. For instance, when applied to a 3D ventilation network, the Q-H graph image was unavoidably segmented into rectangular blocks during the drawing process. However, Xie and Wang (2023) addressed this issue by refining the independent path sorting algorithm. They employed GA to expedite the creation of characteristic maps of ventilation networks on the Q-H axes.

3D reconstruction of mine airways is another important direction in the development of AI technologies in both mine ventilation and geotechnology (Ren et al., 2019; Du et al., 2023). Machine vision was utilized to process measurement data of the geometry of mine airways and mining equipment using various sensors: visual, inertial, LiDAR, and their combinations (Artan et al., 2011; Jiang et al., 2019; Zhai et al., 2020; Singh et al., 2023). This information can be further used to estimate changes in mine air resistance (Wong et al., 2011; Lavigne and Marshall, 2012; Watson and Marshall, 2018; Fahle et al., 2023).

In general, literature contains many works on the graphical methods for analyzing topologically complex mine ventilation networks (Maleki et al., 2018; Wu et al., 2019; Liu et al., 2022b; Bosikov et al., 2023), but we do not discuss these works here, since they are not use AI technologies.

2.3 Dynamics of gases and emergency ventilation

Mine ventilation, employing AI technologies, plays a crucial role in predicting harmful impurity release and emergency situations like fires. However, pinpointing emission locations and quantities can be challenging due to geological, geographical, and operational factors. Karacan and Goodman (2008) used principal component analysis and ANN to predict methane emission rates in longwall mines, aiding in selecting optimal degassing systems. Mathatho et al. (2019) developed an ANN model predicting methane concentration in coal mines based on microclimatic air parameters. Lin et al. (2022) analyzed gas emission monitoring data, predicting emissions in a dead-end face using SVM and GA for parameter optimization.

To a lesser extent, the literature provides examples of the implementation of AI to predict the generation and dynamics of dust in underground mines. Dust from blasting operations in open-pit mines has mainly been studied, wherein the dynamics of the dust cloud depend on numerous weather and technical factors that are challenging to formalize and accurately determine (Nagesha et al., 2016; Bakhtavar et al., 2021; Hosseini and Pourmirzaee, 2024).

Comfort and safety in mines depend not only on gases and dust but also on thermal factors (Cheng and Yang, 2012). Roy et al. (2022) employed GA to correlate environmental parameters with heat stress, albeit few studies focus on the thermal regime using AI. AI models, such as the PSO-SVR proposed by Deng et al. (2018), can predict coal spontaneous combustion temperatures based on gas concentrations in working areas. Ihsan et al. (2024a) applied a hybrid integrated numerical method and an ANFIS method to predict the wet bulb globe temperature.

Hong et al. (2022) utilized a supercomputer to simulate 1000 instances of a 3D mine tunnel fire under varying ventilation, thermal, and geometric conditions. They employed SVM, CART, RF, and ANN to predict fire dynamics, successfully forecasting backflow occurrence and smoke layer length. Basu et al. (2019) introduced a novel fuzzy logic system for underground coal mine fire hazard prediction, integrated into a wireless monitoring setup. Input parameters included air temperatures and impurity concentrations. Brodny et al. (2022) developed a similar system based on fuzzy logic and ANFIS to forecast methane accumulation hazards in a longwall.

Liu et al. (2021) adopted SVR to analyze shock wave propagation from methane explosions in mine ventilation networks. Their model, trained on numerically simulated airflow parameters, enables rapid assessment of explosion consequences.

2.4 Mine ventilation control systems

The mine ventilation system must not only be safe but also energy-efficient (de Vilhena Costa and Margarida da Silva, 2020; Ihsan et al., 2024b). The issue of selecting the optimal energy consumption parameters for the operation of main fans and ventilation doors is difficult to formalize for modern ventilation networks with a large number of air regulators. For such mines, finding the optimum can be very challenging (Wallace et al., 2015; Semin et al., 2020). To address this problem, Kashnikov and Levin (2017) proposed an Artificial Neural Network (ANN) model to enhance the performance of an algorithm for optimal ventilation control in a potash mine. Kashnikov and Kruglov (2022) applied fuzzy logic to determine fan influence zones under conditions of their dynamic change.

Huang and Liu (2022) laid out a theoretical basis for the intelligent design of mine ventilation. They demonstrated that an intelligent mine ventilation system should utilize full real-time monitoring data. Yang et al. (2023) introduced a method for remote intelligent air control based on machine learning, comprising three main components: fan frequency regulation, associated branch air resistance regulation, and their comprehensive integration. The authors employed five different models to predict the operating parameters of ventilation equipment with a given air volume. The results indicated that the Least Squares Support Vector Machine (LS-SVM) provides the most accurate predictions of target air parameters in the ventilation network, while maintaining a relatively short calculation time. These results were demonstrated on a laboratory bench of the mine consisting of 12 branches. Cheng et al. (2010) utilized fuzzy logic to optimize and evaluate the mine ventilation plan under conditions of a large number of varying parameters.

Hati and Kumar (2023) proposed a new algorithm that combines Adaptive Neural Fuzzy Interface System (ANFIS) and Genetic Algorithms (GA) to predict energy consumption and airflow in a mine ventilation system. This study compared the performance of the proposed algorithm with three other AI models: ANN, ANN-GA, and ANFIS.

Ihsan et al. (2024b) investigated AI-based Ventilation on Demand, which addresses both safety and energy efficiency concerns in mine ventilation. The authors suggested integrating real-time sensors, data, and ANFIS. However, the effectiveness of the system has only been assessed in laboratory experiments.

Wang et al. (2024) developed a non-linear optimization mathematical model of a mine ventilation network that minimizes total energy consumption for ventilation needs. They proposed a modified Sooty Tern Optimization Algorithm (STOA), belonging to the class of evolutionary algorithms, inspired by the behavior of gray terns during their long migrations.

3 Discussion

It is known that deterministic methods are more effective in the study of deterministic physical processes, while heuristic and intelligent methods demonstrate their efficacy in tasks where an explicit connection between the studied parameters and phenomena is not readily apparent. It is in this context that AI technologies are being integrated into mine ventilation systems today. Physical processes within mine atmospheres are well-understood by engineers and scientists and are typically modeled using deterministic approaches, such as solving systems of Kirchhoff equations to determine air distribution and solving differential equations for convective-diffusion transfer of heat and harmful impurities through mine workings (Olkhovsky et al., 2024).

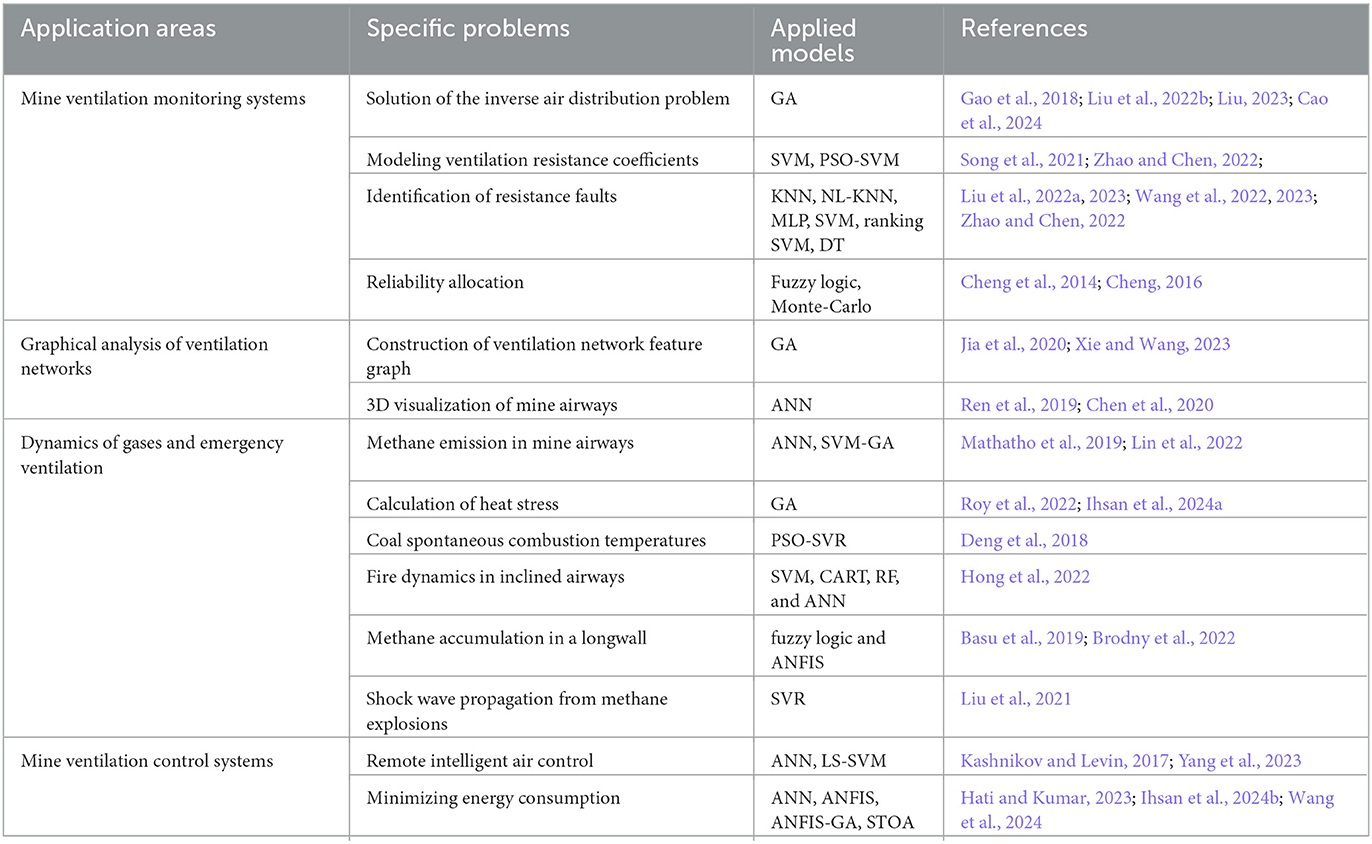

However, the mine ventilation network is a complex system with numerous unpredictable and unaccounted factors. Analyzing these factors within deterministic frameworks often proves challenging or leads to failure, making heuristic approaches and machine learning methods more suitable. A summary of the AI technologies used today in mine ventilation is given in Table 1.

It is noteworthy that despite the achieved results, researchers have primarily applied these methods to ventilation networks with a relatively small number of branches (10–20). In rare cases, the number of branches may reach 100–200, which still falls short of fully meeting the needs of mine ventilation specialists. Many mine ventilation networks consist of thousands of branches (Semin and Levin, 2019). Hence, it is imperative to focus on studying the effectiveness of AI technologies for analyzing ventilation networks in large mines in the future.

Another interesting question is how many measuring stations are needed to correctly assess air distribution in the entire mine while accurately determining the location of resistance failures in mine airways. The answer to this question depends on the number of branches in the ventilation network and should also consider the topology features such as through-flow and U-tube ventilation layouts.

A change in the air resistance of mine airways is not the only unaccounted factor that can lead to alterations in air distribution within a mine ventilation network. Other possible reasons for observed deviations in measured air velocities at measuring stations could include thermal depression (Nikolaev and Klishin, 2021) and gas depression (Zhou and Wang, 2018). For example, unaccounted-for heat and gas emissions from mining equipment, as well as gas emissions from rock masses, can also significantly impact mine air distribution.

Calculations of unsteady transport of harmful impurities and propagation of shock waves on deterministic models of ventilation networks are time-consuming due to the need for greatly reduced cell sizes and time steps. Therefore, it is sometimes appropriate to use heuristic approaches to solve deterministic problems in order to conserve computing resources. The most computationally expensive problems include calculating fires in mining systems (Hong et al., 2022) and propagating shock waves (Liu et al., 2021). Consequently, scientists are currently working on developing faster methods for performing these calculations. While the proposed models to date are still far from perfect due to several unaccounted factors and errors, this approach is likely to receive active development in the future. This is because in emergency mine ventilation situations, the speed of calculations is crucial for quickly finding effective solutions (Onifade, 2021).

Another promising area for utilizing AI in mine ventilation may be determining the shock losses of mine airways when calculating air distribution. Semin and Levin (2023) highlighted the importance of shock loss factors, especially in airways with large cross-sections. However, existing approaches to calculating shock losses lack both sufficient accuracy and versatility, particularly in their applicability to various types of mine airway junctions. The use of surrogate modeling could facilitate the selection of an approximating function for shock loss factors based on mine airway parameters, potentially providing accurate solutions across a wide range of mine airway junctions.

4 Conclusion

We anticipate that the utilization of intelligent methods for solving mine ventilation problems will increase in the future. This trend will be propelled by advancements in computing power and the emergence of new, more efficient AI technologies. Recognizing the existing gaps, AI will be progressively deployed across a broader spectrum of mine ventilation challenges. Concurrently, deterministic approaches will persist in analyzing mine ventilation systems, fostering a growing integration with heuristic and machine learning methodologies.

Author contributions

MS: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft. DK: Conceptualization, Funding acquisition, Investigation, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The study was carried out with the financial support of the Ministry of Science and Higher Education of the Russian Federation within the state assignment (project nos. 122030100425–6 and 121111800053–1).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Amiri, L., Ghoreishi-Madiseh, S. A., Hassani, F. P., and Sasmito, A. P. (2020). Friction factor correlation for airflow through broken rocks and its applications in mine ventilation. Int. J. Mining Sci. Technol. 30, 455–462. doi: 10.1016/j.ijmst.2020.05.003

Artan, U., Marshall, J. A., and Lavigne, N. J. (2011). Robotic mapping of underground mine passage ways. Mining Technol. 120, 18–24. doi: 10.1179/1743286311Y.0000000001

Bakhtavar, E., Hosseini, S., Hewage, K., and Sadiq, R. (2021). Green blasting policy: simultaneous forecast of vertical and horizontal distribution of dust emissions using artificial causality-weighted neural network. J. Cleaner Prod. 283:124562. doi: 10.1016/j.jclepro.2020.124562

Basu, S., Pramanik, S., Dey, S., Panigrahi, G., and Jana, D. K. (2019). Fire monitoring in coal mines using wireless underground sensor network and interval type-2 fuzzy logic controller. Int. J. Coal Sci. Technol. 6, 274–285. doi: 10.1007/s40789-019-0244-7

Bosikov, I. I., Martyushev, N. V., Klyuev, R. V., Savchenko, I. A., Kukartsev, V. V., Kukartsev, V. A., et al. (2023). Modeling and complex analysis of the topology parameters of ventilation networks when ensuring fire safety while developing coal and gas deposits. Fire 6:95. doi: 10.3390/fire6030095

Brodny, J., Felka, D., and Tutak, M. (2022). The use of the neuro-fuzzy model to predict the methane hazard during the underground coal mining production process. J. Cleaner Prod. 368:133258. doi: 10.1016/j.jclepro.2022.133258

Cao, P., Liu, J., Wang, Y., Liu, X., Wang, H., Wang, D., et al. (2024). Inversion of mine ventilation resistance coefficients enhanced by deep reinforcement learning. Proc. Safety Environ. Prot. 182, 387–404. doi: 10.1016/j.psep.2023.12.005

Chen, C., Wang, B., Lu, C. X., Trigoni, N., and Markham, A. (2020). A survey on deep learning for localization and mapping: Towards the age of spatial machine intelligence. arXiv:2006.12567.

Cheng, J. (2016). Assessment of mine ventilation system reliability using random simulation method. Environ. Eng. Manage. J. 4:91. doi: 10.30638/eemj.2016.091

Cheng, J., and Yang, S. (2012). Data mining applications in evaluating mine ventilation system. Safety Sci. 50, 918–922. doi: 10.1016/j.ssci.2011.08.003

Cheng, J., Yang, S., and Luo, Y. (2010). “Mathematical models for optimizing and evaluating mine ventilation system,” in Proceedings of the 13th United States/North American Mine Ventilation Symposium. Sudbury, ON, Canada, 13–16.

Cheng, J., Zhou, F., and Yang, S. (2014). A reliability allocation model and application in designing a mine ventilation system. Iranian J. Sci. Technol. Trans. Civil Eng. 38:61.

de Vilhena Costa, L., and Margarida da Silva, J. (2020). Cost-saving electrical energy consumption in underground ventilation by the use of ventilation on demand. Mining Technol. 129, 1–8. doi: 10.1080/25726668.2019.1651581

Deng, J., Lei, C., Xiao, Y., Cao, K., Ma, L., Wang, W., et al. (2018). Determination and prediction on “three zones” of coal spontaneous combustion in a gob of fully mechanized caving face. Fuel 211, 458–470. doi: 10.1016/j.fuel.2017.09.027

Du, Y., Zhang, H., Liang, L., Zhang, J., and Song, B. (2023). Applications of machine vision in coal mine fully mechanized tunneling faces: a review. IEEE Access. 11. doi: 10.1109/ACCESS.2023.3317048

Fahle, L., Petruska, A. J., Walton, G., Brune, J. F., and Holley, E. A. (2023). Development and testing of octree-based intra-voxel statistical inference to enable real-time geotechnical monitoring of large-scale underground spaces with mobile laser scanning data. Remote Sensing 15:1764. doi: 10.3390/rs15071764

Gao, K., Deng, L., Liu, J., Wen, L., Wong, D., Liu, Z., et al. (2018). Study on mine ventilation resistance coefficient inversion based on genetic algorithm. Arch. Mining Sci. 63, 813–826. doi: 10.24425/ams.2018.124977

Hati, A. S. (2021). A comprehensive review of energy-efficiency of ventilation system using artificial intelligence. Renew. Sust. Energ. Rev. 146:111153. doi: 10.1016/j.rser.2021.111153

Hati, A. S., and Kumar, P. (2023). An adaptive neural fuzzy interface structure optimisation for prediction of energy consumption and airflow of a ventilation system. Appl. Energ. 337:120879. doi: 10.1016/j.apenergy.2023.120879

Hong, Y., Kang, J., and Fu, C. (2022). Rapid prediction of mine tunnel fire smoke movement with machine learning and supercomputing techniques. Fire Safety J. 127:103492. doi: 10.1016/j.firesaf.2021.103492

Hosseini, S., and Pourmirzaee, R. (2024). Green policy for managing blasting induced dust dispersion in open-pit mines using probability-based deep learning algorithm. Exp. Syst. Appl. 240:122469. doi: 10.1016/j.eswa.2023.122469

Huang, X., and Liu, Y. (2022). Research and design of intelligent mine ventilation construction architecture. Int. J. Low-Carbon Technol. 17, 1232–1238. doi: 10.1093/ijlct/ctac104

Ihsan, A., Cheng, J., Widodo, N. P., Wang, E. Y., Waly, F. Z., Syachran, S. R., et al. (2024a). Hybrid method for analyzing air thermal conditions in underground mines. Exp. Syst. Appl. 245:123026. doi: 10.1016/j.eswa.2023.123026

Ihsan, A., Widodo, N. P., Cheng, J., and Wang, E. Y. (2024b). Ventilation on demand in underground mines using neuro-fuzzy models: modeling and laboratory-scale experimental validation. Eng. Appl. Artif. Int. 133:108048. doi: 10.1016/j.engappai.2024.108048

Jia, J., Li, B., Ke, D., Wu, Y., Zhao, D., Wang, M., et al. (2020). Optimization of mine ventilation network feature graph. PloS ONE 15:e0242011. doi: 10.1371/journal.pone.0242011

Jiang, G., Yin, L., Jin, S., Tian, C., Ma, X., Ou, Y., et al. (2019). A simultaneous localization and mapping (SLAM) framework for 2.5 D map building based on low-cost LiDAR and vision fusion. Appl. Sci. 9:2105. doi: 10.3390/app9102105

Jo, B., and Khan, R. M. A. (2018). An internet of things system for underground mine air quality pollutant prediction based on azure machine learning. Sensors 18:930. doi: 10.3390/s18040930

Karacan, C. Ö., and Goodman, G. V. R. (2008). “Artificial neural networks to determine ventilation emissions and optimum degasification strategies for longwall mines,” in Proceedings of the 12th US/North American Mine Ventilation Symposium. Reno, NV, United States, 9–11.

Kashnikov, A. V., and Kruglov, Y. V. (2022). Estimating energy consumption of mine fans in underground mines in case of uncertainty of fan influence zones. J. Mining Sci. 58, 588–598. doi: 10.1134/S1062739122040081

Kashnikov, A. V., and Levin, L. (2017). “Applying machine learning techniques to mine ventilation control systems,” in 2017 XX IEEE International Conference on Soft Computing and Measurements (SCM) (St. Petersburg: IEEE), 391–393.

Kychkin, A., and Nikolaev, A. (2020). “IoT-based mine ventilation control system architecture with digital twin,” in 2020 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM) (Sochi: IEEE), 1–5.

Lavigne, N. J., and Marshall, J. A. (2012). A landmark-bounded method for large-scale underground mine mapping. J. Field Rob. 29, 861–879. doi: 10.1002/rob.21415

Li, Y. C., Li, J. Q., Deng, C. B., and Liu, R. Z. (2019). Improved algorithm of air quantity calculating resistance based on diagonal subnetwork. J. China Coal Soc. 44, 1147–1153.

Lin, H., Liu, S., Zhou, Z., Xu, P., and Shuang, H. (2022). Prediction method and application of gas emission from mining workface based on STL-EEMD-GA-SVR. Coal Geol. Exp. 50:14. doi: 10.12363/issn.1001-1986.22.04.0218

Liu, H., Mao, S., Li, M., and Lyu, P. (2020). A GIS based unsteady network model and system applications for intelligent mine ventilation. Discr. Dyn. Nat. Soc. 2020, 1–8. doi: 10.1155/2020/1041927

Liu, J. (2023). “Design of mine ventilation system based on BP neural network optimized by GA,” in 2023 8th International Conference on Information Systems Engineering (ICISE). IEEE, 362–365.

Liu, L., Liu, J., Zhou, Q., and Huang, D. (2022a). Machine learning algorithm selection for windage alteration fault diagnosis of mine ventilation system. Adv. Eng. Inf. 53:101666. doi: 10.1016/j.aei.2022.101666

Liu, L., Liu, J., Zhou, Q., and Huang, D. (2023). Influence of sample attributes on generalization performance of machine learning models for windage alteration fault diagnosis of the mine ventilation system. Exp. Syst. Appl. 213:119320. doi: 10.1016/j.eswa.2022.119320

Liu, L., Liu, J., Zhou, Q., and Qu, M. (2021). An SVR-based machine learning model depicting the propagation of gas explosion disaster hazards. Arab. J. Sci. Eng. 46, 10205–10216. doi: 10.1007/s13369-021-05616-5

Liu, Y., Liu, Z., Gao, K., Huang, Y., and Zhu, C. (2022b). Efficient graphical algorithm of sensor distribution and air volume reconstruction for a smart mine ventilation network. Sensors 22:2096. doi: 10.3390/s22062096

Maleki, S., Sotoudeh, F., and Sereshki, F. (2018). Application of VENTSIM 3D and mathematical programming to optimize underground mine ventilation network: a case study. J. Mining Environ. 9, 741–752. doi: 10.22044/jme.2018.6793.1503

Mathatho, S., Owolawi, P. A., and Tu, C. (2019). “Prediction of methane levels in underground coal mines using artificial neural networks,” in 2019 International Conference on Advances in Big Data, Computing and Data Communication Systems (icABCD). IEEE, 1–4.

McPherson, M. J. (2012). Subsurface Ventilation and Environmental Engineering. Cham: Springer Science and Business Media.

Nagesha, K., Chandar, K. R., and Sastry, V. (2016). Prediction of dust dispersion by drilling operation using artificial neural networks. Int. J. Prev. Control Ind. Pollut. 1, 1–13. doi: 10.37628/jpcip.v1i2.78

Nikolaev, A. V., and Klishin, V. I. (2021). Use of natural draught for improvement of airing efficiency in the oil mine production unit. IOP Conf. Series Earth Environ. Sci. 823:012047. doi: 10.1088/1755-1315/823/1/012047

Olkhovsky, D., Zaitsev, A., and Bublik, S. (2024). Study on the influence of radiation heat transfer on microclimatic parameters in the blind heading of a deep potash mine. Int. J. Therm. Sci. 199:108904. doi: 10.1016/j.ijthermalsci.2024.108904

Onifade, M. (2021). Towards an emergency preparedness for self-rescue from underground coal mines. Proc. Safety Environ. Prot. 149, 946–957. doi: 10.1016/j.psep.2021.03.049

Ren, Z., Wang, L., and Bi, L. (2019). Robust GICP-based 3D LiDAR SLAM for underground mining environment. Sensors 19:2915. doi: 10.3390/s19132915

Roy, S., Mishra, D. P., Bhattacharjee, R. M., and Agrawal, H. (2022). Genetic programming for prediction of heat stress hazard in underground coal mine environment. Nat. Hazards 114, 2527–2543. doi: 10.1007/s11069-022-05478-6

Semin, M., and Levin, L. (2023). Mathematical modeling of air distribution in mines considering different ventilation modes. Mathematics 11:989. doi: 10.3390/math11040989

Semin, M. A., Grishin, E. L., Levin, L. Y., and Zaitsev, A. V. (2020). Automated ventilation control in mines. Challenges, state of the art, areas for improvement. J. Mining Inst. 246, 623–632. doi: 10.31897/PMI.2020.6.4

Semin, M. A., and Levin, L. Y. (2019). Stability of air flows in mine ventilation networks. Proc. Safety Environ. Prot. 124, 167–171. doi: 10.1016/j.psep.2019.02.006

Shriwas, M., and Pritchard, C. (2020). Ventilation monitoring and control in mines. Min. Metallurgy Exp. 37, 1015–1021. doi: 10.1007/s42461-020-00231-8

Singh, S. K., Banerjee, B. P., and Raval, S. (2023). A review of laser scanning for geological and geotechnical applications in underground mining. Int. J. Mining Sci. Technol. 33, 133–154. doi: 10.1016/j.ijmst.2022.09.022

Skopintseva, O. V., and Balovtsev, S. V. (2020). Evaluation of the influence of aerodynamic aging of production on aerological risks on coal mines/MIAB. Mining Inf. Anal. Bull. 2020, 74–83. doi: 10.25018/0236-1493-2020-61-0-74-83

Song, Y., Zhu, M., Wei, N., and Deng, L. (2021). Regression analysis of friction resistance coefficient under different support methods of roadway based on PSO-SVM. J. Phys. Conf. Ser. 1:012046. doi: 10.1088/1742-6596/1941/1/012046

Wallace, K., Prosser, B., and Stinnette, J. D. (2015). The practice of mine ventilation engineering. Int. J. Mining Sci. Technol. 25, 165–169. doi: 10.1016/j.ijmst.2015.02.001

Wang, D., Liu, J., Deng, L., and Wang, H. (2022). Intelligent diagnosis of resistance variant multiple fault locations of mine ventilation system based on ML-KNN. PloS ONE 17:e0275437. doi: 10.1371/journal.pone.0275437

Wang, D., Liu, J., Lijun, D., and Honglin, W. (2023). A supervised diagnostic experiment of resistance variable multifault locations in a mine ventilation system. Sci. Rep. 13:5259. doi: 10.1038/s41598-023-32530-7

Wang, J., Xue, Y., Wen, L., and Shi, D. (2024). Optimization of airflow distribution in mine ventilation networks using the modified sooty tern optimization algorithm. Min. Metallur. Expl. 41, 239–257. doi: 10.1007/s42461-023-00895-y

Watson, C., and Marshall, J. (2018). Estimating underground mine ventilation friction factors from low density 3D data acquired by a moving LiDAR. Int. J. Mining Sci. Technol. 28, 657–662. doi: 10.1016/j.ijmst.2018.03.009

Wong, U., Morris, A., Lea, C., Lee, J., Whittaker, C., Garney, B., et al. (2011). “Comparative evaluation of range sensing technologies for underground void modeling,” in 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems. IEEE, 3816–3823.

Wu, F., Chang, X., and Dan, Z. (2019). “A mine ventilation program integrated with gob flow field simulation,” in Proceedings of the 11th International Mine Ventilation Congress. Singapore: Springer, 888–898.

Wu, F., Zhao, H., and Wang, T. (2024). Development and implementation of mine ventilation network calibration using a two-step method. Min. Metallur. Expl. 41, 193–205. doi: 10.1007/s42461-023-00910-2

Xie, L., and Wang, L. (2023). Study on optimization of mine ventilation network characteristic map based on improved GA algorithm. AIP Adv. 13:4417. doi: 10.1063/5.0174417

Xu, R. L., and Tien, J. C. (1993). “Two-dimensional mine characteristic graph for ventilation planning,” in Proceedings of the 6th US Mine Ventilation Symposium. Englewood, CO: Society for Mining, Metallurgy and Exploration Inc.

Xue, Y., Wang, J., and Xiao, J. (2024). Bibliometric analysis and review of mine ventilation literature published between 2010 and 2023. Heliyon. 15:e26133. doi: 10.1016/j.heliyon.2024.e26133

Yang, S., Zhang, X., Liang, J., Xu, N., and Mei, S. (2023). Research on intelligent control of regional air volume based on machine learning. Processes 11:3296. doi: 10.3390/pr11123296

Yi, H., Kim, M., Lee, D., and Park, J. (2022). Applications of computational fluid dynamics for mine ventilation in mineral development. Energies 15:8405. doi: 10.3390/en15228405

Zhai, G., Zhang, W., Hu, W., and Ji, Z. (2020). Coal mine rescue robots based on binocular vision: a review of the state of the art. IEEE Access 8, 130561–130575. doi: 10.1109/ACCESS.2020.3009387

Zhao, D., and Chen, Z. (2022). Study on roadway fault diagnosis of the mine ventilation system based on improved SVM. Min. Metallur. Exp. 39, 983–992. doi: 10.1007/s42461-022-00595-z

Zhou, A., and Wang, K. (2018). Role of gas ventilation pressure on the stability of airway airflow in underground ventilation. J. Min. Sci. 54, 111–119. doi: 10.1134/S1062739118013425

Keywords: mine ventilation, artificial intelligence, air distribution, monitoring systems, ventilation faults, underground fires, shock losses

Citation: Semin M and Kormshchikov D (2024) Application of artificial intelligence in mine ventilation: a brief review. Front. Artif. Intell. 7:1402555. doi: 10.3389/frai.2024.1402555

Received: 20 March 2024; Accepted: 22 April 2024;

Published: 02 May 2024.

Edited by:

Daniel Adomako Asamoah, Wright State University, United StatesReviewed by:

Kwaku Boakye, Colorado State University, United StatesJianwei Cheng, China University of Mining and Technology, China

Copyright © 2024 Semin and Kormshchikov. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mikhail Semin, bWlzaGthc2VtaW5AZ21haWwuY29t

Mikhail Semin

Mikhail Semin Denis Kormshchikov

Denis Kormshchikov