- Department of Civil Engineering, The University of Texas at Arlington, Arlington, TX, United States

Pipes have been used for thousands of years, the first record of copper piping dates to the Egyptians in 3000 BC. In today's time, pipelines play a dramatic role in our everyday life and is a backbone of our society. Replacing and renewing our vast piping system is extremely important to maintain and grow the infrastructure around us. Trenchless methods (TM) can renew pre-existing piping, replace, and offer installation of new pipe(s). Two very common TMs are cured-in-place piping (CIPP) and spray-applied pipe lining (SAPL). These are great alternatives compared to open cut pipeline installation (OCPI) due to minimizing environmental impact and the total cost associated with renewing or replacing a pipe. Owners and engineers involved in a project which contain pipe renewal and or replacement should consider the time and social cost associated with each method. Cost alone should not be the one and only deciding factor. The objective of this review is to compare and contrast CIPP and SAPL pipeline renewal methods with references found over these renewal methods. This will be demonstrated with the use of a table that will consist of these parameters; environmental, mechanical properties, performance, cost, and methods. The method used for selecting specific articles/papers is intended to locate major factors that play a role in pipeline renewal using publications from the past years. Results show that reviewing, comparing, and understanding current research relating to pipeline renewal will allow for safer applications, increased efficiency, and pipeline longevity.

Introduction

Pipelines are a necessity in this day and age and have been for quite some time. Pipes are used for supplying water to our houses, removing sewage, extracting oil and natural gas, and lastly moving gases one location to another. With a vastly expanding world population it is evident that more piping will need to be created and renewed. The majority of preexisting pipes were installed 40–50 years ago and have reached their expected lifetime (CUIRE, 2018).

With this being said the piping industry is not going anywhere and demands are only going to increase. Traditional open cut pipe lining methods negatively impact the environment and is not the most cost-effective renewal method. This is because many tasks go into open cut such as fabrication, heavy duty vehicles for transportation and a lot of manpower, reducing all of these will reduce costs and improve productivity (Figure 1).

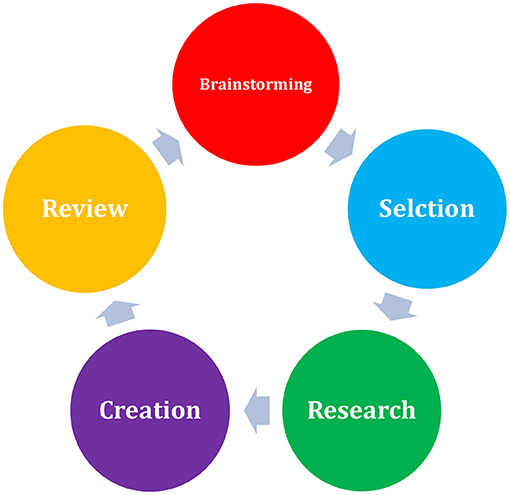

Figure 1. Displaying SAPL & CIPP pipe renewal methods. https://www.trenchless-pipelining.com/miami-epoxy-pipe-lining-company/.

Traditionally replacing a pipe, you must dig a trench that is the entire length of the pipe in question. Along with ensuring that the quality and appropriate material(s) are underneath the new pipe and lastly backfilling the entire distance of the proposed pipe. Trenchless technologies are solutions to common problems with OCPI. Open cut pipe renewal incurs high expenses along with contributing higher fossil fuel and CO2 emissions (Ajdari, 2016). Other common difficulties consist of locating and protecting wires and pipes under the surface of densely populated areas. SAPL & CIPP are alternatives that solve this problem by only needed to inspect a much smaller area to accomplish the same goal. Instead of using an entirely brand-new pipe, a lining will be used to patch and repair any damage causing the pipe to malfunction. Pipe linings consist of coatings or integration of resin-saturated liners and are impeded within the pipe (Kharazmi, 2019) (Figure 2).

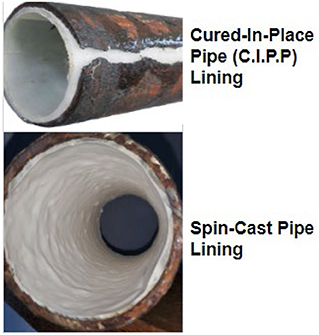

Figure 2. Machine pipe renewal for SAPL. https://www.estormwater.com/pipe-distribution/pipeline-rehabilitation-products.

Linings increase the structural ability which allows a pipe to handle more stress than before and repairing the previous issues. The materials used in the lining process are critical to analyze to ensure proper mechanical properties are meeting the necessary safety and city requirements. Different styles of pipes work better with specific materials and methods. When working on domestic water piping for plumbing fixtures its important to ensure the proper steps are taken to preserve the health and wellbeings of others (CUIRE, 2018).

Trenchless renewal methods avoid disrupting large sections of neighborhoods and cities and prevent lengthy construction times. In doing so traffic accumulation and social costs are kept to a minimum (Argyrou et al., 2018). This is because only a small portion of the pipe is needing to be accessed in order to repair/renew unlike open cut pipe renewal methods. Trenchless pipe lining renewal methods remove much of the headache associated with restoring the much-needed restoration of underground piping systems across North America (Figure 3).

Figure 3. SAPL method used for large conduits. https://www.vector-construction.com/geospray-pipe-and-culvert-lining.

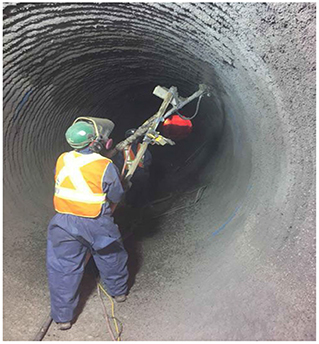

Trenchless CIPP (Figure 4) process involves a liquid thermoset resin-saturated material that is inserted into the existing pipeline by hydrostatic or air inversion, or by mechanically pulling-in and inflating by air or water (Kozman, 2013). The liner material is cured-in-place using hot water, steam- or light-cured using UV light resulting in the CIPP product (Kozman, 2013; CUIRE, 2018; Kaushal et al., 2019a,b). CIPP method can be used effectively for a wide range of applications that include storm and sanitary sewers, gas pipelines, potable water pipelines, chemical and industrial pipelines, and similar applications. The flexibility of uncured material makes CIPP especially suitable for different types of pipe geometries including straight pipes, pipes with bends, pipes with different cross-sectional geometries, pipes with varying cross sections, pipes with lateral connections, and deformed and misaligned pipelines. the old pipe and the like must be assessed before making a choice on the renewal system (Kozman, 2013; CUIRE, 2018; Kaushal et al., 2019a,b). CIPP is also used for localized repairs in a wide range of applications.

Figure 4. Equipment used during the installation of CIPP. https://www.aegion.com/capabilities/cured-in-place-pipe/insituform-cipp.

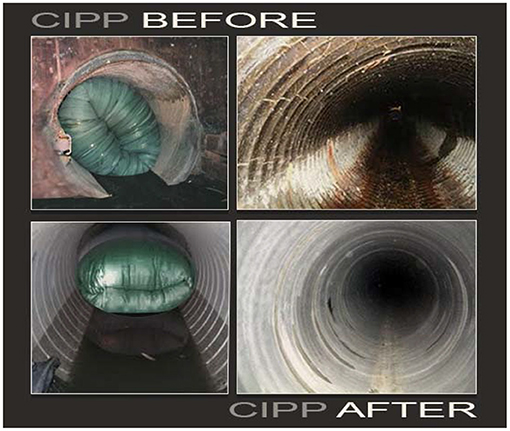

Several factors must be evaluated before choosing CIPP as the method of renewal for an individual project. Space availability, chemical composition of the fluid carried by the pipeline, number of service laterals, number of manholes, installation distance, renewal objectives, structural capabilities of vinyl ester and epoxy resin systems are typically used in industrial and pressure pipeline applications, where their tensile properties, special corrosion resistance, solvent resistance, and higher temperature performance are needed (Donaldson and Baker, 2008; Kampbell, 2009; Donaldson, 2012; Heinselman, 2012). These systems can also be used for sanitary sewers and house service laterals, however, will increase the costs (Zhao and Rajani, 2002; Najafi and Gokhale, 2005; Ajdari, 2016; Alsadi, 2019; Kaushal et al., 2019a) (Figure 5).

Figure 5. CIPP before, during, and after installation. https://www.prweb.com/releases/uspipeliningpressrelease/june2016/prweb13466103.htm.

Spray applied pipe linings (SAPLs) are trenchless technology solutions for large diameter gravity stormwater conveyance conduits rehabilitation that prevent further deterioration, such as corrosion, abrasion, etc., and can provide structural support for severely damaged host pipes.

SAPL is applicable for both fully and partially deteriorated culverts in cases of fully or partially structural, and even in non-structural applications. This review, focused on fully structurally application of using SAPL in a fully deteriorated culvert or drainage system. It is a critical point that knows that a fully deteriorated culvert is not a culvert under/before the collapsing time. A fully deteriorated culvert is still under operation without any sign of structurally or geotechnically problems. If any structurally or geotechnically issues, such as settlement in the road, large deformation of the crown, etc., appeared in culvert periodic investigations, more research must be done prior to select SAPL (Figure 6).

The purpose of this paper is to provide a table differentiating aspects related to CIPP & SAPL covered in various recent publications over these methods. The table created can be used as a guide to locate specific details pertaining to these renewal methods such as environmental impact, dollar cost, means and methods, materials, and mechanical properties. The methodology behind picking these topics were to find and assess the key aspects of pipe renewal as a whole.

Spray-Applied Pipe Lining

Spray applied linings are installed by applying polymeric and cementitious materials on the interior surface of a pipe. The previous mentioned materials can be applied by humans, or pre-programmed technologies depending on the pipe's diameter. Characteristics such as type, and size of a pipe will depict the material and amount being used in the renewal process. For the time being, there is not a standard when approaching SAPL, and the use of soil box testing is approaching the correction (CUIRE, 2018).

The research behind soil box testing is an important component of SAPL and TT to ensure the safety and structurally capabilities after renewal methods have been performed. It provides assurance that after renewal has been completed, there will be less probability of any issues within the short-term period after installation, along with providing an accurate life cycle of the materials used.

When sprayed applied liners are chosen to restore piping related to water functionalities, there is a concern involving human health. Issues may arise if the proper steps are not taken into consideration to prevent problems. As a result, this can negatively impact water sources by having unwanted particles in the supply. In addition, reactions can occur between renewal materials and elements prevalent in the renewed pipe (Donaldson and Whelton, 2012).

On the flip side different material mixtures can be paired together to become insensitive when encountering high moisture areas if properly executed. Polyurea linings can offer quick curing times in only a couple seconds which will rapidly increase productivity in field applications. A downside associated with Polyurea is there are difficulties with repairs and touch ups (O'Donoghue and Datta, 2013). Thickness of applied liners are essential in maintaining a sufficient and safe bonding. The amount used is related to the state the pipe is in.

Typically, a pipe's condition can fall under two categories, partially deteriorated, and completely deteriorated. Based on what category the pipe falls under will determine how much material will be applied (Korky et al., 2022). There is an abundant number of parameters surrounding pipe renewal methods with each offering a great insight into the world of pipe rehabilitation.

By overviewing and understanding the important components going into trenchless technologies, we can learn from previous mistakes. This will allow the pipelining industry to pave the way for upholding ethical and environment friendly materials and methodologies. SAPL is an ideal alternative to open cut and when proper precautions are taken it is an obsolete tool in the toolbox.

Cured-in-Place Pipeline

The invention of CIPP occurred in 1971 and was implemented in foreign countries during the 1970' for commercial and residential applications. CIPP is one of the most widely used pipe renewal methods and applications include water, gas, sewer, and even chemical pipelines. Resin lined fabric tubes typically made from polyester or fiberglass-reinforced is placed inside an existing pipe (Serajiantehrani, 2019).

Methods and materials correlated to cured in place renewal have drastically improved over time. In addition, tracking and calculating potential adverse effects of installation are and have been gaining traction. This has been made possible through extensive research and testing with procedures such as TRACI. TRACI is a tool for reduction and assessment of chemicals and other environmental impacts. A few categories tracked by this tool are ozone depletion, global warming, and smog (Kaushal and Najafi, 2020).

By understanding and evaluating possible installation repercussions knowledge can be gained and preventative measures can be taken. This will allow for innovation and continued research to further improve an already outstanding pipe renewal method (CIPP) restores pipes usually within the 0.10–2.80 meters (2–110 inches) range (Mitchell, 2020). Pipe rehab can often be challenging due to abnormal pipe configurations and site conditions. Providing technologies that are able to condense and demonstrate pipe renewal scenarios will allow for accurate steps to be taken before using the (CIPP) method (Matthews, 2013).

Based on testing for CIPP the standard life expectancy is estimated to be 50 years, and, in some cases, it surpasses it. Being able to have an accurate approximation for the design life of materials making up liners will allow maintenance and future renewal to be predictable (Ji et al., 2018).

The objective of this paper is to provide information pertaining to (CIPP) & (SAPL) which will be presented in the format of a table. The table will contain key aspects correlated to the previous mentioned pipelining renewal methods. Parameters will be set in place and were chosen for the reason being they are driving factors that influence the decision-making process. This can be used as a navigation tool to find details quickly across numerous references.

Methodology

The articles used within this paper discuss critical focal points directly associated with the pipeline renewal methods SAPL & CIPP. Articles were found by using Google Scholar and selection was based on relevant and up to date findings. The goal is to provide accurate research and reviews to maintain a high level of credibility.

The method used to assess and compare SAPL & CIPP will be prepared in a table to clearly observe the main talking points within the articles listed. The beginning phases consisted of choosing topics of discussion and after examination SAPL & CIPP became the central focus of this paper. The next step was to locate and review serval papers and publications along with narrowing down the number of parameters. Once articles were reviewed the primary elements were summarized and appropriately characterized. This was done for the purpose of organization and acting as an apparatus for designated references.

Constructing the table accompanied by formatting this paper was one of the last steps, using the parameters previously selected became the constraints within the table. The finalized parameters used in the table are deemed as the major influences that affect the decision-making process for pipeline renewal. Every (x) within the table represents a parameter discussed within the specific article noted on the left-hand side. The paper was structured with the intention of clearly expressing the properties and background correlated to SAPL and CIPP. After months of research, we concluded that providing a comprehensive review would become our contribution and purpose of this paper.

Table 1 shows the parameters along with the symbols correlated with them.

Table 1. Symbols of the parameters used in Table 2.

Comparative Review of SAPL and CIPP

Table 2 has SAPL & CIPP being the main focus of the comparative review with a deep dive into the parameters below. This review offered great insight into various avenues across spray applied and cured in place pipelining renewal methods (Table 2).

This was accomplished by finding similarities and differences along with the pros and cons within each parameter. The articles used within Table 2, discuss multiple talking points, a X will signify that it was a key component in the article listed. Reviewing and comparing is a beneficial tool in order to understand and seeing various points of view which in turn can help formulate an opinion or finalizing a decision.

Conclusions

Linings increase the structural ability which allows a pipe to handle more stress than before and repairing the previous issues. The materials used in the lining process are critical to analyze to ensure proper mechanical properties are meeting the necessary safety and city requirements. Different styles of pipes work better with specific materials and methods. Project owners, decision makers, and contractors commonly take into consideration the construction costs only, and sometimes overlook the environmental and social cost aspects while making a choice between different trenchless renewal methods. Spray applied and cured in place renewal methods are a staple within the renewal pipe lining industry and will continue to be so. By diving deep into the vast realm of pipe renewal methods it was decided to create a comparative review which can be a useful tool in navigating dominant characteristics of SAPL & CIPP.

The table developed in this paper helps highlight major talking points within various articles on SAPL & CIPP from various authors and publishers. The information presented within this review shows that by understanding and improving the current standards for SAPL & CIPP that human health, environmental impact, infrastructure, and cost will be of great value to everyone. Reviewing, comparing, and understanding current research relating to pipeline renewal will allow for safer applications, increased efficiency, and pipeline longevity. By doing so we can reach beyond the current scope and ideals recognized by the vast majority of the pipe rehabilitation industry and continue to improve the quality of life for generations to come.

Recommendations for Future Research

Further comparisons can offer great insight and details over topics surrounding pipeline renewal methods. Two directions could be narrowing down to one method and or evaluating a smaller or larger number of parameters. Another option could be reviewing more methods across a larger number of constraints for a broader overview. Constructing a number of various comparative analyses will provide a great resource to locate various topics of interest within the scope of pipe rehabilitation. In doing so it will act as a central hub of information and will help aid anyone starting out or continuing their research in this field.

Author Contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adebola, T. (2019). “Service performance of a cured in place polymer pipe liner for deteriorated cast-iron pressure pipes,” in Home. Available online at: https://qspace.library.queensu.ca/jspui/handle/1974/27480 (accessed November 12, 2021).

Ajdari, E. B. (2016). “Volatile organic compound (VOC) emission during cured-in-place-pipe (CIPP) sewer pipe rehabilitation,” in ScholarWorks@UNO. Available online at: https://scholarworks.uno.edu/td/2126/ (accessed November 12, 2021).

Alsadi, A. (2019). Evaluation of Carbon Footprint During the Life-Cycle of Four Different Pipe Materials. Ph.D. Dissertation, Louisiana Tech.

Argyrou, C., Bouziou, D., O'Rourke, T. D., and Stewart, H. E. (2018). Retrofitting pipelines with cured-in-place linings for earthquake-induced ground deformations. Soil Dyn. Earthq. Eng. 115, 156–168. doi: 10.1016/j.soildyn.2018.07.015

Bakry, I., Alzraiee, H., Masry, M. E, Kaddoura, K., and Zayed, T. (2016). Condition prediction for cured-in-place pipe rehabilitation of Sewer Mains. J. Perform.Constr. Facil. 30.

CUIRE (2018). Evaluation of potential release of organic chemicals in the steam exhaust and other release points during pipe rehabilitation using the trenchless cured-in-place pipe (cipp) method. Final Report, NASSCO's Phase 1 CIPP Steam Emissions Study.

Das, S., Bayat, A., Gay, L., Salimi, M., and Matthews, J. (2016). A comprehensive review on the challenges of cured-in-place pipe (CIPP) installations. J. Water Supply. Res. Technol. Aqua 65, 583–596. doi: 10.2166/aqua.2016.119

Donaldson, B. (2012). Water Quality Implications of Culvert Repair Options: Vinyl Ester Based and Ultraviolet Cured-in-Place Pipe Liners. Virginia Center for Transportation Innovation & Research, Virginia.

Donaldson, B. M., and Baker, A. (2008). The Environmental Implications of Cured-in-Place Pipe Rehabilitation. VTRC 08-CR12, Virginia Transportation Research Council, Charlottesville.

Donaldson, B. M., and Whelton, A. J. (2012). “Water quality implications of culvert repair options: cementitious and polyurea spray-on liners,” in Welcome to ROSA P, Virginia Center for Transportation Innovation and Research. Available online at: https://rosap.ntl.bts.gov/view/dot/25491 (accessed November 12, 2021).

Heinselman, W. (2012). The History of Cured-in-Place-Pipe Lining in the United States, Express Sewer & Drain.

Ji, H. W., Yoo, S. S., Kim, J., and Koo, D. D. (2018). “The mechanical properties of high strength reinforced cured-in-place pipe (CIPP) liner composites for urban water infrastructure rehabilitation,” in MDPI (Multidisciplinary Digital Publishing Institute). Available online at: https://www.mdpi.com/2073-4441/10/8/983 (accessed November 12, 2021).

Kampbell, E. (2009). Understanding Environmental Implications of CIPP Rehab Technology. Rehabilitation Technology, Underground Technology Cutting Edge Technical Information for Utility Construction and Rehabilitation.

Kaushal, V., and Najafi, M. (2020). Comparative analysis of environmental and social costs of trenchless cured-in-place pipe renewal method with open-cut pipeline replacement for sanitary sewers. J. Pipeline Syst. Eng. Pract. 11. doi: 10.1061/%28ASCE%29PS.1949-1204.0000480

Kaushal, V., Najafi, M., Sattler, M., and Schug, K. (2019a). “Evaluation of potential release of organic chemicals in the steam exhaust and other release points during pipe rehabilitation using the trenchless cured-in-place pipe (cipp) method,” in Proc. North American Society for Trenchless Technology-No-Dig Conference (Chicago, IL).

Kaushal, V., Najafi, M., Sattler, M., and Schug, K. (2019b). “Review of literature on chemical emissions and worker exposures associated with cured-in-place pipe (CIPP) installation,” in Proc. ASCE Pipelines 2019 (Nashville, TN).

Keresten, A., Ostanin, S., and Zuev, V. (2021). Advanced liquid epoxy and polyurethane materials: internal and external coatings for pipeline and tubing protection. E3S Web Conf. 225, 05004. doi: 10.1051/e3sconf/202122505004

Kharazmi, P. (2019). Experimental assessment of the state of the lining materials used in the rehabilitation of sewers in residential buildings. Case Stud. in Constr. Mater. 11, e00291. doi: 10.1016/j.cscm.2019.e00291

Korky, S. J., Najafi, M., Kaushal, V., and Serajiantehrani, R. (2022). State-of-the-Art Review on Application of Spray-Applied Pipe Linings in Gravity Stormwater Conveyance Conduits. Journal of Pipeline Systems Engineering and Practice, 13, 03122001.

Kozman, D. P. (2013). Evaluation of Cured-in-Place Pipe Allows Structural Renewal of Drinking Water Pipe. R S Technik LLC.

Matthews, J. (2013). Sewer rehabilitation using an ultraviolet-cured GFR cured-in-place pipe. Pract. Period. Struct. Design Construct. 20.

Mitchell, C. (2020). “Investigation into the process of cured-in.. - pearl home,” in Investigation Into the Process of Cured-in-Place Pipe Sewer Rehabilitation. Available online at: https://pearl.plymouth.ac.uk/bitstream/handle/10026.1/16514/TPSS-2020-Vol13n1_290-327Mitchell.pdf?sequence=1andisAllowed=y (accessed November 12, 2021).

Najafi, M., and Gokhale, S. B. (2005).Trenchless Technology: Pipeline and Utility Design, Construction, and Renewal. New York, NY: McGraw-Hill.

O'Donoghue, M., and Datta, V. (2013). Titans of the abyss: polyurethane, polyurea, and hybrid lining technology. J. Prot. Coat. Linings.

Serajiantehrani, R. (2019). “Development of a machine learning-based prediction model for construction and environmental costs of trenchless spray-applied pipe linings, cured-in-place pipe, and sliplining methods in large diameter culverts,” in ResearchCommons Home. Available online at: https://rc.library.uta.edu/uta-ir/handle/10106/28867 (accessed November12, 2021).

Siringi, D. O. (2016). “Testing and design life modeling of polyurea.. - iekenya.org,” in Testing and Design Life Modeling of Polyurea Liners for Potable Water Pipes. Available online at: https://www.iekenya.org/forms/papers/IEK_CONF_2015_4.4_PAPER_SIRINGI.pdf (accessed November15, 2021).

Zhao, J. Q., and Rajani, B. (2002). Construction and rehabilitation costs for buried pipe with a focus on trenchless technologies. Final Report, Institute for Research in Construction National Research Council Canada, Ottawa, Canada.

Keywords: spray applied pipe lining (SAPL), cured in place pipelining (CIPP), open cut pipeline installation (OCPI), trenchless technologies (TT), pipelines

Citation: Hicks J, Kaushal V and Jamali K (2022) A Comparative Review of Trenchless Cured-in-Place Pipe (CIPP) With Spray Applied Pipe Lining (SAPL) Renewal Methods for Pipelines. Front. Water 4:904821. doi: 10.3389/frwa.2022.904821

Received: 25 March 2022; Accepted: 06 May 2022;

Published: 21 June 2022.

Edited by:

Abbas Roozbahani, University of Tehran, IranReviewed by:

Katarzyna Pietrucha-Urbanik, Rzeszów University of Technology, PolandHongyuan Fang, Zhengzhou University, China

Copyright © 2022 Hicks, Kaushal and Jamali. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Vinayak Kaushal, VmluYXlhay5rYXVzaGFsQHV0YS5lZHU=

John Hicks

John Hicks Vinayak Kaushal

Vinayak Kaushal Koosha Jamali

Koosha Jamali