95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. , 02 October 2023

Sec. Circular Economy

Volume 4 - 2023 | https://doi.org/10.3389/frsus.2023.1243374

Circular economy has become a prominent topic in scientific discourse and has gained significant presence as a strategic factor for business and industry. Both, as crucial enabler of a sustainable economy, and as lever for overcoming resource dependencies. Previous studies have identified multiple benefits of implementing circular principles, as well as enablers for a transformation to circular economy. However, studies with a focus on a specific industry and regional context that offer practical guidance for the transformation to a circular economy are still somewhat underrepresented. This paper addresses this gap by analyzing major obstacles to a transformation to circular economy, in the context of the Austrian manufacturing industry. It is based on a literature review, in which 369 articles were reviewed, complemented by a structured online survey in which 229 managers from 192 companies in the manufacturing industry participated. In the survey, the obstacles were ranked according to their relevance on two levels: assessing 10 clusters of obstacles on a higher level, followed by a deep-dive evaluation of specific obstacles within the clusters. Based on the research findings, it is evident that the circular economy plays a significant role in long-term corporate success and most surveyed companies recognize its strategic importance. The results also reveal that market and customer demand are the biggest drivers of a transformation to circular economy, followed by general concerns about the environment and regulatory pressure. The biggest barriers on the way toward circular economy are the need for more financial government support, challenges with setting up an effective circular supply chain, economic challenges resulting from customer behavior and barriers in the redesign of products. The interdisciplinarity of the challenges leads to a high complexity in the transformation process. This means that most of the major barriers are external, and therefore companies cannot tackle these barriers by themselves. Governments should consider developing more incentive systems to support companies in their transition to the circular economy. To effectively navigate the transition, companies should adopt integrated strategies that encompass supply chain optimization, in-depth analysis of customer buying behaviors, and investment in sustainable and recyclable product design.

The simultaneously increasing world population and demand for natural resources are having devastating effects on the environment (Haunss and Sommer, 2020). Politicians come together to define targets like the Paris Agreement or the Sustainable Development Goals to counteract negative environmental development (Hák et al., 2016; Moser et al., 2021; United Nations, 2021). In this situation, the industry plays an important role and is advised to produce and consume in a more responsible way (Hák et al., 2016). As a result, the current linear economic system is under scrutiny, posing the question of how primary resources can be replaced by recycled materials or reusable components (Korhonen et al., 2018). The common linear economic system (take-make-waste) is generally defined by raw material extraction from the environment and subsequent processing, use and disposal (Otekenari, 2020). Numerous drawbacks result from this linear approach like losing valuable resources or reducing biodiversity (Walcher and Leube, 2017).

The origin of the circular economy which dates back as far as 1966 is one solution to this problem (Lotz et al., 2021). Materials and end-of-life products that are already available in the economic system are used as resources for new production processes (Fellner et al., 2017). This decouples the consumption of finite resources from economic activities and enables, that products and materials can circulate to minimize emerging waste (Scheel et al., 2020; Pieroni et al., 2021). An endless and efficient flow of materials is created in which waste is seen as a valuable resource (Ghisellini et al., 2016; Röhr, 2021).

The circular economy is also gaining increasing academic and political attention, and new processes are defined and broken down (Walcher and Leube, 2017). The core activities of the circular economy to reorientate the economic system are described as the 10 R strategies of circular economy (D’Amato, 2021). The R strategies “Refuse,” “Rethink” and “Reduce” focus on smarter product use and manufacturing (Hermann and Vetter, 2021). “Reuse,” “Repair,” “Refurbish,” “Remanufacture,” and “Repurpose” explore options to extend the lifespan of a product and its parts (Venturini, 2021). Finally, “Recover” and “Recycle” aim at the reclamation of raw materials or energy from end-of-life products (Vermeulen et al., 2019).

In special consideration of the politics in Austria, an Austrian Circular Economy Strategy was defined, to support companies from different branches in the transformation process (Jacobi et al., 2018; Hauer et al., 2020; Lotz et al., 2021). The Environment Agency Austria outlined 600 concrete measures which contribute to the development of the Austrian Circular Economy Strategy 2050 (Schally, 2018; Angelini et al., 2021; Schöggl et al., 2022). The Austrian strategy goes along with the initiative of the European Union to achieve carbon net neutrality in 2050 (Madeddu et al., 2020; Tillner and Peverini, 2021). There are different measures that the European Union focuses on to reach this target, besides changing the habits and lifestyle of the end-users, technological change, CO2 capturing and storage plus the transformation to the circular economy are important topics (Rodrigues et al., 2022). The circular economy approach should predominantly support the industrial sector, which accounts for 11.4% of the greenhouse gas emissions in Austria in 2020 (Zechmeister et al., 2022), to reduce their CO2 emissions and resource consumption and become more independent, resilient, and economically successful in the long term (Hysa et al., 2020).

The potential of the circular economy is increasingly recognized by society and companies, as more than 80% of the participants of an Austrian survey think that the circular economy will have an impact on their organization in the coming years (Huber-Heim and Kronenberg, 2019). Nonetheless, companies face different obstacles in the process of closing the loops and as a result, the level of implementation is low (Sharma et al., 2021; Kara et al., 2022). There is still a lack of knowledge about circular economy in Austria. In an Austrian survey more than 60% of the participants from politics, education and economy indicate that they would need more information about the circular economy (Huber-Heim and Kronenberg, 2019). Furthermore, a missing separation between the circular economy and waste management is highlighted (Huber-Heim and Kronenberg, 2019; Schöggl et al., 2022). Achieving circular products requires systems thinking on a larger scale beyond waste management. Aspects include eco-design, efficient production, intensive use of products (Bengtsson et al., 2018), extension of the life cycle of products and a purposeful recovery of materials (Walsh, 2010). The companies cannot meet these requirements due to processes being fixated on consumption and not on the strive for maximum economic benefits (Sousa-Zomer et al., 2018; Dieckmann et al., 2020).

In Austria just only about 10% of the economy is structured according to the principles of the circular economy. The circular material use rate, which quantifies the percentage of material recovered and redirected into the economy system, in 2017 in Austria was at 11.6% (European Commission, 2018), thus just over the EU27 average of 11.5% (while the Netherlands scored highest with 29.7%) (European Commission, 2018). Raw material consumption per capita in Austria in 2017 was 33 tons while the EU-28 average was 23 tons (Eisenmenger et al., 2020). In general, the Environment Agency Austria considers that the Austrian economic system has a good recycling performance (Frischenschlager et al., 2010; Salmenperä, 2021). However, the areas of repair, reuse, refurbish are underdeveloped resulting in a drastic overall need to reduce consumption of primary raw materials (Perstel and Hölzl, 2014; Wieser and Tröger, 2018; Moser et al., 2021).

The question arises why the Austrian industry cannot take on a leading role in terms of the circular economy. Given the worldwide gap between the potential of the circular economy and its level of implementation, which can also be observed in Austria, practical and theoretical approaches to implementing circular principles deserve great attention. However, there are numerous gaps in the existing research regarding practical barriers to the implementation of a circular economy (Kirchherr et al., 2017). The existing literature offers a solid theoretical framework for implementing a circular economy, but repeatedly fails to:

• sufficiently consider or describe barriers to implementation (Rieg et al., 2019),

• present important practical details for individual companies or in specific economic sectors with their particular challenges (Hina et al., 2022),

• focus on and differentiate between specific geographical areas, meaning that scientific findings cannot necessarily be applied to a European or Austrian context (Agrawal et al., 2021).

This paper addresses these research gaps by analyzing and prioritizing the main challenges on the path from a linear economy to a circular economy for the Austrian manufacturing industry. This is of particular interest when looking at the structure of manufacturing companies in Austria, where it is shown that the industry is responsible for 45% of the revenue of manufacturing companies (Statistik Austria, 2020). Therefore, in the following paper the research questions are answered:

• What are the biggest challenges on the way from a linear economy to a circular economy for the Austrian manufacturing industry?

• What are the reasons for the strategic importance and the change from a linear to a circular economy?

Therefore, in this paper, the main barriers from a literature review are outlined and clustered. Furthermore, a survey (the survey can be viewed in Supplementary material) for Austrian companies was conducted to rank the defined barrier clusters and barriers. The methodology and procedure, the results and the discussion of the survey are described in the following chapters to prioritize the barriers on the way to the circular economy.

A systematic literature review and qualitative content analysis are conducted to provide an overview of the current situation in the transition from linear economy to circular economy. Known challenges and barriers on the way to a circular economy are identified and listed (Gläser-Zirkuda, 2011; Bayer et al., 2021).

The methodology of the systematic literature review is separated into the steps of the definition and linkage of search terms, the research on databases and the selection and classification of the found papers (Barbosa-Póvoa et al., 2018). Since the focus of the research is on the state of the art of the barriers to the circular economy in the manufacturing industry, the keywords were defined and linked with Boolean operators to restrict the findings to the research question (Bayer et al., 2021). ScienceDirect, Scopus and Google Scholar were used as databases and the search terms are adapted to the restrictions of the respective input masks. As an example, the inputs in the database ScienceDirect are shown: (“circular economy” OR “CE”) AND (implementation OR realization OR application) AND (“manufacturing industry” OR manufacturing) AND (challenges OR barriers). The search terms were found in the title, abstract or the keywords of the article. As you can see in Figure 1, overall, 369 articles from the three databases were considered. In the first round of screening the titles and abstracts were read. After this step and the elimination of double entries, 73 articles remained. In the second round of screening, the whole papers were read and 43 articles with different barriers were found. These papers were the basis for the final third screening round, during which articles were classified by their relevance (Mark et al., 2021). The criteria of the evaluation are listed here and only papers with high relevance are considered afterwards for the qualitative literature analysis.

i. Low relevance: 9 articles only deal with superficial or isolated barriers and are therefore rejected.

ii. Medium relevance: 12 papers cover some barriers, but these challenges can also be found in the high relevance papers.

iii. High relevance: 22 papers show barriers and challenges on the way to the circular economy on different levels.

Hence, 22 articles and their corresponding barriers, are the basis for the qualitative literature analysis, in which, at first, the level of analysis for the barrier examination was determined (Gläser-Zirkuda, 2011). The challenges were divided into specific barriers and barrier categories. Thereby the focus is on the specific barriers, whereas the categories are just used for a back-check of the own clustering afterwards. The challenges are unified by using macro operators like generalization, bundling or skipping (Gläser-Zirkuda, 2011). As a result, 485 barriers from the 22 papers were elaborated by paraphrasing. In a second reduction step, these barriers are examined for their relevance, and similar descriptions of specific obstacles were bundled into new statements (Gläser-Zirkuda, 2011). The new statements were clustered in terms of content. These generated categories were then cross-checked with the categories from the literature (Mayring and Gläser-Zikuda, 2008). Figure 2 shows the detailed methodology of the literature review.

A total of 485 challenges were identified in the examined papers, which were then standardized so that 57 key challenges on the path to a circular economy were defined and queried through a subsequent survey. The barriers were furthermore clustered into 10 barrier categories. The 22 papers examined show above all that the authors describe the challenges at different levels.

Hina et al. focus on the definition of barrier categories. In this paper 11 categories are established and divided into internal and external barriers. In a continuous text these categories are defined and examples of in-depth challenges are given (Hina et al., 2022). Salmenperä et al. made a stronger differentiation between the level of detail of the analysis of the challenges. In this paper the challenges are separated in categories (e.g., “Technological and information-related barriers”), sub-categories (e.g., “Information exchange”) and specific barriers (e.g., “Business secrecy poses a challenge for exchange of data”) (Salmenperä et al., 2021). Other than Salmenperä et al. who chose three levels of distinction, Sousa-Zomer et al. or Kumar et al. only separate between categories and specific challenges (Sousa-Zomer et al., 2018; Kumar et al., 2019). Agyemang et al. take an even more general categorization of the challenges. The specific barriers, which are mentioned in the paper are only divided into internal and external barriers (Agyemang et al., 2019). Agrawal et al., Jaeger and Upadhyay or Werning and Spinler are limited to the listing and analysis of specific barriers and do not consider any categories or clustering (Jaeger and Upadhyay, 2020; Werning and Spinler, 2020; Agrawal et al., 2021).

In this research paper, the 57 key challenges are grouped into 10 challenge categories. Six of these categories concern challenges that occur within the company, the so-called internal challenges (barriers of corporate strategy and policy, financial barriers, technological barriers, barriers in product material and design, barriers in the transformation process, barriers with internal stakeholders and resources). Four categories include challenges that are faced outside the company, the so-called external challenges (barriers regarding cooperation, barriers in the supply chain, barriers due to regulatory environment, social and consumer barriers).

In the following section, first, the six categories with internal challenges and then the four categories with external challenges are briefly described.

Corporate strategies and policies are important cornerstones for the successful implementation of the circular economy and a corresponding business model (Lieder and Rashid, 2016). The absence of a corporate strategy aiming at circular economy limits organizations in effective implementation (Bhandari et al., 2019).

A company’s transition to a circular economy requires massive investments in for example technological projects, adaptation of the company structure, production, and distribution of circular products (Kumar et al., 2019). Consequently, companies are reluctant to invest in circular projects. Furthermore, sustainable profitable business models in the circular economy are neither routinely tested nor widespread (Garcés-Ayerbe et al., 2019).

Technology is a core element of the circular economy and an essential prerequisite for its implementation. The lack of technological capacity of organizations and the lack of external availability to access such resources have proven to be barriers to circular economy implementation (Agyemang et al., 2019; Bhandari et al., 2019).

Product material and design are important factors in meeting the challenges of the circular economy. The characteristics of certain materials do not allow for substitution without compromising product quality. In addition, circular products pose special design challenges, such as avoiding the use of adhesives or the reusability of product elements (Lieder and Rashid, 2016; Braun et al., 2021).

The key to a successful implementation of the circular economy is that it takes a prominent role in an organization’s agenda. Lack of organizational prominence can be a significant barrier to the transformation, given the complexity of and expertise needed in implementing the circular economy (Agyemang et al., 2019; Agrawal et al., 2021).

Various internal stakeholders such as shareholders, employees, works councils, etc. have an influence on the transformation to a circular economy (Lieder and Rashid, 2016). Closely linked to the stakeholders are the internal resources that can be contributed to the implementation of the circular economy. Lack of commitment from internal stakeholders to implement a circular economy, even with sufficient resources, can hinder the successful implementation of circular economy (Rizos et al., 2016).

Cooperations facilitate the implementation of technologically demanding and capital-intensive changes. Key challenges with regard to the circular economy include setting cooperative incentives and creating win-win scenarios for the partners involved, whether between partner companies or when communicating the promised offer to consumers (Sousa-Zomer et al., 2018). A lack of equal willingness to cooperate is therefore an obstacle (Agyemang et al., 2019).

Successful implementation of a circular economy requires a high level of partnership integration along the supply chain (Kumar et al., 2019). Diverse factors in supply chain management act as barriers: complicated business patterns, lack of transparency, low trust, incompatibility of partners, implementation of reverse logistics, uncertainty of material flow, etc. (Rizos et al., 2016; Prajapati et al., 2019).

The regulatory environment is oriented toward a linear economic system and does not serve the requirements of a circular economic model. The lack of uniform legislative regulations and government incentives currently impede implementation of efforts toward a circular economic system (Kumar et al., 2019; Salmenperä et al., 2021).

A circular economy expects consumers to dynamically participate in the reuse of products, change their throwaway culture, and thus form an awareness of sustainability (Prajapati et al., 2019). Consumers may perceive circular products to be of lower quality. In addition, there is a preference for traditional purchasing among some customer groups and an aversion to simply using products (product-as-a-service model) (Werning and Spinler, 2020).

Table 1 lists the 57 different barriers on the path to the circular economy, with reference to the source. The described categories were defined by the clustering of the challenges and the backtesting with the categories from the literature review. These barriers form the basis for the rest of the study.

As the listing and clustering do not yet provide any information about the significance of the challenges for the Austrian manufacturing industry, a survey is conducted to prioritize the challenges. The target group of the study is exclusively employees from companies in the Austrian manufacturing industry, to ensure the industry focus and the regional focus in the prioritization.

This study is based on a survey of Austrian companies from the manufacturing industry, conducted with the online software Limesurvey. The predominant aim of this study is to prioritize the barrier clusters and barriers within these clusters that have been identified from the literature. Additionally, the study assesses to what extent circular principles are already integrated into operational processes. These findings will then be compared to the companies’ own assessment of how important circular principles will be to its own long-term success.

The structure, is aligned with survey design theory of Groves, progresses from general to more specific queries (Groves, 2009). This gradual approach enhances participant comfort and engagement, thereby increasing the validity of responses (Groves, 2009). The first section collects basic data while also assessing the strategic relevance and degree of implementation of the circular economy in the companies. The second and third sections contain the main part of the survey which is built on a 5-part Likert scale (Joshi et al., 2015). In these sections, the barriers on the way to circular economy are ranked by the survey participants. While in the second section the individual barrier cluster are classified according to their relevance, in the third section an in-depth look at the challenges within these categories is provided. In the fourth section, survey participants are asked what motivates companies to incorporate circular economy into their operational processes.

The survey was designed using a mixed-methods approach according to Creswell and Plano Clark (2018). Sections two and three utilize quantitative methods using a Likert scale. This provides measurable, numerical data that can be statistically analyzed. In contrast, section four uses qualitative methods, asking open-ended questions. This approach was chosen to offset the limitations of each individual method, facilitating a broader, more nuanced understanding of the challenges faced by Austrian manufacturing companies. Not only does this mixed-methods approach enhance the depth and breadth of findings, it also offers flexibility, allowing for varied interpretations from the same dataset (Creswell and Plano Clark, 2018).

The barriers are classified by the participants according to the Likert scale where numerical values of a metric scale are assigned to the individual answer options, which are equated to a point system for ranking purposes (Baggaley and Hull, 1983; Maurer and Pierce, 1998). The answer options are “no relevance (0),” “low relevance (Haunss and Sommer, 2020),” “relevant (Hák et al., 2016),” “very relevant (Moser et al., 2021),” and “highly relevant (United Nations, 2021).” Based on this value assignment, the collected data is evaluated, weighted averages are calculated, and the barriers are ranked (Maurer and Pierce, 1998).

The survey is aimed exclusively at companies from the Austrian manufacturing industry, which encompasses a total of 2,574 firms, and only data from these relevant sector companies are included in the evaluation (Statistik Austria, 2021). Within the scope of this study, 1,002 companies were engaged during the data acquisition process. From the 1,002 companies contacted in the study, a sum of 229 individuals, representing 192 distinct companies, responded, and actively participated in the survey. The Dillman formula was used to assess representativity of the Austrian population of manufacturing firms (Dillman, 2007). This allows for generalization of the results at a 95% confidence level, with a margin of error of ±6.8%, affirming satisfactory generalizability for this study. The respondents’ affiliations were confirmed, either by directly inquiring about the company’s name at the conclusion of the survey or in cases of early termination. This was further substantiated by verifying additional company details such as business sector, headquarters location, and company size. These respondents completed, at the very least, the initial set of questions. This represents a response rate of 19.12%. The acquisition phase was structured, spanning 2 months, and ensuring a representative and robust data set for analysis. The individuals are classified according to the degree of completion of the survey, with only fully completed sections being considered. A total of 188 participants assessed 10 barrier clusters and 152 of them also rated the individual challenges while 142 persons of the respondent pool disclosed their drivers for transformation.

In the first section of the survey, the demographic information of the participants was elicited. It was specified which business sector the company (that the survey participants are employed in) is active in, what size the company is in terms of the number of employees, and where the company is located. Furthermore, the field of activity and the position of the participants in the company was asked. Table 2 displays the evaluation of this section, whereas only Austrian companies are considered.

As shown in Table 2, in addition to classic manufacturing industry sectors, such as mechanical engineering and the automotive industry, the steel industry, electrical engineering & electronics, plastics technology, and the metalworking industry are also strongly represented. Almost 2/3 of the participating companies are considered as large companies with over 250 employees. The participants are mostly from the management sector of the companies and over 2/3 have a leading position in the company.

The survey aims to look at the circular economy in the Austrian manufacturing industry from different perspectives. The paper briefly examines which level of importance Austrian companies attribute to circular economy and whether they already initiate concrete steps in the transformation process. Additionally, the main part of the survey aims at identifying the major barriers that hinder Austrian manufacturing companies along their transformation to a circular economy.

Due to the different nature and type of these two research questions, different evaluation methods and diagrams were chosen for the presentation of the results.

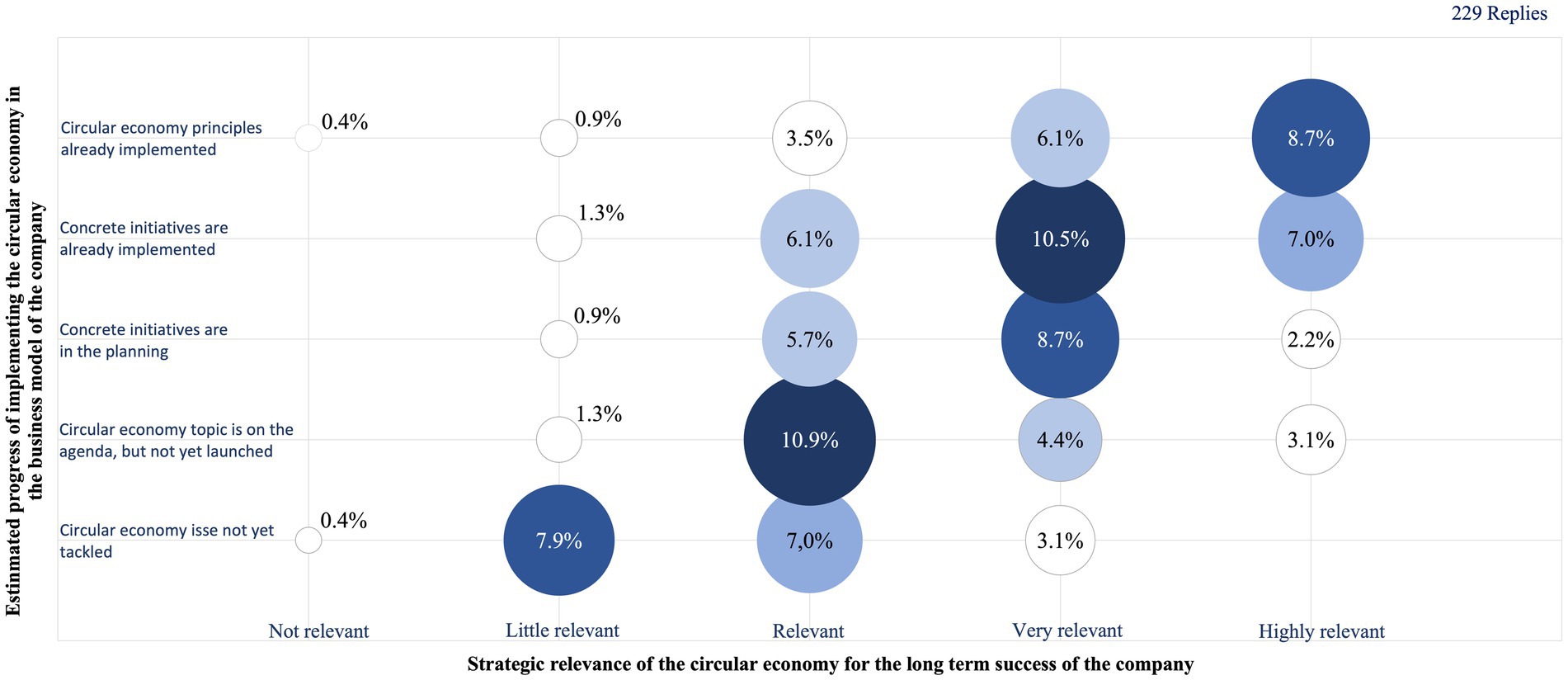

In the first part of the survey with 229 replies, the strategic relevance attributed to the circular economy for the long-term success of the company and the progress in implementing the circular economy in the respective company is assessed. The results are shown in one diagram, which links both questions.

In the bubble chart in Figure 3 the horizontal axis shows the distribution of the answers to the question about strategic relevance whereas the vertical axis sums up the results from the question about the progress in the implementation of circular economy. The size of the bubbles represents how many participants chose a distinctive answer combination.

Figure 3. Comparison of the progress and the relevance of circular economy in Austrian manufacturing industry.

The study shows that around 87% of the participants attribute relevance to high relevance to the long-term success of the company to the circular economy. Nevertheless, more than 1/4 of these companies (27.5% of the total responses) have not yet taken any planning steps or concrete activities in the direction of circular economy. Another 1/6 of these companies (16.6% of all participants) attribute strategic relevance to high relevance to circular economy and are already in the planning process but have not yet taken the step into implementation. Around 13% of the participants attribute little to no strategic relevance to the circular economy for the company’s success.

When asked about the motivation for implementing a circular economy, participants had the option to select up to 3 answer options. In total 400 replies from 142 participants for this section of the survey were collected. The drivers of circular economy in Figure 4 are ranked by the percentage of collected answers for each response option.

“Customer request for a circular economy” is at the top of the list. The second most frequently stated reason is “concerns about the environment” from the perspective of the companies as market players, followed up by “regulatory pressure.” “Pressure from the supply chain” ranks last.

The main part of the survey deals with the barriers on the way to a circular economy. The barriers are specified on 2 different levels of detail (Sousa-Zomer et al., 2018; Kumar et al., 2019). This section ranks the 10 pre-defined barrier clusters and their relevance for Austrian manufacturing companies. For ranking the barrier clusters, each of the five response options was attributed a number value, from 0 for “no relevance” up to 4 for “highly relevant.” The clusters were then ranked by the average value that each of them reached, based on the 188 survey responses. The result is shown in Figure 5.

In addition to the ranking by average value, the diagram also displays the percentage distribution for each of the 10 barrier clusters.

The ranking shows, that the barrier cluster with the highest mean value is “Barriers in product material and design” which also has the highest ratio of answers for the response opportunity “highly relevant.” The subsequent three barrier clusters “Technological barriers,” “Barriers in the supply chain” and “Financial barriers” also achieve high average values and their relevance can be seen as above average. The overall allocated average value of all replies in this survey section is 2.02. While the mean values of the barrier clusters “Barriers in the transformation process” and “Barriers due to regulatory environment conditions” are in this range, the values of the categories “Hurdles with internal stakeholders and resources,” “Social and consumer barriers,” “Barriers relating to corporate strategy and policy” and “Barriers regarding cooperations” have lower average ratings.

After the assessment on cluster levels, 152 participants ranked the 57 individual challenges within the 10 categories. Figure 6 shows the survey participants’ assessment in terms of importance assigned to the individual barriers. The individual barriers are ranked by their mean value according to the value allocation of the answer opportunities.

The challenge “Insufficient political support in the form of incentives and subsidies” with an average value of 2.69 clearly stands out from the following hurdles “Limited availability of suppliers” and “Replacing problematic materials with sustainable materials” with average values of 2.52 and 2.50, respectively. The high average value can be explained by the fact that over 60% of the survey participants rated this hurdle as “very relevant” or “highly relevant” and not even 14% allocated “low relevance” or “no relevance” to this barrier.

In the case of the challenge “Replacing problematic materials with sustainable materials,” the comparatively high proportion of replies for the response options “low relevance” and “no relevance” is striking at first glance for the good ranking. However, the high mean value of this challenge results from the fact that this hurdle was most often considered “highly relevant” with 29.8% of the responses.

The top five challenges include three challenges from the category “Barriers in the supply chain,” namely “Limited availability of suppliers,” “Complexity of coordination along the supply chain” and “Inadequate infrastructure for a functioning traceability system.” Additionally, participating companies also struggle with “Quantity uncertainties in return rates of end-of-life products.” In addition to the already mentioned top-ranked challenges of the category “Barriers in the supply chain,” the challenges regarding the cluster “Barriers in product material and design” are particularly noteworthy, as four hurdles from this cluster can be found in the top 15 ranked barriers.

The barriers at the end of the ranking have completely different reply distributions except for the high shares of the response option “relevant.” From the last 15 barriers, none of the challenges reaches the 10% mark for the response option “highly relevant.” In particular, the last-ranked hurdle “Internal reservations about cross-company collaborations” is rated as “highly relevant” by only 2% of the survey participants. With a mean value of 1.42, this hurdle is in last place behind the challenges “Integration of the Internet of Things (IoT) and Big Data” and “Current company structure and organizational setup” with values of 1.48 and 1.51.

In the initial stages of transformation, many companies prioritize the enhancement of intra-corporate processes that are not reliant on external stakeholders, as this represents the first step toward integrating the principles of the circular economy. Changes in the business models are rarely implemented up to now, because the prerequisites are not given (Chiarot et al., 2022). Austrian manufacturing companies try to eliminate inefficiencies in use of material and energy in production lines, and also close internal circular loops to avoid or reuse production waste (Schöggl et al., 2022). As the next strategic milestone, manufacturing companies should attempt to increase their know-how regarding circular economy as well as on the potential benefits that this concept brings for their individual products (Valusyte, 2021). Improving sustainability and profitability requires systems thinking at large combined with individually tailored solutions.

The strategic relevance of the circular economy and the will to implement these changes and take the necessary steps to achieve the strategic milestones, as underlined by the survey results, is integral to the long-term success of corporations. Responding to this question, only 2 of the 229 survey participants state that the circular economy is “not relevant” to the development of the company. Additionally, Figure 2 indicates a correlation between the strategic relevance attributed to the circular economy for the company’s success and the progress in implementing the circular economy in the respective company. The assessment shows that the higher the score of strategic relevance is, the further the progress of implementation.

In the discussion of barrier prioritization, the survey results indicate that companies primarily miss political support in the form of incentives and subsidies. This call for increased financial support indicates that a transformation to circularity goes hand in hand with significant investments, costs, and risks. In the following, one might ask what specific form of incentive system and subsidies are needed. The other main challenges of the company survey show that, for example, incentives for the use of sustainable and recyclable raw materials or for the use of secondary raw materials could be a potential solution. Another approach would be to subsidize product prices.

In addition to the missing incentives and subsidies, the survey shows that there are also key problem areas along the supply chain. The need for setting up and coordinating return logistics to close circular material loops poses major challenges to the manufacturing industry. The respondents face a lack of suitable infrastructure as well as a lack of suppliers. Furthermore, the high complexity and uncertainty of return rates make managing reverse logistics a major challenge. This culminates in the fact that the supply of recyclates on the market is also too low. The lack of pressure from the supply chain toward circular economy is also illustrated by the question about the drivers of circular economy. Only if supply chains are designed sustainably, can they promote circular economy.

Looking at barriers that were indicated to be of less significance, it becomes clear that companies do not believe that internal reservations and organizational structures present significant challenges on the way to circular economy. The survey participants also see few problems in rethinking to a long-term strategy and taking certain risks. So, although internal reservations and a long-term planning horizon are not obstacles for companies, at present, management pressure is hardly perceived as a driver of the circular economy. This, together with the fact that regulatory pressure and social and cultural pressure are perceived to be significantly higher than the internal managerial pressure, indicates that companies are currently dependent on external requirements, regulations, and incentives for the implementation of the circular economy. The compatibility of a circular business model with the corporate strategy which is considered a big issue in the literature is also seen as a minor problem (Agrawal et al., 2021; Pieroni et al., 2021). The only internal challenge category receiving a high ranking is “barriers in product material and design,” listed in first place. It includes the highly ranked barriers “replacement of problematic materials by sustainable materials” and “recyclable and demountable design.”

The comparison between barriers and drivers of the circular economy reveals a contradiction between market demand and perceived customer behavior: while the “customer request toward the circular economy” is seen as the most important driver of strategic relevance of the circular economy for business success, the lack in change in consumer behavior is one of the biggest barriers.

In addition to “satisfaction with current consumption patterns,” two more external market barriers related to the end customer are among the top-rated barriers. On the one hand, the participants consider the resulting increase in the price of a product as non-justifiable and on the other hand a lower value perception for remanufactured products is seen as a clear hurdle. In combination with slowly changing consumption habits, this poses an economic risk to companies (Bhandari et al., 2019; Hermann and Vetter, 2021).

In sum, the hurdles on the path to the circular economy are very complex, which leads to the last overarching challenge. Companies are confronted with complexity in the transformation to the circular economy, which arises from the holistic restructuring of functioning processes. They have to face a multitude of interdependent variables that need to be managed in a results-oriented manner and coordinated efficiently during a transformation: customer buying behavior, investments and costs, technological feasibility, employee skills, changes in the organizational model, cultural aspects of a transformation and many more (Sousa-Zomer et al., 2018; Agrawal et al., 2021). The participating companies attribute great importance to this totality of complex interwoven factors.

In the broader context of Austria’s economy-wide circularity efforts, this paper’s findings offer a nuanced understanding of the strategic changes required. The current Austrian circularity gap, which stands at 62.6% (Circle Economy and ARA, 2019), is a challenge that aligns with the barriers identified in the survey. The Circularity Gap Report emphasizes the importance of economic incentives, a taxation shift toward consumption and materials usage, and the necessity of influencing international value chains to deliver circular inputs (Circle Economy and ARA, 2019). These challenges corroborate the significant barriers identified by Austrian manufacturing companies. To mitigate this gap, a comprehensive national strategy is needed that addresses both the micro-level barriers identified in this paper and maintains a holistic approach. Consequently, this paper provides an additional perspective to inform a targeted roadmap for the promotion of the circular economy.

This study contributes to substantiating and expanding the existing literature regarding the most significant barriers to business. The results of this study show partial similarities with comparable studies from other regions and industries while also providing new insights. The highest ranking of the barrier “Insufficient political support in the form of incentives or subsidies” corresponds with the importance assigned to barriers concerning policies and governmental regulations identified in the literature (Ormazabal et al., 2018; Caldera et al., 2019; Kumar et al., 2019). Specifically, Kumar et al. identified the “lack of governmental incentives” and “inadequate policies and legislations” as big barriers (Kumar et al., 2019). Caldera et al. pointed to the “lack of effective legislation” and a “weak regulatory environment” as significant barriers (Caldera et al., 2019). Ormazabal et al. highlighted the “lack of support from public organizations” as a major barrier (Ormazabal et al., 2018). In terms of supply chain issues, our survey points out the significance of “Limited availability of suppliers,” which is consistent with the high relevance of infrastructural and resource barriers identified in the literature (Masi et al., 2018; Kumar et al., 2019). Kumar et al. identified the “lack of appropriate partners in supply chains” as a key barrier (Kumar et al., 2019). Masi et al. noted the “limited availability and quality of recycling material” as a significant issue (Masi et al., 2018). In the context of barriers in product material and design, which is the highest-ranked barrier cluster according to the results of the underlying study, the importance is confirmed by the major barrier identified in another survey conducted in the UK by Masi et al. “limited attention to the end-of-life phase in current product design,” thus underscoring the need for greater consideration of this aspect in design processes. In the context of barriers in the transformation process to a circular economy, our findings highlight the major hurdle of a lack of expertise identified in the literature. The present study found that a lack of expertise hinders the transformation to a circular business model, a conclusion supported by the findings of (Ormazabal et al., 2018; Agyemang et al., 2019; Kumar et al., 2019). Kumar et al. identified a “lack of personnel with expertise on the circular economy” as a significant barrier. Agyemang et al. noted a broad “lack of expertise,” and Ormazabal et al. cited both a “lack of leaders’ commitment” and a “lack of qualified people” as contributing factors. These results underline the importance of expertise in successfully adopting a circular economy.

Our study results provide differentiated insights into the financial and management-related barriers in the context of the circular economy. While high initial investment costs have been identified as a significant or even the most significant barrier in the literature (Masi et al., 2018; Ormazabal et al., 2018; Agyemang et al., 2019; Caldera et al., 2019; Kumar et al., 2019), even though our survey results showed that financial barriers are ranked as the fourth most important cluster, it is not so much the direct investment costs that companies find challenging. Instead, the financing options for these investments and the unpredictability of long-term returns are the key issues. Our study results help to paint a more detailed picture of the challenges and barriers to implementing a circular economy.

While this study provides a comprehensive overview of the circular economy in Austria, its scope is limited to the perspectives of the surveyed companies, which vary in size and field of activity. Most respondents were from larger companies, with 62.9% having over 250 employees. Also, the study focused on the manufacturing sector, with over 50% from the mechanical engineering sector, the automotive industry, or the steel industry. The study’s findings may not fully capture the complexities of the circular economy in other sectors or smaller companies due to the predominance of larger companies and certain sectors in the sample. Furthermore, the specific challenges and opportunities within each sector and company size may not have been fully explored due to the broad scope of the study.

As the study focuses on larger manufacturing companies, future studies could examine the circular economy in the context of smaller companies or other sectors in Austria. In addition, more detailed studies could be conducted to examine the specific challenges and opportunities within each sector and company size and provide a more nuanced understanding of the circular economy in different contexts. In addition, based on the present analysis, it would be of interest to see to what extent and through which strategic changes, orientations and business model innovations pioneering companies are currently overcoming these barriers and thus advancing the circular economy.

Looking at the current implementation of the circular economy in Austria, Schöggl et al. found that companies focus mainly on avoiding toxic substances and increasing efficiency (Schöggl et al., 2022). In product design, companies are currently primarily concerned with recycling-oriented product design. Strategic approaches such as “Design for X” are rarely used. This is also confirmed by the results of the study, which classify the “Barriers in product material and design” cluster as the most relevant. The greatest challenge here is “Replacing problematic materials with sustainable materials.” This again shows the operational and cost-driven focus of the companies, which see the most significant barrier in the substitution of materials rather than in the long-term and strategic design of products. In this context, it would be instrumental in promoting the circular economy by strategically promoting sufficiency through durable and extendable design and product life extension services (Niessen et al., 2023).

The strategic orientation of Austrian manufacturing firms up to the present time has been analyzed. It is observed that these firms have already initiated the incorporation of strategies and planning for a circular economy. Nonetheless, these companies are reluctant to publicize their strategies or share them with others. Moreover, based on an assessment by Schöggl et al., companies currently perceive their capacity for innovation within the circular economy as inadequate. The principal challenges identified in this study include “insufficient political support in the form of incentives and subsidies,” “limited availability of suppliers,” “complexity of coordination along the supply chain,” and “inadequate infrastructure for a functioning traceability system.” To mitigate these barriers, it is suggested that companies could transcend their boundaries and form industrial clusters to achieve a symbiotic effect. Through such a symbiosis, the firms could potentially increase the quantifiability of their goals, foster innovation by sharing knowledge and expertise, bolster their political and strategic standing in advocating for the circular economy, enhance the availability of secondary raw material suppliers, and establish and streamline the infrastructure necessary for a functional circular supply chain (Albino and Fraccascia, 2015; Fraccascia et al., 2019).

The circular economy is a practical response to challenges such as resource scarcity and climate change. Despite broad recognition of its benefits, implementation is slow. R-strategies, circular business models, and product life extension measures are rarely applied. The result is a circularity gap, which indicates a lack of circular loops in different processes. When efforts do occur, they tend to focus on short-term, immediately feasible actions rather than transformative, structural changes. To further understand these limitations, the study investigates the specific barriers hindering the transition to a circular economy within Austria’s manufacturing industry. A literature review identified 57 key barriers, categorized into 10 clusters to capture their complexity. These were subsequently prioritized and assessed within the Austrian manufacturing context.

The results of the corresponding survey present that the main barriers are external challenges, which cannot be handled by the companies by themselves, the biggest barriers are a lack of support and financial incentives from governments and policymakers. In Austria, this stagnation is accentuated by a policy focus on recycling, neglecting other facets of the circular economy. Accordingly, closing the circularity gap requires increased policy support that supports the full range of circular strategies, not just a focus on waste management and recycling. The participants of the survey indicate that an internal willingness for a change in the direction of sustainability is given, but there is a need for incentives and subsidies from the political side to enable or accelerate the transformation process. According to the survey, this financial support should be used to restructure the supply chains to implement return logistics. There are also major barriers in product design and in the selection of materials. The sustainable design of products would often be technically possible but leads to an increase in the price of the product, which customers are not willing to pay.

The major barriers to the Austrian manufacturing industry can be summed up with 5 key points. Companies are facing a lack of financial support; a restructuring of the supply chain is needed; the product design process must be geared toward sustainability and market-side barriers must be handled. These barriers lead to the fifth overlapping challenge. Companies are confronted with complexity in the transformation toward a circular economy, which arises from the holistic restructuring of functioning processes.

The strategic relevance of the circular economy for long-term corporate success, underscored by the survey results, suggests its importance, despite the identified barriers, the survey shows that many companies have circular economy initiatives on their agenda, with several projects either under implementation or already completed. A detailed analysis of the literature as well as the survey results show that barriers to the implementation of the circular economy are as various as the chances and benefits of implementing a circular approach. These findings offer valuable insights for stakeholders and lay the groundwork for future research in the dynamic arena of the circular economy.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethical review and approval was not required for the study on human participants in accordance with the local legislation and institutional requirements. Written informed consent from the participants was not required to participate in this study in accordance with the national legislation and the institutional requirements.

FH was the initiator of the study. He accompanied the implementation from start to finish, conducted expert interviews, helped to draw up the interview guide, evaluated the results and largely wrote the paper as well as incorporated the comments of the reviewers. GK co-initiated the study, helped develop the interview guide and analysed the results. MB conducted expert interviews, created the interview guide, sought contact with the companies, analysed results and wrote a good part of the paper. SF and PO co-developed the interview guide and analysed the results. SS provided scientific support for the study and gave input on all steps of the procedure. All participants contributed to the writing of the paper. The interpretations from the results of the study were largely prepared by the consortium. All authors contributed to the article and approved the submitted version.

The authors acknowledge TU Wien Bibliothek for financial support through its Open Access Funding Program and Clemens Schild for the support during the reviewing process.

GK, MB, SF, and PO were employed by the EFS Unternehmensberatung GesmbH. FH and SS were employed by the Fraunhofer Austria Research GmbH.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2023.1243374/full#supplementary-material

Agarwal, S., Tyagi, M., and Garg, R. K. (2021). Conception of circular economy obstacles in context of supply chain: a case of rubber industry. Int. J. Prod. Perform. Manag. 72, 1111–1153. doi: 10.1108/IJPPM-12-2020-0686

Agrawal, R., Wankhede, V. A., Kumar, A., and Luthra, S. (2021). Analysing the roadblocks of circular economy adoption in the automobile sector: reducing waste and environmental perspectives. Bus. Strat. Env. 30, 1051–1066. doi: 10.1002/bse.2669

Agyemang, M., Kusi-Sarpong, S., Khan, S. A., Mani, V., Rehman, S. T., and Kusi-Sarpong, H. (2019). Drivers and barriers to circular economy implementation: an explorative study in Pakistan’s automobile industry. Manag. Decis. 57, 971–994. doi: 10.1108/MD-11-2018-1178

Albertsen, L., Richter, J. L., Peck, P., Dalhammar, C., and Plepys, A. (2021). Circular business models for electric vehicle lithium-ion batteries: an analysis of current practices of vehicle manufacturers and policies in the EU. Resour. Conserv. Recycl. 172:105658. doi: 10.1016/j.resconrec.2021.105658

Albino, V., and Fraccascia, L. (2015). The industrial symbiosis approach: A classificatiaon of business models. 19th International Trade Fair of Material & Energy Recovery and Sustainable Development. 2, 217–223.

Angelini, A., Benda-Kahri, S., Frischenschlager, H., Heinfellner, H., Hohenblum, P., Karigl, B., et al. (2021). Ergebnisdokumentation der Themen-Workshops zur Erarbeitung der Österreichischen Kreislaufwirtschaftsstrategie. doi: 10.13140/RG.2.2.11787.41764

Asif, F. M. A., Roci, M., Lieder, M., Rashid, A., Štimulak, M., Halvordsson, E., et al. (2018). A practical ICT framework for transition to circular manufacturing systems. Proced CIRP 72, 598–602. doi: 10.1016/j.procir.2018.03.311

Baggaley, A. R., and Hull, A. L. (1983). The effect of nonlinear transformations on a Likert scale. Eval. Health Prof. 6, 483–491. doi: 10.1177/016327878300600408

Barbosa-Póvoa, A. P., da Silva, C., and Carvalho, A. (2018). Opportunities and challenges in sustainable supply chain: an operations research perspective. Eur. J. Oper. Res. 268, 399–431. doi: 10.1016/j.ejor.2017.10.036

Bayer, O., and Ortolano, L. C., and Hoffmann, D. (2021). Praxisleitfaden Systematische Literaturrecherche der Universitätsmedizin Mainz. Available at: https://seafile.rlp.net/d/b87dc2b6b57a486a874d/files/?p=%2FArchiv%20alle%20Versionen%20%2FPraxisleitfaden-Systematische-Literaturrecherche-Version-2-0-beta.pdf

Bengtsson, M., Alfredsson, E., Cohen, M., Lorek, S., and Schroeder, P. (2018). Transforming systems of consumption and production for achieving the sustainable development goals: moving beyond efficiency. Sustain. Sci. 13, 1533–1547. doi: 10.1007/s11625-018-0582-1

Bhandari, D., Singh, R. K., and Garg, S. K. (2019). Prioritisation and evaluation of barriers intensity for implementation of cleaner technologies: framework for sustainable production. Resour. Conserv. Recycl. 146, 156–167. doi: 10.1016/j.resconrec.2019.02.038

Braun, N., Hopfensack, L., and Fecke, M. (2021). Chancen und Risiken im Automobilsektor für die Umsetzung einer klimaneutralen und ressourceneffizienten zirkulären Wirtschaft. Umwelt, Energie gGmbH: Wuppertal Institut für Klima, 36.

Caldera, H. T. S., Desha, C., and Dawes, L. (2019). Evaluating the enablers and barriers for successful implementation of sustainable business practice in ‘lean’ SMEs. J. Clean. Prod. 218, 575–590. doi: 10.1016/j.jclepro.2019.01.239

Chiarot, C., Cooper Ordoñez, R. E., and Lahura, C. (2022). Evaluation of the applicability of the circular economy and the product-service system model in a bearing supplier company. Sustainability 14:12834. doi: 10.3390/su141912834

Circle Economy and ARA. Circularity gap report Austria - insights - Circle Economy. (2019). Available at: https://www.circle-economy.com/resources/circularity-gap-report-austria

Creswell, J. W., and Plano Clark, V. L. Designing and conducting mixed methods research. 3rd ed. Los Angeles, CA: SAGE (2018).

D’Amato, D. (2021). Sustainability narratives as transformative solution pathways: zooming in on the circular economy. Circ. Econ. Sust. 1, 231–242. doi: 10.1007/s43615-021-00008-1

Dieckmann, E., Sheldrick, L., Tennant, M., Myers, R., and Cheeseman, C. (2020). Analysis of barriers to transitioning from a linear to a circular economy for end of life materials: a case study for waste feathers. Sustainability 12:1725. doi: 10.3390/su12051725

Dillman, D. A. Mail and internet surveys: the tailored design method—2007 update with new internet, visual, and mixed-mode guide, 2nd ed. Hoboken, NJ: Wiley (2007).

Eisenmenger, N., Plank, B., Milota, E., and Gierlinger, S. Resource use in Austria. Wien: BMK, (2020).

European Commission (2018). Circular material use rate: calculation method. 2018th Edn Publications Office Available at: https://data.europa.eu/doi/10.2785/132630.

European Commission. Measuring progress towards circular economy in the European Union – key indicators for a monitoring framework. Strasbourg: European Commission, (2018).

Fellner, J., Lederer, J., Scharff, C., and Laner, D. (2017). Present potentials and limitations of a circular economy with respect to primary raw material demand: present potentials and limitations of a circular Economy. J. Ind. Ecol. 21, 494–496. doi: 10.1111/jiec.12582

Fraccascia, L., Giannoccaro, I., and Albino, V. (2019). Business models for industrial symbiosis: a taxonomy focused on the form of governance. Resour. Conserv. Recycl. 146, 114–126. doi: 10.1016/j.resconrec.2019.03.016

Frischenschlager, H., Karigl, B., Lampert, C., Pölz, W., Schindler, I., Tesar, M., et al. (2010). Klimarelevanz ausgewählter Recycling-Prozesse in Österreich (Endbericht REP-0303). Umweltbundesamt GmbH, 106.

Garcés-Ayerbe, C., Rivera-Torres, P., Suárez-Perales, I., and Leyva-de la Hiz, D. (2019). Is it possible to change from a linear to a circular economy? An overview of opportunities and barriers for European small and medium-sized enterprise companies. Int. J. Environ. Res. Public Health 16:851. doi: 10.3390/ijerph16050851

Ghisellini, P., Cialani, C., and Ulgiati, S. (2016). A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 114, 11–32. doi: 10.1016/j.jclepro.2015.09.007

Gläser-Zirkuda, M. Empirische Bildungsforschung [internet]. Wiesbaden: VS Verlag für Sozialwissenschaften (2011) Available at: http://link.springer.com/10.1007/978-3-531-93015-2

Hák, T., Janoušková, S., and Moldan, B. (2016). Sustainable development goals: a need for relevant indicators. Ecol. Indic. 60, 565–573. doi: 10.1016/j.ecolind.2015.08.003

Hauer, W., Merstallinger, M., Allesch, A., Beigl, P., and Wellacher, M. Möglichkeiten zur umsetzung der eu vorgaben betreffend getränkegebinde, pfandsysteme und mehrweg. Wien: BMK, (2020).

Haunss, S., and Sommer, M., editors. Fridays for future - die Jugend gegen den Klimawandel: Konturen der weltweiten Protestbewegung. 1st ed. Bielefeld: Verlag (2020). Available at: https://www.transcript-open.de/isbn/5347

Hermann, C., and Vetter, O. (2021). Ökologische und ökomomische Bewertung des Ressourcenaufwands - remanufacturing von Produkten. Berlin: Bundesministeriums für Umwelt, Naturschutz und nukleare Sicherheit.

Hina, M., Chauhan, C., Kaur, P., Kraus, S., and Dhir, A. (2022). Drivers and barriers of circular economy business models: where we are now, and where we are heading. J. Clean. Prod. 333:130049. doi: 10.1016/j.jclepro.2021.130049

Huber-Heim, K., and Kronenberg, D. C. (2019). Unternehmen auf dem Weg zur Kreislaufwirtschaft - Studie zu Perspektiven, Wissensstand und Erwartungen der Österreichischen Stakeholder. Circular Economy Forum Austria, 11.

Hysa, E., Kruja, A., Rehman, N. U., and Laurenti, R. (2020). Circular economy innovation and environmental sustainability impact on economic growth: an integrated model for sustainable development. Sustainability 12:4831. doi: 10.3390/su12124831

Jacobi, N., Haas, W., Wiedenhofer, D., and Mayer, A. (2018). Providing an economy-wide monitoring framework for the circular economy in Austria: status quo and challenges. Resour. Conserv. Recycl. 137, 156–166. doi: 10.1016/j.resconrec.2018.05.022

Jaeger, B., and Upadhyay, A. (2020). Understanding barriers to circular economy: cases from the manufacturing industry. JEIM 33, 729–745. doi: 10.1108/JEIM-02-2019-0047

Joshi, A., Kale, S., Chandel, S., and Pal, D. (2015). Likert scale: explored and explained. BJAST 7, 396–403. doi: 10.9734/BJAST/2015/14975

Kara, S., Hauschild, M., Sutherland, J., and McAloone, T. (2022). Closed-loop systems to circular economy: a pathway to environmental sustainability? CIRP Ann. 71, 505–528. doi: 10.1016/j.cirp.2022.05.008

Kirchherr, J., Reike, D., and Hekkert, M. (2017). Conceptualizing the circular economy: an analysis of 114 definitions. Resour. Conserv. Recycl. 127, 221–232. doi: 10.1016/j.resconrec.2017.09.005

Korhonen, J., Honkasalo, A., and Seppälä, J. (2018). Circular Economy: the concept and its limitations. Ecol. Econ. 143, 37–46. doi: 10.1016/j.ecolecon.2017.06.041

Kumar, V., Sezersan, I., Garza-Reyes, J. A., Gonzalez, E. D. R. S., and AL-Shboul, M. A. (2019). Circular economy in the manufacturing sector: benefits, opportunities and barriers. Manag. Decis. 57, 1067–1086. doi: 10.1108/MD-09-2018-1070

Lieder, M., and Rashid, A. (2016). Towards circular economy implementation: a comprehensive review in context of manufacturing industry. J. Clean. Prod. 115, 36–51. doi: 10.1016/j.jclepro.2015.12.042

Lotz, M. T., Herbst, A., and Rehfeldt, M. (2021). Kreislaufwirtschaft für die Dekarbonisierung des Bausektors—Modellierung ausgewählter Stoffströme und dazugehöriger THG-Emissionen. 12. Internationale Energiewirtschaftstagung an der TU Wien, 21.

Madeddu, S., Ueckerdt, F., Pehl, M., Peterseim, J., Lord, M., Kumar, K. A., et al. (2020). The CO2 reduction potential for the European industry via direct electrification of heat supply (power-to-heat). Environ. Res. Lett. 15:124004. doi: 10.1088/1748-9326/abbd02

Mark, B. G., Rauch, E., and Matt, D. T. (2021). Worker assistance systems in manufacturing: a review of the state of the art and future directions. J. Manuf. Syst. 59, 228–250. doi: 10.1016/j.jmsy.2021.02.017

Masi, D., Kumar, V., Garza-Reyes, J. A., and Godsell, J. (2018). Towards a more circular economy: exploring the awareness, practices, and barriers from a focal firm perspective. Prod. Plan. Control 29, 539–550. doi: 10.1080/09537287.2018.1449246

Maurer, T. J., and Pierce, H. R. (1998). A comparison of Likert scale and traditional measures of self-efficacy. J. Appl. Psychol. 83, 324–329. doi: 10.1037/0021-9010.83.2.324

Mayring, P., and Gläser-Zikuda, M., editors. Die praxis der qualitativen Inhaltsanalyse. 2nd ed. Weinheim: Beltz Verlag (2008).

Moser, G., Karigl, B., and Benda-Kahri, S. Grundlagendokument - Entwicklung einer Kreislaufwirtschaftsstrategie. Wien: BMK (2021).

Niessen, L., Bocken, N. M. P., and Dijk, M. (2023). Sufficiency as trend or tradition?—Uncovering business pathways to sufficiency through historical advertisements. Front. Sustain. 4:4. doi: 10.3389/frsus.2023.1165682

Ormazabal, M., Prieto-Sandoval, V., Puga-Leal, R., and Jaca, C. (2018). Circular Economy in Spanish SMEs: challenges and opportunities. J. Clean. Prod. 185, 157–167. doi: 10.1016/j.jclepro.2018.03.031

Otekenari, D. (2020). Moving beyond take-make-dispose to take-make- use for sustainable economy. Int. J. Sci. Res. 13, 497–516.

Perstel, P., and Hölzl, M. Define re-design: Austrian initiatives for sustainability-driven entrepreneurship. Graz: University of Graz, (2014).

Pieroni, M. P. P., McAloone, T. C., Borgianni, Y., Maccioni, L., and Pigosso, D. C. A. (2021). An expert system for circular economy business modelling: advising manufacturing companies in decoupling value creation from resource consumption. Sustain. Prod. Consumpt. 27, 534–550. doi: 10.1016/j.spc.2021.01.023

Pieroni, M. P. P., McAloone, T. C., and Pigosso, D. C. A. (2021). Circular economy business model innovation: sectorial patterns within manufacturing companies. J. Clean. Prod. 286:124921. doi: 10.1016/j.jclepro.2020.124921

Piyathanavong, V., Garza-Reyes, J. A., Kumar, V., Maldonado-Guzmán, G., and Mangla, S. K. (2019). The adoption of operational environmental sustainability approaches in the Thai manufacturing sector. J. Clean. Prod. 220, 507–528. doi: 10.1016/j.jclepro.2019.02.093

Prajapati, H., Kant, R., and Shankar, R. (2019). Prioritizing the solutions of reverse logistics implementation to mitigate its barriers: a hybrid modified SWARA and WASPAS approach. J. Clean. Prod. 240:118219. doi: 10.1016/j.jclepro.2019.118219

Rieg, L., Meyer, A., and Bertignoll, H. (2019). Potentiale der Kreislaufwirtschaft zur Reduktion des Ausstoßes von Treibhausgasen. Berg Huettenmaenn Monatsh. 164, 169–172. doi: 10.1007/s00501-019-0843-z

Rizos, V., Behrens, A., van der Gaast, W., Hofman, E., Ioannou, A., Kafyeke, T., et al. (2016). Implementation of circular Economy business models by small and medium-sized enterprises (SMEs): barriers and enablers. Sustainability 8:1212. doi: 10.3390/su8111212

Rodrigues, R., Pietzcker, R., Fragkos, P., Price, J., McDowall, W., Siskos, P., et al. (2022). Narrative-driven alternative roads to achieve mid-century CO2 net neutrality in Europe. Energy 239:121908. doi: 10.1016/j.energy.2021.121908

Röhr, T. (2021) in Kreislaufwirtschaft nach dem cradle-to-cradle-Vorbild: Wie kann ein geschlossener Ressourcenkreislauf erreicht werden? Eine Untersuchung unternehmerischer Konzepte mit Beispielen aus der praxis, Schriftenreihe Betriebliche Umweltökonomie und Nachhaltigkeitsmanagement. ed. M. Arnold. 1st ed (Chemnitz: Technische Universität Chemnitz).

Salmenperä, H. (2021). Different pathways to a recycling society – comparison of the transitions in Austria, Sweden and Finland. J. Clean. Prod. 292:125986. doi: 10.1016/j.jclepro.2021.125986

Salmenperä, H., Pitkänen, K., Kautto, P., and Saikku, L. (2021). Critical factors for enhancing the circular economy in waste management. J. Clean. Prod. 280:124339. doi: 10.1016/j.jclepro.2020.124339

Schally, H. M. (2018). Die Europäische Union und ihre Mitgliedstaaten auf dem Weg in die Kreislaufwirtschaft. Wien: EUropainfo.

Scheel, C., Aguiñaga, E., and Bello, B. (2020). Decoupling economic development from the consumption of finite resources using circular economy. A model for developing countries. Sustainability 12:1291. doi: 10.3390/su12041291

Schöggl, J. P., Stumpf, L., Rusch, M., and Baumgartner, R. J. (2022). Die Umsetzung der Kreislaufwirtschaft in österreichischen Unternehmen – Praktiken, Strategien und Auswirkungen auf den Unternehmenserfolg. Österr Wasser Abfallw 74, 51–63. doi: 10.1007/s00506-021-00828-3

Shahbazi, S., Wiktorsson, M., Kurdve, M., Jönsson, C., and Bjelkemyr, M. (2016). Material efficiency in manufacturing: swedish evidence on potential, barriers and strategies. J. Clean. Prod. 127, 438–450. doi: 10.1016/j.jclepro.2016.03.143

Sharma, N. K., Govindan, K., Lai, K. K., Chen, W. K., and Kumar, V. (2021). The transition from linear economy to circular economy for sustainability among SMEs: a study on prospects, impediments, and prerequisites. Bus Strat Environ 30, 1803–1822. doi: 10.1002/bse.2717

Sousa-Zomer, T. T., Magalhães, L., Zancul, E., and Cauchick-Miguel, P. A. (2018). Exploring the challenges for circular business implementation in manufacturing companies: an empirical investigation of a pay-per-use service provider. Resour. Conserv. Recycl. 135, 3–13. doi: 10.1016/j.resconrec.2017.10.033

Statistik Austria. (2020). Produktions- und Dienstleistungsunternehmen (ÖNACE 2008: Abschnitte B - N; S95) - ausgewählte Strukturmerkmale. Available at: https://www.statistik.at/services/tools/tools/wirtschaftsatlas

Statistik Austria. (2021). Leistungs- und Strukturdaten. Available at: https://www.statistik.at/statistiken/industrie-bau-handel-und-dienstleistungen/leistungs-und-strukturdaten

Tillner, S., and Peverini, M. The circular economy in affordable housing to reach carbon neutrality – refurbishment. In: Proceedings of the 57th ISOCARP World Planning Congress. ISOCARP (2021). Available at: https://isocarp.org/app/uploads/2022/01/ISOCARP_2021_Tillner_61.pdf

United Nations. (2021). The sustainable development goals report 2021. Availabe at: https://unstats.un.org/sdgs/report/2021/The-Sustainable-Development-Goals-Report-2021.pdf

Valusyte, R. Circular design strategies in manufacturing SME’s: from material to the meaning and dematerialization. In: 2021 IEEE International Conference on Technology and Entrepreneurship (ICTE). Kaunas: IEEE (2021), 1–8. Available at: https://ieeexplore.ieee.org/document/9584534/

Venturini, F. (2021). Circular economy and zero waste for environmental education. Semestrale Di Studi e Ricerche Di Geografia. 143–161. doi: 10.13133/2784-9643/16954

Vermeulen, W., Witjes, S., and Reike, D. (2019). Circular Economy 3.0 - Solving confusion around new conceptions of circularity by synthesising and re-organising the 3R’s concept into a 10R hierarchy. Renewablematter. 27.

Walcher, D., and Leube, M. Kreislaufwirtschaft durch Co-Creation. Kundenintegration and consumer empowerment. (2017). Available at: http://arbeitsgemeinschaft.marketing/praxiswissen-marketing

Walsh, B. (2010). PSS for product life extension through remanufacturing. Proceedings of the 2nd CIRP IPS2 Conference 2020. 261–266.

Werning, J. P., and Spinler, S. (2020). Transition to circular economy on firm level: barrier identification and prioritization along the value chain. J. Clean. Prod. 245:118609. doi: 10.1016/j.jclepro.2019.118609

Wieser, H., and Tröger, N. (2018). Exploring the inner loops of the circular economy: replacement, repair, and reuse of mobile phones in Austria. J. Clean. Prod. 172, 3042–3055. doi: 10.1016/j.jclepro.2017.11.106

Zechmeister, A., Anderl, M., Bartel, A., Frei, E., Gugele, B., Gössl, M., et al. (2022). Klimaschutzbericht 2022. Umweltbundesamt GmbH, 260.

Keywords: circular economy, production industry, transition, barriers, literature review, survey

Citation: Holly F, Kolar G, Berger M, Fink S, Ogonowski P and Schlund S (2023) Challenges on the way to a circular economy from the perspective of the Austrian manufacturing industry. Front. Sustain. 4:1243374. doi: 10.3389/frsus.2023.1243374

Received: 20 June 2023; Accepted: 11 September 2023;

Published: 02 October 2023.

Edited by:

Konstantinos P. Tsagarakis, Technical University of Crete, GreeceReviewed by:

Ana Ramos, University of Porto, PortugalCopyright © 2023 Holly, Kolar, Berger, Fink, Ogonowski and Schlund. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Fabian Holly, ZmFiaWFuLmhvbGx5QHR1d2llbi5hYy5hdA==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.