95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. , 09 February 2023

Sec. Circular Economy

Volume 4 - 2023 | https://doi.org/10.3389/frsus.2023.1092107

This article is part of the Research Topic Accelerating the Circular Economy Transition: Innovations and Developments from Africa View all 12 articles

Despite the rise of plastic waste regulation and rising trends in the adoption of circular economy (CE) policies globally, investigations of their impact on businesses remain limited. Research on adoption of CE policies in Africa is particularly limited despite African countries leading the uptake of plastic ban laws and CE-related policies. This paper examines how the 10-R principles of CE feature in Rwanda's sustainability policies, and provides the experiences of Rwandan manufacturers following the implementation of the plastic ban. A qualitative review of key environmental sustainability policies in Rwanda shows alignment to different levels of 10-R principles of the circular economy. Meanwhile, field interviews with leading manufacturers comprising producers and users of single-use plastics in Rwanda indicate that businesses have faced internal and external challenges complying with the plastic ban and CE-related policies. These challenges range from limited capital to acquire new industrial technology, lack of expertise to develop circular business models, lack of alternative packaging to plastics, to loss in market competition since Rwanda's competitors in the international market still use cheap plastic packaging. Consequently, our findings indicate that insufficient government support such as lack of finance and capacity development to develop new business models, ambiguous regulatory framework, and inadequate stakeholder consultations impedes business uptake of CE and other sustainability policies. In addition to providing policy and managerial implications, we conclude by underscoring the importance of continued collaboration between government in terms of regulation, innovation from businesses, and consumer actions, in tackling environmental challenges caused by plastic waste and implementation of CE and other green policies.

Plastics are widely used globally in product packaging, manufacturing, and in households since they are cheap, lightweight, durable, and strong. The demand for plastics is expected to continue, and estimates indicate production will double by 2035 and probably quadruple by 2050 (UNEP, 2018a). Plastics are mainly produced using non-renewable resources such as oil, natural gas, and coal (Clapp and Swanston, 2009). A UN report notes that if current trends continue, the plastic industry could account for 20% of the world's total oil consumption by 2050. Plastics have thus emerged as one of the most pressing environmental issues since they are not naturally biodegradable. Furthermore, 60% of the estimated 8.3 billion tons of plastic produced since 1950 (UNEP, 2018b), have ended up in landfills or the natural environment, affecting climate change, marine life, biodiversity, and human health (Leonard and Barra, 2018).

Tackling the environmental challenges caused by plastic waste require collaboration between governments in terms of regulation, innovation from business and action from individuals (UNEP, 2018b). While plastic garbage is taken up by a waste management system in developed nations and at least partly recycled, in low-income countries such as Rwanda, appropriate waste collection management or recycling infrastructure, though upcoming, is often lacking. Still, developing countries such as Rwanda are increasingly adopting mitigation strategies in response to the environmental damage caused by plastic waste. The most common has been to ban single-use plastics and encourage the production and use of environment-friendly alternatives. The prohibition of single-use plastics has been particularly popular in Africa, where 34 of 54 countries have implemented policies restricting single-use plastics since 2,000 (Greenpeace Africa, 2020). Rwanda became the first country in East Africa to introduce anti-plastic legislation in 2008 when it prohibited the manufacturing, use, sale, and importation of all plastic bags. Uganda and Kenya followed in 2009 and 2017, respectively. At the regional level, the East African Community (EAC) an intergovernmental body representing seven countries (Kenya, Tanzania, Uganda, Rwanda, Burundi, South Sudan, and the Democratic Republic of the Congo) banned the manufacturing, sale, importation, and use of polythene bags through the East African Community Polythene Materials Control Bill 2017 (Karuhanga, 2017).

Following the ban on single-use plastics, Rwanda has subsequently emerged as a proponent of sustainability policies in Africa, including in the implementation of circular economy (CE) policies. A circular economy (CE) is an economic system that emphasizes processes and economic activities in which raw materials and products maintain a high value as long as possible and waste is reduced significantly (Kirchherr et al., 2017). The adoption of CE policies and implementation of the plastic ban disrupted the business models of Rwandan manufacturers. To stay in business in Rwanda, the policy requires that companies transition from manufacturing or using single-use plastics to production, and or use of environmentally friendly alternative materials. However, transitioning to alternative materials is capital intensive, and firms have faced challenges complying with the policy. Moreover, economic crises during the transition period can further exacerbate the challenges faced and derail the process, as Rwandan businesses experienced during the recent COVID-19 pandemic. In this study, we examined the experiences of Manufacturers in Rwanda as they navigate the ban on plastics, and Rwanda's drive toward sustainability policies aligned with CE principles.

Transitioning from one regulatory policy to another requires collaboration among all stakeholders, including business and government. Studies have found that absence of adequate government support in the form of funding opportunities, capacity development, business-friendly taxation policies, laws and regulations, impedes uptake of CE policies by SMEs (Rizos et al., 2016). In many African countries, including Rwanda, the legal and regulatory frameworks that foster circularity are still in their infancy stages (Desmond and Asamba, 2019). Moreover, policies such as plastic ban are not always followed with mechanisms such as capacity that would support full realization of a country's circular or green economy initiatives. For example, Rwandan manufactures faced constraints in complying with plastic ban legislation (Behuria, 2021; Shabiti, 2021). The constraints initially ranged from a lack of knowledge to differentiate between permitted plastics and those outlawed, insufficient stakeholder consultation during policy design and implementation, and lack of capacity and finance to implement new business models necessitated by the ban (UNEP, 2018c; Behuria, 2021; Shabiti, 2021). Moreover, the emergence of a lucrative black market of smuggled plastic from neighboring countries initially affected implementation of the policy and the competitiveness of Rwandan manufacturers, but this was mitigated with stricter regulations. Punishments for violators included between 2 to 12 months in prison and hefty fines ranging from 5,000 to 100,000 Rwandan francs (between US$5 and $110) (Government of Rwanda, 2005).

To support the transition process, the Rwandan government provided support in the form of fiscal policies such as tax waivers and special exemptions that allow eligible firms to continue using or importing plastics. Eligible firms include those that require plastic materials in their business operations such as packaging, especially exporters and importers of home compostable single-use plastics. The policy was also implemented in transition stages that allowed firms to comply over a period of time. Meanwhile, donor communities offered technical and capacity-building support, including training businesses on CE business models and financial support in the form of venture funding to start-ups engaged in plastic waste management.

The study contributes to the literature on CE-related policies in Africa by providing Rwanda's experiences implementing the CE principles. We frame the plastic ban as a key feature of Rwanda's CE and other sustainability policies. We also examine the experiences of Rwanda manufacturers with implementation of the plastic ban and CE policies, focusing on understanding the challenges they face, and the strategies they employ to address those challenges. Moreover, we examine existing forms of support provided by the government to support firms as Rwanda transitions from linear to CE policies. The experiences of the Rwandan private sector in the transition from single-use plastics to alternative materials, including challenges faced, offers lessons on the impact of anti-plastic legislation. The research was primarily exploratory, focusing on providing results of a field survey conducted in Rwanda in between May and June 2022, and complemented with secondary data collected through desktop research on circular economy and sustainability policies in Rwanda. This exploratory nature limits theoretical discussion to the definition or contextualization of CE principles within the Rwandan sustainability context. Nonetheless, it contributes to the qualitative research on CE and sustainability in Africa, within the context of plastic waste management, and the impact of such policies on business.

The study is structured as follows. Building on the introduction, Section 2 explores the literature on CE and sustainability in Rwanda. The section also highlights the research gap and significance of the study. Section 3 presents discusses the research questions, approach, and methodology. Section 4 presents the results of the investigation. Sections 5 and 6 analyze the findings and provides concluding recommendations, respectively.

Kirchherr et al. (2017) collated 114 definitions of a CE and argued that a common theme among them is that they describe the concept to be a combination of reduce, reuse, and recycle practices, and not a modification of systems geared toward economic prosperity, environmental sustainability, and social equity. These three circular processes are usually termed as the “3R framework” highlighted by authors such as King et al. (2006) and Ghisellini et al. (2016). Other frameworks based on modifying the 3R framework with additional features that aim to holistically encompass the CE processes have been formulated and used by other specialists. For example, the 4Rs used by the European Parliament (2008), 6Rs used by Sihvonen and Ritola (2015) as a product's end-of-life technique, 9Rs by Van Buren et al. (2016) and 10Rs described by the PBL Netherlands Environmental Assessment Agency (2017) (see Table 1). The CE concept often contrasts with linear economy where materials are sourced, converted to products, and then used by the consumers who dispose of them after use. Kirchherr et al. (2017) defined CE as an economic system that replaces the “end-of-life” concept with reducing, alternatively reusing, recycling, and recovering materials in production/distribution and consumption processes. CE operates at the micro level (products, companies, and consumers), meso-level (eco-industrial parks), and macro level (city, region, nation and beyond), with the aim of accomplishing sustainable development, thus simultaneously creating environmental quality, economic prosperity, and social equity, to the benefit of current and future generations. CE is enabled by novel business models and responsible consumers who, for example, implement circular processes in their production or consumption, respectively. However, the concept has also been criticized as being too vague to be used practically (Valenzuela and Böhm, 2017; Corvellec et al., 2021). Critics of the model claim that it is more of a theoretical than a practical concept to drive sustainability of scarce resources and wastes commonly associated with the traditional linear economy (Corvellec et al., 2021). Despite these critiques, the CE concept is increasingly gaining prominence and has been widely adopted by stakeholders exploring mechanisms to address the impact of climate change, waste management, and environmental conservation.

Sustainability has emerged as a strong component in Rwanda's social and economic development journey post-1994 genocide. In 2005, Rwanda adopted Organic law No. 04/2005 which determines the modalities of protection, conservation, and promotion of the environment (Government of Rwanda, 2005). The adoption of the 2005 Organic law followed a 2004 study by the Rwanda Ministry of Environment which found that plastic litter threatened agricultural production, contaminated water sources, killed fish and created visual pollution that tarnished the image of the country (Dsilva, 2019). This law established the initial framework for policies relating to sustainability. Indeed, guided by the Organic law of 2005, in September 2008 Rwandan parliament passed Law N57/2008 which prohibited the manufacture, importation, use, and sale of polyethylene bags in Rwanda. The law defined polythene bags as synthetic plastic made up of numerous simple chemicals called ethene (monomer). In August 2019, this regulation was expanded to include other single-use plastic products, including straws, bottles, and food containers (Government of Rwanda, 2019).

Protecting the environment and sustainable management of natural resources has become integral in Rwanda's national development plans. It was a central part of Rwanda's Vision 2020, in which Rwanda sought to diminish pressure on natural resources and reverse environmental degradation (Government of Rwanda, 2012). In the successor Vision 2050, conservation is recognized as important to the sustainability of the tourism industry and the preservation of Rwanda's national heritage. Through Vision 2050, the government plans to continue positioning Rwanda as the global frontier for conservation (Government of Rwanda, 2020).

While Rwanda has consistently used the plastic ban to position itself as champion of CE and sustainability in Africa, few studies [see for example, Behuria (2021)], have explored the implementation of such policies in Rwanda without focusing much on their climate-change and conservation related effects. While scholars have explored implementation of environmental protection policies in Rwanda (Siegel et al., 2011; Nibeza, 2015; Danielsson et al., 2017; Whyte et al., 2020; Behuria, 2021), a few studies have explored strategies adopted by Rwandan manufacturers to ensure compliance with anti-plastic regulations [see for example, Behuria (2021). Similarly lacking is research exploring the effectiveness of government support to manufacturers following the ban on plastics and the implementation of CE-related policies. Existing studies tend to focus on the business-government dynamics environment and the politics surrounding the implementation of policies banning plastic (Behuria, 2019, 2021), or the environmental impacts of plastics, approaches to alleviate plastics and the attendant effects of such policies on the country's image, such as the “cleanest city” moniker given to Rwanda's capital Kigali by media commentators and scholars (see Hakuzimana, 2021). Other scholars have also found that despite efforts to make Rwanda a plastic-free country, scientific studies on plastic pollution and the impact of adopted policies in Rwanda are still lacking (Hakuzimana, 2021). The absence of such studies makes it challenging to obtain reliable data, and to understand the implications of adopted policies, for example, on the business environment. However, the lack of studies on the impact of sustainability-related policies, such as CE policies on business is not unique to Rwanda. In Africa, investigations on the impacts of CE policies on business, though upcoming are still limited (Andersen et al., 2021; Behuria, 2021). The limitation of studies on Africa is partly due to the lack of reliable data sources (Andersen et al., 2021) and the reluctance of businesses to participate in empirical research involving their relationship with the government, which is true in the case of our study. In states like Rwanda, with a centralized political system and a high degree of government involvement in business (Behuria, 2015, 2021), manufacturers often fear that their data may be transferred to authorities, whom they often perceive as “policing” them through environmental regulations. Furthermore in East Africa, such fears are not unique to Rwanda as manufacturers in Kenya and Uganda (Behuria, 2021), and Tanzania exhibited similar sentiments (Andersen et al., 2021). Lastly, the reluctance of manufacturers to participate in empirical studies, as one business leader informed us, is further caused by the fact that researchers do not always share the results of their studies with the private sector.

As aforementioned, the study thus sought to explore the experiences of Manufacturers in Rwanda as they navigate the ban on plastics and Rwanda's drive toward sustainability. More specifically, the questions we explored include: What are the challenges manufacturers face in their transition to alternative materials (question 1)? What strategies did Rwandan manufacturers adopt as they transitioned from the production or use of single-use plastics, which are prohibited, to alternative materials (question 2)? How has the Rwandan government been supporting manufacturers as they transition—and what other form of support do businesses require as they transition (question 3)? Finally, how does circular economy principles feature in Rwanda's sustainability policies, including national development plans (question 4)? Since Rwanda is a leading pioneer in plastic regulation and CE policies in Africa, a critical analysis of the experiences of its private sector with the implementation of related policies offers lessons other jurisdictions may consider in developing plastic management regulations and other green policies.

The study employed a descriptive qualitative research design based on qualitative data collected through field interviews with Rwanda manufacturers and desk review of literature on CE-related policies in Rwanda. Descriptive studies systematically describe a situation, problem, phenomenon, service, or programme (Kumar, 2011). The research was informed by the study focus, which sought understand the experiences of Rwandan manufacturers with the plastic ban policy.

Study participants were identified through a purposive sampling technique, which identifies respondents based on the nature and intent of the study (Groenewald, 2004; Tongco, 2007). The sampling process involved a desk study of firms manufacturing or using plastics in their business operations, and those responsible for implementing economic and sustainability policies in Rwanda. This resulted in the classification of firms into either primary or secondary manufacturers. Primary manufacturers are firms that manufacture single-use plastics, while secondary manufacturers are firms that use single-use plastic products to develop their final product. For example, a plastic bottle manufacturer would be classified as a primary manufacturer, while a water company that uses the bottle to package water for sale is classified as a secondary manufacturer. The total sample included 35 respondents comprising 14 primary manufacturers, 14 secondary manufacturers, three government agencies and two leading industry groups representing manufacturers (see Table 2). Despite this large sample, empirical data was collected from only nine participants, comprising four primary manufacturers, four secondary manufacturers and the government agency responsible for implementing and enforcing environmental policies in Rwanda. Some of the targeted respondents declined to participate despite ethical assurances and our framing of the study as necessary in understanding the experiences of firms as Rwanda implements CE policies. As aforementioned, businesses in Rwanda, and indeed most East African countries, are often reluctant to participate in studies that examine their relationship with the government (Andersen et al., 2021; Behuria, 2021). Manufacturers that participated in the study shared our view that the study could help inform policy changes that positively improve the business environment. The interviews were complemented with reliable secondary materials including media reports that contained statements from business leaders and business community representatives such as officials from Rwanda Association of Manufacturers and the Private Sector Federation (PSF), public officials such as the Rwandan Minister for Environment and Members of Parliament. The sample size is summarized in Table 2.

Secondary data was collected through a desk review of the Rwandan CE landscape by reviewing Rwanda's sustainable development policies and its adoption and implementation of regulations to manage plastics. The review covered academic articles, media publications, and government policy documents. The academic documents reviewed were those discussing CE concepts and its implementation, and those examining implementation of regulations banning plastics in Rwanda and Africa broadly. For media articles, the study focused on publications by leading Rwandan business and environmental journalists; these included their interviews with public officials such as parliamentarians and ministers. Finally, the study reviewed key Rwanda policy documents related to environmental conservation and sustainability, national development plans such as Rwanda Vision 2020 and Vision 2050 and the country's manufacturing-related policies. These documents outline Rwanda's sustainable economic development plans and related policies. Following desk research, empirical data was collected from the sampled population through field interviews using semi-structured questionnaires. The questionnaires were designed to collect information on business responses to the plastic ban, challenges faced, and available government support to enhance transition. Semi-structured questionnaires allowed participants to share their experiences broadly, allowing the researchers to ask follow-up questions based on participant responses. The data was manually cleaned and analyzed thematically to identify themes and patterns that respond to the research questions.

This section presents the results of the fieldwork interviews with select Rwandan manufacturers is the study participants consisted of businesses that are primary and secondary manufacturers of single-use plastics. There were four primary manufacturers and four secondary manufacturers. To triangulate data on government support since the ban on plastic, Rwanda Environmental Agency (REMA) was also interviewed. REMA is the government regulatory agency responsible for ensuring that environmental issues and climate change are integrated into Rwanda's development plans. REMA enforces environmental policies, including the plastic ban. For anonymity purposes, the names of firms interviewed into participant 1–9. Table 3 presents a summary of the participant's demographic data. The results are presented based on the research questions, and the data is summarized in tables based on key themes.

Results of thematic analysis of qualitative data show that there are two broad categories of challenges that manufacturers experienced as they transitioned from single-use plastics to environmentally friendly packaging. These challenges are classified as internal and external and summarized in Table 4.

Considering the ban of single-use plastic, the study sought to understand the available support provided by the government to support manufacturers. Thematic analysis of interviews indicate that manufacturers received support in the form of capacity development on the production of alternative materials, financial support, and tax exemption. In addition, the policy is implemented in phases, allowing them to transition their processes gradually. Moreover, firms that use plastic in their operations may apply to the government for a special waiver to the policy that enables them to continue using plastics in their operations. Given the highlighted challenges, the study explored what form of interventions would better support manufacturers in their transition processes. Table 5 summarizes the available government support and the type of interventions required.

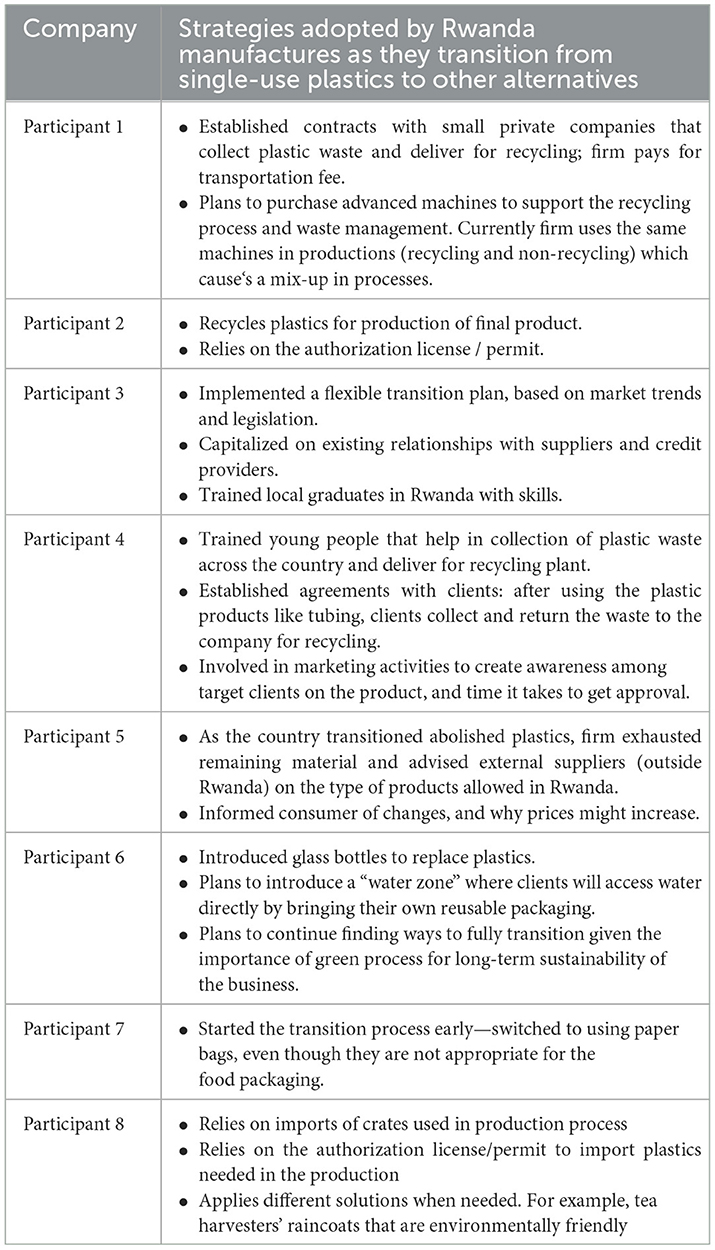

This research question sought to understand the strategies and approaches manufacturers adopt to transition to production or use environmentally friendly materials. Seven of the eight firms interviewed (87.5%) reported having a transition plan. The strategies adopted under these plans include being flexible to easily adapt to changing government policy, working with recycling and waste management companies to collect and process plastic waste, engaging in consumer awareness activities, and using new packaging materials such as paper bags and glass in replacement of plastics. Thematic analysis of the data collected from firms that reported having transition plans is summarized in Table 6.

Table 6. Strategies adopted by Rwanda manufactures as they transition from single-use plastics to other alternatives.

The key aspect of this study was to understand the implementation of CE-related principles in Rwanda. One of the research questions thus sought to explore how CE-related principles feature in Rwanda's sustainability and national development policies. The results indicate that since banning single-use plastics, Rwanda has consistently been implementing sustainable development policies and encouraging the adoption of CE principles. Rwanda has adopted various policies that align with the 10-R principles of circular economy (R0, Refuse; R1, Rethink; R2, Reduce; R3, Reuse; R4, Repair; R5, Refurbish; R6, Remanufacture; R7, Repurpose; R8, Recycle; R9, Recover) as summarized in Table 7.

The implementation of anti-plastic legislation in Rwanda has not been without challenges. Studies have found that while most SMEs are aware of the benefits of CE-related policies, their uptake of CE in business model development is hampered by various barriers, including a lack of financial resources and technical skills (Rizos et al., 2016; Andersen et al., 2021). For the firms studied, the policy resulted in increased business costs to acquire alternative materials and a lengthy licensing process to obtain exemption to the law from the environmental agency—for those eligible businesses. Primary manufacturers that initially produced plastic packaging have struggled to acquire capital to invest in a circular production process, such as introducing new technology to create alternative materials. They suffered from skills shortages as most were not better trained on new business models at the industry and managerial levels, a challenge further compounded by the lack of overall employability skills among graduates in Rwanda. Those firms are unable to compete by innovating new products or business models aligned with the new policies were forced to wind-up their operations (Participant 3).

More than 17 years since Rwanda first banned plastics, the most widely used packaging material, the country has not been able to produce or find a reliable source of alternative packaging materials. Secondary manufacturers that require packaging materials in their operations continue to face a supply crisis and have been unable to find a reliable supply chain to support the scale of their operations. When available, the alternative materials are costlier compared to plastics. Small and medium-sized enterprises (SMEs) are particularly affected, as one Rwanda-based fruits and vegetable processing company that exports to European and North American markets reported. Though the firm has transitioned and mainly uses paper-based packaging instead of plastics, it noted that paper bags are not appropriate for packaging agricultural products as wet consumables can easily destroy them. According to the company:

“It's not easy to find packaging material that is environment-friendly and what we use we import from Kenya. Before they prohibited plastic bags, we used them [as] was much easier. After the ban, we had to find another packaging tool…, [this] was very difficult because our products are delicate, and one can't use any type of packaging. We [have] to find appropriate packaging that [is] suitable for our products. But sometimes we stop production due to a lack of packaging tools (Participant 7).

Previous studies found that the plastics prohibition in Rwanda increased the packaging cost for manufacturers (Danielsson et al., 2017). For instance, following the ban on single-use plastics, the price of packaging materials for the food-processing industry increased from RWF 29.55 (USD 0.03) to RWF 118.20 (USD 0.12) (Afadhali, 2022). One firm that transitioned to packaging its products in aluminum bags saw the cost of the final product increase from RWF 236.40 (USD 0.24) to RWF 305.35 (USD 0.31) per unit. For Inyange industries, one of Rwanda's largest manufacturers, the price of packaging increased from RWF 59.10 (USD 0.06) to RWF 295.50 (USD 0.30) (Afadhali, 2022). Meanwhile, a plastic straws manufacturer noted that they invested Rwandan Francs (RWF) 250 million (US$241,000) to start the factory years ago, but would require at least RWF600 million (US$578,592) to invest in new technology to produce eco-friendly straws (Nkurunziza, 2022).

Internally, Rwanda lacks the capacity to develop a quality and reliable supply of packaging materials, and most secondary manufacturers rely on imports. Rwanda spent US$9.7 million on imports of polythene packaging in 2015, despite its ban on polythene bags (Bishumba, 2018). One firm observed that: “we have to import our material because we are looking for better quality material, and as you know Rwanda hasn't reached that level yet” (Participant 8). Before Rwanda introduced anti-plastic policies, chemicals, rubber, and plastics production accounted for <1 percent of its GDP in Rwanda. This was despite plastic production growing at an annual rate of 4.5 percent between 2004–07 (Jian and Martin, 2022). Between 2004 when Rwanda first banned plastic bags, and 2016, imports of plastics sharply reduced, falling from 1,092 tons in 2003 to just 18 tons in 2006, before bouncing back in 2008 when Rwanda formally introduced the national law banning plastic bags (Jian and Martin, 2022). Imports remained generally low, around 100 tons per year between 2009–2011 and reached 323 tons in 2016. Meanwhile, exports have drastically reduced (Jian and Martin, 2022).

The reliance on imports brings the added challenge of transportation and high import fees. Transporting materials to Rwanda can be very costly, especially if the shipment is made by flight (Government of Rwanda, 2016). According to one of the participants, the implication of the high cost of imported packaging materials makes the entire product more expensive in both local and export markets, resulting in lost or low market share. The participant reported that “the only issue is the packaging which makes the entire product more expensive… during the COVID-19 pandemic period, we had to ship all our packaging material by flight which cost us a lot money” (participant 3). Rwanda relies primarily on imports for non-agricultural products, including packaging. But transporting materials to Rwanda can be very costly, especially if the shipment is made by flight (Government of Rwanda, 2016). A manufacturer of paper products noted that the challenges of being a landlocked country and fluctuations in exchange rates make raw materials expensive since it results in high transportation costs (Participant 3). Similarly, due to lack of managerial and technical skills, some firms are forced to bring in foreign labor, which is costly and sometimes unreliable when workers have to repatriate to their home countries on short notice or when movement is hindered due to global health crises such as the COVID-19 pandemic.

Policies that support the development of firms' internal and industrial capacity to manufacture alternative materials to plastics and in general, innovate new business models and products are necessary to support firms' transition process. Policies that aim to develop Rwanda's nascent manufacturing industry will not only support continued business operations during the transition process but will help alleviate Rwanda's over-reliance on imports in the long term. Participants noted that monetary and non-monetary incentives such as training needed to support previous manufacturers of single-use plastics to align their business models with CE principles, for example, in developing alternative packaging to plastics. Besides, firms also need training and tools to respond better to changing government regulations. This is especially crucial since most products, including Rwanda's famous Akabanga chili, are still packaged in plastic bottles. While most products can be packaged in glass, the industry does not yet exist. The packaging sector is cross-cutting since packaging is required by manufacturers across all sectors. Developing the local capacity to manufacture sustainable packaging materials will be crucial since the manufacturing industry is key to realizing Rwanda's national development priorities.

Except for one company, all the firms interviewed have not fully transitioned their business models and still use plastics at some point in their operations. The firms interviewed adopted different strategies to ensure compliance with plastic regulations and transform their operations from linear to circular production models. The strategies include employing a flexible approach to business strategy development based on monitoring, and responding to government policy-making since the law kept changing, building long-term relationships with suppliers and credit institutions, investing in new products and technology, training graduates with required business skills, and utilization of the special authorization license that allows eligible companies to import or use plastics in their operations.

Though this was not a critical part of our study, we found that the firms are engaged in some form of circularity. All firms encourage their clients to practice recycling and proper waste disposal. For example, manufacturers who use single-use plastics in their product development process work with waste management companies in the waste disposal process. One firm manufactures construction products and plastic-sheeting materials used in greenhouse firms has a contractual agreement with its clients. The contract requires clients to return the materials to the company for recycling post-usage (Participant 4). These firms also use a mix of paper-based products and non-prohibited plastics. Meanwhile, a leading manufacturer transitioned from packing water in plastic bottles to glass bottles but reported that making glass is costly, and there is no reliable supply (Participant 6).

A primary manufacturer of single-use plastics reported that starting the transition process earlier, when the policy was announced in 2008 was instrumental in their overall shift and continued business stability. The company shifted from producing plastic products to the production of paper-based packaging products. The company adopted an approach where instead of importing and supplying bags, it imports plastic reels and manufactures them locally for clients authorized by the environment management authority (Participant 3). Effective communication and cooperation of suppliers is also crucial in ensuring a seamless transition process. A paint manufacturing firm whose imports initially came wrapped in plastic bags reported that when the ban came into place, they informed their suppliers of the policy change. The suppliers had no alternative but to comply. While this particular company was not directly affected, they acknowledged that their suppliers may have incurred additional costs in finding alternative packaging.

In general, businesses appeared to support the regulatory processes that protected the environment and noted that such regulations, if well implemented, are crucial to the long-term sustainability of their business and consumer markets. For example, Participant 6 reported that:

“We are not phasing plastic bottles just because the government has asked us. But we believe it is the right thing to do. Our raw material comes from the farmers—cow farmers and fresh food farmers. These sectors are most affected by climate change. If we pollute the environment, it affects the cows and farming. And it will become very hard for us in the future to get the raw materials. We understand that this is better for our business sustainability in the long term.”

Though Rwanda has banned plastics, companies can apply for a special exemption to import or use plastics in their operations (discussed in the next section). Due to shortage of alternative materials in Rwanda, especially packaging, and the lack of reliable supply, Rwandan firms are taking advantage of the special permit. According to the Rwanda Environment Management Authority (NEMA), manufacturers must apply for a license every time they import a prohibited plastic product (Participant 9). While some of the firms interviewed complained that the licensing process is time-consuming and the license itself amounts to the government policing their business, they understand it is the only way for them to continue some of their operations. To cope with the lengthy process, firms sometimes engage in marketing activities that sensitize their clients about their product and the process required to buy the product. Both firms and clients need a license to sell or purchase regulated plastics. The companies thus engage their clients first-hand and ask them to consider the time it takes to get the license to purchase the products. Firms reported that sometimes clients are frustrated by the process and often request them to apply on their behalf, which transfers the time-related costs to the business.

The special authorization license to import, sell or use single-use plastics is the cornerstone of government support to Rwandan manufacturers following the ban on single-use plastics. The exception is allowed by Article 4 of Rwanda's Law No. 17/2019, the legal framework for the plastic ban. Article 4 states that “a person who intends to manufacture, import, export, or use prohibited items for an ‘exceptional reason' may apply for authorization in writing to REMA” (Government of Rwanda, 2019). Special authorization is granted to stakeholders in the public and private sectors with products without other technically viable alternative packaging to plastics (REMA, 2019). During application for the authorization, applicants are required to provide details of the products to be packaged, the type(s) of plastics used, why the special authorization is needed, expected quantities, origin of the packaging materials and waste management plan (for management and disposal of the accompanying plastic waste). REMA will then assess and approve or deny the application, including with specific pre-approval conditions where necessary. In case the authorization is granted, there is a follow-up, reporting and approval for clearance of the plastics from the customs—in case of imports—to verify compliance with approval conditions. The Rwandan firms that participated in the study have applied for the special authorization at some point, particularly during the early stages of the plastic ban.

Studies have found that when not accompanied with a coherent and strict legislative framework, compliance with green economic policies often result in administrative burden, especially for SMEs without strong in-house legal capacities (Rizos et al., 2016). In Rwanda, the interviewed firms observed that the authorization process is sometimes frustrating, especially to their clients, who must also get authorization before they can purchase single-use plastics from local sellers.

Meanwhile, while the special authorization supports Rwanda's transition process from single-use plastics, it was initially necessitated by a need to comply with various international trade agreements Rwanda has signed. For example, due to the non-discriminatory principle of the World Trade Organization (WTO), Rwanda cannot impose a complete ban on competing imports such as products that enter the country wrapped in plastics or it risks violation of its international obligations (Simo, 2019). Moreover, most of the European and North American markets where some Rwandan companies export food products such as processed fruits and vegetables (in the case of participant 7), have not entirely restricted plastics. This situation puts domestic firms at a distinct disadvantage. The special authorization thus allows companies producing packaged food products such as processed chillies and beverages for exports to import the plastic needed in their business operations while simultaneously allowing the importation of products wrapped in plastics under strict regulations.

The second intervention the government provides to manufacturers is a grace period for the transition process. When the 2019 law was enacted, factories manufacturing single-use plastics were granted 2 years grace period from the date of publication. They were required to phase out the outlawed plastics by September 2021 (Nkurunziza, 2019). Though this enabled some manufacturers to partially transition, many companies have not found a reliable supply of alternative packaging. Besides, due to lack of proper sensitization, some retailers cannot differentiate between permitted and restricted plastics (Elisabeth, 2021). According to media reports, in January 2022, local manufacturers petitioned REMA to extend the grace period, citing the impact of the COVID-19 pandemic and lack of finance to invest in modern technology. However, the agency denied their requests (Nkurunziza, 2022). NBG Limited which manufactures plastic drinking straws noted that before the COVID-19 pandemic, the company had invested more than 250 million Rwanda Franc (RWF) (US$250 thousand) to start the factory, but would require at least RWF 600 million (US$600 thousand) to invest in new technology to produce eco-friendly straws. Furthermore, the pandemic compounded the challenges faced and to change the business model, the company requires an additional 5-year grace period (Nkurunziza, 2022).

Furthermore, firms noted that the transition timeline was insufficient to allow them to convert their machines and facilities from linear to circular production models. Interestingly, Rwandan legislators had initially warned of the potential consequences of the short transition time. During the approval of the draft law in 2019, members of parliament requested that businesses be given a longer phase-out period, or the country risked a shortage of packaging materials (Mbonyinshuti, 2019). One legislator observed that the transition process required research and consultation with stakeholders, while another noted that since the ban in 2008, Rwanda had “sustained the shortage of packaging materials” and that “10 years down the road there seems to be no alternative. “How sure are we that there will be packaging alternatives once we ban [all] single-use plastics?” The MP questioned (Mbonyinshuti, 2019).

Rwanda has generally been at the forefront of supporting the development of a thriving manufacturing industry. One strategy to encourage local manufacturing capacity development is the exemption of customs and value-added tax (VAT) on imported raw materials and capital goods such as machines. To qualify for exemptions firms must meet specific requirements, including certifying that they do not intend to resell the imported product. The firms interviewed reported that they have benefited from tax exemption. To support the development of the local packaging industry and prevent competition between local and foreign suppliers, in 2018 Rwanda started taxing imported packaging materials. Imported packaging materials were initially cheaper than those produced locally, and local manufacturers complained of unfair competition. Even then, investments in alternative packaging materials have been slow, and the gap is still filled by imports mainly from Kenya and China.

According to firms, beyond tax exemptions and special authorizations, government support can be designed in the form of financial assistance in the acquisition of new technologies, and training on best practices from other jurisdictions. These may be in the form of capacity development on circular business model development or development of biodegradable packaging materials. Regarding finance, some manufacturers noted that state and financial institutions should offer competitive credit terms which would be more sustainable than grants that are sometimes provided by non-governmental organizations (Participant 3). To develop the necessary skills, the government could work with educational institutions to develop curriculum and industrial academies to provide skills beyond those offered by existing TVET (technical and vocational education and training) institutions.

Collaboration between government and private sector in adopting CE and sustainability policies is intensifying in Rwanda. In June 2021, the Rwanda Private Sector Federation, an industry body, and the Rwanda environment management authority jointly established the Sustainable Management of Single Use Plastics Project (PET) (REMA, 2021). The PET project comprises three components: (i) collection, transportation, disposal, and recycling of single-use plastics, (ii) capacity development, research and awareness raising, and (iii) financial contribution from industries and importers. The project intends to contribute to Rwanda's plastic waste management processes through funding by private-sector companies who produce, import, or use plastic products in their business processes. As part of the project, the private sector federation expects to mobilize about RWF690.6 million (RWF) (US$0.7 million) during the first 5 years of the collaboration. Under the project one Rwandan investor has invested over US$3 million in a project that recycles plastic waste into construction materials (Moraes, 2021). In August 2021, the environment agency announced that all eligible manufacturers requiring special authorization to import plastic materials into Rwanda would have to contribute to the programme (REMA, 2021). Each firm that imports products packaged in single-use plastics into Rwanda will contribute RWF 90 (US$0.87) per kg of imported products; or US$90 for a ton of plastics imported. However, this requirement contributes to unfair competition between local manufacturers and importers since firms that export to Rwanda are not required to contribute to the Fund. While the private sector seeks to mobilize funding from their members for the project, the government has not provided similar financial incentives to complement their efforts. Indeed, most investments following the plastic ban, including in plastic waste management have come mostly from the private sector or the donor community.

Nonetheless, the government has welcomed projects that support its CE and sustainability initiatives. This is evident in the rapidly increasing number of waste management and recycling companies, including start-ups engaged in other CE-related initiatives in Rwanda, as observed during fieldwork. By 2019, there were about fourteen recycling companies compared to none in 2008. Together, these companies recycle 70–80 percent of the total plastic waste in Rwanda. These firms have been critical in the sustainable disposal and management of imported plastic waste in the country and in promoting the recycling culture, despite facing financial and technological challenges. Some of the imported plastic include plastic from ports of entry, mainly the airport. One recycling company estimated that they collect more than a ton of plastic waste each week from the airport alone.

In addition to the Sustainable Management of Single Use Plastics Project (PET), the government continues to collaborate with the private sector, including small and medium-sized enterprises, and civil society organizations. Initiatives involving civil society include promoting voluntary actions such as the National Circular Economy Forum that encourages business to lead in establishing a coalition on plastics and knowledge exchange between SMMEs and large companies. Rwanda has also developed policies that feature CE-principles in an effort to balance between growth and environmental efficiency (see Table 6) and is developing a draft National Strategy on CE. According to REMA, Rwanda will continue to explore initiatives and legal frameworks such as an environmental levy on imported consumer goods packaged in single-use plastics, training and research on circular economy and circular business models (Participant 9).

This study explored the experiences of Rwandan manufacturers following the plastic ban by investigating strategies adopted by manufacturers in response to the plastic ban, and the challenges manufacturers face in their transition process, and how they respond to those challenges. The study also sought to examine how CE principles feature in key sustainability policies in Rwanda.

Although the effects of single-use plastics are clear and immediate actions need to be taken to reduce the manufacture and usage of plastics, and adoption of alternative materials, insights from the study indicate that the transition to a plastic-free world should be gradual. The prohibition of single-use plastics in Rwanda positively transformed the country's image, but also presented economic implications such as business shutdowns, job losses, and an increase in prices for different products. Moreover, alternative materials have not been developed to match the scale in which plastic products are used. The innovation of sustainable products to replace plastics falls on both private and public sector stakeholders. However, in Rwanda, following the ban on plastics, that responsibility appears to have been left to manufacturers. Manufacturers have faced transition challenges to comply with anti-plastic legislation, including expensive start-up resources such as capital, technology, manpower, and time constraints. The socioeconomic and political effects of the ban on plastic (bags) perhaps explain why it was initially unsuccessful or took longer to implement in Rwanda's neighboring countries, notably Kenya and Uganda (Behuria, 2021). Behuria (2021) argued that the ban was quickly implemented in Rwanda since the business power of the private sector is limited.

Manufacturing is a sustainable growth engine that serves as an impetus for innovation and generates economies of scale. The Rwandan government has provided some support, including tax incentives, to companies willing to invest in plastic recycling equipment or manufacture environment-friendly alternatives. However, the manufacturing industry in Rwanda is still in its infancy stages, evidenced by the reliance on the import of most non-agricultural products. Regular collaboration between business and government remains crucial in balancing Rwanda's sustainability objectives and the development of the manufacturing industry.

As the manufacturers who participated in the study observed, Rwanda should complement private sector initiatives, for example, by developing partnerships with financial institutions to offer capital or credit to assist firms to acquire the necessary technology to transition from linear to circular production models. The government should also continue raising awareness of the importance of CE in business efficiency. However, activities should be targeted to educate firms on how to repurpose their business models, including through research and development (R&D) support to allow them to remain relevant in the ever-changing marketplace. Manufacturers are aware that business regulations and policies are bound to change at some point in response to developments in society. However, they cautioned that the uptake of CE principles in business may be hard if firms are not trained on critical methodologies for meaningful CE-based business model innovation. Encouraging research and development may also allow manufacturers to dig deeper and discover more ways of incorporating circular economy principles into their processes.

Furthermore, Rwanda needs to develop local capacity to produce alternative materials to plastic or develop a reliable global supply chain. This is necessary to cushion its manufacturing industry from the perennial shortage of packaging materials. Indeed, countries considering Rwanda's approach to the plastic ban should conduct an internal analysis to determine the potential impact of the ban on plastics on manufacturers and consumers beyond the well-documented positive environmental benefits. The challenges facing Rwanda firms after the prohibition are parallel to the challenges facing countries in the transition toward green energy. For example, the debates on the effectiveness and sustainability of green energy vs. fossil fuels such as coal in massive industrial development are necessary for job creation. In Rwanda, initial research on the potential impact of the ban on plastic seemed to have focused on the improvements in the environment and other dividends, such as the clean-country view, and largely ignored implications on the broader economy, such as constraints faced by manufacturers.

Finally, Rwanda should work with local and international stakeholders to address the situation that warrants the issuance of exceptional authorization to import single-use plastics. While the license is necessary to ensure Rwanda complies with its international obligations, it indirectly hinders innovation and full adoption of the CE principles in business and other sustainability policies. Local manufacturers will likely continue to rely on the incentive until a local industry develops to provide alternative packaging materials. International companies exporting to Rwanda, protected by non-discriminatory clauses of global trade agreements, will similarly lack incentives to develop alternative packaging materials for products destined for Rwanda. Initiatives such as an international treaty to ban plastics which Rwanda participates in, if successful, could help address this challenge (United Nations, 2022). Rwanda should also consider joining the coalition of WTO countries participating in The Informal Dialogue on Plastics Pollution and Environmentally Sustainable Plastics Trade (IDP) that seeks to complement discussions in the Committee on Trade and Environment (CTE) (WTO, 2022). Despite its leadership in plastic management policies, at the time of writing, Rwanda was not among the 75 WTO members (including eight African countries) participating in the IDP, which is gradually emerging as a forum for setting informal agenda on trade in plastic products within the WTO framework.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

The studies involving human participants were reviewed and approved by the African Leadership University (ALU) Circular Economy Research Ethics Committee. The patients/participants provided their written informed consent to participate in this study.

MO, JA, and MM conceived the paper. The research grant was awarded to MO who also supervised the research project and wrote the first manuscript. JA supervised the fieldwork and data collection in Rwanda and contributed to the section on CE principles. CN and OH students at the African Leadership University, Rwanda, assisted with fieldwork and data collection in Rwanda. MM reviewed and improved the final manuscript. All authors reviewed and approved the final version.

This research was undertaken as part of the CE Programme at African Leadership University (ALU). We thank MAVA Foundation for the support to the programme through their contribution to the ALU CE Programme.

We are grateful for the support provided through the Circular Economy Research Programme at ALU. We also thank Elke Nijman, Elisée Bahati Ntawuhiganayo, Dr. Theresa Lisita, and Lea McDonald for commenting on earlier drafts of the manuscript. Finally, we thank all our stakeholders and participants for their contributions to this research.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Afadhali, P. (2022). Rwanda banks on single-use plastic ban to tackle plastic pollution. InfoNile, Available online at: https://infonile.org/en/2022/02/rwanda-banks-on-single-use-plastic-ban-to-tackle-plastic-pollution/ (accessed February 16, 2022).

Andersen, M., Ogallo, E., and Faria, L. (2021). Green economic change in Africa – green and circular innovation trends, conditions and dynamics in Kenyan companies. Innov. Develop. 12, 231–57. doi: 10.1080/2157930X.2021.1876586

Behuria, P. (2015). Between party capitalism and market reforms – understanding sector differences in Rwanda. J. Mod. African Stud. 53, 415–450. doi: 10.1017/S0022278X15000403

Behuria, P. (2019). “The comparative political economy of plastic bag bans in East Africa: why implementation has varied in Rwanda, Kenya and Uganda,” in Global Development Institute Working Paper Series 372019, GDI, The University of Manchester. Available online at: https://ideas.repec.org/p/bwp/bwppap/372019.html (accessed October 25, 2022).

Behuria, P. (2021). Ban the (plastic) bag? Explaining variation in the implementation of plastic bag bans in Rwanda, Kenya and Uganda. Environ. Plan. C. 39, 1–18. doi: 10.1177/2399654421994836

Bishumba, N. (2018). Imported packaging materials to be struck off the tax-exempt list. The New Times. Available online at: https://www.newtimes.co.rw/article/148895/News/imported-packaging-materials-to-be-struck-off-tax-exempt-list (accessed October 25, 2022).

Clapp, J., and Swanston, L. (2009). Doing away with plastic shopping bags: international patterns of norm emergence and policy implementation. Environ. Polit. 18, 315–332. doi: 10.1080/09644010902823717

Corvellec, H., Stowell, A., and Johansson, N. (2021). Critiques of the circular economy. J. Ind. Ecol. 26, 1–12. doi: 10.1111/jiec.13187

Danielsson, M., Wockelberg, H., and Kall, W. (2017). The Plastic Bag Ban in Rwanda: Local Procedures and Successful Outcomes -A Case Study on how Rwanda Implemented a Nation-wide Ban on Plastic Bags. Available online at: https://www.diva-portal.org/smash/get/diva2:1067480/FULLTEXT01.pdf (accessed October 25, 2022).

Desmond, P., and Asamba, M. (2019). “Accelerating the transition to a circular economy in Africa: Case studies from Kenya and South Africa,” in The Circular Economy and the Global South: Sustainable Lifestyles and Green Industrial Development, eds. Schröder, P., Anantharaman, M., Anggraeni, K., and Foxon, T.J, . (London: Routledge). doi: 10.4324/9780429434006-9

Dsilva, E. (2019). Going surgical on plastics in Rwanda. Available online at: https://www.downtoearth.org.in/news/waste/going-surgical-onplastics-in-rwanda-68446 (accessed March 25, 2021).

Elisabeth, I. (2021). REMA once again issues warning on the Use of Plastic Items on Rwandan soil (Top Africa News). Available online at: https://www.topafricanews.com/2021/05/03/rema-once-again-issues-warning-on-the-use-of-plastic-items-on-rwandan-soil/ (accessed May 3, 2021).

European Parliament (2008). Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Official Journal of the European Union.

Ghisellini, P., Cialani, C., and Ulgiati, S. (2016). A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 114, 11–32. doi: 10.1016/j.jclepro.2015.09.007

Government of Rwanda (2020). Vision 2050. Available online at: https://www.nirda.gov.rw/uploads/tx_dce/Vision_English_Version_2050_-31_Dec_2020.pdf (accessed October 25, 2022).

Government of Rwanda (2019). Official Gazette n° 37 bis of 23/09/2019. LAW N° 17/2019 OF 10/08/2019 Relating to the Prohibition of Manufacturing, Importation, use and sale of plastic carry bags and single use plastic items. Available online at: https://elaw.org/system/files/attachments/publicresource/Law_relating_to_the_prohibition_of_manufacturing__importation__use_and_sale_of_plastic_carry_bags.pdf (accessed October 25, 2022).

Government of Rwanda. (2005). Organic Law 4/2005 Determining the Modalities of Protection, Conservation, and Promotion of Environment in Rwanda. Official Gazette of the Republic of Rwanda. Available online at: https://www.climate-laws.org/geographies/rwanda/laws/organic-law-4-2005-determining-the-modalities-of-protection-conservation-and-promotion-of-environment-in-rwanda (accessed February 20, 2022).

Government of Rwanda (2012). Rwanda Vision 2020 - Revised 2012. Available online at: https://www.nirda.gov.rw/uploads/tx_dce/05_-_Vision_2020_06.pdf (accessed June, 2022).

Government of Rwanda (2016). Rwanda AGOA Action Plan. Available online at: https://agoa.info/images/documents/6212/rwanda-agoa-strategyr.pdf (accessed October 25, 2022).

Greenpeace Africa (2020). 34 Plastic Bans in Africa | A Reality Check. Greenpeace Africa. Available online at: https://www.greenpeace.org/africa/en/blogs/11156/34-plastic-bans-in-africa/ (accessed October 25, 2022).

Groenewald, T. (2004). A phenomenological research design illustrated. Int. J. Qualit. Method. 3, 42–55. doi: 10.1177/160940690400300104

Hakuzimana, J. (2021). Break free from plastics: environmental perspectives and evidence from Rwanda. Environ. Ecosyst. Sci. (EES). 5, 27–36. doi: 10.26480/ees.01.2021.27.36

Jian, X., and Martin, J. (2022). Plastic Waste Management in Rwanda: An Ex-post Policy Analysis. Washington, DC: The World Bank. Available online at: https://openknowledge.worldbank.org/handle/10986/37607 (accessed October 25, 2022).

Karuhanga, J. (2017). EALA votes to ban polythene bags. The New Times, 2 June. Available online at: https://www.newtimes.co.rw/section/read/213545/ (accessed October 25, 2022).

King, A. M., Burgess, S. C., Ijomah, W., and McMahon, C. A. (2006). Reducing waste: repair, recondition, remanufacture, or recycle? Sustain. Develop. 14, 257–267. doi: 10.1002/sd.271

Kirchherr, J., Reike, D., and Hekkert, M. (2017). Conceptualising the circular economy: an analysis of 114 definitions. Resour. Conser. Recycl. 127, 221–232. doi: 10.1016/j.resconrec.2017.09.005

Kumar, R. (2011). Research Methodology: A Step-by-Step Guide for Beginners, 3rd Edn. New Delhi: Sage.

Leonard, S., and Barra, R. (2018). Plastics and the circular economy. Scientific and Technical Advisory Panel to the Global Environment Facility. Washington, DC. Available online at: https://stapgef.org/resources/advisory-documents/plastics-and-circular-economy (accessed October 25, 2022).

Mbonyinshuti, J. (2019). Firms should be given more time to phase out single use plastics: MPs. Available online at: https://www.newtimes.co.rw/news/phase-single-use-plastics (accessed February 18, 2019).

Moraes, C. (2021). Rwandan Investor funding project to recycle plastic waste into construction materials. Construct Africa. Available online at: https://www.constructafrica.com/news/rwandan-investor-funding-project-recycle-plastic-waste-construction-materials (accessed December 31, 2021).

Nibeza, S. (2015). Sustainable environment, a key to sustainable development, a case study of Rwanda. Int. J. Res. Econ. Soc. Sci. 5, 20–36. Available online at: https://euroasiapub.org/wp-content/uploads/2016/09/3ESSJune-2261-1.pdf (accessed May 20, 2021).

Nkurunziza, M. (2019). How banning of single-use plastics will contribute to environment protection for Rwanda's green development. New Times Rwanda. Available online at: https://www.newtimes.co.rw/news/featured-how-banning-single-use-plastics-will-contribute-environment-protection-rwandas-green (accessed December 03, 2019).

Nkurunziza, M. (2022). No extension of grace period for single-use plastics - Rema. New Times Rwanda. Available online at: https://www.newtimes.co.rw/article/193139/News/no-extension-of-grace-period-for-single-use-plastics—rema (accessed August 20, 2022).

PBL Netherlands Environmental Assessment Agency (2017). Circular Economy: Measuring Innovation in the Product Chain. Policy Report.

REMA (2019). Guidelines on Procedures and Conditions for Eligibility to grant exceptional permission to manufacture, use, import, or sell single-use plastic items or pack goods in single use plastics. Available online at: https://elaw.org/system/files/attachments/publicresource/RW_BanException_Guidelines_2019.pdf (accessed October 25, 2022).

REMA. (2021). All eligible manufacturers who want to get REMA authorization to import PET materials will have to contribute to the sustainable management of Single Use Plastics Project (PET). Twitter. Available online at: https://twitter.com/rema_rwanda/status/1426165570253246468 (accessed October 20, 2022).

Rizos, V., Behrens, A., Van der Gaast, W., Hofman, E., Ioannou, A., Kafyeke, T., et al. (2016). Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability. 8, 1212. doi: 10.3390/su8111212

Shabiti, D. (2021). Rwanda Steps Up Single Use Plastic Ban Ahead of September Deadline. KT PRESS. Available online at: https://www.ktpress.rw/2021/05/rwanda-steps-up-single-use-plastic-ban-ahead-of-september-deadline/ (accessed October 25, 2022).

Siegel, P. B., Gatsinzi, J., and Kettlewell, A. (2011). Adaptive social protection in Rwanda: ‘Climate-proofing the Vision 2020 Umurenge Programme. IDS Bull. 42, 71–78. doi: 10.1111/j.1759-5436.2011.00276.x

Sihvonen, S., and Ritola, T. (2015). “Conceptualizing ReX for aggregating end-of-life strategies in product development,” in Procedia CIRP. p. 639–644. doi: 10.1016/j.procir.2015.01.026

Simo, R. Y. (2019). Of sustainable development in africa: addressing the (In)congruence of plastic bag regulations with international trade rules. Brooklyn J. Int. Law. 45, 240–299. doi: 10.2139/ssrn.3391826

Tongco, M. D. C. (2007). Purposive sampling as a tool for informant selection. Ethnob. Res. Applic. 5, 147–158. doi: 10.17348/era.5.0.147-158

UNEP (2018a). United Nations Environment Programme News and Stories, “Back to School Plastic Challenge,”. Available online at: https://www.unenvironment.org/news-and-stories/story/school-year-help-us-turn-tide-plastic (accessed Octomber 14, 2019).

UNEP (2018b). Single-use plastics: A Roadmap for Sustainability (Rev. ed., pp. vi; 6). Available online at: https://www.unep.org/resources/report/single-use-plastics-roadmap-sustainability (accessed October 25, 2022).

UNEP (2018c). Our planet is drowning in plastic pollution. This World Environment Day, it's time for a change. Available online at: https://www.unep.org/interactive/beat-plastic-pollution/ (accessed October 25, 2022).

United Nations (2022). Speakers Call for International Treaty on Plastic Pollution, Circular Economic Models to Promote Reusability, Reduce Waste, as Stockholm+50 Meeting Concludes. Available online at: https://press.un.org/en/2022/envdev2048.doc.htm (accessed October 25, 2022).

Valenzuela, F., and Böhm, S. (2017). Against wasted politics: A critique of the circular. Ephemera. 17, 23–60. Available online at: https://ephemerajournal.org/sites/default/files/2022-01/17-1valenzuelabohm.pdf (accessed May 20, 2021).

Van Buren, N., Demmers, M., Van der Heijden, R., and Witlox, F. (2016). Towards a circular economy: The Role of Dutch Logistics Industries and Governments. Sustainability. 8, 647. doi: 10.3390/su8070647

Whyte, C., Irakoze, G., Katanisa, P., Desmond, P., Hemkhaus, M., Ahlers, J., et al. (2020). Circular economy in the Africa EU cooperation - Country Report for Rwanda. Country report under EC Contract ENV.F.2./ETU/2018/004 Project: “Circular Economy in Africa-EU cooperation”, Trinomics B.V., ACEN, Adelphi Consult GmbH and Cambridge Econometrics Ltd. Available online at: https://trinomics.eu/wp-content/uploads/2020/12/Country-Report-Rwanda_Final_20122020.pdf (accessed October 25, 2022).

WTO. (2022). Plastics pollution and environmentally sustainable plastics trade. Available online at: https://www.wto.org/english/tratop_e/ppesp_e/ppesp_e.htm (accessed January 06, 2023).

Keywords: circular economy in Africa, sustainability policy, environmental policy, plastic ban, manufacturing, Rwanda

Citation: Ogutu MO, Akor J, Mulindwa MS, Heshima O and Nsengimana C (2023) Implementing circular economy and sustainability policies in Rwanda: Experiences of Rwandan manufacturers with the plastic ban policy. Front. Sustain. 4:1092107. doi: 10.3389/frsus.2023.1092107

Received: 07 November 2022; Accepted: 16 January 2023;

Published: 09 February 2023.

Edited by:

Olawale Olayide, University of Ibadan, NigeriaReviewed by:

Sonu Rajak, National Institute of Technology Patna, IndiaCopyright © 2023 Ogutu, Akor, Mulindwa, Heshima and Nsengimana. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Moses Onyango Ogutu,  bW9ndXR1MDA1QGdtYWlsLmNvbQ==

bW9ndXR1MDA1QGdtYWlsLmNvbQ==

†These authors have contributed equally to this work and share last authorship

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.