- 1Department of Food, Environmental and Nutritional Sciences, University of Milan, Milan, Italy

- 2Department of Agricultural and Environmental Sciences, University of Milan, Milan, Italy

- 3Department of Environmental Science and Policy, University of Milan, Milan, Italy

- 4Department of Civil Engineering, Architecture, Land, Environment and of Mathematics, University of Brescia, Brescia, Italy

The horticultural industry claims the substitution of plastic plantlet containers, which derive from oil-based raw materials and cannot be recycled, with bio-based ones, aiming to decrease waste management costs and increase the overall production sustainability. Bio-based fully biodegradable nursery pots can be directly placed in soil, thus decreasing the plantlet transplant stress and labor, and avoiding waste generation. The development of biomaterials specifically obtained from food-derived wastes like fruit and vegetables will add further advantages by an improved use of resources, the production of added-value materials and the replenishment of food losses, in a perfect circular economy approach. A multidisciplinary strategy combining material science, microbiology, agronomy and economy will, moreover, allow the development of functionalized food-waste derived materials, enriched in biostimulant extracts, alive plant-growth promoting microorganisms and thermal buffering molecules, obtaining biodegradable and biofertilising plant multiplication plugs with the potential to increase the sustainability of the overall agri-food production chain.

Introduction

Over the last decades, several factors had a dramatic impact on the food sector. Growing food demand, food supply chain globalization, agricultural intensification, and increased wealth of population in several countries claimed the need to consider new models of development in this sector, with the goal of achieving a more sustainable economic, environmental, and societal growth (Scarano et al., 2022). Within this scenario, the efficient use of resources and the reduction of food losses and wastes have been identified as the main priorities for the next years and are included among the UN Sustainable 2030 Development Goals Agenda. Accordingly, the transition from a linear to a circular economy model is imperative in overcoming the problems of food waste and to reach a sustainable resource management (Jõgi and Bhat, 2020).

Among others, the sector of fresh-cut and ready-to-eat fruits and vegetables generates a significant large amounts of organic waste, which represents an evident economic, social, and ethical problem (Campos et al., 2020). At the same time, bio-waste can also be a great opportunity to obtain new resources as added-value products. According to a circular scheme, the organic waste can be profitably used as raw biomass, without any specific restriction other than the specific content in the target molecules/biopolymer, for the generation of functionalized biodegradable materials which could find several applications. One application could be the fabrication of plant nursery plugs used for vegetable production, generating a virtuous circular loop. Today the plant nursery industry largely relies on plugs made of plastic, a non-renewable oil-based raw materials. Plastic plugs are characterized by optimal mechanical properties, chemical, and microbial degradation resistance, durability, as well as low cost but after use in plant nursery they result contaminated by organic matter and chemicals and cannot be properly recycled. To face this problem in the last years alternative plant containers have been developed from a variety of animal- and plant-based renewable sources, including bioplastics, providing several additional advantages over the thermoplastic containers (Evans et al., 2010; Kratsch et al., 2015).

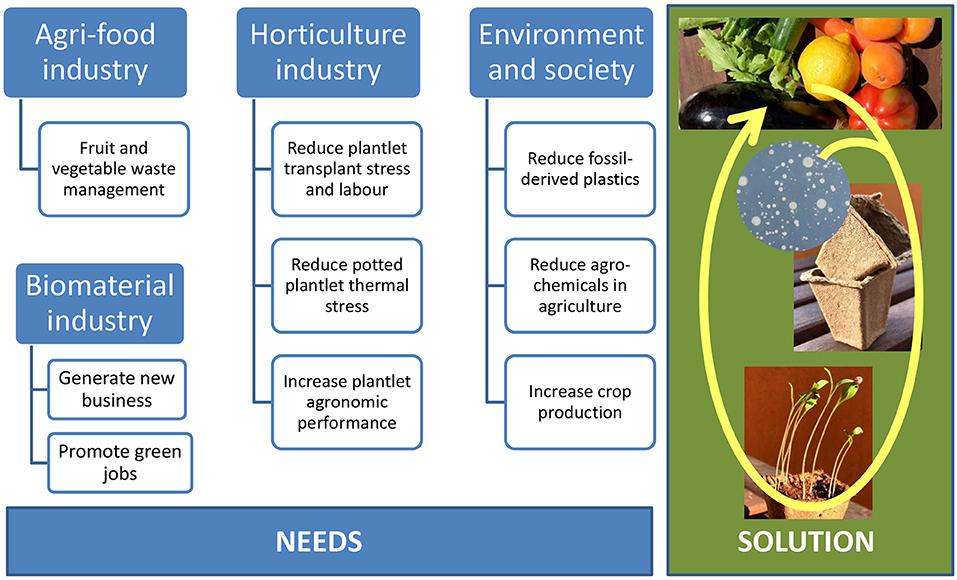

The development of bio-based and biodegradable plant nursery plugs will certainly intercept multiple needs at different levels: (i) the agri-food industry to manage the fruit and vegetable waste material; (ii) the bio-based industry to find new green materials while implementing new job opportunities; (iii) the horticulture industry to obtain nursery plant plugs able to improve plantlet yield and productivity, decrease planting labor, and costs related to the plastic plug disposal; (iv) the society to decrease both the amount of fossil-derived plastics and the use of chemicals while increasing the food production (Figure 1).

Figure 1. Food waste-derived biomaterials enriched by biostimulant agents have the potential to respond to multiple needs in a circular approach.

This kind of approach moves in a complex and multi-faceted framework and can be implemented only through a multidisciplinary strategy that requires the integration of different expertise. Material science plays a pivotal role to select the best agri-food wastes and obtain the biopolymers to design biodegradable plant nursery plugs, but other disciplines like microbiology and agronomy can contribute to functionalize this innovative product, by the addition of biofertilizers and biostimulants assessing their efficacy in the field. Lastly but not least, the economic and life cycle assessment aspects are fundamental to demonstrate the sustainability of the product and its production process.

Design of Food-Waste Derived Bio-Based Materials for Plant Cultivation

The use of biodegradable bio-based pots implies some intrinsic technical advantages over the conventional plastic ones with petrochemical origin. Plantlet transplant stress is indeed strongly mitigated by the biodegradability of the bio-based plug that permits to place it directly in soil avoiding the plantlet extraction, even by reducing and simplifying planting operations. Transplant stress has been indicated as one of the factors affecting crop productivity (Latimer et al., 1991), hence its reduction is of great interest for farmers and would contribute to increase the efficiency of plant food production with a consequent more efficient resource use.

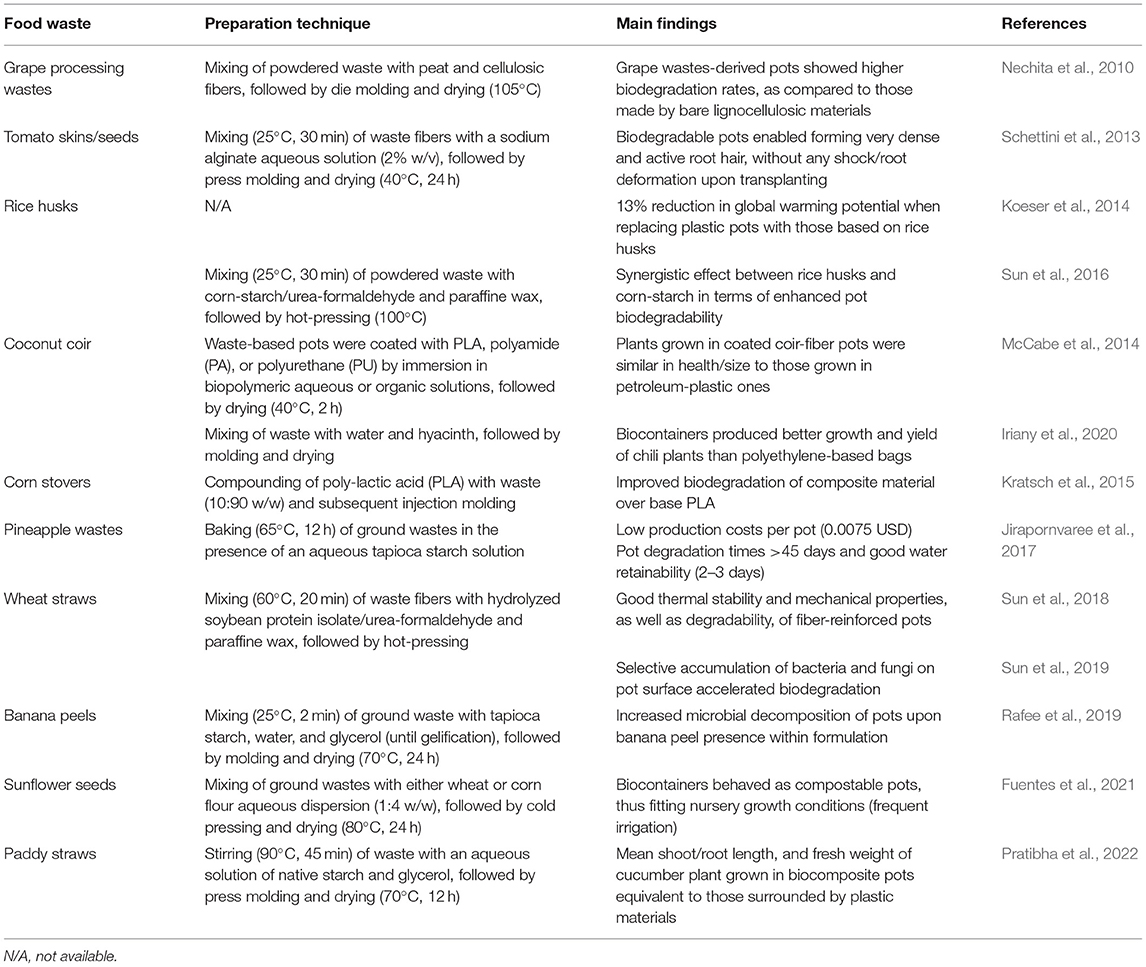

Table 1 summarizes the main outcomes of the research works encompassing the production of food waste-derived pots for horticulture applications, as a viable and sustainable alternative to conventional containers made by thermoplastic resins. Schettini et al. (2013) performed a study on the mechanical properties, water absorption ability, and biodegradability during pepper plant cultivation in soil using novel bio-based pots consisting with sodium alginate as the main polymer phase and tomato wastes/hemp fibers as natural structuring disperse phase. Specifically, bio-containers were developed by cold-pressing the formulation inside a pot-shaped molding system. It was demonstrated that the utilization of bio-pots loaded with reinforcing fibers yielded a smooth development of plant roots, accompanied by a good secondary branching structure, thus prompting water and nutrients uptake with respect to that granted by polystyrene-based containers. Moreover, in the same study, the authors observed an overall pot degradation process occurring within 16 days elapsing from the transplanting phase, with roots spreading in a radial mode from the containers to the surrounding soil. Noteworthy, further experiments unveiled a faster biodegradation rate of samples added with tomato skin/seed alone over those also containing an amount of hemp fibers. This behavior was attributed to the food waste-derived fibers which provided a higher contact surface to soil microorganisms and a higher availability of hydroxyl groups standing as attack sites along pectin, starch, and cellulose chains (Schettini et al., 2013).

Table 1. Summary of the main preparation techniques adopted to produce biodegradable pots from food wastes.

Fuentes et al. (2021) assessed the fertilization ability of several biodegradable pots, as a function of both the utilized structural matrix (e.g., gelatin, wheat/corn waste flour, and cellulose paper) and the solid waste/by-product integrated as filler (e.g., sunflower seed/rice husks, and yerba mate) within the composite material formulation. All the containers were prepared by cold pressing the formulation in a manual press, except for gelatin-based biocomposites, which were generated using a hot-compression system operating at 120°C, 50 kgf/cm2 of applied pressure, and 5 min of holding time. Corn-waste flour and rice seed husks-derived pots showed poor performances, on the contrary wheat waste flour-based containers loaded with sunflower seed husks exhibited a preventive action toward leaf damages during plant development which was estimated around 30% less than plantlet cultivated in corn-waste flour and rice seed husks derived pots. As in Schettini et al. (2013) experimentation, the filler particle size demonstrated a pivotal role in explaining such discrepancies, since rice husks particles, being ~10-fold greater in size than those belonging to sunflower wastes (0.6 mm), decreased the decomposition rate of bio-pots hampering plant growth.

Santos et al. (2017) implemented a suitable strategy to develop 0.5 mm thin-walled containers made of biodegradable material, Bioplast GS 2189, classified as a mixture of poly-lactic acid and starch—via injection molding technology with injection pressure 150 MPa, processing and mold temperature 210 and 25°C, respectively. The authors pinpointed the crucial roles played by both design and manufacture of the mold and the tuning of injection parameters to improve process effectiveness and competitiveness. Nonetheless, as emerging from the comparative characterization of pre-processed (grains) and post-processed (biodegradable pots) samples, an incipient degradation effect toward intrinsic properties of materials cannot be excluded, due to the intense shear forces and thermal variations experienced. Even though not including any food waste-derived material within product formulation, the achieved results offered technical guidelines on the proper development of biodegradable pots (Harris et al., 2020).

Besides the advantages related to material biodegradability, bio-based pots have also the potential to improve plantlet growth. An optimization study of bio-container composition aimed to improve the quality and growth of chili plants throughout the nursery stage was successfully executed by Iriany et al. (2020). In this work the effect of water hyacinth petiole (WHP) to coconut coir (CC) mass ratio was investigated on several parameters associated with either plant growth or yield by using a randomized complete block design-based approach, comparing the results achieved with conventional polyethylene plastic pots. Bio-pots were obtained from raw materials by cutting and weighing, pulping, molding and drying, with WHP subjected to a 20 min boiling treatment in water before pulping. Interestingly, the molded bio-pot optimal composition [i.e., 70:30 (w/w) WHP to CC], significantly improved the plant yield parameters compared with plastic pots, as shown by higher number of fruits per plant and fruit weight (+ 53% on average).

As a general trend, all the reported research works developing bio-based pots (Table 1) demonstrated the increased material biodegradability, independently from the intrinsic characteristics (i.e., shape, size) of the food waste employed during bio-pot fabrication, as compared to materials achieved from the processing of bare polymeric substrates alone. Although most of the cited research works relied on the molding technology to shape disparate formulations into food waste-based pots, none of them inferred whether the choice of set operative conditions would stem from a preliminary optimization study. The latter might have allowed an intensification of the molding process efficiency, with a positive impact on the economic performance of the horticulture industry.

Based on these findings, additional efforts are yet to be performed in the direction of overcoming the main limitations associated with the molding technique (e.g., high initial costs, long processing times, poor versatility, among others), in the perspective of industrial scale-up for commercial applications relying on the exploitation of food wastes. In parallel, the use of multiple crop species during in-field performance evaluation might allow to gain more insight into the effect of bio-based materials on crop performance during growth/transplant stages.

Novel Functionality of Bio-Based Materials for Sustainable Agriculture

A further innovation of designing bio-based materials is the possibility to enrich and functionalize them using different types of biologically active components, such as biostimulant agents and thermal buffering molecules, to improve plant growth further increasing the sustainability of the agri-food sector.

Plantlets cultivated in plastic plugs experience a thermal stress due to heat accumulation, a disadvantage that can be overcame by using novel bio-based materials enriched by thermal absorbing particles. Thermal adsorbing particles are based on the phase change material (PCM) technology. PCMs are materials that undergo a phase change, e.g., from solid to liquid state, at a specific temperature (or in a narrow range of temperatures) near the envisaged application. In such systems, energy is stored during melting and recovered during freezing (Li et al., 2009). The latent heat is the thermal energy that needs to be absorbed or released when PCMs change phase and are hence capable to store or release large amounts of energy (Khudhair and Farid, 2004). If a PCM is added to a pot inner side, it increases the thermal energy storage capacity of the container (Rentas et al., 2004), representing the most ideal solution for off peak storage (Castell et al., 2011). PCM technology thus represents a powerful approach to mitigate the thermal stress affecting plant nurseries when germination plugs are irradiated and soil temperature rises.

The interest of the market for the use of bioactive compounds in crop production is constantly increasing and their production and commercialization have been recently regulated by the European regulation n. 1009/2019, which classified them into two categories: microbial and non-microbial biostimulants. Biostimulants can be obtained from organic matrices of different nature and origin exploiting different extraction processes. Biostimulant molecules can be collected in nature (marine algae, Battacharyya et al., 2015), produced through cultivation (botanical species with a high content of bioactive compounds, Bulgari et al., 2017) or recovered from agro-industrial processes (Xu and Geelen, 2018). The choice of the latter approach would further foster the circularity of the bio-based and biodegradable plug production. Extracts, depending on the organic source and the extraction method applied, have a variable composition with a different concentration of active compounds like minerals, amino acids, sugars, vitamins, antioxidants (polyphenols), plant hormones (Battacharyya et al., 2015; Rodrigues et al., 2020). Plant residuals, such as leaves or flowers of fresh-cut industrial waste, are commonly used as source of bioactive compounds, which can be extracted through maceration in water, using water as a solvent (Franzoni et al., 2021).

Furthermore, the addition of Plant Growth-Promoting Microorganisms (PGPMs) would be extremely interesting to design novel biomaterials for agricultural practices aimed at reducing the use of chemicals, including fertilizers. PGPMs are common members of the plant microbiome able to enhance nutrient bioavailability, promote seed germination and root development through hormone regulation, and protect plants against pathogens as well as abiotic stresses (Rolli et al., 2015; Carrión et al., 2019; Soldan et al., 2019). Overall, they exert a beneficial effect on plant growth, health and production (Riva et al., 2022) and different commercial formulations are available. A bottleneck reducing their effectiveness in the field is the delivery method (Sessitsch et al., 2019), which strongly impacts the microbial colonization of the root system and the attached soil particles (i.e., rhizosphere). Multiplication plugs made of PGPMs enriched biomaterials can overcome this problem by providing the plant roots with alive PGPMs soon after their emergence from the seed, thus allowing the most favorable conditions for the establishment of beneficial strains.

More researches are needed in order to develop competitive functionalized biomaterials especially in relation to mechanical properties, chemical and microbial degradation resistance, low cost and durability, the latter especially in relation to the content in alive beneficial microorganisms.

Potential Impact of Bio-Based Multifunctional Materials Toward Sustainable Circular Practices in Horticulture

Research activities aimed at developing bio-based multifunctional materials are crucial to deal with the current societal challenges. The design of these materials will contribute to achieve the goals of the UN Sustainable Development Goals 2030 Agenda (e.g., SDG12—Ensure sustainable consumption and production patterns). Firstly, they will be obtained recycling organic waste and by-products generated from the food industry, promoting the transition toward a circular economy. Food loss and waste along the food supply chains is given by upstream (including production and postharvest) and downstream processes (including processing, distribution, and consumption). In 2019 food waste reached around 1.3 billion tons annually, with a cost of more than 1,000 billion dollars per year (FAO, 2019) and estimates pointed-out that 8–10% of global greenhouse gas emissions were associated with food that is not consumed (United Nations Environment Programme, 2021). This represents a clear economic, environmental and ethical problem that can be solved only by adopting circular economy models.

The obtainment of biodegradable plugs would be strategic for the horticulture sector, considering that the current plugs are largely made of fossil-derived plastic polymers (e.g., polystyrene, polyethylene, and polypropylene) thus representing a disposal cost. Harris et al. (2020) reported that USA produces four billion container/plant units annually, of which 1.6 billion are petroleum-based plastic containers. Besides fossil resource-independence, further significant advantages of bio-based materials particularly derived from food waste are that they do not compete for resources and land with food production and do not foresee raw material costs (Rosenboom et al., 2022). Life Cycle Assessment (LCA) studies highlighted how the use of plastic materials in the horticultural sector has a non-negligible environmental effect (Lazzerini et al., 2016) both considering the energy used for plastic manufacturing and the end-of-life of the plastic containers (Schwarzwälder et al., 2001). The same occurs for bioplastics whose environmental results is controversial, mainly due to the waste management operations (Razza and Cerutti, 2017). In this context, the substitution of plastic pots with bio-based 100% biodegradable materials involves environmental benefits related to the reduction of plastic consumption and the elimination of disposal. Furthermore, the development and adoption of nature-based solutions to increase farm productivity in an environmentally sustainable way is of compelling interest. In this framework, innovative bio-based materials embedding beneficial microorganisms isolated and selected from the plant microbiome, plant waste-derived biostimulants and thermal adsorbing particles would be extremely useful, having the potential to improve plantlet growth and agronomic performance since the nursery stage and limiting physiological stresses related to transplant.

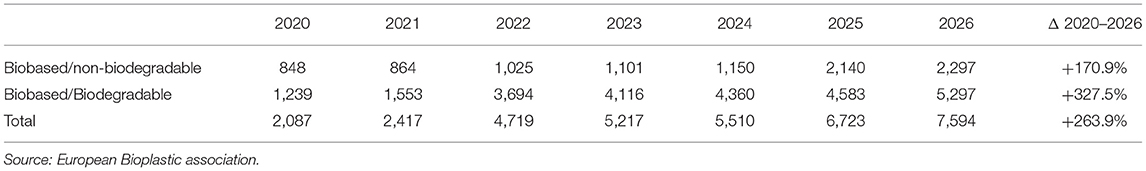

The huge market potential for bio-based materials is confirmed by the European Bioplastic association, estimating an increase in production from around 4.7 million tons in 2022 to ~7.59 million tons in 2026 (https://www.european-bioplastics.org/market/). What is more, the highest growth rate is expected for biodegradable bioplastic compared to bio-based non-biodegradable products (Table 2). The main market driver is represented by the evolution of consumers' demand toward sustainable products: in a recent report, Nielsen (2018) stated that environmentally friendly and recycled packaging are the sustainability attributes that consumers prioritize in their purchasing behaviors. This aspect is of special relevance for European consumers, since the recent Eurobarometer report (2021) revealed that the 78% of respondents feel that environmental issues have an impact on their daily life and health, and almost the 90% are worried about the impact of plastic products in the environment.

Data Availability Statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author Contributions

SB, FM, and SF conceived the work. All authors contributed to manuscript writing and editing and approve its content.

Funding

This work was funded by the Cariplo Foundation Project Circular Agri-food Systems: development of biodegradable and biostimulant plant multiplication plugs from fruit and vegetable wastes—BBPlug (Grant No. 2021-0742).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Battacharyya, D., Babgohari, M. Z., Rathor, P., and Prithiviraj, B. (2015). Seaweed extracts as biostimulants in horticulture. Sci. Horticult. 196, 39–48. doi: 10.1016/j.scienta.2015.09.012

Bulgari, R., Morgutti, S., Cocetta, G., Negrini, N., Farris, S., Calcante, A., et al. (2017). Evaluation of borage extracts as potential biostimulant using a phenomic, agronomic, physiological, and biochemical approach. Front. Plant Sci. 8, 935. doi: 10.3389/fpls.2017.00935

Campos, D. A., Ricardo, G., Vilas-boas, A. A., Madureira, A. R., and Pintado, M. M. (2020). Management of fruit industrial by-products—a case. Molecules 25, 320. doi: 10.3390/molecules25020320

Carrión, V. J., Perez-Jaramillo, J., Cordovez, V., Tracanna, V., De Hollander, M., Ruiz-Buck, D., et al. (2019). Pathogen-induced activation of disease-suppressive functions in the endophytic root microbiome. Science 366, 606–612. doi: 10.1126/science.aaw9285

Castell, A., Belusko, M., Bruno, F., and Cabeza, L. F. (2011). Maximisation of heat transfer in a coil in tank PCM cold storage system. Appl. Energy 88, 4120–4127. doi: 10.1016/j.apenergy.2011.03.046

Evans, M. R., Taylor, M., and Kuehny, J. (2010). Physical properties of biocontainers for greenhouse crops production. Horttechnology 20, 549–555. doi: 10.21273/HORTTECH.20.3.549

Food and Agriculture Organization of the United Nations. (2019). The State of Food and Agriculture, Moving Forward on Food Loss and Waste Reduction. Rome: Food and Agriculture Organization of the United Nations.

Franzoni, G., Bulgari, R., and Ferrante, A. (2021). Maceration time affects the efficacy of borage extracts as potential biostimulant on rocket salad. Agronomy. 11, 2182. doi: 10.3390/agronomy11112182

Fuentes, R. A., Berthe, J. A., Barbosa, S. E., and Castillo, L. A. (2021). Development of biodegradable pots from different agroindustrial wastes and byproducts. Sustain. Mater. Technol. 30, e00338. doi: 10.1016/j.susmat.2021.e00338

Harris, B. A., Florkowski, W. J., and Pennisi, S. V. (2020). Horticulture industry adoption of biodegradable containers. Horttechnology 30, 372–384. doi: 10.21273/HORTTECH04563-19

Iriany, A., Sari, O. A. W., and Hasanah, F. (2020). Optimization of biopot compositions made from water hyacinth and coconut coir for improving the growth and yield of chili (Capsicum annum l.). Int. J. Recycl. Org. Waste Agric. 9, 287–296. doi: 10.30486/IJROWA.2020.1894411.1048

Jirapornvaree, I., Suppadit, T., and Popan, A. (2017). Use of pineapple waste for production of decomposable pots. Int. J. Recycl. Org. Waste Agric. 6, 345–350. doi: 10.1007/s40093-017-0183-5

Jõgi, K., and Bhat, R. (2020). Valorization of food processing wastes and by-products for bioplastic production. Sustain. Chem. Pharm. 18, 100326. doi: 10.1016/j.scp.2020.100326

Khudhair, A. M., and Farid, M. M. (2004). A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 45, 263–275. doi: 10.1016/S0196-8904(03)00131-6

Koeser, A. K., Lovell, S. T., Petri, A. C., Brumfield, R. G., and Stewart, J. R. (2014). Biocontainer use in a Petunia × hybrida greenhouse production system: a cradle-to-gate carbon footprint assessment of secondary impacts. HortScience 49, 265–271. doi: 10.21273/HORTSCI.49.3.265

Kratsch, H. A., Schrader, J. A., McCabe, K. G., Srinivasan, G., Grewell, D., and Graves, W. R. (2015). Performance and biodegradation in soil of novel horticulture containers made from bioplastics and biocomposites. HortTechnology 25, 119–131. doi: 10.21273/HORTTECH.25.1.119

Latimer, J. G., Johjima, T., and Harada, K. (1991). The effect of mechanical stress on transplant growth and subsequent yield of four cultivars of cucumber. Scientia Horticulturae. 47, 221–230. doi: 10.1016/0304-4238(91)90005-J

Lazzerini, G., Lucchetti, S., and Nicese, F. P. (2016). Green House Gases (GHG) emissions from the ornamental plant nursery industry: A Life Cycle Assessment (LCA) approach in a nursery district in central Italy. J. Clean. Prod. 112, 4022–4030. doi: 10.1016/j.jclepro.2015.08.065

Li, J., Xue, P., Ding, W., Han, J., and Sun, G. (2009). Micro-encapsulated paraffin/high-density polyethylene/wood flour composite as form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 93, 1761–1767. doi: 10.1016/j.solmat.2009.06.007

McCabe, K. G., Schrader, J. A., Madbouly, S., Grewell, D., and Graves, W. R. (2014). Evaluation of biopolymer-coated fiber containers for container-grown plants. Horttechnology 24, 439–448. doi: 10.21273/HORTTECH.24.4.439

Nechita, P., Dobrin, E., Ciolacu, F., and Bobu, E. (2010). The biodegradability and mechanical strength of nutritive pots for vegetable planting based on lignocellulose composite materials. BioResources 5, 1102–1113. doi: 10.15376/biores.5.2.1102-1113

Nielsen. (2018). Sustainable shoppers. Available online at: https://www.nielsen.com/wp-content/uploads/sites/3/2019/04/global-sustainable-shoppers-report-2018.pdf

Pratibha, Saha, S., and Hariprasad, P. (2022). Paddy straw-based biodegradable horticultural pots: An integrated greener approach to reduce plastic waste, valorize paddy straw and improve plant health. J. Clean. Prod. 337, 130588. doi: 10.1016/j.jclepro.2022.130588

Rafee, S. N. A. M., Lee, Y. L., Jamalludin, M. R., Razak, N. A., Makhtar, N. L., and Ismail, R. I. (2019). Effect of different ratios of biomaterials to banana peels on the weight loss of biodegradable pots. Acta Technol. Agric. 22, 1–4. doi: 10.2478/ata-2019-0001

Razza, F., and Cerutti, A. K. (2017). “Life cycle and environmental cycle assessment of biodegradable plastics for agriculture,” in Soil Degradable Bioplastics for a Sustainable Modern Agriculture (Berlin; Heidelberg: Springer), 169–185. doi: 10.1007/978-3-662-54130-2_7

Rentas, F. J., Macdonald, V. W., Houchens, D. M., Hmel, P. J., and Reid, T. J. (2004). Extreme temperatures for over 78 hours. Transfusion 44, 210–216. doi: 10.1111/j.1537-2995.2004.00642.x

Riva, V., Mapelli, F., Bagnasco, A., Mengoni, A., and Borin, S. (2022). A meta-analysis approach to defining the culturable core of plant endophytic bacterial communities. Appl. Environ. Microbiol. 88, 1–10. doi: 10.1128/aem.02537-21

Rodrigues, M., Baptistella, J. L. C., Horz, D. C., Bortolato, L. M., and Mazzafera, P. (2020). Organic plant biostimulants and fruit quality-A review. Agronomy. 10, 988. doi: 10.3390/agronomy10070988

Rolli, E., Marasco, R., Vigani, G., Ettoumi, B., Mapelli, F., Deangelis, M. L., et al. (2015). Improved plant resistance to drought is promoted by the root-associated microbiome as a water stress-dependent trait. Environ. Microbiol. 17, 316–331. doi: 10.1111/1462-2920.12439

Rosenboom, J. G., Langer, R., and Traverso, G. (2022). Bioplastics for a circular economy. Nat. Rev. Mater. 1–21. doi: 10.1038/s41578-021-00407-8 [Epub ahead of print].

Santos, C., Mateus, A., Mendes, A., and Malça, C. (2017). Processing and characterization of thin wall and biodegradable injected pots. Proc. Manuf. 12, 96–105. doi: 10.1016/j.promfg.2017.08.013

Scarano, P., Sciarrillo, R., Tartaglia, M., Zuzolo, D., and Guarino, C. (2022). Circular economy and secondary raw materials from fruits as sustainable source for recovery and reuse. A review. Trends Food Sci. Technol. 122, 157–170. doi: 10.1016/j.tifs.2022.02.003

Schettini, E., Santagata, G., Malinconico, M., Immirzi, B., Scarascia Mugnozza, G., and Vox, G. (2013). Recycled wastes of tomato and hemp fibres for biodegradable pots: physico-chemical characterization and field performance. Resour. Conserv. Recycl. 70, 9–19. doi: 10.1016/j.resconrec.2012.11.002

Schwarzwälder, B., Estermann, R., and Marini, L. (2001). “The role of life-cycle-assessment for biodegradable products: bags and loose fills,” in Biorelated Polymers (Boston, MA: Springer), 371–382. doi: 10.1007/978-1-4757-3374-7_33

Sessitsch, A., Pfaffenbichler, N., and Mitter, B. (2019). Microbiome applications from lab to field: facing complexity. Trends Plant Sci. 24, 194–198. doi: 10.1016/j.tplants.2018.12.004

Soldan, R., Mapelli, F., Crotti, E., Schnell, S., Daffonchio, D., Marasco, R., et al. (2019). Bacterial endophytes of mangrove propagules elicit early establishment of the natural host and promote growth of cereal crops under salt stress. Microbiol. Res. 223–225, 33–43. doi: 10.1016/j.micres.2019.03.008

Sun, E., Huang, H., Sun, F., Wu, G., and Chang, Z. (2016). Degradable nursery containers made of rice husk and cornstarch composites. Bioresources 12, 785–798. doi: 10.15376/biores.12.1.785-798

Sun, E., Liao, G., Zhang, Q., Qu, P., Wu, G., and Huang, H. (2019). Biodegradable copolymer-based composites made from straw fiber for biocomposite flowerpots application. Compos. Part B Eng. 165, 193–198. doi: 10.1016/j.compositesb.2018.11.121

Sun, E., Liao, G., Zhang, Q., Qu, P., Wu, G., Xu, Y., et al. (2018). Green preparation of straw fiber reinforced hydrolyzed soy protein isolate/urea/formaldehyde composites for biocomposite flower pots application. Materials 11, 1695. doi: 10.3390/ma11091695

United Nations Environment Programme (2021). Food Waste Index Report. Nairobi: United Nations Environment Programme.

Keywords: sustainable agriculture, food waste-derived material, plant nursery, plant growth promoting bacteria, circular economy

Citation: Mapelli F, Carullo D, Farris S, Ferrante A, Bacenetti J, Ventura V, Frisio D and Borin S (2022) Food Waste-Derived Biomaterials Enriched by Biostimulant Agents for Sustainable Horticultural Practices: A Possible Circular Solution. Front. Sustain. 3:928970. doi: 10.3389/frsus.2022.928970

Received: 26 April 2022; Accepted: 10 June 2022;

Published: 07 July 2022.

Edited by:

Nahum Andres Medellin Castillo, Autonomous University of San Luis Potosì, MexicoReviewed by:

Sara Di Lonardo, Research Institute on Terrestrial Ecosystems (CNR), ItalyYesid Murillo, University of America, Colombia

Copyright © 2022 Mapelli, Carullo, Farris, Ferrante, Bacenetti, Ventura, Frisio and Borin. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Sara Borin, c2FyYS5ib3JpbkB1bmltaS5pdA==

Francesca Mapelli

Francesca Mapelli Daniele Carullo

Daniele Carullo Stefano Farris

Stefano Farris Antonio Ferrante

Antonio Ferrante Jacopo Bacenetti

Jacopo Bacenetti Vera Ventura

Vera Ventura Dario Frisio3

Dario Frisio3 Sara Borin

Sara Borin