95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. , 11 January 2023

Sec. Circular Economy

Volume 3 - 2022 | https://doi.org/10.3389/frsus.2022.1051091

This article is part of the Research Topic Rethinking Food Systems: Circular Economy and Urban Agriculture View all 4 articles

Alternative food production technologies are being developed to meet the global increase in population and demand for a more sustainable food supply. Aquaponics, a combined method of vegetable and fish production, is an emerging technology that is widely regarded as sustainable. Yet, there has been limited research on its environmental performance, especially at a commercial scale. In this study, life cycle analysis (LCA) was used to assess the environmental impacts of food produced by an urban commercial aquaponic system located next to a retail store in a cold-weather region (Östersund, Sweden). The functional unit (FU) used is 1 kg of fresh produce, which includes cucumber (Cucumis sativus), tomatoes (Solanum Lycopersicum), and Atlantic salmon (Salmo salar). The system boundary is set from cradle to farm or retailer's gate due to the proximity of the aquaponic system to the retail store. Results were reported employing eight environmental impact categories, including global warming potential (GWP), marine eutrophication (MEU), and cumulative energy demand (CED). According to contribution analysis, the main hotspots of the system are electricity, CO2 enrichment, and heating. Potential areas to mitigate the impact of these parameters were highlighted in this study, including the establishment of symbiotic links to utilize urban waste and by-products. The impact per vegetable or fish produced was partitioned using energy and economic allocation and compared to other common cultivation methods. The yearly harvest from the aquaponic system was also compared to importing these food items from other European countries which showed lower annual greenhouse gas (GHG) emissions for the aquaponic system.

The world's population is expected to reach 9.7 billion by 2050, with cities housing an additional 2.5 billion people (UN, 2014). Food demand is estimated to rise by 70% over the same period, putting an additional burden on production systems (Linehan et al., 2012). Major environmental impacts, such as climate change, water pollution, and land use, are directly linked to food production and distribution (Willett et al., 2019; Delshad, 2022). Farms are responsible for the majority of this impact since they are the physical source of production (McAuliffe et al., 2020). Alternative food production systems have been developed to meet the growing demand for food items while trying to reduce the negative impact of conventional farming (Breitenstein and Hicks, 2022). To address the challenge of sustainable food production, it is important to understand the extent of environmental impacts related to these systems in order to make an informed decision about their application.

Aquaponics is an emerging food production technology that is being promoted as a sustainable method for growing both aquatic animals and plants (König et al., 2018; Goddek et al., 2019; Greenfeld et al., 2022). The system combines recirculating aquaculture systems (RAS) with hydroponics for optimized nutrient and water fluxes between the two units (Proksch and Ianchenko, 2019). As the fish consume fish feed, they produce waste, which is employed as a fertilizer that the plants can absorb. The plants serve as a water filter by absorbing these nutrients, and the water is recycled back to the fish tank. As a result, aquaponic systems typically use fewer pesticides, herbicides, or other harsh chemicals (Farhan, 2021; Greenfeld et al., 2022). The synergy between aquaculture and hydroponics in these systems has been reported to reduce energy use (Körner et al., 2017), water consumption (Cohen et al., 2018; Goddek et al., 2019), and lower the overall environmental impacts of food products as opposed to conventional farming (Yacout et al., 2016; Jaeger et al., 2019).

Aquaponic systems can also play a major role in enabling the local production of food items in cities. This provides the urban population with access to high-quality fresh products while supporting cities to become self-sufficient (Llorach Massana, 2017; Goddek et al., 2019). Urban aquaponics are also able to establish relationships with local businesses to exchange resources for mutual benefits through urban and industrial symbiosis, which can help reduce the overall impact and improves resource efficiency (Martin and Harris, 2018; Parker and Svantemark, 2019). Additionally, by reducing the distance that food needs to travel (food miles), urban farming can lessen the impacts of transportation, packaging, storage, and food wasted during these processes (De Bon et al., 2010; dos Santos, 2016). However, many authors have argued that reducing food miles is not an effective measure of food sustainability due to its small impact compared to production systems (Edwards-Jones et al., 2008; Coley et al., 2009; Ziegler et al., 2013; Heller, 2017). Heller (2017) emphasized the need for research to evaluate regional variations in food production as well as possible trade-offs in transportation as an appropriate approach to mitigating the environmental impacts of food.

Despite the growing scientific knowledge on agri-food systems, there has been limited research that focuses on the environmental implications of aquaponics (Wu et al., 2019; Greenfeld et al., 2022). To the best of the authors' knowledge, there are a total of 23 studies published that performed LCA on aquaponic systems between 2014 and 2022. The majority of these studies were conducted on small or pilot-scale research systems (e.g., Hindelang et al., 2014; Gennotte et al., 2017; Verdoodt, 2019; Chen et al., 2020; Bhakar et al., 2021), theoretical systems (Forchino et al., 2017; Cohen et al., 2018; Körner et al., 2021), and only five were based on large-scale commercial aquaponics (Boxman, 2015; Thorarinsdottir, 2015; Boxman et al., 2016; Hollmann, 2017; Greenfeld et al., 2021). Greenfeld et al. (2022) highlighted the importance of quantifying the impact of large-scale commercial aquaponics as a way to inform policymakers and justify public support. The impact of food production can be greatly influenced by climate conditions. Cold-climate countries have lower temperatures and shorter daylight hours, resulting in aquaponics requiring more energy to operate, which can significantly increase their environmental impacts (Valappil, 2021). While several studies have been conducted on cold-weather aquaponics (Cohen et al., 2018; Ghamkhar et al., 2020, 2022; Körner et al., 2021; Valappil, 2021), they are based on theoretical or small-scale applications.

In terms of produce, most LCA studies of aquaponic systems have focused on similar types of fish (e.g., tilapia, rainbow trout, or ornamental fish), but no studies on salmon production were identified. This can be attributed to the fact that salmon is a cold-water fish and is challenging to raise in warm regions (Brooke, 2019; Tennøy, 2022). Leafy greens (including lettuce, basil, and kale) are the predominantly researched vegetables from the hydroponic units of aquaponic systems. Despite tomato and cucumber being commonly grown vegetables in aquaponics according to surveys [about 69%, 42% based on an international survey and 32%, 16% based on a European survey respectively (Love et al., 2014; Villarroel et al., 2016)], there have been relatively few studies that assessed their environmental performance (Hindelang et al., 2014; Thorarinsdottir, 2015; Körner et al., 2021).

In this study, LCA was used to quantify the environmental impacts of an urban commercial-scale, cold-weather aquaponic system (Östersund, Sweden), which cultivates cucumber, tomato, and salmon. A total of eight environmental impact categories were used to provide a holistic view of the environmental performance of the system, identify major contributing parameters, and highlight potential mitigation strategies for these impacts. The results from the aquaponic system's produce were compared with other production systems. A comparison was also made for the global warming trade-offs between the urban aquaponic system and food imported from other European countries.

The aquaponic system assessed in this study is based on a commercial system called “Complete” developed by the company Agtira AB. This study focuses on Agtira's first Complete system, which was under construction at the time of this study. The aquaponic system is considered one of the largest facilities in the world for combined salmon and vegetable production in an urban environment (Svedin, 2021). The system is roughly 1,200 m2 in area and is located in the parking lot of ICA Maxi supermarket in Östersund. Due to the proximity in location, the cultivated food can be sold in the retail store hours after harvest. The aquaponic system is designed to produce roughly 75 tons of cucumbers, 15 tons of tomatoes, and 8 tons of Atlantic salmon annually.

The main purpose of this study was to assess the environmental impacts of a commercial-scale urban aquaponic system located in northern Sweden. The functional unit (FU) used for the study is 1 kg of fresh produce. This FU was chosen as the system is designed to produce three key products (salmon, tomato, and cucumbers) all of equal importance. To calculate the impacts of each these products, two allocation methods were employed to partition the impacts of the system. The time scale is set for food produced from the aquaponic system over a period of 1 year.

The system boundaries, i.e., which processes are to be included or omitted, are set from cradle-to-gate (ISO, 2006). This can be considered as the farm or retailer's gate due to the proximity in locations of the two systems. The impact evaluation thus includes the production side of the food value chain including input materials, transportation, energy use, and infrastructure as shown in Figure 1. Waste from the aquaponics system was excluded from the scope of the study due to a lack of data.

Allocation, i.e., the process of partitioning the share of the environmental impact of a unit or process to the system under study, was used to calculate how much impact is contributed by each crop and fish produced (Lee and Inaba, 2004). The choice of allocation method, however, can largely influence the results. According to ISO 14044 standards, allocation should be used based on physical relations between the different products (e.g., energy), or other relations including their economic value (ISO, 2006).

Due to the sensitivity of the results to the method chosen, two methods were considered for this study (energy and economic allocation) in order to show their influence on the results. Using multiple methods also helps in reflecting the relationship between the different products in the system from multiple perspectives. Table 1 shows the allocation factor for the three products grown in the aquaponic system studied. Data for the cost of products in Sweden in 2022 was retrieved from Selina Wamucii (2022), while data for food energy content is based on the USDA database (USDA, 2019).

The fish are grown in a hatchery and transported to the aquaponic system with an average size of approximately 100 g/fish. A hatchery process was created based on inventory data from Song et al. (2019) for Chinese salmon production adjusted to represent a Swedish hatchery condition (e.g., electricity source and transportation). Fish feed was modeled based on data from Jaeger et al. (2019). Plants are also purchased and brought to the farm as seedlings with an assumed weight of about 95 g/plant (Klapwijk and De Lint, 1974). Transportation for input plants and fish as well as fish feed are conducted employing trucks, with a total transportation distance of 1,034 km.

CO2 is supplied to the system for carbon enrichment, as CO2 is required for plant growth during the day. The source of CO2 is a by-product of industrial processes and is transported in a liquid form at about 545 km. Data for liquid CO2 production was taken from Ecoinvent and accounts for processes such as purification and liquefaction of the gas (Ecoinvent, 2019). Most nutrients needed for plant fertilization come from the fish tank, with a small amount of external nutrients added to the system due to deficiencies in some micro and macronutrients. This was assumed based on Davis et al. (2011) and Lall and Kaushik (2021), considering 10% of the amount typically used by aquaculture or hydroponic systems (Agtira, 2022).

Water is recycled inside the system and used for plant growth with an average daily usage of about 4,000 liters. District heating is used to maintain an adequate indoor temperature. Calculations for district heating were assumed based on Davis et al. (2011) for the amount of heating needed for tomato and cucumber production in Swedish greenhouses.

Lighting is a major component of the aquaponic system and consumes more than 90% of the electricity used. Due to limitations in the databases for ready-to-use electric components, an LED process was created based on data from Casamayor et al. (2018). Other assumptions were also made for comparable products in the database, including oxygen generators and greenhouse fans. Sensors and actuators were excluded from the study due to a lack of data. Transportation of materials used for infrastructure is assumed to be included in the Ecoinvent database, i.e., the “market for” datasets (Ecoinvent, 2019). Waste from the system and plant residues are partly reintroduced to the greenhouse, with other waste streams treated as biowaste. This process is excluded from the scope of the study due to a lack of data. Table 2 shows the inventory data including all the processes and materials used for the impact assessment.

SimaPro version 5.19.1.0.8 was used to model the life cycle inventory data and calculate impact results (PRé Sustainability, 2020). The software is a comprehensive LCA tool capable of simulating different systems including agricultural ones. Life cycle impact analysis results were calculated using the ReCiPe 2016 methodology. This method was considered suitable for the European context and most appropriate for LCA in the food sector by Amani and Schiefer (2011). This is due to its extensive quantitative assessment for all impact categories including 18 midpoint and three endpoint results (Amani and Schiefer, 2011).

Seven impact categories were analyzed and included in this study considering their appropriateness for food production systems. These categories are (abbreviation, unit) global warming (GWP, kg CO2-eq), terrestrial acidification (TAC, kg SO2-eq), freshwater eutrophication (FWEU, kg P-eq), marine eutrophication (MEU, kg N-eq), fossil depletion (FD, kg oil-eq), water consumption (WC, m3), and ecotoxicity (EC, kg 1.4-DCB). The ecotoxicity category includes the impact of freshwater ecotoxicity (FWEC, kg 1.4-DCB), marine ecotoxicity (MEC, kg 1.4-DCB), and terrestrial ecotoxicity (TEC, kg 1.4-DCB). Previous studies have also included similar impact categories for aquaponic, hydroponic, and aquaculture systems (see e.g., Ayer and Tyedmers, 2009; Jaeger et al., 2019; Martin et al., 2022). In addition to the ReCiPe methodology, the cumulative energy demand (CED, MJ) was also included in this study to showcase the direct and indirect energy use throughout the food production cycle.

Sensitivity analysis (SA) was carried out to determine the most influential input parameters that affect the impact results received (ISO, 2006). Identifying these influential parameters can also assist in prioritizing mitigation strategies that have the highest potential in reducing the overall impact of the system.

In this study, SA was performed with each value from the inventory inputs varied by ±10%, with other parameters held constant. The impact results were then recalculated to identify the input parameters that are most sensitive. A sensitivity factor (SF) was also calculated by dividing the relative variation of the results by the relative change in input data (Ghamkhar et al., 2020, 2022). For input parameters with a SF of < 0.1 in all impact categories (i.e., changing the input parameter by ±10% will lead to < 1% change in the results), the impact results are excluded, and the parameter is thought to be less influential. The sensitivity of the choice of electricity source (as one of the most influential inputs) was also performed by using the Nordic mix and EU mix instead of the Swedish electricity mix.

The following sections outline the results of the life cycle assessment, followed by an analysis of the sensitivity to parameters and data and finally the influence of the allocation method on the results.

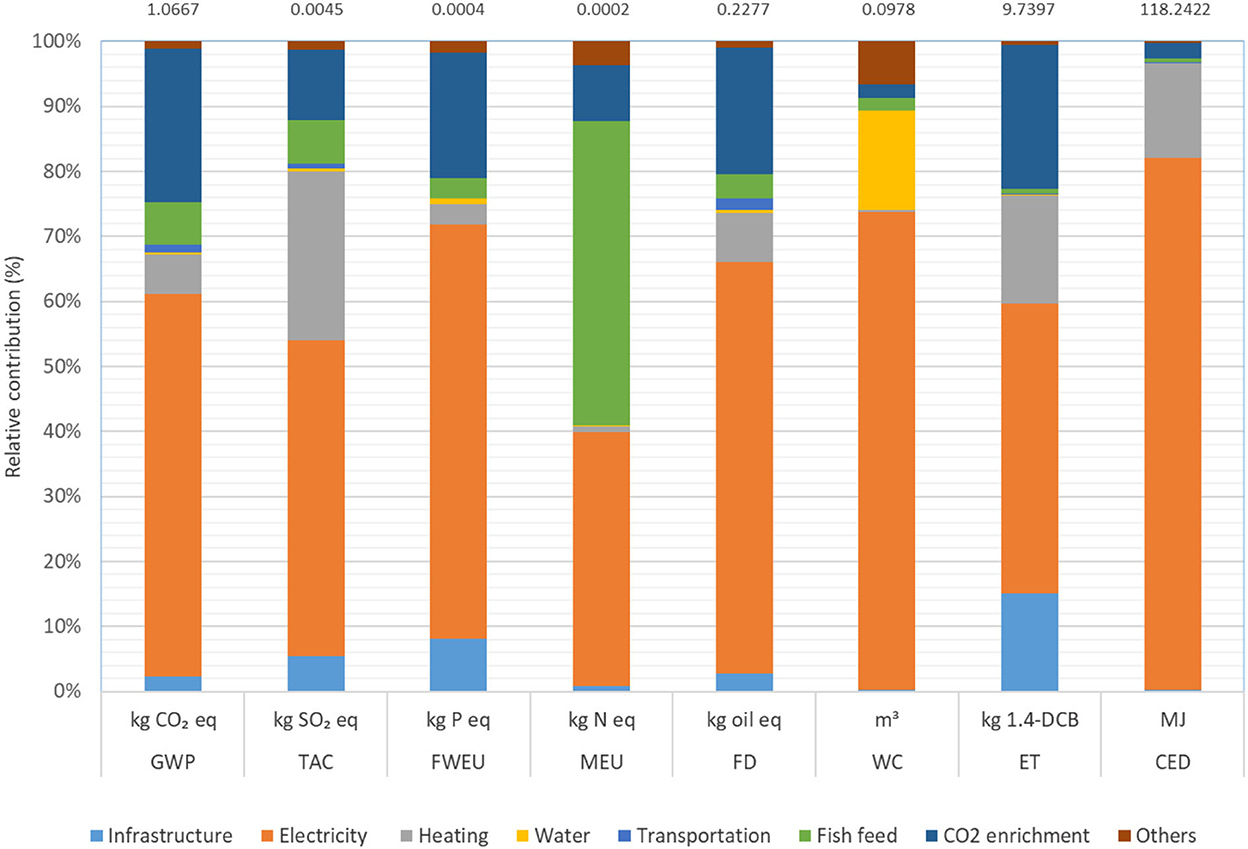

Impact analyses were performed on the aquaponic system based on 1 kg of fresh produce over a period of 1 year. The impact results and contribution of the different input parameters are shown in Figure 2.

Figure 2. The overall parameter contributions for each impact category under study. The other parameters include the impacts from input seedlings and fish as well as fertilizers. The transportation parameter excludes transportation of infrastructure and fertilizers as they were included in the Ecoinvent datasets for these processes. The numbers above each bar represent the quantified environmental impact of that category per 1 kg of food produced. Data for the figure are provided in Supplementary Table A2.

The contribution analysis revealed that electricity, CO2 enrichment, and heating are the major sources of the system's impact (hotspots), accounting for more than 80% in all categories except EU (75.8%) and WC (48.7%). Fish feed scored high in terms of EU, with 64% of impact in that category but < 7% in other categories. Similarly, the impact from water use was primarily toward WC (15%), with other categories accounting for < 1%. Apart from EU, electricity consumption is responsible for the majority of the environmental impact (more than 40%), indicating the need for mitigation measures in electricity use in order to reduce the overall impact.

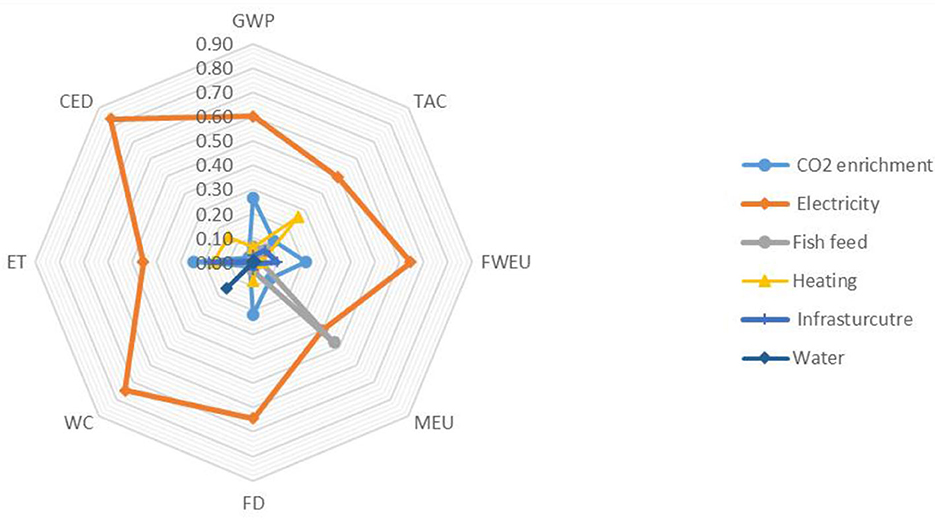

SA was performed to assess which of the inventory parameters the results were most influenced by. This was calculated as SF by dividing the absolute percentage change of the final results by the absolute percentage change in input value (10%). Parameters with SF < 0.1 were excluded due to low sensitivity (fertilizers, transportation, and input seedlings/fish). On the other hand, impact results were sensitive to input parameters from electricity, CO2 enrichment, heating, infrastructure, fish feed, and water, as can be seen in Figure 3.

Figure 3. SFs (axis) for the most influential parameters in each impact category (outer labels). Further details are provided in Supplementary Table A3.

Electricity consumption was the most influential parameter in all impact categories except MEU, which was more sensitive to fish feed. The model was also highly influenced by the CO2 enrichment process, having the second highest results in GWP, FWEU, FD, and ET categories. Water use was the least influential parameter in all categories except for WC. Heating was the second most sensitive parameter in TAC and CED after electricity use. The SF for all input parameters can be seen in Supplementary Table A3.

The sensitivity to the choice of electricity source was also investigated by using Nordic mix (Nordic Countries Power Association) and EU grid mix instead of the Swedish mix. For GWP, using the Nordic mix would increase the results by 15% compared to the Swedish mix, and the EU mix would increase it by 370%. The EU mix also gave the highest impact in all categories except for WC, where more impact resulted from the Nordic mix. The Swedish mix gave the lowest results in most categories except FWEU, MEU, and ET, Nordic mix scored lower in these categories. Figure 4 and Table 3 show the results for the assessed categories based on the different electricity sources.

Table 3. The sensitivity to the choice of electricity mix, results for the Swedish, Nordic and EU grid mixes for the impact categories under study.

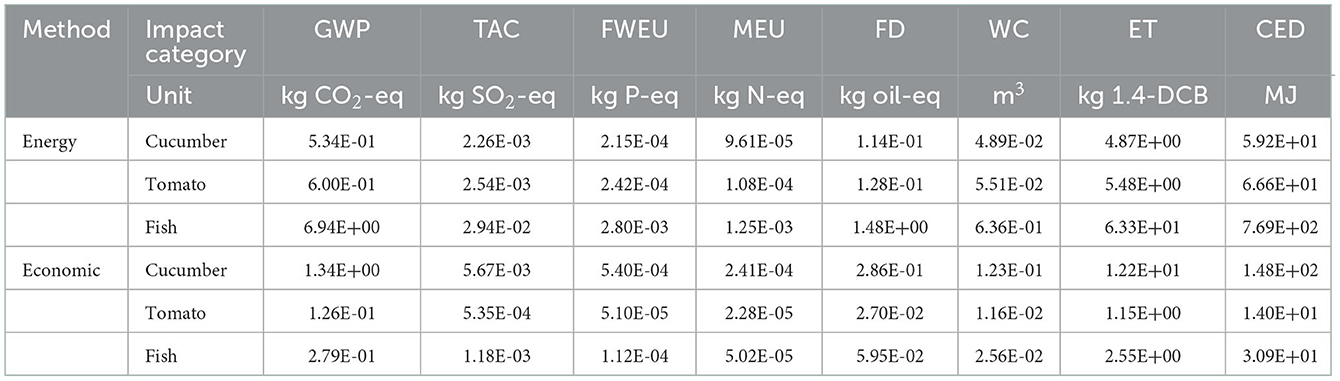

Table 4 shows the allocation of impact for all categories based on energy and economic allocation. The results are reported per 1 kg of each product in the system (cucumber, tomato, and salmon). The choice of allocation method provides different results for emission contribution from each product. Cucumbers have the highest share of impact in economic allocation due to their high price value but the least impact based on energy content. Salmon had the highest impact on energy allocation due to a higher calorific value compared to the crops harvested.

Table 4. Comparison of the results based on different allocation approaches based on energy and economic allocation (per 1 kg of each product).

The results of this study presented the environmental impact of an aquaponic system based in a cold-weather region of northern Sweden. According to the contribution analysis, the system's main sources of impacts were electricity consumption, CO2 enrichment, and heating.

Electricity is widely regarded as the most significant contributor to the impact of aquaponic systems (Hindelang et al., 2014; Boxman et al., 2016; Maucieri et al., 2018; Jaeger et al., 2019; Verdoodt, 2019), with more electricity required in cold weather aquaponics (Chen et al., 2020; Ghamkhar et al., 2020, 2022; Valappil, 2021) due to lower temperatures and shorter daylight hours (Valappil, 2021). Similar results were observed in this study, with electricity consumption (primarily for lightning) accounting for more than half of the impact in nearly all categories. The Swedish grid system is primarily powered by renewable sources, which significantly reduces the overall impact of the system. Food produced in aquaponics powered by fossil-based electricity has been reported to have a significantly higher impact. In contrast to this study's maximum of 6.94 kg CO2-eq/kg of fish, Valappil (2021) reported a GWP of 68 kg CO2-eq/kg of fish from an aquaponic system in Canada, with fossil and coal-based grid systems accounting for 95% of the impact. Valappil (2021) considered a scenario with wind energy and energy efficiency measures, which reduced the GWP by 97% compared to the original impact. The aquaponic system under investigation also employs LED lights, which are known for their efficiency. The system additionally uses high-tech devices to optimize operation conditions and minimize losses, which was identified as a recommended strategy for energy efficiency as well as reducing manpower (see e.g., Junge et al., 2017; Valappil, 2021).

In terms of heating, the contribution reported in this study was lower than other cold-weather aquaponics research, which can also be attributed to the heating source. For example, Ghamkhar et al. (2020, 2022) used natural gas for heating, whereas Chen et al. (2020) and Valappil (2021) used fossil-based electricity; of which 88% was derived from coal in Chen et al. and about 21% renewable in Valappil. The utilization of district heating by the aquaponic system under study can be considered an advantage in reducing the overall emissions from heating. Similar findings on the use of district heating for aquaculture in Sweden have been found (see e.g., Nilsson and Martin, 2022).

Further reduction in heating demand can be achieved through better insulation and effective space heating through optimization of the volume of the aquaponic system (reducing unnecessary space) (Ghamkhar et al., 2022). Heating can also be recycled from exhaust heat in nearby buildings or factories, including the refrigerated cooling rooms in the adjacent supermarket as suggested by Körner et al. (2021). According to a Finnish study on greenhouse tomato production, using industrial waste heat can reduce GWP by more than half when compared to district heating (Marttila et al., 2021).

In this study, CO2 enrichment was identified as a major contributor, with sensitivity analysis indicating that it has the potential to reduce the overall impact. To the best of the authors' knowledge, this input material was not considered in the inventory data in previous aquaponic studies, which could be due to the majority of these studies being on a small scale and that CO2 enrichment is not an essential additive to the hydroponics systems. CO2 enrichment, on the other hand, is common in commercial greenhouses due to its role in increasing food production efficiency (Li et al., 2018; Marttila et al., 2021). This study demonstrates the importance of including this parameter in the analysis, if used, due to its considerable contribution to the overall impact.

Part of the emissions from the supplied CO2 is caused by energy used for gas liquefaction, as well as transportation (~550 km) from the industrial source. To mitigate this impact, a local supply of CO2 via pipeline from an industrial facility or the combined heat and power (CHP) plant in Östersund can be used. Transportation of CO2 via pipeline is also regarded as more cost-effective and stable than road transport (Johansson and Pétursdóttir, 2021). This method is used at Thanet Earth, a greenhouse complex in the United Kingdom, where a CHP plant uses water pumps to supply CO2 in addition to heat and electricity to five greenhouses through water pumps (Gentry, 2019; Goddek et al., 2019).

In the current study, fish feed had a relatively low impact in most categories, with the exception of EU, which contributed nearly half of the impact in this category. Feed conversion ratio (FCR) is used to describe the quantity of feed required to produce 1 kg of fish, and the value in this study was 0.62. Many authors have identified fish feed as a hotspot for impact in aquaponics (Boxman, 2015; Boxman et al., 2016; Forchino et al., 2017; Cohen et al., 2018; Ghamkhar et al., 2020, 2022; Valappil, 2021) and aquaculture systems (Ayer and Tyedmers, 2009; Yacout et al., 2016). This can be attributed to the high FCR values reported by these studies, which are typically >1, with Ghamkhar et al. (2022) reporting FCR up to 5.4. A low FCR indicates efficiency in converting feed into fish weight (Charles Bai et al., 2022). More analysis into feed ingredients and composition can provide an insight into how this impact can be reduced. These ingredients can also be sourced locally through an industrial symbiotic network including microalgae farms and breweries (Haller et al., 2022).

Infrastructure is often excluded in agri-food LCA research due to assumptions of negligible contribution to the overall impacts (Ayer and Tyedmers, 2009; Ghamkhar et al., 2020), while identified by others as a main contributor in aquaponics, recommending that it should not be excluded (Forchino et al., 2017; Valappil, 2021; Ghamkhar et al., 2022). In this study, the impact from infrastructure was the highest and most sensitive toward ET (15%) and FWEU (8.2%), iterating the importance of considering this parameter in the analysis. Mitigating the impact of these categories can be achieved through choosing lower-impact materials and increasing the life span of equipment, e.g., through regular maintenance (Forchino et al., 2017; Ghamkhar et al., 2022). Aquaponic systems are often praised for low water usage compared to other systems (Hindelang et al., 2014; Xie and Rosentrater, 2015; Junge et al., 2017; Cohen et al., 2018). Further reduction was suggested in previous research by employing rainwater collection systems and minimizing daily losses (e.g., by using covers and vent traps) (Junge et al., 2017; Pattillo, 2017; Valappil, 2021). Other parameters (fertilizers, input fish and seedlings, and transportation) were the least impactful and sensitive parameters in this study.

The allocation of impact per crop cultivated generated quite different results depending on the method employed. Cucumber had the largest impact when measured by economic allocation due to its high economic value. However, when the system is seen in terms of energy content, cucumber had the least impact and fish production accounted for the majority of the emissions (53%). This illustrates the sensitivity of the results to the allocation method and the importance of considering several methods in order to obtain a good understanding of the system under study.

In the following sub-sections, results from the allocated impact are compared to the same produce in conventional, aquaculture, and hydroponics systems. External comparison with other systems is common in aquaponics research (Hindelang et al., 2014; Thorarinsdottir, 2015; Hollmann, 2017; Verdoodt, 2019; Ghamkhar et al., 2022) to help put the results into perspective. For this study, this is presented with respect to 1 kg of fresh product at the farm gate to provide a common basis for comparison. The assessment is based on the GHG emissions (i.e., GWP), which is the most reported category in LCA literature (Bjørn et al., 2020), as well as FCR for the fish product. To highlight the food mile's part of the impact, this comparison mentions the GWP of food items imported to Sweden based on data from Moberg et al. (2019), which includes transportation, packaging, storage, refrigeration, and losses along the supply chain.

Tomatoes produced from the aquaponic system had a GWP of roughly 0.6 and 0.13 kg CO2-eq per kg based on energy and economic allocation, respectively. Tomatoes are commonly cultivated in open fields, heated, and unheated greenhouses.

Open field cultivation takes place in warm regions and its impact is usually low due to minimal energy requirements. Lam et al. (2018) reported that GWP for open field tomato production in different countries ranged between about 0.02 and 0.06 kg CO2-eq per kg of fresh product. This is in line with a study from Iran at 0.05 kg CO2-eq/kg (Zarei et al., 2019), and lower than those reported for the US at 0.11 kg CO2-eq/kg (Parajuli et al., 2021).

For greenhouses located in Sweden, Anders et al. (2006) estimated a GWP of about 2.7 kg CO2-eq/kg while several studies (Karlsson, 2011; Röös and Karlsson, 2013; Bosona and Gebresenbet, 2018) reported a GWP of roughly 0.3 kg CO2-eq per kg of tomato from heated greenhouses. The greatest contribution to the impact in these studies was electricity consumption, which is in line with the results of this study. Unheated greenhouses reported a lower GWP at about 0.21 kg CO2-eq/kg (Karlsson, 2011; Röös and Karlsson, 2013). The results of this study are higher than open field farming but lower than greenhouses in Sweden with economic allocation.

Tomatoes from heated greenhouses in the Netherlands have a GWP of 0.95 and 2 kg CO2-eq/kg according to Torrellas et al. (2012) and Röös and Karlsson (2013), respectively. For Spain, unheated tunnel greenhouses reported 0.25 kg CO2-eq/kg (Torrellas et al., 2012) and heated greenhouses at 0.54 kg CO2-eq per kg (Röös and Karlsson, 2013). Regardless of allocation methods, this study shows lower impact than heated greenhouses in the Netherlands but higher than greenhouses in Spain with energy allocation.

Sweden mostly imports tomatoes from the Netherlands (about 52%) and Spain (21%) (OEC, 2020). The impact of tomatoes at the retailer's gate in Sweden from the Netherlands (greenhouses) is estimated at 2.05 kg CO2-eq/kg, while from Spain at 0.45 and 0.51 kg CO2-eq/kg from greenhouses and open-field, respectively (Moberg et al., 2019). Tomatoes imported from the rest of Europe had a GWP of 1.35 kg CO2-eq/kg from greenhouses and 0.48 kg CO2-eq/kg from open-field cultivation (Moberg et al., 2019). The impact reported in this study is higher than imports from open field cultivation with energy allocation and lower than imports from greenhouses beside Spain.

According to this study, the GWP from cucumbers was approximately 0.53 and 1.34 kg CO2-eq per kg for energy and economic allocation, respectively. Contrary to tomato farming, there is a lack of LCAs on cucumber production in Europe to be used as a basis for comparison.

Potter et al. (2020) reviewed the environmental impact of plant-based foods and identified only two studies on the environmental impact of cucumbers that are relevant to the Swedish market. The GWP from heated greenhouses in Sweden was estimated by Davis et al. (2011) to be around 1 kg CO2-eq per kg, and González et al. (2011) reported a GWP of heated greenhouses using electricity and fuel oil to be 0.75 and 2.6 kg CO2-eq per kg of cucumber, respectively. The GWP from average global cucumber production in heated greenhouses is estimated at 2.1 kg CO2-eq per kg according to meta-analysis data by Clune et al. (2017) (based on 7 studies).

Cucumber farming in warm regions reported a lower GWP impact due to low heating requirements. According to Zarei et al. (2019), cucumber cultivation in Iran's open fields has a GWP of 0.162 kg CO2-eq/kg and greenhouse cultivation has 0.07 kg CO2-eq per kg. The GWP from cucumber reported in this study is lower than the global average from heated greenhouses and greenhouses in Sweden heated with fuel oil according to González et al. (2011). The results are however higher than cucumber grown in Iran as well as heated greenhouses in Sweden with economic allocation according to other studies.

Similar to tomatoes, Sweden imports cucumbers mostly from the Netherlands and Spain at roughly 64% and 29%, respectively (OEC, 2020). Moberg et al. (2019) estimated that cucumbers imported from the Netherlands (greenhouses) have a GWP of 1.54 kg CO2-eq per kg at retailer's gate in Sweden and from greenhouses and open-fields in Spain at 0.44 and 0.51 kg CO2-eq/kg, respectively. The rest of Europe has 0.49 kg CO2-eq per kg based on open-field cultivation (Moberg et al., 2019). The cucumbers cultivated from the aquaponic system have a lower GWP than imports from the Netherlands but higher for Spain and the rest of Europe.

Salmon production had GWP of roughly 6.94 and 0.28 kg CO2-eq per kg based on energy and economic allocation.

Martin and Carlsson (2018) reported a GWP of 1.9 kg CO2-eq per kg for land-based RAS in Sweden. For open net-pen systems, Liu et al. (2016) reported a GWP of about 3.4 kg CO2-eq per kg for a study based in Norway. Ayer and Tyedmers (2009) assessed the impact of salmon production from four salmon farming systems in Canada. The study reported a GWP of roughly 2 kg CO2-eq /kg from marine net-pen, marine floating bags, and land-based flow-through systems. Land-based RAS had a GWP of more than 28 kg CO2-eq/kg of salmon due to reliance on electricity for production. Pelletier et al. (2009) estimated the environmental impact of salmon production based in Norway, the UK, Canada, and Chile. The study reported an average GWP of roughly 2 kg CO2-eq per kg of salmon produced in these countries.

Sweden imports most of its Atlantic salmon from Norway (92%) (OEC, 2020). Moberg et al. (2019) assessed the average impact of salmon production in Norway at the farm's gate at 3.03 kg CO2-eq per kg and at the retailer's gate in Sweden (edible weight) at 6.07 kg CO2-eq /kg. The aquaponic system in this study shows lower results for salmon production based on economic allocation but higher with energy allocation except for land base RAS in Ayer and Tyedmers (2009).

FCR for the aquaponic system is calculated at 0.62 which is also lower when compared to common systems. The FCR from the previous studies was 1.1 in Martin and Carlsson (2018), 1.27 in Liu et al. (2016), and between 1.1 and 1.5 in Pelletier et al. (2009). Having a lower FCR in aquaponics is in line with experimental results by Atique et al. (2022) where aquaponics recorded FCR around 0.85 compared to separate RAS at roughly 1.06.

Because the aquaponics system in this study is located next to the retail store, the impacts of transportation, packaging, cooling, and storage are avoided. The impact of food waste during distribution is also eliminated, with roughly a quarter of global food production lost between the farm and the retailer's gate (Onwude et al., 2020).

Several authors have argued that long-distance transport of food items is more environmentally beneficial than off-season local production in cold climates (Benis et al., 2017; Goldstein, 2017). Heller (2017) after reviewing 17 studies in greenhouse tomato production concluded that heated greenhouses for local tomato production outweigh the impacts of long-distance transportation. However, this was due to high GWP from greenhouses reported in their review (average about 1.8 kg CO2-eq/kg) as opposed to on-field production (0.25–0.4 kg CO2-eq /kg). Comparing the results of this study to other system showed mixed results with open field cultivation mostly having lower GWP and greenhouses having higher or lower impact depending on the allocation method. The aquaponic system also showed lower GWP than imports from the Netherlands as oppose to Spain where the system mostly have higher impact.

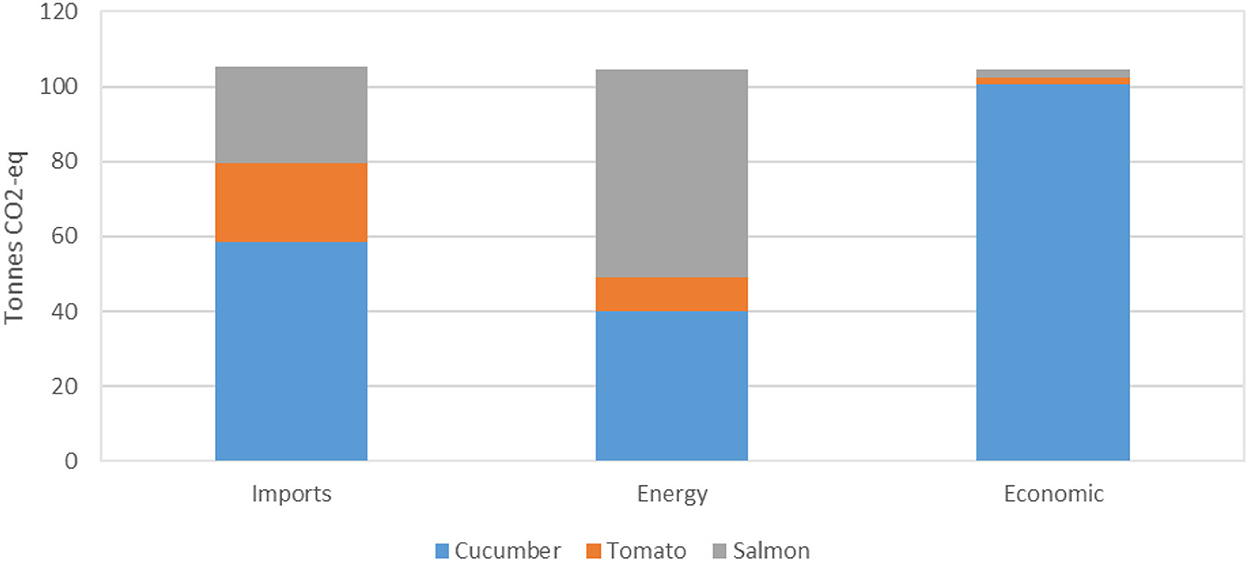

The total yearly harvest from the aquaponic system is 75 tons of cucumbers, 15 tons of tomatoes, and 8 tons (live weight) of salmon. Measuring the GWP impact from the total yearly harvest results in around 104.5 tons CO2-eq. The impact of importing the same amount according to data from Moberg et al. (2019) and statistics from OEC (2020) mentioned in section 4.2 will result in about 105.3 tons CO2-eq. The production from the aquaponic system have lower GWP than importing the same amount of food items. The share of each produced or imported food item can be seen in Figure 5.

Figure 5. Comparison of GWP from the aquaponics' harvest as opposed to importing the same amount of items at retailer's gate. Further details on the calculations are provided in Supplementary Tables A4, A5.

Another advantage of the symbiosis is the opportunity to utilize urban infrastructure and cooperate with local industries through industrial and urban symbiosis. Establishing symbiotic links between different businesses can lead to better utilization of resources that, otherwise, would be wasted or not fully utilized. This can lead to benefit sharing and further reduction in impact from input heat, fertilizers, fish feed, and carbon dioxide. Similar findings are also highlighted in Martin and Carlsson (2018) and Martin et al. (2022) for symbiotic production of foods.

There are a few limitations of this study that can influence the quality of the results received. Firstly, as the aquaponic system was under construction at the time of this study, some data were missing on the operation condition of the system. As such the results are only an indication of the potential impacts of the system and should be confirmed once the system is in place. Furthermore, several datasets were also lacking from SimaPro databases. Assumptions were made from secondary literature or for comparable processes which may not accurately describe the actual situation.

The system under study uses high-tech devices and artificial intelligence for automatic production processes. Automation in agri-food production is a new area of research with the potential to reduce emissions due to optimized operations and resource usage. This was not investigated during this study due to a lack of data and warrants future research.

This study presents the environmental impact of a commercial cold-weather aquaponic system located in an urban environment in northern Sweden. The environmental impacts were assessed through eight impact categories, and the results suggest that electricity, CO2 enrichment, and heating were the main contributors in all categories. Results were also most sensitive to these parameters indicating that intervention in them will lead to a noticeable reduction in the overall emissions. The presence of the aquaponic system in an urban environment provides the potential to utilize industrial waste and by-products (e.g., exhaust heat and CO2) to mitigate these impacts. Further research is needed to quantify these potential symbiotic benefits.

The combination of aquaculture and hydroculture in aquaponics revealed that synergies can potentially lead to reductions in the environmental burden for these systems compared to operating them separately. Salmon grown in the aquaponics' RAS, for example, have less than fifth the GWP impact than from independent RAS or other common production systems with economic allocation. However, looking at the system in term of energy content will result in mostly higher impact from the salmon grown in the aquaponics. This demonstrates the potential for aquaponic systems in meeting the future demand for sustainable food products. In addition, the system can contribute to cities realizing self-sufficiency of food items with lower GWP than importing them from elsewhere.

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author/s.

ME and HH contributed to conceptualization and data collection. ME contributed to life cycle assessment, data analysis, and manuscript writing. MM and HH contributed with supervision as well as reviewing and editing the final manuscript. All authors contributed to the article and approved the submitted version.

This research was partly funded by the Swedish research council for sustainable development Formas (Grant Number: 2021-00068). It was also funded by the Swedish Innovation Agency (Vinnova), within the Research Program, Innovations for a Sustainable Society, in the project Urban farming for resilient and sustainable food production in urban area (Grant Code: 2019-03178).

We would like to thank Daniel Juhlin from Agtira AB for providing the necessary data for this study. We are also thankful to anonymous reviewers for their inputs and suggestions that helped improve the quality of the article.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2022.1051091/full#supplementary-material

Amani, P., and Schiefer, G. (2011). Review on suitability of available LCIA methodologies for assessing environmental impact of the food sector. Int. J. Food Syst. Dynam. 2, 194–206. doi: 10.18461/ijfsd.v2i2.228

Anders, B., Kerstin, B., Annika, C. -K., Christian, F., Charlotte, L. -F., Helena, S., et al (2006). Environmental Information in the Food Supply System. Available online at: https://www.foi.se/rest-api/report/FOI-R–1903–SE (accessed December 27, 2022).

Atique, F., Lindholm-Lehto, P., and Pirhonen, J. (2022). Is aquaponics beneficial in terms of fish and plant growth and water quality in comparison to separate recirculating aquaculture and hydroponic systems? Water 14, 1447. doi: 10.3390/w14091447

Ayer, N. W., and Tyedmers, P. H. (2009). Assessing alternative aquaculture technologies: life cycle assessment of salmonid culture systems in Canada. J. Clean. Prod. 17, 362–373.

Benis, K., Reinhart, C., and Ferrão, P. (2017). Building-Integrated Agriculture (BIA) In Urban Contexts: Testing A Simulation-Based Decision Support Workflow. Available online at: https://www.semanticscholar.org/paper/Building-Integrated-Agriculture-(-BIA-)-In-Urban-%3A-Benis-Reinhart/bd45f1ac186e3173d2cc23a402f08cc24109a944

Bhakar, V., Kaur, K., and Singh, H. (2021). Analyzing the Environmental Burden of an Aquaponics System using LCA. Proc. CIRP 98, 223–228. doi: 10.1016/j.procir.2021.01.034

Bjørn, A., Chandrakumar, C., Boulay, A.-M., Doka, G., Fang, K., Gondran, N., et al. (2020). Review of life-cycle based methods for absolute environmental sustainability assessment and their applications. Environ. Res. Lett. 15, 083001. doi: 10.1088/1748-9326/ab89d7

Bosona, T., and Gebresenbet, G. (2018). Life cycle analysis of organic tomato production and supply in Sweden. J. Clean. Prod. 196, 635–643. doi: 10.1016/j.jclepro.2018.06.087

Boxman, S. (2015). Resource Recovery Through Halophyte Production in Marine Aquaponics: An Evaluation of the Nutrient Cycling and the Environmental Sustainability of Aquaponics. Available at: https://digitalcommons.usf.edu/etd/5915 (accessed December 27, 2022).

Boxman, S., Zhang, Q., Bailey, D., and Trotz, M. (2016). Life Cycle Assessment a Commercial-Scale Freshwater Aquaponic System. Environ. Eng. Sci. 34, e0510. doi: 10.1089/ees.2015.0510

Breitenstein, M., and Hicks, A. (2022). Review and harmonization of the life cycle global warming impact of five United States aquaponics systems. Aquacultural Engineering 96, 102224.

Brooke, I. C. K. (2019). Salmon Aquaponics: Pro's, Cons, and Facts - HowtoAquaponic. Available online at: https://www.howtoaquaponic.com/fish/salmon-aquaponics/

Casamayor, J., Su, D., and Ren, Z. (2018). Comparative life cycle assessment of LED lighting products. Light. Res. Technol. 50, 801–826. doi: 10.1177/1477153517708597

Charles Bai, S., Hardy, R. W., and Hamidoghli, A. (2022). “Chapter 10 - Diet analysis and evaluation,” in Fish Nutrition (Fourth Edition), eds. R. W. Hardy and S. J. Kaushik (Academic Press) 709–743.

Chen, P., Zhu, G., Kim, H.-J., Brown, P. B., and Huang, J.-Y. (2020). Comparative life cycle assessment of aquaponics and hydroponics in the Midwestern United States. J. Clean. Prod. 275, 122888. doi: 10.1016/j.jclepro.2020.122888

Clune, S., Crossin, E., and Verghese, K. (2017). Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 140, 766–783. doi: 10.1016/j.jclepro.2016.04.082

Cohen, A., Malone, S., Morris, Z., Weissburg, M., and Bras, B. (2018). Combined fish and lettuce cultivation: An aquaponics life cycle assessment. Proc. CIRP 69, 551–556. doi: 10.1016/j.procir.2017.11.029

Coley, D., Howard, M., and Winter, M. (2009). Local food, food miles and carbon emissions: A comparison of farm shop and mass distribution approaches. Food Policy 34, 150–155. doi: 10.1016/j.foodpol.2008.11.001

Davis, J., Wallman, M., Sund, V., Emanuelsson, A., Cederberg, C., and Sonesson, U. (2011). Emissions of Greenhouse Gases From Production of Horticultural Products: Analysis of 17 Products Cultivated in Sweden. Geteborg: SIK - Institutet for livsmedel och bioteknik.

De Bon, H., Parrot, L., and Moustier, P. (2010). Sustainable urban agriculture in developing countries. A review. Agron. Sustain. Dev. 30, 21–32. doi: 10.1051/agro:2008062

Delshad, A. B. (2022). Community gardens:An investment in social cohesion, public health, economic sustainability, and the urban environment. Urban Forest. Urban Green. 70, 127549. doi: 10.1016/j.ufug.2022.127549

dos Santos, M. J. P. L. (2016). Smart cities and urban areas—Aquaponics as innovative urban agriculture. Urban Forest. Urban Green. 20, 402–406. doi: 10.1016/j.ufug.2016.10.004

Ecoinvent (2019). Ecoinvent Version 3.6. Available online at: https://ecoinvent.org/

Edwards-Jones, G., Milà i Canals, L., Hounsome, N., Truninger, M., Koerber, G., Hounsome, B., et al. (2008). Testing the assertion that ‘local food is best': the challenges of an evidence-based approach. Trends Food Sci. Technol. 19, 265–274. doi: 10.1016/j.tifs.2008.01.008

Farhan, M. (2021). Challenges and Opportunities of Smart Aquaponics. CropForLife. Available online at: https://cropforlife.com/challenges-and-opportunities-of-smart-aquaponics/

Forchino, A. A., Lourguioui, H., Brigolin, D., and Pastres, R. (2017). Aquaponics and sustainability: The comparison of two different aquaponic techniques using the Life Cycle Assessment (LCA). Aquacult. Eng. 77, 80–88. doi: 10.1016/j.aquaeng.2017.03.002

Gennotte, V., Forchino, A. A., Mélard, C., Rougeot, C., and Pastres, R. (2017). Life Cycle Assessment (LCA) of an Indoor Pilot Aquaponics Production Facility in Belgium. Available online at: https://orbi.uliege.be/handle/2268/217322

Gentry, M. (2019). Local heat, local food: Integrating vertical hydroponic farming with district heating in Sweden. Energy 174, 191–197. doi: 10.1016/j.energy.2019.02.119

Ghamkhar, R., Hartleb, C., Rabas, Z., and Hicks, A. (2022). Evaluation of environmental and economic implications of a cold-weather aquaponic food production system using life cycle assessment and economic analysis. J. Indust. Ecol. 26, 862–874.

Ghamkhar, R., Hartleb, C., Wu, F., and Hicks, A. (2020). Life cycle assessment of a cold weather aquaponic food production system. J. Clean. Prod. 244, 118767. doi: 10.1016/j.jclepro.2019.118767

Goddek, S., Joyce, A., Kotzen, B., and Burnell, G. M. (2019). Aquaponics Food Production Systems: Combined Aquaculture and Hydroponic Production Technologies for the Future. Cham: Springer International Publishing

Goldstein, B. P. (2017). Assessing the Edible City: Environmental Implications of Urban Agriculture in the Northeast United States. DTU Management.

González, A. D., Frostell, B., and Carlsson-Kanyama, A. (2011). Protein efficiency per unit energy and per unit greenhouse gas emissions: Potential contribution of diet choices to climate change mitigation. Food Policy 36, 562–570. doi: 10.1016/j.foodpol.2011.07.003

Greenfeld, A., Becker, N., Bornman, J. F., Spatari, S., and Angel, D. L. (2021). Monetizing environmental impact of integrated aquaponic farming compared to separate systems. Sci. Total Environ. 792, 148459. doi: 10.1016/j.scitotenv.2021.148459

Greenfeld, A., Becker, N., Bornman, J. F., Spatari, S., and Angel, D. L. (2022). Is aquaponics good for the environment?—evaluation of environmental impact through life cycle assessment studies on aquaponics systems. Aquacult. Int. 30, 305–322. doi: 10.1007/s10499-021-00800-8

Haller, H., Fagerholm, A.-S., Carlsson, P., Skoglund, W., van den Brink, P., Danielski, I., et al. (2022). Towards a resilient and resource-efficient local food system based on industrial symbiosis in Härnösand: A Swedish case study. Sustainability 14, 2197. doi: 10.3390/su14042197

Hindelang, M., Gheewala, S. H., Mungkung, R., and Bonnet, S. (2014). Environmental sustainability assessment of a media based aquaponics system in Thailand. J. Sustain. Energ. Environ. 5, 109–116. Available online at: https://www.thaiscience.info/Journals/Article/JOSE/10985108.pdf

Hollmann, R. (2017). An Aquaponics Life Cycle Assessment: Evaluating an Inovative Method for Growing Local Fish and Lettuce. Available online at: https://www.semanticscholar.org/paper/An-Aquaponics-Life-Cycle-Assessment%3A-Evaluating-an-Hollmann/d6e86d76a6acf6803c7d8d3029be9de280afcd6f

Jaeger, C., Foucard, P., Tocqueville, A., Nahon, S., and Aubin, J. (2019). Mass balanced based LCA of a common carp-lettuce aquaponics system. Aquacult. Eng. 84, 29–41. doi: 10.1016/j.aquaeng.2018.11.003

Johansson, E., and Pétursdóttir, V. (2021). Evaluation of Onshore Transportation Methods for Captured CO2 between Facility and Harbour in Stockholm. Available online at: http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-297664.

Junge, R., König, B., Villarroel, M., Komives, T., and Jijakli, M. H. (2017). Strategic Points in Aquaponics. Water 9, 182.

Karlsson, H. (2011). Seasonal Vegetables; An Environmental Assessment of Seasonal Food. p. 67. Available online at: https://nmbu.brage.unit.no/nmbu-xmlui/bitstream/handle/11250/189423/Hanna%20Karlsson.pdf?isAllowed=y&sequence=1 (accessed December 27, 2022).

Klapwijk, D., and De Lint, P. J. A. L. (1974). Fresh weight and flowering of tomato plants as influenced by container type and watering conditions. Acta Hortic. 1974, 237–248.

König, B., Janker, J., Reinhardt, T., Villarroel, M., and Junge, R. (2018). Analysis of aquaponics as an emerging technological innovation system. J. Clean. Prod. 180, 232–243. doi: 10.1016/j.jclepro.2018.01.037

Körner, O., Bisbis, M. B., Baganz, G. F. M., Baganz, D., Staaks, G. B. O., Monsees, H., et al. (2021). Environmental impact assessment of local decoupled multi-loop aquaponics in an urban context. J. Clean. Prod. 313, 127735. doi: 10.1016/j.jclepro.2021.127735

Körner, O., Gutzmann, E., and Kledal, P. R. (2017). A dynamic model simulating the symbiotic effects in aquaponic systems. Acta Hortic. 2017, 309–316. doi: 10.17660/ActaHortic.2017.1170.37

Lall, S. P., and Kaushik, S. J. (2021). Nutrition and metabolism of minerals in fish. Animals (Basel) 11, 2711. doi: 10.3390/ani11092711

Lam, W. Y., van Zelm, R., Benítez-López, A., Kulak, M., Sim, S., King, J. M. H., et al. (2018). Variability of greenhouse gas footprints of field tomatoes grown for processing: interyear and intercountry assessment. Environ. Sci. Technol. 52, 135–144. doi: 10.1021/acs.est.7b04361

Lee, K. -M., and Inaba, A. (2004). Life Cycle Assessment: Best Practices of ISO 14040 Series. Center for Ecodesign and LCA(CEL), Ajou University. Available online at: https://www.apec.org/docs/default-source/Publications/2004/2/Life-Cycle-Assessment-Best-Practices-of-International-Organization-for-Standardization-ISO-14040-Ser/04_cti_scsc_lca_rev.pd (accessed December 27, 2022).

Li, Y., Ding, Y., Li, D., and Miao, Z. (2018). Automatic carbon dioxide enrichment strategies in the greenhouse: A review. Biosyst. Eng. 171, 101–119. doi: 10.1016/j.biosystemseng.2018.04.018

Linehan, V., Thorpe, S., Andrews, N., Kim, Y., and Beaini, F. (2012). Opportunities for Australian agriculture in Canberra, Australia. p. 21. Available online at: https://www.agriculture.gov.au/sites/default/files/sitecollectiondocuments/abares/publications/Outlook2012FoodDemand2050.pdf (accessed December 27, 2022).

Liu, Y., Rosten, T. W., Henriksen, K., Hognes, E. S., Summerfelt, S., and Vinci, B. (2016). Comparative economic performance and carbon footprint of two farming models for producing Atlantic salmon (Salmo salar): Land-based closed containment system in freshwater and open net pen in seawater. Aquacult. Eng. 71, 1–12. doi: 10.1016/j.aquaeng.2016.01.001

Llorach Massana, P. (2017). Mitigating the Environmental Impacts of Urban Agriculture: Innovative Materials, GHG Emissions Analysis and New By-Products. (Tesis Doctorals en Xarxa). Available online at: http://www.tdx.cat/handle/10803/405303

Love, D. C., Fry, J. P., Genello, L., Hill, E. S., Frederick, J. A., Li, X., et al. (2014). An international survey of aquaponics practitioners. PLoS ONE 9, e102662. doi: 10.1371/journal.pone.0102662

Martin, M., and Carlsson, P. (2018). Environmental Assessment of the Sotenäs Industrial Symbiosis Network. IVL Swedish Environmental Research Institute. Available online at: https://www.ivl.se/download/18.2aa269781609727880714b0/1519639105074/C275.pdf (accessed December 27, 2022).

Martin, M., and Harris, S. (2018). Prospecting the sustainability implications of an emerging industrial symbiosis network. Resourc. Conserv. Recycl. 138, 246–256. doi: 10.1016/j.resconrec.2018.07.026

Martin, M., Weidner, T., and Gullström, C. (2022). Estimating the potential of building integration and regional synergies to improve the environmental performance of urban vertical farming. Front. Sustain. Food Syst. 6:849304. doi: 10.3389/fsufs.2022.849304

Marttila, M. P., Uusitalo, V., Linnanen, L., and Mikkilä, M. H. (2021). Agro-industrial symbiosis and alternative heating systems for decreasing the global warming potential of greenhouse production. Sustainability 13:9040. doi: 10.3390/su13169040

Maucieri, C., Forchino, A. A., Nicoletto, C., Junge, R., Pastres, R., Sambo, P., et al. (2018). Life cycle assessment of a micro aquaponic system for educational purposes built using recovered material. J. Clean. Prod. 172, 3119–3127. doi: 10.1016/j.jclepro.2017.11.097

McAuliffe, G. A., Takahashi, T., and Lee, M. R. F. (2020). Applications of nutritional functional units in commodity-level life cycle assessment (LCA) of agri-food systems. Int. J. Life Cycle Assess. 25, 208–221. doi: 10.1007/s11367-019-01679-7

Moberg, E., Walker Andersson, M., Säll, S., Hansson, P.-A., and Röös, E. (2019). Determining the climate impact of food for use in a climate tax—design of a consistent and transparent model. Int. J. Life Cycle Assess. 24, 1715–1728. doi: 10.1007/s11367-019-01597-8

Nilsson, J., and Martin, M. (2022). Exploratory environmental assessment of large-scale cultivation of seaweed used to reduce enteric methane emissions. Sustain. Product. Consumption 30, 413–423. doi: 10.1016/j.spc.2021.12.006

OEC (2020). The Observatory of Economic Complexity | OEC- The Observatory of Economic Complexity. Available online at: https://oec.world/

Onwude, D. I., Chen, G., Eke-emezie, N., Kabutey, A., Khaled, A. Y., and Sturm, B. (2020). Recent advances in reducing food losses in the supply chain of fresh agricultural produce. Processes 8, 1431. doi: 10.3390/pr8111431

Parajuli, R., Matlock, M. D., and Thoma, G. (2021). Cradle to grave environmental impact evaluation of the consumption of potato and tomato products. Sci. Total Environ. 758, 143662. doi: 10.1016/j.scitotenv.2020.143662

Parker, T., and Svantemark, M. (2019). Resilience by industrial symbiosis? A discussion on risk, opportunities and challenges for food production in the perspective of the food-energy-water nexus. Sustain. Earth 2, 7. doi: 10.1186/s42055-019-0016-7

Pattillo, D. A. (2017). An Overview of Aquaponic Systems: Aquaculture Components. Available online at: https://www.ncrac.org/files/publication/aquaculture_components.pdf (accessed December 27, 2022).

Pelletier, N., Tyedmers, P., Sonesson, U., Scholz, A., Ziegler, F., Flysjo, A., et al. (2009). Not all salmon are created equal: Life Cycle Assessment (LCA) of global salmon farming systems. Environ. Sci. Technol. 43, 8730–8736. doi: 10.1021/es9010114

Potter, H. K., Lundmark, L., and Röös, E. (2020). Environmental Impact of Plant-Based Foods. Uppsala: Swedish University of Agricultural Sciences. Available online at: https://pub.epsilon.slu.se/17699/1/Report112.pdf (accessed December 27, 2022).

PRé Sustainability (2020). SimaPro Database Manual Methods Library. Available online at: https://simapro.com/wp-content/uploads/2020/10/DatabaseManualMethods.pdf

Proksch, G., and Ianchenko, A. (2019). Urban Food Systems: Applying Life Cycle Assessment in Built Environments and Aquaponics.

Röös, E., and Karlsson, H. (2013). Effect of eating seasonal on the carbon footprint of Swedish vegetable consumption. J. Clean. Prod. 59, 63–72. doi: 10.1016/j.jclepro.2013.06.035

Selina Wamucii, (2022). Sweden Prices, Trends & Insights| Sweden Agriculture Statistics. Selina Wamucii. Available online at: https://www.selinawamucii.com/insights/prices/sweden/

Song, X., Liu, Y., Pettersen, J. B., Brandão, M., Ma, X., Røberg, S., et al. (2019). Life Cycle Assessment of Recirculating Aquaculture Systems: A Case of Atlantic Salmon Farming in China.

Svedin, L. (2021). Mer närodlat kan det inte bli. Available online at: http://www.epochtimes.se/Mer-narodlat-kan-det-inte-bli

Tennøy, A. K. (2022). Exploring the Potential for Hydroponic Plant Growth in Water from Atlantic Salmon Recirculating Aquaculture Systems (Aquaponics). Available online at: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/3003277

Thorarinsdottir, R. (2015). Report on LCA, Economic Analysis and Cost-Benefits Analysis. CIP EcoInnovation, pilot and market replication projects, call 2012.

Torrellas, M., Antón, A., Ruijs, M., García Victoria, N., Stanghellini, C., and Montero, J. I. (2012). Environmental and economic assessment of protected crops in four European scenarios. J. Clean. Prod. 28, 45–55. doi: 10.1016/j.jclepro.2011.11.012

UN (2014). World's Population Increasingly Urban With More Than Half Living in Urban Areas | UNDESA | United Nations Department of Economic and Social Affairs. Available online at: https://www.un.org/development/desa/en/news/population/world-urbanization-prospects.html

USDA (2019). U.S. Department of Agriculture, Agricultural Research Service. Food Data Central. Available online at: fdc.nal.usda.gov

Valappil, G. (2021). Environmental and Economic Implications of Small-Scale Canadian Aquaponics: A Life Cycle Study. Available online at: https://uwspace.uwaterloo.ca/handle/10012/16951

Villarroel, M., Junge, R., Komives, T., König, B., Plaza, I., Bittsánszky, A., et al. (2016). Survey of aquaponics in Europe. Water 8, 468. doi: 10.3390/w8100468

Willett, W., Rockström, J., Loken, B., Springmann, M., Lang, T., Vermeulen, S., et al. (2019). Food in the anthropocene: The EAT–lancet commission on healthy diets from sustainable food systems. Lancet 393, 447–492. doi: 10.1016/S0140-6736(18)31788-4

Wu, F., Ghamkhar, R., Ashton, W., and Hicks, A. L. (2019). Sustainable seafood and vegetable production: Aquaponics as a potential opportunity in urban areas. Integr. Environ. Assess. Manag. 15, 832–843. doi: 10.1002/ieam.4187

Xie, K., and Rosentrater, K. (2015). “Life cycle assessment (LCA) and Techno-economic analysis (TEA) of tilapia-basil aquaponics,” in 2015 ASABE International Meeting (American Society of Agricultural and Biological Engineers).

Yacout, D. M. M., Soliman, N. F., and Yacout, M. M. (2016). Comparative life cycle assessment (LCA) of Tilapia in two production systems: Semi-intensive and intensive. Int. J. Life Cycle Assess. 21, 806–819. doi: 10.1007/s11367-016-1061-5

Zarei, M. J., Kazemi, N., and Marzban, A. (2019). Life cycle environmental impacts of cucumber and tomato production in open-field and greenhouse. J. Saudi Soc. Agricult. Sci. 18, 249–255. doi: 10.1016/j.jssas.2017.07.001

Keywords: aquaponic system, environmental impacts, life cycle assessment, urban farming, food production, cold climate agriculture

Citation: Elnour M, Haller H and Martin M (2023) Life cycle assessment of a retail store aquaponic system in a cold-weather region. Front. Sustain. 3:1051091. doi: 10.3389/frsus.2022.1051091

Received: 22 September 2022; Accepted: 19 December 2022;

Published: 11 January 2023.

Edited by:

George Tsalidis, Delft University of Technology, NetherlandsReviewed by:

Enrica Vesce, University of Turin, ItalyCopyright © 2023 Elnour, Haller and Martin. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Henrik Haller,  SGVucmlrLmhhbGxlckBtaXVuLnNl

SGVucmlrLmhhbGxlckBtaXVuLnNl

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.