- 1PK Sinha Centre for Bioenergy and Renewables, Indian Institute of Technology Kharagpur, Kharagpur, India

- 2School of Environmental Science and Engineering, Indian Institute of Technology Kharagpur, Kharagpur, India

- 3Department of Civil Engineering, Indian Institute of Technology Kharagpur, Kharagpur, India

With the plausible depletion of fossil fuels in the near future and its associated environmental impacts, researchers have instigated the search for eco-friendly renewable bioenergy. Moreover, the increase in water pollution by industrial and anthropogenic activities is another alarming global concern. In this regard, the production of renewable and sustainable green bioenergy utilizing wastewater through microbial electrochemical technologies (METs) can alleviate these crucial problems by providing a sustainable solution to meet both the demands of energy and fresh water supply. Moreover, different bio-centered techniques such as nitrification and denitrification for nitrogen removal, and elimination of carcinogenic metals, pathogens, and organic components utilizing microbiota followed by toxicity sensing of different pollutants have been efficaciously exhibited through METs. However, inferior bioenergy production and recovery of low biomass yield in METs with high operational cost are noteworthy bottlenecks that hinder the scalability of this technology. Therefore, this review elaborates different physicochemical factors affecting the performance of METs, microbial interaction for the development of stable biofilm and so forth. Moreover, a broad overview on the production of bioenergy, along with the removal of pollutants from wastewater through different types of METs are also highlighted. Furthermore, the production of biofuels like ethanol, methanol, biodiesel, and gaseous fuel like bio-H2 coupled with power generation using photosynthetic microorganisms via CO2 sequestration through METs are also discussed. Additionally, recent developments with future scope for the field-scale implementation of METs along with their bottlenecks have been discussed, which has not been critically reviewed to date.

Introduction

The growing energy crisis is an inexorable anxiety for human beings because of enlarging industrial activities with the ever-increasing global population. In addition, excessive use of fossil fuels, like coal, petroleum, diesel, crude oil, and natural gas, has caused tremendous energy cravings, which would emerge to be a serious threat globally in the near future (Silveira et al., 2020). Moreover, the depletion of these non-renewable fuels with their adverse impacts on the environment is another prominent concern for the mankind. To alleviate this global energy crisis, scientists are trying to focus on developing eco-friendly, renewable, and sustainable bioenergy sources (Jatoi et al., 2021). Thus, the production of bioenergy like bioelectricity and biofuel via the biodegradation of organic and other oxidizable compounds present in wastewater by microbiota could evolve as a suitable renewable and self-sustainable cost-effective revelation.

Although the anaerobic digestion process is generally used for the production of biogas and other value-added products from organic matter present in wastewater, nutrients like phosphorus and nitrogen, acidic components, and toxic metals still persist in the effluent after the treatment via anaerobic digestion, which must be eliminated prior to its disposal into natural water bodies (Puyol et al., 2017; Rambabu et al., 2020). Therefore, researchers invented a novel wastewater treatment approach through microbial electrochemical technologies (METs) that can treat wastewater along with simultaneous recovery of the bioenergy and other valuables from wastewater.

In the recent era, METs have been extensively researched for their incredible potential to generate green energy and valuables with the concomitant treatment of wastewater (Neethu and Ghangrekar, 2017; Vinayak et al., 2021). Generally, in different kinds of METs, electroactive microorganisms formally known as exoelectrogens consume organic matter present in the wastewater as a substrate for their cell growth and eliminate contaminants with simultaneous generation of bioelectricity (Jatoi et al., 2021). Therefore, self-sustainable METs are advantageous due to their low energy-intensive, cost-effective, and eco-friendly nature over other conventional wastewater treatment processes (Crini and Lichtfouse, 2019). Thus, METs have gained more interest among budding researchers for the generation of bioenergy with value-added recovery of bioethanol, methanol, or bio-hydrogen from wastewater, while offering treatment to it.

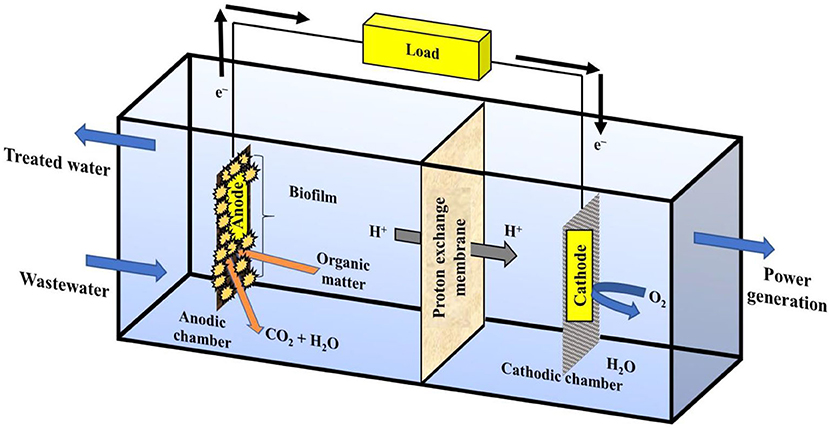

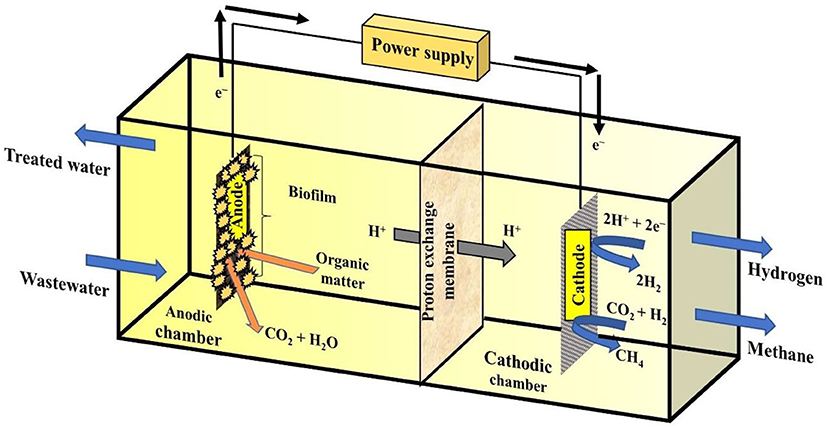

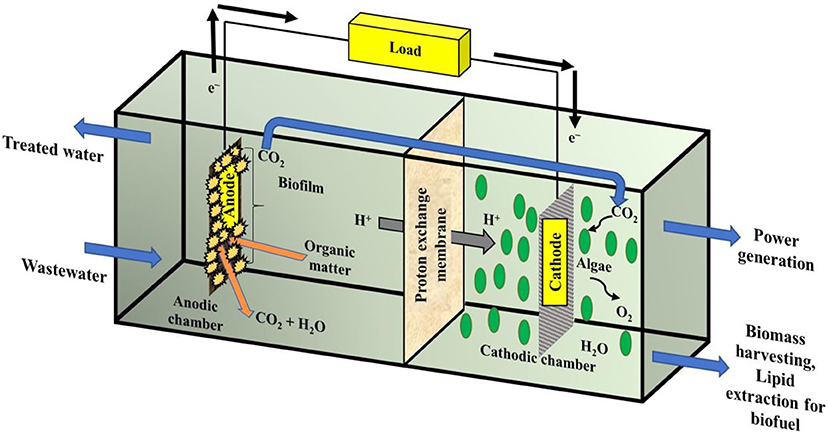

In microbial fuel cell (MFC), exoelectrogens, the green biocatalysts, degrade organic components from wastewater used as fuel for their cellular mechanism, and release CO2, protons, and electrons in the anodic chamber (Neethu and Ghangrekar, 2017; Vinayak et al., 2021). Furthermore, the protons are transferred toward the cathode via the proton exchange membrane (PEM). Moreover, electrons are transported through the external circuit from the anode to the cathode, and later, they combine with oxygen to produce H2O in the cathodic chamber of a MFC for the recovery of sustainable bioelectricity with the holistic treatment of wastewater (Modin et al., 2012). However, in another significant METs, namely microbial electrolysis cell (MEC), external power is required to promote the production of bio-hydrogen in its cathodic chamber. However, the recovery of bioelectricity from different large-scale METs is still a challenge due to the major bottlenecks of lower yield and economic sustainability.

Therefore, this review article summarizes the different applications of METs for the treatment of wastewater and the generation of bioelectricity and biofuels with value-added products recovery. Furthermore, different types of physicochemical parameters like cell potential, substrate concentration, pH, temperature, electrode material, membrane separator, and different reactor configurations, such as single, double chamber, or stacked cells that affect bioenergy production with simultaneous wastewater treatment are articulated. Also, the effect of bacterial signaling molecules and intercellular mechanism of exoelectrogens to enhance the power generation of METs are also highlighted in this review. To the best of our knowledge, the role of exoelectrogens and their selection based on their robustness to survive in the extreme conditions and bacterial cellular interaction to enhance the biofilm formation, which improves the performance of the METs, have not been well explained previously. Additionally, the recent development pertaining to METs with novel techniques to circumnavigate the roadblocks of field-scale applications, which have not been critically reviewed in the past, are also highlighted in this article. Moreover, this review provides recent practical applications of METs that would abet to scale-up this technology in terms of bioenergy production with concomitant wastewater treatment, which also has not been critically reviewed until now. Therefore, this review can guide the budding researchers in better understanding the distinctions of METs, which could pave the way toward the effective commercialization of the same.

Microbial Electrochemical Technologies

The METs are a newly developed system employed for wastewater abatement, in which instead of just degrading or destroying the pollutants, decontamination of polluted water is carried out by transforming organic contaminants into useful recoverable energy in the form of bioelectricity and other valuable chemical products, such as hydrogen, hydrogen peroxide, methane, alcohols, acetate, etc. (Das et al., 2020g). Simultaneous wastewater treatment and energy recovery through METs is achieved by synergistically amalgamating the electrochemical breakdown mechanism with microbial degradation. Specialized electroactive microorganisms are employed during the bioelectrochemical degradation of organics that are capable of exchanging electrons with other receptive materials/chemicals, like electrodes, electron mediators, nitrate, sulfate, and insoluble metal oxides (Logan et al., 2019).

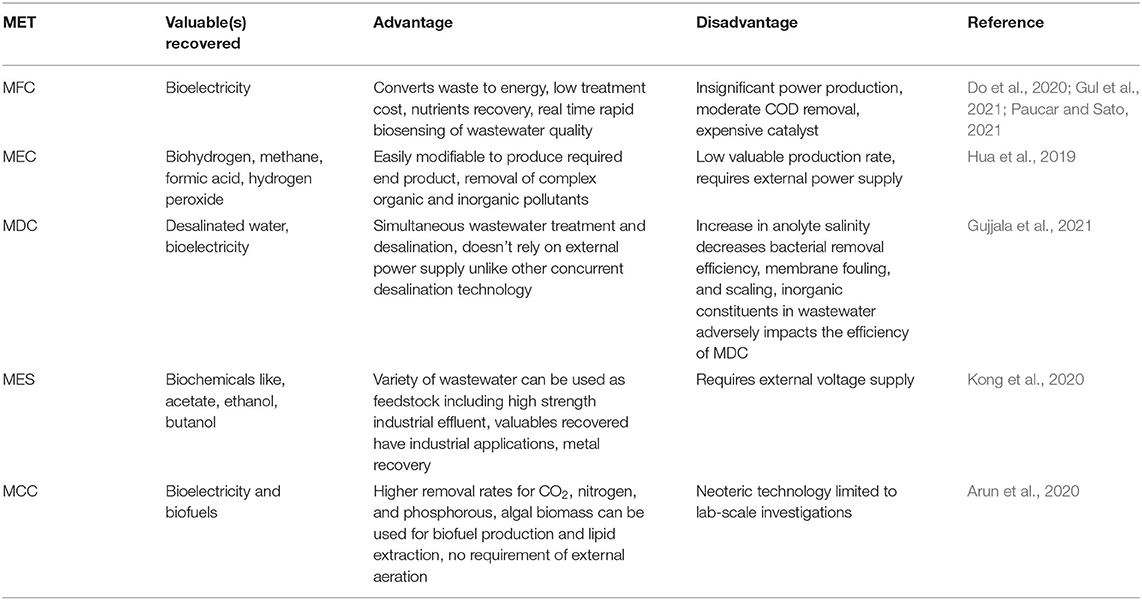

Different METs have been developed and are distinguished based on their applicability and value-added product recovered through them, such as MFC for the generation of bio-electricity, MEC for valuables like H2 and methane production, microbial electrosynthesis (MES) for biofuels like acetate, ethanol, butyrate production, microbial desalination cell (MDC) for desalination of brackish water along with power generation and microbial carbon-capture cell (MCC) for bioelectricity production with concomitant carbon sequestration (Priyadarshini et al., 2021). Nevertheless, MFC, MEC, and MDC are among the most widely applied and investigated METs owing to their ease of operation, vast applicability, and potential of higher economic and environmental sustainability.

Types of Microbial Electrochemical Technologies With Their Diverse Mechanism

A typical MFC (Figure 1) is comprised of a dual-electrode compartments, each housing anode and cathode, and separated by a semi-permeable PEM. The anodic chamber is operated under anaerobic condition to favor the growth of anaerobic exoelectrogenic microbes that are capable of transferring electrons extracellularly to an electron receptor (Gul et al., 2021). These exoelectrogenic microbes carry out the oxidation of the organic ingredients present in wastewater and produce electrons, protons, and carbon dioxide. These electrons and protons are further transported to the cathodic chamber via an external circuit connecting both electrodes and through PEM, respectively, thereby producing bio-electricity (Li et al., 2018). Aerobic environment is maintained in the cathodic chamber of a MFC to ensure the availability of O2 as a terminal electron acceptor. Moreover, the cathode material chosen should possess enhanced electrocatalytic activity to speed up the sluggish oxygen reduction reaction (ORR) occurring on the cathode, thus improving the power generation of MFC (Das et al., 2021a). If photosynthetic microorganism algae can provide the oxygen required for the cathodic reaction, then such a setup is termed as MCC (Das et al., 2019b). Therefore, MCC is a cost-effective way of producing bioelectricity through the principles of MFC with the added advantage of carbon sequestration and biofuel production from the harvested algae cultured in the cathodic chamber of an MCC.

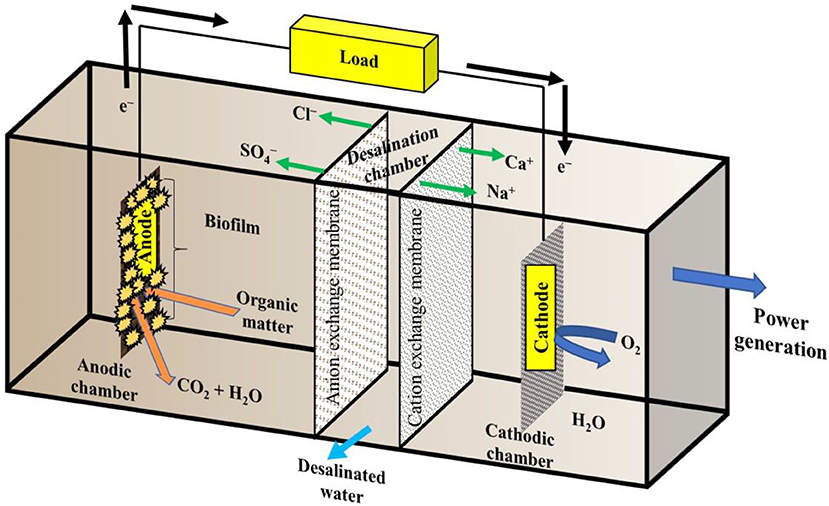

An MFC can be modified to produce valuable biohydrogen through the application of external potential and then it is termed as MEC (Ahmad et al., 2021). The construction and working of a MEC is analogous to that of a MFC with concomitant H2 production through application of externally applied voltage of 0.2 V or greater (Figure 2). Despite the need of an external power supply, MECs are considered as a much more sustainable method for the production of H2 as the magnitude of the applied voltage is significantly lower than that required during the electrolysis of water for producing H2 (2.3 V) (Call et al., 2009). Also, MECs can be modified to reduce CO2 in the cathodic chamber by electrotrophic microbes coupled with anodic water splitting with the supplementation of external potential to produce biofuels or organic chemicals. Such systems are commonly termed as MES, which demonstrate biofuel production and carbon sequestration, thus alleviating the problem of global warming (Das et al., 2021b). The MDCs are an extension to MFC, which consists of an additional centrally located desalination chamber in order to remove salts from brackish water with simultaneous bioelectricity generation (Figure 3) (Bejjanki et al., 2021). The details of valuables recovered by different METs with their respective advantages and drawbacks are summarized in the Table 1.

Types of Microorganisms Used in Microbial Electrochemical Technologies

Microbes are the drivers of any MET and a healthy growth of microbial biomass is a compulsory perquisite for the efficacious treatment of wastewater. An array of microorganisms can be cultured inside this bio-electrochemical system depending on the type of wastewater fed and inoculum used. However, electroactive microorganisms are the predominant species employed in METs because of their extracellular electron transferring abilities (Nath et al., 2021). Based on their role in electron exchange, they are further classified into two categories (a) exoelectrogens, that can transfer electrons to solid electrodes and (b) electrotrophs, that are capable of accepting electrons from the electrode (Das et al., 2020f).

Exoelectrogens, such as bacteria of Geobacter and Shewanella genera are the most common electroactive organisms frequently found in MFCs (Zheng et al., 2020). However, other bacterial species, such as Klebsiella pneumoniae, Escherichia coli, Pseudomonas sp., Anaerolinaceae sp., and Burkholderiaceae sp. have also shown amenability in forming electroactive biofilm over the anode surface of a MFC (Obata et al., 2020). The development of biofilm over anode surface is critical to the concomitant bioelectricity generation in MFCs. For instance, during an experiment as the proliferation of Geobacter sp. occurred in the anodic biofilm, voltage developed in the MFC increased from 100 mV on the 5th to approximately 400 mV after 20 days (Paitier et al., 2017). Additionally, enrichment of electroactive Geobacter sp. along with the enhancement of extracellular electron transfer efficiency has made it possible to yield ameliorated power density and current density as high as 4.99 W m−2 and 12.30 A m−2, respectively (Paitier et al., 2017).

Electrotrophs aid in transporting electrons from the cathode to the terminal electron acceptors, like O2, CO2, nitrate, iron, manganese chlorinated solvents, etc., and thus are a critical component of cathode-based METs, such as MECs and MES (Zaybak et al., 2013; Yu et al., 2015). Application of electroactive bacteria Acinetobacter calcoaceticus and Shewanella putrefaciens has shown improvement in cathodic O2 reduction (Paitier et al., 2017). Moreover, biocathodes have been efficiently applied for MES for acetic acid and CH4 production from CO2 using Sporomusa ovata and Methanobacterium sp. and for denitrification by developing electroactive nitrate-reducing genera of Azoarcus sp. and Pontibacter sp. in the biofilm (Philippon et al., 2021). Furthermore, different investigations have ascertained the role of different strains of Desulfopila sp. and Desulfovibrio sp. in the reduction of sulfate, and of electroactive heterotroph Clostridium pasteurianum in the electrosynthesis of butanol at the cathode (Beese-Vasbender et al., 2015). Besides, many other species of microorganism may also develop in cathodic and anodic biofilm, which are not active in exchanging electrons; however, these microspecies can have a major impact on the susceptibility and resilience of biofilm to the environmental changes within the bio-electrochemical setup (Paitier et al., 2017).

Factors Affecting the Performance of Microbial Electrochemical Technologies

The extent to which contaminants are removed through METs and the rate of resource recovery is largely dependent on the development and efficient functioning of electroactive biofilms over the electrode surface and the electrochemical activity of the electrocatalysts employed (Das and Ghangrekar, 2021). Accordingly, adequate time is provided for the colonization of electrodes by electroactive organisms in a bio-electrochemical system post-inoculation. Besides biological factors, like inoculum source and type of microorganism cultured, many physico-chemical parameters, such as electrode and membrane material, inoculum pre-treatment method adopted, applied potential, electrolyte pH, temperature, salinity, etc., can also affect the efficacy of METs (Das et al., 2020e; Ghorai et al., 2021). Some of the key physico-chemical parameters influencing the performance of METs are elucidated below.

Electrode Material

Electrodes are vital component of any MET and serve as the base material for biofilm formation and active catalysts layer and also facilitates the transfer of electrons for conducting redox reactions. An ideal electrode for functioning as bioanode or biocathode must have high conductivity, should be biocompatible, must possess large specific surface area for better biofilm adhesion, and should be chemically stable, when subjected to different wastewater streams (Hindatu et al., 2017). Carbon and metal-based electrodes along with conductive polymers, like polythiophene and polyaniline are preferred in METs as they exhibit most of the properties of an ideal anode (Zhang et al., 2019a; Das et al., 2020a). Metal electrodes have excellent conductivity; however, the smoother metal surface prohibits the formation of a stronger bond with the biofilm. Moreover, metals are susceptible to corrosion, which can hinder electron transfer and some of the metals like nickel and copper can be toxic for the microbial cultures (Das et al., 2018).

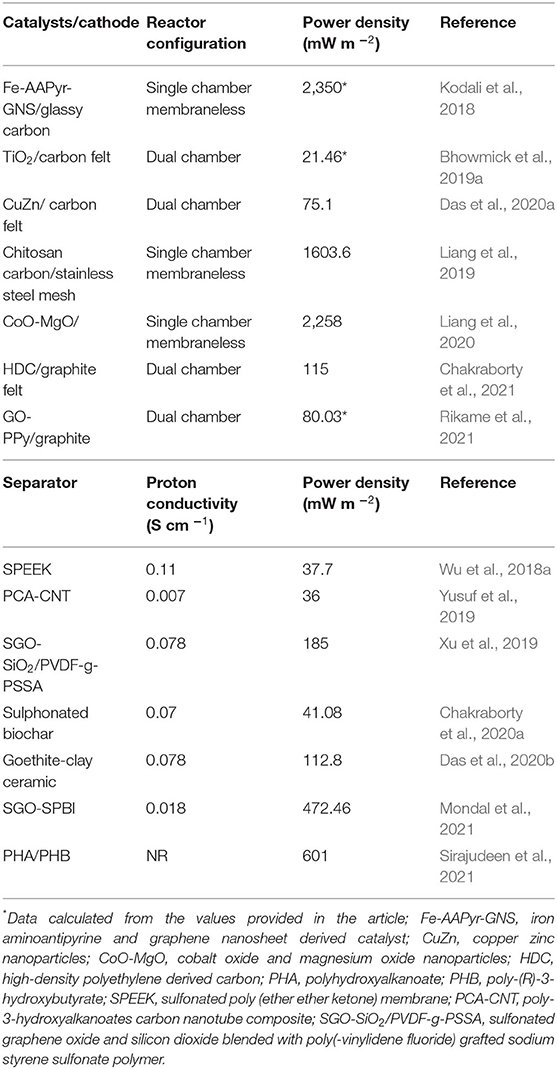

Carbon electrodes, made up of graphite felt and carbon paper, are low-cost and have exhibited better performance than metal anodes, such as stainless steel, because of their higher specific surface area that promotes healthy biofilm tethering (Zhang et al., 2012). In a more recent investigation assessing different anode materials for the treatment of petroleum hydrocarbon contaminated soil through MFC, graphite felt anode attained the highest pollutants removal (average removal of 64.20%) and bioelectricity generation (power density of 24 mW m−2), when compared to alternatives, like aluminum sheet, activated carbon, carbon fiber felt, graphite paper, and carbon clothes (Yu et al., 2021). The better performance of graphite felt was attributed to the presence of greater microbial diversity and abundance of microbial population on the anode surface. Furthermore, different alternate materials, such as waste medicine wrappers and blended metal cathodes with conductive coating, have also been used to enhance the efficiency of MFCs (Bhowmick et al., 2019b). In addition, cathode of a MFC and other METs is often supplemented with catalyst to accelerate the rate of ORR for ameliorating the recovery of bioresources. Nobel metals like platinum are very efficient in pacing up the cathodic reaction; however, using expensive catalyst like platinum is discouraged in scaled-up reactors as it drastically increases the cost of reactor fabrication. Therefore, facile modifications of cathode using much cheaper alternate catalysts has been widely investigated in different METs for reducing the treatment cost (Table 2).

Membrane Separator Materials

Membrane separators are semipermeable material used for separating the anodic chamber from the cathodic chamber in a bio-electrochemical reactor. The PEM used as membrane separator assists in the migration of protons from anodic chamber to the cathodic chamber in a MFC. Whereas, in MDC anion and cation exchange membrane are used as separators for the construction of desalination chamber. Moreover, separator membranes also prevent the penetration of unwanted substances, like substrate, oxygen, etc., from the cathodic to the anodic chamber and vice versa, which can diminish energy recovery of METs (Sadhasivam et al., 2017).

Ideally, an ion exchange membrane must have a low internal resistance, able to perform mass transfer between aerated water present in cathodic chamber and anaerobic electrolyte present in the anodic chamber, high ionic conductivity, efficient energy recovery, and long service life (Das et al., 2020c). Thus, the selection of a suitable membrane separator is instrumental in dictating the performance of METs (Shabani et al., 2020). Polymeric membranes made up of Nafion 117, Nafion 112, sulfonated poly ether ketone (SPEEK), etc., are commonly used in MFC as PEMs (Bakonyi et al., 2018). Nevertheless, polymeric membranes are costly and prone to frequent biofouling, which has a detrimental effect on the performance of METs (Koók et al., 2019).

Lately, researchers have been investigating more efficient and cost-effective PEMs. In this regard, Das and co-workers tested goethite supplemented natural clay ceramic as an alternative PEM for MFC and reported 22 and 6% improvement in chemical oxygen demand (COD) removal and coulombic efficiency (CE), respectively, when compared to Nafion 117 as PEM (Das et al., 2020b). Furthermore, the application of cost-effective PEM in MFC, such as sulphonated biochar derived from the pyrolysis of food waste at 600°C exhibited comparable COD removal efficiency (81%) compared to Nafion 117 PEM (88%) (Chakraborty et al., 2020a). Moreover, the power harvested per unit cost of PEM was 26 times higher for sulphonated biochar (0.278 W$ −1), when compared to Nafion 117 (0.011 W$ −1); hence elucidating the economic sustainability of this biochar-based PEM (Chakraborty et al., 2020a).

Electrolyte pH, Inoculum Pre-treatment, and Other Parameters

In METs, such as MFC and MES, electrolyte pH can significantly affect the electrochemical as well as the biological reactions (Behera et al., 2010). Anolyte pH is crucial in regulating the microbial yield and metabolic pathways of biocatalyst, that ultimately defines the performance of the entire system (Wilson and Kim, 2016). Usually, most microorganisms thrive at near neutral pH as many enzymes involved in metabolic activities function optimally at neutral pH and slight change in pH can bring instability in the biomolecules, thus hampering their normal functioning (Butti et al., 2016). In a research investigating the effect of pH on bioelectricity generation in MFC employing Geobacter sulfurreducens, maximum current density of 8,210 mA m−2 was attained at pH of 7 (Patil et al., 2010). Extreme acidic or alkaline condition can also alter the ionic concentration of electrolyte, which can have an adverse impact on proton shuttling through membrane separators (Srikanth and Mohan, 2012). However, the optimum removal efficiency of an individual pollutant in METs can be different, depending on the physicochemical characteristic of the target compounds. For instance, the optimum pH reported for sulfate removal through a MFC was 4.5, whereas for 2,4-dichlorophenol removal, the same was 5 (Leon-Fernandez et al., 2021).

Pre-treatment of inoculum before feeding it to a MET is usually performed to proliferate the growth of a specific species in the anodic chamber of a MET. Some of the usually adopted pre-treatment method includes heat treatment, ultrasonic treatment, microwave treatment, combined heat/alkali treatment, fungal treatment, fermentation treatment, and many more (Butti et al., 2016). Ultrasonic pre-treatment and combined heat/alkali pre-treatment of different sludge inoculum elevated the COD removal efficiency and power generation in MFC (Oh et al., 2014). Another investigation on treating palm oil effluent via MFC demonstrated 25 and 24% augmentation in power generation and COD removal efficiency, respectively, post ultrasonic pre-treatment (Leano et al., 2012).

Operating factors, such as applied voltage, in MEC has shown an important role in the removal of acetate from polluted water containing chloride ions (Baek et al., 2021). In abiotic MEC, COD removal of 62.6% was achieved at an applied voltage of 4 V, which was 1.8 times of COD removal attained at an applied voltage of 1 V due to the generation of free chlorine species at an elevated voltage (Baek et al., 2021). On the contrary, higher applied voltage had an adverse effect on biotic MEC as it inactivated electroactive microorganisms and accordingly, COD removal efficiency decreased from 89 to 73%, when the applied voltage was increased from 1 to 4 V (Baek et al., 2021).

Addition of alternate carbon sources in the form of acetate and glucose leads to the greater removal of complex compounds, like dyes, in MET mainly due to the proliferation of electroactive microorganisms because of the abundance of food source (Hou et al., 2021). Also, increasing salinity of electrolyte tends to increase power output as well as COD removal efficiency due to the enhancement in the conductivity of the medium; however, increasing salinity beyond an optimum concentration, known as tolerance limit, drops both power generation, and contaminant removal as microorganisms in the biofilms are inhibited because of an unfavorable environment (Lefebvre et al., 2012). Tremouli et al. reported optimum salinity of 4.1 mg L−1 for the treatment of curated wastewater through MFC with the initial COD of 0.7 g L−1, attaining 70% COD removal efficiency and power output of 66 mW m−2 (Tremouli et al., 2017). Furthermore, in the same experiment, peak voltage surged by 46%, when temperature was raised from 24°C (62 mV) to 35°C (92 mV) probably due to an escalated metabolic activity of microbes and reduction in internal resistance at elevated temperature (Tremouli et al., 2017).

Moreover, the role of bacterial cellular interaction via quorum sensing (QS) signaling mechanism among interspecies and intraspecies in the field of METs has gained attention among nascent researchers. In this QS mechanism, bacteria secrete specific sensing molecules for their communication that control their population density, cellular movement and other cellular activities. Therefore, utilization of QS molecules for the development of the stable and mature biofilm results in higher power generation in METs (Das et al., 2021c). In this regard, Taşkan and Taşkan (2021) developed a novel MFCs by culturing immobilized Rhodococcus sp. BH4 in the anodic chamber, which can control the thickness of biofilm via the inhibition of QS molecules namely acyl-homoserine-lactone (AHL). The maximum 1,924 mW m−2 of power density with 73% removal of total organic carbon were obtained by utilizing 20 mg L−1 of AHL degrading Rhodococcus sp. BH4 strain grown in a MFC (Taşkan and Taşkan, 2021). Therefore, microbial QS possess significant potential for the improvement in power generation with simultaneous treatment of wastewater through METs. Therefore, these investigations prove that these above-mentioned physico-chemical parameters are imperative in governing the performance of METs and thus should be optimized to extract maximum yield from METs.

Bioenergy Production From Waste Using METs

Recovery of H2, CH4, and Other Valuable Biogas Employing METs

Over the past decade, researchers have gained attention for the production of bio-gaseous fuels CH4 and H2 along with other valuable by-products, such as acetate and formic acid, by using different types of METs (Sogani et al., 2021). As an example, Kundu et al. applied an external cathode potential of −0.41 V vs. standard hydrogen electrode (SHE) in a MEC for the recovery of bio-H2 at neutral pH conditions (Kundu et al., 2013). Usually, two electrochemical reactions occurring in cathodic (Equation 1) and anodic (Equation 2) chamber are responsible for the generation of bio-H2 through MEC.

When, acetate is used as a substrate in a MEC,

Different electroactive microorganisms, like Geobacter sp., Caloranaerobacter sp., Clostridium sp., act as a biocatalyst in a MEC that has the potential to boost the biochemical reaction for the generation of bio-H2 and other valuables at a higher yield (Bibra et al., 2018). Therefore, the utilization of electrogens as a biocatalyst can replace the popularly used expensive metal catalysts platinum. Also, MEC has shown significant enactment in the production of H2O2 with the continuous production of bioelectricity. However, the performance of MEC is affected by different factors, such as the substrate used as anolyte, alkaline condition of the catholyte, cathode catalyst, applied potential, and so forth (Gupta et al., 2020). In this regard, Sim et al. reported that MEC recovered a higher concentration of H2O2 at the rate of 141 mg L−1 h−1 using acetate as a substrate. However, the production of H2O2 was drastically reduced at the rate of 6 mg L−1 h−1, when the anolyte was replaced with domestic wastewater. Therefore, this investigation proved that the performance of MEC can be enhanced by using easily biodegradable substrates (Sim et al., 2015). Likewise, researchers investigated that the production of H2O2 from MEC is also dependent on pH and the recovery rate of H2O2 is enhanced by maintaining acidic catholyte pH in MEC (Yang et al., 2017).

Researchers also developed self-sustainable MEC for the production of CH4 and CH3COOH at a higher yield with the simultaneous production of bioelectricity and concomitant treatment of wastewater. For instance, Jiang et al. applied a potential of −1.15 V (vs. SHE) in the cathodic chamber of MECs for the synthesis of CH3COOH and CH4. The maximum production rate of 193.32 mg L−1 day−1 and 263.91 ml L−1 day−1 of CH3COOH and CH4 was achieved from MEC, respectively (Jiang et al., 2013). Furthermore, Cheng et al. obtained a maximum 96% yield of CH4 from a novel biocathode of MEC at an imposed potential of −1.0 V vs. SHE (Cheng et al., 2009). Researchers also recovered other value-added products like formic acid and acetate by utilizing MEC with simultaneous wastewater treatment. For instance, Wang et al. incorporated a Sn-loaded gas diffusion electrode in a self-sustainable MEC for the production of formic acid via the electrochemical reduction of CO2 (Wang et al., 2015). The CE of this self-sustainable MEC was enhanced by 36.1% with a yield of 30.6% of formic acid (Wang et al., 2015). However, higher fabrication costs and the lower yield from MEC are the significant bottlenecks that devoid the large-scale application of this technology.

To reduce the extra fabrication cost of imposed potential, researchers also developed a promising MET, such as MDC that has the potential to desalinate saltwater along with the recovery of bioenergy without energy consumption. In this regard, Wen et al. developed a biocathode MDC for the production of bioelectricity without imposing any potential. The maximum voltage of 609 mV was observed that was 136 mV higher compared to the air cathode MDC (Wen et al., 2012). Moreover, the maximum CE of 96.2 ± 3.8% was achieved along with total desalination rate of 2.83 mg h−1 from this biocathode MDC (Wen et al., 2012). Furthermore, Bejjinki et al. developed an advanced recirculation MDC for the production of bioenergy with the holistic treatment of saline wastewater (Bejjanki et al., 2021). Maximum power density of 931 ± 29 mW m−2 was achieved from this novel MDC accompanied with the treatment of saline wastewater from 25 mM phosphate buffer solution. Also, saline wastewater containing NaCl with the initial concentration of 20 g L−1 was desalinated by 37% through this recirculation MDC (Bejjanki et al., 2021).

Production of Methanol, Ethanol, Butanol, Biodiesel, and Other Biofuel Employing METs

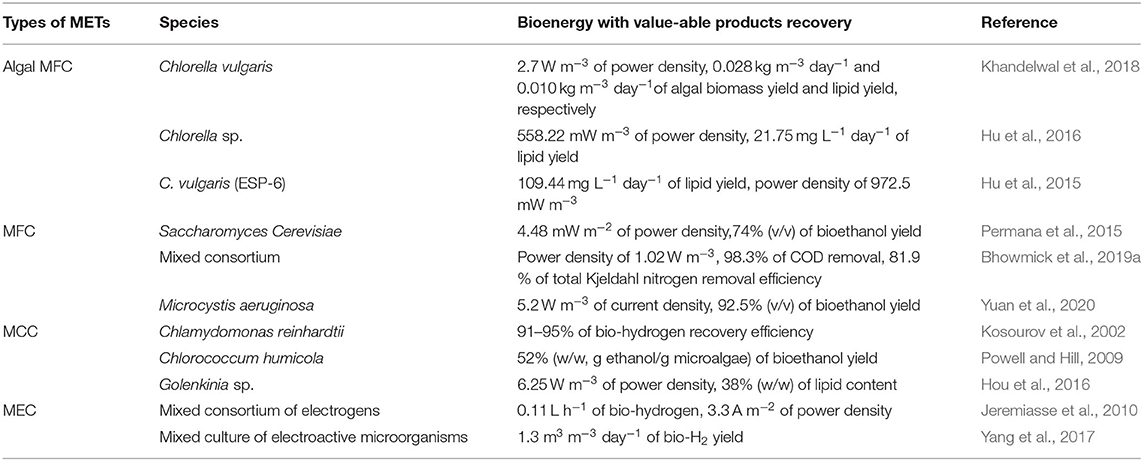

Researchers also utilized photosynthetic microorganisms for the production of bioenergy with simultaneous wastewater treatment and recovery of value-added biofuels. In this regard, MCC has gained a plenty of attention among researchers for its wide-ranging application. Generally, the MCC was designed based on the synergistic relationship of different photosynthetic microorganism like cyanobacteria and algae with anaerobic electroactive microorganisms for power generation and valuable biomass (Figure 4). After harvesting the biomass from the cathodic chamber of a MCC, biomass of photosynthetic microorganisms can be used as a feedstock for biofuel generation (Das et al., 2019a). The photosynthetic microorganisms residing in the cathodic chamber of a MCC captures CO2, released via anaerobic electroactive microbiota living in the anodic chamber of MCC. Therefore, the growth of photosynthetic microorganisms in the cathodic chamber of a MCC exhibits an effective approach for CO2 sequestration with the holistic treatment of wastewater besides providing an opportunity for concomitant power production without external aeration (Das et al., 2019a).

Generally, microalgal biomass contains 20–70% of lipids, which is relatively higher compared to other photosynthetic microorganisms. Due to higher lipid accumulation in the cell, microalgae are chosen as third-generation biofuels feedstock, particularly for biodiesel and bioethanol production. In this veneration, Hu et al. cultured microalgae Chlorella vulgaris utilizing municipal wastewater in the cathodic chamber of an airlift reactor-based MCC system (Hu et al., 2015). After 7 days of cultivation, green microalgal strain C. vulgaris produced a maximum of 482.50 ± 20.03 mg L−1 day−1 of biomass with 887.81 ± 36.86 mg L−1 day−1 of CO2 fixation rate (Hu et al., 2015). Additionally, the maximum lipid productivity of 109.44 mg L−1 day−1 with 972.5 mW m−3 of power density was recovered from this airlift type of MCC (Hu et al., 2015). Furthermore, Powell and Hill achieved 52% (w/w, g ethanol/g microalgae) of the bioethanol yield from an advanced MCC system by culturing Chlorococcum humicola (Powell and Hill, 2009). Therefore, METs have significant potential in the production of carbon-neutral biofuel, which may assist to circumnavigate the global energy demand (Table 3).

Removal of Pollutants and Resource Recovery From Different Wastewater Sources

Removal of Organic, Inorganic Compound, and Other Suspended and Volatile Matters

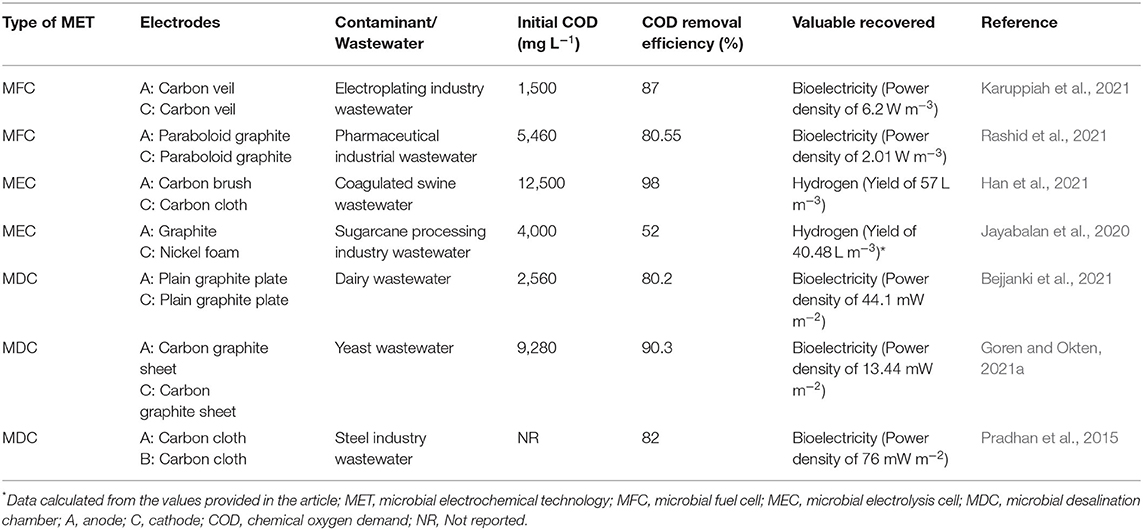

The METs have been found suitable for the treatment of variety of wastewaters including, sewage, piggery wastewater, industrial effluents, and hospital wastewater (Brastad and He, 2013; Sahu, 2019). Moreover, in sewage treatment, researchers successfully achieved higher COD removal efficiency of more than 80% via different kinds of lab-scale or field-scale METs (Das et al., 2020a, 2021a; Jafary et al., 2020). In this veneration, Ren et al. combined MFC fabricated with graphite brush anode and carbon cloth cathode, with anaerobic membrane bioreactor to attain a high COD removal efficiency of 92.5% for domestic wastewater with an initial COD of 210 mg L−1. The improved COD removal efficiency was mainly due to the degradation of suspended matter in membrane bioreactor, which is not efficiently removed through MFCs (Ren et al., 2014). More recently, researchers are favoring the use of single-chamber MFC, which has shown greater power generation capability along with better contaminant removal owing to simplified bioreactor construction that reduces the internal resistance offered to the flow of electrons. For instance, 92.31% of COD removal efficiency was attained while treating dairy wastewater with the influent COD of 6,000 mg L−1, by a single chamber MFC employing acrylic platinum-coated carbon cloth electrodes and Shewanella algae as biocatalyst in the anodic compartment with contaminant 50 mW m−2 of bioelectricity generation (Choudhury et al., 2021). Dairy wastewater is comparatively richer in organic contaminants and nutrients than domestic wastewater, which makes it conducive for the proliferation of electroactive microorganisms leading to the better performance of MFC as observed in the previous investigation.

Moreover, different METs have also been employed for the remediation of wastewater contaminated with heavy metals and persistent recalcitrant compounds, such as estrogens and antibiotics (Chakraborty et al., 2020b). In this regard, Cheng et al. (2020) investigated the performance of MFC employed for the treatment of swine wastewater containing sulfonamide antibiotics. The MFC with carbon-based electrodes was able to reduce the concentration of sulfamethoxazole, sulfamethazine, sulfadiazine by 99.51, 66.91, and 67.21%, respectively, each having an initial concentration of 300 μg L−1 (Cheng et al., 2020). Furthermore, the use of biocathode in MFC has been fruitful in augmenting the removal of heavy metals, like cadmium and nickel, and has attained a removal efficiency of 92 and 87%, respectively, both having an initial concentration of 10 mg L−1. This removal efficiency was 10 times higher than the removal efficiency obtained using abiotic cathodes (Singh and Kaushik, 2021).

Moreover, photosynthetic microorganism, like algae assisted MFCs, are neoteric technologies that are being investigated to overcome the drawbacks of conventional MFCs. Besides acting as a biocatalyst in the cathodic reduction reaction, algae are also known to attenuate residual organic load by using it for their cellular growth (Cheng et al., 2019; Chai et al., 2020). Moreover, harvested algal biomass can be further utilized as a feedstock to produce biofuels and other valuable chemicals for industrial application (Show et al., 2021). In a separate investigation on the assessment of MFC in removing surfactants, titanium dioxide photo-cathode MFC assisted with laterite filter and was able to remove 96% of surfactant sodium dodecyl sulfate having an influent concentration of 10 mg L−1 (Sathe et al., 2020). Therefore, it's clearly evident that the MFCs are quite efficient in handling variety of wastewater and complex biorefractory contaminants (Table 3).

The use of MECs for remediating wastewater is also gaining a lot of attention due to the prospect of simultaneous recovery of biohydrogen during wastewater treatment. In research assessing the comparative performance of MEC and MFC for eliminating Ni2+ ions from contaminated water with an initial concentration of 50 mg L−1, MEC with carbon felt anode and stainless steel cathode for an applied cell potential of 0.9 V, attained 99% nickel removal efficiency, which was three times higher than that achieved using MFC (Qin et al., 2012). The ameliorated removal of Ni2+ ions in MEC can be attributed to the development of higher cathodic potential, which favors electrodeposition of Ni2+ ions on the cathode (Qin et al., 2012).

Gas diffusion membrane integrated MEC employing titanium/stainless steel cathode was able to remove more than 90% of nitrogen at an externally applied cell voltage of 0.8 V, thus reinforcing hydrogenotrophic denitrification as a plausible nitrogen removal technique (Liang et al., 2021). Also, MEC has been effective in the remediation of more concentrated and complex wastewater streams, such as landfill leachate and dairy plant effluent (Rani et al., 2020). Rani et al. (2020) employed MEC fabricated with carbon electrode for the treatment of combined leachate and dairy wastewater with the initial COD of 8,400 mg L−1 and attained COD removal efficiency of 73% at an externally applied cell potential of 0.8 V and with the hydrogen production rate of 15 ml L−1 day−1 (Rani et al., 2020). However, while treating only dairy effluent with COD of 361 mg L−1, a much higher COD removal efficiency of 94.3% was observed along with a maximum hydrogen recovery rate of 21.6 ml L−1 day−1 under similar operating conditions because of lesser accumulation of volatile fatty acids at lower biological loading rate, which tends to reduce contact between microorganism and substrate in the bioreactor (Rani et al., 2020).

The MDCs have been widely applied for the production of potable water from saline and brackish water (Saeed et al., 2015). Jafary et al. were able to accomplish desalination of seawater at the rate of 24.3 mg h−1 with the COD removal efficiency of 85% using MDC employing carbon-based electrodes (Jafary et al., 2020). Carbon felt, carbon paper, and graphite electrodes are generally used in MDC, which yielded unsatisfactory performance due to the drawbacks, like low specific surface area, unconducive surface for biofilm formation, low flexibility, and cumbersome maintenance procedures (Pant et al., 2010; Zhang et al., 2019b). Goren and Okten applied a novel 3D carbonaceous electrode for the treatment of geothermal water containing boron and attained 55.5% removal efficiency for boron with simultaneous 91.5% of COD removal in addition to the generation of 9.04 mW m−3 of power density, thus affirming the efficacy of 3D electrodes for application in MDC (Goren and Okten, 2021b).

Kokabian and Gude designed a photosynthetic MDC (PMDC) using microalgae as a catalyst in biocathode for the generation of power with the removal of salts from saline wastewater (Kokabian and Gude, 2013). Under anoxic conditions, the PMDC system produced a maximum power density of 84 mW m−3 with the removal of 40% of salt from saline wastewater (Kokabian and Gude, 2013). Furthermore, Wang et al. also developed a 1 L up-flow-stacked MDC (USMDC) for the removal of salts from synthetic wastewater with the simultaneous production of bioelectricity (Wang et al., 2020). After 120 days of continuous operation, 32.91 W m−3 of power density was obtained from the USMDC with a salt removal efficiency of 91.9%, which was 1.5 times more than single-up-flow MDC (Wang et al., 2020). Thus, the MDCs hold potential to become a sustainable wastewater treatment and desalination technology in the future (Table 4).

Nutrients and Other Valuable Products Recovery From Contaminated Wastewater

Recovery of nutrients such as nitrogen and phosphorus from wastewater is a sustainable approach for the conversion of these nutrients into environmentally friendly fertilizer used for ecological and agricultural purposes. Generally, different forms of nitrogen and phosphorous are disposed into the natural water streams from different anthropogenic actions, such as agricultural runoff, pharmaceutical industrial effluents, swine wastewater, human, and other animal excreta. Moreover, the release of untreated/partially treated wastewater in natural water sources causes nutrient build-up in the aquatic ecosystem. The existence of these nutrients in untreated wastewater provides nutrient build-up in the aquatic environment that delivers a favorable growth condition for algae and other water hyacinths. Therefore, the abundant growth of these micro and macro-organisms in water bodies causes eutrophication that affects the aquatic ecosystem adversely by deteriorating the water quality via diminishing the level of dissolved oxygen (Vijay et al., 2020). Hence, the removal of excess nutrients from the water bodies is an utmost necessity to improve the quality of water.

Removal of Ammonium Nitrogen Using Different Types of METs

Removal of ammonium nitrogen and nitrate ions present at a higher concentration through different types of METs from domestic wastewater is a noteworthy approach for the wastewater treatment process. Following on this point, Jung et al. reported almost 60% of ammonium nitrogen removal through double-chamber MFC in 6 days from swine wastewater containing 219 mg L−1 of influent concentration of ammonia (Jung et al., 2008). Moreover, Vijay et al. developed a dual-chamber MFC, where a maximum 0.130 kg -N m−3 day−1 of nitrate was removed with the simultaneous production of 2.91 W m−3 of power (Vijay et al., 2020). In another research, Kim et al. obtained a maximum power density of 48.1 mA m−2 along with removal of 61.1% of COD and 77.5% of ammonia nitrogen from dual-chamber MFC coupled with anaerobic digester (Kim et al., 2015).

Researchers have investigated that the MEC has a higher potential to remove and recover higher concentration of ammonia from wastewater compared to MFC (Liu et al., 2016). After imposing anodic potential of +0.2 V (vs. SHE) and continuously feeding the setup with acetate as substrate (influent acetate load of 1.08 g COD L−1 d−1) for the retention time of 8.35 day, cathodic ammonium concentration reached to 318 mg L−1 compared to the anodic ammonium concentration of 44.5 mg L−1 (Villano et al., 2013). Consequently, at steady state condition, a maximum 91% of CE was achieved along with 91.2 and 50.9 meq L−1 d−1 of CH4 and bio-H2 production rate, respectively, from this dual chamber MEC. In another investigation, Kuntke et al. developed a MEC for the treatment of human urine along with an ammonia removal rate of 162.2 g day−1 m−2, while simultaneously producing a current of 23.07 ± 1.15 A m−2 (Kuntke et al., 2014). Also, bio-hydrogen at the rate of 48.6 m3 m−3 day−1 was successfully achieved through this MEC with the simultaneous COD removal rate of 171.0 ± 16.9 g m−2 day−1 (Kuntke et al., 2014). Therefore, these investigations demonstrate that wastewater with even a moderate concentration of ammonium nitrogen can be treated through METs with the recovery of different value-added products.

Domestic wastewater containing human and other animal excreta is a rich source of nutrients like nitrogen and phosphorus, and thus can be sustainably used as feedstock to produce valuables (Kuntke et al., 2012). In this regard, Ieropoulos et al. utilized human urine as a substrate in a MFC for the production of bioelectricity (Ieropoulos et al., 2012). The maximum 8 mA m−2 of current was reported from single chamber MFC through direct conversion of the organic constituents present in urine into bioelectricity (Ieropoulos et al., 2012). Consequently, Kuntke et al. recovered ammonia at a rate of 3.29 g day−1 m−2 from urine with the maximum power density of 0.50 A m−2 through MFC via adsorption into boric acid solution (Kuntke et al., 2012). Therefore, the recovery of ammonium nitrogen with concomitant power generation from urine has established a novel approach for the wastewater treatment process.

Another critical source of high concentration of ammonium nitrogen in the wastewater treatment plant is the effluent from the sludge dewatering process. This excessive nitrogen-loaded effluent has an adverse effect during the biological secondary wastewater treatment process. Therefore, the utilization of sludge dewatering effluent as a catholyte in different METs can mitigate these fundamental difficulties. In this respect, Wu and Modin designed a MEC using real reject water and synthetic reject wastewater as catholyte (Wu and Modin, 2013). It was reported that under the applied anodic potential of 0.20 V vs. SHE, 94 and 79% of ammonium nitrogen was recovered from synthetic and real reject wastewater, respectively, through MEC (Wu and Modin, 2013). Also, 76% of bio-H2 hydrogen gas along with 96% of cathodic CE was successfully achieved from of this MEC (Wu and Modin, 2013).

Removal and Recovery of Phosphate Through Different Types of METs

Recovery of phosphate, orthophosphate, and other phosphoric compounds through METs is achieved in the form of struvite. Generally, struvite consists of phosphate, ammonium, and magnesium existing in equivalent molar ratios and precipitates easily at a higher alkaline condition (Nancharaiah et al., 2018). Firstly, Fischer et al. developed a MFC by dosing ammonium hydroxide and magnesium chloride to enhance the recovery efficiency of phosphate in the form of struvite. In this investigation, almost 90% of phosphorous was recovered in the form of struvite from the digested sewage sludge (Fischer et al., 2011). However, the external addition of chemicals like Mg salt to enhance the recovery of struvite is an uneconomical approach that minimize the field-scale applicability of MFC. In this respect, Ichihashi and Hirooka fabricated an air cathode MFC with Pt/C coated carbon paper using swine wastewater as a feed that contains a higher concentration of Mg salt (Ichihashi and Hirooka, 2012). The maximum current density of 7.0 A m−2 along with the 82% removal of phosphorus from swine wastewater was reported. Under alkaline conditions (pH of 8–9), the maximum 27% of phosphorus was recovered from the struvite precipitates with the simultaneous 91% removal of COD (Ichihashi and Hirooka, 2012).

The MEC also has significant potential for the recovery of phosphate and orthophosphate from wastewater. As an example, Zhang et al. removed 52.4% phosphate along with the recovery of 83.4% of ammonium nitrogen, and 96% of COD was removed from synthetic wastewater for the applied potential of +0.8 V vs. SHE (Zhang and Angelidaki, 2014). Hence, ammonium nitrogen is recovered through METs via the electron transfer mechanism followed by the redox reaction whilst phosphorus is removed via the precipitation process. Thus, METs have shown the capability to recover phosphate and other phosphoric compounds from different wastewaters. However, a long-term nutrient recovery through METs has not been successfully operationalized till now. Therefore, this review article elucidates low energy input and higher recovery-based MET approaches, which will provide wide guidance to the researchers to render large-scale feasibility to this technology.

Bottlenecks and Recent Advancement in the Field of METs

Holistic wastewater treatment with the recovery of bioelectricity and biofuels along with other value-added by-products have been successfully achieved through different kinds of METs over the past decade. However, different roadblocks, such as pH variation, time taken to degrade the substrate, expensive cathode catalysts, presence of pathogens, low biomass productivity, and lower yield of value-added products with energy loss and so forth are normally perceived in the different types of METs. In this veneration, Yang et al. developed a self-buffering MEC by applying periodic polarity reversal for the enhancement in the production rate of H2 along with decrement of the pH gradient between the anolyte and catholyte in a MEC (Yang et al., 2017). The maximum 1.3 m3 m−3 day−1 of H2 yield was achieved after the addition of 50 mM of NaCl salt in the catholyte of this MEC (Yang et al., 2017).

Furthermore, the fabrication of cost-effective and biocompatible electrodes for the enhancement of bioelectricity production is another significant challenge in METs. Moreover, carbon-based electrodes are extensively used in the field of METs owing to its higher porosity, better electrical conductivity and high specific surface area. In recent years, researchers utilized different nanoparticles for development of materials possessing higher mechanical resistivity, better electrical conductivity, and high thermal stability to be used as electrodes that aid to ameliorate the performance of METs. However, a cost-effective approach must be implemented for the establishment of sustainable and eco-friendly METs. In this regard, Sonawane et al. utilized stainless steel as an anode material for the achievement of a higher current density from MFC. After the addition of steel wool-polyaniline-polypyrrole nanocomposites in the electrode, a maximum power density of 2,880 mW m−2 was observed from the MFC (Sonawane et al., 2018). Furthermore, N-doped TiO2 nano-sheets have also been utilized for the improvement of the electrochemical properties of a carbon-based electrodes in MFC (Yin et al., 2019). Therefore, this kind of modification of electrodes can enhance the performance and stability of the different types of METs.

Recently, the utilization of nanomaterials for the fabrication of different METs to ameliorate its efficacy in terms of electron conductivity, power density, cost, thermal stability, ORR activity and anti-corrosion, particularly the modification of electrodes (anode and cathode) by nanomaterials have been well-documented in the literature (Wu et al., 2018b). In this regard, Zou et al. (2017) fabricated a novel MFC coupled with the nano porous molybdenum carbide doped carbon felt (Mo2C@CF) as electrode to improve the electrocatalytic performance via promoting the growth of electrogens with excretion of endogenous electron shuttle molecules like flavins (Zou et al., 2017). After incorporating 8.31% of Mo2C@CF as anode, the maximum power density of 1025 mW m−2 was achieved from this novel MFC, which was almost five-times higher compared to bare carbon felt anode (215 mW m−2) (Zou et al., 2017). In another investigation, biopolymer pectin derived three dimensional nano porous nickel oxide and graphene composite anode has shown higher electrocatalytic capability resulting in the production of 3.632 W m−2 of power density through Shewanella putrefaciens assisted MFC (Wu et al., 2018b). Moreover, other different metal nanoparticles such as Cu, Pt, Ag, and numerous quantum dots like Cds, ZnS, CdSe, and different metal-oxides CeO2, ZnO, SiO2, Al2O3, and MnO2 were also used as electrodes, which could improve the yield of METs. However, utilization of nanomaterials in the large-scale application of METs are still in the embryonic stage due to its high production cost.

Another recent trends in the field of METs is the fabrication of economical and high performing METs as biosensor for the detection of pathogens, toxic particles, corrosion, and measurement of biochemical oxygen demand (BOD), COD, and other pollutants (Olias et al., 2020; Simoska et al., 2021). As an example, Spurr et al. (2018) stacked three MFCs in series as a biosensor utilizing mixed consortium of Geobacter sp. for the measurement of BOD and COD from synthetic wastewater. The linear response of 5 days BOD and COD in 2.3 h was measured up to 720 and 1,175 mg L−1, respectively, from MFC sensor with 97% of regression efficiency (Spurr et al., 2018). Furthermore, sensitivity of organic compounds present in wastewater was enhanced by 50–81% through MFC sensor operated in transient mode. Moreover, this MFC sensor demonstrated a proficiency to sense acid toxicity (pH ranging from 4 to 6) and heavy metal (Cu2+) toxicity (ranging from 2 to 8 mg L−1) (Jiang et al., 2017). Also, other emergent contaminants like 4-nitrophenol, phenol, and n-butanol, n-cyclohexyl-2-pyrrolidone and, different volatile organic matters and pathogens were successfully detected through MFC-based biosensor (Kannan et al., 2019; Godain et al., 2020; Olias et al., 2020). Therefore, removal of organic, inorganic and emerging pollutants from wastewater with recovery of different economically viable resources through METs can abet this technology toward its commercialization (Khoo et al., 2020; Ahmed et al., 2021).

Scalability of Different Types of METs and Respective Future Prospect

The conception of METs was established more than a decade ago by scientist M. C. Potter (Potter, 1911); however, high operational costs and low yield of valuables with poor energy recovery has burdened the scalability of this promising technology. A lot of research has been conducted for scaling-up for METs. As an example, Clauwaert et al. designed a 2.5 L MFC utilizing acetate as a substrate with the initial COD of 150 mg L−1 (Clauwaert et al., 2008). After 70 days of operation, CE of 50% was observed in this MFC. In another investigation, Zhang et al. developed a 8 L MFC utilizing municipal wastewater as an anolyte (Zhang et al., 2013). After 400 days of operation 65–70% of COD was removed from municipal wastewater from the influent COD of 279.7 ± 144.4 mg L−1 accompanied by 10.6% of CE.

Another successful field-scale implementation of MFC was observed in India, where 25 L of cylinder-based single chamber MFC, was operated using septic tank sewage sludge slurry as a substrate. After 140 days of continuous operation of this field-scale MFC, a maximum power density of 75.1 and 110.6 mW m−2 along with the COD removal efficiency of 87%, and 90% were successfully achieved by employing CuZn and Pt/C as cathode catalyst, respectively (Das et al., 2020a). Likewise, same research group utilized Cu0.5Mn0.5Fe2O4 composite as cathode catalyst for the improvement of power production in a field-scale MFC (25 L of volume) with the achievement of 7.74 mW m−2 of power density (Das et al., 2021a). Moreover, Feng et al. fabricated a self-sustainable stacked MFC with 250 L reactor volume of each unit for the treatment of municipal wastewater (Feng et al., 2014). In addition to this, Liang et al. designed a 1,000 L MFC by utilizing municipal wastewater treatment plant effluent as a substrate having initial COD of 150 mg L−1. A maximum power density of 0.42–3.64 W m−2 with 41–75% of CE was achieved from this MFC (Liang et al., 2018). For the treatment of brewery wastewater, Dong et al. operated a 90 L MFC for 6 months and yielded a maximum power density of 171 mW m−2 accompanied with a maximum CE of 19.1% (Dong et al., 2015).

Although different efforts are implemented by scientists for the practical applications of METs, they have yet to demonstrate a significant proficient approach for the large-scale application of wastewater treatment with the recovery of bioenergy to date. Moreover, it was observed that the CE and current density decreases significantly with the increase in the volume of a bio-electrochemical setup. To overcome this drawback, the application of stacked MFCs is a noteworthy step for scaling-up of METs. However, maintenance of conducive growth conditions with an appropriate substrate flow, prevention of voltage reversal, and a high capital cost are a serious concern for the field-scale application of METs. Therefore, significant and more novel techniques must be implemented to render economic and environmental sustainability to METs.

In addition to this, Das et al. (2020d) implemented another pilot-scale MFC for the treatment of sewage by developing six-chamber 720 L of MFC with the utilization of goethite as anode catalyst, and Sn5Cu84 and Co0.5Zn0.5Fe2O4 as cathode catalyst. The maximum 61 mW of power was achieved through this scaled-up MFC accompanied with 78.4% of COD removal efficiency. Moreover, human urine was treated in 330 L volume of 432 stacked MFCs in England with the achievement of maximum 300 mW of power (Ieropoulos et al., 2016). Also, Li et al. (2017) constructed a large-scale 350 L benthic microbial electrochemical system (BMES) for the production of power with concomitant treatment of polluted river sediment. This BMES successfully removed 74% of different polycyclic aromatic hydrocarbons, such as benzo(a)pyrene, benzo(b)fluoranthene, and benzo(k)fluoranthene, from river sediment along with the recovery of maximum 63 ± 3 mW m−2 of power density. Therefore, a wide range of organic and inorganic compounds and other emerging pollutants have been extensively treated through MFCs, thus demonstrating the field-scale applicability of this technology (Abbasi et al., 2016; Khoo et al., 2020; Ahmed et al., 2021).

Conclusions

Over the past decade, the METs have been extensively utilized for the production of renewable bioenergy like bioelectricity, liquid fuel, biogas, and other valuables. Moreover, the use of different kinds of METs also exhibits a holistic treatment of wastewater due to its proficiency to eliminate organic and inorganic compounds, and pathogens from wastewater. The METs are successfully established for the recovery of higher yield on a smaller scale; however, the overall cost of these pioneering technique must be reduced by developing cost-effective electrocatalysts, electrodes, and membranes, which would be fruitful for the pilot-scale application of METs. Moreover, different advanced techniques, such as the utilization of genetically modified strain and adaptation of symbiotic techniques for culturing multiple microbial strains, should be implemented for the improvement in the yield of valuables recovered from METs. Therefore, this review article intends to guide budding researchers to circumnavigate the different bottlenecks leading toward the efficacious large-scale implementation of METs.

Data Availability Statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author/s.

Author Contributions

SwD: conceptualization, visualization, validation, writing—original draft, writing—review, editing, software support, formal analysis, and investigation. RR: visualization, methodology, validation, writing—original draft, writing—review, editing, and software support. SoD: data curation, methodology, validation, writing—original draft, writing—review, editing, and software support. MG: resources, funding acquisition, supervision, project administration, writing—review, and editing. All authors contributed to the article and approved the submitted version.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

The funding received from the Ministry of New and Renewable Energy, Government of India (IIT/SRIC/R/REF/2018/101) is duly acknowledged.

References

Abbasi, U., Jin, W., Pervez, A., Bhatti, Z. A., Tariq, M., Shaheen, S., et al. (2016). Anaerobic microbial fuel cell treating combined industrial wastewater: correlation of electricity generation with pollutants. Bioresour. Technol. 200, 1–7. doi: 10.1016/j.biortech.2015.09.088

Ahmad, A., Priyadarshani, M., Das, S., and Ghangrekar, M. M. (2021). Role of bioelectrochemical systems for the remediation of emerging contaminants from wastewater: a review. J. Basic Microbiol. 2021, 1–22, doi: 10.1002/jobm.202100368

Ahmed, S., Mofijur, M., Nuzhat, S., Chowdhury, A. T., Rafa, N., Uddin, M. A., et al. (2021). Recent developments in physical, biological, chemical, and hybrid treatment techniques for removing emerging contaminants from wastewater. J. Hazard. Mater. 416:125912. doi: 10.1016/j.jhazmat.2021.125912

Arun, S., Sinharoy, A., Pakshirajan, K., and Lens, P. N. (2020). Algae based microbial fuel cells for wastewater treatment and recovery of value-added products. Renew. Sustain. Energy Rev. 132:110041. doi: 10.1016/j.rser.2020.110041

Baek, G., Shi, L., Rossi, R., and Logan, B. E. (2021). The effect of high applied voltages on bioanodes of microbial electrolysis cells in the presence of chlorides. Chem. Eng. J. 405:126742. doi: 10.1016/j.cej.2020.126742

Bakonyi, P., Koók, L., Kumar, G., Tóth, G., Rózsenberszki, T., Nguyen, D. D., et al. (2018). Architectural engineering of bioelectrochemical systems from the perspective of polymeric membrane separators: a comprehensive update on recent progress and future prospects. J. Membr. Sci. 564, 508–522. doi: 10.1016/j.memsci.2018.07.051

Beese-Vasbender, P. F., Nayak, S., Erbe, A., Stratmann, M., and Mayrhofer, K. J. (2015). Electrochemical characterization of direct electron uptake in electrical microbially influenced corrosion of iron by the lithoautotrophic SRB Desulfopila corrodens strain IS4. Electrochim. Acta 167, 321–329. doi: 10.1016/j.electacta.2015.03.184

Behera, M., Jana, P. S., More, T. T., and Ghangrekar, M. (2010). Rice mill wastewater treatment in microbial fuel cells fabricated using proton exchange membrane and earthen pot at different pH. Bioelectrochemistry 79, 228–233. doi: 10.1016/j.bioelechem.2010.06.002

Bejjanki, D., Muthukumar, K., Radhakrishnan, T., Alagarsamy, A., Pugazhendhi, A., and Mohamed, S. N. (2021). Simultaneous bioelectricity generation and water desalination using Oscillatoria sp. as biocatalyst in photosynthetic microbial desalination cell. Sci Total Environ. 754:142215. doi: 10.1016/j.scitotenv.2020.142215

Bhowmick, G., Das, S., Ghangrekar, M., Mitra, A., and Banerjee, R. (2019a). Improved wastewater treatment by combined system of microbial fuel cell with activated carbon/TiO2 cathode catalyst and membrane bioreactor. J. Inst. Eng. A 100, 675–682. doi: 10.1007/s40030-019-00406-7

Bhowmick, G., Das, S., Verma, H., Neethu, B., and Ghangrekar, M. (2019b). Improved performance of microbial fuel cell by using conductive ink printed cathode containing Co3O4 or Fe3O4. Electrochim. Acta 310, 173–183. doi: 10.1016/j.electacta.2019.04.127

Bibra, M., Kumar, S., Wang, J., Bhalla, A., Salem, D. R., and Sani, R. K. (2018). Single pot bioconversion of prairie cordgrass into biohydrogen by thermophiles. Bioresour. Technol. 266, 232–241. doi: 10.1016/j.biortech.2018.06.046

Brastad, K. S., and He, Z. (2013). Water softening using microbial desalination cell technology. Desalination 309, 32–37. doi: 10.1016/j.desal.2012.09.015

Butti, S. K., Velvizhi, G., Sulonen, M. L., Haavisto, J. M., Koroglu, E. O., Cetinkaya, A. Y., et al. (2016). Microbial electrochemical technologies with the perspective of harnessing bioenergy: maneuvering towards upscaling. Renew. Sustain. Energy Rev. 53, 462–476. doi: 10.1016/j.rser.2015.08.058

Call, D. F., Wagner, R. C., and Logan, B. E. (2009). Hydrogen production by Geobacter species and a mixed consortium in a microbial electrolysis cell. Appl. Environ. Microbiol. 75, 7579–7587. doi: 10.1128/AEM.01760-09

Chai, W. S., Tan, W. G., Munawaroh, H. S. H., Gupta, V. K., Ho, S.-H., and Show, P. L. (2020). Multifaceted roles of microalgae in the application of wastewater biotreatment: a review. Environ. Pollut. 269:116236. doi: 10.1016/j.envpol.2020.116236

Chakraborty, I., Das, S., Dubey, B., and Ghangrekar, M. (2020a). Novel low cost proton exchange membrane made from sulphonated biochar for application in microbial fuel cells. Mater. Chem. Phys. 239:122025. doi: 10.1016/j.matchemphys.2019.122025

Chakraborty, I., Das, S., Dubey, B. K., and Ghangrekar, M. M. (2021). High-density polyethylene waste-derived carbon as a low-cost cathode catalyst in microbial fuel cell. Int. J. Environ. Res. 15, 1085–1096. doi: 10.1007/s41742-021-00374-6

Chakraborty, I., Sathe, S., Khuman, C., and Ghangrekar, M. (2020b). Bioelectrochemically powered remediation of xenobiotic compounds and heavy metal toxicity using microbial fuel cell and microbial electrolysis cell. Mater. Sci. Energy Technol. 3, 104–115. doi: 10.1016/j.mset.2019.09.011

Cheng, D., Ngo, H. H., Guo, W., Lee, D., Nghiem, D. L., Zhang, J., et al. (2020). Performance of microbial fuel cell for treating swine wastewater containing sulfonamide antibiotics. Bioresour. Technol. 311:123588. doi: 10.1016/j.biortech.2020.123588

Cheng, S., Xing, D., Call, D. F., and Logan, B. E. (2009). Direct biological conversion of electrical current into methane by electromethanogenesis. Environ. Sci. Technol. 43, 3953–3958. doi: 10.1021/es803531g

Cheng, S. Y., Show, P.-L., Lau, B. F., Chang, J.-S., and Ling, T. C. (2019). New prospects for modified algae in heavy metal adsorption. Trends Biotechnol. 37, 1255–1268. doi: 10.1016/j.tibtech.2019.04.007

Choudhury, P., Ray, R. N., Bandyopadhyay, T. K., Basak, B., Muthuraj, M., and Bhunia, B. (2021). Process engineering for stable power recovery from dairy wastewater using microbial fuel cell. Int. J. Hydrog. Energy 46, 3171–3182. doi: 10.1016/j.ijhydene.2020.06.152

Clauwaert, P., Aelterman, P., De Schamphelaire, L., Carballa, M., Rabaey, K., and Verstraete, W. (2008). Minimizing losses in bio-electrochemical systems: the road to applications. Appl. Microbiol. Biotechnol. 79, 901–913. doi: 10.1007/s00253-008-1522-2

Crini, G., and Lichtfouse, E. (2019). Advantages and disadvantages of techniques used for wastewater treatment. Environ. Chem. Lett. 17, 145–155. doi: 10.1007/s10311-018-0785-9

Das, I., Das, S., Das, S., and Ghangrekar, M. (2021a). Proficient sanitary wastewater treatment in laboratory and field-scale microbial fuel cell with anti-biofouling Cu0.5Mn0.5Fe2O4 as cathode catalyst. J. Electrochem. Soc. 168:054519. doi: 10.1149/1945-7111/abfe77

Das, I., Das, S., Dixit, R., and Ghangrekar, M. (2020b). Goethite supplemented natural clay ceramic as an alternative proton exchange membrane and its application in microbial fuel cell. Ionics 26, 3061–3072. doi: 10.1007/s11581-020-03472-1

Das, I., Das, S., and Ghangrekar, M. (2020a). Application of bimetallic low-cost CuZn as oxygen reduction cathode catalyst in lab-scale and field-scale microbial fuel cell. Chem. Phys. Lett. 751;137536. doi: 10.1016/j.cplett.2020.137536

Das, I., Das, S., Sharma, S., and Ghangrekar, M. (2020c). Ameliorated performance of a microbial fuel cell operated with an alkali pre-treated clayware ceramic membrane. Int. J. Hydrog. Energy 45, 16787–16798. doi: 10.1016/j.ijhydene.2020.04.157

Das, I., Ghangrekar, M., Satyakam, R., Srivastava, P., Khan, S., and Pandey, H. (2020d). On-site sanitary wastewater treatment system using 720-l stacked microbial fuel cell: case study. J. Hazard. Toxic Radioact. Waste 24:04020025. doi: 10.1061/(asce)hz.2153-5515.0000518

Das, S., Chatterjee, P., and Ghangrekar, M. M. (2018). Increasing methane content in biogas and simultaneous value added product recovery using microbial electrosynthesis. Water Sci. Technol. 77, 1293–1302. doi: 10.2166/wst.2018.002

Das, S., Das, I., and Ghangrekar, M. M. (2020e). Role of applied potential on microbial electrosynthesis of organic compounds through carbon dioxide sequestration. J. Environ. Chem. Eng. 8:104028. doi: 10.1016/j.jece.2020.104028

Das, S., Das, S., Das, I., and Ghangrekar, M. (2019b). Application of bioelectrochemical systems for carbon dioxide sequestration and concomitant valuable recovery: a review. Mater. Sci. Energy Technol. 2, 687–696. doi: 10.1016/j.mset.2019.08.003

Das, S., Das, S., and Ghangrekar, M. (2019a). Quorum-sensing mediated signals: a promising multi-functional modulators for separately enhancing algal yield and power generation in microbial fuel cell. Bioresour. Technol. 294:122138. doi: 10.1016/j.biortech.2019.122138

Das, S., Das, S., and Ghangrekar, M. (2021b). Application of TiO2 and Rh as cathode catalyst to boost the microbial electrosynthesis of organic compounds through CO2 sequestration. Process Biochem. 101, 237–246. doi: 10.1016/j.procbio.2020.11.017

Das, S., Das, S., and Ghangrekar, M. (2021c). Bacterial signalling mechanism: An innovative microbial intervention with multifaceted applications in microbial electrochemical technologies: a review. Bioresour. Technol. 344:126218. doi: 10.1016/j.biortech.2021.126218

Das, S., Diels, L., Pant, D., Patil, S. A., and Ghangrekar, M. M. (2020f). Review-microbial electrosynthesis: a way towards the production of electro-commodities through carbon sequestration with microbes as biocatalysts. J. Electrochem. Soc. 167:155510. doi: 10.1149/1945-7111/abb836

Das, S., and Ghangrekar, M. M. (2021). Performance comparison between batch and continuous mode of operation of microbial electrosynthesis for the production of organic chemicals. J. Appl. Electrochem. 51, 715–725. doi: 10.1007/s10800-020-01524-y

Das, S., Mishra, A., and Ghangrekar, M. (2020g). Concomitant production of bioelectricity and hydrogen peroxide leading to the holistic treatment of wastewater in microbial fuel cell. Chem. Phys. Lett. 759:137986. doi: 10.1016/j.cplett.2020.137986

Do, M. H., Ngo, H. H., Guo, W., Chang, S. W., Nguyen, D. D., Liu, Y., et al. (2020). Microbial fuel cell-based biosensor for online monitoring wastewater quality: a critical review. Sci. Total Environ. 712:135612. doi: 10.1016/j.scitotenv.2019.135612

Dong, Y., Qu, Y., He, W., Du, Y., Liu, J., Han, X., et al. (2015). A 90-liter stackable baffled microbial fuel cell for brewery wastewater treatment based on energy self-sufficient mode. Bioresour. Technol. 195, 66–72. doi: 10.1016/j.biortech.2015.06.026

Feng, Y., He, W., Liu, J., Wang, X., Qu, Y., and Ren, N. (2014). A horizontal plug flow and stackable pilot microbial fuel cell for municipal wastewater treatment. Bioresour. Technol. 156, 132–138. doi: 10.1016/j.biortech.2013.12.104

Fischer, F., Bastian, C., Happe, M., Mabillard, E., and Schmidt, N. (2011). Microbial fuel cell enables phosphate recovery from digested sewage sludge as struvite. Bioresour. Technol. 102, 5824–5830. doi: 10.1016/j.biortech.2011.02.089

Ghorai, A., Roy, S., Das, S., Komber, H., Ghangrekar, M. M., Voit, B., et al. (2021). Preparation of sulfonated polytriazoles with a phosphaphenanthrene unit via click polymerization: fabrication of membranes and properties thereof. ACS Appl. Polym. Mater. 3, 4127–4138. doi: 10.1021/acsapm.1c00600

Godain, A., Spurr, M. W., Boghani, H. C., Premier, G. C., Yu, E. H., and Head, I. M. (2020). Detection of 4-nitrophenol, a model toxic compound, using multi-stage microbial fuel Cells. Front. Environ. Sci. 8:5. doi: 10.3389/fenvs.2020.00005

Goren, A. Y., and Okten, H. E. (2021a). Energy production from treatment of industrial wastewater and boron removal in aqueous solutions using microbial desalination cell. Chemosphere 285:131370. doi: 10.1016/j.chemosphere.2021.131370

Goren, A. Y., and Okten, H. E. (2021b). Simultaneous energy production, boron and COD removal using a novel microbial desalination cell. Desalination 518:115267. doi: 10.1016/j.desal.2021.115267

Gujjala, L. K. S., Dutta, D., Sharma, P., Kundu, D., Vo, D.-V. N., and Kumar, S. (2021). A state-of-the-art review on microbial desalination cells. Chemosphere 288:132386. doi: 10.1016/j.chemosphere.2021.132386

Gul, H., Raza, W., Lee, J., Azam, M., Ashraf, M., and Kim, K. H. (2021). Progress in microbial fuel cell technology for wastewater treatment and energy harvesting. Chemosphere 281:130828. doi: 10.1016/j.chemosphere.2021.130828

Gupta, A., Das, S., and Ghangrekar, M. (2020). Optimal cathodic imposed potential and appropriate catalyst for the synthesis of hydrogen peroxide in microbial electrolysis cell. Chem. Phys. Lett. 754, 137690. doi: 10.1016/j.cplett.2020.137690

Han, X., Qu, Y., Li, D., Dong, Y., Chen, D., Yu, Y., et al. (2021). Combined microbial electrolysis cell–iron-air battery system for hydrogen production and swine wastewater treatment. Process Biochem. 101, 104–110. doi: 10.1016/j.procbio.2020.11.002

Hindatu, Y., Annuar, M. S. M., and Gumel, A. M. (2017). Mini-review: anode modification for improved performance of microbial fuel cell. Renew. Sustain. Energy Rev. 73, 236–248. doi: 10.1016/j.rser.2017.01.138

Hou, Q., Nie, C., Pei, H., Hu, W., Jiang, L., and Yang, Z. (2016). The effect of algae species on the bioelectricity and biodiesel generation through open-air cathode microbial fuel cell with kitchen waste anaerobically digested effluent as substrate. Bioresour. Technol. 218, 902–908. doi: 10.1016/j.biortech.2016.07.035

Hou, Y., Tu, L., Qin, S., Yu, Z., Yan, Y., Xu, Y., et al. (2021). Dye wastewater treatment and hydrogen production in microbial electrolysis cells using MoS2-graphene oxide cathode: effects of dye concentration, co-substrate and buffer solution. Process Biochem. 102, 51–58. doi: 10.1016/j.procbio.2020.12.008

Hu, X., Liu, B., Zhou, J., Jin, R., Qiao, S., and Liu, G. (2015). CO2 fixation, lipid production, and power generation by a novel air-lift-type microbial carbon capture cell system. Environ. Sci. Technol. 49, 10710–10717. doi: 10.1021/acs.est.5b02211

Hu, X., Zhou, J., and Liu, B. (2016). Effect of algal species and light intensity on the performance of an air-lift-type microbial carbon capture cell with an algae-assisted cathode. RSC Adv. 6, 25094–25100. doi: 10.1039/C5RA26299B

Hua, T., Li, S., Li, F., Zhou, Q., and Ondon, B. S. (2019). Microbial electrolysis cell as an emerging versatile technology: a review on its potential application, advance and challenge. J. Chem. Technol. Biotechnol. 94, 1697–1711. doi: 10.1002/jctb.5898

Ichihashi, O., and Hirooka, K. (2012). Removal and recovery of phosphorus as struvite from swine wastewater using microbial fuel cell. Bioresour. Technol. 114, 303–307. doi: 10.1016/j.biortech.2012.02.124

Ieropoulos, I., Greenman, J., and Melhuish, C. (2012). Urine utilisation by microbial fuel cells; energy fuel for the future. Phys. Chem. Chem. Phys. 14, 94–98. doi: 10.1039/c1cp23213d

Ieropoulos, I. A., Stinchcombe, A., Gajda, I., Forbes, S., Merino-Jimenez, I., Pasternak, G., et al. (2016). Pee power urinal–microbial fuel cell technology field trials in the context of sanitation. Environ. Sci. Water Res. Technol. 2, 336–343. doi: 10.1039/C5EW00270B

Jafary, T., Al-Mamun, A., Alhimali, H., Baawain, M. S., Rahman, S., Tarpeh, W. A., et al. (2020). Novel two-chamber tubular microbial desalination cell for bioelectricity production, wastewater treatment and desalination with a focus on self-generated pH control. Desalination 481:114358. doi: 10.1016/j.desal.2020.114358

Jatoi, A. S., Akhter, F., Mazari, S. A., Sabzoi, N., Aziz, S., Soomro, S. A., et al. (2021). Advanced microbial fuel cell for waste water treatment-a review. Environ. Sci. Pollut. Res 28, 5005–5019. doi: 10.1007/s11356-020-11691-2

Jayabalan, T., Naina Mohamed, S., Matheswaran, M., Radhakrishnan, T. K., Pugazhendhi, A., and Alagarsamy, A. (2020). Enhanced biohydrogen production from sugar industry effluent using nickel oxide and cobalt oxide as cathode nanocatalysts in microbial electrolysis cell. Int. J. Energy Res. 45, 17431–17439. doi: 10.1002/er.5645

Jeremiasse, A. W., Hamelers, H. V., and Buisman, C. J. (2010). Microbial electrolysis cell with a microbial biocathode. Bioelectrochemistry. 78, 39–43. doi: 10.1016/j.bioelechem.2009.05.005

Jiang, Y., Liang, P., Liu, P., Miao, B., Bian, Y., Zhang, H., et al. (2017). Enhancement of the sensitivity of a microbial fuel cell sensor by transient-state operation. Environ. Sci. Water Res. Technol. 3, 472–479. doi: 10.1039/C6EW00346J

Jiang, Y., Su, M., Zhang, Y., Zhan, G., Tao, Y., and Li, D. (2013). Bioelectrochemical systems for simultaneously production of methane and acetate from carbon dioxide at relatively high rate. Int. J. Hydrog. Energy. 38, 3497–3502. doi: 10.1016/j.ijhydene.2012.12.107

Jung, R. K., Zuo, Y., Regan, J. M., and Logan, B. E. (2008). Analysis of ammonia loss mechanisms in microbial fuel cells treating animal wastewater. Biotechnol. Bioeng. 99, 1120–1127. doi: 10.1002/bit.21687

Kannan, P., Jogdeo, P., Mohidin, A. F., Yung, P. Y., Santoro, C., Seviour, T., et al. (2019). A novel microbial-Bioelectrochemical sensor for the detection of n-cyclohexyl-2-pyrrolidone in wastewater. Electrochim. Acta 317, 604–611.

Karuppiah, T., Uthirakrishnan, U., Sivakumar, S. V., Authilingam, S., Arun, J., Sivaramakrishnan, R., et al. (2021). Processing of electroplating industry wastewater through dual chambered microbial fuel cells (MFC) for simultaneous treatment of wastewater and green fuel production. Int. J. Hydrog. Energy. doi: 10.1016/j.ijhydene.2021.06.034

Khandelwal, A., Vijay, A., Dixit, A., and Chhabra, M. (2018). Microbial fuel cell powered by lipid extracted algae: a promising system for algal lipids and power generation. Bioresour. Technol. 247, 520–527. doi: 10.1016/j.biortech.2017.09.119

Khoo, K. S., Chia, W. Y., Tang, D. Y. Y., Show, P. L., Chew, K. W., and Chen, W.-H. (2020). Nanomaterials utilization in biomass for biofuel and bioenergy production. Energies 13:892. doi: 10.3390/en13040892

Kim, T., An, J., Jang, J. K., and Chang, I. S. (2015). Coupling of anaerobic digester and microbial fuel cell for COD removal and ammonia recovery. Bioresour. Technol. 195, 217–222. doi: 10.1016/j.biortech.2015.06.009