- Division of Environmental Technology and Management, Department of Management and Engineering, Linköping University, Linköping, Sweden

In an economic paradigm where companies think that more is better and resources are considered infinite, waste, pollution, and environmental degradation are often the result. This can, in turn, be addressed by companies focusing on offerings that are both effective and resource efficient. However, this type of offerings can be more uncertain and complex due to multiple factors such as multiple actors and conflicting objectives taking place at once. Dedicated design support for the relatively new offerings will be helpful for designers in industry. Large and small companies could benefit from the dedicated design support to successfully realize these types of offerings. However, the type of support they might need is not clear. Differences and similarities among large and small companies could guide researchers in providing more reliable support. Therefore, the aim of this research is to present differences and similarities of design support needs among large companies and small and medium enterprises. This is carried out through semi-structured interviews and follow-up meetings. The results show that differences include a formal product realization process for large companies and an informal or no process for smaller ones. Similarities point at design support for better communication and management of their offerings with regard to lead time as well as lifecycle and strategic thinking for decision making. The conclusions highlight the importance for researchers to provide design support that purposefully addresses specific needs.

Introduction

It used to be accepted that a product could be defined as “something tangible” and a service as something “intangible” (see Hill, 1999). This earlier understanding of product vs. service has much evolved, and today it is more common to see a continuum between products and services or rather a bundle of them (Baines et al., 2007). Regarding this newer understanding, Spring and Araujo (2009) discuss the term offering and suggest that this term allows for a flexible combination of product, services and value to customers who co-produce parts of that offering (see also Matschewsky et al., 2018). This notion allows for a more encompassing concept with which companies can provide and gain value from offering products, services or systems with customer involvement (Isaksson et al., 2009). Offerings that are both effective and resource efficient can be described as those that are successful in addressing customers or users' needs satisfactorily (see a discussion in Tukker, 2015) and that use natural resources efficiently, which is often operationalized by the ratio of economic value divided by environmental impact (Huppes and Ishikawa, 2005).

However, offerings that are both effective and resource efficient can be more uncertain and complex1 (Pieroni et al., 2021) since the knowledge needed to realize them requires new elements from traditional design (Brambila-Macias and Sakao, 2021) and could be spread across multiple disciplines (Sakao and Brambila-Macias, 2018). Moreover, more actors could be involved, for example, to close material flows (see Coenen et al., 2018), and collaboration with unusual partners, even competitors, could be required (Brambila-Macias et al., 2018). These characteristics are clearly essential for a circular system that is increasingly demanded by our societies (van Hemel and Cramer, 2002; Sato and Nakata, 2020; Boldoczki et al., 2021)2. Realizing these new offerings is primarily carried out by design, similarly with conventional products. Design in industry is often aided by design support to improve the quality, lead time, etc. and therefore design support has been an important target of design research (Blessing and Chakrabarti, 2009). However, few have looked into the differences and similarities of the design support used for these offerings in different companies, in particular, in terms of the sizes; see, for example, Deutz et al. (2013). This lack of closer investigation of the design support usage in practice may be one of the reasons for the low uptake of academic design support in industry (Tomiyama et al., 2009).

Apart from the differences in size (e.g., SMEs with <250 employees), the literature points out that SMEs are limited with regard to their technical and financial resources (Prieto-Sandoval et al., 2019), competences (e.g., skills and knowledge) and capabilities (e.g., unable to identify customer needs) (de Jesus Pacheco et al., 2019). Based on these inherent differences, a common understanding seems to be available in that SMEs need tools designed specifically for their organizational needs and that those tools differ from those for large companies, as argued in, for example, Moultrie et al. (2007). The literature, however, also points out some similarities among large and smaller companies, including environmental innovations as a source to competitive advantage (Forsman, 2013) and looking for certifications to comply with environmental regulations (Borsatto and Amui, 2019). The conclusion is that the community working on3 or design for sustainability (DfS) lacks the knowledge of how useful design support differs between large companies and SMEs.

Hence, a better understanding of the differences and similarities of support needs between large companies and SMEs can contribute to realizing these new offerings successfully. For example, SMEs could also be suppliers to larger companies, and a common understanding of their design support needs could increase their successful involvement in the final offering (Silva and Moreira, 2021). Differences and similarities among larger and smaller companies could provide insights to guide researchers and practitioners to implement reliable support and increase the chances of companies providing successful offerings. In this respect, the aim of this research is to present differences and similarities of design support needs among large companies and small and medium enterprises. The following research question guides this research: What are the differences and similarities of the design support needs between large and small to medium-sized manufacturing enterprises to realize effective and resource-efficient offerings?

The next sections of this paper include relevant earlier research on support for efficient and resource-effective offerings (section Design Support for Realizing Effective and Resource-Efficient Offerings), the methodology used for this research (section Methodology) and the results showing differences and similarities among companies (section Results and Analysis). The analysis and discussion in section Discussion compare the findings with previous literature. Finally, section Limitations of the Study provides limitations to the study and section Conclusions and Further Research the conclusions and further research.

Design Support for Realizing Effective and Resource-Efficient Offerings

Earlier Research on Design Support

Design support is a term that includes, for example, strategies, methodologies, procedures, methods, techniques, software tools, guidelines and information sources (Blessing and Chakrabarti, 2009). Design support has often focused on providing methods and tools (Wallace and Burgess, 1995). A method can be described as a systematic procedure to reach a specific goal (Pahl and Beitz, 1996) or as a goal-oriented rationalization or simplification of engineering work in the form of a standardized work description (see Andreasen et al., 2015). A tool can be described as an implement that facilitates the use of a method (Norell, 1996) or an instrument that enables the performance of a certain task (Lutters, 2014).

The literature offers different ways in which design support for effective and resource-efficient offerings can be categorized. For instance, Baumann et al. (2002) reviewed more than 150 support tools in environmental product development and divided them into frameworks, checklists and guidelines, rating and ranking tools, analytical tools, software and expert systems and organizing tools. Bovea and Pérez-Belis (2012) provided a taxonomy of support in three large categories, namely (1) methods for evaluating the environmental impact, (2) tools for integrating environmental aspects into the design process, for example, quality function deployment for the environment (QFDE), and lifecycle assessment (LCA), and (3) methods for integrating environmental and other requirements, for instance, the design matrix, and failure mode effect analysis (FMEA). More general design support is available; for instance, multi-criteria decision making (MCDM) (Zavadskas et al., 2014). Schöggl et al. (2017) categorized support for sustainable product development into qualitative, for example, 10 golden rules; semi-qualitative, for example, ecodesign checklist; and quantitative, for example, streamlined and full LCA. More specifically, ecodesign support has shown to be highly influential on the environmental performances of the products and the firms because design logically determines the performances of the products throughout their lifecycles. As statistical evidence, Seth et al. (2018) applied interpretive structural modeling (ISM) methodology to data from companies in India to show that ecodesign is a driver for environmental performances to a high degree with a difference not shown between large companies and SMEs. Design activity in industrial settings benefits from using suitable design support.

Design Support for Large Companies and SMEs to Realize Effective and Resource-Efficient Offerings

According to the European Commission (2021), in the year 2020, SMEs accounted for 99.8% of all enterprises, 65.2% of the total employment and 53% of the value-added to the European economy. Similarly, in the year 2018 in Sweden, SMEs accounted for 99.9% of all enterprises, with 65% of total employment and contributed 40% of the value-added to the Swedish economy (Tillväxtverket, 2021). Additionally, several authors suggest that SMEs account for ~60–70% of harmful emissions on the global scale (Parker et al., 2009; Quintás et al., 2018). A survey within a campaign for electrical and electronics SMEs in Europe in 2005 reported that the application of ecodesign tools and methods by SMEs is limited (Schischke et al., 2006), and more recently, the European Commission (2021) reported that SMEs have stalled in their progress to a green transition in part due to the lack of support measures in place for SMEs to comply with environmental regulations. This means that a great degree of attention needs to be paid to SMEs to help the entire manufacturing industry move toward global sustainability. An example of how SMEs benefit from improved environmental performance is presented by Hussey and Eagan (2007), which, based on a survey with 458 small manufacturers in the USA, found that total quality management contributes to pollution reduction and environmental management systems improve environmental performance.

However, how SMEs in comparison to large ones could be better aided for designing the new type of offerings explained in section Introduction is unclear in the literature. Literature that addresses support for effective and resource-efficient offerings in SMEs often describes barriers and drivers to engage in, for example, ecodesign initiatives (van Hemel and Cramer, 2002) or advantages and disadvantages of eco-efficiency (Fernández-Viñé et al., 2010). Le Pochat et al. (2007) suggest that lack of expertise is often a barrier to integrate environmental aspects in SMEs, more recently also stated by Kasiri et al. (2020). Moreover, it is common to see large companies and SMEs as presenting opposite characteristics, hence needing a different type of support. For example, Nicholas et al. (2011) suggested that large companies tend to be more hierarchical and have limited top management visibility. Large companies often have better access to human and financial resources as well as higher resistance to change and less encouragement for individual creativeness. In contrast, SMEs are often characterized by a flatter structure, high top management visibility and limited access to human and financial resources (Nicholas et al., 2011). SMEs can also be more flexible, present negligible resistance to change and have higher degrees of individual creativeness. Some of these characteristics are reflected in the study by Short et al. (2012) when comparing Swedish and UK companies. The authors further suggest that the larger the company, the more likely it is to adopt sustainability through, for example, Ecodesign or DfS in its realization process. The authors conclude that large companies use formal design processes, while SMEs rely on an informal process or no process at all. The use of a formal design process in large companies was also found by Deutz et al. (2013), who, through a questionnaire survey, concluded that large companies tend to use more of a full design process compared to SMEs. Finally, Poulikidou et al. (2014) suggested that successful integration of methods and tools in the realization process will depend on providing the necessary education in, for example, environmental requirements and competence in the use of tools, among other measures, to increase employee participation in their offerings.

Methodology

In this research, the semi-structured interview (see the guiding questions in Appendix A) with multiple case companies was the method selected. Semi-structured interviews allowed participants to discuss the general realization process of their offerings as well as other relevant aspects, such as actors involved and design support used and further needed. The explorative method fits well the aim and the research question (stated in section Introduction) that address the new type of offerings in industry, as well as the lack of much research performed with the aim (explained in section Design Support for Realizing Effective and Resource-Efficient Offerings). The semi-structured interview is a popular data collection method due to its flexibility and versatility (Kallio et al., 2016). Advantages of this method are that it allows reciprocity between the interviewer and interviewee and enables the interviewer to improvise follow-up questions when necessary (Galletta, 2013). Disadvantages include the challenge of listening and taking notes at the same time, the needed preparation before and after the interviews for planning questions and transcriptions (Opdenakker, 2006). To overcome the disadvantages, two researchers were present during the interviews, one asking questions and follow-ups and the other taking notes, observing, making sure all questions were asked and tracking the time.

A pilot interview was carried out before the interviews with practitioners to verify that the questions were clear and relevant. The pilot study was conducted with a product development engineer with 7 years of experience in manufacturing. During the pilot study, it was noticed that some wording, structure and concepts used in the interview may need further clarification. Hence, the interview structure and specific topics of interest were sent to all interviewees ahead of the interview (see Appendix B in the Supplementary Material). Furthermore, definitions for some concepts were used during interviews when necessary (see Appendix B).

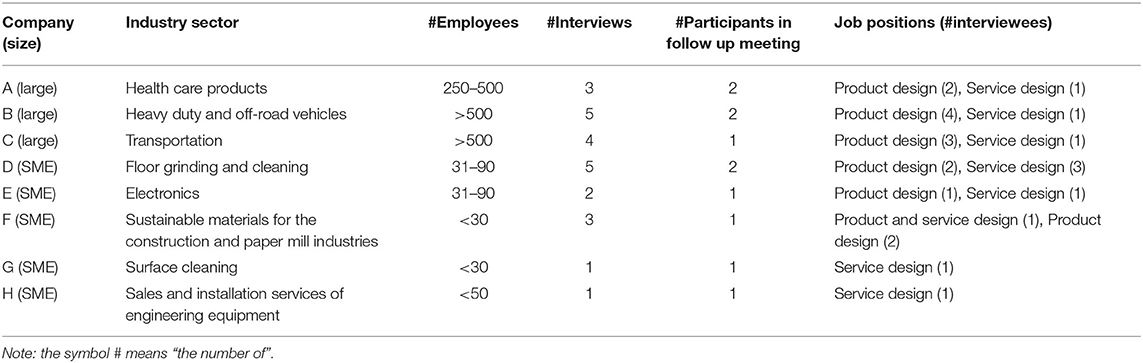

The semi-structured interviews were later carried out in mid-2015 with three large companies and five SMEs in Swedish with a total of 24 practitioners (see Table 1). Additionally, one follow-up meeting with each company was carried out in early 2016 to validate the interviews and add any additional information (see Table 1) The companies, all located in Sweden, were selected based on their interest to provide more effective and resource-efficient offerings. The interview participants were chosen based on their involvement in producing or delivering the offering and categorized into either product or service design. Interviews ranged from 54 to 112 min and were all sound recorded. Video recording was used in interviews when permission was granted to capture any drawings made on paper and corresponding explanations. The semi-structured interviews were used to first identify how the early stages of the realization of its offerings worked at each company, an “as-is state,” and second to gather information on how it could be improved, a “to-be state.” The questions during the semi-structured interviews covered (1) the early stages of the realization process, (2) the actors involved early in the process, and (3) the support used and further needed in this process. A summary report of the interviews can be found in the authors' project report, Brambila-Macias et al. (2017). Additionally, in follow-up meetings in early 2016, participants had the opportunity to add information regarding their design support needs, which were documented in meeting minutes also confirmed by all participants. Table 1 below shows the type of companies that participated in the semi-structured interviews and their industry sectors.

The analysis of the semi-structured interviews consisted of gathering the data into a spreadsheet and dividing it into early realization process, relevant actors, current design support used and further design support needed (see Appendix B). This was later compared to reports and meeting minutes from follow-up meetings. The comparison between the data analysis in the spreadsheet and the reports and minutes from the semi-structured interviews (validated by interviewees) aimed at enhancing the quality of the data and add further relevant information. Coding and theme categorization were used to group the data in a meaningful manner and whether the answers were part of the early realization process, the actors involved, the current design support used and further needs (see Appendices C–E).

Results and Analysis

The semi-structured interviews and meeting minutes from the follow-up meetings provided the necessary information as results for analysis to obtain a clear view of (1) the early stages of the realization process, (2) the actors involved early in the process, and (3) the design support used and further needed by the participating companies.

Early Stages of the Realization Process

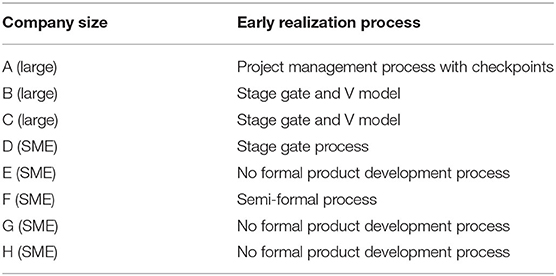

Companies were classified as large or SME according to the European Commission (2015b) definition. Table 2 shows that larger companies (A to D) have a well-defined design process with formal stages, which is often not the case for smaller companies (E to H). Company D, although classified as an SME had a well-developed design process. The circumstances in which companies operate are also important to mention as they impact the design output and hence possible major changes. These circumstances are that companies in full control of their conceptual design output were B, C, D, and F. Companies that were either subsidiaries or dependent on external actors for their conceptual design output were A, E, G, and H.

Actors Involved Early in Realization Process

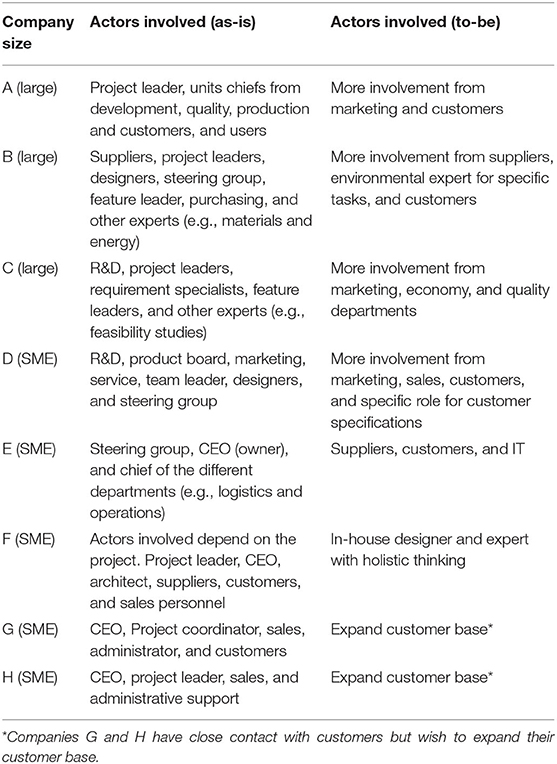

The actors involved in the current (as-is) and desired (to-be) realization process are summarized in Table 3. Note that according to interviews from companies G and H categorized as SMEs, close relationships with suppliers and customers were already established, and the companies rather wanted to expand their customer base willing to pay for a premium offering that is more effective and resource efficient (see Table 3).

Design Support Used and Further Needed

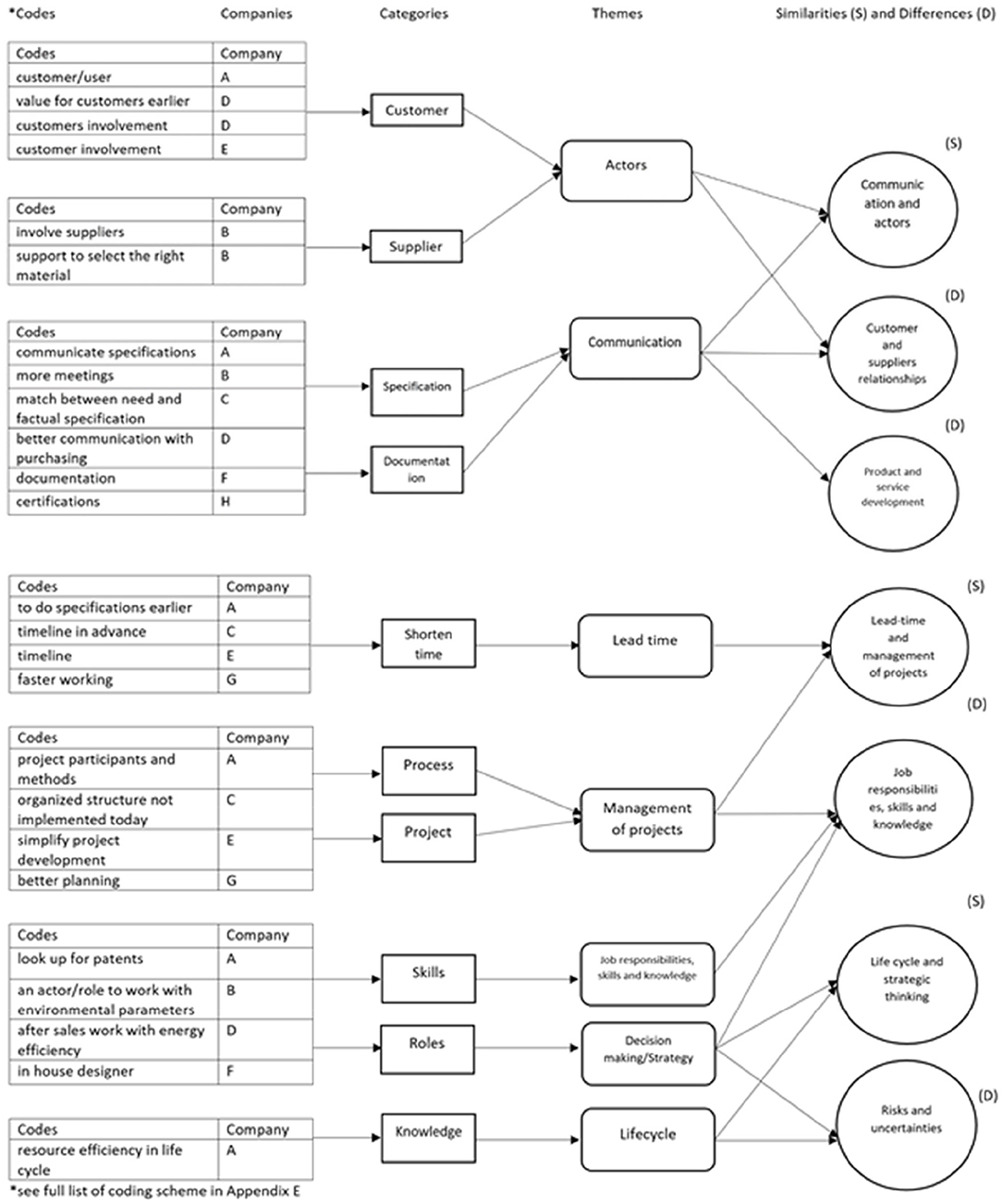

The support used by both large companies and SMEs is provided in Appendix D. This support ranges from well-known methods in the literature, such as QFD and FMEA, to pulse meetings used in the management of their offerings. Differences and similarities between large companies and SMEs were analyzed by the authors and depicted by Figure 1 (see the full coding scheme used in the analysis in Appendix E).

Discussion

Design support needs were obtained by thematic analysis (see Figure 1). The four themes found for differences include customer and supplier relationships, product and service development, job responsibilities, skills and knowledge and the theme of risks and uncertainties. The themes for similarities were three: lead time and management of their projects, communication and actors, and lifecycle and strategic thinking.

Differences Among Large Companies and SMEs

Customer and Supplier Relationships

SMEs in this research showed that they rely on closer relations with customers and suppliers to build trust and seem more flexible to adapt to customers' needs. For example, SMEs G and H emphasized that trust is needed for customers to understand the benefits of a premium offering specifically adapted to the customer, and they have close relationships with their customers and suppliers. An interviewee from SME G suggested that one must always be present in place to know if the customers have a need and mentioned that gatherings with stakeholders, for example, suppliers, for informal social events are common. Interviewee from SME H was interested in knowing more specifically how their offering benefits their customers' internal operations regarding costs. In contrast, large companies tend to emphasize clearer requirements specifications (see Table 3). This is in line with previous research suggesting that smaller firms have a different customer and purchasing behavior than larger ones. Morrissey and Pittaway (2006) and Fernández-Viñé et al. (2010) have previously highlighted the role of trust for SMEs when seeking to create effective customer and supplier relationships. In contrast, larger companies are governed by formal arrangements with regard to, for example, contracts and credit terms (Morrissey and Pittaway, 2006; Fernández-Viñé et al., 2010).

Product and Service Development

Another difference corroborates the results obtained by Schischke et al. (2006), Short et al. (2012), and Deutz et al. (2013) that point at larger companies having a formal product design process for the early offering realization, while SMEs tend to be informal or have no process at all. An interviewee from SME D suggested that the requirements specifications are not that detailed adding that There is no template for how we should work. SME H said something similar in that there is no declared process. Also, this is in line with a proposal for a general framework, based on collaboration with 16 Colombian SMEs for sustainable product-service systems in a leather manufacturing industry, rather than a rigid one, readymade procedure or tool (Hernandez-Pardo et al., 2013). For instance, a comment from a staff member in an SME regarding FMEA was that it takes too much time and makes no difference. In contrast, large companies have a wider range of support used than SMEs. This could be the case since little to no training is given in SMEs, reflected in the often-encountered barrier of lack of knowledge and skills (Kasiri et al., 2020). The support used in large companies covers a wider range, while support in SMEs seems to have more limited use of design support (see Appendix C).

Furthermore, it is worth noting that one relevant factor resulting in the difference in the development processes between SMEs and large ones is that of the complexity of the offering that the focal firm contributes to; a large company tends to need a large organization because of the higher complexity of its own offering, while a small one tends to be highly specialized. Note that the contribution of a firm differs from involvement; many small firms are involved in highly complex offerings (e.g., a part of a gas turbine may be manufactured by a small supplier). Therefore, offerings by large companies tend to involve multiple domains, and their designers tend to specialize in areas such as mechanics, software, service and systems. In this type of setting, coordination, cooperation, and collaboration are more relevant, requiring pre-defined procedures; Gericke et al. (2016) stated that ease in understanding across the areas is required in general product development processes. This is reflected upon the tools used: Gericke et al. (2016) showed, after interviewing seven SMEs (design studios and consultancies) and four large engineering companies, that smaller companies use common methods applicable to smaller groups such as user interviews, videos and personas, while larger ones tend to use more advanced or specialized methods such as lifecycle assessment, TRIZ, and FMEA.

Job Responsibilities, Skills, and Knowledge

Staff in SMEs are fewer, and employees will carry tasks in different functions as opposed to large companies, where more well-defined responsibilities are in place. In large companies B and C, several experts are involved in the offering, whereas in smaller companies, one employee can be responsible for various tasks (e.g., CEOs and owners of companies are involved in daily operations, owner-manager). For instance, in SME G, one staff member works as sales support, administrator, and in finance, a key staff member, it was suggested. This was similar for SME F, where one person had varying tasks from functioning as the link between sales and administrative tasks to production calculations and contacting subcontractors. In SMEs E to H, CEOs and owners are involved in their companies' daily operations, which is not the case for large companies.

Moreover, SMEs lack knowledge on how to address environmental aspects with, for example, LCAs, whereas large companies have access to experts. These findings also corroborate previous research (see de Jesus Pacheco et al., 2019) pointing out that SMEs face competency barriers. The need for staff training is an important issue not only for SMEs, as stated by many papers including Knight and Jenkins (2009), but it ought to be extra important for SMEs lacking resources in general compared with large companies.

Risks and Uncertainties

Risks and uncertainties are addressed more formally in large companies with, for example, FMEA and environmental impact description for projects (see Appendix C), whereas smaller ones tend to be more informal or even go for intuition or gut feeling. For instance, in Company B, a steering committee exists where uncertainties can be lifted and discussed, and risk analysis is systematically carried out to identify possible risks early in the projects. In company C there is on-going planning of future scenarios, 10–15 years ahead. In contrast, SME F suggested that some risk analysis is performed but that it is not done in a systematic manner. SME H suggested that risk identification is carried out by technicians when visiting a customer but that there is no method to analyze or evaluate their offerings and that rather risks and uncertainties are based on discussions with customers and what they want to have as a service. SMEs G and H also pointed out that it is difficult for them to provide any service guarantees to their customers as the circumstances of their services vary in each project. The lack of formal management of risks and uncertainties in SMEs has been previously researched. For example, Henschel (2006) stated that risk management in German SMEs was rather “rudimentary” and that the link between risk management and business planning in most SMEs was not well-developed. This more intuitive type of problem solving is also found by Giroux (2009) when researching in Canadian SMEs. It is also worth noting that smaller companies do not make use of as many methods or tools for the analysis and evaluation of their offerings as larger companies do (see Appendix C), and not having in place a more formal design or project process could contribute to difficulty in identifying sources of uncertainties and risks as well as their management resulting in a serious threat to their survival (Marcelino-Sádaba et al., 2014). Note that successful application of an extended FMEA method in the context of a circular system was reported through collaboration with an SME by Kimita et al. (2021).

Similarities Among Large Companies and SMEs

Lead Time and Management of Their Projects

Both large and small companies mentioned that lead time is an important constraint and that clear goals are needed to realize their offerings. This could be explained by the fact that the practitioners interviewed work in a project format. A project is temporary; it has a defined beginning and end, with defined scope and resources. A project is also unique; it is not a routine operation, but a specific set of activities performed to accomplish a goal (PMI, 2000; Turner and Müller, 2003). This observation could support a conclusion obtained by collaboration with a manufacturer in the UK (Knight and Jenkins, 2009), where it was stated that design support ease of use and limited resource (i.e., staff time) are highly interesting to practitioners irrespective of the firm size, as there are other pressures during the design process. Knight and Jenkins (2009) even stated that addressing other pressures in a given setting may be the greatest obstacle. An important similarity is then found in the need for management skills for the companies' projects to improve lead time. This implies knowing which actors, when and why should be included in the project.

Communication and Multiple Actors

Communication was a recurring theme for both types of companies for internal and external purposes. For example, Company A and C had needs for better communicating customer requirements inside the company and SME F was interested in implementing GRI standards to better report the environmental benefits of its offerings as a way of branding to its customers. Better communication included aspects such as the need for better documentation of product specifications e.g., Company B, or implementing digitalization i.e., SMEs E, G, and H. Research in design communication has looked at internal and external communication as well as the use of technology (see Eckert et al., 2005), pointing out that causes of communication breakdown can be attributed to, for example, the difficulty for an individual designer to fully understand a complex product/service, designers not being told what they need to know or the producer of information not knowing what the needs of the recipient are, which could result in delays (Alink et al., 2011) or even mistakes (Gericke et al., 2016). Hence, communication support seems imperative. Moreover, both types of companies make use of standards, for example, ISO 14001 and need to communicate their environmental sustainability to different stakeholders.

Another similarity is found in the various actors involved in the early realization process. These are not only engineer designers but also project managers, buyers, and, when possible, even suppliers. It also shows that decision-makers (often non-engineer designers) have a strong influence on the final offering. The literature relevant to more complex product/services points at a wide range of actors involved in the offering, which means different areas of knowledge and expertise (see da Costa Fernandes et al., 2019), which could, in turn, cause communication breakdown as different understandings of the product/services could emerge. Gericke et al. (2016) report that both small and large companies use methods such as brainstorming, storyboarding, requirements lists, use case modeling, mock-ups and prototyping. Such methods hint as necessary for effective communication.

Lifecycle and Strategic Thinking

Long-term strategy, understanding the whole picture and lifecycle thinking were terms mentioned by both large and small companies; various ways for implementing these features are proposed and an example of strategic product design is found in Vanegas et al. (2018). Lifecycle thinking seems needed to address economic vs. environmental impacts and make choices to, for example, invest in recycling (see an example research for recycling in Gigli et al., 2019) or remanufacturing (see categorized measures for remanufacturing proposed by Sakao and Sundin, 2019). A practitioner from Company B stated CO2 is no longer the only important issue … [it is] time to look at other environment-related challenges such as material use. SME D mentioned that the real value lies in making the machines' designs so that they are adapted to service so that they are easy to service on the worn parts. Company C addressed the need for calculation models to see the value of developing certain products for remanufacturing and that today's calculations do not include environmental values. Likewise, a practitioner from SME F stated the need to weigh costs between environmental materials and what customers want and that environmental aspects should be an important factor in the economic assessment of offerings. This shows substantial knowledge also exists in SMEs: the lifecycle perspective is spread as an important notion and might be an indication of the advancement in industry compared with one or two decades ago (Schischke et al., 2006).

Moreover, the analysis of interviews also showed that strategic thinking is needed to prioritize requirements and decide on the most importance aspects of an effective and resource-efficient offering. A practitioner from an SME wished for a requirement specification at a high strategic level. It is worth noting is that in both types of companies, decisions are made in board meetings or steering groups where project continuation, the scale of a project or offering niche are decided. These decisions are mainly based on the profitability of the offering, hence a need for more strategic thinking that includes environmental aspects to prioritize the most relevant ones. However, neither large companies nor SMEs seem to apply MCDM methods as reported in the literature which points at an opportunity to apply these methods to address companies' needs.

Differences Between Large Companies and SMEs From Other Subjects

This section aims to explore the inherent characteristics of SMEs that may cause the differences observed in this research field (described in section Differences Among Large Companies and SMEs) by taking advantage of the differences found in other scientific subjects. A large number of publications address the differences in other subjects, for instance, entrepreneurship and business management. In the subject of entrepreneurship, Birley and Norburn (1985) summarized SMEs' characteristics as (1) control, (2) reporting systems, (3) size and complexity, (4) experimentation, and (5) time scales. What is relevant to Ecodesign is the first three items. Birley and Norburn (1985) use the metaphor of a tanker captain (manager of a large company) vs. a yacht sailor (the owner of an SME): “The tanker captain relies on his instruments, the sailor on his contact with the elements” (p. 86), meaning the difference in terms of the size and complexity is implicative also to Ecodesign. This coincides with a perception that in SMEs, the management is more centralized, and a person plays multiple roles simultaneously (Giroux, 2009). In large companies, a tendency is that managers on multiple levels are relied on by the management and given individual freedom. On the other hand, this freedom could be understood as combined with heavier reporting systems. This way, their characterization of SMEs could be factors toward such differences observed as the development processes as well as skills and knowledge.

In the realm of innovation, Wagner and Hansen (2005) studied the role of innovation in large vs. small companies with the US wood products industry through 43 interviews with top executives. They found that the firm size impacts the innovation type pursued by companies; large companies clearly outrun smaller ones in process innovation, while small ones level the field with larger ones when considering all three innovation types (process, product, and business systems). For instance, large wood products companies invest intensively in cutting-edge facilities to keep up with process innovation. Their analysis regarding the emphasis by large companies on the process innovation could be a source of the more developed ecodesign process of large ones. Giroux (2009), in the subject of small business management, performed an interpretive study of 11 small firms in Canada about general problem-solving processes. The authors showed an intuitive, improvised and non-linear nature of how problems are actually solved in small firms, in contrast with well-defined and delineated steps in the problem-solving process. Many elements of design activities are a kind of problem-solving (see Simon, 1996). This also supports that the phenomena that defined ecodesign processes are barely observed within SMEs.

Regarding closer fields of study, Beheshti and Lollar (2003) state that the focus of the scientific literature in quality management has been on large organizations. Mendes and Lourenço (2014) point out a shared perception that smaller firms did not have the resources necessary to implement complex quality programs effectively. They then identified factors that hinder quality improvement programs' implementation in SMEs through 95 responses from Portuguese companies on a questionnaire regarding top management's education/training level and priorities, costs and actual performance, lack of support from external agents, human resources' overload, aversion to change, lack of resources, and culture and training. This list shows a variety of hindrances, and some of them are common to ecodesign, especially relating to resource limitation and training issues.

Keeping in mind that the research question of this paper concerns the differences and similarities of the support needs between large and small to medium-sized manufacturing enterprises to realize effective and resource-efficient offerings, investigating the factors to the differences is beyond the paper's aim. Nonetheless, some of the differences obtained from this research are found to be related to those found in other subjects. This topic requires further research, and the authors invite the readers to carry out research on it.

Managerial Implications

Section Discussion thus far discussed theoretical contributions of the results and analysis from this research onto earlier scientific publications. Several managerial implications are present: A company is recommended to choose design support to be implemented depending on their own practices for, e.g., communication, internal management, and customer/supplier relationship management, which are considered influenced by their size. More specifically speaking, a design support that has shown effective in a large company may not provide the same effect in an SME, and vice versa, because of different ways of practice. When a company develops a design support with academia, they are recommended to give requirements on the support based on their own practices.

Limitations of the Study

This research had several limitations. The first is the number of companies contacted and staff interviewed, three large companies and five SMEs, with a total of 24 interviews carried out. This is a small sample of how both large and small companies develop their offerings; research that includes a larger sample could provide more conclusive evidence of the differences and similarities of these types of companies. The second limitation is that of the Swedish context. All companies interviewed are located in Sweden, and although an effort was made to compare the findings of this research with other literature in other contexts, a comparative study could provide more accurate results. Lastly, the qualitative nature of this research limits the findings to the interviewees' personal experiences and interpretations of the realization process of their offerings.

Conclusions and Further Research

It is common to see large companies and SMEs presenting opposite characteristics, possibly needing a different type of support. However, this paper shows that there are also several similarities in their needs, for example, lead time, communication and lifecycle thinking. The research question that guided this research was stated as follows: What are the differences and similarities of the design support needs between large and small and medium-sized manufacturing enterprises? The answer to the research question is that differences corroborate previous research, which showed that larger companies tend to have a formal product design process as shown in previous literature, while SMEs have a less formal process or none. Staff in SMEs have multiple responsibilities, and the business owners and CEOs are active in the daily business operations, which is not the case in larger companies. Similarities include making use of standards and a need to communicate their environmental sustainability to different stakeholders. However, in both types of companies, environmental aspects do not seem to be demanded by customers but rather by legislation. These findings are the main contribution to the existing body of knowledge; see an example in Seth et al. (2018). The discussion in section Differences Between Large Companies and SMEs From Other Subjects aiming to compare the findings with those from other subjects is one of the first of its kind, and therefore it is also the contribution of this paper. The answer to the research question is that differences corroborate previous research, which showed that larger companies tend to have a formal product design process as shown in previous literature, while SMEs have a less formal process or none. Staff in SMEs have multiple responsibilities, and the business owners and CEOs are active in the daily business operations, which is not the case in larger companies. Similarities include making use of standards and a need to communicate their environmental sustainability to different stakeholders. However, in both types of companies, environmental aspects do not seem to be demanded by customers but rather by legislation. These findings are the main contribution to the existing body of knowledge; see an example in Seth et al. (2018). The discussion in section Differences Between Large Companies and SMEs From Other Subjects aiming to compare the findings with those from other subjects is one of the first of its kind, and therefore it is also the contribution of this paper.

Further research could take the findings from this paper and purposefully address practitioners' needs, for example, support in the form of methods or tools that provide better communication among actors about the lifecycle of their products and services. Further research could also look at differences among large companies and SMEs in other countries as the research presented here only covered the Swedish context. Another important aspect is that researchers could also look at the domain knowledge and skills of the users of the support (see Brambila-Macias and Sakao, 2021) to find a better match between the user of the support and the support itself.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author Contributions

SB-M and TS developed the paper idea together. SB-M carried out the research along with participants in the acknowledgments and wrote sections Introduction to Conclusions and Further Research (except Differences Between Large Companies and SMEs From Other Subjects and Managerial Implications). TS wrote sections Differences Between Large Companies and SMEs From Other Subjects and Managerial Implications, contributed with suggestions and inputs in all sections of the manuscript, supervised and guided the work, contributed to improving and finalizing the text, and contributed to the funding of the program. All authors contributed to the article and approved the submitted version.

Funding

This research was supported by the Mistra REES (Resource Efficient and Effective Solutions) program (Grant No. 2014/16) and funded by Mistra (The Swedish Foundation for Strategic Environmental Research).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

This is a revised and considerably different version of a paper presented at the International Conference on Engineering Design in 2019. The conference paper is cited as Brambila-Macias and Sakao (2019). Several people were involved during the interviews and reporting. Special thanks to Maria Widgren, Sara Nilsson, Ganesh Deshmukh, and Anna Adolfsson for their participation in data collection and reporting.

Supplementary Material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2021.758625/full#supplementary-material

Footnotes

1. ^Complexity is understood here as the state of having many parts and being difficult to understand or find an answer to, and uncertainty as a situation in which something is not known or something that is not known for certain (Cambridge Dictionary, 2020).

2. ^The European Commission (2015a) suggests that SMEs are those with <250 employees not exceeding EUR 50 million in annual turnover or an annual balance sheet not exceeding EUR 43 million.

3. ^In this article, the word ecodesign is capitalized when referring to the area in the literature. When referring to ecodesign as a design activity, it is not capitalized.

References

Alink, T., Eckert, C., Ruckpaul, A., and Albers, A. (2011). Different function breakdowns for one existing product: experimental results. Design Comput. Cogn. 10, 405–424. doi: 10.1007/978-94-007-0510-4_22

Andreasen, M. M., Hansen, C. T., and Cash, P. (2015). Conceptual Design. Interpretations, Mindset and Models. Springer. doi: 10.1007/978-3-319-19839-2

Baines, T. S., Lightfoot, H. W., Evans, S., Neely, A., Greenough, R., Peppard, J., et al. (2007). State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 221, 1543–1552. doi: 10.1243/09544054JEM858

Baumann, H., Boons, F., and Bragd, A. (2002). Mapping the green product development field: engineering, policy and business perspectives. J. Clean. Prod 10, 409–425. doi: 10.1016/S0959-6526(02)00015-X

Beheshti, H., and Lollar, J. (2003). An empirical study of US SMEs using TQM. Total. Qual. Manag. Bus. Excell 14, 839–847. doi: 10.1080/1478336032000090798

Birley, S., and Norburn, D. (1985). Small vs. large companies: the entrepreneurial conundrum. J. Bus. Strategy 6, 81–87. doi: 10.1108/eb039103

Boldoczki, S., Thorenz, A., and Tuma, A. (2021). Does increased circularity lead to environmental sustainability? The case of washing machine reuse in Germany. J. Indust. Ecol. 25, 864–876. doi: 10.1111/jiec.13104

Borsatto, J. M. L. S., and Amui, L. B. L. (2019). Green innovation: unfolding the relation with environmental regulations and competitiveness. Resour. Conserv. Recycl 149, 445–454. doi: 10.1016/j.resconrec.2019.06.005

Bovea, M., and Pérez-Belis, V. (2012). A taxonomy of ecodesign tools for integrating environmental requirements into the product design process. J. Clean. Prod 20, 61–71. doi: 10.1016/j.jclepro.2011.07.012

Brambila-Macias, S. A., Nilsson, S., Widgren, M., Lindahl, M., and Sakao, T. (2017). Support for Designing Resource Efficient and Effective Solutions: Current Use and Requirements by Swedish Industry: Report from “Product and Service Design Support for REES” Project of Mistra REES Program. Linköping: Linköping University Electronic Press.

Brambila-Macias, S. A., and Sakao, T. (2019). “Analysis and evaluation in the early stages of designing resource efficient offerings: a comparison among large companies and small and medium enterprises,” in Proceedings of the Design Society: International Conference on Engineering Design (Cambridge, Cambridge University Press), 1, 3161–3170.

Brambila-Macias, S. A., and Sakao, T. (2021). Effective ecodesign implementation with the support of a lifecycle engineer. J. Clean. Prod. 279:123520. doi: 10.1016/j.jclepro.2020.123520

Brambila-Macias, S. A., Sakao, T., and Kowalkowski, C. (2018). Bridging the gap between engineering design and marketing: insights for research and practice in product/service system design. Des. Sci. 4. doi: 10.1017/dsj.2018.3

Cambridge Dictionary. (2020). Cambridge International Dictionary of English. Available online at: https://dictionary.cambridge.org/ (accessed May 20, 2020).

Coenen, J., van Der Heijden, R. E., and van Riel, A. C. (2018). Understanding approaches to complexity and uncertainty in closed-loop supply chain management: past findings and future directions. J. Clean. Prod. 201, 1–13. doi: 10.1016/j.jclepro.2018.07.216

da Costa Fernandes, S., Martins, L. D., and Rozenfeld, H. (2019). Who are the stakeholders mentioned in cases of product-service system (PSS) design? Proc. Design Soc. Int. Conf. Eng. Design 1, 3131–3140. doi: 10.1017/dsi.2019.320

de Jesus Pacheco, D. A., ten Caten, C. S., Jung, C. F., Sassanelli, C., and Terzi, S. (2019). Overcoming barriers towards sustainable product-service systems in small and medium-sized enterprises: state of the art and a novel decision matrix. J. Clean. Prod. 222, 903–921. doi: 10.1016/j.jclepro.2019.01.152

Deutz, P., McGuire, M., and Neighbour, G. (2013). Eco-design practice in the context of a structured design process: an interdisciplinary empirical study of UK manufacturers. J. Clean. Prod 39, 117–128. doi: 10.1016/j.jclepro.2012.08.035

Eckert, C., Maier, A., and McMahon, C. (2005) “Communication in design,” in Design Process Improvement, eds J. Clarkson C. Eckert (London: Springer). doi: 10.1007/978-1-84628-061-0_10

European Commission. (2015a). User Guide to the SME Definition. Available online at: https://op.europa.eu/en/publication-detail/-/publication/79c0ce87-f4dc-11e6-8a35-01aa75ed71a1 (accessed June 15, 2018).

European Commission. (2015b). User Guide to the SME Definition. Luxembourg: Publications Office of the European Union.

European Commission. (2021). SME Performance Review. Available online at: https://ec.europa.eu/growth/smes/sme-strategy/performance-review_en (accessed August 8, 2021).

Fernández-Viñé, M. B., Gomez-Navarro, T., and Capuz-Rizo, S. F. (2010). Eco-efficiency in the SMEs of Venezuela. Current status and future perspectives. J. Clean. Prod. 18, 736–746. doi: 10.1016/j.jclepro.2009.12.005

Forsman, H. (2013). Environmental innovations as a source of competitive advantage or vice versa? Bus. Strat. Environ. 22, 306–320. doi: 10.1002/bse.1742

Galletta, A. (2013). Mastering the Semi-Structured Interview and Beyond: From Research Design to Analysis and Publication. New York, NY: New York University Press.

Gericke, K., Kramer, J., and Roschuni, C. (2016). An exploratory study of the discovery and selection of design methods in practice. J. Mech. Des. 138:101109. doi: 10.1115/1.4034088

Gigli, S., Landi, D., and Germani, M. (2019). Cost-benefit analysis of a circular economy project: a study on a recycling system for end-of-life tyres. J. Clean. Prod. 229, 680–694. doi: 10.1016/j.jclepro.2019.03.223

Giroux, I. (2009). Problem solving in small firms: an interpretive study. J. Small Bus. Enterp. Dev. 16, 167–184. doi: 10.1108/14626000910932944

Henschel, T. (2006). Risk management practices in German SMEs: an empirical investigation. Int. J. Entrep. Small Bus. 3, 554–571. doi: 10.1504/IJESB.2006.010543

Hernandez-Pardo, R. J., Bhamra, T., and Bhamra, R. (2013). Designing sustainable product service systems in SMEs. Int. J. Des. Manag. Prof. Pract. 6, 57–71. doi: 10.18848/2325-162X/CGP/v06i04/38592

Hill, P. (1999). Tangibles, intangibles and services: a new taxonomy for the classification of output. Can. J. Econ. 32, 426–446. doi: 10.2307/136430

Huppes, G., and Ishikawa, M. (2005). Eco-efficiency and Its xsTerminology. J. Ind. Ecol. 9, 43–46. doi: 10.1162/108819805775247891

Hussey, D. M., and Eagan, P. D. (2007). Using structural equation modeling to test environmental performance in small and medium-sized manufacturers: can SEM help SMEs? J. Clean. Prod. 15, 303–312. doi: 10.1016/j.jclepro.2005.12.002

Isaksson, O., Larsson, T. C., and Öhrwall-Rönnbäck, A. (2009). Development of product-service systems: challenges and opportunities for the manufacturing firm. J. Eng. Des. 20, 329–348. doi: 10.1080/09544820903152663

Kallio, H., Pietilä, A. M., Johnson, M., and Kangasniemi, M. (2016). Systematic methodological review: developing a framework for a qualitative semi-structured interview guide. J. Adv. Nurs. 72, 2954–2965. doi: 10.1111/jan.13031

Kasiri, N., Movassaghi, H., and Lamoureux, S. (2020). Sustainability engagement or not? US SMEs approach. J. Small Bus. Strategy 30, 16–32.

Kimita, K., Brambila-Macias, S. A., Sakao, T., and Tillman, A.-M. (2021). Failure analysis method for enhancing circularity through systems perspective. J. Indust. Ecol. 25, 544–562. doi: 10.1111/jiec.13069

Knight, P., and Jenkins, J. O. (2009). Adopting and applying eco-design techniques: a practitioners perspective. J. Clean. Prod. 17, 549–558. doi: 10.1016/j.jclepro.2008.10.002

Le Pochat, S., Bertoluci, G., and Froelich, D. (2007). Integrating ecodesign by conducting changes in SMEs. J. Clean. Prod. 15, 671–680. doi: 10.1016/j.jclepro.2006.01.004

Lutters, E. (2014). “Design methodology,” in CIRP Encyclopedia of Production Engineering, L. Laperrière and G. Reinhart, eds (Berlin, Heidelberg: Springer Berlin Heidelberg), 386–388.

Marcelino-Sádaba, S., Pérez-Ezcurdia, A., Lazcano, A. M. E., and Villanueva, P. (2014). Project risk management methodology for small firms. Int. J. Proj. Manag. 32, 327–340. doi: 10.1016/j.ijproman.2013.05.009

Matschewsky, J., Kambanou, M. L., and Sakao, T. (2018). Designing and providing integrated product-service systems-challenges, opportunities and solutions resulting from prescriptive approaches in two industrial companies. Int. J. Prod. Res. 56, 2150–2168. doi: 10.1080/00207543.2017.1332792

Mendes, L., and Lourenço, L. (2014). Factors that hinder quality improvement programs' implementation in SME: definition of a taxonomy. J. Small Bus. Enterp. Dev. 21, 690–715. doi: 10.1108/JSBED-03-2014-0054

Morrissey, W. J., and Pittaway, L. (2006). Buyer-supplier relationships in small firms: the use of social factors to manage relationships. Int. Small Bus. J. 24, 272–298. doi: 10.1177/0266242606063433

Moultrie, J., Clarkson, P. J., and Probert, D. (2007). Development of a design audit tool for SMEs. J. Prod. Innov. Manag. 24, 335–368. doi: 10.1111/j.1540-5885.2007.00255.x

Nicholas, J., Ledwith, A., and Perks, H. (2011). New product development best practice in SME and large organisations: theory vs. practice. Eur. J. Innov. Manag. 14, 227–251. doi: 10.1108/14601061111124902

Norell, M. (1996). Competitive industrial product development processes-a multidisciplinary knowledge area. NordDesign 96, 125–132.

Opdenakker, R. (2006). Advantages and disadvantages of four interview techniques in qualitative research. Forum Qual. Sozialforschung/forum: Qual. Soc. Res. 4:11.

Pahl, G., and Beitz, W. (1996). Engineering Design: A Systematic Approach: Springer Science and Business Media. London: Springer-Verlag.

Parker, C. M., Redmond, J., and Simpson, M. (2009). A review of interventions to encourage SMEs to make environmental improvements. Environ. Plan C Politics Space. 27, 279–301. doi: 10.1068/c0859b

Pieroni, M. P., McAloone, T. C., and Pigosso, D. C. (2021). Circular economy business model innovation: sectorial patterns within manufacturing companies. J. Clean. Prod. 286:124921. doi: 10.1016/j.jclepro.2020.124921

PMI. (2000). A Guide to the Project Management Body of Knowledge (PMBOK guide), Vol. 2. Newtown Square, PA: Project Management Institute.

Poulikidou, S., Björklund, A., and Tyskeng, S. (2014). Empirical study on integration of environmental aspects into product development: processes, requirements and the use of tools in vehicle manufacturing companies in Sweden. J. Clean. Prod. 81, 34–45. doi: 10.1016/j.jclepro.2014.06.001

Prieto-Sandoval, V., Jaca, C., Santos, J., Baumgartner, R. J., and Ormazabal, M. (2019). Key strategies, resources, and capabilities for implementing circular economy in industrial small and medium enterprises. Corp. Soc. Responsib. Environ. Manag. 26, 1473–1484. doi: 10.1002/csr.1761

Quintás, M. A., Martínez-Senra, A. I., and Sartal, A. (2018). The role of SMEs' green business models in the transition to a low-carbon economy: differences in their design and degree of adoption stemming from business size. Sustainability 10:2109. doi: 10.3390/su10062109

Sakao, T., and Brambila-Macias, S. A. (2018). Do we share an understanding of transdisciplinarity in environmental sustainability research? J. Clean. Prod. 170, 1399–1403. doi: 10.1016/j.jclepro.2017.09.226

Sakao, T., and Sundin, E. (2019). How to improve remanufacturing? A systematic analysis of practices and theories. J. Manuf. Sci. Eng. 141, 1–13. doi: 10.1115/1.4041746

Sato, F. E. K., and Nakata, T. (2020). Recoverability analysis of critical materials from electric vehicle lithium-ion batteries through a dynamic fleet-based approach for Japan. Sustainability 12:147. doi: 10.3390/su12010147

Schischke, K., Mueller, J., and Reichl, H. (2006). “EcoDesign in european small and medium sized enterprises of the electrical and electronics sector status quo and the road towards EuP,” in Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment, (Scottsdale, AZ) 233–238.

Schöggl, J.-P., Baumgartner, R. J., and Hofer, D. (2017). Improving sustainability performance in early phases of product design: a checklist for sustainable product development tested in the automotive industry. J. Clean. Prod. 140, 1602–1617. doi: 10.1016/j.jclepro.2016.09.195

Seth, D., Rehman, M. A. A., and Shrivastava, R. L. (2018). Green manufacturing drivers and their relationships for small and medium (SME) and large industries. J. Clean. Prod. 198, 1381–1405. doi: 10.1016/j.jclepro.2018.07.106

Short, T., Lee-Mortimer, A., Luttropp, C., and Johansson, G. (2012). Manufacturing, sustainability, ecodesign and risk: lessons learned from a study of Swedish and English companies. J. Clean. Prod. 37, 342–352. doi: 10.1016/j.jclepro.2012.07.037

Silva, L. F., and Moreira, A. C. (2021). Alignment in collaborative new product development. Comparing small and large firms. Int. J. Bus. Innov. Res. 24, 167–196. doi: 10.1504/IJBIR.2021.112813

Spring, M., and Araujo, L. (2009). Service, services and products: rethinking operations strategy. Int. J. Oper. Prod. Manage. 29, 444–467. doi: 10.1108/01443570910953586

Tillväxtverket. (2021). Basfakta om Företag. Available online at: https://tillvaxtverket.se/statistik/foretagande/basfakta-om-foretag.html (accessed August 6, 2021).

Tomiyama, T., Gu, P., Jin, Y., Lutters, D., Kind, C., and Kimura, F. (2009). Design methodologies: industrial and educational applications. CIRP Ann. Manuf. Technol. 58, 543–565. doi: 10.1016/j.cirp.2009.09.003

Tukker, A. (2015). Product services for a resource-efficient and circular economy-a review. J. Clean. Prod. 97, 76–91. doi: 10.1016/j.jclepro.2013.11.049

Turner, J. R., and Müller, R. (2003). On the nature of the project as a temporary organization. Int. J. Proj. Manag. 21, 1–8. doi: 10.1016/S0263-7863(02)00020-0

van Hemel, C., and Cramer, J. (2002). Barriers and stimuli for ecodesign in SMEs. J. Clean. Prod. 10, 439–453. doi: 10.1016/S0959-6526(02)00013-6

Vanegas, P. J., Peeters, D., Cattrysse, P., Tecchio, F., Ardente, F., Mathieux, W., et al. (2018). Ease of disassembly of products to support circular economy strategies. Resour. Conserv. Recycl. 135:323–334. doi: 10.1016/j.resconrec.2017.06.022

Wagner, E. R., and Hansen, E. N. (2005). Innovation in large versus small companies: insights from the US wood products industry. Manag. Decis. 43, 837–850. doi: 10.1108/00251740510603592

Wallace, K., and Burgess, S. (1995). Methods and tools for decision making in engineering design. Des. Stud. 16, 429–446. doi: 10.1016/0142-694X(95)00019-N

Keywords: design, effectiveness, efficiency, method, practice, process, support, tool

Citation: Brambila-Macias SA and Sakao T (2021) Design Support Needs to Realize More Effective and Resource-Efficient Offerings: A Comparison Among Large Companies and Small and Medium Enterprises. Front. Sustain. 2:758625. doi: 10.3389/frsus.2021.758625

Received: 14 August 2021; Accepted: 20 October 2021;

Published: 12 November 2021.

Edited by:

Ernesto D. R. Santibanez Gonzalez, University of Talca, ChileReviewed by:

Muhammad Zulqarnain Arshad, Ghulam Ishaq Khan (GIK) Institute of Engineering Sciences and Technology, PakistanWiebke Reim, Luleå University of Technology, Sweden

Copyright © 2021 Brambila-Macias and Sakao. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Tomohiko Sakao, dG9tb2hpa28uc2FrYW9AbGl1LnNl

Sergio A. Brambila-Macias

Sergio A. Brambila-Macias Tomohiko Sakao

Tomohiko Sakao