94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. , 15 October 2021

Sec. Circular Economy

Volume 2 - 2021 | https://doi.org/10.3389/frsus.2021.739052

This research paper is part of an investigation about the national competences in the field of Circular Economy (CE) within the so-called technological infrastructures. The purpose was to map these competences among the Technological Interface Centers (CIT) to support Portuguese companies in the transition to a more circular economy. A survey was designed under a general principle that all types of competences should have a straight contribution to the circular strategies included in the Portuguese Circular Economy Action Plan. Four main domains of competences were surveyed: “Guidance and Awareness;” “Eco-design;” “Resource Efficiency;” and “Industrial Symbiosis.” It was possible to ascertain CE competences profiles for the three groups of CIT (Technological Centers, Technology Transfer Centers, and Institutes of New Technologies) and recognize different and characteristic profiles of competences. Technological Centers have characteristic competences in all four domains, with greater emphasis on “Eco-design” and “Resource Efficiency.” Technology Transfer Centers also have characteristic competences in the four domains; however, its offer is more distributed, with no particular intensity noted in any specific domain. Institutes of New Technologies only present characteristic competences in “Eco-design.” Gaps identified in the “Guidance and Awareness” domain are “self-diagnosis tools for the efficient use of resources” and “maturity assessment tools in Circular Economy.” In the domain of “Eco-design” the only gap is the “skills to assist in the implementation of circular business models.” “Databases with examples of good practices for resource efficiency” and the “human resources and tools capable of carrying out energy and materiel audits” are the major gaps in the domain of “Resource Efficiency.” Finally, the “network of specialists with technical and commercial knowledge that enhances the use of by-products and residues in industry” and the “technical capacity or means to mediate the transfer of waste and by-product flows between industrial processes” are gaps in the domain of “Industrial Symbiosis.” A characterization sheet for each CIT was set up with the competences' makeup of every CIT structured. The business community in Portugal will be able to identify, in an objective way, competences that might be useful in the process of adapting their businesses toward more circular models.

The concept of Circular Economy has received special attention in recent years, not only on European level but all over the world, this economic model is gaining prominence amongst the world's largest companies, governments and policymakers, and is seen as a strategy to increase economic prosperity (has the potential to increase EU GDP by 0.5% by 2030 and create around 700,000 new jobs) and at the same time reduce dependence on primary materials and energy (Ellen MacArthur Foundation et al. et al., 2015; European Commission, 2020). Although there is already a wide range of literature on Circular Economy, there is a lack of conceptual coherence and the field is found to be filled with divergent approaches (Kalmykova et al., 2018). There are currently more than 114 different definitions of Circular Economy (Kirchher and Priscicelli, 2019).

Currently, one of the organizations at the forefront of dissemination and implementation of this economic model, the Ellen MacArther Foundation, defines the Circular Economy in the following way: Looking beyond the current take-make-waste extractive industrial model, a Circular Economy aims to redefine growth, focusing on positive society-wide benefits. It entails gradually decoupling of economic activity from the consumption of finite resources, and designing waste out of the system. Underpinned by a transition to renewable energy sources, the circular model builds economic, natural, and social capital. It is based on three principles: design out waste and pollution, keep products and materials in use, and regenerate natural systems.

The transition for a more Circular Economy is a fundamental priority for the European Union (European Commission, 2020). However, achieving a circular model requires cyclical and regenerative environmental innovations in the way society legislates, produces, and consumes (Prieto-Sandoval et al., 2018). The implementation of circular practices that will transform society, the way companies do business and the consumption systems, requires the acquisition of complex knowledge and certain competences. The European Centre for the Development of Vocational Training (CEDEFOP) defines “green skills” as knowledge, skills, values, and attitudes necessary to live, develop and support a society, which reduces the impact of human activity on the environment (Bainbridge, 2014).

The study developed by Prieto-Sandoval et al. (2019) relies on the integrated view that environmental business strategies, which drive eco-innovation and create competitive advantages in the Marketplace, result from the use of external and internal factors. According to Prieto-Sandoval et al. (2019), the external factors include public policies, market conditions, technological development, and stakeholders. While the internal factors are resources, capabilities, and competences (RCCs) of the company. Resources are assets, capabilities, organizational processes, firm attributes, information, and knowledge, used in achieving a sustained long-term competitive advantage in dynamic markets. Capabilities are generally acquired through development, learning and knowledge exchange. In turn, competences are the capabilities that become sources of competitive advantage over competitors. The competences have a strategic value, which implies the need to continuously update them. Prieto-Sandoval et al. (2019), in a recent paper, identified a set of resources, capabilities and competences that they anticipate as being useful for implementing the Circular Economy in SMEs. In their work, the authors identify a set of resources, capabilities and competences distributed over six areas of action: take, make/transform, distribute, use/consume, recover, and industrial symbiosis. The authors identify 13 resources that they consider essential for the implementation of the CE, such as, for example, materials database, design and creativity, traceability systems, maintenance services platform, among others. Regarding capabilities and competences, 13 were also identified, including, develop successful, green, and circular products or services, perform reverse logistics, include consumers in product design, design circular processes and products, among others.

The work developed by Kalmykova et al. (2018) aims to make available the tools to implement the concept for a circular economy, with the main objective being the development of two tools: a Circular Economy Strategies Database which includes 45 circular economy strategies applicable to different parts of the value chain; and a Circular Economy Implementation Database which includes more than 100 implementation cases of 35 of the 45 strategies described in the Circular Economy Strategies Database. Cross-referencing between these two databases allows the identification of the lack of strategies or tested cases for a given value chain stage, as well as the maturity of available strategies (pilot or market-ready stage).

The transition to a Circular Economy is a complex and multifaceted process that requires the acquisition of new competences and knowledge through education. It will be important to record all the progress made, but also to identify where more work is needed to achieve the desired change (European Environment Agency, 2016). The KΛTCH-e project, that involved entities from four countries, including Portugal (LNEG–Laboratório Nacional de Energia e Geologia, Universidade de Aveiro e Amorim Cork Composites), is a knowledge alliance between Higher Education, companies, and research centers and aimed at promoting the creation and development of skills in the field of product-services development for the Circular Economy and sustainability in the construction and furniture sectors. The KΛTCH-e project led to the conclusion that there is “a lack of knowledge, skills and competences to adapt business concepts and implement Circular Economy strategies, although a lot of information is available” (Celades et al., 2017).

Eco-design is seen by many experts as the way to create sustainable industrial systems (McDonough and Braungart, 2002) and achieve an increasingly Circular Economy (Franco, 2019), since, the design of a product affects the entire value chain (Charnley, 2015), as such, it is necessary to establish which competences should be cultivated in designers. The development of new design capabilities and competences are key to a more sustainable future and to support closed loop systems. According to Charnley (2015), some necessary competences are: a deep scientific knowledge of materials composition, engineering techniques and operational processes, proficiency in service design, and a thorough understanding of human behavior. In her work, Charnley (2015) proposes a list of 10 learning objectives for designers to be able to support the transformation of the industry with strategies for eco design, namely sharing platforms, products as services, product life extension (consumables), product life extension (high-end), product life extension (refurbish and upgrade), products as services (remanufacture), material recovery, and circular supplies.

The transition to an increasingly Circular Economy requires significant changes at various levels, such as: the acquisition of complex knowledge and new competences; legislative changes (Prieto-Sandoval et al., 2018); changes in the way organizations operate, from creating a sustainability mindset among designers, to reshaping operations along the supply chain (Jabbour et al., 2019). The same authors also underline the need to create partnerships between organizations, that allows the exchange on information and collaborative work. While there is already a wide range of literature on Circular Economy, there is a need for further knowledge on the competences that are required for businesses to be able to make this transition and turn the current theoretical knowledge base into practice.

To make this transition to the CE, companies often have difficulties in identifying the competences they need and/or understand if they should internalize them. In these cases, the solution is to resort to specialized technical-scientific assistance services provided by entities with these competences.

In Portugal, it was not found in the literature works that provide information in a structured way on the competences in CE of the different actors of the Portuguese Innovation System that can facilitate the adoption by companies of the circular strategies indicated in the Portuguese Action Plan for Circular Economy.

This research work is part of an investigation about national competences in Circular Economy and the overall aim of the present study was to identify and assess the existing CE competencies on the Technological Interface Centers (CIT) to assist Portuguese companies in the transition to the Circular Economy. The hypothesis tested was that the pattern of CE competencies varies with CIT nature and some gaps of competences are common to any CIT. To test the hypothesis all the population of CIT was requested to answer a survey, where each CIT had the opportunity to indicate their CE competencies within four relevant domains, with the purpose to discuss a general and specific distribution of the competencies by domain and CIT group.

The mapping and dissemination of these competences will allow the business fabric to objectively identify competences that may be useful in the process of adapting their businesses to more circular business models. It is also expected that the dissemination of national competences in Circular Economy will facilitate innovation practices and that it will allow a better international connection of the CIT, through the dissemination of their competences in international networks. The research is also a contribution for the identification of new stakeholders who foster and support the transition to a circular economy and the knowledge produced could be useful for the development of new funding programs to support similar technological interface structures activities.

This paper has the following structure: section Materials and Methods describes the features of the study targeted CIT (section Study Target–The CIT); provides details about the methodological approach (section Methodological Approach), method and principles used to develop the survey (section Survey Development), how the survey was answered (section Survey Answers), the validation process of the answers and criteria to validate the evidence of competencies (section Validation of Answers). Section Results provides the general distribution of competences by domain and CIT group (section General Distribution of Competences by Domain and CIT Group); specific distribution of competences by domain and CIT group (section Specific Distribution of Competences by Domain and CIT Group). Section Discussion summarizes this study's main outcomes and their applications.

The Technological Interface Centers (CIT) are technological infrastructures of the National Scientific and Technological System. In the terms of the Order of Secretary of State of Economy no. 8563/2019 (Despacho n° 8563/2019 de 27 de setembro do Gabinete do Secretário de Estado da Economia, 2019), CIT are acknowledged as entities of the national innovation system and agents for enhancing scientific and technological knowledge, that promotes the technology transfer and innovation in companies, namely through the certification processes, improving quality and efficiency of the product, supporting innovation activities, access to developing technology, and human resources training (Resolução do Conselho de Ministros n°84/2016 de 21 de dezembro, 2016).

For the purposes of this study, the three typologies of Technology Interface Centers were the same considered by (Agência de Inovação, 2006). Currently, the CIT are distributed as follows: 8 Technology Centers, 14 Technology Transfer Centers, and 9 Institutes of New Technologies.

The Technological Centers (CT) are infrastructures for technical and technological support to industry, aimed at sectors of activity that particularly lack technical support for technological innovation, namely companies from traditional industrial activity sectors, contributing to the increase of their competitiveness through convenient structures.

The Technology Transfer Centers (CTT) contribute to industrial development through highly qualified specialization in production technology and production management in its multiple aspects of system or product development, demonstration, productivity improvement, certification, and professional training.

The Institutes of New Technologies (INT) aim to increase technological intensity in the production of industrial companies by assimilating new technologies based on scientific and technological research, to take advantage of local synergies to make research-industry interaction efficient.

Kalmykova et al. (2018) performed a literature research using Scopus database, Google and Google Scholar, and using “circular economy” as a keyword in the title, keywords and abstract of the documents; however, they did not considered different terminology that may be used for concepts similar to circular economy, “as closed loop economy,” “zero waste economy,” “green supply chain management,” “performance economy,” “cradle to cradle,” or “industrial symbiosis.” After performing a screening of the literature and discarding any article that didn't have circular economy as the main topic, the authors divided the selected articles into four categories: theory, policy, case studies, and practice. Literature from all four categories was used to develop the CE Strategies Database and the literature from case studies and practice was used to develop the CE Implementation Database. The CE Strategy Database was built so that each strategy was associated with a phase of the value chain, and for each implementation case in the CE Implementation Database a suitable strategy was matched. In cases where an implementation case was missing a CE strategy, that strategy was added to the CE Strategy Database. The authors also did not perform any screening of the strategies nor the implementation cases, i.e., all the strategies and all de cases identified in the reviewed literature were considered in the databases.

Charnley (2015) analyzed eight case studies, regarding the implementation of strategies for climate change, from the databases of Ellen MacArthur Foundation and Accenture. To select the case studies, the author defined four criteria: manufacturing-led companies were considered the most relevant; case studies must exemplify a variety of strategies for climate change; case studies must illustrate the application of CE in a wide variety of products; the case study analysis should include B2B and B2C markets. Using the evidence from the case studies and the literature framework the author identified a group of design abilities and skills needed to develop circular products. To avoid any bias and provide robust findings, any deductions regarding the case studies were validated by CE experts, researchers, and stakeholders from relevant companies.

In the research carried out by Upadhyay (2020) and Kumar et al. (2019) with the aim of investigating the current state of green supply chain practices in India and understanding the green practices being adopted with the focus on improving the operational performance in China respectively, the authors adopted a case study approach where semi-structured interviews were carried out with three Indian automobile manufacturing companies and seven Chinese SMEs in the packaging sector. The case studies adopted in both studies describe the current state of green supply chain practices in the respective industrial sectors, and how critical they are to develop an efficient green supply chain; however, the studies were not designed to map competences that intermediary entities providing support to companies might need to help implement those green practices.

The methodology adopted for the development of the present study followed a practical approach, since the competences that were intended to be mapped were not searched from the literature, or from identified case studies, which makes an important difference of other authors approach, namely Kalmykova et al. (2018) and Charnley (2015). Similarly to Upadhyay (2020) and Kumar et al. (2019) a structured engagement with CIT was carried out, with the objective of characterizing these entities and understanding what circular economy competences they have. However, the set of competences intended to ascertain was defined a priori. The objective was not to look for all the circular economy competences that might exist amongst the CIT, but rather to look for a specific set of competences that were considered relevant for the implementation of the CE strategies defined in the Portuguese Circular Economy Action Plan (PAEC, 2017–2020). To verify the existence of this set of competences, a questionnaire was developed, from which was possible to determine the competences of each CIT as well as to gather all the evidence necessary to support those competences. It was also carried out a screening and review of all the evidence presented, and for that a set of criteria was defined, and presented to the technicians of the CIT for validation, to ensure the objectivity and thoroughness of the work.

The methodological process used in the development of this research work takes places in three main phases:

– Survey development

– Survey answers

– Validation of answers

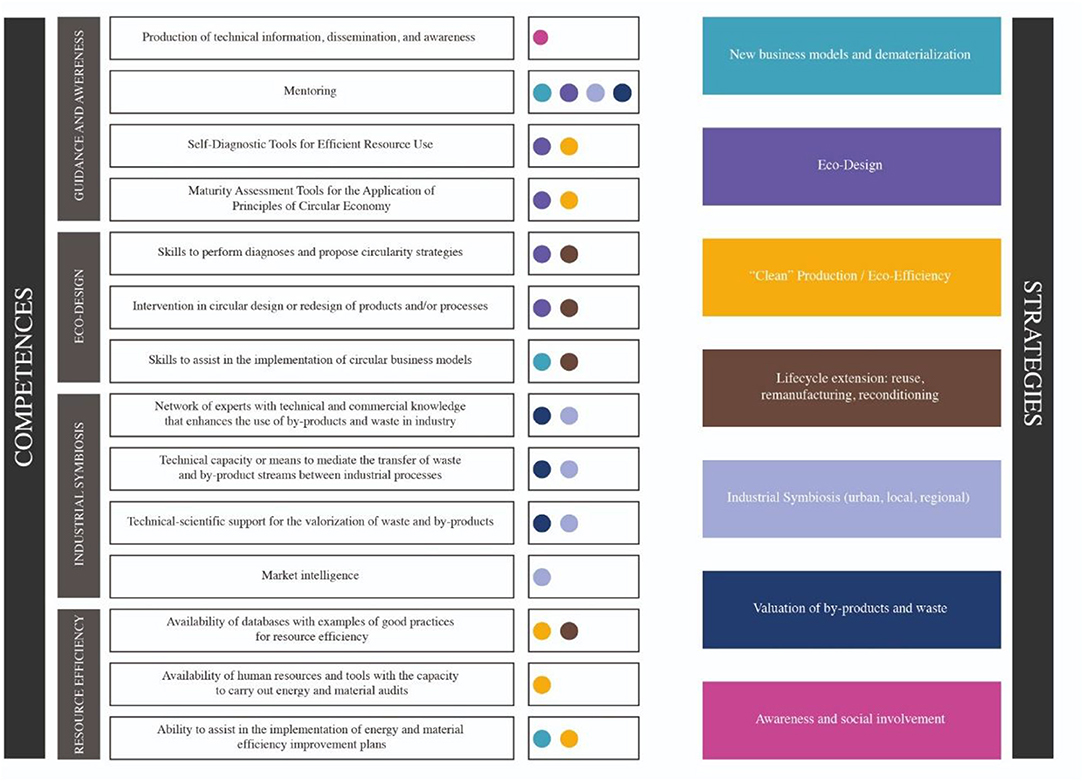

The first step of this phase was the construction of a questionnaire. It was developed over approximately two months, a meta-analysis of the diverse literature, where the aim was to identify domains of competences, namely in international networks that provide services for SMEs in resource efficiency. Thus, the work developed by EREK (European Resource Efficiency Knowledge Centre) was particularly useful with the aim of identifying competences that allow companies to move toward a more Circular Economy. EREK is an initiative of the European Commission, implemented by a consortium of organizations, which provides information on business service providers and business support organizations, key tools, and learning resources, as well as access to a network of experts (European Commission, 2018). Based on the results of this meta-analysis, 16 core competences were defined that were guaranteed to contribute to support the implementation of the Circular Economy strategies foreseen in the Portuguese Circular Economy Action Plan: 2017–2020 (Resolução do Conselho de Ministros 190-A/2017 de 11 de dezembro, 2017), namely (i) New business models and dematerialization, (ii) Design, Eco design, (iii) Clean production/eco-efficiency, (iv) Life cycle extension: reuse, remanufacturing, reconditioning, (v) Industrial symbioses, (vi) Valorization of by-products and waste, (vii) Awareness raising and social involvement. In Figure 1 is presented the relation between the strategies and the relevant competences to support these strategies around four domains of competences that allow companies doing a transition to a more Circular Economy, namely, Guidance and Awareness, Eco-design, Resource Efficiency, and Industrial Symbiosis.

Figure 1. Relevant competences to support the circular economy strategies foreseen in the Portuguese Circular Economy Action Plan (2017–2020).

For the purpose of this mapping, “Circular Economy competencies” have been considered as the pooling and coordination of knowledge, experiences, and skills that enable the Technology Interface Centers to carry out technology interface activities that promote Circular Economy development.

Considering the research conducted and the concept of competences mentioned, a survey divided into two parts was designed. The first part consists of closed-ended questions, addressed to the four domains of competences identified as relevant. The second part consisted mostly of open-ended questions, which aimed to identify reference services, projects, tools, and/or initiatives that reflect the Circular Economy competences for which the CIT should be recognized and any competences that are under development. The questionnaire resulting from this phase is presented in Annex 1.

In this mapping work and taking into account the specificities of the questionnaire requests, the data collection method used was the accompanied completion of the survey. To this end, meetings were scheduled with the technicians of each CIT, where all the questions in the survey were discussed, in order to ensure that the questions asked were correctly understood, so as to ensure the harmonization of the answers obtained. After the meetings, each CIT was asked to submit the completed survey, considering the aspects discussed at the meeting.

Of the 31 CIT enquiries, 29 answers were obtained to the survey (8 CT, 13 CTT, 8 INT), with one CIT stating that it does not have competences for the Circular Economy and another not responding to the survey, as such, 93.5% of valid responses were obtained.

After the first analysis of the answers from CIT, it was verified that open questions were not fully answered. An email was therefore sent to each CIT with a clarification of these issues, and they were asked to review the answers given.

The data collection period took place from November 2019 to February 2020, including the whole process of accompanied completion of the survey and email iteration for clarification and adjustment of some aspects of the open-ended questions.

Once all the answers were recorded and reviewed respectively, a statistical analysis was carried out.

For the purposes of analysis, the following aspects were taken into consideration:

– For a CIT to be represented in one of the four domains of competences considered in this mapping, it is necessary that it possesses at least one of the competences of that domain.

– For a competence to be considered a characteristic of one of the three CIT groups, 60% or more of the CIT in that group must possess that competence.

– For a competence to be considered a gap in one of the three CIT groups, <50% of the CIT in that group must possess that competence.

In a next step, the references submitted by the CIT as evidence for the Circular Economy competences for which each CIT considers it should be recognized, and the links sent were validated. For the purpose of this mapping work, a hierarchy of evidence was established with the following order of relevance, (i) regular services in Circular Economy provided by the CIT, (ii) projects with the request of competences and Circular Economy support tools, (iii) initiatives developed, such as debates, conferences, seminars, lectures, dissemination sessions, and workshops, and (iv) projects in which the CIT was involved as a stakeholder. Services were considered to be the most relevant evidence, as services are concrete actions with a direct impact on companies (e.g., service provision contracts). Some of the projects and initiatives may also have a direct impact on companies, as they were carried out in partnership, however in other cases this impact will be indirect, with projects and initiatives being carried out in partnership with other CIT and other national and international entities. All the evidences presented that fit the mentioned typologies of evidence were considered valid, with the exception of projects in which the CIT was involved only as a stakeholder and for which no competences in Circular Economy were requested, even if these projects have themes associated with the CE as subject matter. Additionally, an evidence was only considered valid if it was accompanied by the respective reference, i.e., link to content that presents or is associated with the competence that the CIT intends to evidence.

The survey of this information allowed to create a characterization sheet for each CIT, in which the specific competences that the CIT has in the Circular Economy domains are listed, along with the respective services, projects and/or reference initiatives that the CIT has developed. The purpose of preparing these sheets is to allow businesses to objectively identify competences that are useful in adapting their businesses to more circular models, as well as to disseminate them in international networks.

To ensure that all CIT understood the importance of the evidence, as well as the criteria that ANI used to define a competence and validate the evidence and respective references, it was considered that it would be useful in the methodological process to introduce a workshop in which all CIT participated. Therefore, to harmonize the competence sheets developed, a workshop was organized with the main objectives of presenting the results of the survey and discussing some of the problems identified in the competence mapping exercise, namely the difficulty in obtaining references in a harmonized manner, as well as the necessary next steps to complete the mapping work.

Prior to the workshop, each CIT received a commented version of their respective competence sheet, with indications to be met, in order to facilitate its improvement. The workshop was held on 29 September, 2020 and, after the workshop, the CIT were asked, in accordance with the guidelines given in the document sent and with the discussion at the workshop, to make the necessary adjustments to their sheets and definitively validate their competences. This final validation process ended in November 2020.

The workshop was a key piece to ensure that technically all CIT followed the same criteria and to provide an opportunity to discuss any disagreement or alternative to the method followed, which did not occur.

A consultation form was also developed (Reflection on the dynamic nature of the competences for Circular Economy), which was also sent prior to the workshop, and which aimed to confirm the interest in a periodic update of the competences' sheets.

Of the 31 recognized CIT, 24 were mapped, of which 8 are Technology Centres (CT), 10 are Technology Transfer Centres (CTT), and 6 are Institutes of New Technology (INT). Table 1 identifies the competences of each of the CIT, in the four mapped domains. Of all the evidence presented by the CIT, 227 were validated, of which 37 are services, 163 are projects with the request of competences and Circular Economy support tools, and 27 are initiatives developed by the CIT.

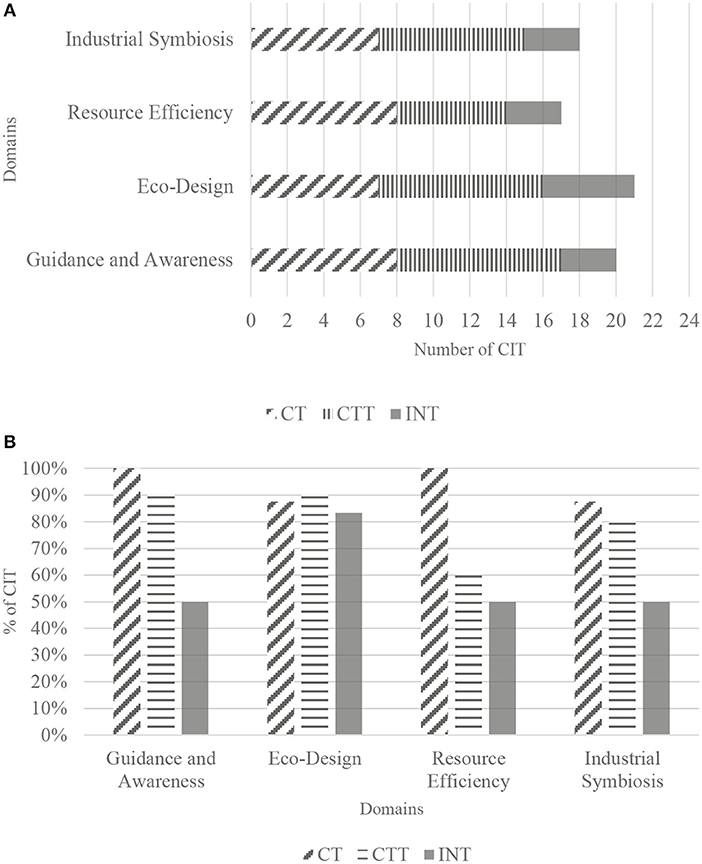

The first approach was to analyze the richness of competences in each of the domains studied. Figure 2A shows that two dimensions are richer in competences: Eco-design and then Guidance and Awareness. On the other hand, Resource Efficiency is the domain with the least richness in competences. Figure 2A also shows that for the Technological Centers (CT) there is a greater wealth of competences in Guidance and Awareness and Resource Efficiency. In the case of the Technology Transfer Centers (CTT), the Eco-design and Guidance and Awareness domains are the most competence-rich and the Resource Efficiency domain is the least competence-rich. Finally, in the case of the Institutes of New Technologies (INT), the Eco-design domain stands out as being the domain with the greatest richness in competences, as had been predicted through the analysis of the answers to the survey. The remaining three domains are equally rich.

Figure 2. (A) Abundance of competences in each mapped domain. (B) Distribution of the technological interface center groups by domain of competences.

Figure 2B shows that, in general, all the CIT groups possess competences in all domains. In the set of all Technology Centers (CT) it is observed that all of them somehow possess at least one competence in the domains Guidance and Awareness and Resource Efficiency. As far as the Technology Transfer Centers (CTT) are concerned, it can be seen that, although there are also contributions of competences in all domains, there is a significant percentage of them that do not have competences, namely in the Resource Efficiency domain. With regard to Institutes of New Technology (INT), it can be seen that they contribute to all four domains of competences, but it should be noted that a greater number of INT have competence in the area of Eco-design.

Through the analysis of Figure 3 it was possible to conclude which competence carries most weight in each domain.

Regarding the domain of Guidance and Awareness, the competence that is presented by the most CIT is “Production of technical information, dissemination, and awareness.” The least expressed competences are “assessment tools” and “self-diagnostic tools.” A very small number of CIT have this type of competences: of the 24 mapped CIT, only two have “self-diagnostic tools,” a Technology Centre (CT) and an Institute of New Technologies (INT), and only one INT has “assessment tools.” None of the Technology Transfer Centers (CT) has “self-diagnostic tools” or “assessment tools.” It should be noted that the INT do not seem to be geared toward “training” and that none of the CT has “assessment tools.”

Regarding the Eco-design domain, it can be seen that the competence that brings together the most CIT is “Intervention in circular design or redesign of products and/or processes,” and it is worth noting that of the three competences mapped, a very small number of CIT have “Skills to assist in the implementation of circular business models,” only one CT, one CTT and one INT.

In the domain of Resource Efficiency, “Ability to assist companies in determining material and energy productivity” is a competence with good coverage in all three CIT groups. Almost all CT have the “Ability to assist in the implementation of energy and material efficiency improvement plans.” It can be seen that few CT and CTT have “Databases with examples of good practices for resource efficiency” and “Human resources and tools with the capacity to carry out energy and material audits.” The latter competences are practically non-existent among INT.

In general, competences can be found in the Industrial Symbiosis domain in all the CIT groups. CTT dominates three of the four competences mapped, with the one with the most CIT (17) being “Technical-scientific support for the valorization of waste and by-products,” With regard to the competences “Network of experts with technical and commercial knowledge that enhances the use of by-products and waste in industry” and “Technical capacity or means to mediate the transfer of waste and by-product streams between industrial processes,” few CIT present them. As for the former, it was only mapped in two CT, two INT, and four CTT; as for the latter, the scenario is similar, but still with one INT less.

Through Figure 4 it was possible to find a profile of characteristic competences of each CIT group, as well as to identify gaps of competences. The characteristic competences and gaps of each CIT group are listed in Table 2.

Regarding Figure 4, it is important to highlight a set of gaps that were identified in each of the domains and that are common to the three CIT groups. In the field of Guidance and Awareness, it was found that a very small number of CIT have competences for the use of “self-diagnostic tools for the efficient resource use” and “Maturity Assessment Tools.” In the domain of Eco-design, the gap is in “skills to assist in the implementation of circular business models.” It can also be concluded that, in the domain of Resource Efficiency, few CIT “make available databases with examples of good practices for resource efficiency” and “have human resources and tools with the capacity to carry out energy and material audits.” Regarding the domains of Industrial Symbiosis, the gaps of competences identified focus essentially on the “network of experts with technical and commercial knowledge to enhance the use of by-products and waste in industry” and the “technical capacity or means to mediate the transfer of waste and by-product streams between industrial processes.”

By analyzing Table 2, each CIT group showed a profile of competences which, although they overlap, are different and characteristic. It seems to be characteristic of the Technological Centers (CT) to have competences in all four domains, with greater emphasis on Eco-design and Resource Efficiency.

The Technology Transfer Centers (CTT) have characteristic competencies in the four domains; however, this offer is more distributed, with no particular intensity in any specific domain.

Contrary to the other groups, since the Institutes of New Technologies (INT) present a profile of competences only in the field of Eco-design, it indicates that they are more inclined to intervene in this domain.

Of all the CE competences mapped, it was found that only “intervention in circular design or redesign of products and/or processes” is characteristic of the three CIT groups.

It was also tried to understand the CIT's competences by domain of intervention in circular design/redesign. Figure 5 shows that the main intervention domains of circular design/redesign are:

• Design for recycling

• Prototyping and testing new products

• Design for durability

Regarding the distribution of the domains of intervention by CIT group, the Technology Centers (CT) only presented evidence for three domains: design for recycling, conducting prototyping and testing of new products, and design for durability.

The analysis of evidence presented by the Technology Transfer Centers (CTT) and the Institutes of New Technologies (INT) allows us to identify as the main domains of intervention in the circular design/redesign competence the realization of prototyping and testing of new products and design for recycling.

None of the three CIT groups showed evidence for the intervention domain design for remanufacturing.

The analysis of Figure 6 shows that all groups have “Skills to perform diagnoses and propose circularity strategies.” Of the three groups, the Institutes of New Technologies (INT) can be highlighted at the level of “connection to expert networks,” the Technology Transfer Centers (CTT) at the level of “specialized human resources” and the Technology Centers (CT) regarding “life cycle analysis tools.”

In Figure 7 it is possible to see that the three CIT groups presented evidence for the three competences to “assist companies in determining material and energy productivity.” Of the three competences, the one with the highest coverage is “qualified human resources.” The Institutes of New Technologies (INT) were the group that presented more evidence for the competence “tools for data acquisition and reference analysis” and the Technology Transfer Centers (CTT) were the group that presented more evidence for “access to experts and industrial reference information.”

From the set of 29 answers to the survey, it can be observed, through Figure 8, that the strategies that the CIT see with more interest for the future development of competences are:

• Industrial symbioses (urban, local, regional)

• Valuation of by-products and waste

• Life cycle extension: reuse, remanufacturing, reconditioning

Analyzing the CIT groups separately, the main strategies on which the Technology Centers (CT) intend to focus on the future development of competences for Circular Economy are:

• Valuation of by-products and waste

• Life cycle extension: reuse, remanufacturing, reconditioning

• “Clean” production/eco-efficiency

• Design, eco-design

The main strategies on which the Technology Transfer Centers (CTT) intend to focus on the future development of competences for Circular Economy are:

• Industrial symbioses (urban, local, regional)

• Valuation of by-products and waste Life cycle extension: reuse, remanufacturing, reconditioning

The main strategies on which Institutes of New Technologies (INT) intend to focus on the future development of competences for the Circular Economy are:

• Industrial symbioses (urban, local, regional)

• Life cycle extension: reuse, remanufacturing, reconditioning clean production/eco-efficiency

In the research work developed, the aim was to map a set of 16 competences in Circular Economy, divided into four intervention domains. In general, at least one CIT was always found for all competences. The analysis of the collected information allowed concluding that the CIT, currently, are more focused on supporting Guidance and Awareness and Eco-design. It was also concluded that in each domain there is a recurring competence that is predominant.

A profile of characteristic competences was found for each of the CIT groups, as well as a set of gaps that highlight needs for further competence development. Kalmykova et al., in a recent study reported several case studies of implementation of circular economy strategies applied on different parts of the value chain. One of the outcomes of the study was a matching exercise between a CE Strategies Database and a CE Implementation data base. Authors recognized some gaps on the implementation of CE strategies namely associated with “community involvement,” “material productivity,” “new business models/sharing use,” and “upcycling.” In opposition, the present study was able to map evidence of competences associated to the implementation of these strategies.

From the specific analysis of the evidence presented in Eco-design, in particular the intervention domains of design and redesign, it was concluded that, currently, the CIT are more prepared to develop “design for recycling.” Although this is the area of intervention identified by more CIT, its number is still small in the total number of CIT.

Regarding the competences associated with carrying out diagnoses and proposing circularity strategies, it was found that there are still few CIT with competences to use “life cycle analysis tools.”

The three groups of CIT have different natures and as such, it was expected to find different characteristic competences in each group. In the case of the CT, a greater intensity of competences was found in the domains of Guidance and Awareness and Resource Efficiency, which is in line with what was expected, since CT are a group aimed at providing support to traditional industrial sectors, namely through the provision of services and specialized training, with the aim of improving the quality of products and processes. When analyzing the results obtained for the CTT and INT, it is necessary to consider the fact that in these two groups not all CIT were mapped and, therefore, there may be a deviation of results from the actual reality of existing characteristic competences. For the CTT, there was a greater intensity of competences in the domains of Guidance and Awareness and Eco-design, which is natural since CTT have a company/project level approach, with the aim of boosting the transfer of knowledge and technologies to industrial enterprises. Finally, in the case of the INT there was a greater intensity of competences in the domain of Eco-design and the same intensity was found in the three remaining domains. The INT are tailored to be specialists in certain technological areas and don't work in the logic of supporting the technological development of a specific industrial sector, but with the aim supporting the development of technologies that are transversal to several sectors. Therefore, one would expect a greater prominence in the domains of Resource Efficiency and Industrial Symbioses compared to the domain of Guidance and Awareness, which might be explained by the one third of INT that were not mapped.

Another outcome from this study was the recognition that within the CIT competences mapping there was not any evidence of competences oriented to support the mining industry. Upadhyay et al. (2021), concluded in a recent study, the circular economy concept is still in its early stages in the mining industry as it is with most primary sectors. On the other hand, it was stated the mining sector has a crucial role to play in the transition to a low carbon economy and embracing the move to a circular economy can help to reduce the negative impacts of its activities. This could be a new industrial field for CIT to deploy new CE competences.

In general, the CIT intend to put the focus of future competences development in Circular Economy, mostly associated to the circular strategies of “Industrial symbioses (urban, local, regional)” and “Valuation of by-products and waste.” In the case of CT, they intend to focus on “Valuation of by-products and waste” and CTT and INT on “Industrial symbioses (urban, local, regional).”

This first mapping and benchmarking work of the current CE competences of the CIT, indicated in their respective competence sheets, allowed to highlight their dynamic nature. Therefore, it is expected that the CIT competence profile shall have an evolving character and should be updated with some regularity.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

All authors listed have made a substantial, direct and intellectual contribution to the work, and approved it for publication.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The authors would like to thank Cláudia Azevedo for the support in the stakeholder's engagement effort and to the CIT network for the constructive feedback. The authors would like to thank Rodrigo Sousa for the design work in Figure 1.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2021.739052/full#supplementary-material

Agência de Inovação (2006). As Infra-estruturas Tecnológicas no Sistema de Inovação Nacional de Inovação – Evolução 1995-2005. Lisboa: Agência de Inovação.

Bainbridge, S. (2014). “Skills for the circular economy: changing mindsets,” in 17th European Forum on Eco-Innovation. Available online at: https://ec.europa.eu/environment/archives/ecoinnovation2014/2nd_forum/slidespdf/06_bainbridge.pdf (accessed January 8, 2021).

Celades, I., Ros, T., Rocha, C., Camocho, D., Schmidt, K., Pammiger, R., et al. (2017). “KΛTCH-e: introducing circular economy into higher education design curricula. Overview of the training needs, state of the art,” in 18th European Roundtable on Sustainable Consumption and Production Conference (ERSCP 2017). Available online at: https://www.katche.eu/wp-content/uploads/2017/10/Celades_Irinia_2_ERSCP2017_def-1.pdf (accessed January 2021).

Charnley, F. (2015). “Skills and capabilitiest for a sustainable and circular economy: the changing role of design,” in Fourth International Conference on Multinational Enterprises and Sustainable Developmen (Lisboa). Available online at: https://www.researchgate.net/publication/303749441. (accessed September 2021).

Despacho n° 8563/2019 de 27 de setembro do Gabinete do Secretário de Estado da Economia (2019). Diário da República n°186 –2ªsérie. Lisboa.

Ellen MacArthur Foundation, SUN, McKinsey Center for Business and Environment. (2015). Growth Within: A Circular Economy Vision for a Competitive Europe. Available online at: https://www.ellenmacarthurfoundation.org/publications/growth-within-a-circular-economy-vision-for-a-competitive-europe (accessed January 2021).

European Commission (2018). EREK: European Resource Efficiency Knowledge Center. Available online at: https://www.resourceefficient.eu/en/about (accessed January 2021).

European Commission (2020). “A New Circular Economy Action Plan. For a Cleaner and More Competitive Europe.” Communication From the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN#footnote6 (accessed January 2021).

European Environment Agency (2016). Circular Economy in Europe: Developing the Knowledge Base. EEA Report No. 2. Lisboa.

Franco, M. A. (2019). A system Dynamics approach to product design and business model strategies for the circular economy. J. Clean. Prod. 241:118327. doi: 10.1016/j.jclepro.2019.118327

Jabbour, A., Luiz, J., Luiz, O., Jabbour, C., Ndubisi, N., de Oliveira, J., et al. (2019). Circular economy business models and operations management. J. Clean. Prod. 235, 1525–1539. doi: 10.1016/j.jclepro.2019.06.349

Kalmykova, Y., Sadagopan, M., and Rosado, L. (2018). Circular economy – From review of theories and practices to development of implementation tools. Resourc. Conserv. Recyc. 135, 190–201. doi: 10.1016/j.resconrec.2017.10.034

Kirchher, J., and Priscicelli, L. (2019). Towards Education for the Circular Economy (ECE): five teaching principles and a case study. Conserv. Recyc. 150:1004406. doi: 10.1016/j.resconrec.2019.104406

Kumar, N., Brint, A., Shi, E., Upadhyay, A., and Ruan, X. (2019). Integrating sustainable supply chain practices with operational performance: an exploratory study of Chinese SMEs. Prod. Plan. Control 30, 464–478. doi: 10.1080/09537287.2018.1501816

McDonough, M., and Braungart, M. (2002). Design for the triple top line: new tools for sustainable commerce. Corp. Environ. Strat. 9, 251–258. doi: 10.1016/S1066-7938(02)00069-6

Prieto-Sandoval, V., Jaca, C., and Ormazabal, M. (2018). Towards a consensus on the circular economy. J. Clean Prod. 179, 605–615. doi: 10.1016/j.jclepro.2017.12.224

Prieto-Sandoval, V., Jaca, C., Santos, J., Baumgartner, R. J., and Ormazabal, M. (2019). Key strategies, resources, and capabilities for implementing circular economy in industrial small and medium enterprises. Corp. Soc. Resp. Environ. Manag. 26, 1473–1484. doi: 10.1002/csr.1761

Resolução do Conselho de Ministros 190-A/2017 de 11 de dezembro (2017). Diário da República n° 236 – 1ª Série. Lisboa.

Resolução do Conselho de Ministros n°84/2016 de 21 de dezembro (2016). Diário da República n° 243 – 1ª Série. Lisboa.

Upadhyay, A. (2020). Antecedents of green supply chain practices in developing economies. Manag. Environ. Qual. doi: 10.1108/MEQ-12-2019-0274

Keywords: competences, circular economy, technological interface centers, survey, guidance and awareness, eco-design, resource efficiency, industrial symbiosis

Citation: Ferreira L and Matias R (2021) Mapping Competences of the Technological Interface Centers to Support the Transition of Portuguese Companies Toward the Circular Economy. Front. Sustain. 2:739052. doi: 10.3389/frsus.2021.739052

Received: 09 July 2021; Accepted: 15 September 2021;

Published: 15 October 2021.

Edited by:

Mariale Moreno, Universidade de Lisboa, PortugalReviewed by:

Raffaella Taddeo, University of Studies G. d'Annunzio Chieti and Pescara, ItalyCopyright © 2021 Ferreira and Matias. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Luís Ferreira, bHVpcy5mZXJyZWlyYUBhbmkucHQ=

†These authors have contributed equally to this work and share first authorship

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.