- Department of Food Science, University of Guelph, Guelph, ON, Canada

Co extrusion sausage technology has been a game changer in the industry as it has transformed the traditional way of filling meat betters into premade casings (e.g., synthetic materials such as cellulose or natural casings) to producing the casings on top of the meat batter as it comes out of the stuffer. This allows full automation of the process (working 24/7) with lower waste, while also increasing food safety standards. The main material used is collagen which today is extracted from a limited type of beef hides. It is then treated with a strong alkaline solution, to breakdown some of the original structures, and later with a strong acid to allow swelling of the resulting suspension. The application of the collagen gel requires special equipment to line up the collagen fibers in such a way that they provide the strength and elasticity during the cooking operation (meat expends during cooking) and later provide the consumer with the characteristics bit/“snap” similar to natural casings. Understanding the interactions between the chemical and physical properties of collagen is essential in obtaining good results. During production it is important that the collagen is quickly dried and crosslinked so the shape of the product will not be modified. This requires special large horizontal dryers and a unit to apply liquid smoke (source of aldehydes for crosslinking). Currently most systems are built for large capacity production, and therefore require large investment, however the industry is working on developing smaller and more flexible units for future use.

1 Introduction

The meat industry produces many types of meat products but is also known to be a fairly conservative industry. The products can be divided into three main categories: whole muscle, ground, and finely chopped meat products. The last two groups are the ones usually stuffed into casings. However, it should be mentioned that in the ground meat category we also find quite a few products that are not stuffed into casings (e.g., hamburgers, nuggets). Casings are used to hold a portion of the meat, give it a certain shape during cooking (until proteins denature and solidify) and later can stay on the product or be peeled off (i.e., edible and nonedible casings such as cellulose). If they stay on the product, they can also influence the textural properties of the sausage (e.g., natural and some fabricated collagen casings produce the typical “snap”). The oldest method of producing sausages has been with natural casings which has been used for thousands of years (Anonymous, 1990; Savic and Savic, 2016). This technology is still very popular today. It is interesting to note that only over the past 120 years new casing types have been introduced, including the ones manmade with cellulose, cotton fibers, prefabricated collagen, and plastic polymers. The development of those materials took place because they can be mass-produced, easier to apply, more economical, and easier to use at high-speed production lines/automated equipment. This is mainly because they are much more uniform and possess consistent strength compared to natural casings. Co-extrusion collagen technology has been introduced only in the late 1970s (Burke, 1980; Kobussen et al., 2000). This technology has been a game-changing factor to the meat industry as co-extrusion involves forming the casings on top of the meat batter as it comes out of the stuffer, while the traditional casings (e.g., natural, cellulose, plastic) are brought to the plant and then filled/stuffed with meat. One of the big differences from the traditional premade casings is a need for a mechanism to quickly crosslink the collagen paste and form a rigid “envelope” around the product (the exact technology is discussed later). One of the major advantages of this technology is allowing more automation which is critical today when we face labor issues in the food industry. Another important advantage is related to food safety where we can remove people from the production line and also use cook-in-the-bag technology. This means that the product is not touched by people and later heat processed inside the bag, thus avoiding the need to later peel off the casings (e.g., cellulose casings commonly used in many high-volume hot dog production lines today). The removal of the casings from the fully cooked products at the processing plant provides an opportunity for post-cooking contamination. Overall, we have experienced a few major Listeria outbreaks in fully cooked meat products over the past few years (Howell and Miller, 2010; Kurpas et al., 2018). As will be discussed below, the co-extrusion technology also presents some big challenges to meat processors as cooking meat products in a closed package while they are touching each other can result in adhesion of adjacent products, etc. It should also be mentioned that from a sensory point of view, natural casings (sheep, hog, and bovine) still represent the gold standard for casings as they provide the unique and familiar “snap”/bite to sausages. This occurs because of the unique structure of the connective tissue in the GI tract which is composed of aligned collagen and some elastin fibers which together allow some stretching of the casings. The latter is important to the meat processor as the casings can expand during stuffing and heating, and later creating the “snap” effect. The concept of this new co-extrusion casings mainly relies today on collagen; however, this collagen has to first be extracted (mostly from selected beef hides), then limed (exposed to high pH) to break down some of the structures, followed by acidification to allow swelling of the collagen gel. Performing the extraction process in the right way is essential to obtain high quality collagen gel, as will be discussed below.

The advantage of using a collagen gel is the fact that the equipment can produce a very uniform casing with controlled thickness and strength as compared to using natural casings which can have weak spots, variation in diameter, and sometimes even holes/tears. The latter defect is usually caused by the cleaning process of natural casings while the formers are due to natural variation in biological specimens (Bakker et al., 1999). The occurrence of those things usually requires stopping the whole stuffing process and starting a new batch of casings (i.e., not ideal for automation, and results also in wasting some of the meat).

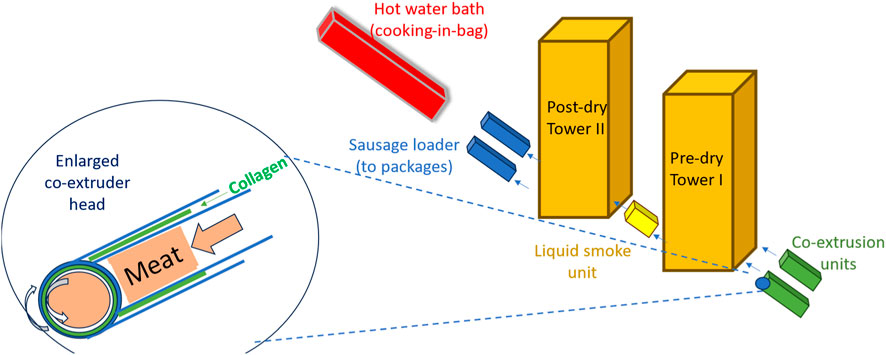

It should also be noted that today there are co-extrusion systems utilizing alginate which employ hydrocolloid gum (obtained from seaweed) and dispense it on the surface of the product and later crosslink it with calcium ions (Harper et al., 2015; Hilbig et al., 2020). However, on a worldwide basis, those systems represent a small market segment, although in certain regions can have a noticeable presence. They will not be discussed here in great detail because of their low representation in the market and because their technology is not as complicated as the collagen co-extrusion. The latter refers to dealing with collagen fibers that need to be aligned around the product to provide strength as well as the unique “snap” (not achieved by alginate) and therefore require special equipment (Figure 1).

FIGURE 1. Schematic setup of a co-extrusion system, showing the nozzle head with the two counter rotating shear rings (used to align the collagen fibers), and the relative size of the different units.

2 Advantages and limitations of using the technology

When introducing a new technology, the industry usually wants to be presented with three to four good reasons to embrace the technology and three to four limitations/disadvantages. A summary of those major points is provided, and those points are further discussed later in this Perspective.

2.1 Advantages

2.1.1 Fully automating the process

The co-extrusion process represents a game-changer as the meat batter, exiting the stuffer, is continuously coated with a collagen gel (commonly contains 4%–6% protein) that is later crosslinked, and heat processed. The traditional sausage stuffing process is a batch operation because it involves finite segments of casings that require stopping/changing the nozzle at the end of each casing’s portion/sleeve. Eliminating this step allows us to fully automate the process, save on labor, and work 24/7.

2.1.2 Improving food safety

Removing people from the line, and then cooking the product in edible casing placed in a hermetically sealed bag that is only opened by the consumer, represents a big improvement. This eliminates the possible post-cooking contamination by pathogens such as Listeria and Salmonella of fully cooked products which can happen during casing removal and packaging the individual cooked sausages (Kurpas et al., 2018). It also reduces the risk of spoilage bacteria contamination and hence significantly improves shelf life, reduces waste, and enhances sustainability.

2.1.3 Producing uniform products

Since the product is continuously coated with collagen gel, very accurate weight control can be implemented and continuously adjusted during the production day when small deviations are detected. Some of the systems have the capacity to check the weight of each individual link and automatically adjust the weight of the product so expensive give-away is minimal. Uniformity also helps in implementing automation as dealing with similar size and shape sausage links is much easier than dealing with products stuffed into natural casings.

2.2 Limitations

2.2.1 Investment cost

The current systems are very big and require a large investment in equipment and floor space. Figure 1 illustrates the equipment used, where a significant space/investment is required mainly for the drying towers. The first tower is used to pre-dry the casings, just after their application and submersion in a saturated salt solution (used to start dewatering). This is an important step as one needs to harden the casing quickly so the meat will not flow out. Actually, the drying is done when the casing is still unstable and therefore products are positioned horizontally and placed in baskets. This is followed by a liquid smoke bath/spray which is used to crosslink the collagen (via the aldehydes in the smoke) and further increase the casing’s strength (Hoogenkamp et al., 2015; Suurs and Barbut, 2020). The next stage is referred to as post-drying (at ∼60°C) and is used to continue drying and hardening the casings. The products coming out have a surface temperature of about 50°C–60°C and are not sticky anymore so they can be packaged in the so-called cook-in-the-bag plastic material. Bags are later submerged in hot water and fully cooked (heat conductivity of water is faster than air and thus more efficient than a regular smoke house; also, no evaporation losses encountered) which are other advantages of this technology. Due to the large investment, a company usually needs to already have a big market share of a certain product. This is currently the case for big companies that sell a large quantity of hot dogs, cocktail sausages, etc., where their traditional systems are working 24/7 and require quite a lot of manual labor. Depending on the production volume, the return on investment of a new co-extrusion system in such a case can be as low as 5 years.

2.2.2 Operation complexity

Operating the system requires substantial knowledge and understanding of material science, meat science, chemistry, and engineering. Integrating all those disciplines is important for the successful operation of the system. Paying attention to the different possible interactions (e.g., meat and casings while being formed together) is also crucial to optimizing such a high volume operation.

It is interesting to note that 40%–50% of the small diameter sausages produced in the United States are produced by co-extrusion (personal communication) and of that, over 50% of this amount is produced at one location. This location specializes only in co-extrusion and also provides co-packing services for the industry. There are a few large operations in Europe but not any significant one in South America, for example.

However, as will be described below, equipment manufacturers are currently working on designing smaller systems that will make it easier to change the product line. The current big system can produce 5 tons of product per hour with a three to four nozzle head, while the smaller systems will be designed for a few hundred kg per hour. Another factor that contributes to the complexity is the lack of enough technical literature and specifications of the gels (Suurs et al., 2022). Currently, most gel suppliers only post basic technical information of the products. This information includes items such as total protein content, pH, number of microorganisms (per g), but not engineering parameters such as viscosity at different temperatures, shear thinning behavior, etc.

2.2.3 Limited flexibility

The large systems are designed to produce a certain diameter product while all the production parameters (e.g., pre-drying, post-drying, cooking time) are preprogrammed and therefore usually can be very time-consuming to change/modify. However, it should be noted that similar diameter products made from chicken, beef, or pork can be produced without any special modifications. Overall, one should realize those systems are very cost effective when calculating the production of each sausage unit.

3 Discussion

3.1 The mechanical process of extrusion

Figure 1 shows the way the collagen is introduced onto the meat batter coming out of the stuffer. It is important to realize that a unique delivery system had to be developed for the deposition of collagen as it is crucial to line up the fibers in a certain way. This is to provide the strength needed for the casings to first go through the cooking process (expansion of the meat batter during heating) and later to provide a good bite (the “snap” effect) when consumers are eating the product. The system that has been developed has two counter rotating cones with a space, tapering off to a size of a few mm at the exit point. The collagen is pumped into that space and the counter rotating cones (commonly 100–300 rpm) force the lining up of fibers around the meat batter in such a way that the outer collagen layer has fibers going around the circumference of the product, the fibers in the middle are randomly distributed, and the inner fibers are again lined up around the circumference of the product. Hoogenkamp et al. (2015) reported on how the differential speed of the two counter rotating cones affect the arrangement of the fibers (using second harmonic single imaging and quantifying the fiber orientation) and later the shear force values of the resulting casings.

3.2 Sources and preparation of the collagen gels

These are very important aspects as collagen quality has a major effect on the strength and sensory characteristics of the meat product. Currently, the main source of collagen is the corium layer obtained from certain beef hides. The layer is found on the inside part of the ventral beef skin and usually appears as a white layer of connective tissue. It is removed prior to processing the beef hide into leather (i.e., a byproduct of the meat industry). The challenge is that collagen quality is affected by factors such as breed, age, nutrition, and climate conditions. Right now, the industry is getting the collagen from a very specific breed of beef animals raised at a few geographical locations where the industry knows it can provide the quality required. However, in the past few years, researchers and industry have been examining other sources such as corium and skin from other beef breeds (Suurs et al., 2023), and broiler skins (Oechsle et al., 2016), as those collagen sources also represent byproducts of the meat industry and are found in large quantities, but currently go into low value pet food/fertilizer use.

The preparation of the collagen is critical to achieve the optimal casing characteristics. It basically involves liming the corium layer (exposing it to high concentration of NaOH at pH 12–13) for a few days to break down some of the collagen structures (note: need to be careful not to overdo this as then the casings cannot be produced). This is followed by washing off the alkaline compounds, physically chopping the collagen (using a device similar to a home food processor) and then acidification with either HCl or organic acids to allow swelling of the collagen paste. Oechsle et al. (2016) describe precisely how different acids and the salts of the Hofmeister series affect the swelling of a collagen paste. Hood (1987) nicely described the effects of different pH values on collagen swelling, where swelling maxima is seen under high alkaline and acid conditions (pH 12 and 2, respectively). Of particular interest is pH 2–3 (i.e., most common pH of commercial casing gels), which also demonstrate maximal gel viscosity, a firmer and more translucent gel.

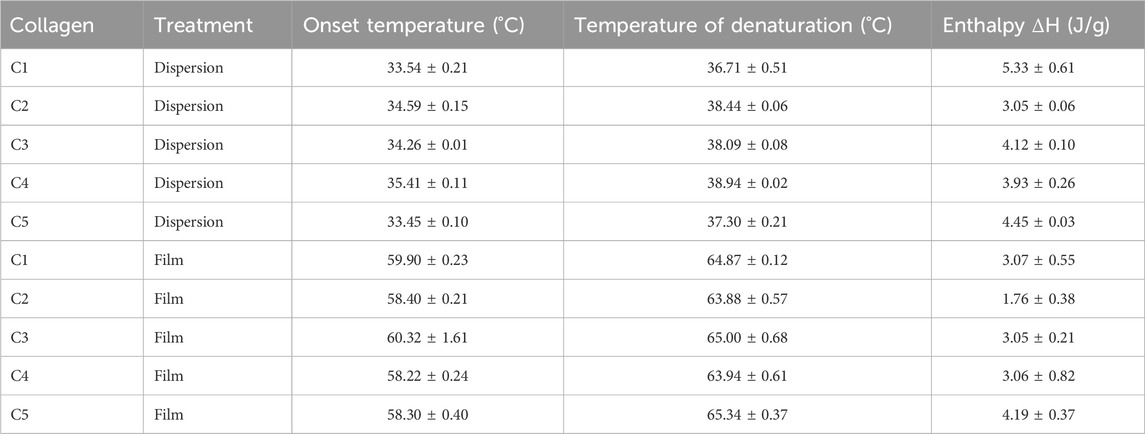

It is important to note that native collagen shows a denaturation transition point at about 60°C (Bernal and Stanley, 1986). After liming and acidification, the denaturation point goes down to about 34°C (Table 1). This is a very important point to understand when using collagen for coextrusion because later the collagen (on the sausage) goes through other modifications while being exposed to the brining process (saturated salt solution) and crosslinking by the aldehydes found in liquid smoke. Overall, crosslinking is an essential part of the process and currently liquid smoke which contains aldehydes is used as the chemical linker. This results in the denaturation point doubling and reaching about 62°C (Table 1). It should also be mentioned that collagen from commercial sources (C1 to 5, see Table 1) exhibit different tensile strength after being crosslinked. For example, the tensile strength of C1 is significantly greater than C3 (0.67 vs 0.38 MPa), while the corresponding percent elongation is 24.8% versus 18.8%, respectively (Barbut and Ioi, 2019). Suurs et al. (2022) also reported that the elastic modulus (G’) curves of coextruded collagen films exposed to heating (5°C–60°C) show a big drop at about 35°C. The exact temperature depended on the source of poultry collagen evaluated (i.e., obtained from young chickens of fast- and slow-growing rates, and older laying hens or broiler breeders). Pretty similar observations were also reported for different sources of cattle collagen (American calves, heavy Dutch veal, ox/heifer, and heavy German cows. Suurs et al., 2023).

TABLE 1. Analysis of endothermic peaks from differential scanning calorimetry (DSC) thermograms of five commercial co-extrusion collagen samples (C1 to 5) tested as collagen dispersions coming out of the box, and as partially dehydrated/brined films. From Barbut et al. (2020).

3.3 Work on improving collagen gels

Only a few academic labs around the world are working on this topic (e.g., Hohenheim University, Wageningen University, University of Guelph) as well as the very few collagen companies involved in the business (their data is confidential). The current source of collagen demonstrates pretty good functionality but is obtained from a very limited group of beef animals. Over the past decade there have been attempts to use other sources such as corium layer from other beef animals, chicken skins, and pork bladder. It should be mentioned that currently there is a limited source of poultry collagen on the market, but the goal is to be able to obtain large amounts of collagen from different species (e.g., overcome religious concerns) and upgrade byproducts of the meat industry, currently going to low-cost streams. Oechsle et al. (2017) reported on the possible modification of extruded chicken skin collagen films and telopeptide-poor collagen from bovine hide by adding salt (0.05 mol/kg) and/or partial substitution by 1.25% soy isolate. Salt addition allowed forming beef and chicken collagen films with high tensile strength and elasticity. In contrast, substitution with soy proteins decreased gel and film strength. This weakening could be compensated by adding salt and leading to more homogenous gels yielding films with higher storage moduli. The compensating salt effect was more pronounced for chicken skins than for beef hides, suggesting differences in the molecular interactions and networks forming between the two collagen types. Later, Suurs et al. (2022) looked at different poultry skin sources (young and old broilers) as potential raw materials. Collagen transition temperatures analysis and SDS-page showed little difference in these parameters among the different sources. However, after exposure to the saturated salt solution, forming films from older broilers (breeders and laying hens) was very poor. The authors concluded that chicken skin collagen from fast and slow growing young broilers has the potential of being a suitable source for co-extrusion. Suurs et al. (2023) also evaluated different cattle skin collagens and reported that American calves, Dutch heavy veal, and Danish ox breeds are potential suitable alternative collagen sources while the German cow breed is not.

3.4 Work on new production systems

Currently, only large collagen production systems are offered to the industry. However, some equipment manufacturers are considering supplying smaller systems that can be much more versatile in terms of changing product lines in a fast and non-complicated manner. Those systems should be able to produce a few hundred to thousand kg per hour, be much less costly and allow meat companies to quickly change various parameters (e.g., nozzle diameter, gel application rate). Such systems can potentially open the market for medium and small processors to adopt the co-extrusion technology while not having to invest large sums for the infrastructure. One of the ideas is to also offer modular systems that can be expanded later on.

4 Summary

Overall, the co-extrusion collagen concept has been a game changer in the industry, allowing fully automated small diameter sausage production. When comparing to, for example, a natural casing stuffing operation which requires a substantial amount of manual labor, the co-extrusion system presents a major advantage in cost-savings and waste-reduction (natural casing operations require initial labor-intensive cleaning of the casings, dealing with rupture of casings, and discarding products’ ends). The concept is also major step in improving food safety as cook-in-the package technology can be used to prevent post-cooking contamination, and also increase shelf life while reducing waste (collagen is an edible material as opposed to the large amount of cellulose casings used to process the product and then removed after 2–3 h). However, currently using the technology requires a big investment in equipment and employing a certain number of highly skilled people. It is expected that a new smaller system will be available on the market and open the way for small/medium size companies to also adopt the technology.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

SB: Conceptualization, Resources, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. No special funding was awarded for this perspective article. The author is a faculty member at the University of Guelph.

Acknowledgments

The author would like to thank his previous students working in this area, and the organizers of the excellent first Soft Matter Conference: Drs. Ali Gilles, Alejandro Marangoni, Frank Alexis, and Mezzenga Raffaele.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bakker, W. A. M., Houben, J. H., Koolmees, P. A., Bindrich, U., and Sprehe, L. (1999). Effect of initial mild curing, with additives, of hog and sheep sausage casings on their microbial quality and mechanical properties after storage at difference temperatures. Meat Sci. 51 (2), 163–174. doi:10.1016/s0309-1740(98)00118-1

Barbut, S., and Ioi, M. (2019). An investigation of the mechanical, microstructural and thermo-mechanical properties of collagen films cross-linked with smoke condensate and glutaraldehyde. Italian J. Food Sci. 31 (3), 644–660.

Barbut, S. M., Ioi, M., and Marcone, M. (2020). Co-extrusion of collagen casings - effects of preparation, brining, and heating on the strength, rheology, and microstructure. Italian J. Food Sci. 32 (1), 91–106.

Bernal, V. M., and Stanley, D. W. (1986). Changes in the melting characteristics of bovine tendon collagen induced by a bacterial collagenase. J. Food Sci. 51, 834–835. doi:10.1111/j.1365-2621.1986.tb13944.x

Harper, B. A., Barbut, S., Smith, A., and Marcone, M. F. (2015). Mechanical and microstructural properties of “wet” alginate and composite films containing various carbohydrates. J. Food Sci. 80, E84–E92. doi:10.1111/1750-3841.12716

Hilbig, J., Hartlieb, K., Gibis, M., Herrmann, K., and Weiss, J. (2020). Rheological and mechanical properties of alginate gels and films containing different chelators. Food Hydrocoll. 101, 105487. doi:10.1016/j.foodhyd.2019.105487

Hood, L. L. (1987). “Collagen in sausage casings,” in Advances in meat research - vols. (New York, NY, USA: AVI Books -Van Nostrand Reinhold Company Inc).

Hoogenkamp, H. R., Bakker, G.-J., Wolf, L., Suurs, P., Dunnewind, B., and Barbut, S., (2015). Directing collagen fibers using counter-rotating cone extrusion. Acta Biomater. 12, 113–121. doi:10.1016/j.actbio.2014.10.012

Howell, G. V. J., and Miller, R. (2010). Maple leaf foods: crisis and containment case study. PCR 1, 47. doi:10.5130/pcr.v1i1.1297

Kobussen, J., Kobussen, M., and Alexander, D. (2000). Brine formulation for curing extruded sausage strand. (United States Patent 6054155). Available at: https://www.freepatentsonline.com/6054155.html.

Kurpas, M., Wieczorek, K., and Osek, J. (2018). Ready-to-eat meat products as a source of Listeria monocytogenes. J. Veterinary Res. 62, 49–55. doi:10.2478/jvetres-2018-0007

Oechsle, A. M., Akgün, D., Krause, F., Maier, C., Gibis, M., and Kohlus, R., (2016). Microstructure and physical–chemical properties of chicken collagen. Food Struct. 7, 29–37. doi:10.1016/j.foostr.2016.02.001

Oechsle, A. M., Bugbee, T. J., Gibis, M., Kohlus, R., and Weiss, J. (2017). Modification of extruded chicken collagen films by addition of co-gelling protein and sodium chloride. J. Food Eng. 207, 46–55. doi:10.1016/j.jfoodeng.2017.03.017

Savic, Z., and Savic, J. (2016). Sausage casings. 2nd. Victus International GmbH, Vienna, Austria. Available at: https://search.worldcat.org/title/sausage-casings/oclc/961939942?referer=di&ht=edition.

Suurs, P., and Barbut, S. (2020). Collagen use for co-extruded sausage casings – a review. Trends Food Sci. Technol. 102, 91–101. doi:10.1016/j.tifs.2020.06.011

Suurs, P., Van Den Brand, H., Daamen, W. F., and Barbut, S. (2022). Properties of different poultry skins sources in relation to co-extruded sausage casings. Food Hydrocoll. 125, 107434. doi:10.1016/j.foodhyd.2021.107434

Keywords: automation, sausage casings, collagen, meat industry, co-extrusion technology

Citation: Barbut S (2024) Advancement in automation of co-extrusion collagen casings. Front. Soft Matter 4:1356641. doi: 10.3389/frsfm.2024.1356641

Received: 15 December 2023; Accepted: 31 January 2024;

Published: 15 March 2024.

Edited by:

Ali Miserez, Nanyang Technological University, SingaporeReviewed by:

Daniel Dikovsky, Technion Israel Institute of Technology, IsraelCopyright © 2024 Barbut. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shai Barbut, c2JhcmJ1dEB1b2d1ZWxwaC5jYQ==

Shai Barbut

Shai Barbut