- 1Department of Chemical Engineering, Taibah University, Madinah, Saudi Arabia

- 2Department of Industrial Engineering, Taibah University, Madinah, Saudi Arabia

- 3Department of Civil Engineering, Taibah University, Madinah, Saudi Arabia

- 4Ministry of Municipalities Rural Affairs and Housing (MOMRAH), Riyadh, Saudi Arabia

By 2030, the Kingdom of Saudi Arabia (KSA) is seeking to increase homeownership to 70%. This has led to a considerable investment in residential construction, with the Housing Ministry establishing a stimulus program to enhance the use of Modern Methods of Construction (MMC). These technologies offer several benefits, including cost and time reduction, improved quality and productivity, and job creation. This study quantitatively analyzes the economic impacts of MMC adaptation on the Saudi economy using the Global Trade Analysis Project (GTAP) model. It considers incentives to adopt MMC, its technological advancements, and the skills currently available in the Saudi labor market. Moreover, the embodied carbon emissions of MMC are calculated using the Input–Output Life Cycle Assessment Approach (IO-LCA); the detailed environmental emissions from the transportation phase, accounting for material reduction, are assessed using the COPERT model and compared to conventional construction. The results reveal an increase of 1.92% in Saudi GDP, along with improved welfare of $28.5 billion and a notable increase in the sectors related to construction. Job creation is demonstrated by an increase in the employment of unskilled and skilled labor by 2.02 and 1.5%, respectively. The paper concludes that MMC’s total embodied carbon emissions were approximately 77 million metric tonnes CO2, while its transport-related emissions are less than conventional approaches.

1 Introduction

The 2030 Vision of the Kingdom of Saudi Arabia (KSA) envisages a progressive future based on the integration of the three interconnected pillars of sustainability, i.e., economy, society and environment. Firstly, economic sustainability is being targeted through growing and diversifying the economy, including supporting innovation, easing market entry for foreign investors, and integrating into the global economy. Secondly, social sustainability is being achieved by encouraging the participation of women and young people in the labor market, along with supporting the non-profit sector and attracting talent regardless of origin. Thirdly, environmental sustainability is being prioritized as the umbrella factor encompassing both economic and social systems (Alshuwaikhat and Mohammed, 2017; Almutairi and Alahmadi, 2023). The KSA has, along with other countries, committed to the Paris Agreement, pledging to curb carbon dioxide emissions by 130 million tons CO2 by 2030 (The intended nationally determined contribution of the Kingdom of Saudi Arabia under the UNFCCC | Arab National Development Planning Portal, 2021), now updated to 278 million tons of CO2 (Ghanem and Alamri, 2023). Furthermore, the country has announced initiatives and programs aligned with the agreement as part of Vision 2030. During the G20 summit in 2020, Saudi Arabia introduced the circular carbon economy scheme to control greenhouse gas emissions (Vahrenkamp et al., 2021; Shehri et al., 2023). In addition, the country launched the Middle East Green initiative in 2021, signifying its commitment to ensuring global sustainability and combatting climate change (Ghanem and Alamri, 2023).

Several high-energy sectors are responsible for greenhouse gas emissions, including industry, buildings, and land transportation. In particular, the construction industry, which forms the focus of this paper, is responsible for over 30% of anthropogenic emissions and is considered a primary contributor to unsustainability (Horvath, 2004; Flower and Sanjayan, 2007; Bonilla et al., 2010; Chauhan et al., 2010; Cabeza et al., 2014; Chuai et al., 2015; Marzouk et al., 2017; Qi et al., 2020; Pakdel et al., 2021). However, this industry is also vital when it comes to meeting basic human needs, as well as being crucial for economic development (Ogunmakinde et al., 2022). The Saudi National Housing Strategy Program (SNHSP) therefore aims to increase homeownership from 62% in 2020 to 70% by 2030 (Saudi Vision2030, 2018) while simultaneously highlighting the vital need for sustainability of the construction industry (Lee et al., 2009; Ortiz et al., 2009; Hamida et al., 2020).

There are many aspects of the construction industry responsible for the emission of gasses, including: firstly, concrete and reinforcement steel; secondly, construction waste; thirdly, the use of diesel by machinery; fourthly, electricity, gasoline and water; and finally, the transportation of building materials (Dimoudi and Tompa, 2008; Mao et al., 2013; Pacheco-Torgal et al., 2014; Hong et al., 2015; Liu et al., 2018; Pakdel et al., 2021). Although carbon emissions are generally lower during construction than those in the operational phase, construction-based emissions cannot be disregarded. For one, they are concentrated over a shorter period compared to a building’s operation (Wang et al., 2015). Moreover, the amount of carbon released during construction is currently increasing despite being considerably mitigated during a building’s operation due to energy efficiency regulations (Faludi et al., 2012; Tumminia et al., 2018). There is the potential to use cost and energy-efficient Modern Methods of Construction (MMC) compared to the traditional cast-in-situ method (Li et al., 2014; Tumminia et al., 2018; Du et al., 2021). It should be noted that the literature reveals disagreement concerning which construction method results in lower carbon emissions. This is particularly so for the transportation phase, which has the potential to result in higher carbon emissions even with MMC’s reduction of material waste. In addition, some studies treat the transportation phase as the sole difference between MMC and conventional methods. The current study, therefore, calculates the embodied carbon emissions of residential construction and focusses on the environmental emissions of transportation through the use of data from a leading MMC supplier in the Saudi construction market (Lim and Kim, 2020; Na et al., 2021; Wang and Sinha, 2021; Wang et al., 2023).

MMC can be considered a potential solution for the current shortage of housing (including affordable housing) in KSA, with the government planning to provide about 300,000 housing units per annum. The Ministry of Housing states that the country is expected to witness a demand for approximately 1.5 million new housing units by 2030 (Muhammad, 2017). Over the previous decade, the Ministry of Housing has addressed the rapid growth in the real estate sector by establishing a building stimulus program to utilize modern construction methods, including the adaptation of MMC. Furthermore, MMC has been heralded as introducing various benefits, including time and cost reduction, enhanced quality and productivity, and creating jobs for the youth. The Ministry of Housing has approved several MMCs, such as structural (i.e., concrete forms and light gage steel) and modular (i.e., concrete modular and modular light gage steel) MMCs. Along with its significant investment in housing, the Ministry of Industry (as represented by industrial centers) is now revitalizing the building technology sector, generating investment while enhancing innovation in MMCs (Ministry of Housing, 2022).

Furthermore, MMC has the potential to enable KSA compliance to align with international trends and meet its pledge to curb carbon dioxide emissions. Additionally, the successful utilization of MMC serves many initiatives and programs aligned with the Paris Agreement as part of Vision 2030. Thus, it is important to assess both the direct and indirect economic and environmental impacts of utilizing this new method of construction in KSA. This research investigates the sustainability of the MMC in KSA. To the best of our knowledge, this is the first study to examine this area. The organization of the paper is as follows. Section 2 introduces MMC technology, including its advantages and disadvantages. Section 3 outlines the methodology and describes the modeled scenario. Section 4 discusses the results and Section 5 presents the conclusion and implications.

2 MMC and its advantages

The literature contains various definitions of MMC in different parts of the world, being described as: Off-Site Production (OSP); Off-site Fabrication (OSF); pre-assembly; Off-site Manufacturing (OSM); and Industrialized Buildings System (IBS). Asia tends to use the terms OSF and IBS (Mohamad Kamar et al., 2014), while the UK favors MMC, and the USA and Australia tend to use the term OSM (Arif and Egbu, 2010; Smith, 2011; Švajlenka and Kozlovská, 2017). To avoid confusion, this paper refers to MMC.

MMC can be perceived as an aggregate term, used to depict creative and inventive development techniques, consisting of technologies whose structures and components are manufactured at plants (Meacham, 2022). According to the National Audit Office (The National Audit Office, 2005), MMC is defined as construction methods in which production processes are efficiently managed to gain more and improved products in less time. Therefore, the fundamental reason for the use of MMC can be seen as improving performance and building quality while minimizing waste and enhancing sustainability (Švajlenka and Kozlovská, 2017).

Gibb (2007) considered the most significant value for MMC to be its time-saving properties. Issues surrounding delays are inherently addressed due to the use of a skilled workforce to construct project components that will be transported from a factory to a site at a scheduled time (Arif et al., 2012). MMC enhances productivity (Tam et al., 2007) and shortens delivery times by about 30–50%, as all the activities of site development, foundations, and building construction can be parallelly performed (Van Mulligen, 2012). Lawson et al. (2012) stated that MMC reduces construction time by at least 50% compared to site-intensive building. In a questionnaire developed by Almutairi et al. (2017), 63.8% of participants agreed that time reduction was their main reason for using offsite techniques. Gibb and Isack (2003) argued that the production quality and output consistency characteristic of MMC result from the controlled factory environment, in contrast to the uncertain conditions of a conventional construction site. Thus, the assembling conditions are controlled in a processing plant, which offers an exact norm of value (Mullens and Arif, 2006). Moreover, MMC enhances sustainability by reducing the environmental impact of a building, as well as the associated processes (Blismas and Wakefield, 2009), while the recycling of waste is considered far easier than that from conventional construction methods (Almutairi et al., 2017). In Hong Kong, a study by Jaillon et al. (2009) identified MMC as resulting in a 52% reduction in waste. Almutairi et al. (2017) found MMC to decrease the wastage of building materials. As stated above, sustainable intervention in the construction industry is vital for mitigating its environmental impact, as well as reducing cost and material waste to enhance sustainability. This can all be largely achieved through the use of MMC. On the other hand, there are barriers and limitations to the adoption of MMC. Accurate planning is required as the process involves complex components that should be designed, produced, transported and assembled. The logistics of transportation are very challenging as the amount and size of the materials require heavy trucks and unique concern for the roads and transported pieces. Furthermore, there is a high initial cost of establishing the manufacturing factory and required equipment for handling the components of MMC. As a final barrier to MMC adoption, a negative public perception of MMC results from a lack of awareness surrounding its positive aspects (Kyjaková and Bašková, 2016; Karthik et al., 2020; Razkenari et al., 2020).

3 Methodology

This study employs the Global Trade Analysis Project (GTAP), a common multi-region, multi-sector Computable General Equilibrium (CGE) model. The model includes a “regional household” account, which collects all regional incomes from taxes, as well as wages and rents paid to the elements of production, i.e., labor, capital, land, and natural resources. According to a Cobb–Douglas function, the regional household distributes income among private households, the government, and savings, with the latter being spent on investment. For each region, the three agents’ optimizing behaviors are described in the following lines. Profit maximization governs the behavior of firms, according to the Cobb–Douglas production function, in which the intermediate inputs and production factors are combined to produce goods. Demand from private households is governed by constant differences of elasticity, and government demand is governed by a Cobb–Douglas function. While the shares of expenditure across goods are constant in the Cobb–Douglas function, changes in consumers’ income have an impact on their demand for goods in the constant difference of elasticity function. In addition, the decision to buy domestic or foreign goods is governed by the Armington assumption (Burfisher, 2011). More details on the GTAP model can be found in Hertel (Corong et al., 2017).

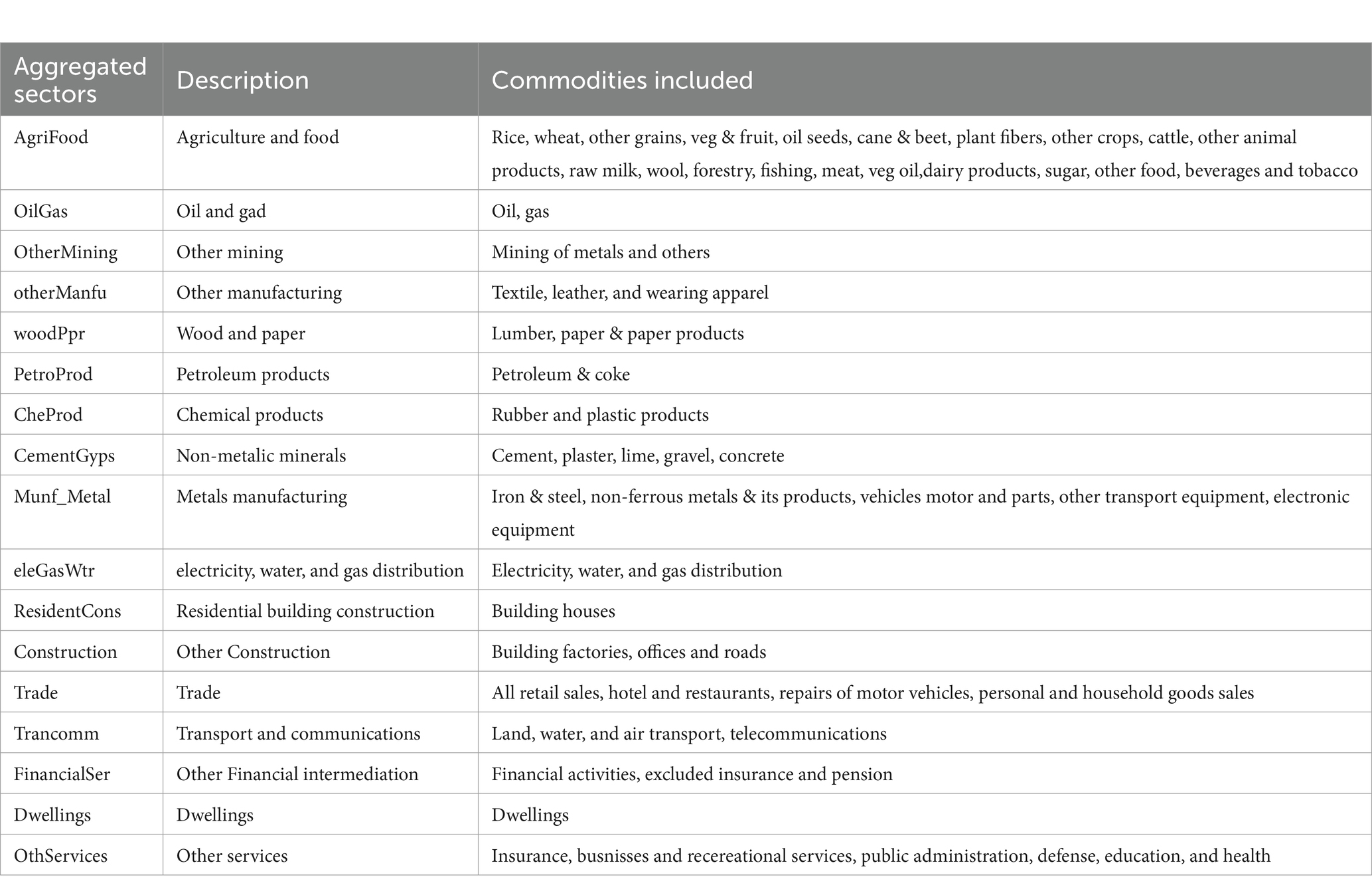

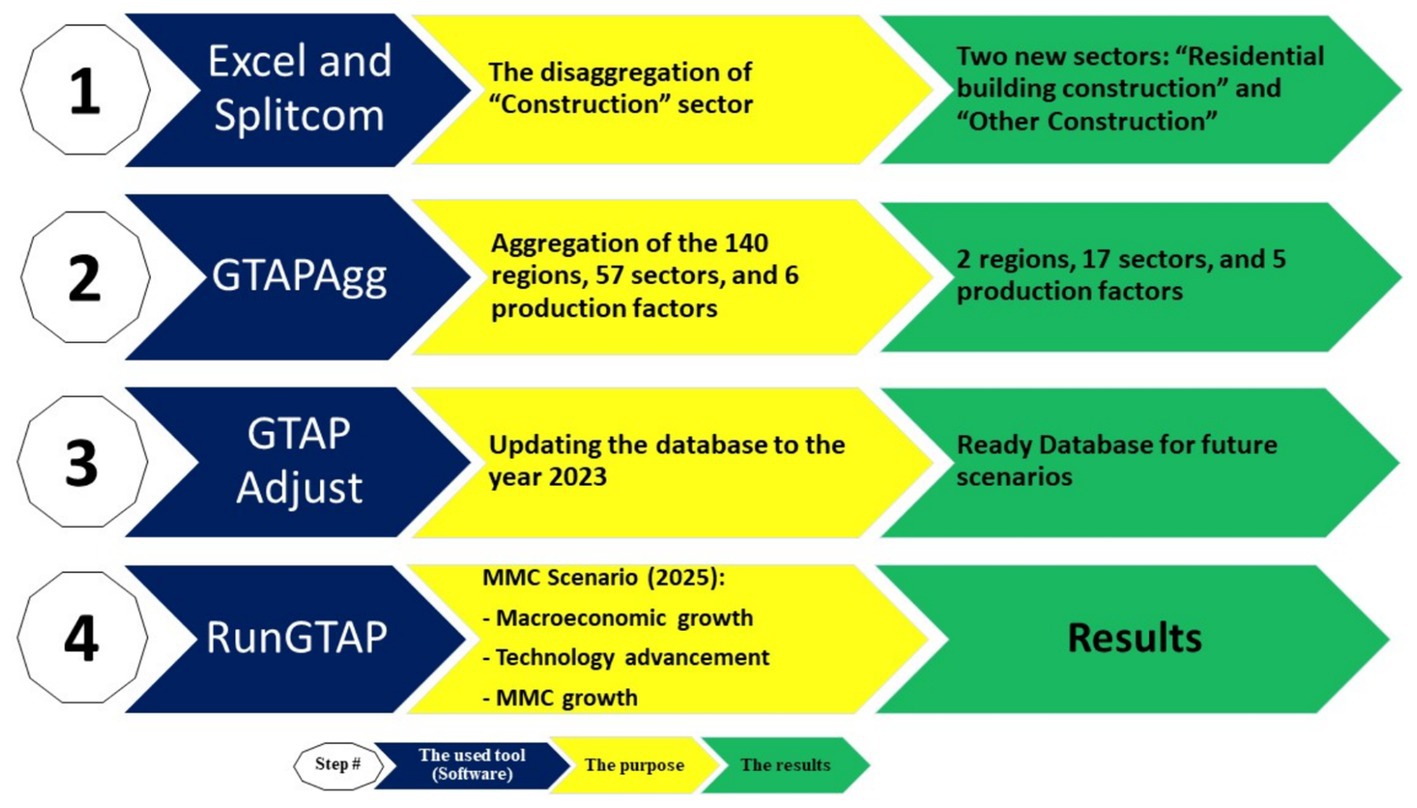

This study utilized the GTAP 9 database, which represents the global economy for the base year 2011. The dataset represents 57 commodities from 140 globally distributed regions (Aguiar et al., 2016). The study focused on examining the impact of the growth in residential building construction using MMC on different sustainable pillars in KSA. It employed multiple steps to disaggregate and update the database for the configured scenario, as shown in Figure 1. As the GTAP database includes one unique sector for construction, this sector represents all construction types, e.g., houses, factories, offices, and roads (GTAP Data bases: detailed sectoral list, 2019). As such, the first step is disaggregating the “Construction” sector in the GTAP database into two new sectors: “Residential building construction” and “Other Construction.” This disaggregation utilized data from the detailed input–output tables published by King Abdullah Petroleum Studies and Research Center (KAPSARC) (Soytas and Havrlant, 2020), whose table was constructed with an emphasis on the key targets of Saudi Vision 2030. The disaggregation was performed using SplitCom software (Horridge M., 2021), due to its ability to split GTAP flows while maintaining the integrity and balance of the database. The second step was to aggregate the 57 GTAP sectors, 140 regions, and 6 production factors into 2 regions, 17 sectors, and 5 factors of production. See Appendix 1 for more information on sectoral aggregation. The 17 GTAP aggregated sectors were chosen based on those most closely linked to the construction sector, being the main focus of the present analysis. The aggregation was carried out using the GTAPAgg program (Horridge J., 2021). See Table 1 for a summary of information on the regions, industries, and production factors. The third step concerned the reference year of the database, i.e., 2011. Thus, the database was scaled up to the most recent year through incorporating the economic growth by employing the GTAPAdjust tool (Horridge, 2011), which is a program allowing GTAP users to modify the database while maintaining its balances. This ensured the database was ready for any future scenarios and experiments.

Figure 1. The methodology employed for preparing and updating the database, and the configured scenario.

This study performed a GTAP modeling technique to examine the likely impacts of adopting MMC. The technique considered the incentive behind adoption, the technological features and improvement of this type of construction, and the labor types and market in KSA, alongside the assumed macroeconomic growth either in KSA or the Rest of World (ROW) for the year of the developed scenario, 2025. Through its Ministry of Housing, the Saudi government launched initiatives aimed at transforming the construction sector from a reliance on a traditional construction method to utilizing MMC, including financial incentives for investors (Saudi government adopts new building technology initiative, 2019). This is expected to increase the number of houses built by means of this new technology. As a GTAP technique, this was modeled by exogenously increasing the output of construction as a result of a provoking endogenous subsidy. In addition, the technological advancement of MMC was taken into account, as it is one of the important factors in the uptake of this method of construction (Hannah and Hunter, 2018). The growth in the residential construction sector was calculated from the number of residential electricity subscribers (Saudi Electricity Company Annual Reports, 2022) and the expected increase in number of residential units (future subscribers) (Algazal, 2019).

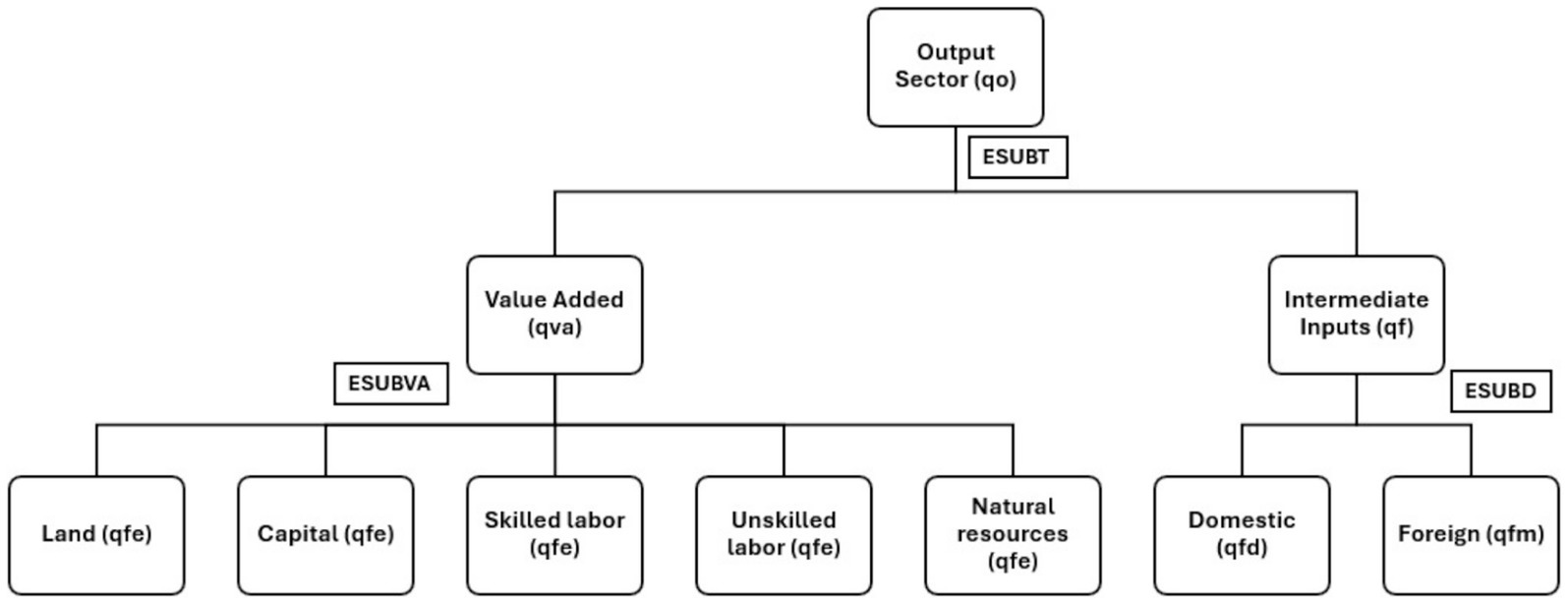

The principles of the simulation and how GTAP reacts to the modeled scenario are explained in the following. As shown at the top of Figure 2, the total output change (qo) in an industry (sector) is a combination of two bundles with no substation between them. These bundles are the intermediate inputs bundle and the primary factors (value added) bundle. The demand of the combination of the two bundles is defined in Equation 1 and 2, respectively.

where q represents quantity change; f, and va represent intermediate inputs and value added, respectively; a represents the augmenting technical change (productivity); p represents price change; o represents output change; ps represents changes in the supply price; i for the traded commodity, j for the sector, r for the source region; and ESUBT represents the substitution elasticity between the two bundles. Thus, from Equation 1 as an example, the increase in productivity is reflected in the model through different ways, e.g., reducing the required inputs, reducing the price of inputs, and altering the cost of the production unit. Moreover, the second-level nests of production in Figure 2 are disaggregated into two bundles: the intermediate inputs and the value added. First, the intermediate inputs bundle (qf) represents the intermediate demand of composite domestic (qfd) or imported (qfm) inputs and is defined as in Equations 3 and 4.

Where pfd and pfm represent the prices of domestic and imported inputs, respectively. ESUBD represents the substitution elasticity between domestic and imported inputs; and s is for the destination region. On the other hand, the value added bundle (qva) represents the demand for the factors of production as in Equation 5.

Where pva represents the price of primary composite of factors, and ESUBVA represents the substitution elasticity between the production factors (Corong et al., 2017).

For the environmental impacts, the well-known Input–Output Life Cycle Assessment Approach (IO-LCA) was used to calculate the total embodied carbon emissions of the residential construction sector. The IO-LCA is a top-down analysis type that gives a holistic estimate of needed resources of a product or service through its life cycle. It uses the economic interdependence between sectors to track the needed resources (Matthews et al., 2014). This product or service has two buyers; the first is the final consumer, which includes a private household, government, and importers. The second buyer is the other sectors that use that product or service as one of their intermediate inputs. The total environmental impacts (direct or indirect) E for each sector can be calculated using Equation 6:

Where R is a vector of environmental impact multipliers (in CO2 kg emissions/$ here); X is the total sector output (in $); I is the identity matrix; A is the technology matrix; and Y is the demand (in $). The number of sources were used to get the carbon emission multipliers of each sector (Steen-Olsen et al., 2014).

Transportation is considered one of the main contributors to the number of environmental implications of the building construction process due to the amount of materials required and the heavy-duty trucks used for their transport (Wang and Sinha, 2021). Moreover, and particularly with the MMC, transportation distance between the factory and the site may play a vital role in determining the sustainability of the MMC project. Also, transportation of the prefabricated modules and the utilizing of the heavy-duty trucks should be considered for the significant impact on the CO2 emissions (Seo, 2020). Ensuring environmental sustainability therefore relies on assessing and managing both the consumption and polluting emissions associated with these vehicles. Various methods are employed, broadly categorized into instantaneous and average models. Instantaneous models (i.e., EMIT and the VT Micro) are known for their sensitivity to maintenance parameters and vehicle-specific variations, necessitating precise adjustment of their parameters (Mądziel, 2023). In contrast, well-known average models include the American MOVES [United States Environmental Protection Agency (US EPA), 2023], HBEFA (Hausberger and Matzer, 2017), IVE [The Information Systems Security Research Center (ISSRC), 2008] and COPERT (European Environment Agency, 2023), with the latter being one of the most frequently used to assess vehicle consumption and emissions (Li et al., 2019). It has therefore been officially adopted, and is regularly updated, by European Union countries. The COPERT model is now utilized for the estimation of polluting vehicular emissions in Iceland, Turkey, Norway, Switzerland, and North Macedonia (COPERT Data, 2022). Its application has been successfully validated in China (Chen et al., 2023), Mexico (Mendoza-Sanchez et al., 2023), and KSA (Halawani and Rehimi, 2021).

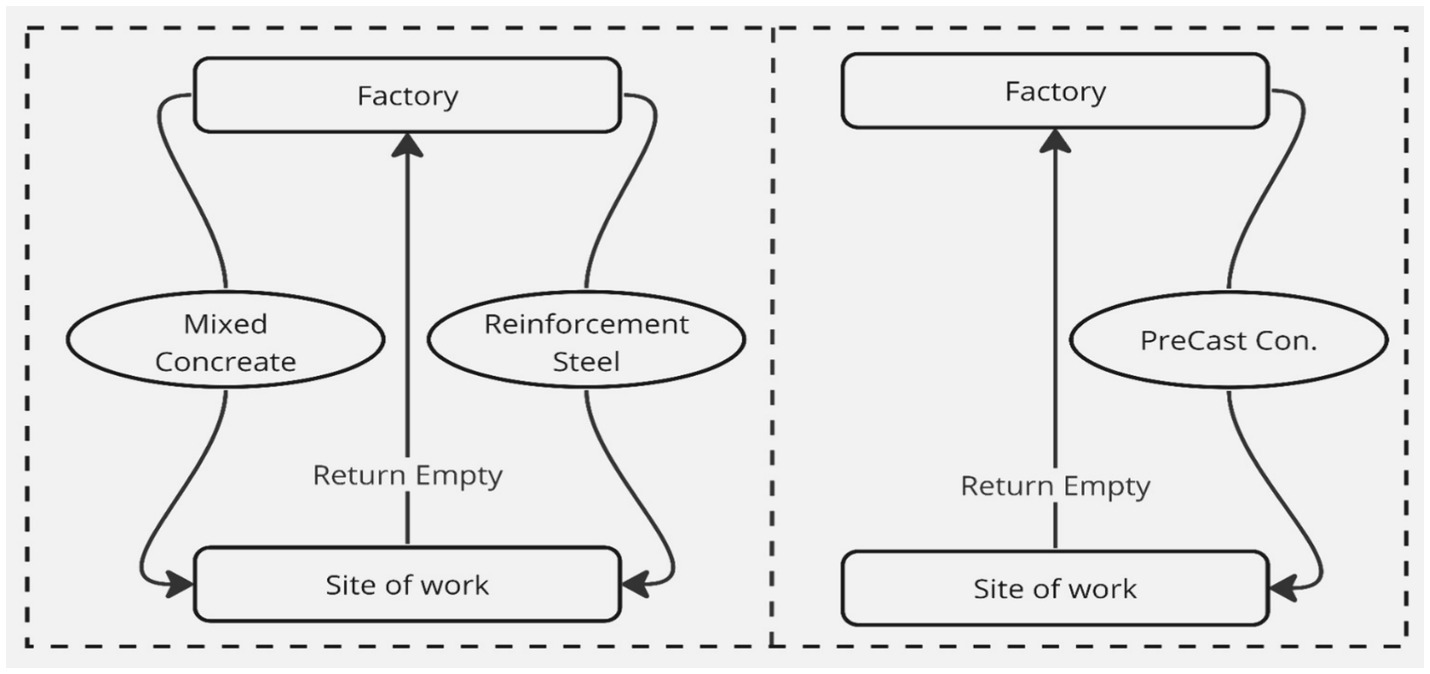

The COPERT 5.7 model was employed to estimate the emissions generated by the transport of one of the most common MMC types (the precast building) and compare this to the cast-in-situ method. The comparison was achieved using real data from a housing project constructed in the western region of KSA by the Al Kifah Precast Company (KPC). The total building area of a villa was 335 m2, involving a total quantity of precast concrete of 125 m3, estimated at 300 tons. The assessment of the consumption and emissions relays the data relating to the vehicle’s model, year of manufacturing, cylinder displacement, fuel type, and distance traveled. The average distance of travel was estimated based on the distance between the casting factory and the center of the new expansion zone of the city, which was found to be 40 km. Figure 3 shows a simplified schematic diagram of the vehicle trips included in the study. The COPERT 5.7 model uses the Euro classification, with the observed vehicular fleet consisting of Euro V, Euro IV, and Euro VI A/B/C vehicles, all using diesel.

4 Results and discussion

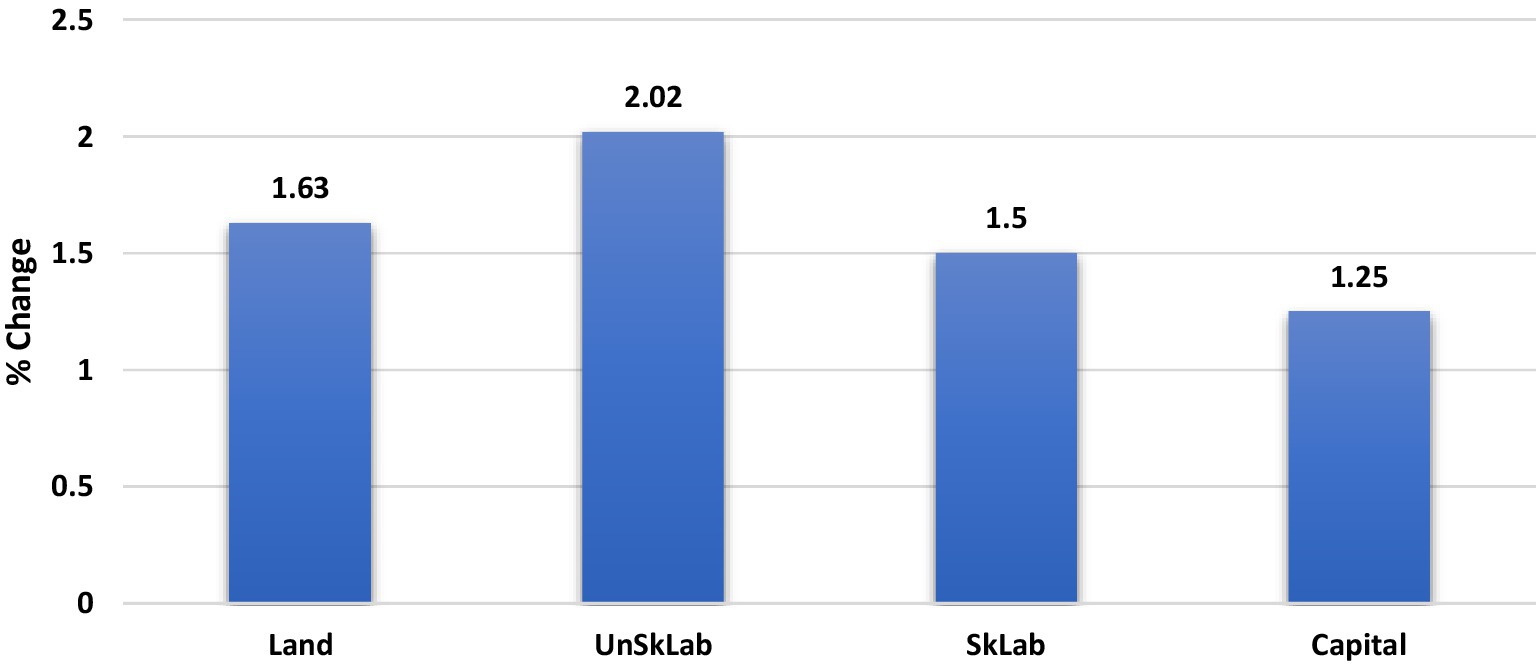

The model captured the direct and indirect impact of the growth of utilizing MMC. Considering the volume of investment required to meet the targeted number of houses, the incurred gain to GDP was found to primarily arise from the increase in investment, followed by consumption. The predicted GDP gain is 1.29% (about $13 billion) with welfare improvement of $28.5 billion. With the latter being evaluated with the Equivalent Variation EV, which measures the differences in expenditure for a region between the new level of utility (at post-shock prices) and the pre-shock level of utility. A positive EV indicates a welfare gain. In addition, the simulation shows an increase in private consumption by 1.73%, while the factors of production were found to increase as a result of the economic growth and considerable investment in MMC. As shown in Figure 4, the employment of unskilled and skilled labor increased by 2.02 and 1.5%, respectively. It is important to note that the labor market is modeled with an assumption of fixed wages, following the common Saudi salary structure system. Thus, the model adjustment occurs in the quantity of labor employed or laid off. Furthermore, land use increases by 1.63%, similar to the output increase of the AgriFood sector (i.e., it includes the agriculture sector). Moreover, the large increase in investment leads, as expected, to an increase in the capital factor of production.

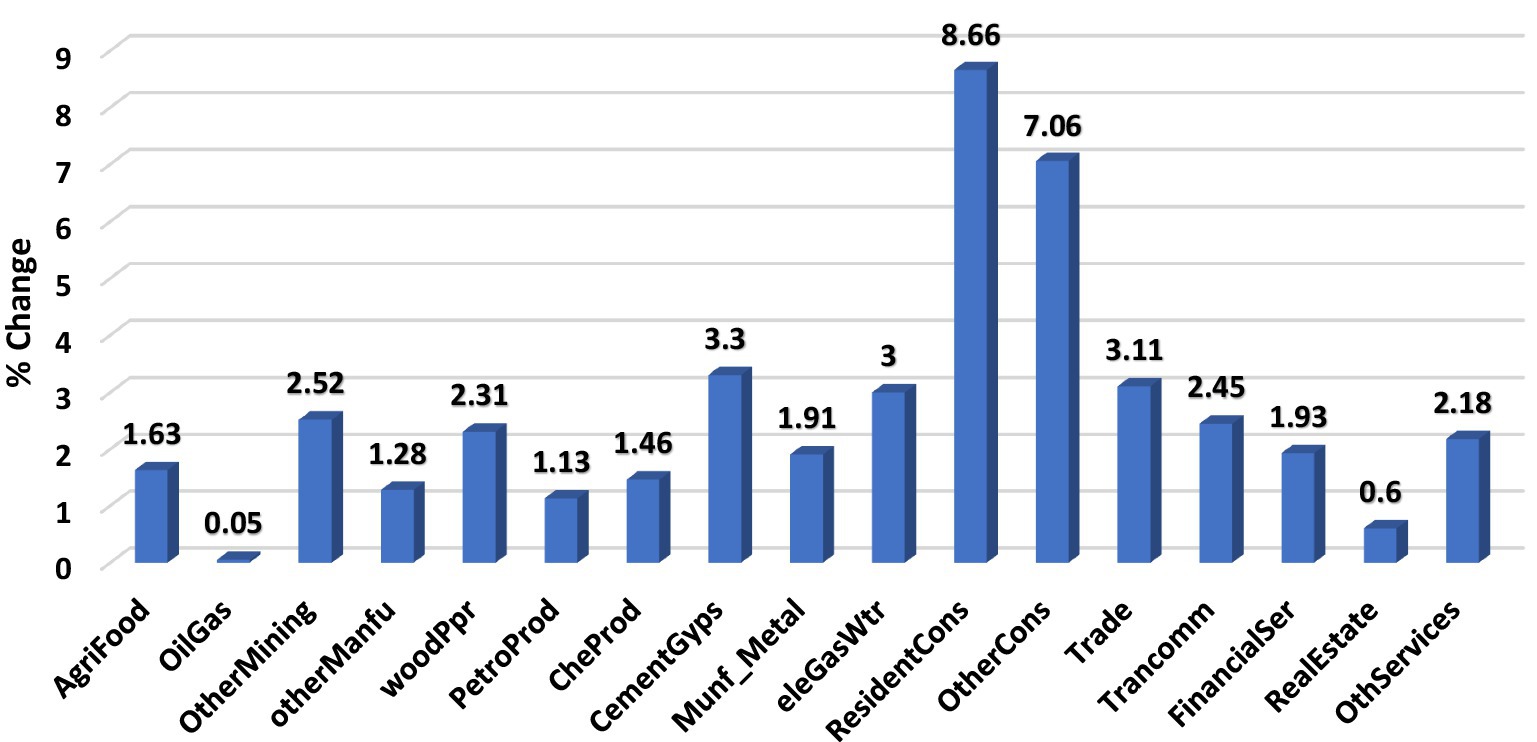

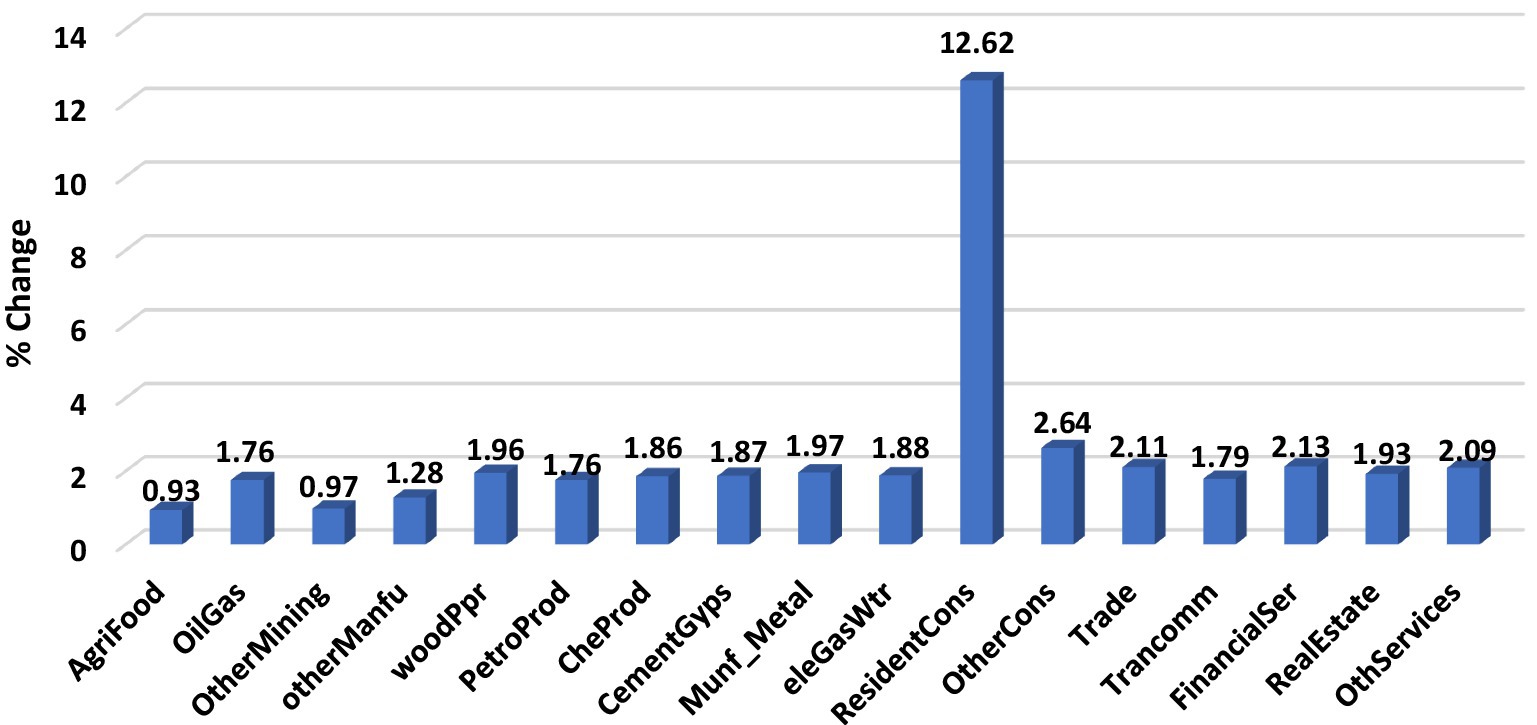

Figure 5 demonstrates the impact of MMC on the sectorial production outputs. Including that GDP growth, combined with the increase in employment and private household expenditure, leads to a rise in the production outputs of all sectors. The sectors linked the most to construction show a pronounced increase, as revealed in OtherCons, CementGyps, woodPpr, and Munf_Metal. Four sectors, consisting of the most popular consumer commodities, are shown to have experienced the greatest benefits from the rise in private household expenditure: (1) AgriFood; (2) eleGasWtr; (3) Trancomm; and (4) OthServices. Table 2 reveals the percentage change in prices for Saudi commodities, with generally small changes (positive or negative), apart from the residential construction sector (ResidentCons), in which prices decreased by 12.29%. Accordingly, the demand for this sector by private households (consumers) increased by 12.62%, as shown in Figure 6. The other sectors encountered a moderate increase in demand by consumers as a result of the rise in expenditure and employment.

Figure 6. Changes to the domestic demands of Saudi consumers within the default elasticity parameters.

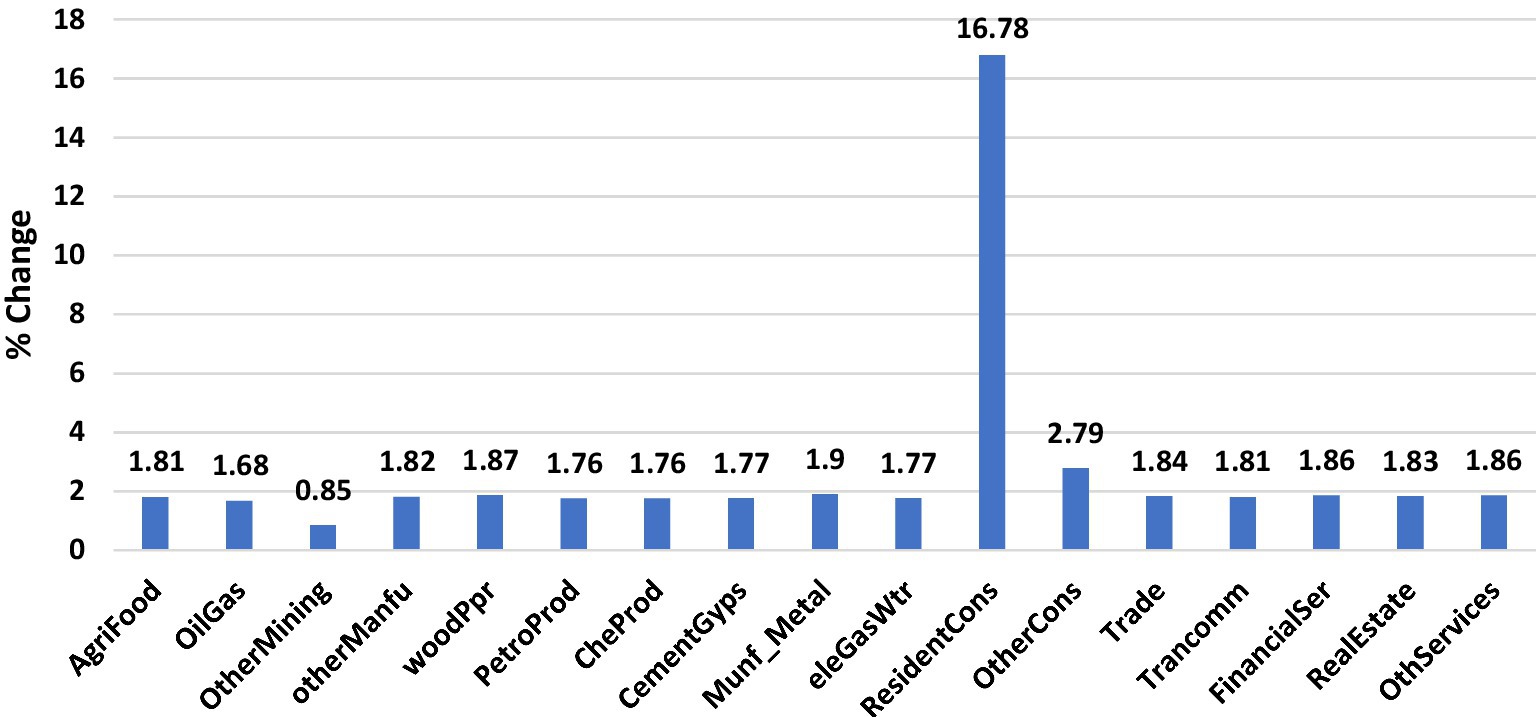

Once all the above-mentioned advantages have been taken into account, along with the promotional initiatives of the Saudi Ministry of Housing, MMC is expected to gain popularity and thus attract additional proponents. The impact of the change in MMC prices and consumer expenditure or income is expected to exert an impact on consumer preferences. Modeling consumer responses to these changes in prices and income is determined by CGE different utility functions. The choice of the utility function representing consumer preferences can be achieved through changes in the values of elasticity parameters of substitution and income. One of most common utility functions is Cobb–Douglas, which implies the fixed budget shares of all commodities in the consumer basket in the face of increased prices related to consumers’ income (Burfisher, 2011). If the cost of a commodity decreases by 10%, or consumer income increases by 10%, then the demand for that commodity increases by 10%. Figure 7 shows changes in domestic demand after modifying the elasticity parameters to represent the new consumer preferences. This reveals that the demand for the residential construction sector (ResidentCons) increased by 16.78% with the new preference modeling from 12.62% with the previous utility function. It is important to note that the default utility function consisted of the Constant Difference of Elasticity (CDE), which is a non-homothetic function, i.e., consumers tend to buy more luxury products as their incomes increase or prices decrease (Burfisher, 2011).

Figure 7. Changes to the domestic demands of Saudi consumers within the modified elasticity parameters.

5 Environmental emissions in MMC

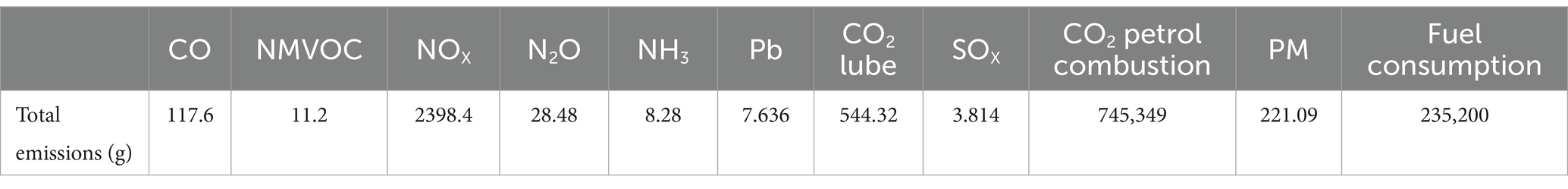

By using the IO-LCA method, the total direct and indirect carbon emissions of the planned residential construction in Saudi Arabia were found to be approximately 77 million metric tonnes CO2. This is about 12.6% of the total forecasted carbon emissions of Saudi Arabia according to King Abdullah Petroleum Studies and Research Center (KAPSARC) (Gasim et al., 2023). Regarding the transportation impacts, the resulting kilometric emissions of an average vehicle used for transporting precast concrete, as outlined in Table 3, was obtained according to the COPERT 5.7 model (European Environment Agency, 2023). See Table 4 for the total energy consumption, as well as the emissions generated by the fleet used to transport precast concrete for a complete villa with the specifications outlined above.

Table 3. Emission rates and fuel consumption (g/km) of an average vehicle used to transport precast concrete.

Table 4. Total emissions and fuel consumption (g/km) of vehicles used to transport precast concrete in the case study.

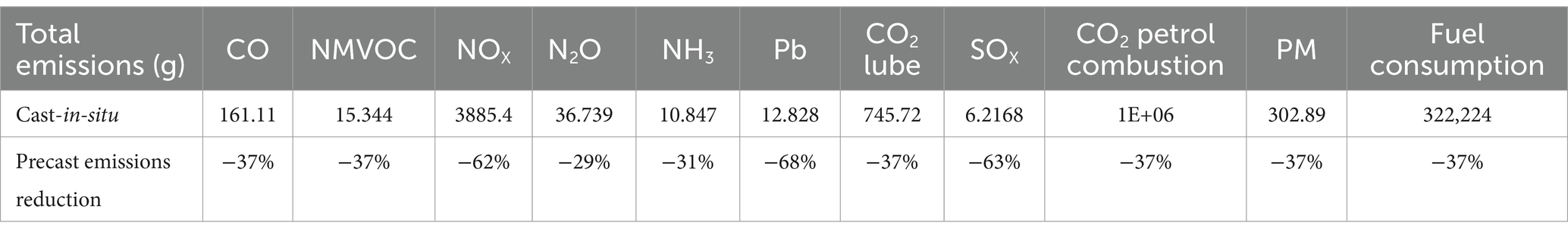

For comparison, the transport-related emissions for a villa constructed using conventional cast-in-situ concrete method were evaluated as shown in Table 5. According to the construction specifications, this study considered an estimated 32 metric tons of steel reinforcement and 367 cubic meters of concrete, including a clause representing industry norms accounting for issues with material waste, along with a 10% loss rate for mixed concrete with cast-in-situ technology (Wang and Sinha, 2021). Table 5 shows both total emissions of transport for a traditional cast-in-situ method and a comparison of emissions with a MMC technology (i.e., Precasting) and the traditional cast-in-situ method. This demonstrates that precast technology reduces transport emissions for all pollutants, ranging between 29% as in Nitrous Oxide (N2O) to 68% as in Lead (Pb).

Table 5. Comparison of total emissions and fuel consumption (g/km) of transport for precast and traditional cast-in-situ technology.

6 Conclusion

This study has established that Saudi Arabia is currently envisioning a progressive future based on the intertwined pillars of sustainability, i.e., economy, environment, and society. KSA’s economic initiatives aim to grow and diversify the economy, and they aim to support innovation and new ideas. KSA’s social measures focus on increasing the participation of women and young people in the labor market. When it comes to the environment, the country has introduced the circular economy to meet its commitment to curb its emissions, particularly as construction and housing causes over 30% of anthropogenic emissions. SNHSP’s focus on increasing housing ownership to 70% by 2030 demands sustainable intervention to ensure the economic benefits while mitigating any environmental impacts. This study concludes that MMC can play a crucial role in achieving the SNHSP’s ambitious target, including through the associated building stimulus program established by the Ministry of Housing, which aims to promote the adaptation of MMC to the Saudi building scheme. This promotion is based on several criteria, including firstly, lower levels of cost and time; secondly, improved quality and productivity; thirdly, the establishment of a more diverse economy; and finally, increasing employment opportunities.

This study has established that the potential economic impact of utilizing MMC in KSA can be quantified using the model of Computable General Equilibrium (CGE), which can track the outcomes of a change in a policy or technological improvement on the whole economy while considering the fundamental microeconomic behavior of consumers and producers. The analysis shows a positive GDP growth for the Saudi economy, mainly as a result of the increase in investment, and an increase in employment which matches an important government priority, particularly in a nation in which 63% of the population are under the age of 30. All sectors were found to be positively influenced, in particular those with a strong intersectoral to MMC. Moreover, the technological enhancement can be seen to reduce the cost of MMC which, as a new technology, has been subject to promotion by the Saudi Ministry of Housing to improve its popularity. The analysis shows that these initiatives have been proved to magnify the positive impacts of utilizing MMC. Finally, when it comes to the issue of environmental sustainability, the total embodied carbon emissions of the planned residential construction in Saudi Arabia were found to be approximately 77 million metric tonnes CO2. A detailed comparison of emissions in the transportation phase, one of the largest contributors to environmental impacts in the construction process, shows that MMC has less transport-related emissions compared to the cast-in-situ method.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

KA: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Software, Supervision, Validation, Writing – original draft. RA: Conceptualization, Investigation, Methodology, Validation, Visualization, Writing – review & editing. AH: Conceptualization, Methodology, Software, Validation, Visualization, Writing – review & editing. YA: Conceptualization, Data curation, Resources, Validation, Writing – review & editing. AA: Conceptualization, Data curation, Formal analysis, Validation, Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aguiar, A., Narayanan, B., and McDougall, R. (2016). An overview of the GTAP 9 Data Base. JGEA 1, 181–208. doi: 10.21642/JGEA.010103AF

Algazal, A. , (2019). Growth in the residential units. Available at: https://wtn.sa/a/1025635 (Accessed on February 26 2024).

Almutairi, K., and Alahmadi, R. (2023). Assessing the impact of the recent unprecedented world events on the economic and environmental conditions of Saudi Arabia. Sustain. For. 15:1610. doi: 10.3390/su15021610

Almutairi, Y., Arif, M., and Khalfan, M. M. A. (2017). Development of implementation strategies for offsite construction techniques in the Kingdom of Saudi Arabia. IJBCG 6:12. doi: 10.1504/IJBCG.2017.087526

Alshuwaikhat, H. M., and Mohammed, I. (2017). Sustainability matters in National Development Visions—Evidence from Saudi Arabia’s vision for 2030. Sustain. For. 9:408. doi: 10.3390/su9030408

Arif, M., Bendi, D., Sawhney, A., and Iyer, K. C. (2012). State of offsite construction in India-drivers and barriers. J. Phys. Conf. Ser. 364:012109. doi: 10.1088/1742-6596/364/1/012109

Arif, M., and Egbu, C. (2010). Making a case for offsite construction in China. Eng. Const. Arch. Man. 17, 536–548. doi: 10.1108/09699981011090170

Blismas, N., and Wakefield, R. (2009). Drivers, constraints and the future of offsite manufacture in Australia. Constr. Innov. 9, 72–83. doi: 10.1108/14714170910931552

Bonilla, S. H., Almeida, C. M., Giannetti, B. F., and Huisingh, D. (2010). The roles of cleaner production in the sustainable development of modern societies: an introduction to this special issue. J. Clean. Prod. 18, 1–5. doi: 10.1016/j.jclepro.2009.09.001

Burfisher, M. E. (2011). Introduction to computable general equilibrium models. 1st Edn. Cambridge, United Kingdom: Cambridge University Press.

Cabeza, L. F., Rincón, L., Vilariño, V., Pérez, G., and Castell, A. (2014). Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: a review. Renew. Sust. Energ. Rev. 29, 394–416. doi: 10.1016/j.rser.2013.08.037

Chauhan, S. K., Sharma, S., Shukla, A., and Gangopadhyay, S. (2010). Recent trends of the emission characteristics from the road construction industry. Environ. Sci. Pollut. Res. 17, 1493–1501. doi: 10.1007/s11356-010-0327-x

Chen, J., Cao, Q., Shen, X., Yu, X., Liu, X., and Mao, H. (2023). Driving factors and clustering analysis of expressway vehicular CO2 emissions in Guizhou Province, China. Environ. Sci. Pollut. Res. 31, 2327–2342. doi: 10.1007/s11356-023-31300-2

Chuai, X., Huang, X., Wang, W., Zhao, R., Zhang, M., and Wu, C. (2015). Land use, total carbon emissions change and low carbon land management in coastal Jiangsu, China. J. Clean. Prod. 103, 77–86. doi: 10.1016/j.jclepro.2014.03.046

Corong, E., Thomas, H., Robert, M., Tsigas, M., and Van Der Mensbrugghe, D. (2017). The standard GTAP model, version 7. JGEA 2, 1–119. doi: 10.21642/JGEA.020101AF

Dimoudi, A., and Tompa, C. (2008). Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 53, 86–95. doi: 10.1016/j.resconrec.2008.09.008

Du, Q., Pang, Q., Bao, T., Guo, X., and Deng, Y. (2021). Critical factors influencing carbon emissions of prefabricated building supply chains in China. J. Clean. Prod. 280:124398. doi: 10.1016/j.jclepro.2020.124398

European Environment Agency, (2023). COPERT - computer programme to calculate emissions from road transport.

Faludi, J., Lepech, M. D., and Loisos, G. (2012). Using life cycle assessment methods to guide architectural decision-making for sustainable prefabricated modular buildings. J. Green Build. 7, 151–170. doi: 10.3992/jgb.7.3.151

Flower, D. J., and Sanjayan, J. G. (2007). Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 12, 282–288. doi: 10.1065/lca2007.05.327

Gasim, A., Hunt, L. C., and Mikayilov, J. (2023). Baseline forecasts of carbon dioxide emissions for Saudi Arabia using the structural time series model and autometrics. Riyadh, Saudi Arabia: King Abdullah Petroleum Studies and Research Center.

Ghanem, A. M., and Alamri, Y. A. (2023). The impact of the green Middle East initiative on sustainable development in the Kingdom of Saudi Arabia. J. Saudi Soc. Agric. Sci. 22, 35–46. doi: 10.1016/j.jssas.2022.06.001

Gibb, A., and Isack, F. (2003). Re-engineering through pre-assembly: client expectations and drivers. Build. Res. Info. 31, 146–160. doi: 10.1080/09613210302000

GTAP Data bases: detailed sectoral list, (2019). Available at: https://www.gtap.agecon.purdue.edu/databases/contribute/detailedsector57.asp

Halawani, A. T. M., and Rehimi, F. (2021). Evaluation of the intention to shift to public transit in Saudi Arabia. Transp. Res. Part D: Transp. Environ. 94:102809. doi: 10.1016/j.trd.2021.102809

Hamida, M. B., Ahmed, W., Asif, M., and Almaziad, F. A. (2020). Techno-economic assessment of energy retrofitting educational buildings: a case study in Saudi Arabia. Sustain. For. 13:179. doi: 10.3390/su13010179

Hannah, M., and Hunter, N., (2018). Modern methods of construction: who’s doing what? | NHBC. Available at: https://www.nhbc.co.uk/foundation/modern-methods-of-construction-whos-doing-what

Hausberger, S., and Matzer, C. (2017). Update of emission factors for euro 3, euro 5 and euro 6 diesel passenger cars for the HBEFA version 3.3. Graz, Austria: Institute for Internal Combustion Engines and Thermodynamics.

Hong, J., Shen, G. Q., Feng, Y., Lau, W. S., and Mao, C. (2015). Greenhouse gas emissions during the construction phase of a building: a case study in China. J. Clean. Prod. 103, 249–259. doi: 10.1016/j.jclepro.2014.11.023

Horridge, J. , (2021). GTAPAgg: Data Aggregation Program. Center for Global Trade Analysis, Purdue University.

Horridge, M. , (2021). GTAP resources: SplitCom. Melbourne, Australia: Centre of Policy Studies, Monash University.

Horvath, A. (2004). Construction materials and the environment. Annu. Rev. Environ. Resour. 29, 181–204. doi: 10.1146/annurev.energy.29.062403.102215

Jaillon, L., Poon, C. S., and Chiang, Y. H. (2009). Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 29, 309–320. doi: 10.1016/j.wasman.2008.02.015

Karthik, S., Sharareh, K., and Behzad, R., (2020). Modular construction vs. traditional construction: advantages and limitations: a comparative study, in: Proceedings of the creative construction E-conference 2020. Presented at the creative construction e-conference 2020, Budapest University of Technology and Economics, online, pp. 11–19. doi: 10.3311/CCC2020-012

Kyjaková, L., and Bašková, R., (2016). Advantages and disadvantages of modern methods of construction used for modular schools in Slovakia. Czasopismo Techniczne, (Budownictwo Zeszyt 1-B (6)), 35–41.

Lawson, R. M., Ogden, R. G., and Bergin, R. (2012). Application of modular construction in high-rise buildings. J. Archit. Eng. 18, 148–154. doi: 10.1061/(ASCE)AE.1943-5568.0000057

Lee, K., Tae, S., and Shin, S. (2009). Development of a life cycle assessment program for building (SUSB-LCA) in South Korea. Renew. Sust. Energ. Rev. 13, 1994–2002. doi: 10.1016/j.rser.2009.01.002

Li, F., Zhuang, J., Cheng, X., Li, M., Wang, J., and Yan, Z. (2019). Investigation and prediction of heavy-duty diesel passenger bus emissions in Hainan using a COPERT model. Atmos. 10:106. doi: 10.3390/atmos10030106

Li, Z., Shen, G. Q., and Xue, X. (2014). Critical review of the research on the management of prefabricated construction. Habitat Int. 43, 240–249. doi: 10.1016/j.habitatint.2014.04.001

Lim, J., and Kim, S. (2020). Evaluation of CO 2 emission reduction effect using in-situ production of precast concrete components. J. Asian Arc. Build. Eng. 19, 176–186. doi: 10.1080/13467581.2020.1726763

Liu, M., Jia, S., and He, X. (2018). A quota-based GHG emissions quantification model for the construction of subway stations in China. J. Clean. Prod. 198, 847–858. doi: 10.1016/j.jclepro.2018.07.067

Mądziel, M. (2023). Vehicle emission models and traffic simulators: a review. Energies 16:3941. doi: 10.3390/en16093941

Mao, C., Shen, Q., Shen, L., and Tang, L. (2013). Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: two case studies of residential projects. Energ. Buildings 66, 165–176. doi: 10.1016/j.enbuild.2013.07.033

Marzouk, M., Abdelkader, E. M., and Al-Gahtani, K. (2017). Building information modeling-based model for calculating direct and indirect emissions in construction projects. J. Clean. Prod. 152, 351–363. doi: 10.1016/j.jclepro.2017.03.138

Matthews, H., Hendrickson, C., and Matthews, D., (2014). Life cycle assessment: Quantitative approaches for decisions that matter.

Meacham, B. J. (2022). Fire performance and regulatory considerations with modern methods of construction. Build. Cities 3, 464–487. doi: 10.5334/bc.201

Mendoza-Sanchez, J. F., Alonso-Guzman, E. M., Martinez-Molina, W., Chavez-Garcia, H. L., Soto-Espitia, R., Obregón-Biosca, S. A., et al. (2023). Measurement of CO2 emissions by the operation of freight transport in Mexican road corridors. Appl. Sci. 13:11391. doi: 10.3390/app132011391

Ministry of Housing, (2022). Modern methods of construction. Available at: https://mc.momrah.gov.sa/index-en.html. (Accessed on February 26 2024).

Mohamad Kamar, K. A., Azman, M. N. A., and Mohd Nawi, M. N. (2014). IBS Survey 2010: drivers, barriers and critical success factors in adopting industrialised building system (IBS) Construction By G7 contractors in Malaysia. J. Eng. Sci. Technol. 9, 490–501.

Mullens, M. A., and Arif, M. (2006). Structural insulated panels: impact on the residential construction process. J. Constr. Eng. Manag. 132, 786–794. doi: 10.1061/(ASCE)0733-9364(2006)132:7(786)

Na, Y., Han, B., and Son, S. (2021). Analysis of CO2 emission reduction effect of on-site production precast concrete member according to factory production environment. Adv. Civil Eng. 2021, 1–8. doi: 10.1155/2021/4569651

Ogunmakinde, O. E., Egbelakin, T., and Sher, W. (2022). Contributions of the circular economy to the UN sustainable development goals through sustainable construction. Resour. Conserv. Recycl. 178:106023. doi: 10.1016/j.resconrec.2021.106023

Ortiz, O., Castells, F., and Sonnemann, G. (2009). Sustainability in the construction industry: a review of recent developments based on LCA. Constr. Build. Mater. 23, 28–39. doi: 10.1016/j.conbuildmat.2007.11.012

Pacheco-Torgal, F., Cabeza, L. F., Labrincha, J., and De Magalhaes, A. G. (2014). Eco-efficient construction and building materials: Life cycle assessment (LCA), eco-labelling and case studies. Sawston, United Kingdom: woodhead Publishing.

Pakdel, A., Ayatollahi, H., and Sattary, S. (2021). Embodied energy and CO2 emissions of life cycle assessment (LCA) in the traditional and contemporary Iranian construction systems. J. Build. Eng. 39:102310. doi: 10.1016/j.jobe.2021.102310

Qi, Z., Song, J., Yang, W., Duan, H., and Liu, X. (2020). Revealing contributions to sulfur dioxide emissions in China: from the dimensions of final demand, driving effect and supply chain. Resour. Conserv. Recycl. 160:104864. doi: 10.1016/j.resconrec.2020.104864

Razkenari, M., Fenner, A., Shojaei, A., Hakim, H., and Kibert, C. (2020). Perceptions of offsite construction in the United States: an investigation of current practices. J. Build. Eng. 29:101138. doi: 10.1016/j.jobe.2019.101138

Saudi Electricity Company Annual Reports. (2022). Available at: https://www.se.com.sa/en/Investors/Reports-and-Presentations/Annual-Reports (Accessed on February 26 2024).

Saudi government adopts new building technology initiative (2019). London, United Kingdom: ZAWYA NEWSLETTERS.

Seo, M. , (2020). Environmental impacts of prefabricated construction: CO2 emissions comparison of precast and cast-in-place concrete case study (Doctoral dissertation).

Shehri, T. A., Braun, J. F., Howarth, N., Lanza, A., and Luomi, M. (2023). Saudi Arabia’s climate change policy and the circular carbon economy approach. Clim. Pol. 23, 151–167. doi: 10.1080/14693062.2022.2070118

Smith, R. E. (2011). Prefab architecture: A guideto modular design and construction. Hoboken, N.J: John Wiley & Sons.

Soytas, M.A., and Havrlant, D., (2020). Saudi vision 2030 dynamic input-output table: a tool for quantifying the sustainable development targets of Saudi Arabia.

Steen-Olsen, K., Owen, A., Hertwich, E. G., and Lenzen, M. (2014). Effects of sector aggregation on co2 multipliers in multiregional input–output analyses. Econ. Syst. Res. 26, 284–302. doi: 10.1080/09535314.2014.934325

Švajlenka, J., and Kozlovská, M. (2017). Modern method of construction based on wood in the context of sustainability. Civ. Eng. Environ. Syst. 34, 127–143. doi: 10.1080/10286608.2017.1340458

Tam, V. W. Y., Tam, C. M., Zeng, S. X., and Ng, W. C. Y. (2007). Towards adoption of prefabrication in construction. Build. Environ. 42, 3642–3654. doi: 10.1016/j.buildenv.2006.10.003

The Information Systems Security Research Center (ISSRC), (2008). IVE Model Users Manual Version 2.0.

The intended nationally determined contribution of the Kingdom of Saudi Arabia under the UNFCCC | Arab National Development Planning Portal, (2021). Beirut, Lebanon.

The National Audit Office, (2005). Using modern methods of construction to build homes more quickly and efficiently. London, United Kingdom.

Tumminia, G., Guarino, F., Longo, S., Ferraro, M., Cellura, M., and Antonucci, V. (2018). Life cycle energy performances and environmental impacts of a prefabricated building module. Renew. Sust. Energ. Rev. 92, 272–283. doi: 10.1016/j.rser.2018.04.059

United States Environmental Protection Agency (US EPA), (2023). Latest version of MOtor vehicle emission simulator (MOVES) | US EPA.

Vahrenkamp, V., Afif, A., Tasianas, A., and Hoteit, H., (2021). The geological potential of the Arabian plate for CCS and CCUS-an overview. Presented at the Proceedings of the 15th Greenhouse Gas Control Technologies Conference, pp. 15–18.

Van Mulligen, C.P. , (2012). Improving the efficiency, Productivity, and Cost-Effectiveness of Modular Design and Construction Processes. doi: 10.7939/R3HS73

Wang, H., Zhao, L., Zhang, H., Qian, Y., Xiang, Y., Luo, Z., et al. (2023). Carbon emission analysis of precast concrete building construction: a study on component transportation phase using artificial neural network. Energ. Buildings 301:113708. doi: 10.1016/j.enbuild.2023.113708

Wang, S., and Sinha, R. (2021). Life cycle assessment of different prefabricated rates for building construction. Buildings 11:552. doi: 10.3390/buildings11110552

Wang, W., Wang, X., and Sun, J. (2015). The construction of carbon emissions control theory research. Presented at the 2015 international forum on energy. Environment Science and Materials: Atlantis Press, 1348–1352.

Appendix 1

Keywords: CGE model, sustainability, modern methods of construction, COPERT model, transportation emissions, GTAP model

Citation: Almutairi K, Alahmadi R, Halawani ATM, Almutairi Y and Alsehaimi A (2024) A sustainability assessment of the modern method of construction in Saudi Arabia. Front. Sustain. Cities. 6:1439024. doi: 10.3389/frsc.2024.1439024

Edited by:

Roberto Alonso González-Lezcano, CEU San Pablo University, SpainReviewed by:

Sofia Melero-Tur, CEU San Pablo University, SpainRalph Horne, RMIT University, Australia

Copyright © 2024 Almutairi, Alahmadi, Halawani, Almutairi and Alsehaimi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence:Kamel Almutairi, YWxtdXRhaXJpa2FtZWxAZ21haWwuY29t; a211dGFpcmlAdGFpYmFodS5lZHUuc2E=

Kamel Almutairi

Kamel Almutairi Ramzi Alahmadi

Ramzi Alahmadi Ahmed T. M. Halawani

Ahmed T. M. Halawani Yasir Almutairi4

Yasir Almutairi4