- Department of the Environment, College of Basic Sciences, Hamedan Branch, Islamic Azad University, Hamedan, Iran

Chemical industries are among the process industries and cause many risks. The present research aimed to analyze the health risks of a chemical warehouse of drilling rigs chemical Supply Company based on COSHH (Control of Substances Hazardous to Health), CHEM-SAM (Chemical Risk Management Self-Assessment Model), and SQRA (Subjective Quantified Risk Assessment) methods in 2021. The information was collected based on document review, MSDS of chemicals, processes, employees, and chemical exposure. Flammability, toxicity, allergy-causing, corrosivity, reactivity, LD50, and permissible thresholds of chemicals were also collected. The present research results showed that out of 59 main chemicals in the operational processes of the chemical warehouse of drilling rigs, 14 chemicals are flammable, 22 cause allergy responses, and three can cause death if inhaled. According to the results of the CHEM-SAM method, the employees and people outside the organization are at medium and low chemical risk based on the current management of the chemical warehouse, respectively. The results of the COSHH health assessment showed that chemicals had low, medium, high, and very high risk in 31, 13, 12, and 3 cases, respectively. The high-risk cases consisted of Ammonium Nitrate، Caustic Soda, and Poly.Aluminum.Chloride. Health risk assessment was also performed using the SQRA method, and results showed that chemicals have a very low, low, medium, high, and very high risk in 27, 12, 8, 9, and 3 cases, respectively. The results showed that the adverse health effects of chemical exposure in the drilling industry are alarming. Employees of different sectors of oil and gas industries are exposed to chemicals.

Introduction

Every year, organizations face billions of dollars of losses in human, equipment, and reputational losses due to work-related accidents and injuries (1). A significant part of these accidents and injuries are related to the chemical industry (2). Chemical exposure to various processes of chemical industries can have various adverse health effects on humans (3–5). Research has shown that more than 25 million workers are exposed to occupational hazards such as dust, various toxins, and noise from the work environment (6). Drilling oil and gas wells are one of the stages of the oil process (7, 8). Many chemicals are used for different purposes in the well drilling process, such as cooling and lubrication of the drill, pressure control, and integration of the well wall (9–11). Such chemicals include barite, caustic, biocide, soda, pipe lax, starch, foam, and even diesel (12, 13). Depending on the characteristics of the well, different geological, climatic, and geographical components, different chemicals are used for the circulating fluid in the drilling well (14, 15). The effects of these substances have been investigated in various researches. Caganova et al. (16) concluded in a study that caustic exposure has significant effects on changes in the acidity characteristics of workers’ bodies. In a study, Kim and Kim (17) investigated the effects of biocide exposure on workers’ skin. The results of this study showed that long-term exposure to this substance, in addition to causing burns, has significantly increased the odds of skin cancer. Ibrahim et al. (18) also stated that calcium chloride had adverse effects on the sexual characteristics of workers. These studies show the necessity of a health-risk study in the storage centers of these chemicals. Health-risk assessment of chemicals helps workers to identify and eliminate the hazards of their work environment to have a safe work environment (19, 20). There are several methods to identify and assess health risks (21, 22). In modern health risk assessment methods, several components are involved in determining the risk level (23). One of the new methods of assessing the health risks of chemicals is COSHH. COSHH regulations require all employers to assess the risks to health arising from hazardous substances in the workplace. Factors such as the possibility of removing and replacing hazardous substances, the existence of a material safety information sheet, process description, risk classification, type of effect, work environment limitations, possible control facilities, and the priority of dealing with hazardous substances are presented in this method. This method was presented by the Institute of Chemical Studies of the European Parliament in 2006 (24). Another relatively new method in health risk assessment is SQRA, which is a semi-quantitative method for health risk assessment of hazardous chemicals. In this method, the LD50 index is used for skin absorption, respiratory, vital organs, and surface absorption. Two factors are important in this method, the hazard rate and exposure rate (25, 43). Another health risk assessment method used in the present research is the CHEM-SAM technique. This technique was designed by the International Chemical Threat Reduction Program Department of Sandia Laboratories in the United States (26). This method answers three basic questions: 1. what can happen? 2. How much is the likelihood of an accident? 3. If it happens, what are the consequences? This method is based on several steps: determining the properties of chemicals, defining the potentially harmful properties of chemicals, calculating the safety risk of chemicals, and determining risk acceptability (27). These chemical risk assessment methods have been used in various research. Tian et al. (18) called the COSHH method a desirable method for risk assessment in the chemical industry. Lee et al. (19) also used the COSHH method to assess the health risks of methyl chloride, isopropanol, and acetone. Karimi Zeverdegani et al. (30) also confirmed the reliability of the CHEM-SAM method based on semi-quantitative models. Overall, one of the hazards of the oil and gas industry is chemicals (31). There is a possibility of various injuries in these industries due to the direct exposure of employees to various chemicals. Considering the high potential of damage caused by exposure to these substances and their wide use in Iranian drilling industries, it seems necessary to conduct comprehensive research on the risk assessment of exposure to these substances using modern assessment techniques.

Chemical supply companies for oil and gas well drilling rigs are among the chemical distribution centers that have received less attention and study. These companies are mainly active in oil-producing countries. Conducting a complete study of the risk potential of chemical substances for employees and other people who are exposed to its activity is considered research innovation. Therefore, the health risk caused by exposure to these substances has been investigated in the present study using COSHH, SQRA, and CHEM-SAM methods.

Materials and methods

MI Services, a chemical supply company for drilling rigs, is located in the oil-rich areas of southwestern Iran. This company has three chemical warehouses used in the drilling industry with a total area of 80,000 m2. On average, 40 tons of chemicals enter and leave warehouses every day. The loading and unloading process of 500 kg and 50 kg packs is carried out by forklifts and drums by warehouse workers manually, respectively. A total of 38 warehouse workers are constantly in direct contact with these substances.

The current descriptive-analytical research was conducted to identify and assess the health risks of raw substances in this company in 2021. After preparing a list of all the raw substances, physicochemical properties such as toxicity, flammability, and reactivity were prepared through the preparation of MSDS or, if necessary, international references and standards such as NIOSH and OSHA. Considering that the health risk levels are based on the employees’ exposure level, related information was also collected by field method. This information included the employees of different departments of the warehouses, working hours, operation processes, and the level of exposure to chemicals. Finally, the health risk of raw substances was identified and assessed using COSHH, CHEM-SAM, and SQRA methods.

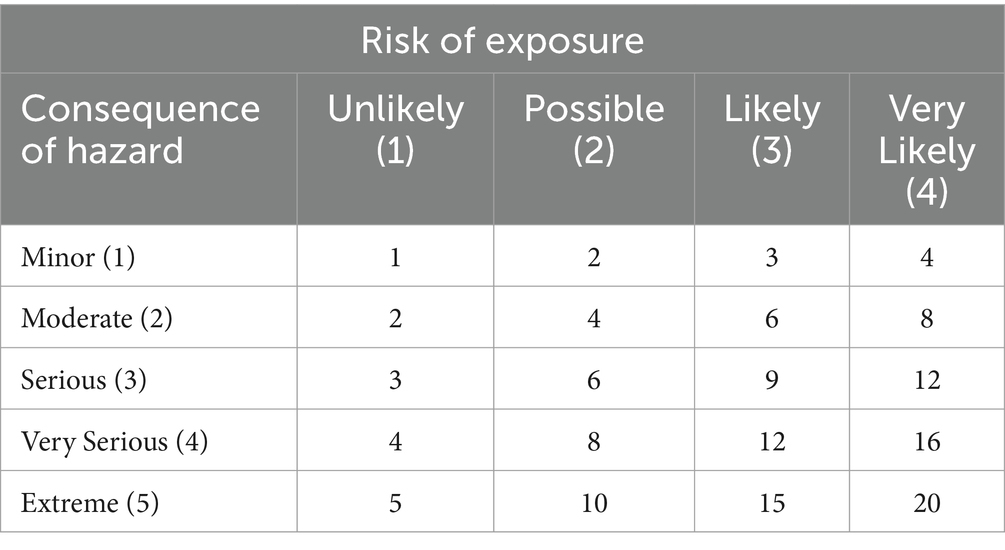

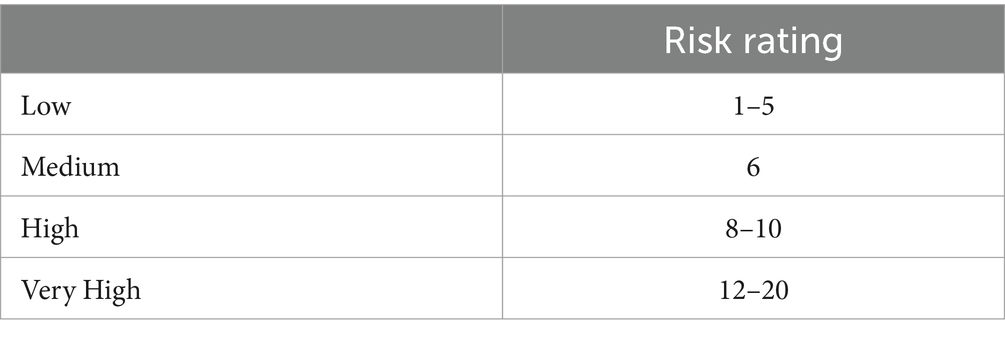

Health risk assessment using COSHH method

The instructions of the Organization for Control of Substances Hazardous to Health for chemical compounds have been classified in the two parameters of consequence and exposure likelihood in the standard matrix and questionnaire, as very low, low, medium, high, and very high risk (44). The exposure likelihood was calculated by expert observations of the work environment, relevant measurements, and by considering parameters such as the type and amount of chemicals used in chemical warehouses. The assessment matrix of the consequence severity and the exposure likelihood in the COSHH method is presented in Table 1 and the risk classification based on the risk priority number is presented in Table 2.

Table 1. Matrix of severity and risk of exposure to chemicals in COSHH method (41).

Table 2. Classification of health risks in COSHH method based on priority number (41).

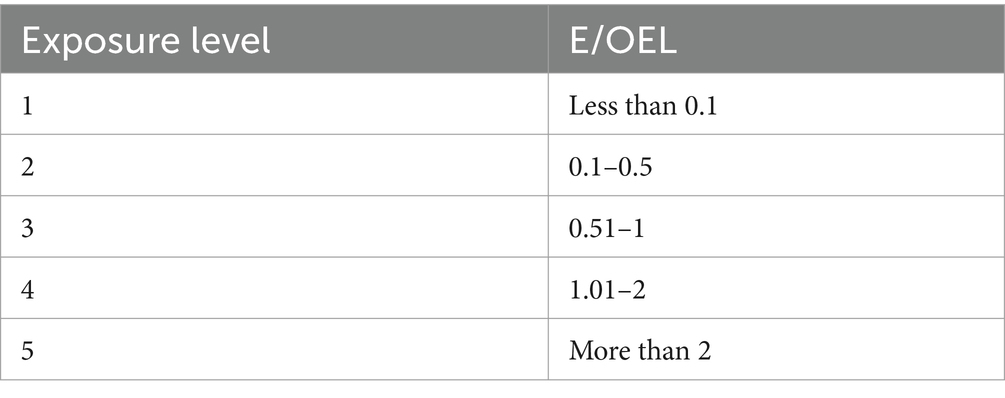

Health risk assessment using the SQRA method

There are two important factors in this method: Hazard rate (HR) and exposure rate (ER). After identifying the chemical raw substances in the company’s warehouses, HR was determined using information on acute toxicity values, LD50 and LC50, or through the toxic effects of chemicals defined in tables. The second factor is the exposure rate (ER), which is obtained using the following two ways:

First: Based on actual exposure levels when air monitoring results are available. The weighted average weekly exposure is calculated using the Equation 1:

The calculated E is compared with the occupational exposure limit (OEL) and then the exposure rate is determined according to Table 3.

When exposure to two or more chemicals with similar effects occurs, combined exposure is taken into consideration.

Second: Using ER index: when air monitoring results are not available, the exposure degree can be obtained using the exposure index (EI) and by the Equation 2:

Table 3. Chemical exposure rate in SQRA method (42).

The EI (exposure index) is determined according to the exposure factors defined in the tables. Finally, the hazard rate is calculated by calculating ER and HR through the Equation 3:

Risk is obtained in five levels: insignificant (0–0.5), low (0.51–1), medium (1–2), high (2–3), and very high (>3).

Health risk assessment using CHEM-SAM method

This method, which was designed by the International Chemical Threat Reduction Department of Sandia National Laboratories in United States, is based on several steps. Defining the potentially harmful properties of chemicals, calculating the safety risk of chemicals, and determining risk acceptability. This method contains 63 questions on variables such as the storage conditions of and substance transfer, toxicity, flammability, volatility, physical form, route of entry into the body, type of exposure, safe packaging conditions of the substance, control conditions in the desired environment, labeling, control conditions outside the work environment, warning items, training to control conditions outside the work environment, warning substances, substance destruction conditions, management, and planning that are designed in Excel software. Each variable includes related questions that are answered based on four options. After answering all the questions in the Excel software, the risk level is determined. This method consists of five levels of risk: very low, low, medium, high, and very high (26) (Figure 1).

Figure 1. Output for assessing the lethality level of chemical risk (A: Outside the enclosure; B: Inside the enclosure)-2021.

Results

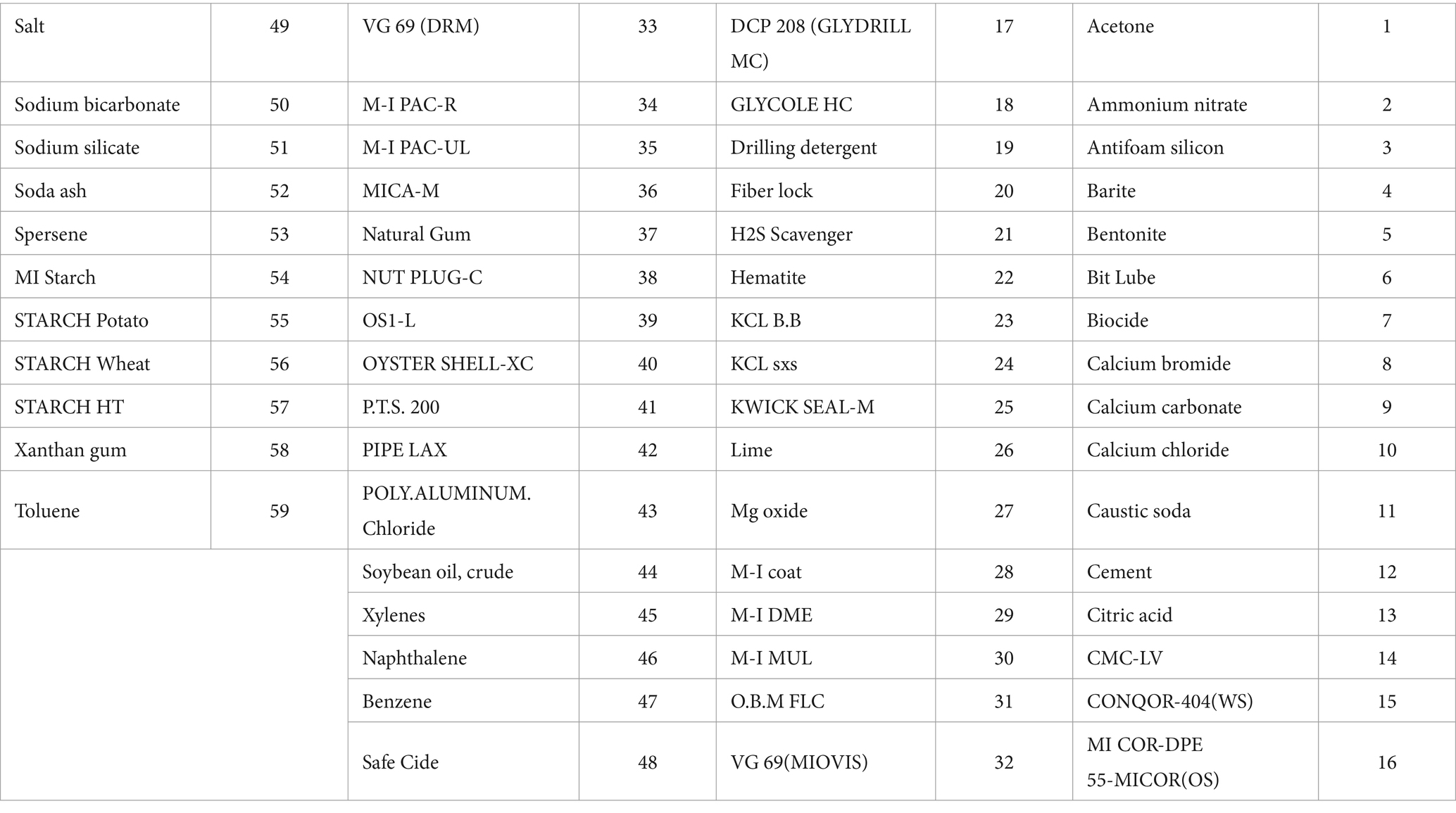

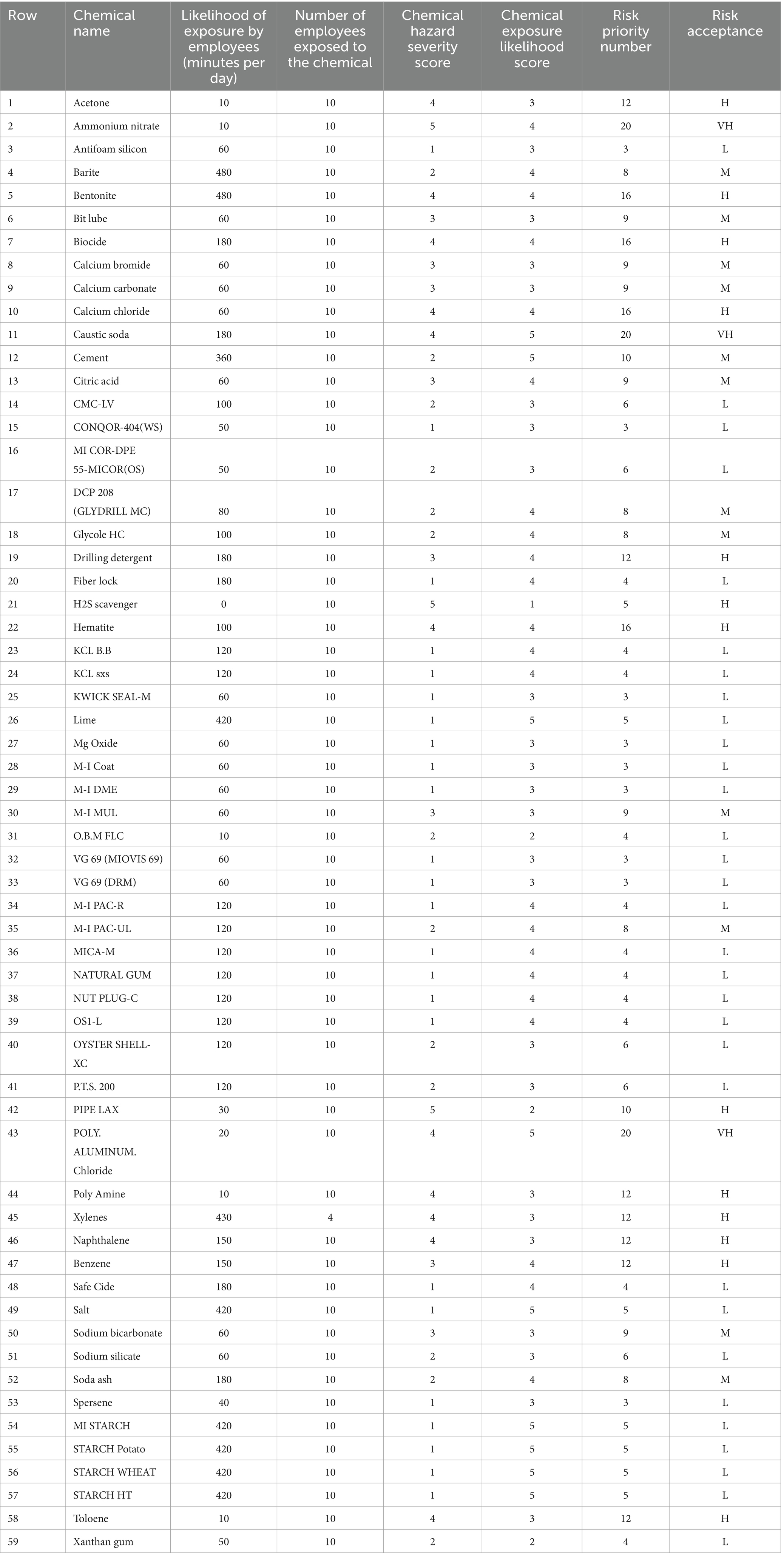

To analyze the health risks of MI Services company’s raw substances, a list of chemicals used in warehouses was prepared. This list contains 59 chemicals (Table 4).

Results of the health risk assessment using of COSHH method

The risk priority in this method is the product of two risk severity components (the severity of the chemical risk) and the risk likelihood (the level of chemical exposure). The severity component is classified into five levels: low, medium, serious, very serious, and severe. The likelihood component is also classified into four levels: unlikely, possible, likely, and highly likely. Part of the results of the COSHH-based health risk assessment of chemicals are presented in Table 5.

Table 5. Results of chemical risk assessment of chemicals in COSHH method in the drilling rig chemical supply company-2021.

The likelihood of exposure is calculated based on the total time of employees’ exposure to chemicals, in minutes per day. The exposure time has been continuous in some cases and interrupted in some cases. The Chemical hazard severity score component was considered based on the degree of danger of each chemical in the MSDS, which is based on international authorities such as NIOSH, ACGIH, and OSHA. Considering that the basis for calculating the risk priority is the level of exposure, some hazardous chemicals that employees have a low level of exposure to are not estimated as a priority.

The results of the COSHH assessment showed that 31 chemicals (52.5%) have low risk, 13 chemicals (22.03%) have medium risk, 12 chemicals (20.3%) have high risk and 3 chemicals consist of Ammonium Nitrate، Caustic Soda, and Poly. Aluminum.Chloride (5.08 %) has a very high risk. The highest risk levels were related to ammonium nitrate and benzene with a priority number of 20. The risk priority number for materials including cement, Poly Amine, Pipe Lax, and Hematite has also been at a high level.

Results of the health risk assessment using CHEM-SAM method

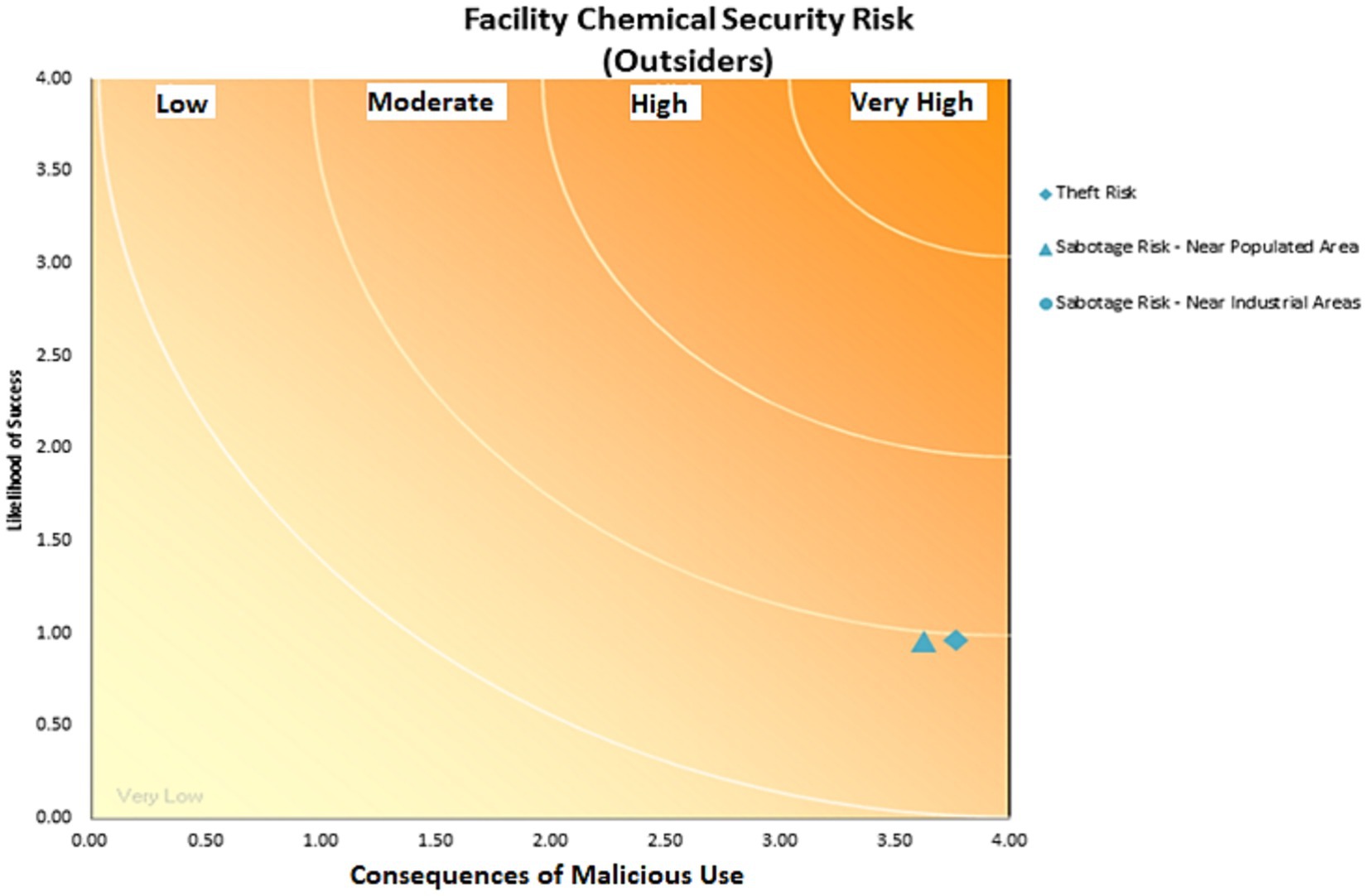

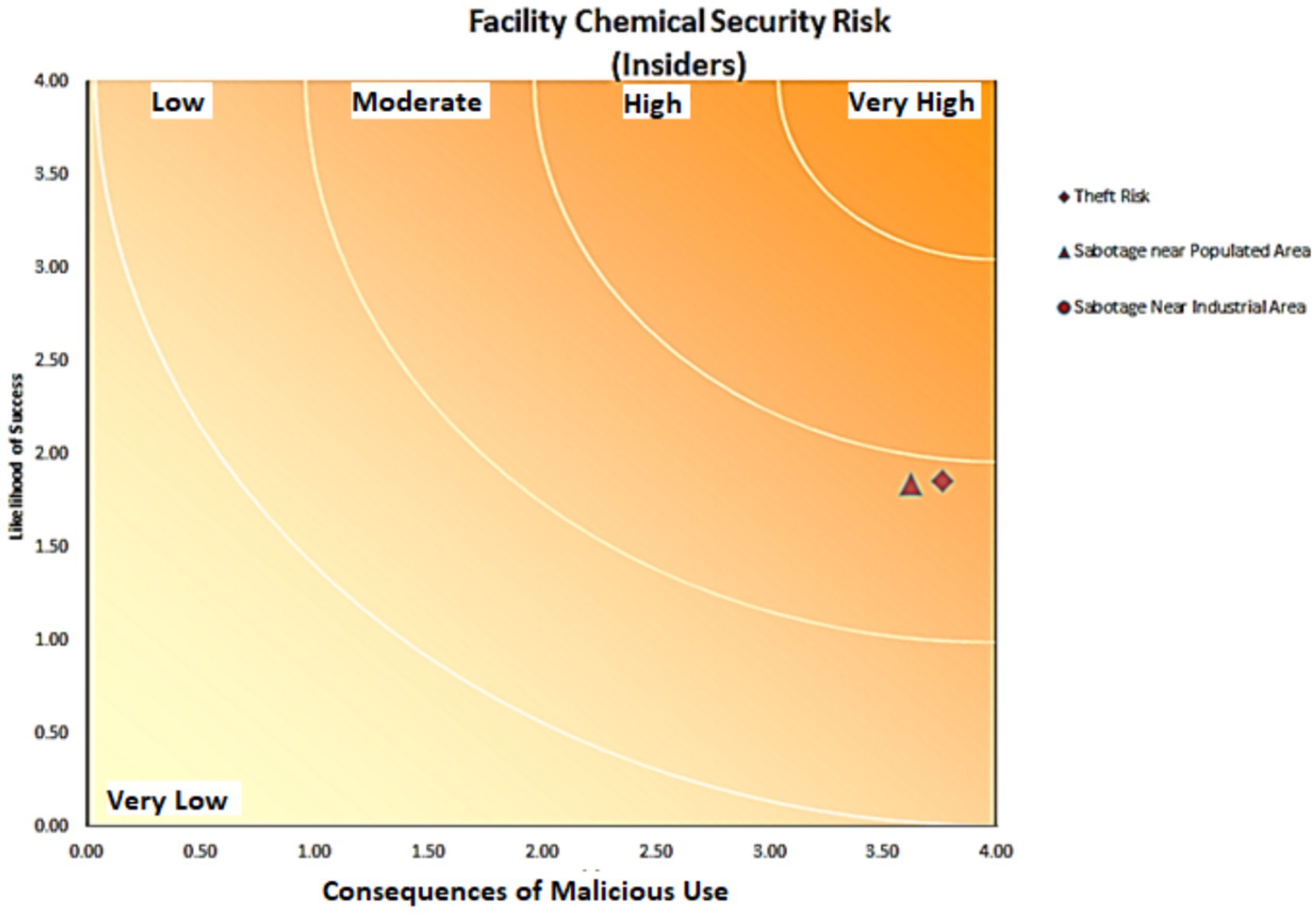

The CHEM-SAM-based health risk assessment relies on the nature of the data and the management of chemicals. In this assessment method, 10 components were evaluated separately for each chemical and 53 components were evaluated in general for all chemicals. The assessment output in this method consists of five levels of very low, low, medium, high, and very high risk for employees and people outside the organization. The results of the health risk assessment of the studied chemicals are shown in the graphs in Figure 2.

Figure 2. Classification of chemicals based on some of the components studied in the CHEM-SAM method-2021. (A) Stability, (B) Flammability, (C) Allergy in case of inhalation, (D) Fatal in case of inhalation, (E) Subject to the Law on Prohibition of Chemical Weapons, (F) Fatal in case of swallow.

According to the results, 7 chemicals, including bentonite, calcium chloride, cement, drilling detergents, biocide, hematite, and KCL BB, have high stability in the environment (Figure 2A).

A total of 14 chemicals in MI company’s chemical warehouse are flammable (23.7%) and 45 chemicals are non-flammable (76.3%) (Figure 2B). Of the 59 studied chemicals, 22 cause allergic responses (in the case of inhalation 37.3 % of the total chemicals) (Figure 2C). Also, a total of 23 cases (39%) of the chemicals used in MI Company cause some kind of chronic effect and 18 cases (30.5%) of them induce an acute effect. Moreover, seven chemicals (11.8%) are stable in the environment. The three substances including biocide, hydrogen sulfide, and pipe lax (5%) can lead to death if inhaled (Figure 2D). The results of Chem-Sam-based chemical risk assessment are shown in Figures 3, 4. The results also showed that no chemicals stored in the company’s warehouse are on the list of the Organization for the Proliferation of Chemical Weapons (Figure 2E). A total of 8 chemicals (13.5%) used in the company’s chemical warehouse, including acetone, ammonium nitrate, bentonite, biocide, calcium chloride, caustic, pipe lax, and toluene, lead to death if swallowed (Figure 2F). The results show the exposure of employees to dangerous chemicals, with various consequences in this Company Supplying Chemicals.

Figure 3. Chemical safety risk of equipment for people outside the drilling rig chemical supply company-2021.

Figure 4. Chemical safety risk of equipment for people inside the drilling rig chemical supply company-2021.

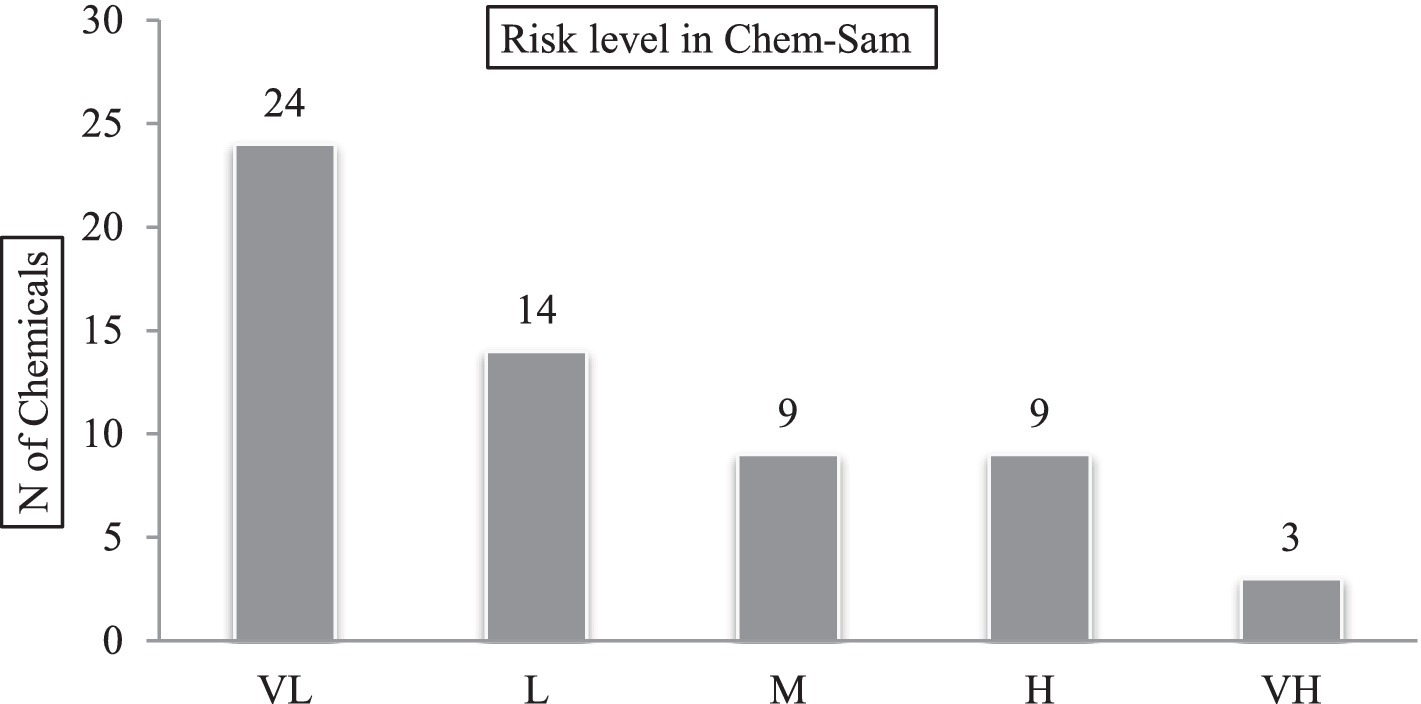

According to the CHEM-SAM method, it was found that employees are at a medium risk of chemicals based on the current management of chemicals in the chemical warehouse of the MI company (Figure 3) and people outside the organization are at a low risk (Figure 4). It was also found that a total of chemicals caused a very low, low, medium, high, and very high risk in 24 (40.67%), 14 (23.7%), 9 (15.2%), 9 (15.2%) and 3 cases (5%), respectively (Figure 5).

Figure 5. Frequency distribution of chemical risk levels based on Chem Sam method in the drilling rig chemical supply company-2021.

Results of health risk assessment using SQRA method

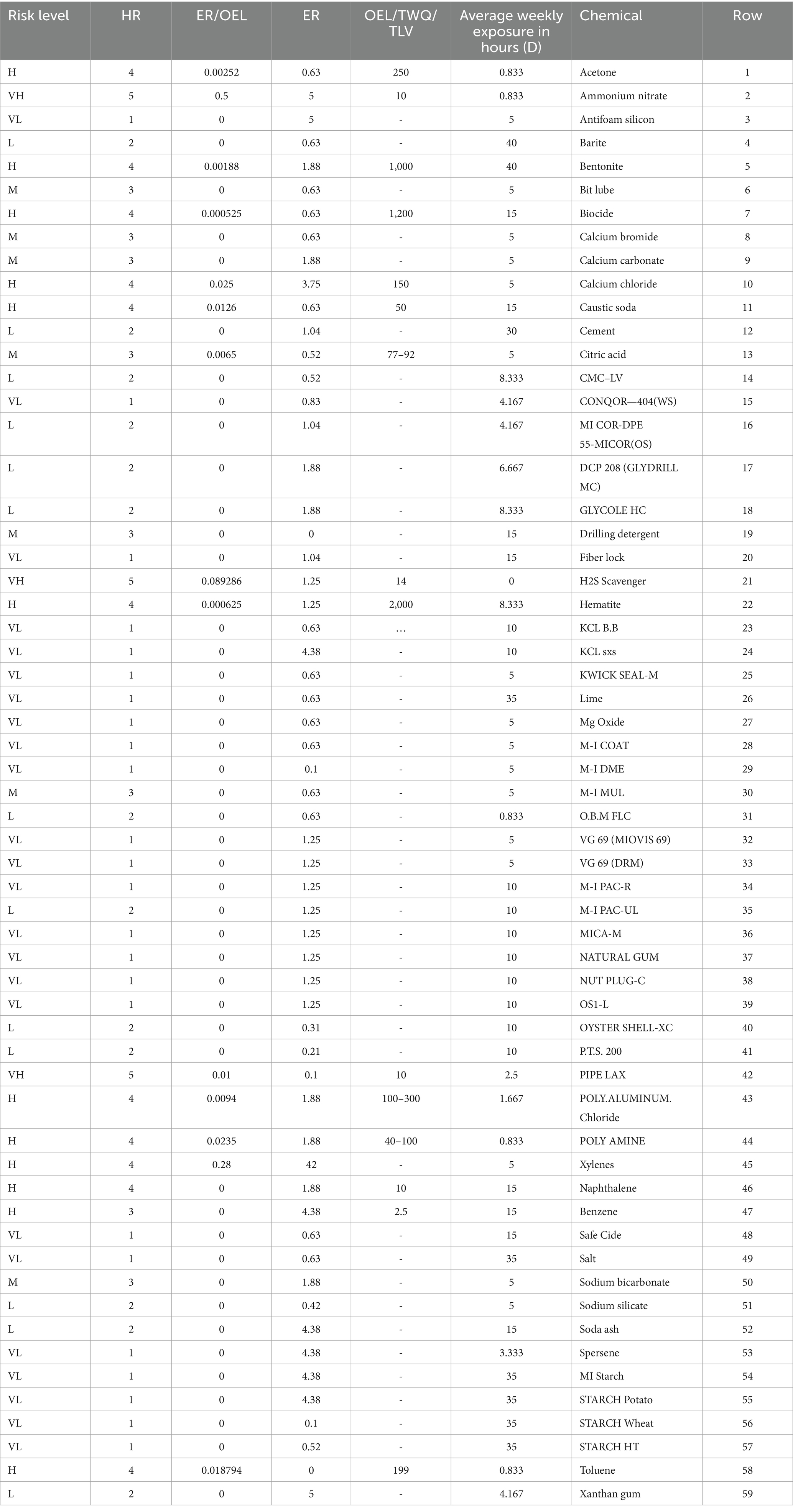

The summary of the results of the health risk assessment of chemicals used in the MI Company is presented in Table 6. SQRA consists of two important factors: Hazard rate (HR) and exposure rate (ER). OEL/TWA and TLV indices have been used for the exposure level. The average minutes of daily exposure were also converted to hours per week. ER was calculated using Equation 2 and, finally, the risk priority of chemicals was calculated by multiplying it by the HR.

Table 6. Results of chemical risk assessment of chemicals in SQRA method in the drilling rig chemical supply company—2021.

HR values are based on the severity of the hazard of each chemical, regardless of the level of employee exposure. By calculating the ratio of ER to OEL/TLV, the risk of exposure to hazardous substances can be quantitatively evaluated. This ratio shows that a percentage of the permissible threshold for exposure to a hazardous substance in the work environment is affected. By analyzing this ratio and checking the allowed thresholds, it is possible to prioritize.

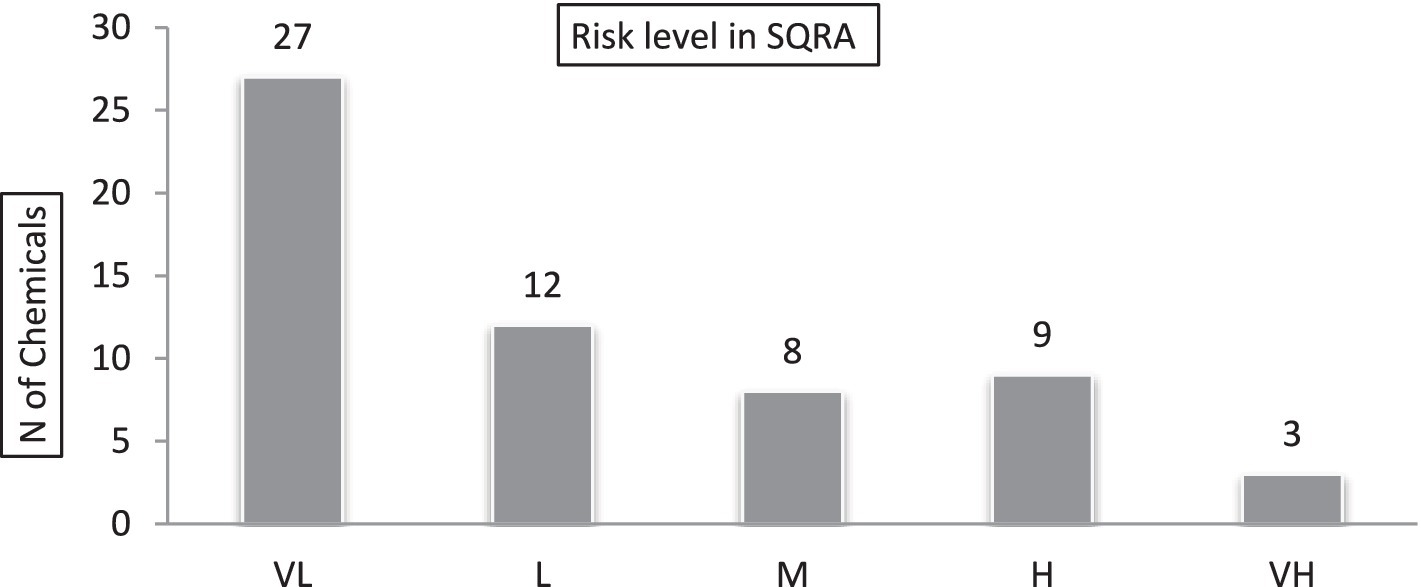

The frequency distribution of the risk of chemicals is presented in Figure 6. These results show that chemicals caused a very low, low, medium, high, and very high risk in 27 (46%), 12 (20%), 8 (14%), 9 (15%) and 3 cases (5%), respectively (Figure 6). The results of the risk assessment using the SQRA method also showed the risk of exposure to Ammonium Nitrate, Caustic Soda, and Poly.Aluminum.Chloride compounds are at a very high level.

Chemical risk assessment methods are based on indicators, so different results can be expected. Adaptation of the results is a method to measure the desirability of any evaluation method.

Figure 6. Frequency distribution of chemical risk levels based on SQRA method in the drilling rig chemical supply company-2021.

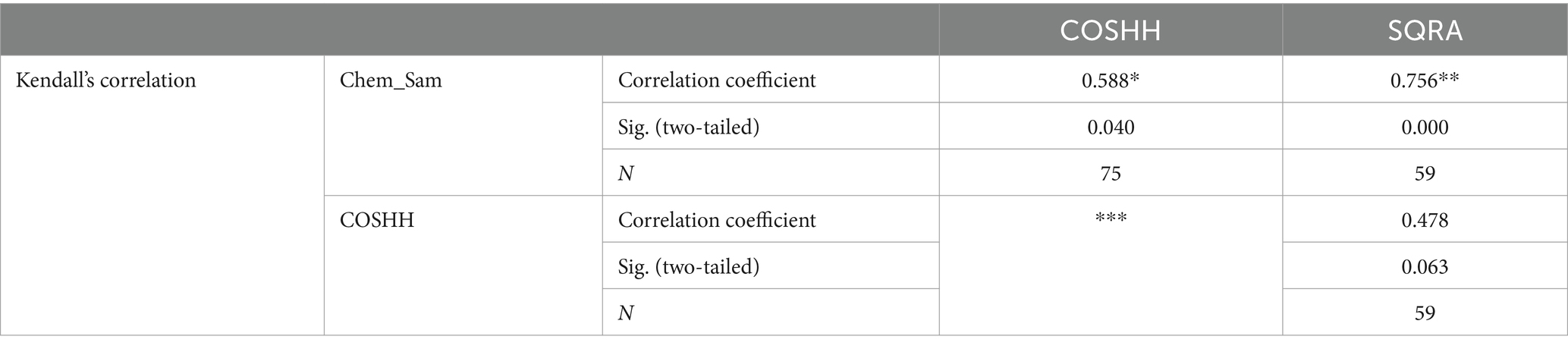

Kendall’s rank correlation coefficient was used to investigate the correlation between the results of chemical health risk assessment methods (COSHH, CHEM-SAM, and SQRA) used in MI Company’s chemical warehouse. These results showed a significant correlation between the results of SQRA and CHEM-SAM methods (Sig = 0.756). Kendall’s rank correlation coefficient was calculated to be 0.756 (Table 7). However, there was no significant correlation between the results of the COSHH with the CHEM-SAM and SQRA methods (p ≥ 0.05), which is probably due to the different priority classification of chemicals in the COSHH method with the CHEM-SAM and SQRA methods.

Table 7. Kendall coordination and correlation coefficient for comparison of COSHH, CHEM-SAM, and SQRA methods—2021.

Discussion

Oil industries, which are among the process industries, cause many risks and can lead to disastrous and irreparable consequences. These industries consist of four main characteristics including the quantity and quality of energy, low flexibility, high complexity, and high energy (32). Workers working in industrial workplaces, such as the chemical storage area of drilling rigs, are the most important group exposed to hazardous chemicals and their health should be protected. The methods used in the current research are based on the analysis and assessment of chemicals used in the chemical warehouse of the drilling industry. The results of the research showed that some of the 59 main chemicals in the chemical warehouse of the drilling rig require special management to reduce the level of health risk. Considering these results, there is a relatively high potential for injuries caused by exposure to chemicals in MI and the prevalence of some chronic symptoms such as respiratory problems and skin allergies.

Among the substances that can lead to allergic skin reactions, cement, calcium chloride, Drilling Detergent, and Caustic Soda can be mentioned. Biocide, which is used to eliminate microorganisms in drilling rig environments, contains chlorine compounds, formaldehyde, ammonium compounds, and sodium hypochlorite (33). The level of exposure risk to Biocide has been assessed as high in the SQRA method, with an average weekly exposure of 5 hours for warehouse personnel. The most significant consequence of exposure to Biocide is respiratory infections. Ammonium nitrate is another chemical compound present in the chemical storage for drilling rigs. It is used for flow control in oil wells. Its effects include respiratory irritation, gastrointestinal damage, and long-term damage to the nervous system (34). The present research indicates that the level of exposure risk to this chemical is very high based on the risk assessment.

Exposure to benzene, toluene, xylene, and naphthalene in the gas phase is another result of the present study. Benzene has been identified as a known carcinogen. Benzene can induce cytogenetic changes such as aneuploidy, gene expression alteration (128), DNA methylation (129), and displacement, leading to the production of carcinogenic proteins (35). Vital genes may also be targeted through gene mutation and/or epigenetic alterations. Additionally, toluene and xylene compounds have adverse effects on the nervous, respiratory, and immune systems. At high doses of toluene, human motor activity has been observed significantly lower than pre-exposure levels (36). According to the results of the present study, the level of exposure to these compounds for warehouse and laboratory staff was found to be high.

The harmful factors in the workplace were measured twice a year. Therefore, considering the nature of the organization’s activity and high exposure to chemicals, it is recommended that in addition to conducting this process every month, equipment for continuous testing of hazardous substances and their concentration in the environment should be prepared by the company. Also, part of the toxic and hazardous emissions from chemicals such as acids, polyamine, ammonium nitrate, and pipe lax are caused by leakage from packaging and drums. The poor packaging quality of chemicals sometimes leads to leakage and some injuries. Increasing the packaging inspection and packaging quality control of substances entering the chemical warehouses of drilling rigs is a suggestion that can prevent some damage. Liu et al. (37) have recommended the labeling of chemicals with flammability and reactivity characteristics and separate storage. Other causes of accidents include human errors during the transportation of chemicals by hand or forklift that requires the development of a response plan in emergencies. Traffic in chemical warehouses (open and isolated warehouses) must be in full compliance with safety standards. The use of gloves, special coveralls, protective glasses, and masks for the warehouse employees when working with chemicals and working with chemicals that have respiratory effects in an isolated room with a negative pressure of 2.5 pascals is one of the things suggested by Bergkamp and Abelkop (38).

Mechanical ventilation in the production area following the ACGIH standard is also one of the other recommendations related to the storage of chemicals.

Determining work shifts is one of the effective solutions to prevent chemical accidents. Bhusnure et al. (39) mentioned short-term work shifts as one of the effective solutions for preventing injuries caused by exposure to chemicals. OEL/TWA and TLV standards are used to determine work shifts. Sharma et al. (40) referred to waste contaminated with chemicals (such as napkins, cloth, cotton, etc.) as one of the factors influencing the chemical contamination of warehouses and laboratories containing chemicals, which requires management. Adjusting the ambient temperature while working with some substances such as chloroform reduces its emission in the air.

Conclusion

The results of the present research showed that the adverse health effects of chemical exposure in the drilling industry are at a worrying level. The results of chemical exposure risk assessment using SQRA, CHEM-SAM and COSHH methods showed that there is a high potential for health consequences from exposure to compounds such as ammonium nitrate, caustic soda and poly-aluminum chloride, benzene, xylene and toluene for There are staff. It is suggested that the techniques used in the present research should be used in other sectors of these industries and its results should be used in health risk management and control programs.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material; further inquiries can be directed to the corresponding author/s.

Author contributions

SA: Conceptualization, Writing – original draft, Writing – review & editing. BL: Investigation, Writing – original draft, Writing – review & editing. MC: Formal analysis, Investigation, Writing – original draft, Writing – review & editing. MK: Data curation, Writing – original draft.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Zhang, J, Fu, J, Hao, H, Fu, G, Nie, F, and Zhang, W. Root causes of coal mine accidents: characteristics of safety culture deficiencies based on accident statistics. Process Saf Environ Prot. (2020) 136:78–91. doi: 10.1016/j.psep.2020.01.024

2. Bragatto, P, and Milazzo, MF. A resilient approach to the safety management of ageing and obsolescence in oil and chemical industries. Chem Eng Trans. (2019) 74:1369–74. doi: 10.3303/CET1974229

3. Asfaw, S, Enquselassie, F, Tefera, Y, Gizaw, M, Wakuma, S, and Woldemariam, M. Determinants of chronic respiratory symptoms among pharmaceutical factory workers. J Trop Med. (2018) 2018:1–10. doi: 10.1155/2018/3815689

4. Kavlock, RJ, Bahadori, T, Barton-Maclaren, TS, Gwinn, MR, Rasenberg, M, and Thomas, RS. Accelerating the pace of chemical risk assessment. Chem Res Toxicol. (2018) 31:287–90. doi: 10.1021/acs.chemrestox.7b00339

5. Tabari, MRR, Sabzalipour, S, Peyghambarzadeh, SM, and Jalilzadeh, R. Dispersion of volatile organic compounds in the vicinity of petroleum products storage tanks. Environ Eng Manag J. (2021) 20:145–63.

6. Hämäläinen, P., Takala, J., and Kiat, T. B. (2017). Global estimates of occupational accidents and work-related illnesses. World 3-4.

7. Satiarvand, M, Orak, N, Varshosaz, K, Hassan, EM, and Cheraghi, M. Providing a comprehensive approach to oil well blowout risk assessment. PLoS One. (2023) 18:e0296086. doi: 10.1371/journal.pone.0296086

8. Zaidi, R, Sedmak, A, Kirin, S, Grbovic, A, Li, W, Vulicevic, LL, et al. Risk assessment of oil drilling rig welded pipe based on structural integrity and life estimation. Eng Fail Anal. (2020) 112:104508. doi: 10.1016/j.engfailanal.2020.104508

9. David Ytrehus, J, Taghipour, A, Golchin, A, Saasen, A, and Prakash, B. The effect of different drilling fluids on mechanical friction. J Energy Resour Technol. (2017) 139:034502. doi: 10.1115/1.4035951

10. Saasen, A., Hoset, H., Rostad, E. J., Fjogstad, A., Aunan, O., Westgård, E., et al. (2001). “Application of ilmenite as weight material in water based and oil based drilling fluids” in SPE Annual Technical Conference and Exhibition. OnePetro.

11. Samnejad, M., Gharib Shirangi, M., and Ettehadi, R. (2020). “A digital twin of drilling fluids rheology for real-time rig operations” in Offshore Technology Conference. OnePetro.

12. Fink, J . Petroleum Engineer's Guide to Oil Field Chemicals and Fluids. Gulf Professional Publishing (2021) 115–117.

13. Masoumi, A, and Yengejeh, RJ. Study of chemical wastes in the Iranian petroleum industry and feasibility of hazardous waste disposal. J Environ Health Sci Eng. (2020) 18:1037–44. doi: 10.1007/s40201-020-00525-5

14. Sarafraz, P, Varshosaz, K, Orak, N, Jaafarzadeh, N, and Aghajari, E. Safety, health, and environmental risk assessment of the aromatic outlet of imam Khomeini petrochemical company using LOPA and fuzzy-LOPA and pollutants and control actions using the Bow-tie method. Front Public Health. (2023) 11:1251548. doi: 10.3389/fpubh.2023.1251548

15. Taugbøl, K., Sola, B., Forshaw, M., and Fjogstad, A. (2021). “Automatic drilling fluids monitoring” in SPE/IADC International Drilling Conference and Exhibition OnePetro.

16. Caganova, B, Foltanova, T, Plackova, S, Placha, K, Bibza, J, Puchon, E, et al. Caustic effects of chemicals: risk factors for complications and mortality in acute poisoning. Monatsh Chem Chem Monthly. (2017) 148:497–503. doi: 10.1007/s00706-016-1900-x

17. Kim, JH, Kim, T, Yoon, H, Jo, A, Lee, D, Kim, P, et al. Health risk assessment of dermal and inhalation exposure to deodorants in Korea. Sci Total Environ. (2018) 625:1369–79. doi: 10.1016/j.scitotenv.2017.12.282

18. Ibrahim, A, Ali, MM, Abou-Khalil, NS, and Ali, MF. Evaluation of chemical castration with calcium chloride versus surgical castration in donkeys: testosterone as an endpoint marker. BMC Vet Res. (2016) 12:46–9. doi: 10.1186/s12917-016-0670-3

19. Raazi Tabari, MR, Sabzalipour, S, Peyghambarzadeh, SM, and Jalilzadeh, R. Vapor loss of volatile organic compounds (VOCs) from the shipping port of Abadan petroleum refinery. Pollution. (2020) 6:863–78. doi: 10.22059/poll.2020.302701.810

20. Zain, SMSM, Azmi, WNFW, Veloo, Y, and Shaharudin, R. Formaldehyde exposure, health symptoms and risk assessment among hospital workers in Malaysia. J Environ Prot. (2019) 10:861–79. doi: 10.4236/jep.2019.106051

21. Sekhavati, E, and Yengejeh, RJ. Assessment optimization of safety and health risks using fuzzy TOPSIS technique (case study: construction sites in the south of Iran). J Environ Health Sustain Dev. (2021) 6:12–28. doi: 10.18502/jehsd.v6i4.8154

22. Sui, Y, Ding, R, and Wang, H. A novel approach for occupational health and safety and environment risk assessment for nuclear power plant construction project. J Clean Prod. (2020) 258:120945. doi: 10.1016/j.jclepro.2020.120945

23. Hayes, AW, Li, R, Hoeng, J, Iskandar, A, Peistch, MC, and Dourson, ML. New approaches to risk assessment of chemical mixtures. Toxicol Res Appl. (2019) 3:239784731882076. doi: 10.1177/2397847318820768

24. Garrod, ANI, Evans, PG, and Davy, CW. Risk management measures for chemicals: the “COSHH essentials” approach. J Expo Sci Environ Epidemiol. (2007) 17:S48–54. doi: 10.1038/sj.jes.7500585

25. Karimi, A, Jamshidi Slukloei, HR, and Eslamizad, S. Designing SQCRA as a software to semi-quantitative chemical risk assessment in workplace. J Occup Hyg Eng. (2014) 1:47–56.

26. Jackson, N. B. (2017). Risk assessment and Chem-SAM (No. SAND2017-0040PE). Sandia National Lab. (SNL-NM), Albuquerque, NM (United States).

27. Konee, ND, and Kuye, A. Chemical security in NIGERIA: a CASE study of selected upstream oil and gas facilities. NSChE J. (2019) 34:49–9.

28. Tian, F, Zhang, M, Zhou, L, Zou, H, Wang, A, and Hao, M. Qualitative and quantitative differences between common occupational health risk assessment models in typical industries. J Occup Health. (2018) 60:337–47. doi: 10.1539/joh.2018-0039-OA

29. Lee, EG, Harper, M, Bowen, RB, and Slaven, J. Evaluation of COSHH essentials: methylene chloride, isopropanol, and acetone exposures in a small printing plant. Ann Occup Hyg. (2009) 53:463–74. doi: 10.1093/annhyg/mep023

30. Karimi Zeverdegani, S, Barakat, S, and Yazdi, M. Validation CHEM-SAM model using SQRA method in exposure to toxic substances in a chemistry research lab. J Milit Med. (2017) 19:291–8.

31. Ferguson, A, Solo-Gabriele, H, and Mena, K. Assessment for oil spill chemicals: current knowledge, data gaps, and uncertainties addressing human physical health risk. Mar Pollut Bull. (2020) 150:110746. doi: 10.1016/j.marpolbul.2019.110746

32. Lawrence, KG, Niehoff, NM, Keil, AP, Jackson, WB II, Christenbury, K, Stewart, PA, et al. Associations between airborne crude oil chemicals and symptom-based asthma. Environ Int. (2022) 167:107433. doi: 10.1016/j.envint.2022.107433

33. Antia, M, Ezejiofor, AN, Obasi, CN, and Orisakwe, OE. Environmental and public health effects of spent drilling fluid: an updated systematic review. J Hazard Mater Adv. (2022) 7:100120. doi: 10.1016/j.hazadv.2022.100120

34. Al-Hajj, S, Dhaini, HR, Mondello, S, Kaafarani, H, Kobeissy, F, and DePalma, RG. Beirut ammonium nitrate blast: analysis, review, and recommendations. Front Public Health. (2021) 9:657996. doi: 10.3389/fpubh.2021.657996

35. Chiavarini, M, Rosignoli, P, Sorbara, B, Giacchetta, I, and Fabiani, R. Benzene exposure and lung Cancer risk: a systematic review and meta-analysis of human studies. Int J Environ Res Public Health. (2024) 21:205. doi: 10.3390/ijerph21020205

36. Wang, TS, Bo, SONG, Sun, QH, Lin, YX, Yuan, SUN, Pin, SUN, et al. Occupational health risk assessment of benzene, toluene, and xylene in Shanghai. Biomed Environ Sci. (2021) 34:290–8. doi: 10.3967/bes2021.038

37. Liu, X, Li, J, and Li, X. Study of dynamic risk management system for flammable and explosive dangerous chemicals storage area. J Loss Prev Process Ind. (2017) 49:983–8. doi: 10.1016/j.jlp.2017.02.004

38. Bergkamp, L, and Abelkop, A. Regulation of chemicals In: L Emma and EV Jorge, editors. The Oxford Handbook of Comparative Environmental Law (2019) 578–60.

39. Bhusnure, OG, Dongare, RB, Gholve, SB, and Giram, PS. Chemical hazards and safety management in pharmaceutical industry. J Pharm Res. (2018) 12:357–69.

40. Sharma, BM, Bečanová, J, Scheringer, M, Sharma, A, Bharat, GK, Whitehead, PG, et al. Health and ecological risk assessment of emerging contaminants (pharmaceuticals, personal care products, and artificial sweeteners) in surface and groundwater (drinking water) in the Ganges River basin, India. Sci Total Environ. (2019) 646:1459–67. doi: 10.1016/j.scitotenv.2018.07.235

41. Jones, RM, and Nicas, M. Margins of safety provided by COSHH essentials and the ILO chemical control toolkit. Ann Occup Hyg. (2006) 50:149–56. doi: 10.1093/annhyg/mei054

42. Hoseini, LK, Yengejeh, RJ, Rouzbehani, MM, and Sabzalipour, S. Health risk assessment of volatile organic compounds (VOCs) in a refinery in the southwest of Iran using SQRA method. Front Public Health. (2022) 10:978354. doi: 10.3389/fpubh.2022.978354

43. Khajeh Hoseini, L, Jalilzadeh Yengejeh, R, Mahmoudie, A, Mohammadi Rouzbehani, M, and Sabz Alipour, S. Prioritization of effective strategic parameters in the removal of VOCs from the ROP system by using AHP: a case study of Abadan oil refinery. J Health Sci Surveill Syst. (2021) 9:199–205. doi: 10.30476/jhsss.2021.90008.1175

Keywords: chemical exposure, toxic material, chemical industry, risk assessment methods, occupational health and safety, drilling industries

Citation: Astani S, Lorestani B, Cheraghi M and Kiani Sadr M (2024) Assessing the health risks of chemicals in a company supplying chemicals to drilling rigs in Southern Iran using COSHH, SHEM-SAM, and SQRA methods. Front. Public Health. 12:1395695. doi: 10.3389/fpubh.2024.1395695

Edited by:

Luigi Vimercati, University of Bari Aldo Moro, ItalyReviewed by:

Abebe Kassa Geto, Dessie Health Science College, EthiopiaKatayoon Varshosaz, Islamic Azad University, Ahvaz, Iran

Reza Jalilzadeh Yengejeh, Islamic Azad University, Ahvaz, Iran

Copyright © 2024 Astani, Lorestani, Cheraghi and Kiani Sadr. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bahareh Lorestani, bG9yZXN0YW5pX2JAaWF1aC5hYy5pcg==

†ORCID: Sajad Astani, orcid.org/0000-0002-5177-8192

Bahareh Lorestani, orcid.org/0000-0003-1838-9088

Mehrdad Cheraghi, orcid.org/0000-0002-7918-8944

Maryam Kiani Sadr, orcid.org/0000-0002-9410-8332

Sajad Astani†

Sajad Astani† Bahareh Lorestani

Bahareh Lorestani