- 1Belt and Road Initiative Center for Chinese-European Studies (BRICCES), Guangdong University of Petrochemical Technology, Maoming, China

- 2Department of Management and Economics, International Institute of Management, Kyiv, Ukraine

- 3Department of Personal Protective Equipment, Central Institute of Labour Protection – National Research Institute, Łódź, Poland

- 4Department of Ecology and Technologies of Environmental Protection, Dnipro University of Technology, Dnipro, Ukraine

- 5Department of Labour Protection and Civil Safety, Dnipro University of Technology, Dnipro, Ukraine

- 6Department of Transportation Management, Dnipro University of Technology, Dnipro, Ukraine

- 7Department of Mining Engineering and Education, Dnipro University of Technology, Dnipro, Ukraine

Purpose: The research purpose is to improve the management of occupational risks associated with hazards as well as the organization’s capabilities to identify hazardous factors (HFs) using the “BOW-TIE” method in accordance with the provisions of the ISO 45001:2019 standard.

Methods: To improve occupational risk management, the “BOW-TIE” method has been introduced into occupational health and safety management systems. This approach facilitates a comprehensive description and analysis of potential risk development from identifying hazardous factors to studying the consequences. It visually integrates fault and event trees to provide a holistic view of risk dynamics.

Results: The improvement of the occupational hazard risk management process considers both internal and external factors affecting the organization, thereby increasing the probability and severity of potential hazardous events. The revised approach categorizes risk levels as acceptable, unacceptable, or verifiable. In addition, occupational risk management requires an in-depth analysis of the organization’s external and internal environment to identify hazards that affect the probability and severity of potential hazardous events.

Conclusion: This research proposes an innovative approach to occupational risk management by determining the magnitude of occupational risk as the cumulative result of assessing risks associated with all external and internal factors influencing the probability of hazardous event occurring. The introduction of the “BOW-TIE” method, combined with a comprehensive analysis of the organizational environments, facilitates a more effective and nuanced approach to occupational risk management.

1 Introduction

For the development of a country and society as a whole on the way to joining the European Union, it is necessary to ensure the implementation of production processes with the least expenditure of effort and resources, together with high occupational safety and health of employees (1–4).

The model of any business for managing losses, including losses of life and health of workers, can be presented in the form of a list of external and internal hazardous factors (hereinafter – HF): social, environmental, economic, industrial, innovative, scientific, and technical and other, which are interconnected and contribute to the improvement or deterioration of business process management systems at enterprises under certain conditions (5).

Under certain conditions, the cumulative impact of all hazardous factors will contribute to the deterioration of the effectiveness of business process management systems at enterprises (6, 7).

Therefore, their analysis, identification of the most influential ORs, or their combinations is the basis for making any decisions based on occupational risk (OR) assessment in occupational safety and health management systems to substantiate protective and precautionary measures to reduce injuries when performing production tasks (8–11). It is this approach that makes it possible to ensure the organization’s resilience to the impact of destructive factors and reduce the impact of negative consequences and financial losses (12).

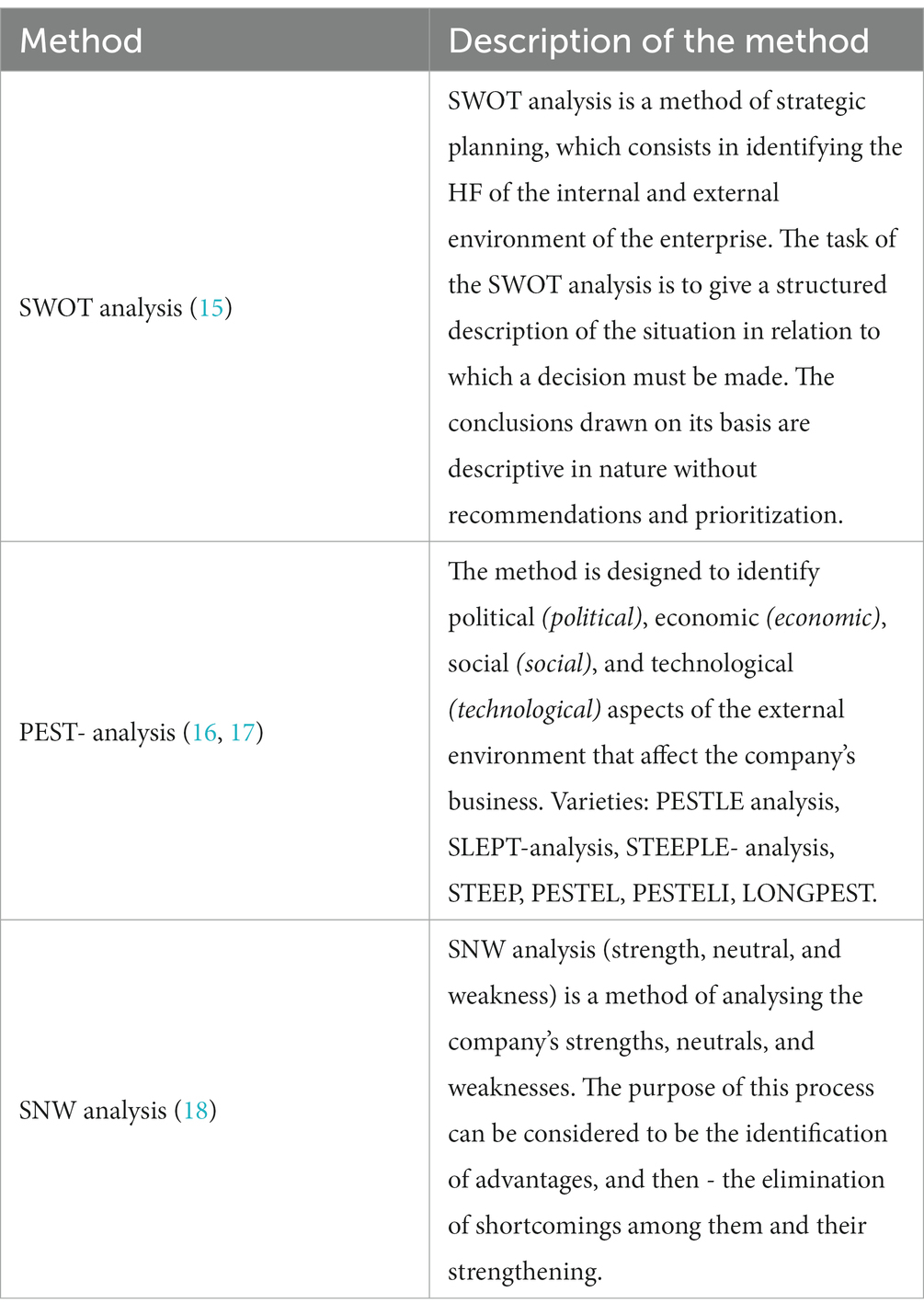

In accordance with the requirements of the ISO 45001:2018 standard (13), each enterprise must determine all external and internal HFs of organization environment that can increase the probability of the occurrence of hazards occurring in occupational safety and health management systems that will not achieve the intended result, reducing injuries and occupational diseases in the organization. In order to identify all the hazardous external and internal factors, the SWOT analysis is the basic one (14). If additional consideration of external groups of HFs (political, economic, social, etc.) is necessary, PEST analysis is added. To identify neutral HFs, which can be either negative or positive, requiring additional analysis, the SNW analysis method is used (Table 1).

At the same time, there is a challenge in identifying the HF impact on the level of occupational risks, the value of which forms awareness of the impact of uncertainty on the objectives set in the relevant management systems (19).

It is a common understanding that the risk assessment process focuses only on the analysis of the potential threat and its consequences. In this case, to determine the cause-and-effect relationship between the hazard and hazardous event, focus is made exclusively on one factor (20, 21).

With this approach to risk assessment, a complete understanding of the structure of the environment in which the enterprise operates is often lost. This does not allow to reflect all possible influences on the OR of hazards (probability and degree of severity of a hazardous event: accident, failure, etc.) at employees’ workplaces (22, 23). Hence, the need arises to conduct appropriate scientific research to develop new or improve known OR management approaches that would allow taking into account the cumulative impact of any internal and external HFs of any enterprise organization.

There are 32 different methods for analyzing the OR management process in an enterprise environment, each having its own strengths and weaknesses (24). However, there is always a question about the effectiveness of known methods for solving the tasks in a particular enterprise. The authors of the publication (25) concluded that in order to choose the best method, first of all, it is necessary to understand what results the company wants to achieve. Because none of the known methods for analyzing the influential HF of the general environment of the enterprise, used in isolation, gives a complete picture of the structure that functions in enterprises, errors occur in management decisions aimed at improving security. However, the study considers the solution of a specific case of environmental impact assessment, which does not allow the developed approach to be applied to other conditions. At the same time, the authors of the scientific study (26) recommend using the results combining several methods to obtain the most complete information about hazards during production operations. However, unfortunately, no recommendations were made how to combine or select them. As the authors of the study (27) noted, in order to promote the progressive, inclusive, and sustainable economic growth of the enterprise, it is necessary that the enterprise management system, which covers the entire set of interrelated elements, is aimed precisely at eliminating all major threats and challenges it faces. At the same time, the biggest problem arises when making an effective decision due to the fact that it is difficult to determine the probability of occurrence of hazardous events from various threats when employees perform production activities (28).

Sometimes this requires quite serious scientific research. However, quite a few enterprises can afford to finance such projects. Moreover, the answer will be received after a certain period of time that is usually lacking. The specified task requires a clear understanding of the action of all possible hazards and HF, which can increase the probability of the occurrence of a hazardous event (29). We should note that the most popular for modeling hazardous processes, including accidents, were diagrams of cause-and-effect relationships, which received the names “failure tree” and “event tree” (30, 31). By getting all the information about the negative external or internal HF of enterprise, it is possible to understand the hazards in this or that scenario; it is possible to estimate the OR. If the OR is not acceptable, it should be reduced; that is, measures should be implemented to reduce the probability of occurrence of a hazardous event and/or the degree of severity of the consequences of a hazardous event. However, in most of the analyzed publications (32–35) regarding the assessment of OR, there is a misunderstanding between hazard and external and internal HF, which have a significant impact on the probability of the occurrence of a hazardous event and the severity of the consequences for the life and health of employees being a condition for OR changing (increasing or decreasing) (36). Therefore, there is a misunderstanding regarding measures to reduce the probability of the occurrence of a hazardous event and its severity since it is sometimes not possible to eliminate the hazard itself.

The purpose of the study is the improvement of the enterprise’s OR risk management process taking into account the requirements of the standard ISO 45001:2019.

2 Materials and methods

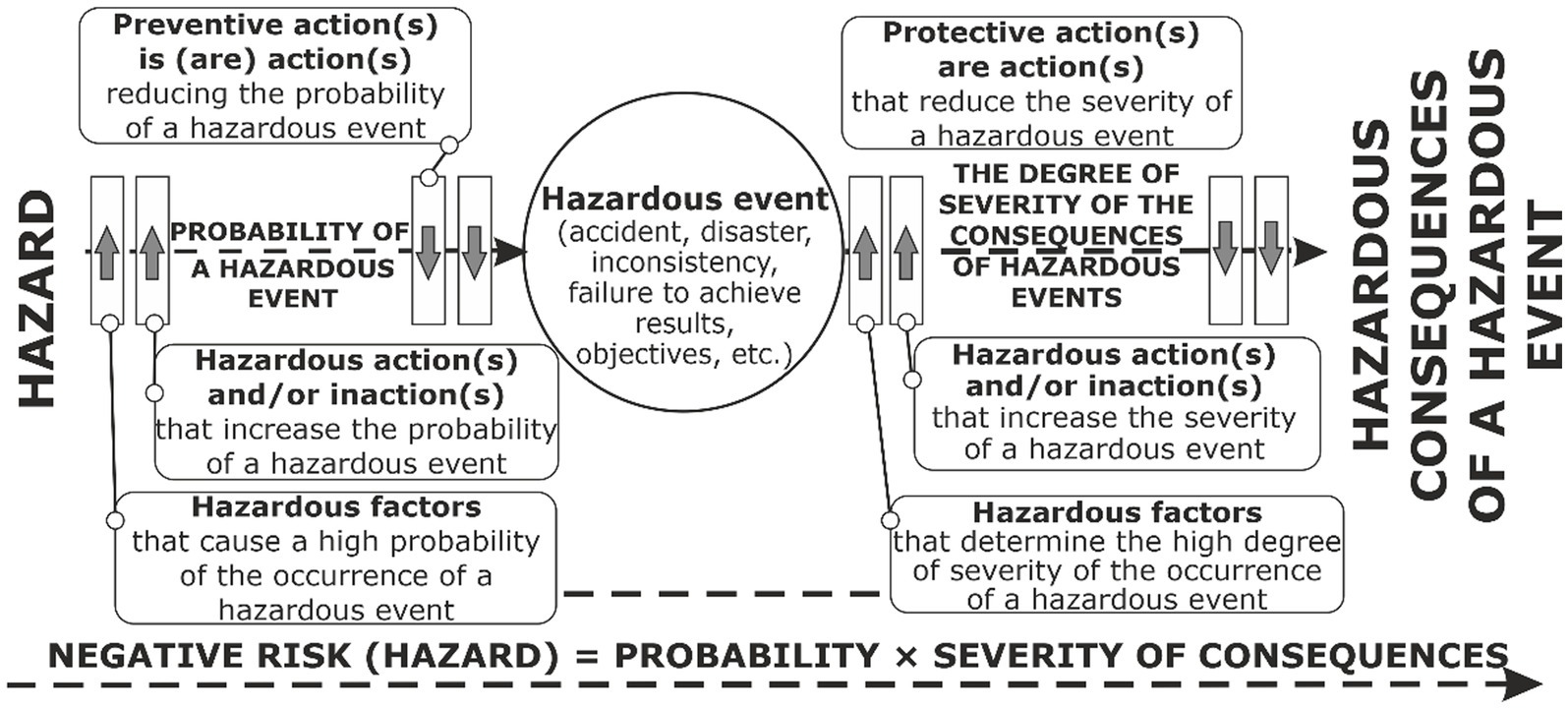

The most common approach to OR management, which is the basis for developing an action plan to achieve the desired result in the operation of the OHSMS system of any organization, is the “BOW-TIE” method. This method provides, on the basis of a cause-and-effect relationship between hazard and a hazardous event, and it allows to describe and analyze occupational risks during any production operations (37, 38).

It can also be used to determine the effectiveness of proposed “barriers” (precautionary or protective measures) to reduce the probability of a hazardous situation on the one hand, and on the other hand, the severity of the consequences of an incident (Figure 1).

In general, the presented method provides for the calculation of the amount of occupational risk:

• Identification of hazards for the development of their register in the organization based on the study of sources of risk.

• Studying the mechanisms of the development of a hazardous event based on a cause-and-effect relationship.

• Determination of the probability of the occurrence of a hazardous event - due to the processing of statistical data on all incidents that occurred anywhere.

• Determining the severity of losses, calculating the number of days of incapacity for work or coefficients of the severity of injuries, economic losses.

• Calculation of occupational risk—by any suitable method, which is defined in IEC 31010:2019 risk management—risk assessment techniques.

Unfortunately, the well-known interpretation of the described method does not take into account the influence of internal and external hazardous factors on the probability of a hazardous event, information about which is collected in the organization by one of the above approaches (Table 1). As a result, there is a lack of clear understanding of what affects the probability of a hazardous event and its degree of severity. At the same time, the ISO 45001:2018 standard mentions the need to determine external and internal factors that affect the final result of the occupational safety and health management system, i.e., reducing the loss of health and life of workers. The standard requires the organization to use these factors to assess occupational risks but does not mention the mechanism for performing this procedure.

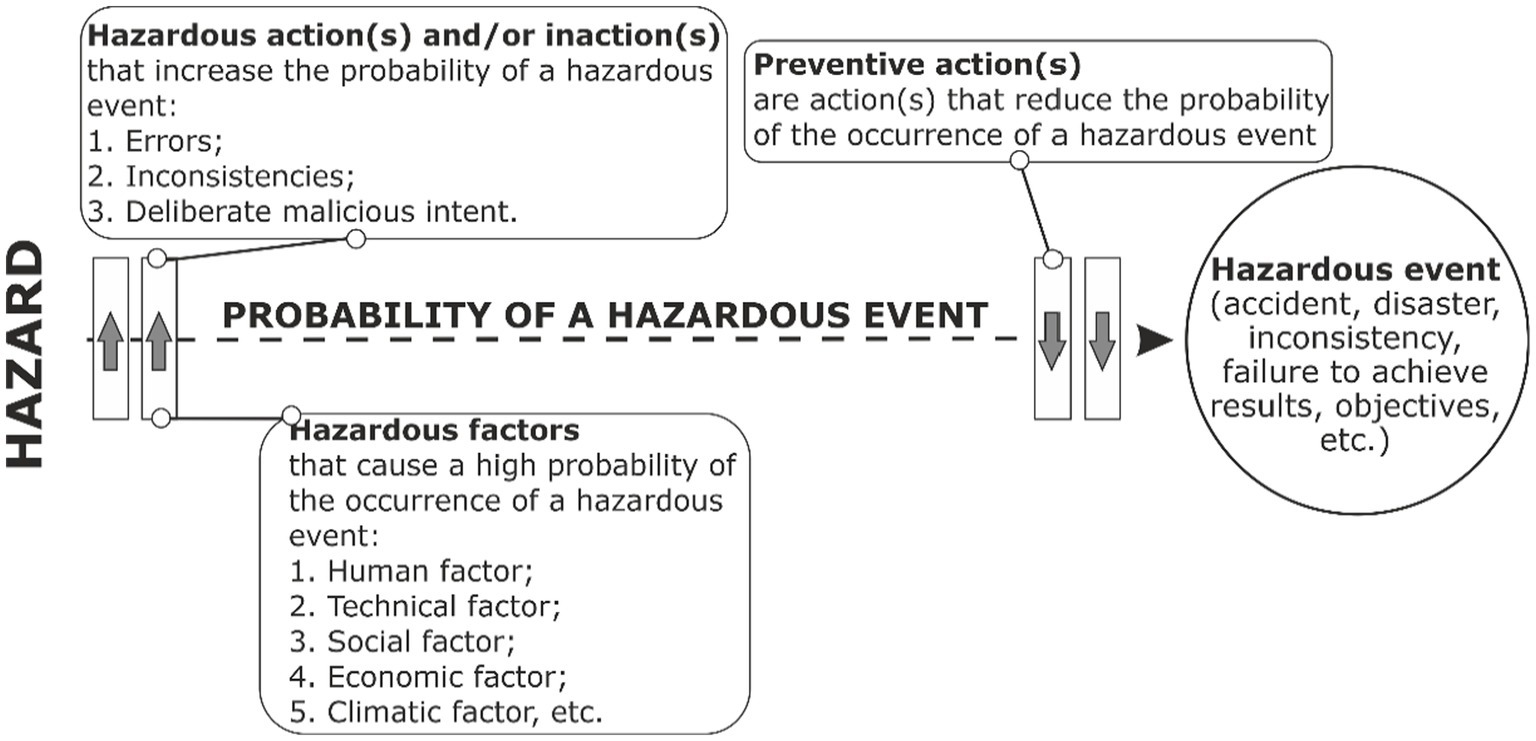

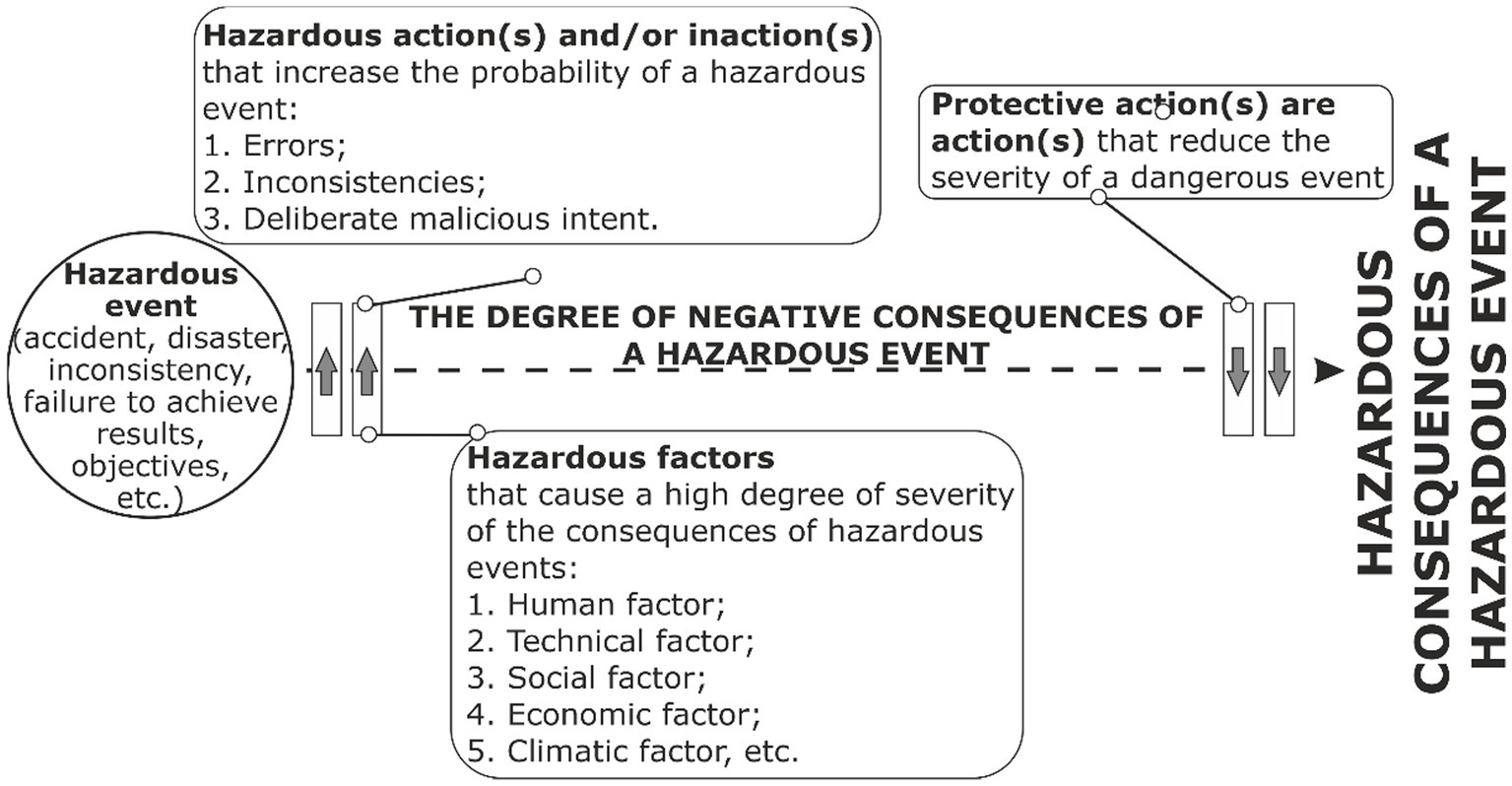

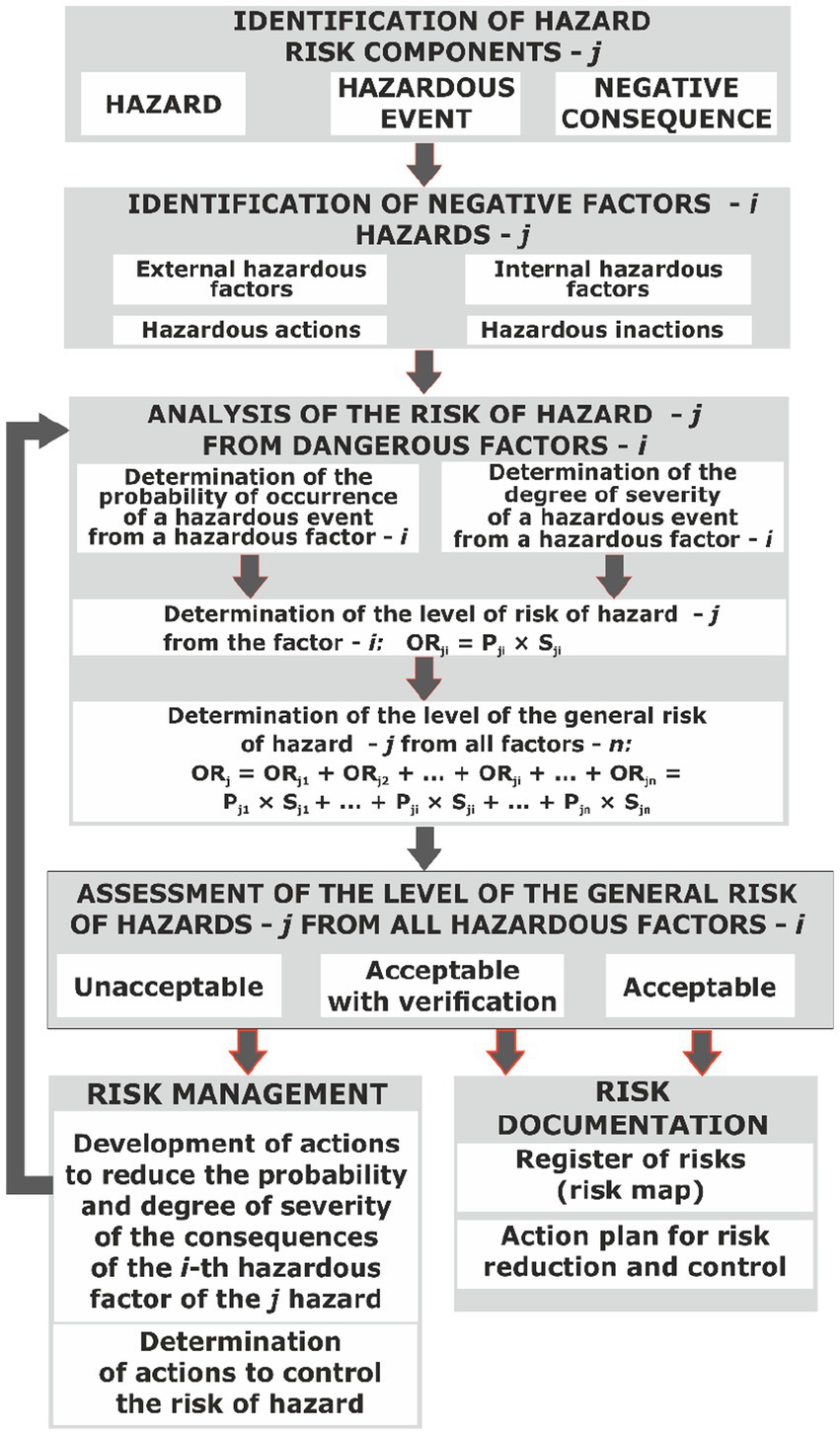

According to the IEC 31010:2019 standard, the “BOW-TIE” method is necessary to establish a cause-and-effect relationship to determine the amount of risk: “hazard–hazardous event consequences” while assessing the probability of the occurrence of a hazardous event and its degree of severity, which is not possible without identifying characteristic hazardous factors of the external and internal environment of the organization, which are related to a specific workplace. Therefore, it is proposed to improve the “BOW-TIE” model, in which, instead of the location of “barriers” [preventive or protective measures and means (Figure 1) that reduce the occurrence of a hazardous event and the severity of the consequences, we provide information about the entire set of negative and safe external and internal factors that increase the probability or severity of the consequences of a hazardous event (Figure 2)].

The basis of the improved “BOW-TIE” method is the calculation of the amount of occupational risk from the combined action of all hazardous factors: physical, chemical, climatic, biological, psychophysiological, ergonomic, technical, organizational, and others, as well as hazardous actions and inactions of employees (errors, malicious intent, professional incompatibility, etc.) in the organization (Figure 2). It should be recalled that according to the ISO 31010 standard, the limitations of this method include the inability to study the occurrence of a hazardous situation in the absence of a clear relationship with the hazard, especially when there is more than one.

As a result, the effectiveness of the occupational risk management process is improved due to a comprehensive consideration of all hazardous external and internal factors or hazardous actions and inactions.

At the first stage of OR evaluation, there is a need for a clear understanding of OHSMS terms in accordance with the requirements of the ISO 45001:2018 standard. It is necessary to clearly distinguish what is a “hazard” and what are “influence factors”—a hazardous factor that increases the probability of a hazardous event.

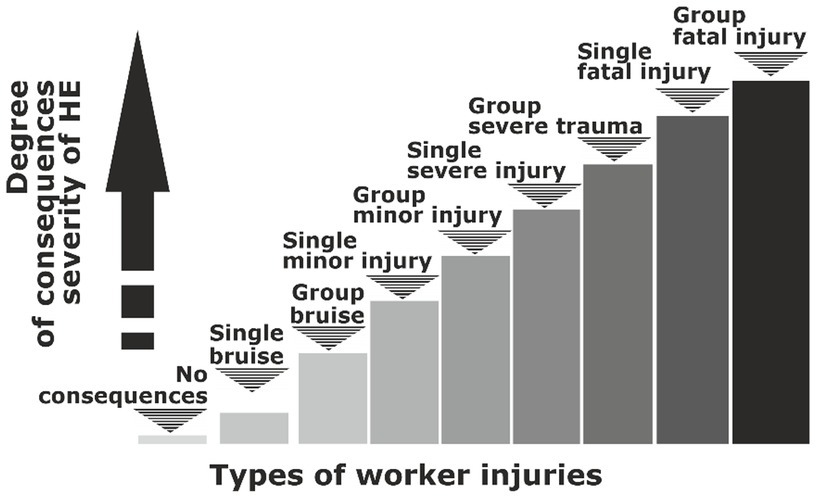

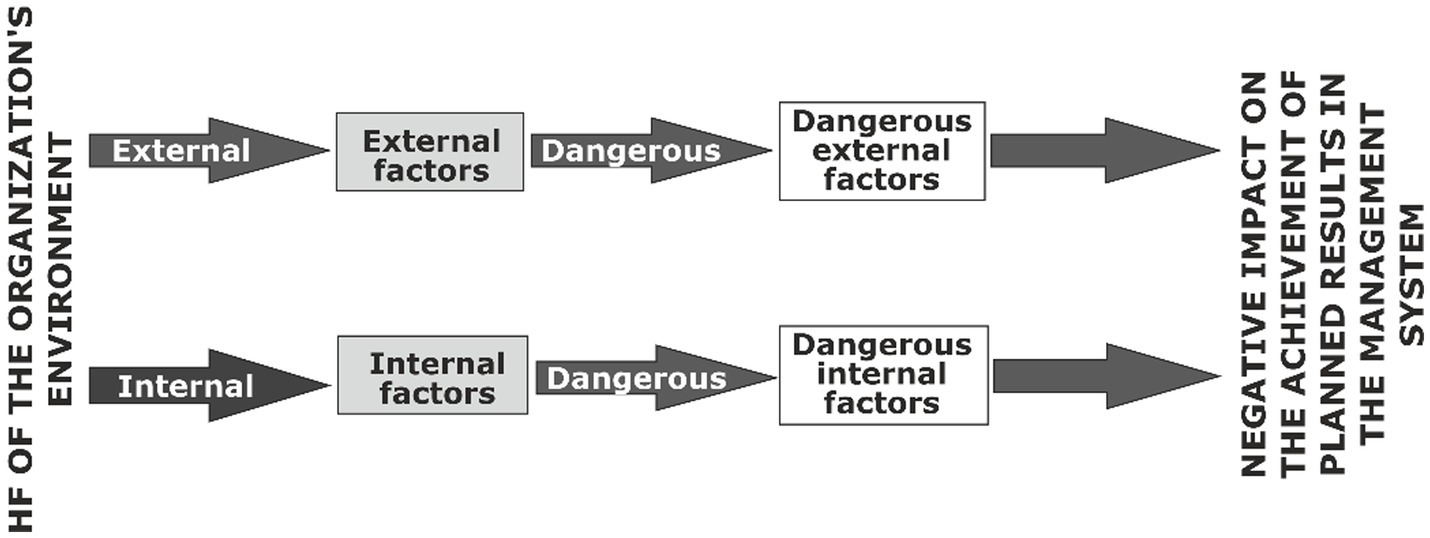

According to ISO 45001:2018, a hazard is defined as any source with the possibility of causing injury and deterioration of health. A hazardous factor increases the probability of occurrence of a hazardous event (incident) or/and also influences and increases the severity of injury and deterioration of health that may be caused by a hazardous event (incident). That is, in order to calculate the probability of occurrence of a hazardous event and its severity, it is necessary to identify all hazardous factors (Figures 3, 4):

Figure 3. Method of OR hazards management of external and internal environment of the enterprise from the point of the probability of the occurrence of a hazardous event.

Figure 4. Method of OR hazards management of external and internal environment of the enterprise from the point of reduction of the degree of severity from the occurrence of a hazardous event.

• Increase the probability of the occurrence of a hazardous event.

• Increase the degree of severity of a hazardous event.

• Increase both the probability of the occurrence of a hazardous event and the severity of its consequences.

In addition, it is proposed to increase the effectiveness of OR management by taking into account hazardous actions and without the action of the employee (39), which are as follows:

• Increase the probability of the occurrence of a hazardous event.

• Increase the degree of severity of a hazardous event.

• Increase the probability of occurrence of a hazardous event, as well as the degree of severity.

Hence, there is a need to improve the OR management process itself. In addition, it is proposed to identify low environmental factors of the enterprise, and hazardous actions and without the actions of employees. That is, in order to calculate the OR of hazard—j, we first identify all external and internal HF, hazardous actions. Next, we conduct a risk assessment for each hazardous factor (40, 41):

Rпjn = Впjn × Тпjn.

Where Rпjn is occupational risk of a hazardous event from hazard j taking into account hazard factors n; Впjn is the probability of the occurrence of a hazardous event from hazard j under the influence of a hazardous factor n; Tпjn is degree of severity of consequences from a hazardous event from hazard j under the influence of a hazardous factor n.

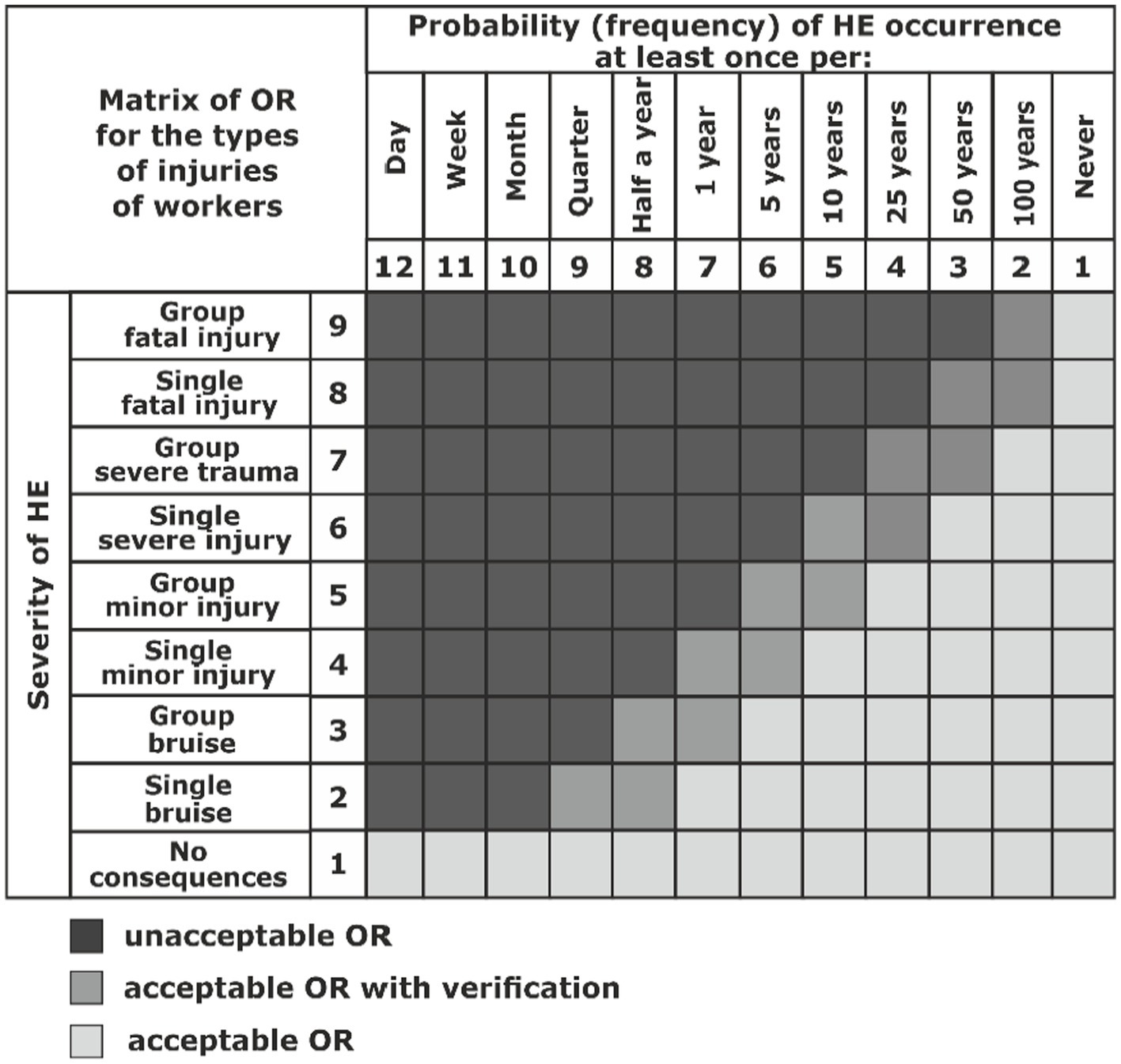

To determine the probability of the occurrence of a hazardous event from hazard j, it is important to use statistical data that will become the basis for substantiating the point scale. Determination of the degree of severity of the consequences is based on the classification of types of injuries (Figure 5).

To estimate the value of the OR, a special matrix with a scale of 9 × 12 (Figure 6) is proposed as an example, which is determined on the one hand by the number of negative consequences and, on the other hand, by the probability of the occurrence of the HE.

Figure 6. Form of the matrix for determining the value of OR by hazardous factors considering of the type of injuries of workers.

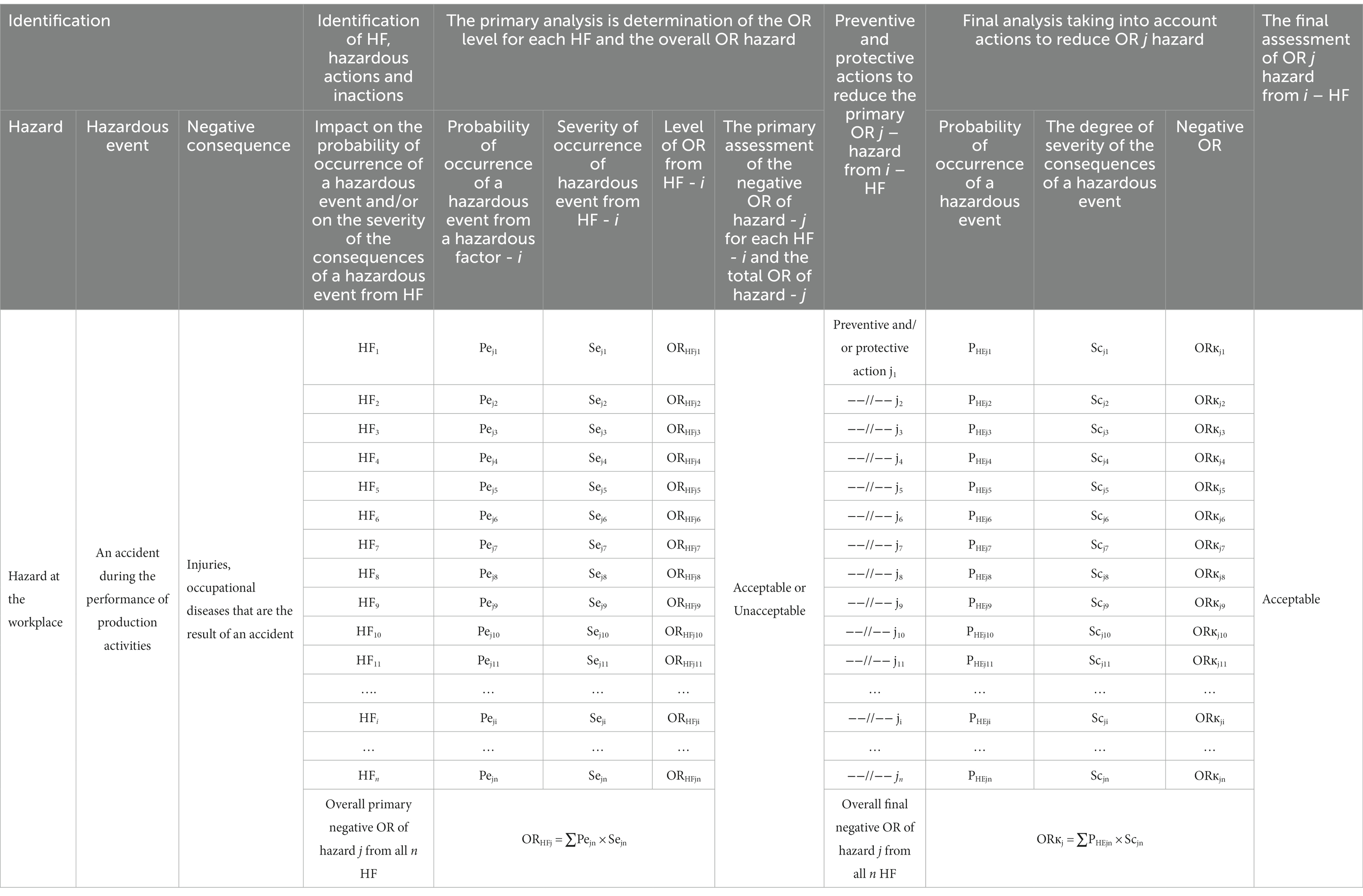

In order to determine the points for the calculation of the occupational risk for each hazardous factor, several experts are invited, the results of whose work are averaged and entered in Table 2, which represents the form of the OR hazard map j according to the proposed OR management process (Figure 7).

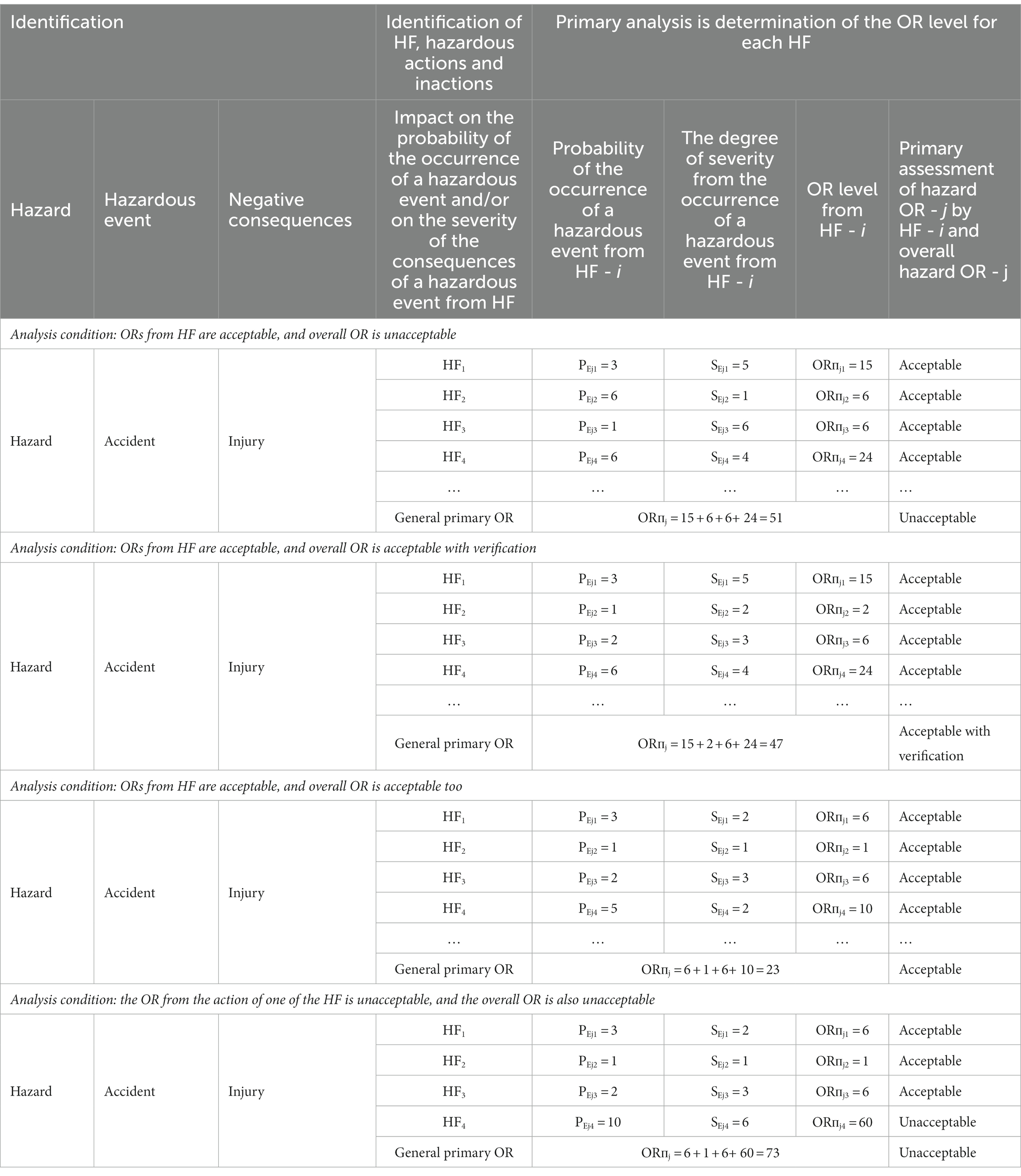

Table 2. Identification of hazards, HF, analysis and assessment of hazard ORs j provided that hazard factor of ORs are acceptable and total OR is not acceptable.

Figure 7. Process of OR managing with additional identification of the HF of enterprise environment and hazardous actions and inaction with the determination of the general OR of the hazard level.

The next step is to determine the value of the occupational risk of hazard from the combined effect of all risks from hazardous factors associated with this hazard according to the formula:

Rпj = Rпj1 + … + Rпjn.

Where Rпj is the total occupational risk from hazard j; Rпj1 is occupational risk from the first hazardous factor; and Rпjn is occupational risk from the n-th hazardous factor.

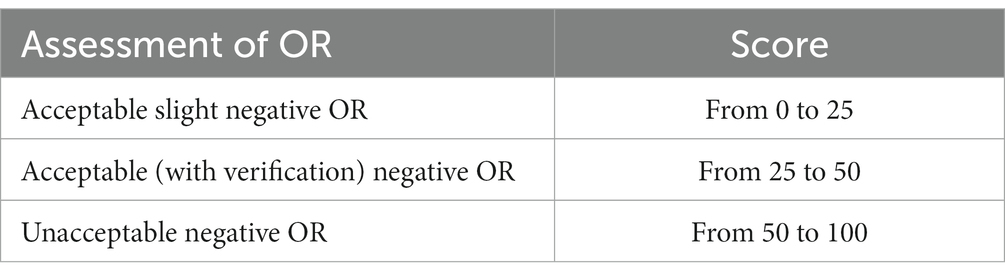

Next, we assess the total risk and assess its level of acceptability or unacceptability according to the criteria listed in Table 3.

3 Results

Based on the requirements of the ISO 45001:2018 standard, external and internal HFs (hazards, threats or opportunities) of the working environment at the enterprise can be determined using one of the acceptable methods given in Table 1. In addition to examining hazards in the employees’ workplaces themselves, attention should be paid to the organization’s policy, planning processes in management systems, production technology, and other processes that form the organization’s “environment.”

Sources of information about external HF of enterprises can be information posted on the Internet: research, publications in periodicals, news sites, and official sites of state bodies. Information about the state of the internal environment of the enterprise can be obtained from reports on the effectiveness of the OHSMS at the enterprise, internal audits, results of self-assessment, minutes of meetings of managers of various levels, etc. It is important to understand that these HFs have an interrelated effect on the achievement of planned results, which leads to the need to identify OR factors that strengthen/weaken their effect (Figure 8).

Figure 8. Interrelationship of various factors of the enterprise environment and their influence on the achievement of planned results.

Based on the analysis performed, we form a register of hazardous factors by relevant groups (42): organizational, technical, operational, ergonomic, environmental, hygienic, psychosocial, military, and others. The formed register makes it possible to determine the most significant hazardous factors for each emergency situation. This can be done by different methods such as Monte Carlo simulation (43) and expert methods such as fuzzy set theory and fuzzy AHP (44, 45).

Considering different variants of the value of OR, which arise from external and internal HF, hazardous actions and inactions, together allow us to determine the value of the total OR of hazard j.

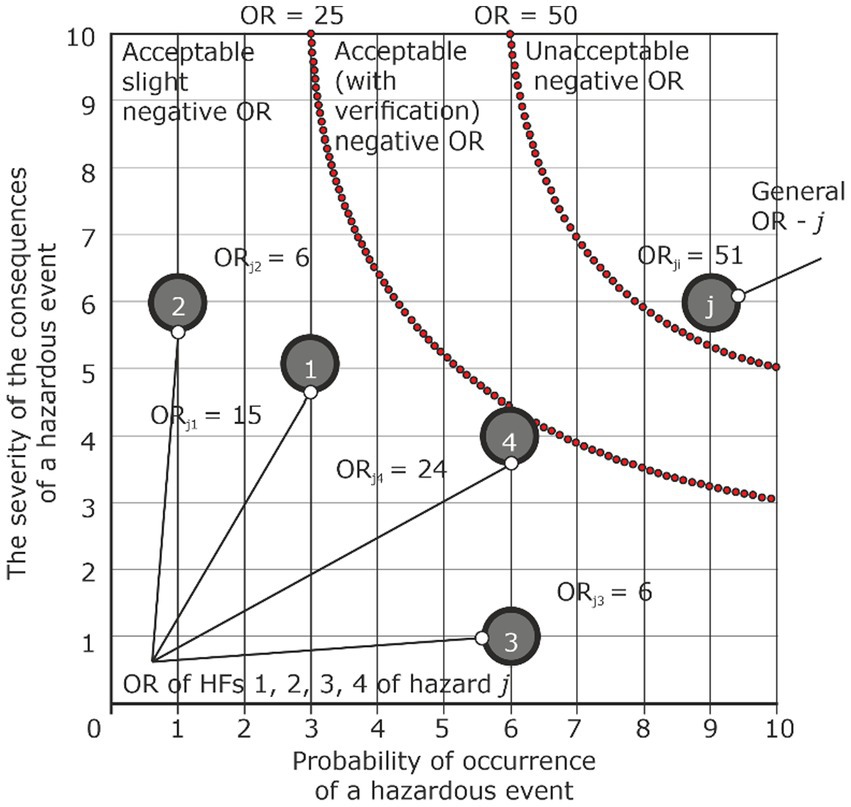

Therefore, when calculating the value of the total OR, situations may arise when all the ORs from HF are acceptable, and the total OR from the hazard is not acceptable (Table 4; Figure 9). In this case, there is a need to stop the production operation to eliminate or reduce the impact from several detected HFs. Such a situation requires a careful analysis of the impact of the most critical HF.

Figure 9. Graphical presentation of assessment of OR hazard j under the condition that the OR of hazardous factors are acceptable, and the general OR is not acceptable.

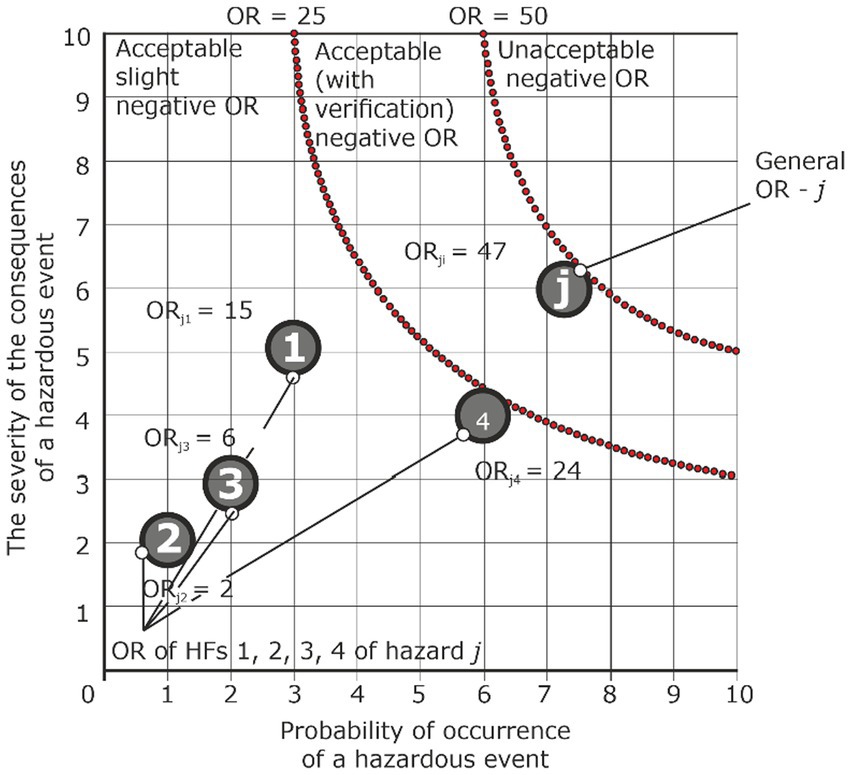

The next option may be a situation where the OR from HF action is acceptable, and the total OR is acceptable with verification, i.e., there is a need to control the hazard, HF, and the value of OR, as well as monitor HF or actions of workers that would allow to avoid an unacceptable level OR (Table 4; Figure 10).

Figure 10. Graphical presentation of assessment of OR hazard j under the condition that the OR of HF is acceptable, and the general OR is acceptable with verification.

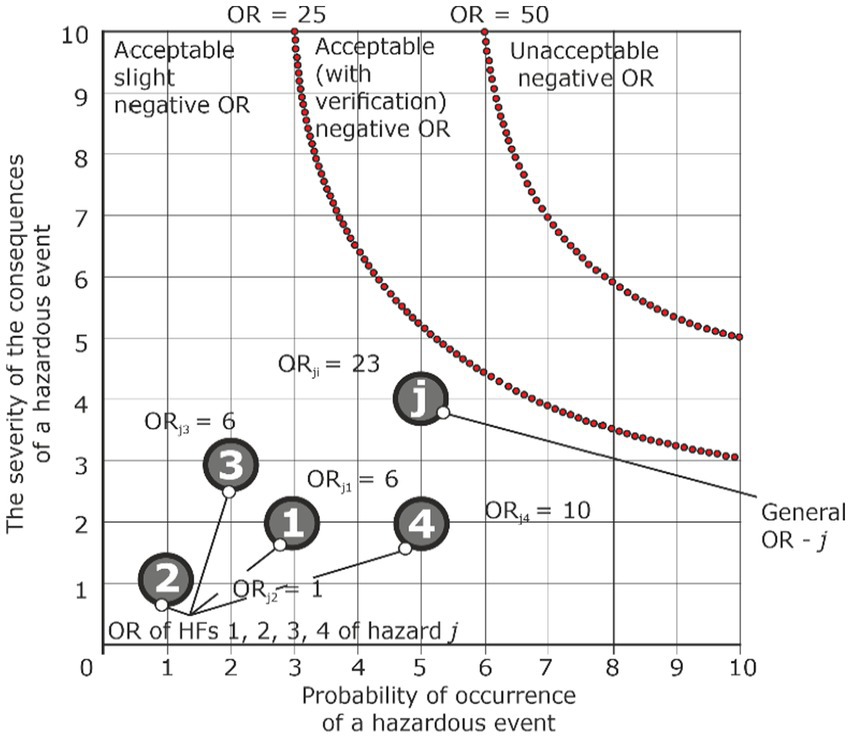

The most acceptable situation is when all ORs from HF and actions are acceptable, which in sum allows us to obtain an acceptable overall OR (Table 4; Figure 11).

Figure 11. Graphical presentation of assessment of OR hazard j under the condition that the OR of HF is acceptable, and the general OR is acceptable too.

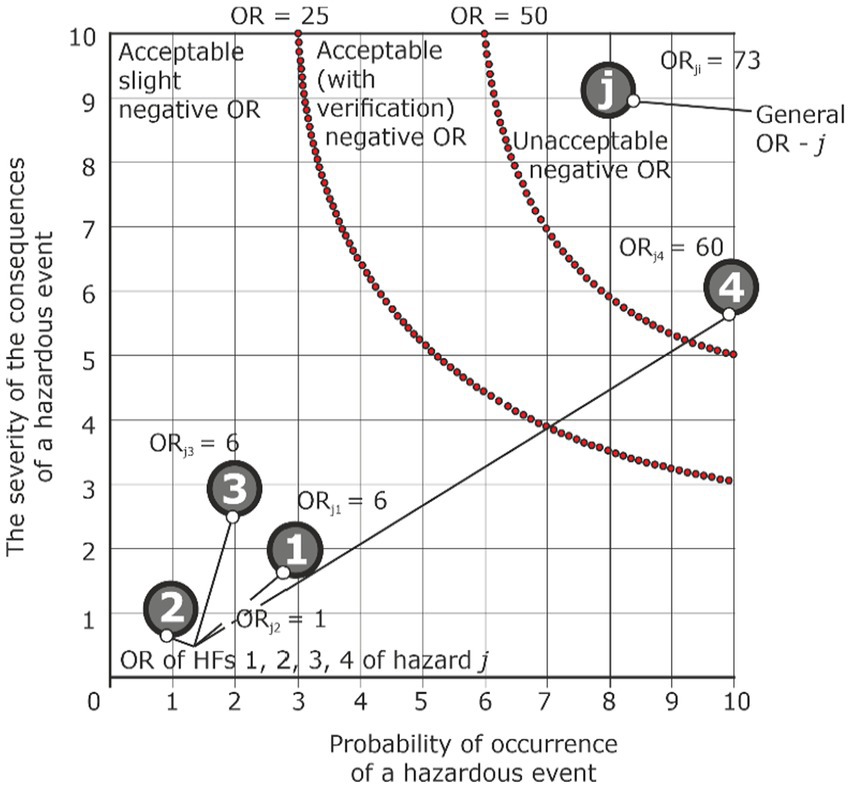

The most difficult situation is when there is a condition that one of the ORs from HF action is unacceptable, and the overall OR will also be unacceptable (Table 4; Figure 12). In this case, there is a need to eliminate the detected HF or introduce actions to reduce its influence and conduct a check on the overall value of the OR level.

Figure 12. Graphical presentation of assessment of OR hazard j under the condition that the OR of one of HFs is unacceptable, and the general OR is unacceptable too.

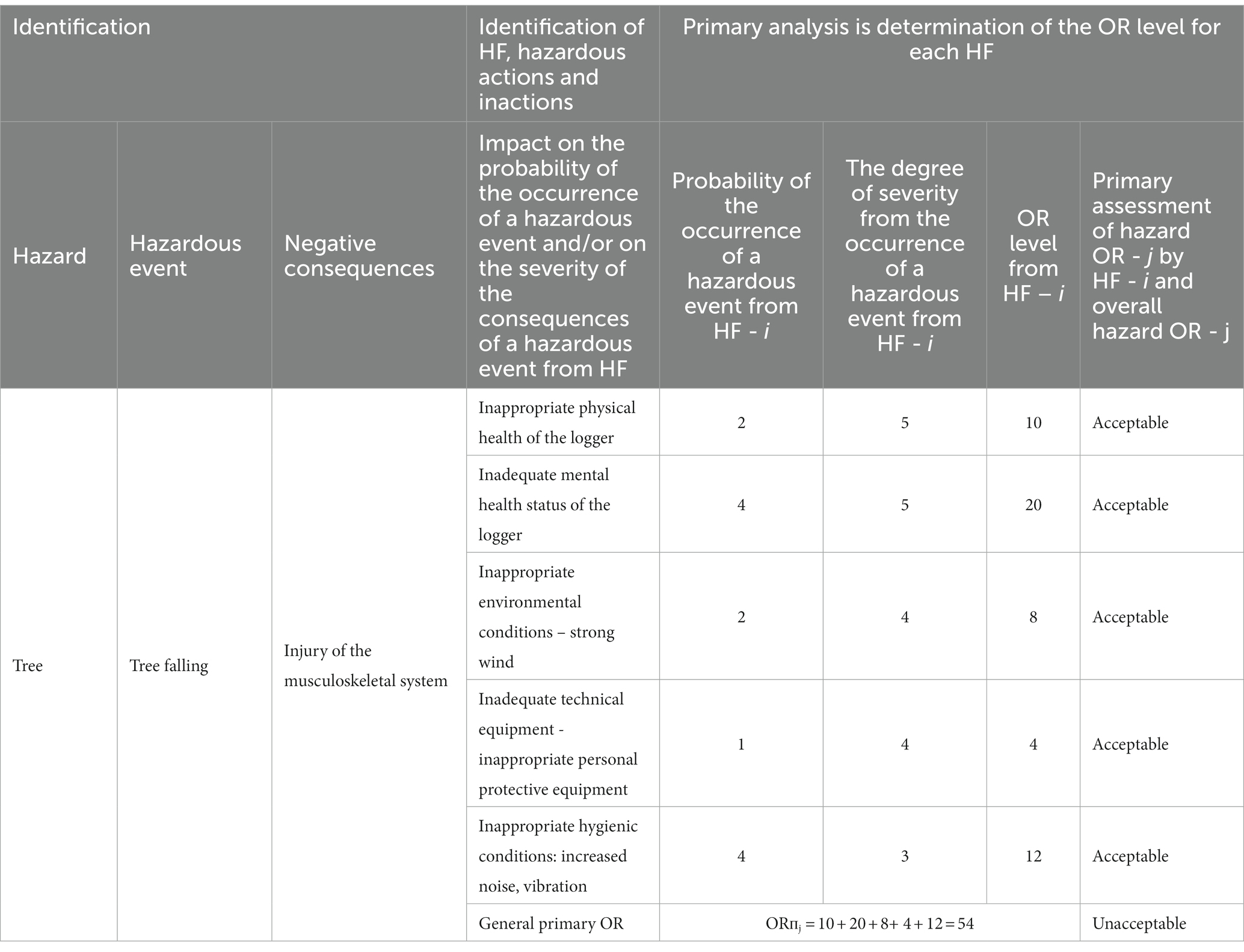

There is a simple example of an occupational risk assessment of a logger who uses a chainsaw to fell trees in hard-to-reach places (Table 5). Work that is physically demanding (46) is characterized by an uncomfortable body position (47). The main hazard that causes injury is a tree (48). A hazardous event is a falling tree, and the consequences can be injuries of varying severity to the logger’s musculoskeletal system (49). Loggers working outdoors are exposed to a number of different HFs, such as strong wind, inappropriate technical equipment (e.g., personal protective equipment), hygienic hazards [vibration (49), noise (50)], ergonomic hazards—unnatural or uncomfortable working position (48, 51), human factors—psychological inconsistency or health problems.

In the above example, each component of the total (cumulative) risk does not exceed acceptable limits, but if certain HFs occur together at any point in time, this will result in unacceptable risk, requiring a review of the impact of each HF. If a traditional method, such as a BOW-TIE, is used to analyze the occupational risk of a logger, each individual hazard will not exceed the critical risk level. This risk assessment often leads to the error that additional precautions are not necessary. It is the total HF value of an unacceptable level that requires again reconsidering the influence of each HF and reducing their influence. In the above example, there is a need to find precautionary measures to reduce the entry of loggers with an inappropriate psychological state into the workplace. At least, we have an understanding of the need for additional introduction of precautionary and protective measures.

4 Discussion

A more advanced approach to the OR management process is proposed, which takes into account the influence of external and internal HFs on the probability of a hazardous event occurring and the severity of consequences by summing up the risks from all hazardous external and internal factors in the workplace, given the hazardous actions and inactions of employees.

Its difference from the BOW-TIE method is the ability to take into account the influence of a combination of HFs when analyzing cause-and-effect relationships, which can increase the probability of a hazardous event occurring. At the same time, obstacles that are determined through the hierarchy of precautionary measures (52–54) are reflected in the proposed model as “precautionary actions” that include the strengths of the production environment.

The proposed improved approach to the OR management process allows for a more thorough analysis of external and internal HF, which affect the probability of the occurrence of a hazardous event or the severity of its consequences and therefore ensures the improvement of business process management systems at the enterprise. We should note that any enterprise to ensure effective operation needs to take into account the wishes of interested parties, identify weak points in technology, management systems (55). For this, it is important to ensure a response to all hazardous external and internal factors that threaten the production process in order to reduce losses.

This is implemented in the algorithm that considers four different situations for assessing the OR level from exposure to HFs, which provide conditions for the acceptability/unacceptability of the OR level from exposure to both individual HF and their combined effect. This will make it possible to identify significant HFs or their combination, which increases the probability of a hazardous event occurring. In addition, such an approach will reduce data uncertainty due to poor understanding of the phenomena characteristic of the production process, which is achieved by increasing information about the nature of the processes occurring in the systems (56, 57).

The Bayesian network has a similar probabilistic approach to assessing occupational risk (58). The method consists of two parts: a qualitative diagram and a probability distribution including a quantitative part of the analysis (21). In addition, it makes it possible to construct the same cause-and-effect relationships between various HFs that influence the occurrence of a hazardous situation, for example, according to Dempster’s rule of combination (59). However, the use of this method for assessing occupational risks is difficult, since the algorithm requires a large amount of data, which is mostly determined heuristically or restrictions are introduced to ensure the construction of appropriate relationships between graphs (60). Based on the recommendations of the ISO 31010 standard, this method should only be used for risk assessment. While for other steps that are characteristic of risk management, identification of hazards, determination of the probability of a hazardous event occurring, there is a need to use other approaches, for example, the FMEA or HAZOP methods.

The BOW-TIE method was developed specifically for security management (61). The ISO 31010 standard recommends its use at all stages of risk management: identifying threats, analyzing consequences, risk probabilities, and assessing operational risks. In this sense, BOW-TIE analysis is a combination of FTA and ETA (62), and is very popular since it includes both the causes and consequences of an incident scenario (54).

Note that one of the important requirements of the ISO 45001 standard is the involvement of all employees in the risk management process (63), requiring an appropriate universal approach characterized by easy comprehension and a minimum number of additional steps to assess risks. The BOW-TIE method satisfies these requirements well, so it was decided to improve it in order to increase the efficiency of decision-making. In addition, the ISO 31000 standard indicates the need to move from simple to complex (64). Hence, each of the above risk assessment methods exists and can be applied based on the tasks set before the organization, taking into account available resources to ensure the implementation of the precautionary or protective measures taken to preserve the life and health of the employee and to avoid emergency situations and accidents.

To manage the OR, it is additionally recommended to conduct an analysis of the external and internal environments of the enterprise in order to determine the HFs that affect the probability of the occurrence of a hazardous event and or the degree of severity of the consequences of a hazardous event. To determine the value of the OR of the hazard, it is taken as the sum of the OR from all external and internal HFs, affecting the probability of occurrence of a hazardous event. This approach is based on the assumption that OR is primarily financial losses; in this case, there is an opportunity to determine the total value as the sum of losses from the occurrence of a hazardous event (65, 66).

OR management methods consider the cause-and-effect chain “hazard-hazardous event-loss.” However, the proposed OR management method shows that the occurrence of a hazardous event is possible not only in the presence of hazard but also in conditions for the occurrence of a hazardous event. They are the HFs set, which are associated with negative human, technical, organizational, and other HFs belonging to HFs of the internal environment of the enterprise, as well as factors of the external environment of the enterprise such as season, presence of precipitation, and time of day. At the same time, it is proposed to consider the cause-and-effect chain “hazard-hazardous event-loss” with the influence of HF on the probability of the occurrence of a hazardous event and/or the degree of severity. It is proposed to define OR of hazard as the sum of OR of all HF of a hazardous event.

The shortcomings of this method, which require further research, include the inability to take into account the variability of HFs over time (67, 68). The analysis of various emergency situations and accidents shows (69–71) that the main reason for the occurrence of a hazardous situation is the sequence or simultaneous occurrence of a certain number of hazardous factors in a certain period of time. At the same time, HFs can have different impact on the probability of a hazardous event occurring when an employee performs production tasks, which is conditioned by the presence of strong points in the production environment (72). In particular, this is the competence of the employee, the periodic occurrence of noise or vibration in the workplace, the appearance of a minor technical malfunction in hard-to-diagnose equipment, etc. All this requires the use of combinatorics to identify the most probable combinations of hazardous factors that have a significant impact on the hazardous situation manifestation.

5 Conclusion

An improved management process of OR hazard has been developed, taking into account the HF of the internal and external environment of the enterprise, which increases the probability of the occurrence of a hazardous event and the severity of the consequences, provided that the level of OR is determined as acceptable, unacceptable, or acceptable with verification. It is suggested that during OR management, an additional analysis of the external and internal environments of the organization is carried out to determine HF, which affects the probability of the occurrence of a hazardous event and the degree of severity of the consequences of a hazardous event. The process of OR management determines the value of OR of hazard as the sum of OR from all external and internal HF, which affects the increase in the probability of the occurrence of a hazardous event and its severity of consequences. Four different situations were considered, regarding the calculation of the total value of OR, and an algorithm and the form of a map for hazard identification and HF estimation of the OR of the hazard were proposed.

The proposed approach to OR management when analyzing the cause-and-effect relationship between a hazard and a hazardous event makes it possible to identify significant HFs, the reduction of which will allow a better substantiation of the appropriateness of precautions in the employee’s workplace.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

OB: Funding acquisition, Project administration, Writing – original draft. VT: Conceptualization, Investigation, Supervision, Writing – original draft. MO: Conceptualization, Investigation, Validation, Writing – original draft. AP: Conceptualization, Methodology, Writing – original draft. SC: Formal analysis, Investigation, Methodology, Supervision, Writing – original draft, Writing – review & editing. OY: Formal analysis, Methodology, Validation, Writing – original draft. OD: Formal analysis, Investigation, Methodology, Visualization, Writing – original draft. VL: Funding acquisition, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This study was carried out as part of the project “Belt and Road Initiative Center for Chinese-European studies (BRICCES)” and was funded by the Guangdong University of Petrochemical Technology.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Walters, D, Johnstone, R, Bluff, E, Limborg, HJ, and Gensby, U. Prevention services for occupational safety and health in the European Union: anachronisms or supports for better practice? Saf Sci. (2022) 152:105793. doi: 10.1016/j.ssci.2022.105793

2. Fallah, SN, Mohabbati-Kalejahi, N, Alavi, S, and Zahed, MA. Sustainable development goals (SDGs) as a framework for corporate social responsibility (CSR). Sustainability. (2022) 14:1222. doi: 10.3390/su14031222

3. Tiep, LT, Huan, NQ, and Hong, T. Role of corporate social responsibility in sustainable energy development in emerging economy. Int J Energy Econ Policy. (2021) 11:172–86. doi: 10.32479/ijeep.10774

4. Walters, D, and Wadsworth, E. Contexts and determinants of the management of occupational safety and health in European workplaces. Policy Pract Health Saf. (2014) 12:109–30. doi: 10.1080/14774003.2014.11667806

5. Saud, YE, Israni, K, and Goddard, J. Bow-tie diagrams in downstream hazard identification and risk assessment. Process Saf Prog. (2014) 33:26–35. doi: 10.1002/prs.11576

6. Zahedi, MR, and Naghdi, KS. The effect of knowledge management processes on organizational innovation through intellectual capital development in Iranian industrial organizations. J Sci Technol Policy Manag. (2021) 12:86–105. doi: 10.1108/JSTPM-11-2019-0113

7. Cook, RI, Render, M, and Woods, DD. Gaps in the continuity of care and progress on patient safety. BMJ. (2000) 320:791–4. doi: 10.1136/bmj.320.7237.791

8. Durso, FT, Nickerson, RS, Dumais, ST, Lewandowsky, S, and Perfect, TJ. Handbook of Applied Cognition. (2007) 361–389. Chichester, England: John Wiley & Sons, Inc.

9. Zheng, F, Zhang, MG, Song, J, and Chen, FZ. Analysis on risk of multi - factor disaster and disaster control in oil and gas storage tank. Procedia Eng. (2018) 211:1058–64. doi: 10.1016/j.proeng.2017.12.110

10. Tsopa, V, Cheberiachko, S, Yavorska, O, Deryugin, O, and Bas, I. Increasing the safety of the transport process by minimizing the professional risk of a dump truck driver. Min Miner Depos. (2022) 16:101–8. doi: 10.33271/mining16.03.101

11. Liu, J, Wan, L, Wang, W, Yang, G, Ma, Q, Zhou, H, et al. Integrated fuzzy DEMATEL-ISM-NK for metro operation safety risk factor analysis and multi-factor risk coupling study. Sustainability. (2023) 15:5898. doi: 10.3390/su15075898

12. Di Noia, AE, and Nicoletti, GM. ISO 14001 certification: benefits, costs and expectations for organization. Studia Oecnomica Posnaniensia. (2016) 4:94–109. doi: 10.18559/SOEP.2016.10.7

13. Standard ISO 45001:2018. Occupational Health and Safety Management Systems: Requirements with Guidance for Use. (2022) Switzerland: International Organization for Standardization.

14. Ifediora, CO, Idoko, OR, and Nzekwe, J. Organization’s stability and productivity: the role of SWOT analysis an acronym for strength, weakness, opportunities and threat. Int J Res Sci Innov Appl Sci. (2014) 2:23–32.

15. Benzaghta, MA, Elwalda, A, Mousa, MM, Erkan, I, and Rahman, M. SWOT analysis applications: An integrative literature review. J Glob Bus Adv. (2021) 6:55–73. doi: 10.5038/2640-6489.6.1.1148

16. Siddiqui, AA. The use of Pestel analysis tool of quality management in the health care business and its advantages. Am J Biochem Biotechnol. (2021) 14:507–12. doi: 10.34297/AJBSR.2021.14.002046

17. Çitilci, T, and Akbalık, M. The importance of PESTEL analysis for environmental scanning process In: H Dinçer and S Yüksel (Editors). Handbook of Research on Decision-Making Techniques in Financial Marketing. Hershey PA, USA: IGI Global. (2020) 336–57.

18. Shtal, TV, Buriak, MM, Amirbekuly, Y, Ukubassova, GS, Kaskin, TT, and Toiboldinova, ZG. Methods of analysis of the external environment of business activities. Rev Espac. (2018) 39:1–22.

19. Ispas, L, Mironeasa, C, and Silvestri, A. Risk-based approach in the implementation of integrated management systems: a systematic literature review. Sustainability. (2023) 15:10251. doi: 10.3390/su151310251

20. He, R, Zhu, J, Chen, G, and Tian, Z. A real-time probabilistic risk assessment method for the petrochemical industry based on data monitoring. Reliab Eng Syst Saf. (2022) 226:108700. doi: 10.1016/j.ress.2022.108700

21. Pirbalouti, RG, Behnam, B, and Dehkordi, MK. A risk-based approach to identify safety-critical equipment in process industries. Results Eng. (2023) 20:101448. doi: 10.1016/j.rineng.2023.101448

22. Bazaluk, O, Tsopa, V, Cheberiachko, S, Deryugin, O, Radchuk, D, Borovytskyi, O, et al. Ergonomic risk management process for safety and health at work. Front Public Health. (2023) 11:1253141. doi: 10.3389/fpubh.2023.1253141

23. Bochkovskyi, A. Improvement of risk management principles in occupational health and safety. Nauk Visn Nats Hirn Univ. (2020) 4:94–104. doi: 10.33271/nvngu/2020-4/094

24. Casañ, MJ, Alier, M, and Llorens, AA. Collaborative learning activity to analyze the sustainability of an innovation using PESTLE. Sustainability. (2021) 13:8756. doi: 10.3390/su13168756

25. Мorgunova, EP, and Bolkina, GI. Influence of external environment analysis on the competitiveness of business operations of an industrial Enterprise (evidence from mining and metallurgical industry). IOP Conf Ser Earth Environ Sci. (2021) 666:062037. doi: 10.1088/1755-1315/666/6/062037

26. Bazaluk, O, Koriashkina, L, Cheberyachko, S, Deryugin, O, Odnovol, M, Lozynskyi, V, et al. Methodology for assessing the risk of incidents during passenger road transportation using the functional resonance analysis method. Heliyon. (2022) 8:e11814. doi: 10.1016/j.heliyon.2022.e11814

27. Onoprienko, S, Sharapova, O, Naranovych, O, Spasenko, I, and Shevtsova, О. On the issue of risk 365 management and assessment in the activities of Ukrainian forensic institutions. Theory Pract Forensic Sci Criminalistics. (2020) 21:252–66. doi: 10.32353/khrife.1.2020_16

28. Kruzhilko, O, Volodchenkova, N, Maystrenko, V, Feshchenko, A, and Yeremenko, S. Mathematical modelling of professional risk at Ukrainian metallurgical industry enterprises. J Achiev Mater Manuf Eng. (2021) 1:35–41. doi: 10.5604/01.3001.0015.4797

29. Tsopa, VA, Cheberiachko, SI, Yavorska, OO, Deryugin, OV, and Aleksieiev, AA. Improvement of the safe work system. Nauk Visn Nats Hirn Univ. (2022) 6:104–11. doi: 10.33271/nvngu/2022-6/104

30. Velikanova, MM. Risk management and its stages: economic and legal analysis. Entrep Econ Law. (2017) 12:20–4.

31. Babadzhanova, O, Vasiichuk, V, and Charlak, M. Application of formalized models of events for evaluation of danger and accident assessment of the compressor station of the main pipeline. Environ Probl. (2022) 7:47–54. doi: 10.23939/ep2022.01.047

32. Yang, S, Ishtiaq, M, and Anwar, M. Enterprise risk management practices and firm performance, the mediating role of competitive advantage and the moderating role of financial literacy. J Risk Fin Manag. (2018) 11:35. doi: 10.3390/jrfm11030035386

33. Cheberiachko, S, Yavorska, O, Deryugin, O, Lantukh, D, Bas, I, Kruzhilko, O, et al. Improving safety of passenger road transportation. Trans Transp Sci. (2023) 14:11–20. doi: 10.5507/tots.2023.003

34. Vesela, M, Cheberyachko, S, Deryugin, O, Yavorskaya, O, Tretyak, O, and Bas, I. Improving the Passenger Road Transportation Safety Management System. Proceedings of 26th International Scientific Conference Transport Means 2022, Vilnius, Lithuania; p. 296–301. (2022).

35. Golovatskaya, S, and Kurak, A. Organizational aspects of providing of the company’s functional 396 risks according to international standards. Nauk Visn Odes Nac Ekon Univ. (2017) 10:28–38.

36. Zabashta, EY. Development of the methodical approach on the risk management process of loss of innovative opportunities. Probl Prospects Entrep Dev. (2020) 24:64–79. doi: 10.30977/PPB.2226-8820.2020.24.0.64402

37. Bashynska, IO, and Makarets, DO. Risk management in projects. Econ Finances Law. (2017) 5:38–40.

38. Nechayeva, I, and Donchik, D. Use of BOWTIE tie technology in risk assessment practice. Econ Soc. (2021) 33:1–5. doi: 10.32782/2524-0072/2021-33-51

39. Wachter, JK, and Yorio, PL. A system of safety management practices and worker engagement for reducing and preventing accidents: An empirical and theoretical investigation. Accid Anal Prev. (2014) 68:117–30. doi: 10.1016/j.aap.2013.07.029

40. Koucha, Y, Forbes, A, and Yang, QP. A Bayesian conformity and risk assessment adapted to a form error model. Meas Sens. (2021) 18:100330. doi: 10.1016/j.measen.2021.100330

41. Aven, T. The risk concept - historical and recent development trends. Reliab Eng Syst Saf. (2012) 99:33–44. doi: 10.1016/j.ress.2011.11.006

42. Aven, T. Risk assessment and risk management: review of recent advances on their foundation. Eur J Oper Res. (2016) 253:1–13. doi: 10.1016/j.ejor.2015.12.023

43. Zhang, J, Yin, XL, Xing, J, and An, X. Dynamic risk assessment for train brake system considering time-dependent components and human factors. Comput Ind Eng. (2023) 185:109687. doi: 10.1016/j.cie.2023.109687

44. Zarei, E, Khakzad, N, Cozzani, V, and Reniers, G. Safety analysis of process systems using fuzzy Bayesian network (FBN). J Loss Prev Process Ind. (2019) 57:7–16. doi: 10.1016/j.jlp.2018.10.011

45. Yazdi, M, and Kabir, S. A fuzzy Bayesian network approach for risk analysis in process industries. Process Saf Environ Prot. (2017) 111:507–19. doi: 10.1016/j.psep.2017.08.015

46. Yoshimura, T, and Acar, HH. Occupational safety and health conditions of forestry workers in Turkey. J For Res. (2004) 9:225–32. doi: 10.1007/s10310-004-0078-y

47. Tsioras, PA, Khooshdohbat, M, Nikooy, M, Naghdi, R, and Heidari, M. The impact of body posture on heart rate strain during tree felling. Int J Environ Res Public Health. (2022) 19:11198. doi: 10.3390/ijerph191811198

48. Li, H, Zhang, X, Li, Z, Wen, J, and Tan, X. A review of research on tree risk assessment methods. Forests. (2022) 13:1556. doi: 10.3390/f13101556

49. Stanˇek, L, Neruda, J, and Nevrkla, P. The magnitude of fatigue recorded in individual body parts of chainsaw operators after work. Forests. (2023) 14:2023. doi: 10.3390/f14102023

50. Kovac, J, Krilek, J, Dado, M, and Beno, P. Investigating the influence of design factors on noise and vibrations in the case of chainsaws for forestry work. FME Trans. (2018) 46:513–9. doi: 10.5937/fmet1804513K

51. Landekić, M, Martinić, I, Mijoč, D, Bakarić, M, and Šporčić, M. Injury patterns among forestry Workers in Croatia. Forests. (2021) 12:1356. doi: 10.3390/f12101356

52. Sousa, V, Almeida, NM, and Dias, LA. Risk-based management of occupational safety and health in the construction industry - part 1: background knowledge. Saf Sci. (2014) 66:75–86. doi: 10.1016/j.ssci.2014.02.008

53. Aust, J, and Pons, D. A systematic methodology for developing bowtie in risk assessment: application to borescope inspection. Aerospace. (2020) 7:86. doi: 10.3390/aerospace7070086

54. Poleto, T, Silva, MM, Clemente, TRN, de Gusmão, APH, Araújo, APB, and Costa, APCS. A risk assessment framework proposal based on Bow-tie analysis for medical image diagnosis sharing within telemedicine. Sensors. (2021) 21:2426. doi: 10.3390/s21072426

55. McLeod, RW. Bowtie analysis as a prospective risk assessment technique in primary healthcare. Policy Pract Health Saf. (2018) 16:177–93. doi: 10.1080/14773996.2018.1466460

56. Ferdous, R, Khan, F, Sadiq, R, Amyotte, P, and Veitch, B. Handling and updating uncertain information in bow-tie analysis. J Loss Prev Process Ind. (2012) 25:8–19. doi: 10.1016/j.jlp.2011.06.018

57. Cockshott, JE. Probability Bow-ties: a transparent risk management tool. Process Saf Environ Prot. (2005) 83:307–16. doi: 10.1205/psep.04380

58. George, PG, and Renjith, VR. Evolution of safety and security risk assessment methodologies towards the use of bayesian networks in process industries. Process Saf Environ Prot. (2021) 149:758–75. doi: 10.1016/j.psep.2021.03.031

59. Shafer, G. Dempster's rule of combination. Int J Approx Reason. (2016) 79:26–40. doi: 10.1016/j.ijar.2015.12.009

60. Barton, DN, Kuikka, S, Varis, O, Uusitalo, L, Henriksen, HJ, Borsuk, M, et al. Bayesian networks in environmental and resource management. Integr Environ Assess Manag. (2012) 8:418–29. doi: 10.1002/ieam.1327

61. de Ruijter, A, and Guldenmund, F. The bowtie method: a review. Saf Sci. (2016) 88:211–8. doi: 10.1016/j.ssci.2016.03.001

62. El Hajj, C, Piatyszek, E, Tardy, A, and Laforest, V. Development of generic bow-tie diagrams of accidental scnarios triggered by flooding of industrial facilities (Natech). J Loss Prev Process Ind. (2015) 36:72–83. doi: 10.1016/j.jlp.2015.05.003

63. Marhavilas, PK, Pliaki, F, and Koulouriotis, D. International management system standards related to occupational safety and health: An updated literature survey. Sustainability. (2022) 14:13282. doi: 10.3390/su14201328

64. Standard ISO 31000:2018. (2018). Risk Management – Guidelines. Available at: https://zakon.isu.net.ua/sites/default/files/normdocs/dstu_iso_31000_2018.pdf (Accessed October 20, 2023).

65. Kruzhilko, O, Mahmoud, AED, Maystrenko, V, Volodchenkova, N, Polukarov, O, Sydorenko, V, et al. Scientific support of occupational risk management decisions in industrial sectors in case of uncertainty. Int J Occup Saf Health. (2023) 13:223–33. doi: 10.3126/ijosh.v13i2.48456

66. Miller, H, and Griffy-Brown, C. Evaluating risk for top-line growth and bottom-line protection: 414 enterprise risk management optimization (ERMO). Environ Syst Decis. (2021) 41:468–84. doi: 10.1007/s10669-021-09819-x416

67. Saurin, TA, and Patriarca, R. A taxonomy of interactions in socio-technical systems: a functional perspective. Appl Ergon. (2020) 82:102980. doi: 10.1016/j.apergo.2019.102980

68. Gattola, V, Patriarca, R, Tomasi, G, and Tronci, M. Functional resonance in industrial operations: a case study in a manufacturing plant. IFAC-PapersOnLine. (2018) 51:927–32. doi: 10.1016/j.ifacol.2018.08.489

69. Bruria, A, Maya, ST, Sadovsky, G, and Orna, T. Impact of emergency situations on resilience at work and burnout of Hospital's healthcare personnel. Int J Disaster Risk Sci. (2022) 76:102994. doi: 10.1016/j.ijdrr.2022.102994

70. Simsek, S, and Turhan, S. Effects of six sigma implementation on occupational health and safety in industrial diesel engine production and maintenance processes. Therm Sci. (2023) 27:3361–72. doi: 10.2298/TSCI2304361S

71. Kalatpour, O, and Farhadi, S. The content analysis of emergency scenarios: thematic survey of the context in the process industries. Saf Sci. (2017) 92:257–61. doi: 10.1016/j.ssci.2016.11.004

Keywords: occupational safety, occupational risk, assessment of occupational risk, hazardous factor, “BOW-TIE” method

Citation: Bazaluk O, Tsopa V, Okrasa M, Pavlychenko A, Cheberiachko S, Yavorska O, Deryugin O and Lozynskyi V (2024) Improvement of the occupational risk management process in the work safety system of the enterprise. Front. Public Health. 11:1330430. doi: 10.3389/fpubh.2023.1330430

Edited by:

Luigi De Maria, University of Bari Aldo Moro, ItalyReviewed by:

Łukasz Rypicz, Wroclaw Medical University, PolandAbu Bakkar Siddique, Jahangirnagar University, Bangladesh

Copyright © 2024 Bazaluk, Tsopa, Okrasa, Pavlychenko, Cheberiachko, Yavorska, Deryugin and Lozynskyi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Vasyl Lozynskyi, bHZnLm5tdUBnbWFpbC5jb20=

Oleg Bazaluk

Oleg Bazaluk Vitalii Tsopa

Vitalii Tsopa Małgorzata Okrasa

Małgorzata Okrasa Artem Pavlychenko

Artem Pavlychenko Serhii Cheberiachko

Serhii Cheberiachko Olena Yavorska

Olena Yavorska Oleg Deryugin

Oleg Deryugin Vasyl Lozynskyi

Vasyl Lozynskyi