- 1Crop Ecophysiology and Cultivation Key Laboratory of Sichuan Province, Sichuan Agricultural University, Chengdu, China

- 2Key Laboratory of Southwest Rice Biology and Genetic Breeding, Ministry of Agriculture and Rural Affairs, Rice and Sorghum Research Institute, Sichuan Academy of Agricultural Sciences, Deyang, China

- 3State Key Laboratory of Crop Gene Exploration and Utilization in Southwest China, Sichuan Agricultural University, Chengdu, Sichuan, China

Introduction: Nitrogen (N) fertilizer management, especially postponing N topdressing can affect rice eating quality by regulating starch quality of superior and inferior grains, but the details are unclear. This study aimed to evaluate the effects of N topdressing on starch structure and properties of superior and inferior grains in hybrid indica rice with different tastes and to clarify the relationship between starch structure, properties, and taste quality.

Methods: Two hybrid indica rice varieties, namely the low-taste Fyou 498 and high-taste Shuangyou 573, were used as experimental materials. Based on 150 kg·N hm-2, three N fertilizer treatments were established: zero N (N0), local farmer practice (basal fertilizer: tillering fertilizer: panicle fertilizer=7:3:0) (N1), postponing N topdressing (basal fertilizer: tillering fertilizer: panicle fertilizer=3:1:6) (N2).

Results: The starch granules of superior grains were more complete, and the decrease in small granules content and the stability of starch crystals were a certain extent less than those of inferior grains. Compared with N1, under N2, low-taste and high-taste varieties large starch granules content were significantly reduced by 6.89%, 0.74% in superior grains and 4.26%, 2.71% in inferior grains, the (B2 + B3) chains was significantly reduced by 1.61%, 0.98% in superior grains, and 1.18%, 0.97% in inferior grains, both reduced the relative crystallinity and 1045/1022 cm-1, thereby decreasing the stability of the starch crystalline region and the orderliness of starch granules. N2 treatment reduced the ΔHgel of two varieties. These changes ultimately contributed to the enhancement of the taste values in superior and inferior grains in both varieties, especially the inferior grains. Correlation analysis showed that the average starch volume diameter (D[4,3]) and relative crystallinity were significantly positively correlated with the taste value of superior and inferior sgrains, suggesting their potential use as an evaluation index for the simultaneous enhancement of the taste value of rice with superior and inferior grains.

Discussion: Based on 150 kg·N hm-2, postponing N topdressing (basal fertilizer: tillering fertilizer: panicle fertilizer=3:1:6) promotes the enhancement of the overall taste value and provides theoretical information for the production of rice with high quality

1 Introduction

Rice is the main food crop and staple food in Asian countries (Chen et al., 2023). As the quality of life improves, the demand for rice with excellent taste has been increasing steadily (Jiang et al., 2022a). Rice quality is influenced by numerous genetic factors, and the underlying genetic mechanisms are complex. Starch constitutes the component of rice, accounting for approximately 90% of the dry matter weight of milled rice. This indicates that starch plays a crucial role in rice quality traits (Chen et al., 2021; Xiong et al., 2022a). Among the factors affecting starch quality, amylose is considered the most significant and is closely associated with rice cooking, texture, and other characteristics (Wani et al., 2012; Zhou et al., 2020). In general, a higher proportion of amylose contributes to increasing rice hardness, thereby diminishing its palatability (Zhou et al., 2015; Li and Gong, 2020; Zhang et al., 2023). In addition, starch properties are also regulated by amylopectin (Zhu et al., 2021). Such as rice with a higher amylopectin average chain length, and a higher proportion of long-chain (B3) amylopectin, increases the relative crystallinity and gelatinization temperature, which makes cooked rice harder. (Cao et al., 2017; Hu et al., 2020; Zhou et al., 2020). Similarly, rice with a higher proportion of short-chain (A and B1 chain) amylopectin, which is stickier after cooking (Li and Gilbert, 2018).

The quality of the rice varies depending on its position on the panicle. In general, superior grains that grow in the middle and upper parts of the panicle show early flowering, good grain filling, and high eating quality, whereas inferior grains that grow in the lower part of the panicle show late flowering, slow rate filling, poor filling, and low taste quality (Jiang et al., 2022b). The quality of superior and inferior grains directly affects the quality of rice. In particular, inferior grains are the key to limiting the overall quality improvement of rice. Therefore, it is of great significance to explore the difference in starch fine structure between superior and inferior grains for improving the quality of the whole panicle of rice. Fewer studies have been conducted on the effects of variations in starch structure and physicochemical properties of superior and inferior grains on eating quality. Jiang et al. (2022a) reported that compared with superior grains, inferior grains have a high content of A chains and low B2 and B3 chain contents of amylopectin, resulting in lower relative crystallinity and higher starch surface order. This increases starch gelatinization enthalpy and retrogradation enthalpy, reduces starch swelling potential and solubility, deteriorates starch gelatinization characteristics, reduces the taste value of inferior grains, and hardens the texture of rice. Jiang et al. (2022b) showed that the lower eating quality of inferior grains can be attributed to smaller starch granules and reduced crystallinity and order degree. These factors lead to a less stable starch crystal structure, resulting in increased breakdown value, decreased setback value, and compromised characteristic parameters of the rice starch rapid viscosity analysis (RVA) spectrum. However, Zhu et al. (2021) contradicted this finding by showing that the cooking and eating quality of inferior grains was higher than that of superior grains. They attributed this difference to the lack of abundant amylose, a high proportion of amylopectin A chains, and a low proportion of B3 chains in inferior grains. The starch granule size and relative crystallinity of the inferior grains decreased, and the crystal structure of starch was destroyed, thereby reducing the gelatinization enthalpy and gelatinization temperature, increasing stickiness, and reducing the hardness of the inferior grains.

Nitrogen (N) fertilizer is a key element for rice yield and quality (Dou et al., 2017). The application amount and management mode of N fertilizer affect the structure and properties of starch, which in turn affects taste quality. Excessive N fertilization application increases the relative crystallinity of starch but reduces rice quality, especially its palatability (Zhu et al., 2017). Conversely, balanced N application enhances starch granule traits, increases the proportion of short (A chain, B1 chain) amylopectin, and optimizes starch thermal properties, swelling properties, and RVA profile characteristics. These factors contribute to the improvement in rice taste value (Yang et al., 2022a).

Low N panicle fertilizer application rate reduced the α-1,6 linkage content and amylopectin short chains content and disrupted the long chain double helix structure of amylopectin, increased breakdown, and decreased the setback, thereby improving rice cooking and eating quality (Xiong et al., 2023). However, high N panicle fertilizer application rate increased the surface order of starch and the stability of the crystalline region. As a result, the swelling and gelatinization of starch granules are hindered, thereby reducing the taste value of rice (Jiang et al., 2023). Based on the total nitrogen application rate of 270 kg N hm-2, postponing N topdressing (basal fertilizer: tillering fertilizer: panicle fertilizer=4:2:4) optimizes the starch granule properties of superior and inferior grains, reduces the values of 1045/1022 cm-1 and relative crystallinity, increases gel consistency, and improves eating quality (Jiang et al., 2022b). Zhou et al. (2022) found that based on the total nitrogen application rate of 270 kg N hm-2, the postponing of nitrogen fertilizer (basal fertilizer: tillering fertilizer: panicle fertilizer=4:2:4) could reduce the proportion of amylopectin (A+B1) chains, increase the content of total starch and amylose, increase the peak viscosity and final viscosity of starch, and thus improve the cooking and eating quality of rice. Yan et al. (2018) showed that matching basal fertilizer: tillering fertilizer: panicle fertilizer=3:1:6 nitrogen management practices based on the reducing nitrogen application by 150 kg N hm-2 would increase the gel consistency and reduce the amylose content of rice, and ultimately improve taste quality.

Extensive research has investigated the differences in starch structure characteristics between superior and inferior grains of the same variety under different nitrogen application rates, and the changes in starch structure characteristics of whole spike grains of different varieties under various nitrogen fertilizer management practices. However, it is not clear what the effects of a high proportion of postponing N topdressing (basal fertilizer: tillering fertilizer: panicle fertilizer=3:1:6) on the starch structure characteristics of superior and inferior grains of hybrid indica rice with different palatability values in nitrogen fertilizer management, as well as their relationship with eating quality. Consequently, this study aims to fill this research gap by selecting two hybrid indica rice varieties with significant differences in taste value as the experimental materials. The objective is to investigate the effects of N fertilizer management on the starch structure and properties of superior and inferior grains within the panicles of these hybrid indica rice varieties. Additionally, the study aims to elucidate the relationship between the starch structure characteristics of superior and inferior grains and their respective taste qualities. We anticipate that the findings from this research endeavor will contribute to establishing a theoretical and practical basis for the cultivation of high-quality and high-yielding hybrid indica rice varieties.

2 Materials and methods

2.1 Test sites and experimental cultivars

Based on the experimental research conducted by our research group from 2020 to 2021 (Guo et al., 2023a), the field experiment was further improved in 2022 at the Chongzhou Experimental Base of Sichuan Agricultural University (30°70′N, 103°83′E). The preceding crop was rape, and the topsoil (0–20 cm) consisted of sandy loam soil with the following characteristics: organic matter content of 20.58 g kg−1, total nitrogen content of 1.53 g kg−1, alkaline hydrolysis nitrogen content of 102.27 mg kg−1, available phosphorus content of 19.42 mg kg−1, available potassium content of 115.45 mg kg−1, and a pH value of 6.61. Two medium indica late-maturing hybrid indica rice varieties (Table 1) with comparable growth periods and yields and significant differences in palatability were selected as the test materials (Guo et al., 2022; Guo et al., 2023b).

2.2 Experimental design

The experiment employed a two-factor, completely randomized design, incorporating diverse strategies for managing N fertilizer and different varieties. Based on a stable and efficient reduction of nitrogen application rate of 150 kg N hm-2 (Sun et al., 2023), three N management practices were established: zero N (denoted as N0), local farmer practice (basal N fertilizer: tillering N fertilizer: panicle N fertilizer=7:3:0, denoted as N1) (Shu et al., 2021; Shu et al., 2022), postponing N topdressing (basal N fertilizer: tillering N fertilizer: panicle N fertilizer=3:1:6, denoted as N2). The N fertilizer (urea) was managed as follows: The base fertilizer was applied 1 d before transplanting, the tillering fertilizer was applied 7 d after transplanting, and the panicle fertilizer was applied at a 1:1 ratio during the inverse fourth-leaf and second-leaf stages. Calcium superphosphate (P2O5 75 kg hm-2) was applied once as basal fertilizer 1 d before transplanting, and potassium chloride (K2O 150 kg hm-2) was applied at two equal doses 1 d before transplanting and at the inverse fourth-leaf stage. on 9 April, seedlings were raised under dry conditions, and individual plants were manually transplanted on 10 May with a row spacing of 33.3 cm×16.7 cm. There were a total of six treatments, each replicated three times, with a plot area of 4 m×7 m=28.0 m2. A ridge (30 cm high) was constructed between adjacent plots and covered with plastic film to ensure separate irrigation and fertilization. Diseases, pests, and weeds control measures followed the management practices of high-yield fields.

2.3 Measurement items and methods

2.3.1 Eating quality

The taste value, hardness, and stickiness of the cooked rice were measured using a Satake Rice Taste Analyzer (STA1A type, Satake, Japan) (Ma et al., 2021; Shi et al., 2022). 30 g of milled rice was weighed and placed into a matching stainless-steel tank, water was added, and the mixture was soaked for 30 min. Water was added at a rice-to-water ratio of 1:1.4, and the mouth of the tank was wrapped with filter paper, placed into a steam electric rice cooker, steamed for 30 min, and then cooled for 2 h. Rice (7 g) was weighed at room temperature and placed into a special rice press instrument to form a rice cake. It was then placed in a taste analyzer to test the taste value, hardness, and stickiness of the rice.

2.3.2 Total starch content, apparent amylose content, and amylopectin content of superior and inferior grains

The grains born on the top three primary branches of rice panicles, excluding the second grain at the top, were considered superior, and the grains that were born on the three secondary branches at the base of the rice panicle, excluding the first grain at the top, were considered inferior grains (Guo et al., 2022).

The total starch content was determined using the anthrone colorimetric method (Wang et al., 2020). The apparent amylose content was determined as described by Chen et al. (2023). To 50 mg of the starch sample, 0.5 mL of anhydrous ethanol was added, followed by 4.5 mL of 1 M NaOH. The mixture was dispersed in a boiling water bath for 10 min. After cooling, the solution was adjusted to a constant volume of 50 mL. This dilution (500 μL) was placed in a centrifuge tube, and 200 μL of I2/KI (0.2%/2%) solution, acetic acid (1 M, 100 μL), and distilled water (9 mL) were added. Absorbance was measured at 620 nm. Amylopectin content was obtained by subtracting the apparent amylose content from the total starch content (Jiang et al., 2022a).

2.3.3 Starch extraction and scanning electron microscope observation of starch granules

Starch was extracted as described by Zhang et al. (2020). Subsequently, 1 mL of anhydrous ethanol was added to the extracted 100.0 mg starch sample to prepare a starch suspension. The suspension was then dropped onto a copper conductive adhesive, evenly spread, and left at 37°C overnight. Afterward, the samples were coated with a layer of gold, and examined under a high-resolution field-emission scanning electron microscope (Zeiss Merlin Compact, Germany) to capture images of the starch granules.

2.3.4 Starch granule size distribution

Referring to the method of Xiong et al. (2022a), 100 mg of starch sample was weighed and dispersed in anhydrous ethanol, and the starch granule size was determined by a Malvern laser granule size instrument (Matersizer 3000, Malvern Instruments Ltd., Worcestershire, England). And starch granules were divided into small granules (diameter < 10 μm) and large granules (diameter > 10 μm).

2.3.5 Amylopectin chain length distribution

Referring to the method of Chen et al. (2023), 10 mg of starch sample was weighed, and isoamylase was used to debranch the branched starch molecules in the starch samples. The samples were analyzed by an ion chromatography system (ICS-500+; Thermo Fisher Scientific, Sunnyvale, USA). The different chain lengths of amylopectin were divided into A chain (DP 6-12), B1 chain (DP 13-24), B2 chain (DP 25-36), and B3 chain (DP>37) (Li et al., 2016).

2.3.6 Starch relative crystallinity

Referring to the method of Jiang et al. (2022b), the crystallinity of starch under 40 kV and 40 mA-Cu-Kα radiation was measured by X’Pert Pro X-ray diffractometer (PANalytical, Netherlands). The scattering angle (2θ) was varied from 4° to 60° at a scanning rate of 0.02 s-1. And calculated starch relative crystallinity.

2.3.7 Structure order of starch

Starch samples (5 mg) were thoroughly mixed with KBr at a ratio of 1:150 and pressed into slices. The samples were determined by Fourier transform infrared spectrometer NicoletiZ-10 (Thermo Fisher Scientific, Inc., Waltham, MA, USA) with 32 scans, an instrument resolution of 4 cm-1, and a scanning range of 400–4000 cm-1.

2.3.8 Starch thermal properties

The thermal properties of starch were determined following the method described by Jiang et al. (2023), using a differential calorimeter (DSC 200 F3 Netzsch, Germany). A starch sample weighing 3 mg was placed in a corresponding aluminum crucible and mixed with 10 uL of deionized water. The sample was then equilibrated at 4°C for 24 h before analysis on the machine. The temperature was gradually increased at a rate of 10 °C/min, from 20°C to 100°C to assess starch gelatinization properties, and from 10°C to 90°C to evaluate starch retrogradation properties. The retrogradation percentage (%) was calculated as the retrogradation enthalpy divided by the gelatinization enthalpy, multiplied by 100 (retrogradation enthalpy/gelatinization enthalpy×100).

2.4 Data analysis

Analysis of variance (ANOVA) was performed using the SPSS software (version 27.0; SPSS Inc., Chicago, IL, USA). The least significant difference (LSD) was used for multiple comparisons, and Origin 2021 (OriginLab Corp., Northampton, MA) was used for plotting. Person correlation analysis was used to analyze the correlations between starch structural properties and rice eating quality at significance levels of 0.05 and 0.01.

3 Results

3.1 Eating quality

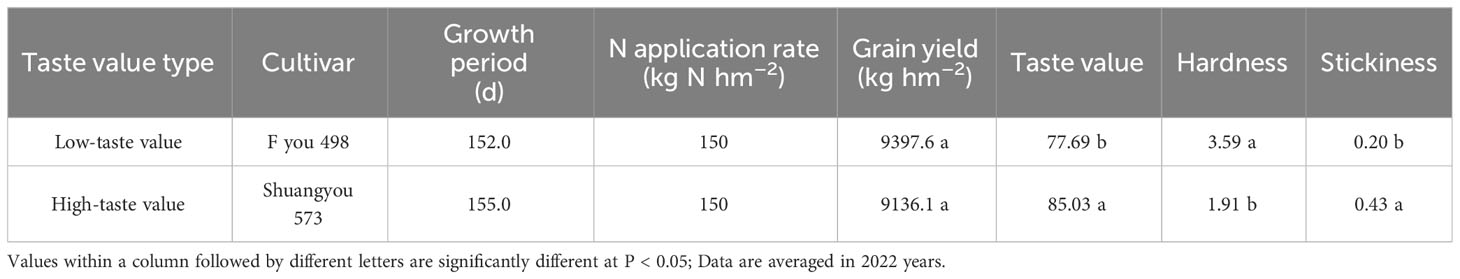

The effects of each cultivar at different grain positions and N fertilizer management on the taste value, hardness, and stickiness of superior and inferior rice grains were found to be significant level. Additionally, there was a significant interaction between these two factors in relation to the hardness of superior and inferior rice grains (Table 2). For each variety at different grain positions, N fertilizer management, the effect of variety differences on taste value was significantly higher than that of N fertilizer management, and the difference in inferior grains between varieties was significantly higher than that in superior grains. Compared to the low-taste variety Fyou 498, the high-taste variety Shuangyou 573 had a significant increase in the taste value of superior grains by 7.49–9.04%, and the taste value of inferior grains had a significant increase of 10.34–10.84%.

Table 2 Effects of postponing N topdressing on taste quality of superior and inferior grains in hybrid indica rice cultivars with different taste values.

N application significantly reduced the taste value of the superior grains of the two varieties. Compared with the N0 treatment, the N1 and N2 treatments significantly reduced the taste value of superior grains of the low-taste variety Fyou 498 by 6.67% and 2.59%, and the high-taste variety Shuangyou 573 by 6.31% and 3.61%, respectively. However, compared to the N1 treatment, the N2 treatment significantly increased the superior grain taste value of the low-taste variety and the high-taste variety by 4.37% and 2.89%, respectively. In contrast to the superior grains, N application treatments significantly increased the taste value of the inferior grains. Compared with N0, the N1 and N2 treatments significantly increased the taste value of inferior grains of the low-taste variety by 2.59% and 7.30%, and the high-taste variety by 2.13% and 7.24%, respectively, and the taste value of inferior grains significantly increased as the N topdressing ratio increased. This shows that the regulation of N fertilizer management on the taste value of inferior grains is greater than that of superior grains. At the same time, N2 treatment is more conducive to improving the taste value of inferior grains.

Table 2 shows that N application treatments significantly increased the hardness of the superior grains, but significantly reduced the stickiness of superior grains in both varieties. Compared with N0, the N1 and N2 treatments significantly increased the hardness of superior grains of the low-taste variety by 11.26% and 40.73%, significantly decreased the stickiness by 32.00%, 12.00%; while the high-taste variety increased by 20.89%, 24.68%, and decreased by 16.33%, 12.24%. The hardness and stickiness of the inferior grains of both varieties were greatest in the N2 treatment. Compared with the N2 treatment, the N0 and N1 treatments significantly reduced the hardness of inferior grains of the low-taste variety by 19.58%, 26.57%, significantly reduced the stickiness by 19.05%, 4.76%; and the high-taste variety reduced by 13.97%, 24.02%, and 13.33%, 6.67%, respectively.

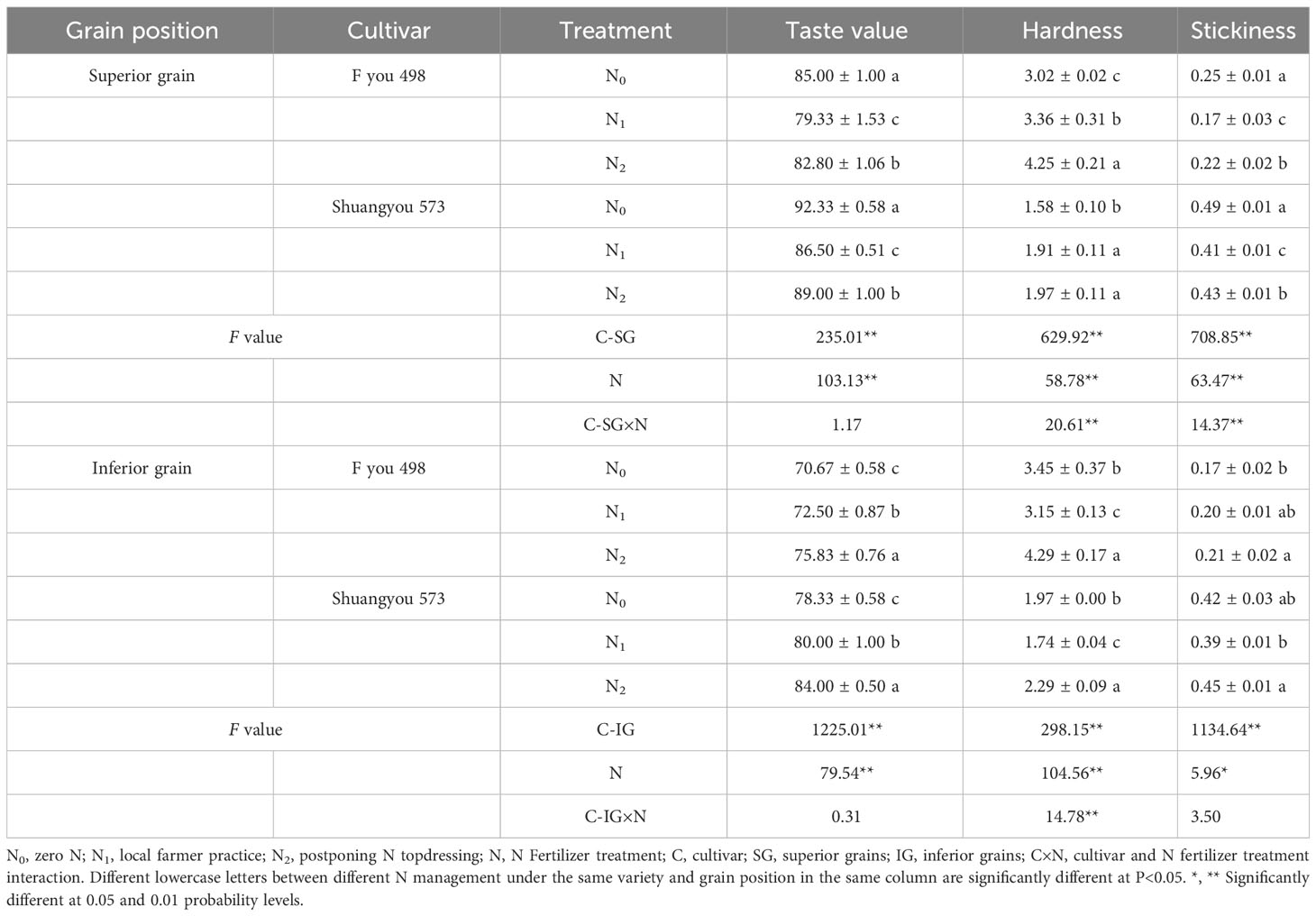

3.2 Rice starch and its composition

The effects of each cultivar at different grain positions on the amylose and amylopectin contents in the superior and inferior grains of rice were extremely significant (Table 3 and Figure 1). The amylose content of superior and inferior grains in the high-taste variety Shuangyou 573 was significantly lower than that in the low-taste variety Fyou 498, whereas the amylopectin content was significantly higher than that in the low-taste variety Fyou 498. Compared with the low-taste variety Fyou 498, the high-taste variety Shuangyou 573 had significantly lower amylose content of 15.64–23.52% and significantly higher amylopectin content of 10.07–14.49% in the superior grains; while the inferior grains had significantly lower amylose content of 32.95–37.58% and significantly higher amylopectin content of 21.64–47.24%.

Table 3 Analysis of variance for starch content characteristics of superior and inferior grains in hybrid indica rice cultivars with different taste values (F values).

Figure 1 Effect of postponing N topdressing on total starch content (A), amylose content (C), amylopectin content (E) of superior grains, and total starch content (B), amylose content (D), and amylopectin content (F) of inferior grains in hybrid indica rice cultivars with different taste values. N0, Zero N; N1, local farmer practice; N2, postponing N topdressing. FY498, F you 498; SY573, Shuangyou 573. Data are presented as mean ± standard deviation. Different lowercase letters above columns indicate significant differences at P<0.05 among treatments at the maturity stage.

N fertilizer management had significant effects on the total starch, amylose, and amylopectin contents of superior and inferior grains. N application treatments significantly increased the total starch and amylopectin contents of the superior grains in both varieties but significantly decreased the amylose content. Compared with N0, the N1 and N2 treatments significantly increased the total starch content of superior grains of the low-taste variety by 4.68%, and 11.49%, and significantly increased amylopectin content by 13.00%, and 18.69%, but significantly decreased amylose by 14.58%, 5.15%; while the high-taste variety increased by 5.38%, 13.25% and 8.64%, 18.21%, and decreased by 5.79%,3.84%. In line with the trend of superior grains, N application treatments significantly increased the total starch and amylopectin content and significantly decreased the amylose content of inferior grains in both varieties. Compared with N0, N1 and N2 significantly increased the total starch content of inferior grains of low-taste variety by 13.13%, 17.48%, significantly increased amylopectin content by 30.86%, 34.30%, significantly decreased amylose content by 19.63%, 13.57%; while the high-taste variety increased by 2.21%, 6.51%, and 8.47%,10.94%, and decreased by 23.69%, 11.84%, respectively.

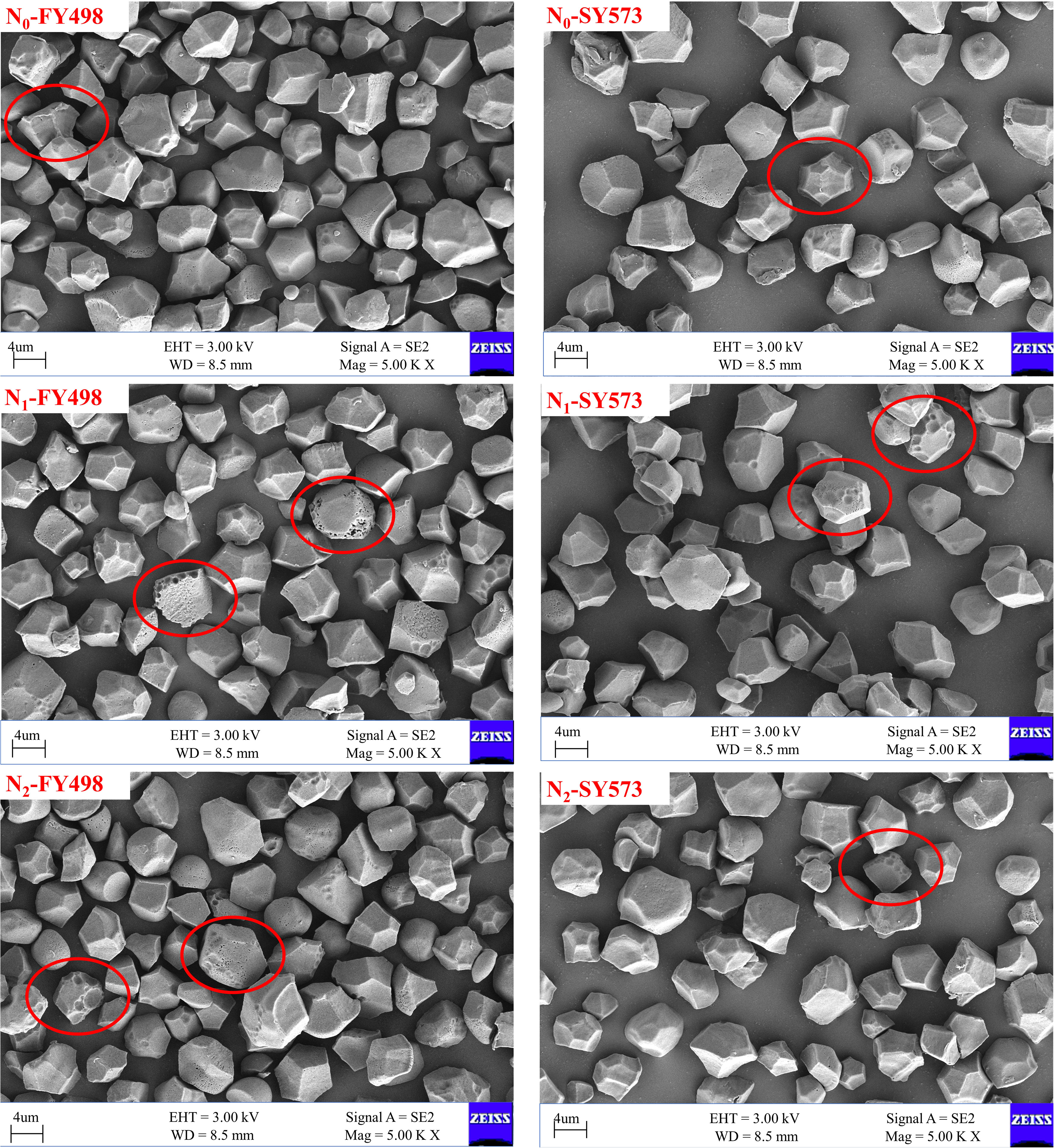

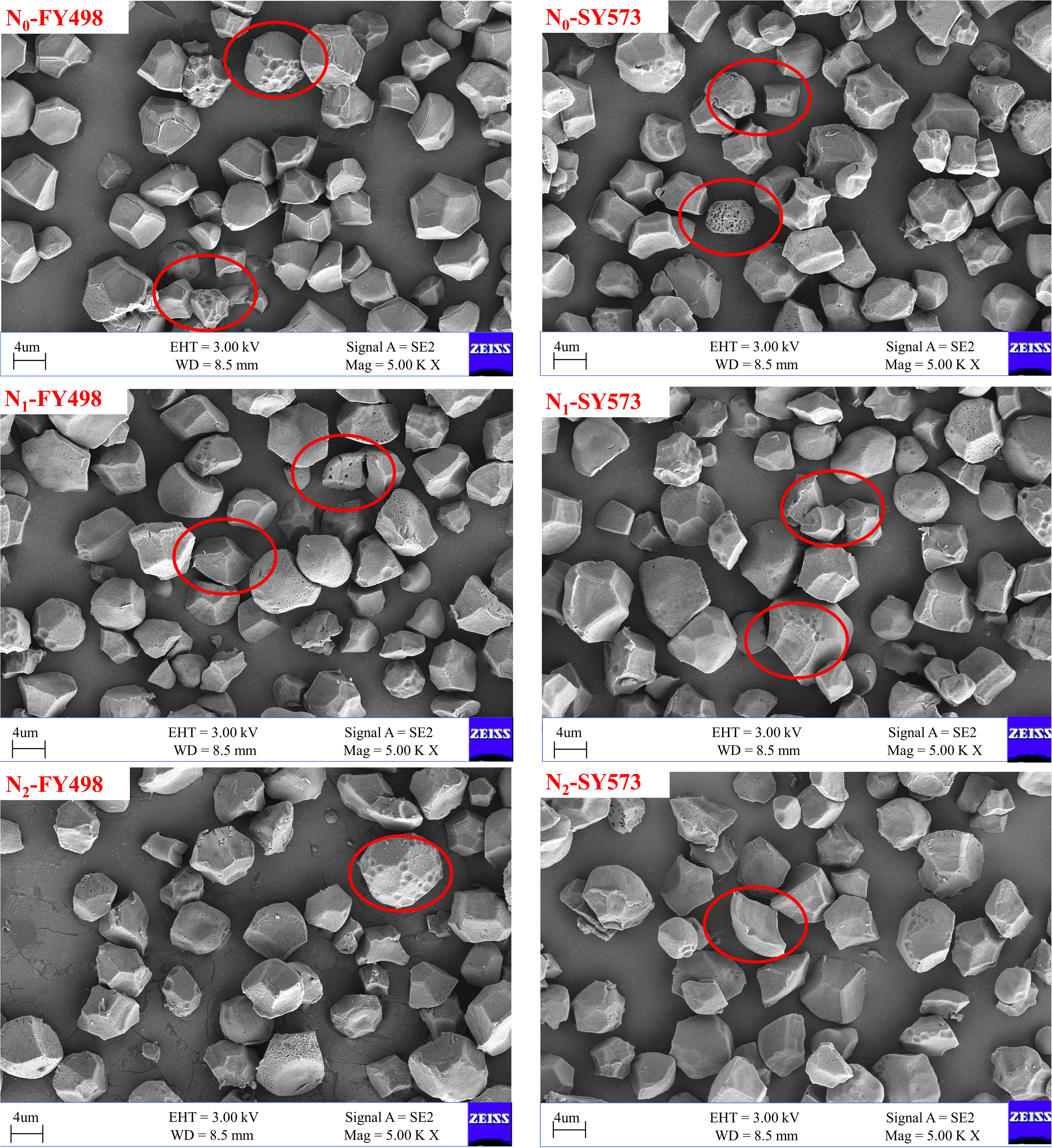

3.3 Scanning electron microscope observation of starch granules

As shown in Figures 2, 3, compared with the low-flavored variety Fyou 498, the starch granule surfaces of the superior and inferior grains of the high-flavored variety Shuangyou 573 were smoother, with fewer holes and pits and more complete and uniform starch granules. In addition, the difference between the inferior grains was more obvious. Under each N treatment, the starch granules of the superior and inferior grains of both varieties exhibited irregular polygons.

Figure 2 Scanning electron microscopic (SEM) of superior starch in hybrid indica rice cultivars with different taste values under postponing N topdressing. N0, Zero N; N1, local farmer practice; N2, postponing nitrogen topdressing; FY498, F you 498; SY573, Shuangyou 573.

Figure 3 Scanning electron microscopic (SEM) of inferior starch in hybrid indica rice cultivars with different taste values under postponing N topdressing. N0, Zero N; N1, local farmer practice; N2, postponing N topdressing; FY498, F you 498; SY573, Shuangyou 573.

Compared with the N0 treatment, there were more holes and pits on the surface of superior grain starch granules and more small granule starch content in the two varieties under N application treatments. In particular, the starch content of small granules was obviously increased under the N2 treatment. The starch granules of the inferior grains under each N fertilizer treatment were more uneven than those of the superior grains, and the surfaces of the starch granules were more uneven and cracked. Compared to the N0 treatment, the N1 and N2 treatments had more complete starch granules and fewer broken starch granules in the inferior grains. The application of nitrogen fertilizer deteriorated the starch granule traits of superior grains but optimized the starch granule traits of inferior grains.

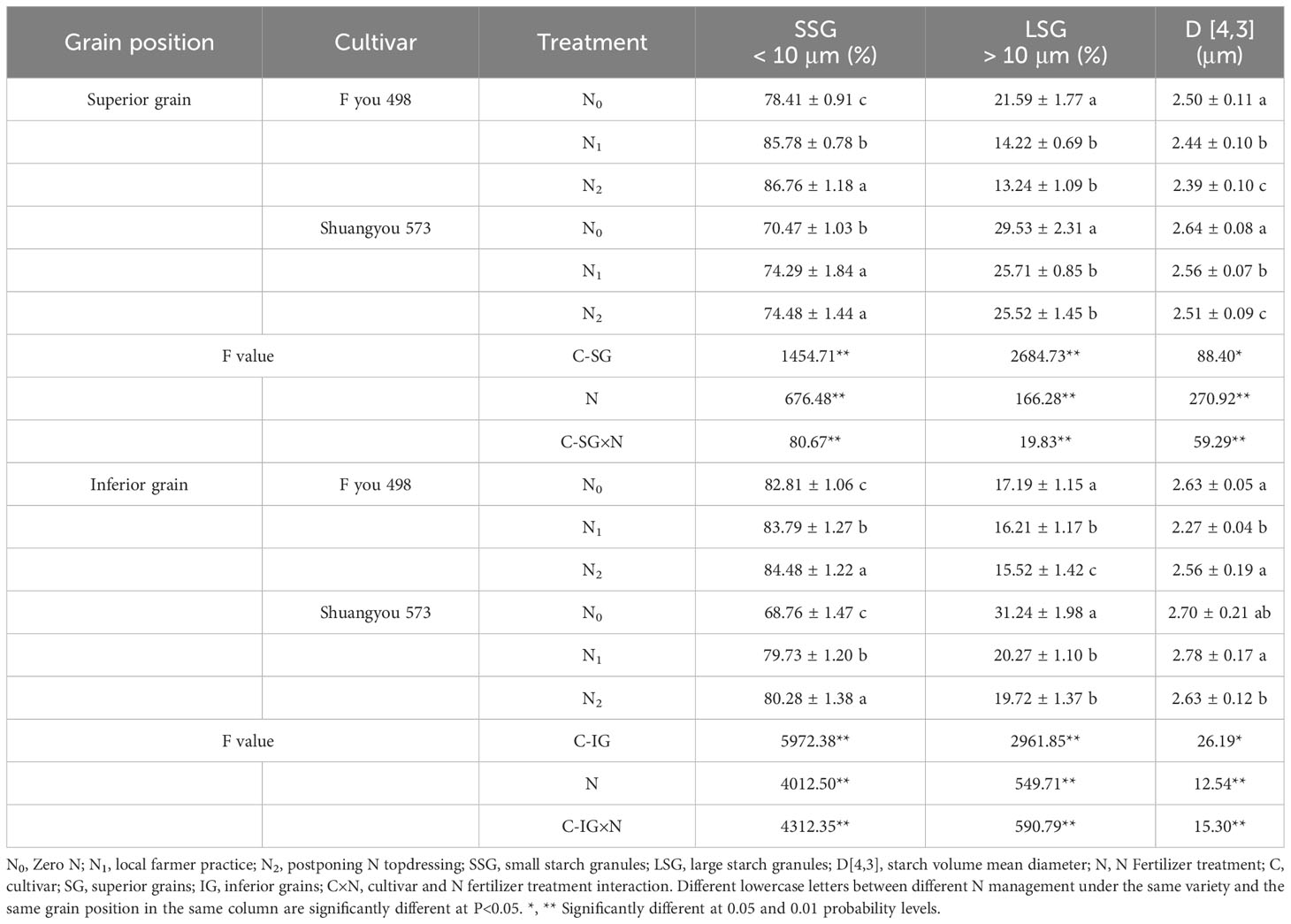

3.4 Starch granule size distribution

As shown in Table 4, the effects of each variety at different grain positions and N fertilizer management on the percentage of superior and inferior grains, small and large starch granules, and starch volume mean diameter (D[4,3]) reached significant or highly significant levels, and the interaction effect of the two factors was highly significant. The N application treatments significantly increased the proportion of small starch granules and reduced the proportion of large starch granules and the D[4,3] of superior grains in both varieties. Compared with N0, the N1 and N2 treatments significantly increased the proportion of small starch granules in superior grains of the low-taste variety Fyou 498 by 9.40%, 10.65%, and significantly decreased the proportion of larger starch granules and D[4,3] by 34.14%, 38.68% and 2.40%, 4.40%, and the high-taste variety Shuangyou 573 increased by 5.42%, 5.69%, and decreased by 12.94%, 13.58%, and 3.03%, 4.92%, respectively. Compared with N1, N2 treatment further increased the proportion of small starch granules in the superior grains and reduced the proportion of large starch granules and D[4,3] of the two varieties. Among them, the increase of superior grains in small starch granules and the decrease in large starch granules in high-taste varieties were lower than those in low-taste varieties. Consistent with the trend in superior grains, both the N1 and N2 treatments significantly increased the proportion of small starch granules and significantly reduced the proportion of large starch granules in inferior grains of both varieties. Compared with the N0 treatment, N1 and N2 treatments significantly increased the proportion of small starch granules in inferior grains of low-taste variety by 1.18% and 2.02%, decreased the proportion of large starch granules by 5.70% and 9.71%; while the high-taste variety increased by 15.95% and 16.75%, and decreased by 35.12% and 36.88%. Meanwhile, the proportion of small starch granules in the inferior grains increased, and the proportion of large starch granules decreased as the proportion of postponed N topdressing. The effects of N management on inferior grain D[4,3] differed between the two varieties. The low-taste variety Fyou 498 inferior grains D[4,3] was the lowest under the N1 treatment, significantly lower by 13.69% compared to the N0 treatment and 11.33% compared to the N2 treatment; while the high-taste variety Shuangyou 573 inferior grains D[4,3] was the highest in the N1 treatment, higher by 2.96% compared to the N0 treatment and 5.70% compared to the N2 treatment. The results showed that the N application treatments increased the percentage of small starch granules and decreased the percentage of large starch granules and D[4,3]. And the percentage of small starch granules increased significantly, and the percentage of large starch granules and D[4,3] decreased significantly with the proportion of N postponed topdressing. Besides, the increase of small starch granules and the decrease of large starch granules in superior grains of high-taste variety Shuangyou 573 under N2 treatment were lower than those of low-taste variety Fyou 498. However, the increase of small starch granules and the decrease of large starch granules in inferior grains were higher than those of low-taste variety, which may be an important reason for Shuangyou 573 under N2 treatment to maintain the high taste value of inferior grains.

Table 4 Effects of postponing N topdressing on starch granule size distribution of superior and inferior grains in hybrid indica rice cultivars with different taste values.

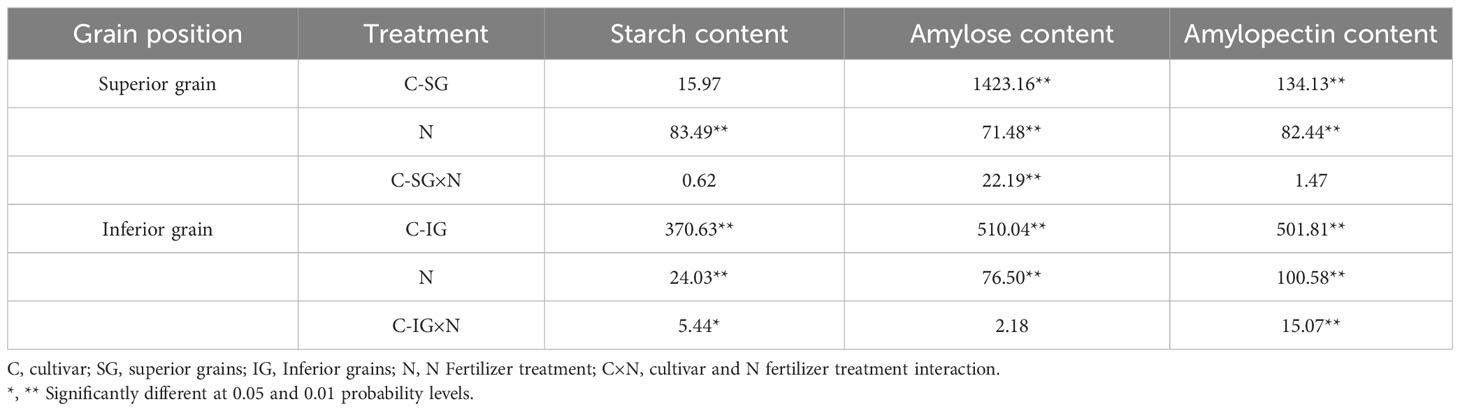

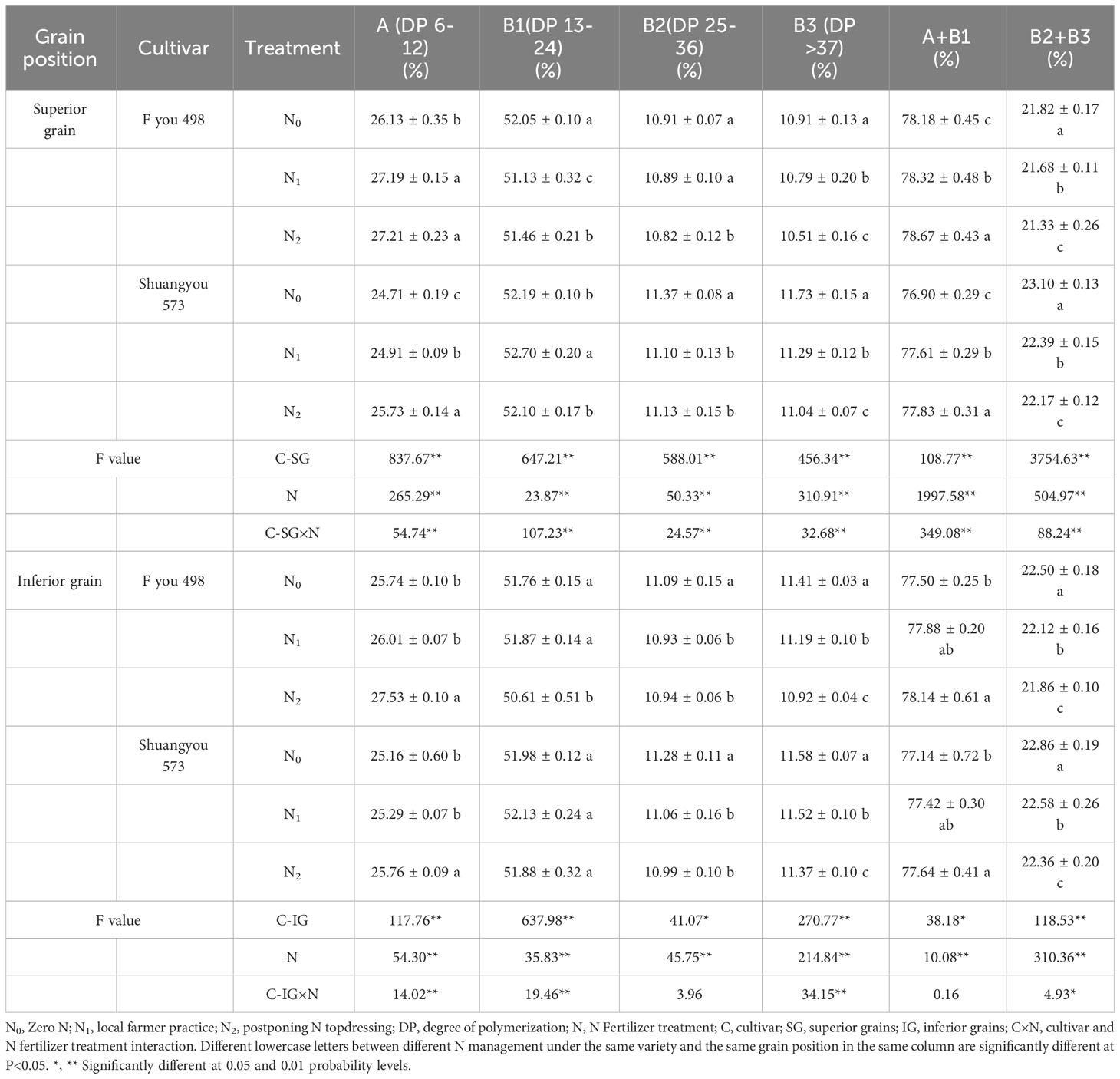

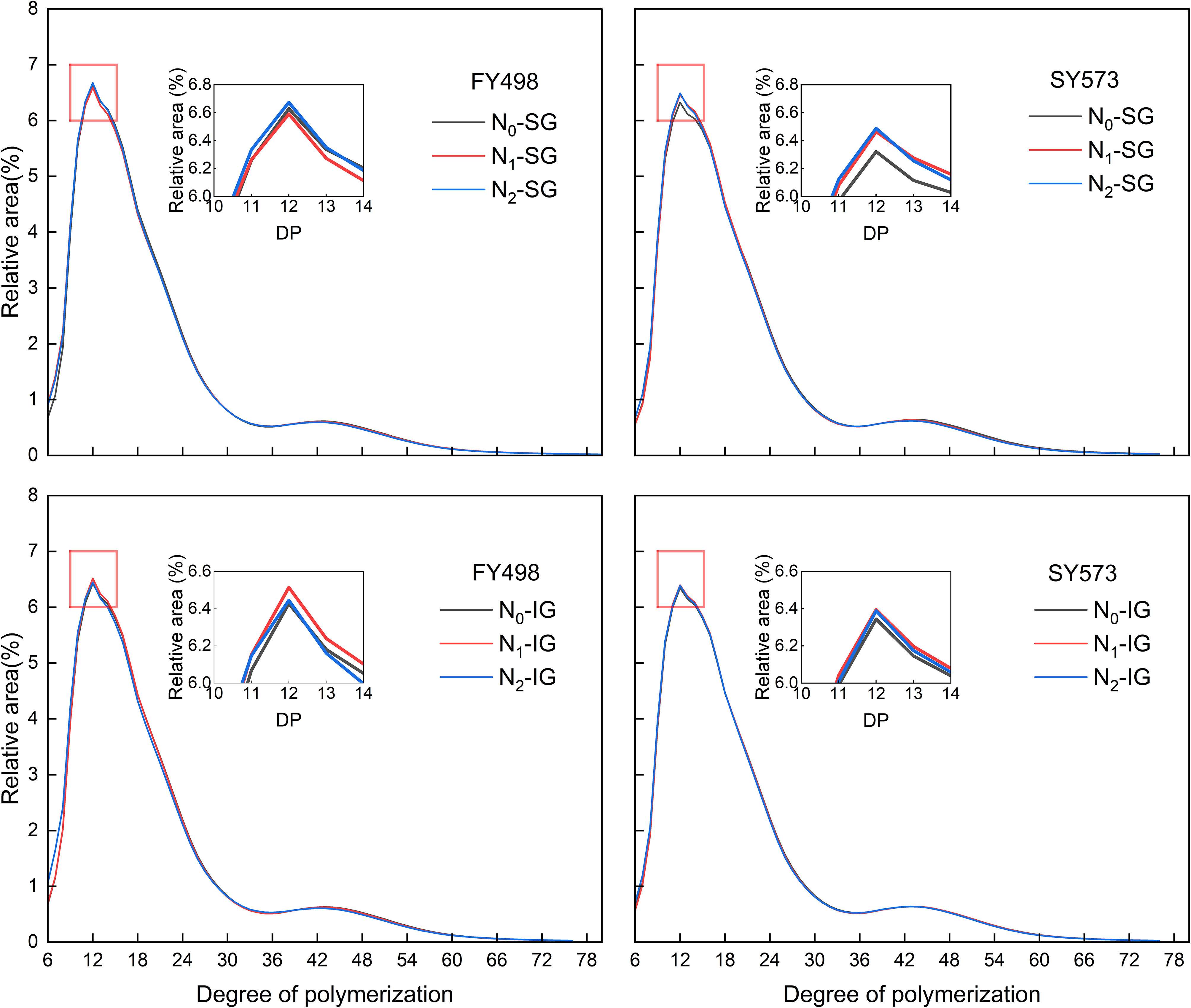

3.5 Amylopectin chain length distribution

As shown in Table 5, the varieties of different grain positions and N fertilizer management had significant effects on the amylopectin chain length distribution index in the superior and inferior grains, and the interaction effect of the two factors had significant effects on the proportions of the A, B1, B3 chains, and (B2+B3) in the superior and inferior grains. The distribution trend of the amylopectin chain length in the superior and inferior grains of low-taste and high-taste variety was consistent and bimodal under each N fertilizer treatment, reaching a peak at DP=12 (Figure 4). This may be related to the fact that the distribution of chain length between superior and inferior grains is mainly determined by genetic background (Jiang et al., 2022a). The N application treatments increased the proportion of A chain and (A+B1) chain and decreased the proportion of B2 chain, B3 chain, and (B2+B3) chain in superior and inferior grains of the low-taste and high-taste variety. Among them, compared with N0, under N1 and N2 treatments, the proportion of A chain in superior grains of the low-taste variety increased by 4.06% and 4.13%, and the B3 chain decreased by 1.10% and 3.67%, while the proportion of A chain of the high-taste variety increased by 0.81% and 4.13%, and the B3 chain decreased by 3.75% and 5.88%, respectively. Meanwhile, the proportion of (B2+B3) in inferior grains of two varieties decreased by 1.69%, 2.84%, and 1.22%, 2.19%. Similarly, compared with N1, the N2 treatment further increased the proportion of A chain and (A+B1) chain of superior grains in two varieties and further significantly reduced the proportion of B3 chain and (B2+B3) chain. Among them, the proportion of the B3 chain was significantly reduced by 2.59% and 2.21%. Significantly, inferior grains trend in line with superior grains. Among them, the proportion of A chain in inferior grains of low-taste and high-taste variety was significantly reduced by 5.84% and 1.86%, and the proportion of B3 chain was significantly reduced by 2.41% and 1.30%.

Table 5 Effects of postponing N topdressing on amylopectin chain length distribution of superior and inferior grains in hybrid indica rice cultivars with different taste values.

Figure 4 Effect of postponing N topdressing on amylopectin chain length distribution of superior grains and inferior grains in hybrid indica rice cultivars with different taste values. N0, Zero N; N1, local farmer practice; N2, postponing N topdressing. FY498, F you 498; SY573, Shuangyou 573.

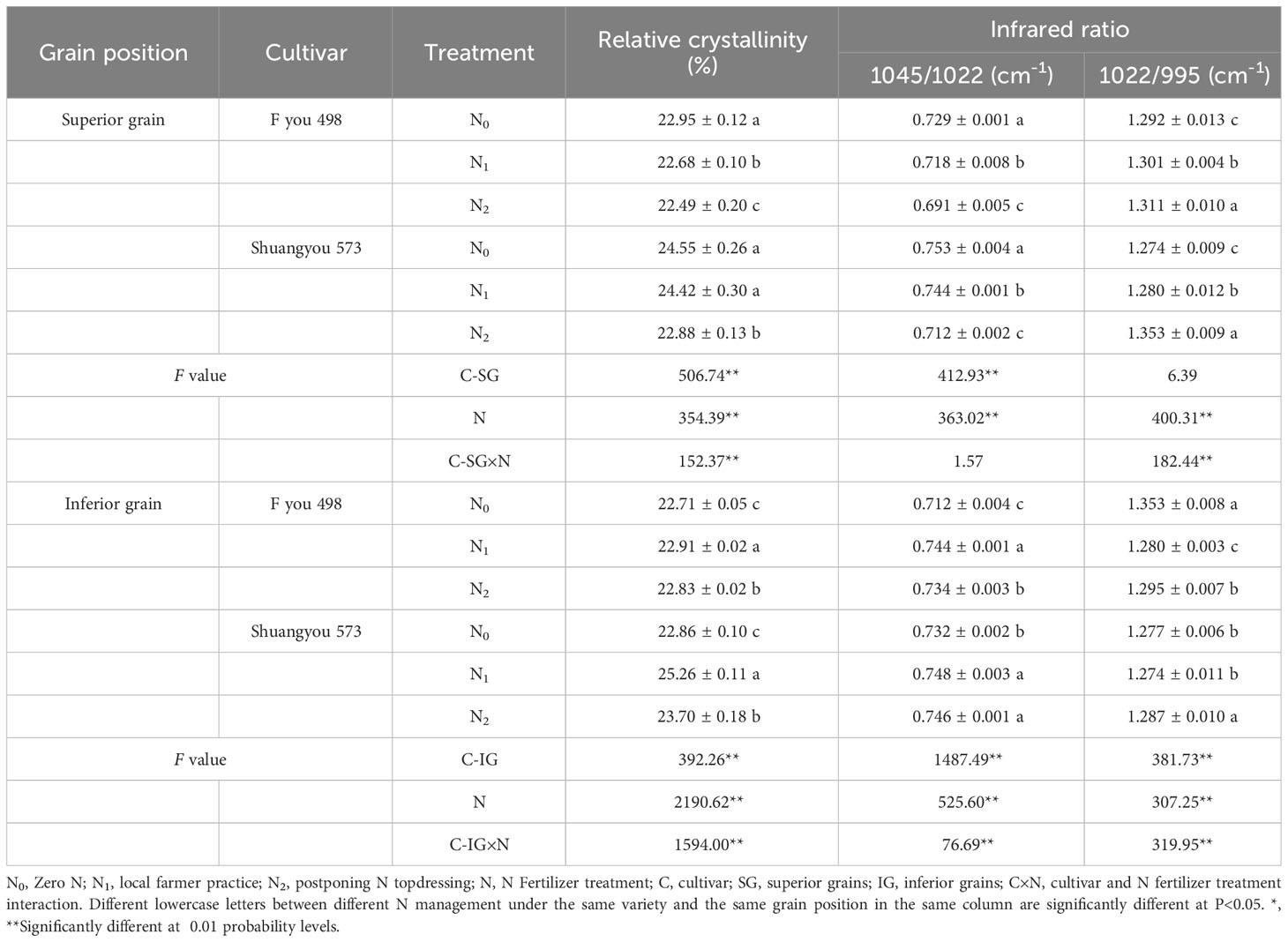

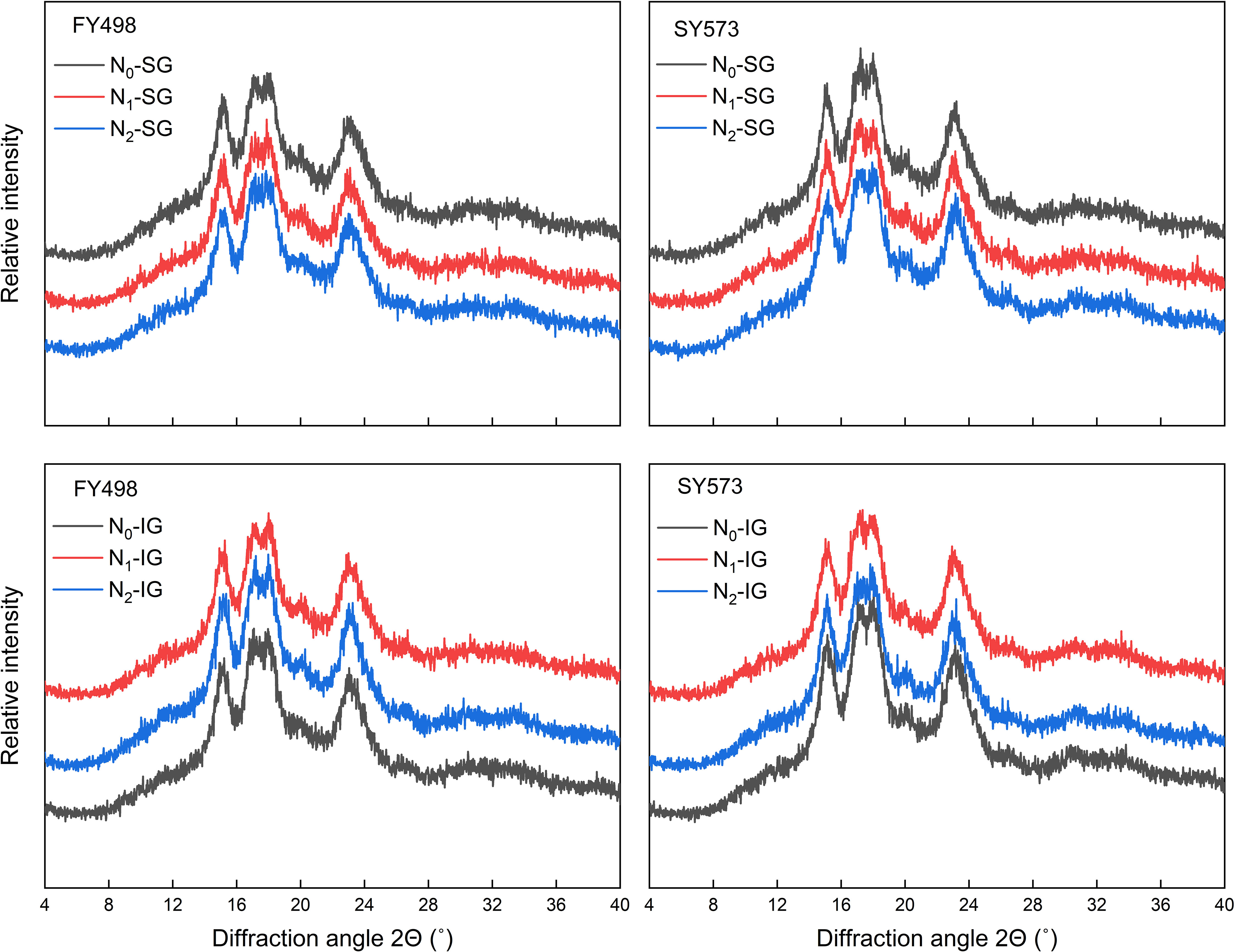

3.6 Relative crystallinity and ATR-FTIR spectrum of starch

As shown in Table 6, each variety at different grain positions had a significant effect on the relative crystallinity and the 1045/1022 cm-1 peak intensity ratio of starch. Comparing the high-taste variety Shuangyou 573 with the low-taste variety Fyou 498, there was a significant increase of 1.73–7.67% and 3.04–3.62% in the relative crystallinity and 1045/1022 cm-1 value of superior grains.

Table 6 Effects of postponing N topdressing on relative crystallinity and the infrared ratio of superior and inferior grains in hybrid indica rice cultivars with different taste values.

Under each treatment, the X-ray diffraction pattern of the superior and inferior starch grains of the two varieties showed two obvious strong peaks at 15° and 23° and two continuous double peaks near 17° and 18°, which are typical A-type crystallization peaks (Figure 5). This indicates that N fertilizer management does not change the crystal structure of starch. Further analysis revealed that N application treatments had a significant impact on the relative crystallinity and infrared ratio (IR) value of superior and inferior grains. Moreover, N application treatments reduced the relative crystallinity and 1045/1022 cm-1 value of the low-taste variety and high-taste variety of superior grains but increased the 1022/995 cm-1 value. Among them, compared with N0, under N2 treatment, the relative crystallinity and the 1045/1022 cm-1 value of the low-taste variety decreased by 2.00% and 5.44%, and the high-taste variety decreased by 6.80% and 5.44%, respectively. In contrast to the superior grains, N application treatments significantly increased the relative crystallinity and 1045/1022 cm-1 peak intensity ratio of the inferior grains. Compared to N0, the N1 and N2 treatments increased the relative crystallinity of inferior grains of the two varieties, with a significant increase of 10.50% and 3.67% of the high-taste variety. Besides, in the N1 and N2 treatments, the 1045/1022 cm-1 value of the inferior grains in the low-taste variety significantly increased by 4.49% and 3.09%, and the high-taste variety significantly increased by 2.19% and 1.91%, respectively. The effects of N fertilizer treatment on the 1022/995 cm-1 peak intensity ratio of inferior grains differed between the two varieties. The low-taste variety exhibited the highest 1022/995 cm-1 peak intensity ratio under the N0 treatment, significantly increasing by 5.40% and 4.29% compared to the N1 and N2 treatments, respectively. In contrast, the high-taste variety was the highest under the N2 treatment, increasing by 1.01%, compared to the N1 treatments. Compared with N1, the N2 treatment significantly reduced the relative crystallinity and the 1045/1022 cm-1 value and significantly increased the 1022/995 cm-1 value of superior grains and inferior grains in both varieties. In particular, the high-taste variety of superior grains and inferior grains showed the greatest reduction in relative crystallinity, 6.31%, and 6.18%, respectively. This indicates that application of N fertilizer reduced the relative crystallinity and order degree of starch granules in superior grains, whereas the opposite trend was observed in inferior grains. Increasing the proportion of N topdressing ratio moderately reduced the relative crystallinity and ordered structure of starch granules, thereby changing their stability of starch granules.

Figure 5 Effects of postponing N topdressing on X-ray diffraction patterns of superior and inferior grains in hybrid indica rice cultivars with different taste values. N0, Zero N; N1, local farmer practice; N2, postponing N topdressing. FY498, F you 498; SY573, Shuangyou 573. SG, superior grains; IG, inferior grains.

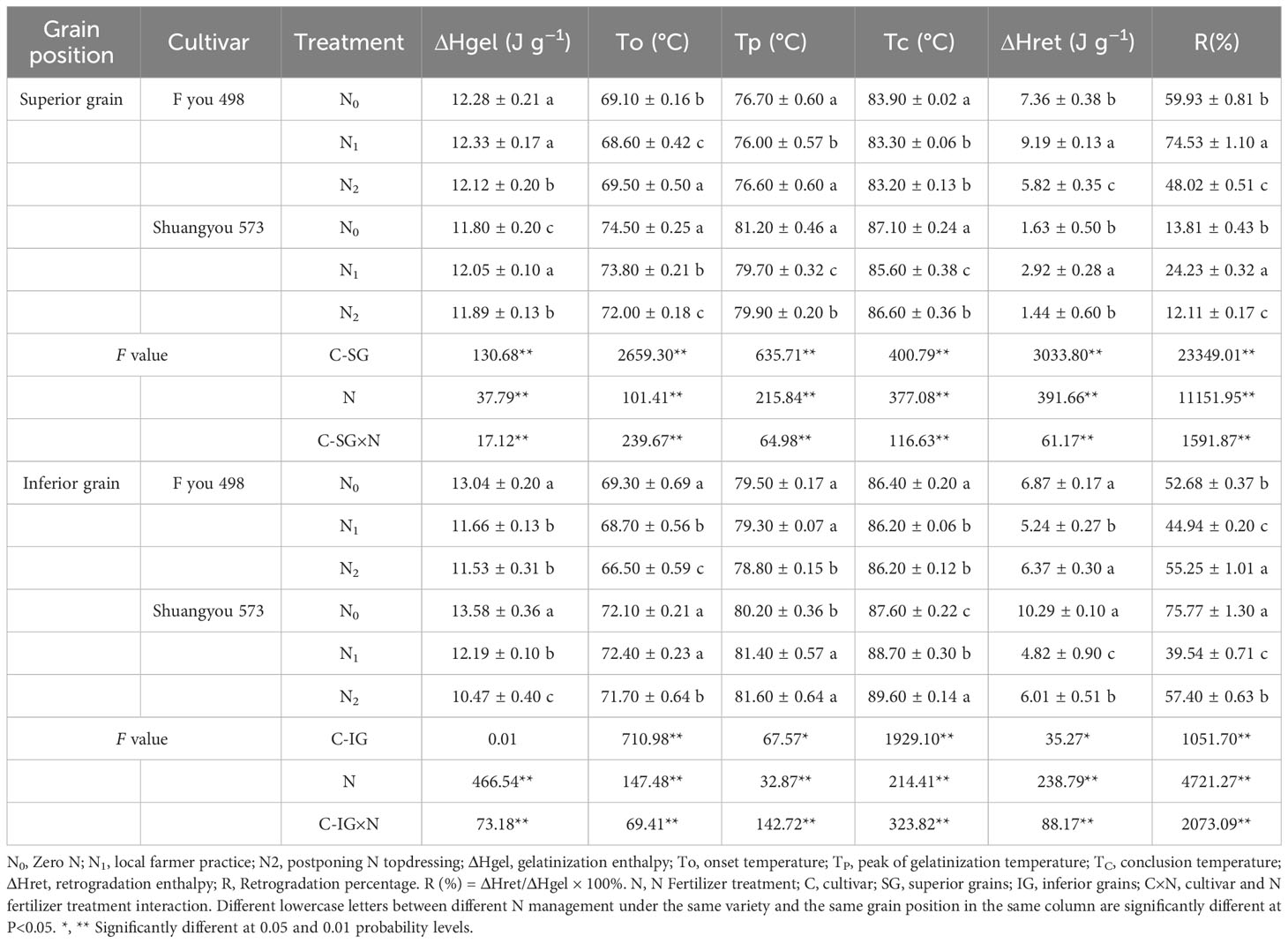

3.7 Starch thermal properties

The cultivars of different grain positions had significant or extremely significant effects on the onset temperature, peak temperature, termination temperature, retrogradation enthalpy, and retrogradation percentage of starch in the superior and inferior grains. N application management had extremely significant effects on the indicators of starch thermal properties in superior and inferior grains, and the interaction effect of the two factors on each index was extremely significant (Table 7). Under each variety of different grain positions, and N fertilizer treatments, the effects of the varieties on the starch onset, peak, and termination temperatures were significantly higher than those of nitrogen fertilizer. Compared with the low-taste variety Fyou 498, the onset, peak, and termination temperatures of superior grains starch of the high-taste variety Shuangyou 573 were significantly increased by 3.47–7.25%, 4.13–5.54%, and 2.69–3.93%, respectively; while the onset, and termination temperatures of inferior grains starch were significantly increased by 3.88–7.25%, and 1.37–3.79%, respectively.

Table 7 Effects of postponing N topdressing on starch thermal properties of superior and inferior grains in hybrid indica rice cultivars with different taste values.

Under different N application treatments, the N1 treatment increased the gelatinization enthalpy of the superior grains, while the N2 treatment decreased the gelatinization enthalpy of both varieties. Moreover, compared with N0, N application reduced the peak and termination temperatures of the superior grain of the two varieties. Inconsistent with the trend of superior grains, N application treatments reduced the gelatinization enthalpy, and retrogradation enthalpy of inferior grains of the two varieties; reduced the starch peak and termination temperature of inferior grains of the low-taste variety Fyou 498; and increased the starch peak and termination temperature of inferior grains of the high-taste variety Shuangyou 573. Among them, compared with N0, in the N1 and N2 treatments, the gelatinization enthalpy in inferior grains of low-taste variety decreased by 10.58% and 11.58%, and retrogradation enthalpy decreased by 23.73% and 7.28%, while the high-taste variety decreased by 10.24% and 22.90%, 41.59%, and 53.16%, respectively. The results showed that the N application improved the gelatinization and retrogradation properties of inferior grains by reducing the gelatinization enthalpy and retrogradation enthalpy of the inferior grains of the two varieties. Increasing the proportion of postponed N topdressing reduced the gelatinization enthalpy of rice, but increased its retrogradation enthalpy.

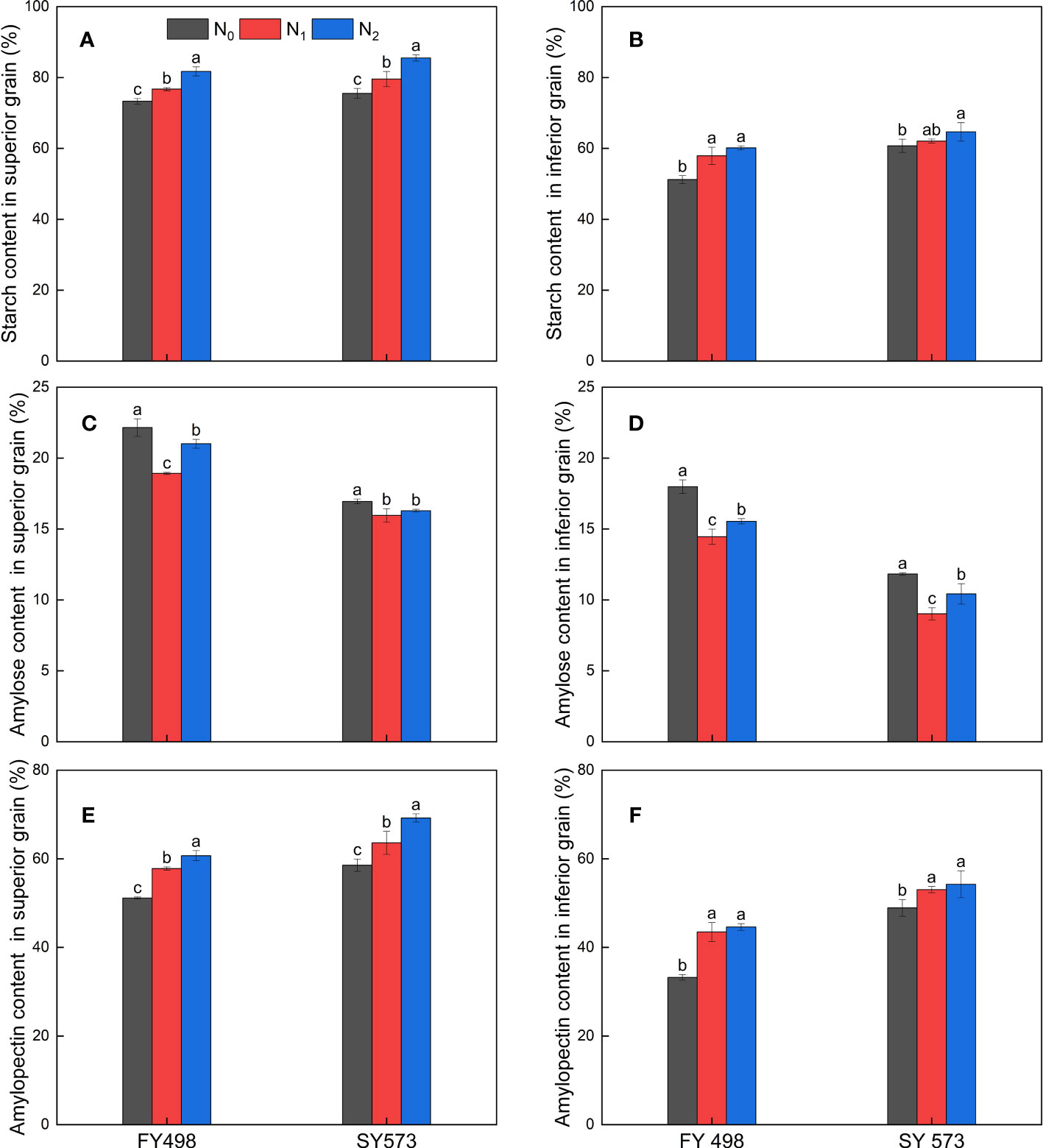

3.8 Relationship between starch structure properties and eating quality of superior and inferior grains

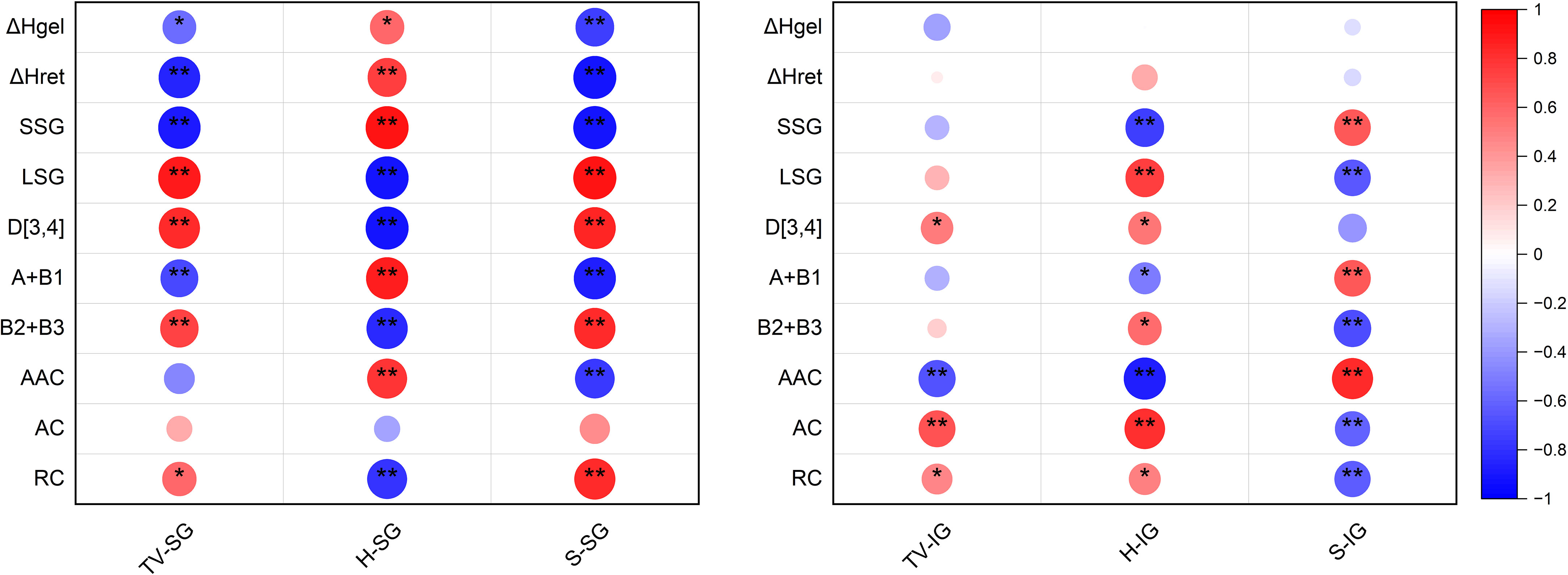

As shown in Figure 6, under different varieties and N fertilizer management, the taste value and stickiness of superior grains were significantly or extremely significantly positively correlated with the proportion of large starch granules, D[4,3], the proportion of (B2+B3) chains, and relative crystallinity, and significantly or extremely significantly negatively correlated with the gelatinization enthalpy, retrogradation enthalpy, proportion of small starch granules, the proportion of (A+B1) chain, and amylose content. The superior grain hardness exhibited an opposite trend to that of stickiness.

Figure 6 Heat map of person correlation in eating quality indicators, starch structure and properties of superior and inferior grains in hybrid indica rice cultivars. TV, taste value; H, Hardness; S, stickiness; SG, superior grains; IG, inferior grains; ΔHgel, gelatinization enthalpy; ΔHret, retrogradation enthalpies; SSG, small starch granules; LSG, large starch granules; D[4,3], starch volume mean diameter; (A+B1), amylopectin chains with DP 6-12 + DP 13-24; (B2+B3), amylopectin chains with DP 25-36 + DP>36. AAC, apparent amylose content; AC, amylopectin content; RC, relative crystallinity. *, ** Significantly different at 0.05 and 0.01 probability levels.

The taste value of inferior grains was significantly or extremely significantly positively correlated with D[4,3], amylopectin content, and relative crystallinity, and significantly negatively correlated with amylose content. Hardness was significantly or extremely significantly positively correlated with the proportion of large-granule starch, D[4,3], (B2+B3) chain, amylopectin content, and relative crystallinity, and significantly negatively correlated with the proportion of small-granule starch, (A+B1) chain, and amylose content. Stickiness was significantly positively correlated with the proportion of small granule starch, the proportion of (A+B1) chains, and relative crystallinity and was significantly negatively correlated with the proportion of large granule starch, the proportion of (B2+B3) chains, amylopectin content, and relative crystallinity.

4 Discussion

4.1 Effects of N fertilizer management on starch structure and thermal properties of superior and inferior grains

The quality of rice starch is regulated by genetic factors and agronomic cultivation practices. Rice varieties with different genetic backgrounds exhibit different starch structures and properties. In this study, the varieties had significant effects on the fine structure and thermal properties of starch in superior and inferior grains. Compared with the low-taste variety Fyou 498, the large proportion of large starch granules and (B2+B3) chains in the superior and inferior grains of the high-taste variety Shuangyou 573 is an important physiological basis for the high relative crystallinity of starch, order degree of starch granules, and range of starch gelatinization temperatures (onset, peak, and termination temperature) of the high-taste variety Shuangyou 573, which further complements and improves the results of previous studies (Peng et al., 2021; Gao et al., 2022; Xiao et al., 2022). This study also showed that the high-taste variety Shuangyou 573 significantly reduced the starch retrogradation enthalpy of the superior and inferior grains, which may have been caused by the low amylose content of Shuangyou 573.

N fertilizer in agronomic cultivation measures has a significant effect on the regulation of starch structure and physicochemical properties of superior and inferior grains (Jiang et al., 2022b). Previous studies have shown that N fertilization affects the morphology and size of starch granules. Optimized N application improved starch granule traits, while excessive postponement of N topdressing resulted in more small starch granules, which may be related to the formation of starch granules at different stages of grain filling (Gao et al., 2022; Xiong et al., 2022a). Generally, the accumulation of large-granule starch is completed preferentially at the early stage of grain filling. With the advancement of grain filling, large-granule starch gradually decomposes into small-granule starch (Jiang et al., 2022a), which in turn leads to a decrease in the proportion of large-granule starch and an increase in the proportion of small-granule starch. The relative crystallinity and 1045/1022 cm-1 value of starch can reflect the stability and order of starch crystals (Sevenou et al., 2002; Vandeputte et al., 2003). In this study, the N1 and N2 treatments reduced the relative crystallinity and order of starch granules of superior grains in both varieties, and with an increase in the proportion of postponed N topdressing, the stability of the starch crystals decreased. Significantly, the stability of starch crystals of superior grains of both varieties was the lowest under the N2 treatment. This is because the relative crystallinity and order degree of starch are mainly affected by the chain length distribution of amylopectin and the starch granule size (Chen et al., 2023). At the same time, both N1 and N2 treatments significantly increased the proportion of A chains and small granule starch in superior grains and significantly reduced the proportion of the (B2+B3) chain in both varieties, with the largest proportion of A chains and small granule starch and the smallest proportion of the (B2+B3) chain under N2 treatment. A higher proportion of the A chain is not conducive to the formation of a good double helix structure, which leads to starch crystal structure defects. In contrast, a lower proportion of the (B2+B3) chain may reduce the number of double helix structures that can cross the entire crystalline lamellae, resulting in a weakened binding force to maintain the internal structure of starch granules, thereby reducing the stability of the starch crystal structure (Wang et al., 2010; Witt et al., 2012; Zhang et al., 2013; Zhu et al., 2023). In addition, the reduction in starch granule size leads to a decrease in relative crystallinity and degree of starch order (Zhang et al., 2013). Previous studies have shown that the application of N fertilizers increases the relative crystallinity of starch in inferior grains (Jiang et al., 2022a). The results of this study are consistent with Jiang’s conclusions. Moreover, this study further showed that the order of starch granules in inferior grains increased, and the disorder of starch granules decreased under N1 and N2 treatments. This indicates that the application of nitrogen fertilizer can improve the crystal structure of starch in inferior grains and the order of starch crystals, which further complements the results of Jiang et al. (2023) and Yang et al. (2020). However, this study also showed that increasing the proportion of postponed N topdressing significantly reduced the relative crystallinity and order of starch granules in inferior grains, which may be related to the high amylose content under the N2 treatment. Higher amylose content destroys the double-helix structure of the starch crystalline region, thus reducing the relative crystallinity of the starch (Jiang et al., 2023).

Starch gelatinization is an endothermic process. The essence of gelatinization is the loss of the starch double-helical structure, expressed as the gelatinization enthalpy (Zhu et al., 2023). Kong et al. (2015) showed that low amylose content and high relative crystallinity are associated with high gelatinization enthalpy. Similar results were observed in this study. In this study, the N1 treatment resulted in a low amylose content and high relative crystallinity of two varieties, while N2 had the opposite trend. This is an important reason why the N1 treatment increased the gelatinization enthalpy of the superior grains, whereas the N2 treatment reduced the gelatinization enthalpy. In addition, this study found that N application reduced the gelatinization enthalpy of inferior grains of two varieties, and the gelatinization enthalpy of inferior grains under the N2 treatment was the lowest. This is related to the increase in the proportion of the A chain under N2 treatment, leading to the instability of the double-helix structure formed in the crystalline region, which can be dissociated at a lower temperature. Thus, it has a lower gelatinization enthalpy (Li et al., 2020). Starch retrogradation is defined as the recrystallization of starch molecular chains that differ from the original structure (Martinez et al., 2018). Amylose content and amylopectin chain length distribution have been proven to be important factors affecting starch retrogradation (Li et al., 2020; Li et al., 2022). Many studies have shown that amylose has a synergistic effect on the retrogradation properties of starch (Li et al., 2022; Yang et al., 2022b; Jiang et al., 2023), and that amylose molecules crystallize rapidly during starch retrogradation, thereby increasing the enthalpy and degree of retrogradation (Jiang et al., 2023). In addition, the A and longer B1 chains in amylopectin enhance the mobility of molecules by forming intermolecular hydrogen bonds and increasing the starch retrogradation rate (Martinez et al., 2018). In this study, both N1 and N2 treatments reduced the retrogradation enthalpy of inferior grains of the two varieties, especially the N1 treatment further reduced the retrogradation degree and improved the retrogradation properties of inferior grain starch. This may be related to the low amylose content and the highest proportion of amylopectin B1 chains in the inferior grains under the N1 treatment (Figure 1, Table 5).

In summary, compared with N1, N2 treatment increased the proportion of small starch granules and the proportion of (A+B1) chains in the superior and inferior grains of the two varieties, and decreased the relative crystallinity and 1045/1022 cm-1 value, resulting in a decrease in starch crystal stability. Compared with superior grains, inferior grains had smaller starch granules, more uneven surface of starch granules, thereby the crystal structure of inferior grains was more unstable. Based on the reduction of nitrogen application (150 kg N hm-2) using a postponing N topdressing treatment helped to reduce the stability of starch crystal structure, improve starch thermal characteristics, and especially reduce the inferior grains gelatinization enthalpy. These results helped to achieve the improvement of the taste quality of the whole spike of grains through the enhancement of the taste value of inferior grains based on the stabilization of high yields.

4.2 Relationship between starch structure, thermal properties of superior and inferior grains and rice eating quality index

Starch structural properties are closely related to the cooking and eating quality characteristics. At present, there are several studies on the effects of starch structure and physicochemical properties on rice eating quality under N fertilizer management, but the conclusions are inconsistent (Xiong et al., 2022a; Yang et al., 2022b; Jiang et al., 2023). Xiong et al. (2022a) showed that the hardness of rice, amylose content, starch granules size, the proportion of amylopectin A chain and B1 chain showed a trend of decreasing first and then increasing as the proportion of postponing N topdressing, and the N application management of the base: tiller: panicle fertilizer=5:2:3 helped to increase the breakdown value, gelatinization enthalpy, reduce the setback value, improve the starch gelatinization properties, and ultimately reduce the hardness of rice and improve the taste. Yang et al. (2022a) reported that postponing N topdressing increased the proportion of amylopectin A and B1 chains, thereby increasing the breakdown value, peak viscosity, and taste value.

This study showed that varieties and nitrogen fertilizer had significant effects on the taste value of superior and inferior grains of the two varieties. Compared with the low-taste variety, the taste value of inferior grains of the high-taste variety significantly increased by 10.34-10.84%. This indicates that the difference in the taste value of inferior grains is an important reason for the overall taste value difference between the high- and low-taste varieties. In this study, N application treatments reduced the taste value of superior grains in both varieties, with the N2 treatment showing the smallest decrease in taste value. However, increased the taste value of inferior grains in both varieties under N application treatments. The taste value of inferior grains was the greatest under the N2 treatment, followed by N1 treatment and N0 treatments. Starch granule size affects the taste of the superior grains. The content of large starch granules and the average diameter of starch granules had a synergistic effect on the taste value of the superior granules (Figure 6). This may be because the average diameter of large and relatively large starch granules increases the surface area for binding with water molecules, which helps water molecules enter the interior of the starch granules to improve their swelling properties (Zhu et al., 2021). Studies have confirmed that the high relative crystallinity of large-granule starch is due to its rich B2 and B3 amylopectin chains (Takeda et al., 1999). This is also why the proportion of large-granule starch and the (B2+B3) chain was positively correlated with the taste value of superior grains in this study. In addition, this study also suggested that increasing the proportion of small granule starch, (A+B1) chains, would reduce the taste value of superior grains, which may be caused by the poor hydration properties of small granule starch rich in A and B1 chains (Takeda et al., 1999; Xiao et al., 2022).

In this study, the gelatinization and retrogradation enthalpies of superior grains were inversely proportional to the taste value of superior grains, which is inconsistent with the conclusion of Jiang et al. (2022a) that the taste value of superior grains is inversely proportional to the gelatinization enthalpy and positively proportional to the retrogradation enthalpy and degree of retrogradation. This may be related to the selection of rice varieties and differences in N fertilizer management. This study also found that increasing the amylopectin content would simultaneously increase the taste value of inferior grains. The small molecular weight of amylopectin components is easily leached from the swollen and broken starch granules during cooking, which increases the stickiness of rice and may be the reason for the increased taste value (Li et al., 2016; Zhang et al., 2023). In particular, the highest amylopectin content and stickiness of inferior grains under the postponed N topdressing treatment supported the higher taste value under postponed N topdressing. The effect of amylose content on the taste value of inferior grains is mainly reflected by an increase in amylose content, which simultaneously increases the hardness of rice and reduces its taste (Zhou et al., 2020). Significantly, in this study, the relative crystallinity and average diameter of the starch granules were important indicators for simultaneously improving the taste value of superior and inferior grains.

The hardness and stickiness of rice are important indicators of its textural properties. Rice hardness is significantly correlated with protein and amylose content (Xiong et al., 2022b). Previous studies have shown that N application treatments increase the protein content, hinder damage to the short-range ordered structure by the entry of water molecules into starch during cooking, and inhibit starch granule swelling and gelatinization, thereby increasing rice hardness (Shi et al., 2023). In addition to co-crystallization with long chains of amylopectin, amylose forms amylose-lipid complexes with lipids to inhibit starch leaching during cooking or the swelling of starch granules during heating, ultimately increasing the hardness of cooked rice (Li and Gilbert, 2018). Stickiness is caused by the exudation of small-molecule amylose and amylopectin, specifically short chains of amylopectin, onto the surface of rice grains during cooking (Li et al., 2016; Li and Gilbert, 2018). In addition, an increase in amylopectin short-chain (DP ≤ 36) content reduces rice hardness (Xiong et al., 2022b). However, a previous study showed that an increase in the proportion of amylopectin A and B1 chains simultaneously increases the hardness of rice, whereas an increase in the proportion of amylopectin B2 and B3 chains simultaneously increases the stickiness of rice (Xiong et al., 2022a).

In this study, the high-taste variety Shuangyou 573 had higher stickiness and low hardness of superior and inferior grains compared to the low-taste variety Fyou 498. The difference in amylose content was the main reason for the difference in rice texture between the two varieties (Figure 1). N application increased the hardness of the superior grains of both varieties and reduced their stickiness. This is because the N1 and N2 treatments increased the proportion of amylopectin (A+B1) chain and decreased the proportion of (B2+B3) chains in both varieties (Table 2), which is consistent with the results of Xiong et al. (2022a). However, this study also showed that the hardness and stickiness of superior grains in two varieties increased with an increase in the proportion of N topdressing. N2 treatment increases the amylose content, amylopectin content, and amylopectin (A+B1) chain ratio of superior grains; thus, the small-molecular-weight amylopectin and short-chain amylopectin of rice grains are preferentially leached during cooking, increasing the stickiness of rice (Li and Gilbert, 2018; Zhang et al., 2023). Subsequently, amylose components and long-chain amylopectin are leached; however, long-chain amylopectin can easily maintain the integrity of starch granules, which bond and co-crystallize with amylose, thereby increasing the heat resistance of the starch crystal structure, hindering starch granule swelling and starch solubility, and ultimately increasing the hardness of the rice grains (Ong and Blanshard, 1995; Yi et al., 2022). In addition, the crystal structure of starch, gelatinization enthalpy, and proportion of small granules in this study were significantly correlated with the hardness and stickiness of superior granule rice. Consistent with the trend of strong grains, N2 treatment of the two varieties of inferior grains hardness, stickiness maximum. This was related to the increase in amylose, amylopectin content, and short chain of amylopectin by N2 treatment, which further supplemented the results of Zhang et al. (2023). In addition, Jiang et al. (2023) reported that large granule starch which was rich in B2 and B3 chains has a more stable crystal structure and higher relative crystallinity. During gelatinization, the long side chains of amylopectin are entangled with amylose, which limits the expansion of starch granules and increases their hardness. This is more similar to our study, i.e., long-chain amylopectin, the proportion of large granular starch, and relative crystallinity were all significantly positively correlated with the hardness and negatively correlated with the viscosity of inferior grains. In conclusion, compared with N1, N2 treatment had a more significant effect on the taste value of superior and inferior grains, especially the inferior grains. It was shown that inferior grains of high-yielding and high-taste value varieties should be screened to synergistically enhance the taste value of superior and inferior grains by enhancing cooked rice stickiness and moderately increasing hardness based on reduction of nitrogen application (150 kg N hm-2) using a postponing N topdressing treatment (basal fertilizer: tillering fertilizer: panicle fertilizer=3:1:6), which provides theoretical information for high-quality rice production.

5 Conclusion

Inferior grains had lower (B2+B3) chains of amylopectin, smaller starch granules, the surface of starch granules was more uneven and more pitting. Compared with N1, N2 treatment increased the proportion of small granule starch, the ratio of (A+B1) chains, amylose, amylopectin, and total starch content in the superior and inferior grains of the two varieties, decreased the relative crystallinity and the value of 1045/1022 cm-1, which contributed to the decrease in the stability and order of the starch crystal structure, the decrease in the enthalpy of pasting, and finally increased the taste value, hardness, and stickiness of the two varieties of superior and inferior grains. Correlation analysis showed that the relative crystallinity and average diameter of the starch granules were significantly positively correlated with the taste value of the superior and inferior grains and can be used as an evaluation index for the simultaneous improvement of the taste value of the superior and inferior grains.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material. Further inquiries can be directed to the corresponding author.

Author contributions

XY mapped and wrote the original draft. YL, YY, KC, and YW performed the experiments and collected the data. HYL and BL contributed to the methodology. YM contributed to the formal analysis. CG, ZC, ZY, and YS revised the manuscript. JM and YS administered the project and provided funding acquisition. All authors contributed to the article and approved the submitted version.

Funding

This work was supported by the National Key Research and Development Program Foundation of Ministry of Science and Technology of China (Grant No. 2022YFD1100204); the Project Foundation of the State Key Laboratory of Crop Gene Exploration and Utilization in Southwest China (Grant No. SKL-ZY202228); the Research Program Foundation of Key Laboratory of Sichuan Province, China, the Cultivation of Green and Efficient Super Rice Varieties (Grant No. 2022ZDZX0012); Sichuan agricultural machinery R&D manufacturing promotion and application integration pilot project (Hilly area rice intelligent transplanted R&D manufacturing promotion and application); the Rice Breeding Project Foundation of Sichuan Provincial Science and Technology Department (Grant No. 2021YFYZ0005)

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Cao, X. M., Sun, H. Y., Wang, C. G., Ren, X. J., Liu, H. F., Zhang, Z. J. (2017). Effects of late-stage nitrogen fertilizer application on the starch structure and cooking quality of rice. J. Sci. Food Agr. 98, 2332–2340. doi: 10.1002/jsfa.8723

Chen, Z. K., Li, P., Xiao, J. C., Jiang, Y., Cai, M. L., Wang, J. P., et al. (2021). Dry cultivation with ratoon system impacts rice quality using rice flour physicochemical traits, fatty and amino acids contents. Food Res. Int. 150, 110764. doi: 10.1016/j.foodres.2021.110764

Chen, R., Ma, M. T., Zhao, J. J., Fang, J. Y., Danino, D., Sui, Z. Q., et al. (2023). Characterization of multi-scale structure and physicochemical properties of starch from diverse Japonica waxy rice cultivars. J. Cereal Sci. 109, 103592. doi: 10.1016/j.jcs.2022.103592

Dou, Z., Tang, S., Li, G. H., Liu, Z. H., Ding, C. Q., Chen, L. (2017). Application of nitrogen fertilizer at heading stage improves rice quality under elevated temperature during grain-Filling stage. Crop Sci. 57, 2183–2192. doi: 10.2135/cropsci2016.05.0350

Gao, L. C., Wan, C. X., Wang, J. L., Wang, P. K., Gao, X. L., Eeckhout, M., et al. (2022). Relationship between nitrogen fertilizer and structural, pasting and rheological properties on common buckwheat starch. Food Chem. 389, 132664. doi: 10.1016/j.foodchem.2022.132664

Guo, C. C., Wuza, R. Q., Tao, Z. L., Yuan, X. J., Luo, Y. H., Li, F. J., et al (2023a). Effects of elevated nitrogen fertilizer on the multi-level structure and thermal properties of rice starch granules and their relationship with chalkiness traits. J. Sci. Food. Agr. doi: 10.1002/jsfa.12886

Guo, C. C., Yuan, X. J., Wen, Y. F., Yang, Y. G., Ma, Y. M., Yan, F. J., et al. (2023b). Common population characteristics of direct-seeded hybrid indica rice for high yield. Agronomy 115, 1606–1621. doi: 10.1002/agj2.21359

Guo, C. C., Yuan, X. J., Yan, F. J., Xiang, K. H., Wu, Y. X., Zhang, Q., et al. (2022). Nitrogen application rate affects the accumulation of carbohydrates in functional leaves and grains to improve grain filling and reduce the occurrence of chalkiness. Front. Plant Sci. 13. doi: 10.3389/fpls.2022.921130

Hu, W. X., Chen, J., Xu, F., Chen, L., Zhao, J. W. (2020). Study on crystalline, gelatinization and rheological properties of japonica rice flour as affected by starch fine structure. Int. J. Biol. Macromol. 148, 1232–1241. doi: 10.1016/j.ijbiomac.2019.11.020

Jiang, Y., Chen, Y., Zhao, C., Liu, G. M., Shi, Y., Zhao., L. T., et al. (2022a). The starch physicochemical properties between superior and inferior grains of japonica rice under panicle nitrogen fertilizer determine the difference in eating quality. Foods 11, 2489. doi: 10.3390/foods11162489

Jiang, Y., Zhao, C., Chen, Y., Liu, G. M., Zhao, L. T., Liao, P. Q., et al. (2023). Effects of nitrogen panicle fertilizer application on physicochemical properties and fine structure of japonica rice starch and its relationship with eating quality. Acta Agronomica Sinica. 49, 200–210. doi: 10.3724/SP.J.1006.2023.12083

Jiang, J. J., Zhou, T. Y., Wei, C. H., Wu, J. N., Zhang, H., Liu, L. J., et al. (2022b). Effects of crop management practices on grain quality of superior and inferior spikelets of super rice. Scientia Agricultura Sin. 55, 874–889. doi: 10.3864/j.issn.0578-1752.2022.05.004

Kong, X. L., Zhu, P., Sui, Z. Q., Bao, J. S. (2015). Physicochemical properties of starches from diverse rice cultivars varying in apparent amylose content and gelatinisation temperature combinations. Food Chem. 172, 433–440. doi: 10.1016/j.foodchem.2014.09.085

Li, H. Y., Gilbert, R. G. (2018). Starch molecular structure: the basis for an improved understanding of cooked rice texture. Carbohydr. Polym. 195, 9–17. doi: 10.1016/j.carbpol.2018.04.065

Li, C., Gong, B. (2020). Insights into chain-length distributions of amylopectin and amylose molecules on the gelatinization property of rice starches. Int. J. Biol. Macromol. 155, 721–729. doi: 10.1016/j.ijbiomac.2020.04.006

Li, H. Y., Prakash, S., Nicholson, T. M., Fitzgerald, M. A., Gilbert, R. G. (2016). The importance of amylose and amylopectin fine structure for textural properties of cooked rice grains. Food Chem. 196, 702–711. doi: 10.1016/j.foodchem.2015.09.112

Li, C., Wu, A., Yu, W. W., Hu, Y. M., Li, E. P., Zhang, C. Q., et al. (2020). Parameterizing starch chain-length distributions for structure-property relations. Carbohydr. Polym. 241, 116390. doi: 10.1016/j.carbpol.2020.116390

Li, E. P., Yang, X. Y., Li, C. (2022). Combined effects of starch fine molecular structures and storage temperatures on long-term rice amylopectin retrogradation property. Int. J. Biol. Macromol. 201, 458–467. doi: 10.1016/j.ijbiomac.2022.01.092

Ma, P., Lan, Y., Lv, X., Fan, P., Yang, Z. Y., Sun, Y. J., et al. (2021). Reasonable nitrogen fertilizer management improves rice yield and quality under a rapeseed/wheat-rice rotation system. Agriculture-Basel 11, 490. doi: 10.3390/agriculture11060490

Martinez, M. M., Li, C., Okoniewska, M., Mukherjee, I., Vellucci, D., Hamaker, B. (2018). Slowly digestible starch in fully gelatinized material is structurally driven by molecular size and A and B1 chain lengths. Carbohydr. Polym. 197, 531–539. doi: 10.1016/j.carbpol.2018.06.021

Ong, M. H., Blanshard, J. M. V. (1995). Texture determinants in cooked, parboiled rice. I: rice starch amylose and the fine stucture of amylopectin. J. Cereal Sci. 21, 251–260. doi: 10.1006/jcrs.1995.0028

Peng, Y., Mao, B. G., Zhang, C. Q., Shao, Y., Wu, T. H., Hu, L. M., et al. (2021). Influence of physicochemical properties and starch fine structure on the eating quality of hybrid rice with similar apparent amylose content. Food Chem. 353, 129461. doi: 10.1016/j.foodchem.2021.129461

Sevenou, O., Hill, S. E., Farhat, I. A., Mitchell, J. R. (2002). Organisation of the external region of the starch granule as determined by infrared spectroscopy. Int. J. Biol. Macromol. 31, 79–85. doi: 10.1016/S0141-8130(02)00067-3

Shi, S. J., Pan, K. Q., Yu, M., Li, L. N., Tang, J. C., Cheng, B., et al. (2022). Differences in starch multi-layer structure, pasting, and rice eating quality between fresh rice and 7 years stored rice. Curr. Res. Food Sci. 5, 1379–1385. doi: 10.1016/j.crfs.2022.08.013

Shi, S. J., Zhang, G. Y., Chen, L. L., Zhang, W. H., Wang, X. D., Pan, K. Q., et al. (2023). Different nitrogen fertilizer application in the field affects the morphology and structure of protein and starch in rice during cooking. Food Res. Int. 163, 112193. doi: 10.1016/j.foodres.2022.112193

Shu, C. H., Li, F. J., Liu, D. D., Qin, J., Wang, M. T., Sun, Y. J., et al. (2021). Heading uniformity: A new comprehensive indicator of rice population quality. Agriculture-Basel 11, 770. doi: 10.3390/agriculture11080770

Shu, C. H., Li, F. J., Tang, Q. Y., Zhu, Y. M., Zhang, J. Y., Sun, Y. J., et al. (2022). Do reduced water and nitrogen input in rice production necessarily reduce yield? Int. Agrophys. 36, 47–58. doi: 10.31545/intagr/146934

Sun, Y. J., Lin, D., Sun, Y. Y., Yan, F. J., Ma, P., Guo, C. C., et al. (2023). Improving yield and nitrogen use efficiency of hybrid indica rice through optimizing nitrogen application strategies in the rice season under different rotation patterns. Paddy Water Environ. 21, 99–113. doi: 10.1007/s10333-022-00916-4

Takeda, Y., Takeda, C., Mizukami, H., Hanashiro, I. (1999). Structures of large, medium and small starch granules of barley grain. Carbohydr. Polym. 38, 109–114. doi: 10.1016/S0144-8617(98)00105-2

Vandeputte, G. E., Derycke, V., Geeroms, J., Delcour, J. A. (2003). Rice starches. II. Structural aspects provide insight into swelling and pasting properties. J. Cereal Sci. 38, 53–59. doi: 10.1016/S0733-5210(02)00141-8

Wang, L., Lin, G., Yu, X., Wu, Y., Chen, G., Xiong, F. (2020). Endosperm enrichment and physicochemical properties of superior and inferior grain starch in super hybrid rice. Plant Biol. 22, 669–678. doi: 10.1111/plb.13106

Wang, L., Xie, B. J., Shi, J., Xue, S., Deng, Q. C., Wei, Y., et al. (2010). Physicochemical properties and structure of starches from Chinese rice cultivars. Food Hydrocolloid. 24, 208–216. doi: 10.1016/j.foodhyd.2009.09.007

Wani, A. A., Singh, P., Shah, M. A., Schweiggert-Weisz, U., Gul, K., Wani, I. A. (2012). Rice starch diversity: effects on structural, morphological, thermal, and physicochemical properties-a review. Compr. Rev. Food Sci. Food Saf. 11, 417–436. doi: 10.1111/j.1541-4337.2012.00193.x

Witt, T., Doutch, J., Gilbert, E. P., Gilbert, R. G. (2012). Relations between molecular, crystalline, and lamellar structures of amylopectin. Biomacromolecules 13, 4273–4282. doi: 10.1021/bm301586x

Xiao, L. T., Li, X. H., Liu, L. J., Ye, F. Y., Zhao, G. H. (2022). Effects of starch granule size on the physical and chemical properties of barley starches. Scientia Agricultura Sinica. 55, 1010–1024. doi: 10.3864/j.issn.0578-1752.2022.05.013

Xiong, R. Y., Chen, L. M., Jiang, D. R., Zhou, Y. J., Tan, X. M., Pan, X. H., et al. (2022b). Effects of different irrigation management on the textural properties of double-cropping late indica rice in south China. Phyton-Int. J. Exp. Bot. 91, 1495–1502. doi: 10.32604/phyton.2022.018485

Xiong, R. Y., Tan, X. M., Yang, T. T., Pan, X. H., Zeng, Y. J., Huang, S., et al. (2022a). Relation of cooked rice texture to starch structure and physicochemical properties under different nitrogen managements. Carbohydr. Polym. 295, 119882. doi: 10.1016/j.carbpol.2022.119882

Xiong, R. Y., Tan, X. M., Yang, T. T., Wang, H. X., Pan, X. H., Zeng, Y. J., et al. (2023). Starch multiscale structure and physicochemical property alterations in high-quality indica rice quality and cooked rice texture under different nitrogen panicle fertilizer applications. Int. J. Biol. Macromol. 252, 126455–126455. doi: 10.1016/j.ijbiomac.2023.126455

Yan, F. J., Sun, Y. J., Xu, H., Yin, Y. Z., Wang, H. Y., Wang, C. Y., et al. (2018). Effects of wheat straw mulch application and nitrogen management on rice root growth, dry matter accumulation and rice quality in soils of different fertility. Paddy Water Environ. doi: 10.1007/s10333-018-0643-1

Yang, Y., Lin, G. Q., Yu, X. R., Wu, Y. F., Xiong, F. (2020). Rice starch accumulation at different endosperm regions and physical properties under nitrogen treatment at panicle initiation stage. Int. J. Biol. Macromol. 160, 328–339. doi: 10.1016/j.ijbiomac.2020.05.210

Yang, G. T., Peng, Y. L., Liu, R., Huang, M., Xiao, Y., Yang, Z. Y., et al. (2022b). Effect of chemical fertilizer reduction on the quality of hybrid rice of different amylose contents. J. Food Biochem. 46, e14066. doi: 10.1111/jfbc.14066

Yang, B., Yong, M. L., Zhao, B. H., Chen, Q., Ye, M., Zhang, Z. J. (2022a). Effect of reducing nitrogen fertilization on the starch structure and the eating quality of japonica rice grain. J. Yangzhou Univ. (Agricultural Life Sci. Edition). 43, 47–46. doi: 10.16872/j.cnki.1671-4652.2022.05.005

Yi, X. E., Li, E. P., Yu, S. Y., Zhang, X. W., Yang, C. T., Shao, S. B., et al. (2022). Combined effects of starch fine molecular structures and water content on starch digestibility of cooked white rice. Int. J. Biol. Macromol. 215, 192–202. doi: 10.1016/j.ijbiomac.2022.06.116

Zhang, X. C., Fu, L. B., Tu, Y. S., Zhao, H. F., Kuang, L. H., Zhang, G. P. (2020). The Influence of nitrogen application level on eating quality of the two indica-japonica hybrid rice cultivars. Plants-Basel 9, 1663. doi: 10.3390/plants9121663

Zhang, Y., Li, F., Huang, K., Li, S., Cao, H. W., Xie, J., et al. (2023). Structural changes of starch under different milling degrees affect the cooking and textural properties of rice. Food Chem. X. 17, 100627. doi: 10.1016/j.fochx.2023.100627

Zhang, B. J., Li, X. X., Liu, J., Xie, F. W., Chen, L. (2013). Supramolecular structure of A- and B-type granules of wheat starch. Food Hydrocolloid. 31, 68–73. doi: 10.1016/j.foodhyd.2012.10.006

Zhou, T. Y., Li, Z. K., Li, E. P., Wang, W. I., Yuan, L. M., Zhang, H., et al. (2022). Optimization of nitrogen fertilization improves rice quality by affecting the structure and physicochemical properties of starch at high yield levels. J. Integr. Agr. 21, 1576–1592. doi: 10.1016/S2095-3119(21)63678-X

Zhou, L. J., Sheng, W. T., Wu, J., Zhang, C. Q., Liu, Q. Q., Deng, Q. Y. (2015). Differential expressions among five Waxy alleles and their effects on the eating and cooking qualities in specialty rice cultivars. J. Integr. Agrc. 14, 1153–1162. doi: 10.1016/S2095-3119(14)60850-9

Zhou, T. Y., Zhou, Q., Li, E. P., Yuan, L. M., Wang, W. L., Zhang, H., et al. (2020). Effects of nitrogen fertilizer on structure and physicochemical properties of ‘super’ rice starch. Carbohydr. Polym. 239, 116237. doi: 10.1016/j.carbpol.2020.116237

Zhu, D. W., Fang, C. Y., Qian, Z. H., Guo, B. W., Huo, Z. Y. (2021). Differences in starch structure, physicochemical properties and texture characteristics in superior and inferior grains of rice varieties with different amylose contents. Food Hydrocolloid. 110, 106170. doi: 10.1016/j.foodhyd.2020.106170

Zhu, D. W., Li, M., Fang, C. Y., Yu, J., Zhu, Z. W., Yu, Y. H., et al. (2023). Effects of storage on the starch fine structure and physicochemical properties of different rice variety types. Carbohydr. Polym. 300, 120273. doi: 10.1016/j.carbpol.2022.120273

Keywords: indica rice, postponing nitrogen topdressing, starch structure, superior and inferior grains, eating quality

Citation: Yuan X, Luo Y, Yang Y, Chen K, Wen Y, Luo Y, Li B, Ma Y, Guo C, Chen Z, Yang Z, Sun Y and Ma J (2023) Effects of postponing nitrogen topdressing on starch structural properties of superior and inferior grains in hybrid indica rice cultivars with different taste values. Front. Plant Sci. 14:1251505. doi: 10.3389/fpls.2023.1251505

Received: 01 July 2023; Accepted: 25 September 2023;

Published: 10 October 2023.

Edited by:

Xiukang Wang, Yan’an University, ChinaReviewed by:

Zhongyang Huo, Yangzhou University, ChinaZhaowen Mo, South China Agricultural University, China

Min Xi, Anhui Academy of Agricultural Sciences (CAAS), China

Copyright © 2023 Yuan, Luo, Yang, Chen, Wen, Luo, Li, Ma, Guo, Chen, Yang, Sun and Ma. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jian Yong Sun, eW9uZ2ppYW5zMTk4MEAxNjMuY29t

Xiaojuan Yuan

Xiaojuan Yuan Yongheng Luo1

Yongheng Luo1 Zongkui Chen

Zongkui Chen Jun Ma

Jun Ma