- Engineering Technology Research Institute of Southwest Oil and Gas Field Company, Chengdu, China

The burial depth of Penglai gas field reservoir in the Sichuan Basin of China exceeds 7,000 m, and the reservoir temperature is 160°C. Penglai gas field belongs to the fractured reservoir, and there are many natural fractures distributed in the reservoir. Natural fractures are not only the storage place of natural gas, but also the transportation channel of natural gas. Gas wells mainly increase natural gas production through acid fracturing. In the early stage, Penglai Gas Field mainly used gelled acid fracturing technology to create an artificial fracture in the reservoir by injecting a large amount of acid fluid. However, the stimulation range of gelled acid fracturing is very small. After acid fracturing, gas wells can only produce 120,000 cubic meters of natural gas per day. To obtain higher natural gas production, this paper proposes a multi-stage temporary acid fracturing technology that can greatly improve the effect of acid fracturing. The temporary plugging agent for acid fracturing has been developed to meet the high-temperature requirements of the Penglai gas field. Based on the simulation of fracture propagation, the feasibility of acid fracturing expansion of natural fractures in the Penglai Gas Field is clarified. Fiber and granular temporary plugging agents that meet the plugging strength greater than 20 MPa are selected by using the dynamic temporary plugging instrument. MultiFracS software is used to optimize the multi-stage temporary acid fracturing process parameters. The research results in this paper have been applied to wells PS101, PS102, and PS103. After fracturing, compared with the gelling acid fracturing, the natural gas production has increased by more than three times, and the multi-stage temporary plugging acid fracturing has achieved a very good stimulation effect.

1 Introduction

Penglai gas field is a newly discovered large carbonate reservoir in the Sichuan Basin, which is located in the north of the gentle slope of the central Sichuan paleo uplift [1, 2]. Sinian Dengying formation is the main production layer of Penglai Gas Field, and several wells have obtained natural gas in Sinian Dengying formation. The burial depth of the Penglai gas field reservoir reaches 7,000 m, the formation pressure coefficient is 1.27, and the reservoir temperature is about 160°C [3, 4]. The core and imaging logging shows that there are a lot of natural fractures in the formation, and the average porosity of the reservoir is 4.8%. Natural fractures not only play an important role in the storage of natural gas, but also are the main channels for the migration of natural gas in the formation. In the early period of Penglai gas field development, gelling acid fracturing was the main method to increase production, but it was difficult for gas wells to maintain high production because of the short action distance of acid fluid at high temperatures and the low conductivity of acid etched fracture [5].

Carbonate reservoirs are very rich in oil and gas resources, and acid fracturing of ultra-deep carbonate reservoirs has been a hot research topic. Yang Wang et al. [6] proposed a technical method to improve the acid etching fracture length and conductivity of low permeability carbonate reservoirs by alternating injection of authigenic acid and gelling acid. Yang Wang et al. [7] carried out the visual test experiment of alternating injection acid fracturing and studied the influence of parameters such as injection displacement, acid ratio, and injection stage on acid fingering morphology. Lufeng Zhang et al. [8] conducted a research on long-term acid conductivity behavior and proposed a new method to raise acid fracture conductivity under high closure stress. Daobing Wang et al. [9] presented a comprehensive workflow to model hydraulic fracture by accounting for interactions with numerous crosscutting natural fractures or joint sets, as well as the effect of temporary plugging in opened fractures. This investigation provides new insight into the formation mechanism of fracture networks in naturally fractured formations. Fangzheng Jiao [10] proposed the idea of “volumetric development” which is based on years of study on the geological features, flow mechanisms, high-precision depiction, and the recovery mode of fractured-vuggy bodies. Yang Wang et al. [11] proposed a temporary plugging segmented acid fracturing technique for horizontal wells. Schlumberger company first proposed the temporary fiber plugging technology, using degradable fiber to temporarily seal the fracture, forcing the acid fracturing fracture extension direction to change [12]. Zhou Fujian et al. [13] carried out the liquid filtration experiment of temporary plugging artificial fracture with fiber, and analyzed the characteristics of liquid filtration in the process of temporary plugging. Daobing Wang et al. [14] presented a systematic study of the fracture diversion mechanisms of the fiber-diverting fracturing technique. Lei Qun et al. [15] put forward a new concept of “Fracture network” fracturing technology for low porosity, low permeability, and no natural fracture reservoirs. Jianye Mou et al. [16] designed a multi-stage triaxial fracturing system and experimental procedures to satisfy the requirements of diverted fracturing in horizontal wells. Nanlin Zhang et al. [17] proposed self-supporting fracturing technology, established a transient temperature model considering reaction heat based on the first law of thermodynamics, and clarified the impact of phase change reaction heat on wellbore temperature. Nanlin Zhang et al. [18] used Permian cores from Sichuan Basin to evaluate fracture conductivity under different conditions, such as proppant size and concentration, acid concentration and activity, and the separate or combined application of acid and proppant. Daobing Wang et al. [19] used the extended finite element method to investigate refracture propagation paths at different initiation angles. Daobing Wang et al. [20] established a comprehensive fracture index model that comprehensively considers the thermal effect and fracture toughness under different temperatures and confining pressures. Yuanqing Wu et al. [21] used the CF model and DBF framework to simulate matrix acidification in fractured porous media, and the simulation results of this work were compared with Khoei’s work, which proved the rationality of this work. On the basis of improving the DBF framework, Yuanqing Wu et al. [22] introduced the energy balance equation into the improved DBF framework and gave the thermal DBF framework. The above research mainly focuses on how to improve the fracture conductivity and the test evaluation of a temporary plugging agent, but there is a lack of relevant research on the evaluation of temporary plugging agents for acid fracturing of ultra-deep and ultra-high temperature gas reservoirs like Penglai Gas Field and the temporary plugging acid fracturing technology based on fracture expansion.

Since there are many natural fractures in the reservoir of the Penglai gas field, this paper proposes a multi-stage temporary plugging acid fracturing technique and develops a temporary plugging agent to meet the high-temperature requirements of the Penglai gas field. The results of this study have been applied to three wells in the Penglai gas field and have achieved good results, further proving the success of multi-stage temporary plugging acid fracturing.

2 Introduction of gas reservoir

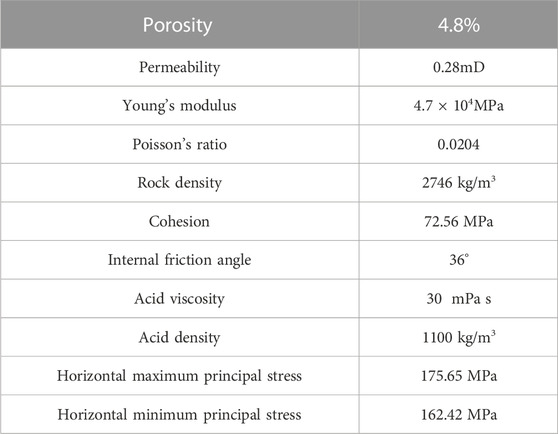

Penglai Gas Field is located in Sichuan Basin, China. The reservoir is buried at a depth of 7,000 m, with an average of 4.8% and an average permeability of 0.28mD. The lithology is mainly dolomite, with a small number of corrosion holes on the core. Both the core and the electric imaging logging show that there are a large number of natural fractures in the reservoir.

According to the measured data, the temperature in the middle part of the formation is 160°C, and the pressure coefficient is about 1.27, belonging to normal temperature and high-pressure gas reservoir.

The Young’s modulus of the Penglai gas field is 4.7 × 104MPa, and Poisson’s ratio is 0.0204. Young’s modulus of the Penglai gas field is lower than that of other gas fields in the Sichuan Basin. The acid corrosion rate of the core in the Penglai gas field is 95.76%. The high acid corrosion rate indicates that the Penglai gas field is suitable for acid fracturing stimulation.

3 Multi-stage temporary plugging acid fracturing

3.1 Solubility of temporary plugging agent

The reservoir temperature of Penglai Gas Field can reach 160°C, and the dissolution rate of the temporary plugging agent increases rapidly under high temperatures [23]. The technical principle of multi-stage temporary plugging acid fracturing is to add a temporary plugging agent in the acid fracturing, so as to achieve the purpose of fracture turning and expanding. Therefore, the temporary plugging agent with a slow dissolution rate under high temperatures should be selected first to carry out the experiment [24].

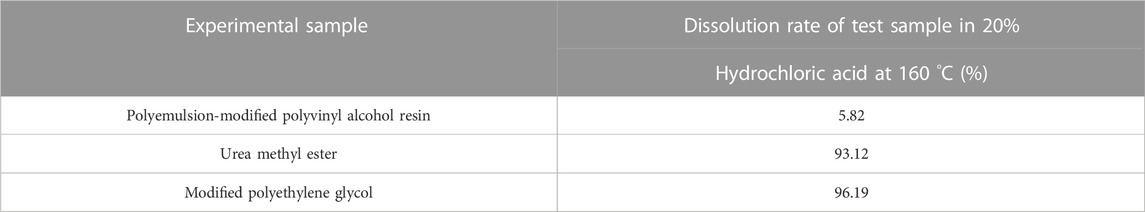

This paper evaluates the high-temperature solubility of three temporary plugging agents. These three temporary plugging agents are Polyemulsion-modified polyvinyl alcohol resin, Urea methyl ester, and Modified polyethylene glycol. We put the three temporary plugging agents in 20% hydrochloric acid at 160°C, and observed the dissolution of the temporary plugging agents after 1 h. The purpose of this experiment is to test the solubility of temporary plugging agent during acid fracturing. In order to ensure the plugging effect, the temporary plugging agent should be as insoluble as possible or have a low dissolution rate during acid fracturing. In this experiment, the temporary plugging agent is first weighed (M1), and then the temporary plugging agent soaked in acid solution is weighed again (M2) to determine the dissolved mass of the temporary plugging agent in acid solution (M1-M2). Define the solubility of temporary plugging agent as (M1-M2)/M2. The equipment used in this experiment mainly includes beaker, heater and electronic balance.

It can be seen from Table 1 that the dissolution rate of Polyemulsion-modified polyvinyl alcohol resin in high-temperature acid solution is the lowest, and the dissolution rate of the temporary plugging agent for the other two materials is more than 90%. Polyemulsion-modified polyvinyl alcohol resin is selected as the temporary plugging agent for acid fracturing in Penglai Gas Field. The low dissolution rate indicates that the temporary plugging agent will maintain good performance during acid fracturing.

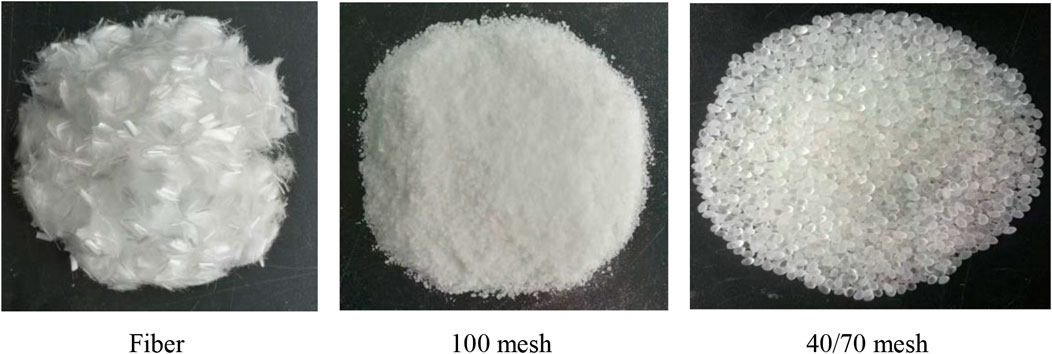

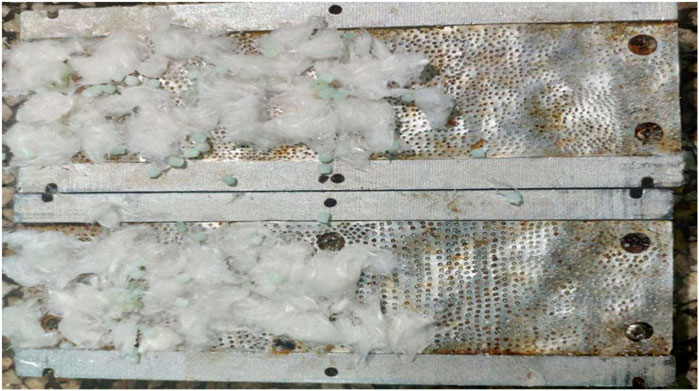

Polyemulsion-modified polyvinyl alcohol resin can be processed into various shapes according to technical requirements, as shown in Figure 1. Polyemulsion-modified polyvinyl alcohol can be processed into fiber, 100 mesh particles, and 40/70 mesh temporary plugging agent.

3.2 Plugging performance test of temporary plugging agent

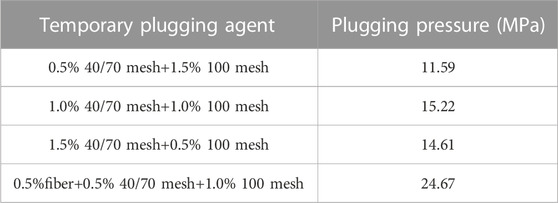

The key technology of multi-stage temporary plugging acid fracturing is to add a temporary plugging agent in natural fracture, so as to increase the net pressure in natural fracture and force the fracture to turn and extend [25]. The width of natural fracture in the Penglai gas field is about 2 mm according to the logging data of electrical imaging. Temporary plugging agents with different concentrations and combinations are selected for the plugging test, so as to select the temporary plugging agent combined with the strongest plugging ability.

The dynamic plugging evaluation instrument is used to carry out this test, and the test fracture width is set as 2 mm according to the natural fracture width of Penglai Gas Field. The dynamic plugging instrument is mainly composed of displacement pump, injection system and simulated fracture. The equipment is mainly used to evaluate the plugging performance of temporary plugging agent under high temperature and high pressure environment. This experiment first injects the temporary plugging agent into the simulated fracture, and records the plugging pressure data in real time through the electronic pressure gauge. The plugging ability is judged by the plugging pressure. The higher the plugging pressure is, the better the plugging performance of the temporary plugging agent for the fracture is. The temporary plugging agent with different concentrations and combinations was used to test its plugging pressure.

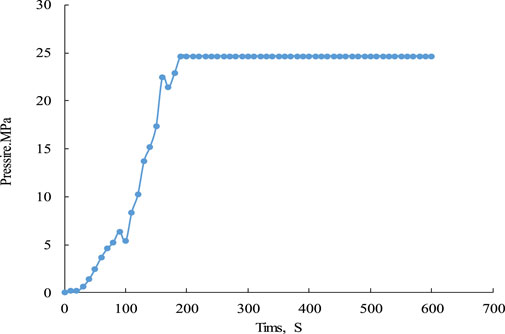

It can be seen from Table 2 and Figure 2 that if only a granular temporary plugging agent is used, the plugging pressure will rise rapidly with the increase of 40/70 mesh granular temporary plugging agent concentration. At the same concentration, when the fiber is added into the granular temporary plugging agent, the plugging pressure increases significantly, and the plugging pressure of 0.5%fiber + 0.5% 40/70 mesh plugging agent + 1.0% 100 mesh plugging agent can reach 24.67 MPa.

It can be seen from Figure 3 that the fiber and granular temporary plugging agent are intertwined in the fracture, the filling layer formed by the temporary plugging agent is quite dense, and the granular temporary plugging agent is wrapped together by fibers. When the temporary plugging agent forms the plugging layer in the fracture, the first is that the fibers are intertwined and sealed in the fracture, and then the fibers catch the temporary plugging particles like fishing nets, and the temporary plugging particles further strengthen the plugging layer formed by the fibers.

3.3 Simulation of acid fracturing fracture propagation in fractured reservoirs

According to the thickness, porosity, permeability, water saturation and other reservoir geological parameters of Penglai Gas Field, the acid fracturing productivity prediction model of Penglai Gas Field is established using Petrel software. According to Petrel software simulation, natural fractures make a huge contribution to production, especially when acid fracturing communicates with a large number of natural fractures, the gas production can be increased by 340% compared with natural fractures without communication. Therefore, the design of acid fracturing scheme should ensure that as many natural fractures as possible will be opened.

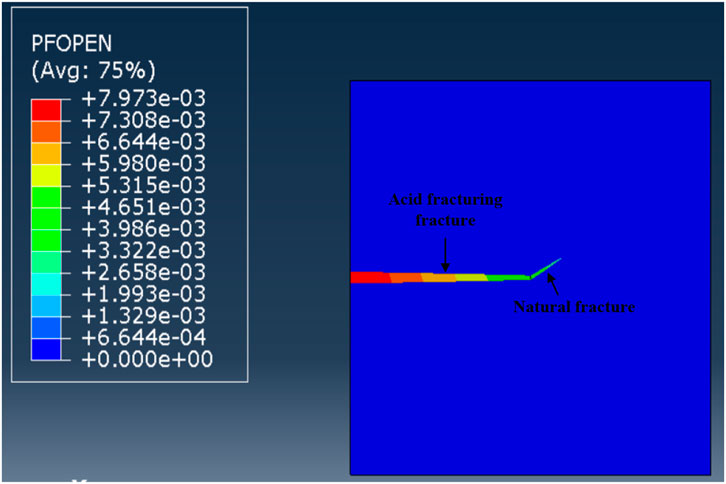

The finite element software is used to simulate the expansion form of acid corrosion fractures in the Penglai Gas Field. Penglai Gas Field is a fractured gas reservoir, and there are many natural fractures in the reservoir. The dip angle of most natural fractures is NE 66°. The maximum horizontal principal stress direction of the Penglai Gas Field reservoir is NE 38°, and the approach angle between acid-etched fractures and natural fractures is 29°.

The finite element method is used to establish a square model with a length and width of 200 m. There is a natural fracture inside the model. The included angle between the natural fracture and the horizontal maximum principal stress is 29°, and the minimum element size is 0.5 m. The horizontal minimum principal stress and horizontal maximum principal stress are applied respectively in the X and Y directions of the model. The model parameters are set according to the reservoir parameters of Penglai Gas Field, and the calculation parameters used are shown in Table 3.

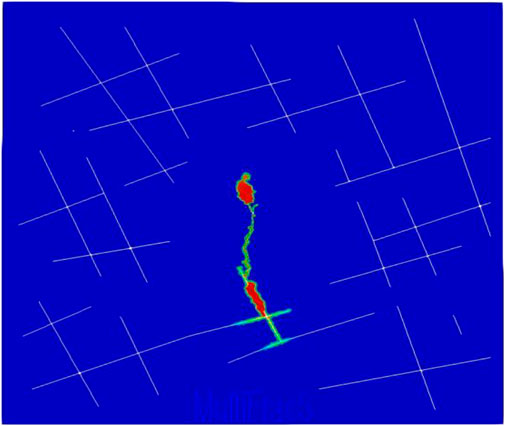

It can be seen from Figure 4 that the acid fracturing fracture of the Penglai Gas Field extends along the direction of the horizontal maximum principal stress before encountering the natural fracture. When the acid fracturing fracture meets the natural fracture, the natural fracture will break, then the acid fracturing fracture deviates from the original expansion direction, and the acid fracturing fracture will deflect along the natural fracture direction at the joint of the fractures, and extends to the end of the natural fracture. The simulation results of acid fracturing fracture propagation show that the natural fractures in the Penglai Gas Field will open during acid fracturing, and the stimulation range of acid fracturing will be significantly improved.

3.4 Optimization of multi-stage temporary plugging acid fracturing parameters

Multi-physical field fracture analysis software MultiFracS is used to optimize the parameters of multi-stage temporary plugging acid fracturing [26, 27]. MultiFracS software is a multi-physical field fracture analysis software based on the finite discrete element coupling method, which can consider the interaction of many factors such as heat, fluid, fracture, and fracture [28].

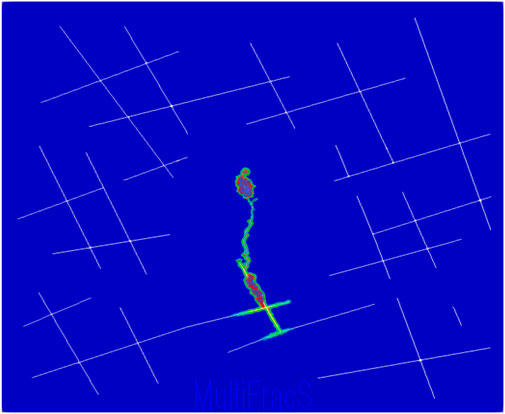

A rock model with a size of 200 × 200 m is established by using MultiFracS software (Figures 5). In the model, many connected natural fractures are randomly distributed, and the inclination angles of natural fractures are between 30° and 60°. A water injection hole is arranged in the middle of the model, and the whole model is divided into 16,851 triangular units.

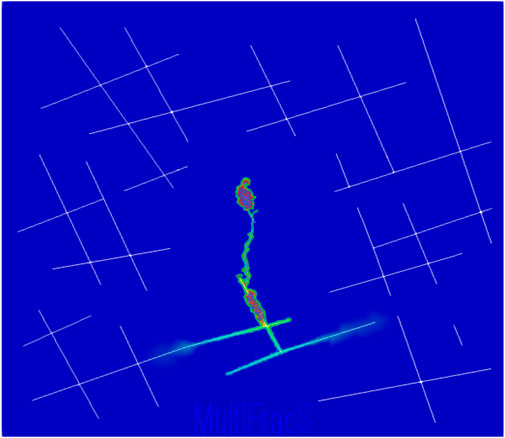

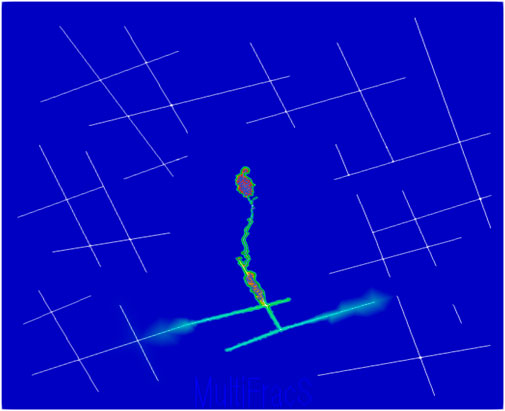

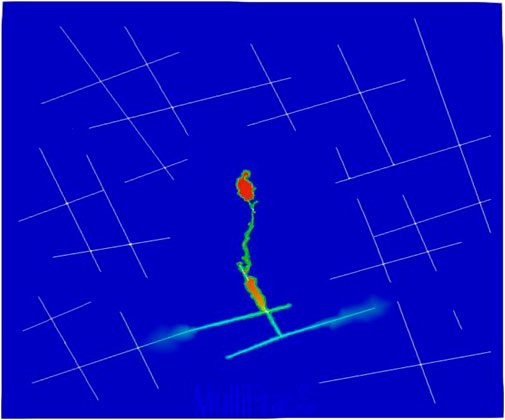

The key to multistage temporary plugging acid fracturing design is the temporary plugging time. The temporary plugging time is when the temporary plugging agent is added to obtain the maximum stimulation range. MultiFracS software is used to simulate the stimulation range of acid fracturing at different temporary plugging times. It can be seen from Figures 6, 7 that compared with adding a temporary plugging agent immediately after acid fracturing fracture pass through the natural fracture, adding a temporary plugging agent after continuing to inject 100 m3 of acid has significantly improved the range of acid fracturing stimulation, and the propagation length of natural fractures is significantly increased.

FIGURE 6. Simulation of acid fracturing stimulation range when temporary plugging agent is added immediately after acid fracturing fracture pass through the natural fracture.

FIGURE 7. Simulation of stimulation acid fracturing range by adding temporary plugging agent after injecting 100 m3 acid.

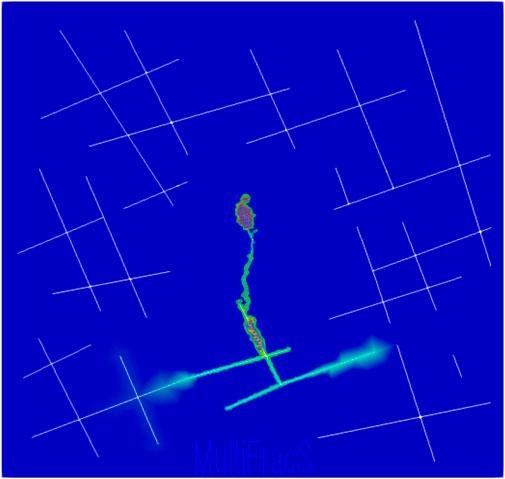

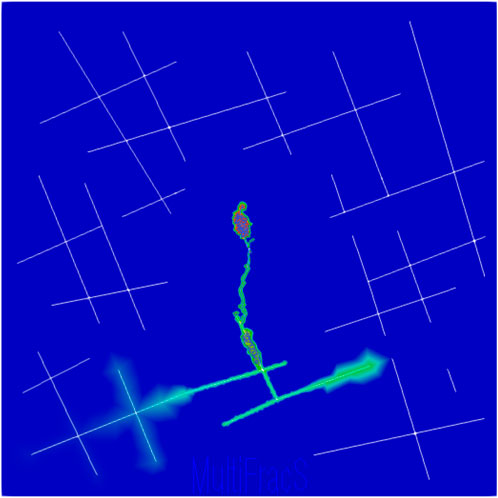

We simulated the acid fracturing stimulation range with different injection displacements after adding a temporary plugging agent. It can be seen from Figure 8, Figure 9, and Figure 10 that with the increase of injection displacement, the expansion range of natural fracture becomes larger, and the acid fracturing stimulation range is significantly improved. Especially when the injection displacement is increased to 8 m3/min, the acid fracturing stimulation range is more than 60% of the injection displacement of 4 m3/min. In order to improve the acid fracturing stimulation range, it is suggested that the acid fracturing displacement of the Penglai gas field should reach 8 m3/min.

We simulated the acid fracturing stimulation range with different temporary blocking pressure. As can be seen from Figure 11 and Figure 12, with the increase of the temporary plugging pressure, the fracture expansion range becomes larger, especially the natural fracture is broken and activated. When the temporary plugging pressure is increased to 20 MPa, the stimulation range of acid fracturing is 81% larger than that of 15 MPa. It is suggested that the temporary plugging pressure of acid fracturing in the Penglai gas field should reach 20MPa, “0.5%fiber + 0.5% 40/70 mesh + 1.0% 100 mesh” is recommended as the temporary plugging agent for acid fracturing in the Penglai gas field.

4 Field application

PS101 is an evaluation well in the Penglai gas field, with a depth of 7,110 m, a reservoir temperature of 160.2°C, and a reservoir porosity of 4.83%. PS101 uses multi-stage temporary plugging acid fracturing technology to increase production. The technical principle of multistage temporary plugging acid fracturing is to first inject fracturing fluid to form a fracture in the formation, then inject acid fluid to, etch the fracture wall, and then inject temporary plugging agent into the fracture to seal the hydraulic fracture tip, forcing the subsequently injected fluid into the natural fracture, thus expanding the stimulation range. PS101 is injected with 320 cubic meters of gelling acid, 100 kg of fiber, 200 kg of 100 mesh granular temporary plugging agent, and 100 kg of 40/70 mesh granular temporary plugging agent. The maximum pressure of acid fracturing in PS101 reaches 111 MPa, the maximum acid injection rate is 5.8 m3/min, and the bottom hole pressure rises by 9 MPa after injection of temporary plugging agent. The G function shows that acid fracturing fractures passes through the natural fractures, and a large number of natural fractures break and are activated, which indicates that multi-stage temporary plugging acid fracturing successfully improves the stimulation range.

PS101, PS102, and PS103 used the multi-stage temporary plugging acid fracturing. After acid fracturing, the average daily gas production of these three wells is 410,000 cubic meters. Compared with the gas wells using gelling acid fracturing technology in the early stage, the average gas production of gas wells using gelling acid fracturing is only 120,000 cubic meters, and the average daily gas production of the gas wells using multi-stage temporary plugging acid fracturing technology has increased by more than three times. The multi-stage temporary plugging acid fracturing technology has achieved success in the Penglai Gas Field.

5 Conclusion

(1) There are a lot of natural fractures in the Penglai gas field reservoir. Fracture propagation simulation shows that acid fracturing fractures can pass through the natural fractures, and natural fractures will be damaged and activated.

(2) ”0.5%fiber + 0.5% 40/70 mesh + 1.0% 100 mesh” is recommended as the temporary plugging agent for acid fracturing in the Penglai gas field, and the temporary plugging pressure of this temporary plugging agent combination can reach 20 MPa.

(3) The successful practice of PS101, PS102, and PS103 shows that multi-stage temporary plugging acid fracturing can greatly improve the production effect of the super-deep reservoirs such as the Penglai gas field.

(4) It is suggested to implement microseismic or wide-area electromagnetic method to monitor fracture morphology during acid fracturing, so as to better guide the optimization of multi-stage temporary plugging acid fracturing parameters.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

YW: Conceptualization, funding acquisition, project administration, re-sources, writing—original draft and software. YF: Data curation, formal analysis, methodology. WC: Data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the project of the PetroChina Southwest Oil and Gas Field Company (Grant Nos. 20200302-14, 20210302-19).

Conflict of interest

Authors YW, YF, and WC were employed by Engineering Technology Research Institute of Southwest Oil and Gas Field Company.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Yu Y, Long W, Zezhang S, Benjian Z, Wei Y, Gang Z, et al. Breakthrough and potential of natural gas exploration in multi-layer system of Penglai gas area in the north of central Sichuan paleo-uplift[J]. Acta Petrolei Sinica (2022) 43(10):1351.

2. Zengye X, Jian L, Chunlong Y, Xingwang T, Lu Z, Jin L, et al. Geochemical characteristics of Sinian-Cambrian natural gas in central Sichuan paleo-uplift and exploration potential of Taihe gas area[J]. Nat Gas Industry (2021) 41(7):1–14.

3. Yu Y, Long WEN, Jirong XIE, Bing L, Pinghui H, Qi R, et al. Progress and direction of marine carbonate gas exploration in the Sichuan Basin[J]. China Pet Exploration (2020) 25(3):44.

4. Luzi Z, Zecheng W, Yu Y, et al. Important discovery in the second member of Dengying formation in Well Pengtan1 and its significance, Sichuan Basin[J]. China Pet Exploration (2020) 25(3):1–12.

5. Wang Y, Zhou C, Yi X, Li L, Zhou J, Han X, et al. Research and Evaluation of a New Autogenic Acid System Suitable for Acid Fracturing of a High-Temperature Reservoir. ACS omega (2020) 5(33):20734–8. doi:10.1021/acsomega.0c00336

6. Wang Y, Fan Y, Wang T, Ye J, Luo Z. A New Compound Staged Gelling Acid Fracturing Method for Ultra-Deep Horizontal Wells. [J] Gels (2022) 8(7):449. doi:10.3390/gels8070449

7. Wang Y, Yang J, Wang T, Hu Q, Lv Z, He T. Visualization experiment of multi-stage alternating injection acid fracturing. Energ Rep (2022) 8:9094–103. doi:10.1016/j.egyr.2022.07.031

8. Zhang L, Zhou F, Mou J, Xu G, Zhang S, Li Z. A new method to improve long-term fracture conductivity in acid fracturing under high closure stress. J Pet Sci Eng (2018) 171:760–70. doi:10.1016/j.petrol.2018.07.073

9. Wang D, Dong Y, Sun D, Yu B. A three-dimensional numerical study of hydraulic fracturing with degradable diverting materials via CZM-based FEM. Eng Fracture Mech (2020) 237:107251. doi:10.1016/j.engfracmech.2020.107251

10. Fangzheng J. Practice and knowledge of volumetric development of deep fractured-vuggy carbonate reservoirs in Tarim Basin, NW China[J]. Pet exploration Dev (2019) 46(3):576–82.

11. Wang Y, Zhou C, Yi X, Li L, Chen W, Han X. Technology and Application of Segmented Temporary Plugging Acid Fracturing in Highly Deviated Wells in Ultradeep Carbonate Reservoirs in Southwest China. ACS omega (2020) 5(39):25009–15. doi:10.1021/acsomega.0c01008

12. Solares JR, Al-Harbi M, Al-Sagr AM, Amorocho R, Ramanathan V Successful application of innovative fiber-diverting technology achieved effective diversion in acid stimulation treatments in Saudi Arabian deep gas producers. In: SPE Asia Pacific Oil and Gas Conference and Exhibition; Perth, Australia (2008). p. 20–2.

13. Zhou F, Yi X, Yang X, Liu X, Wang D Dynamic filtration experiment of fiber temporary plugging artificial fracture[J]. Drill Prod Technol (2014) 37(4).

14. Wang D, Zhou F, Ge H, Shi Y, Yi X, Xiong C, et al. An experimental study on the mechanism of degradable fiber-assisted diverting fracturing and its influencing factors. J Nat Gas Sci Eng (2015) 27:260–73. doi:10.1016/j.jngse.2015.08.062

15. Lei Q, Xu Y, Jiang T, Ding Y, Lu H, et al. “Fracture network” fracturing technique for improving post-fracturing performance of low and ultra-low permeability reservoirs[J]. Acta Petrolei Sinica (2009) 30(2):237.

16. Zhang L, Zhou F, Mou J, Pournik M, Tao S, Wang D, et al. Large-scale true tri-axial fracturing experimental investigation on diversion behavior of fiber using 3D printing model of rock formation. J Pet Sci Eng (2019) 181:106171. doi:10.1016/j.petrol.2019.06.035

17. Zhang N, Chen Z, Luo Z, Liu P, Chen W, Liu F. Effect of the phase-transition fluid reaction heat on wellbore temperature in self-propping phase-transition fracturing technology. Energy (2023) 265:126136. doi:10.1016/j.energy.2022.126136

18. Zhang N, Luo Z, Chen X, Zhao L, Zeng X, Zhao M. Investigation of the artificial fracture conductivity of volcanic rocks from Permian igneous in the Sichuan Basin, China, with different stimulation method using an experiment approach. J Nat Gas Sci Eng (2021) 95:104234. doi:10.1016/j.jngse.2021.104234

19. Wang DB, Zhou FJ, Li YP, Yu B, Martyushev D, Liu XF, et al. Numerical simulation of fracture propagation in Russia carbonate reservoirs during refracturing. Pet Sci (2022) 19(6):2781–95. doi:10.1016/j.petsci.2022.05.013

20. Wang D, Zhou F, Dong Y, Sun D, Yu B. Experimental Investigation of Thermal Effect on Fracability Index of Geothermal Reservoirs. Nat Resour Res (2021) 30:273–88. doi:10.1007/s11053-020-09733-0

21. Wu Y, Kou J, Sun S. Matrix acidization in fractured porous media with the continuum fracture model and thermal Darcy-Brinkman-Forchheimer framework. J Pet Sci Eng (2022) 211:110210. doi:10.1016/j.petrol.2022.110210

22. Wu Y, Kou J, Sun S, Wu YS Thermodynamically consistent Darcy–Brinkman–Forchheimer framework in matrix acidization. Oil Gas Sci Technology–Revue d’IFP Energies nouvelles (2021) 76:8. doi:10.2516/ogst/2020091

23. Wang Y, Fan Y, Zhou C, Luo Z, Chen W, He T, et al. Research and Application of Segmented Acid Fracturing by Temporary Plugging in Ultradeep Carbonate Reservoirs. ACS omega (2021) 6(43):28620–9. doi:10.1021/acsomega.1c03021

24. Yuan L, Zhou F, Li B, Gao J, Yang X, Cheng J, et al. Experimental study on the effect of fracture surface morphology on plugging efficiency during temporary plugging and diverting fracturing. J Nat Gas Sci Eng (2020) 81:103459. doi:10.1016/j.jngse.2020.103459

25. Barraza J, Capderou C, Jones MC, Lannen CT, Singh AK, Shahri MP, et al. Increased cluster efficiency and fracture network complexity using degradable di-verter particulates to increase production: Permian Basin Wolfcamp shale case study[C]. In: SPE Annual Technical Conference and Exhibition; OnePetro (2017).

26. Yan C, Zheng H, Sun G, Ge X. Combined Finite-Discrete Element Method for Simulation of Hydraulic Fracturing. Rock Mech rock Eng (2016) 49(4):1389–410. doi:10.1007/s00603-015-0816-9

27. Yan C, Zheng H. FDEM-flow3D: A 3D hydro-mechanical coupled model considering the pore seepage of rock matrix for simulating three-dimensional hydraulic fracturing. Comput Geotechnics (2017) 81:212–28. doi:10.1016/j.compgeo.2016.08.014

Keywords: temporary plugging, fiber, acid fracturing, Penglai gas field, multifracs

Citation: Wang Y, Fan Y and Chen W (2023) Study and application of temporary plugging agent for temporary plugging acid fracturing in ultra-deep wells of Penglai gas field. Front. Phys. 11:1167307. doi: 10.3389/fphy.2023.1167307

Received: 16 February 2023; Accepted: 20 March 2023;

Published: 30 March 2023.

Edited by:

Chengyuan Xu, Southwest Petroleum University, ChinaReviewed by:

Yuanqing Wu, Shenzhen University, ChinaChen Wang, University of Illinois at Urbana-Champaign, United States

Daobing Wang, Beijing Institute of Petrochemical Technology, China

Nanlin Zhang, Zhejiang University, China

Copyright © 2023 Wang, Fan and Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yang Wang, d2FuZ3lhbmcwOTk2QHBldHJvY2hpbmEuY29tLmNu

Yang Wang

Yang Wang Yu Fan

Yu Fan