- Oak Ridge National Laboratory, Materials Science & Technology Division, Oak Ridge, TN, United States

The American Society of Mechanical Engineers (ASME) publishes the Boiler and Pressure Vessel (BPV) Code, which include guidance for the safe development, construction, and operation of boilers and pressure vessels. ASME BPV Code Section III “Rules for Construction of Nuclear Facility Components” Division 5 focuses on “High Temperature Reactors”. Subsection HH, subpart A lists the different materials properties that are to be measured and how those properties change due to different environmental conditions (oxidation and irradiation damage) for a graphite to be accepted for use in a high temperature reactor core (i.e., “Code Qualified”). Currently there are no nuclear graphite grades that are “Code Qualified” (i.e., a reactor designer can select a graphite grade and build their reactor without any additional testing), which is due in part to development of new graphite grades in the last 20 years and the lack of comprehensive programs needed to produce the data for the code cases. This perspective is going to discuss the requirements, as called out in the ASME BPV Code, that are necessary to “code qualify” a nuclear graphite grade but will primarily focus on the practical and technical challenges associated with irradiation-induced property changes and how to address these to assist with getting graphite ready for use in advanced nuclear reactors. These same technical challenges can be expected to arise for other materials being developed for advanced reactor concepts.

1 Introduction

Advanced nuclear fission reactor designs (commonly referred to as Gen-IV designs) will operate with materials in extreme environments that are not experienced in light-water reactors. Two hurdles for these Gen-IV designs are the elevated temperatures and higher neutron fluences materials will be exposed to during operation. The safe development and use of materials for high temperature nuclear reactors is discussed within the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code an International Code, Section III “Rules for Construction of Nuclear Facility Components”, Division 5 “High Temperature Reactors” (BPV III-5) (ASME, 2021) (i.e., “the code”). The code includes requirements for metallic materials, graphite, and composite materials (added in the 2019 version of the code) which will guide the development of advanced fission reactors.

The code lists requirements for material testing that must be performed before a code case can be submitted to ASME to have a material be included within the code as acceptable for use in specific scenarios (i.e., “code qualified”). Getting a material code qualified is not a small task and usually involves a significant amount of time, money, and coordination between multiple entities. An example of this herculean effort is alloy 617, which was added to the code in fall 2019 and was the first high-temperature material added in 30 years. The effort to generate the code case for alloy 617 spanned 12 years, required a $15 million investment from the US Department of Energy (DOE), and involved researchers from Oak Ridge National Laboratory (ORNL), Idaho National Laboratory, and Argonne National Laboratories (New Alloy, 2020). The code case for alloy 617 required long-term testing at elevated temperatures, under various loading conditions, and a combination of these two, but did not require any irradiation damage studies.

There are currently no graphite grades that are considered “code qualified”, and there are multiple technical and practical reasons as to why this is. This paper will discuss the current requirements in the 2021 version of the ASME BPV III-5 code (ASME, 2021), and the technical challenges associated with getting graphite “code qualified” per the requirements.

2 Code requirements

The ASME BPV III-5 code has explicit requirements of the materials properties that must be provided in the Materials Data Sheet (MDS) for each grade that will be used in a reactor core. These properties are listed in article HHA-II-2000 along with a blank MDS (ASME, 2021). The properties that are to be reported in the MDS include as-manufactured properties, the Weibull distribution (either two or three parameter) and design allowable stress from the as-manufactured properties, and property changes due to oxidation and neutron irradiation.

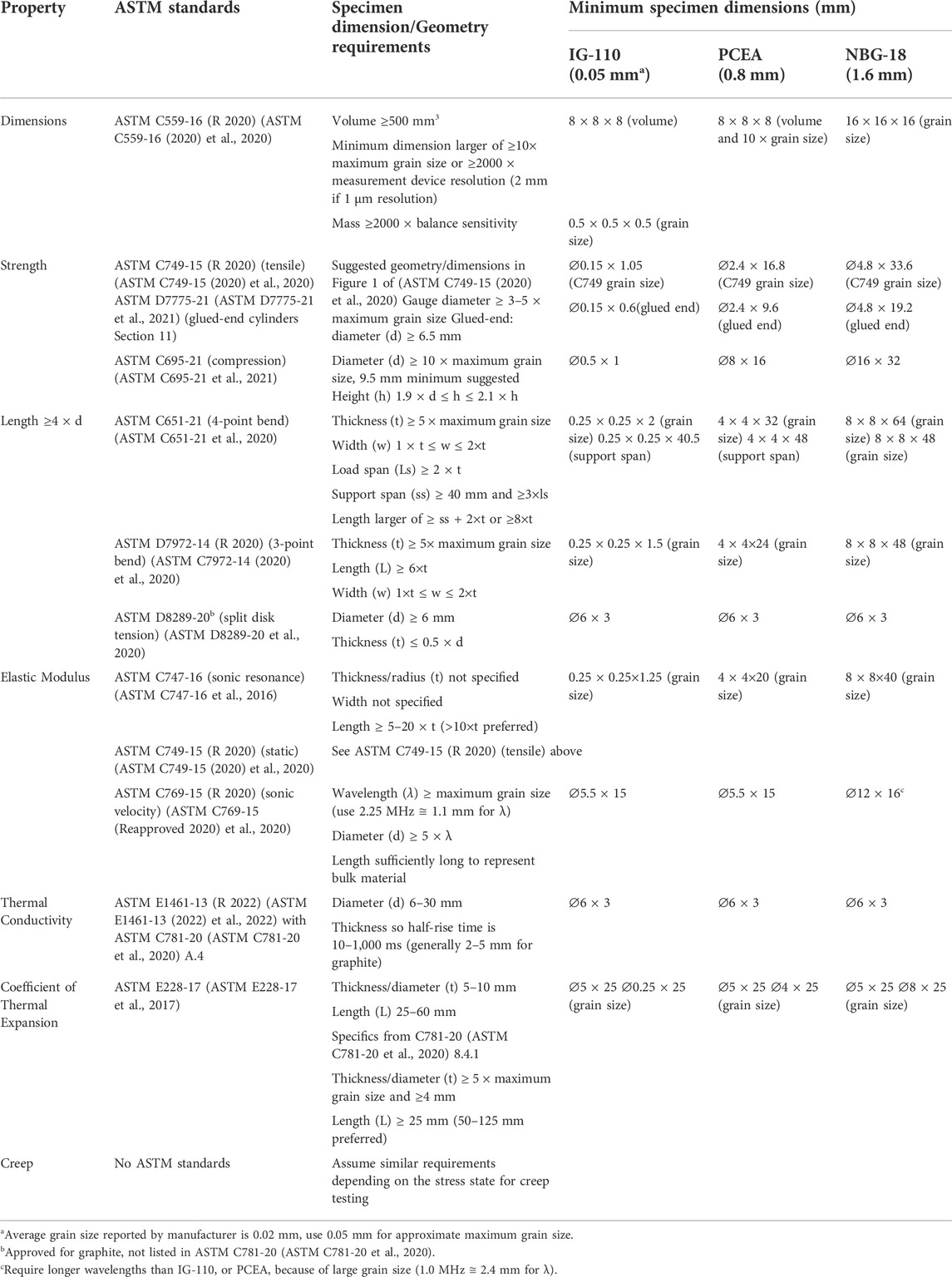

The as-manufactured properties in the MDS include density, strength (tensile, compressive, 4-point flexural), static and dynamic elastic modulus, coefficient of thermal expansion, thermal conductivity, Poisson’s ratio, anisotropy factor, and critical stress intensity factor. The measurement of these properties will adhere to testing procedures listed in ASTM C781 (ASTM C781-20 et al., 2020), and if the ASTM standards are not applicable or do not exist then the test methods must be included with the results. Of these properties at least one strength, the dynamic elastic modulus, coefficient of thermal expansion, and thermal conductivity must be measured as a function of temperature [per Article HHA-III-3000 (ASME, 2021)] with no more than a 200°C increment temperature steps up to a temperature higher than the maximum graphite operating temperature. There are currently no ASTM standards that provide guidance for high-temperature testing of strength or dynamic elastic modulus, so at least these two properties will each require procedure development to perform these measurements. The two- and three-parameter Weibull distributions are to be calculated from the results of the tensile strength measurements, and the values reported in the MDS are the lower limits of the single-sided 95% confidence bound. The allowable stresses for four probability of failures (10−4, 10−3, 10−2, 5 × 10−2) are calculated and reported from the 95% lower limit values of the two-parameter Weibull modulus and characteristic strength.

The effects of environmental conditions on different materials properties must also be studied. In the 2021 version of BPV III-5 (ASME, 2021) this includes the effects of oxidation and neutron irradiation, but no requirements are included for molten salt environments. The effect of oxidative weight loss on the graphite strength, dynamic modulus, and thermal conductivity are to be reported as a function of weight loss. For irradiation the properties that must be studied include dimensional change, elastic modulus, strength, thermal conductivity, coefficient of thermal expansion, creep coefficient, the effects of creep strain on the elastic modulus and coefficient of thermal expansion, and stored energy for cases where graphite will experience in-service temperatures below 200°C and a dose above 0.25 dpa. For the irradiation-induced property changes, the irradiation conditions (i.e., temperature and neutron fluence) must envelope the conditions expected in the reactor (requirements on creep stress are not provided), there must be sufficient data to provide representative interpolation, and the maximum range between irradiation temperatures is 200°C.

The property measurements for as manufactured and oxidized graphite are relatively straightforward measurements. Most of the properties have dedicated ASTM testing standards, and in cases where testing standards are not available modifications to existing standards could typically provide the methods required. Conversely, the irradiation-induced property changes are not easily acquired as these require access to materials test reactors (MTRs) for neutron exposure and all the infrastructure associated with the post-irradiation measurement of the different properties. As such the irradiation effects on the material properties is the rate-limiting step for getting any graphite “code qualified”.

3 Irradiation requirements

3.1 Irradiation envelope

The development of an irradiation program to “code qualify” a graphite grade is not a trivial undertaking. The first step in this procedure is determining the irradiation conditions (irradiation temperature and neutron fluence/dose) that “envelope the irradiation conditions in service” (ASME, 2021) article HHA-III-3300 (f). The “temperature and fluence intervals shall be selected so as to provide adequate confidence in the accuracy of the interpolations” (ASME, 2021) article HHA-II-4000 (a) and the maximum range between irradiation temperatures is 200°C (ASME, 2021) article HHA-III-3300 (f). These requirements can lead to a large number of target irradiation conditions for the envelope. Figure 1 shows a hypothetical dose/temperature profile for a graphite reflector after a 30-year operating life, and the set of targeted dose/temperature combinations (data points) that would be required to create a satisfactory irradiation envelope (28 combinations total) that encompasses the maximum and minimum temperatures, maximum expected doses at each temperature step, and enough dose conditions to confidently interpolate the property changes between doses. The reason for the 150°C range between temperatures, rather than 200°C as called for in the code, is due to the technical challenges that can arise in irradiations that could result in a targeted temperature being too hot or too cold and resulting in the final temperature spacing being larger than 200°C.

FIGURE 1. Hypothetical graphite reflector dose and temperature profile (grey curved line) after a 30-year reactor lifetime and the temperature and dose (in units of dpa) conditions (data points) that would be required for the irradiation envelope.

3.2 Irradiation-induced property changes

The next step in developing the irradiation campaign is determining how to adequately measure the required property changes. Article HHA-III-3000(a) (ASME, 2021) specifies that standards listed in ASTM C781 (ASTM C781-20 et al., 2020) are to be used and when a standard does not exist or is modified that the testing procedure will be provided. Table 1 lists the properties that are to be measured to quantify the irradiation effects and the corresponding ASTM standards that are listed in the current 2020 version of C781 (ASTM C781-20 et al., 2020) for each property. Within each ASTM standard are specimen dimensions and geometric requirements. The specimen dimensions are generally limited by the maximum filler particle (i.e., grain) size of the graphite grade, while the geometry is specified to obtain a specific testing configuration. The dimension/geometry requirements for each property and ASTM standard are also listed in Table 1. Example specimen sizes are also included in Table 1 for three representative nuclear graphite grades, showing how slight differences in maximum grain size can greatly affect minimum specimen dimensions.

The primary limiting factor for the specimen geometries is the space available within MTRs for irradiating specimens. In the ORNL High Flux Isotope Reactor (HFIR), the primary irradiation location for graphite qualification work is in capsules that are inserted into the flux trap. In the flux trap graphite can accumulate 1.2–1.8 dpa per HFIR cycle (∼25 days cycle length), or ∼7–10 dpa per year. The steady-state operation of the HFIR at 85 MW means that passive temperature control can be used for these capsules. But, the high dose rate in the HFIR flux trap comes with a tradeoff in that the internal volume of the capsules available for specimens is 6 × 6 × 48 mm and the application of stress for irradiation creep is not feasible. There is the option in the HFIR flux trap to utilize full-length capsules that span the height of the core that can be designed for irradiation creep experiments, so while they still have a 6 × 6 mm cross sectional area the total length for specimens is 450–500 mm. Facilities are available in the HFIR, and other MTRs, that accommodate larger cross-section specimens, but these options require instrumentation and temperature control (i.e., higher costs), have lower fluxes (i.e., longer irradiation time), and still have size limitations. When compared to the specimen size requirements in Table 1 it becomes apparent that most conforming specimen sizes would not fit in HFIR irradiation capsules. Luckily, when these constraints cannot be met, ASTM D7775-21 (ASTM D7775-21 et al., 2021) provides guidance about how to demonstrate the measurements from nonconforming specimens are still representative of the bulk or if a size correction is necessary:

1 Follow the standards as-written whenever possible

2 When deviating provide basis and support for modified measurement technique and selected specimen sizes

3 When deviating from volume of size perform the following:

a Determine the measurement criteria for the samples (i.e. measurement accuracy, repeatability, tolerance, and uncertainty)

b The criteria must be tested via a method that is compliant with the ASTM standards.

c First perform measurements on specimens conforming with the ASTM required sizes, then perform on progressively smaller specimens, including ones that are smaller than the desired specimen dimensions. It is preferred to resize the original specimens to remove specimen to specimen variability, but not always feasible. Results should provide data to characterize the volume/size dependence of the property. Dimensions and other specimen size/shape parameters should be varied individually to not obscure any dependencies.

d Determine whether a volume or size correction is required for the new specimen geometry.

e Retain specimens for future checks or measurements.

In many cases a 2-3 specimen geometries are selected that can be utilized for multiple property measurements since properties like dimensional change (i.e., contraction followed by swelling) and elastic modulus via impulse or sonic velocity are both non-destructive examination (NDE) techniques. Article HHA-III-3300 (ASME, 2021) states that both coefficient of thermal expansion and thermal conductivity can be measured at temperatures approaching, but not exceeding the irradiation temperature, to prevent annealing of irradiation damage essentially making them NDE. After these NDE measurements are made then the specimens can be used for destructive strength testing, thereby allowing for a significant portion of the data being measured from a small number of specimens.

3.3 Irradiation in MTRs

The capsules used for irradiation in the HFIR flux trap are suitable for non-stressed irradiations, but larger experiments are necessary for irradiation creep experiments. Graphite irradiation creep experiments were performed in the HFIR flux trap using full-length target rods (Campbell and Katoh, 2018), while the larger-scale advanced graphite creep (AGC) campaign is on-going at Idaho National Laboratory (Windes et al., 2020). The need for both stressed and unstressed graphite samples to an irradiation creep campaign means that when correctly designed an irradiation creep campaign can provide most or potentially all the necessary data for “code qualification”. But these types of experiments are more complex due to the need to apply a load to specimens so there’s additional design/engineering challenges, added to the fact that the facilities in MTRs that are suitable for irradiation creep experiments are larger and therefore require instrumentation and on-line temperature control.

The penultimate step in developing the irradiation campaign is determining the size/scope of the program. The two drivers for the size/scope include the irradiation envelope and the material being studied. Referring to the example irradiation envelope in Figure 1, there were 28 temperature/dose combinations. These different points can be achieved either as concurrent or sequential irradiations. Each option has benefits and drawbacks. The recent irradiation programs at ORNL [(Campbell et al., 2016) and (Campbell and Katoh, 2018) were concurrent programs. Concurrent irradiations (this author’s preferred method] means that there will be more specimens and irradiation capsules meaning an overall larger program in total number of capsules and specimens. Three major benefits are 1) the timeline can be compressed since there is no break in MTR irradiation while properties are measured and the next irradiation capsule is assembled, 2) data for different doses can be captured throughout the irradiation program by staggering when specimens start and end irradiation, and 3) specimens at the low and intermediate doses are retained in the event questions about results arise at later dates. A drawback of the concurrent irradiations is that each capsule may have different artifacts to account for because of different irradiation times resulting in some capsule-to-capsule variation of irradiation conditions. Sequential experiments can also be beneficial, the AGC campaign (Windes et al., 2020) and work out of Petten (Heijna et al., 2017) were both sequential programs. These experiments irradiate specimens to a desired dose, at which point the capsule is disassembled, specimens are measured for NDE properties (a small subset may be pulled for destructive strength testing), and then the capsule is rebuilt to continue irradiation. This methodology is generally better suited for reactors where larger and more complex irradiation capsules are required or when the material available for an irradiation program is limited. The main drawbacks for this methodology are: 1) the risk of an experimental artifact that invalidates the entire capsule (i.e., reactor transient, loss of temperature monitoring or control, etc.,), 2) the lack of specimen retention at low and intermediate doses, 3) the extended time needed to disassemble the capsule measure NDE properties and build the new capsule (in some cases building the new capsules needs to be done in special laboratory spaces because of the residual radioactivity of the specimens), 4) the possibility of specimen damage during disassembly resulting in the inability to reuse them, and 5) the inflexibility to capture a subset of high dose results early in the program.

Using unstressed HFIR flux trap capsules and a parallel capsule irradiation program as an example, the irradiation envelope in Figure 1 has 28 dose/temperature combinations, but this does not mean that only 28 capsules will be irradiated; instead, there will be multiple capsules at each temperature/dose condition. The number of capsules at each condition is dependent on the number of specimens that can fit in each capsule and the number of replicate measurements of each property that are required for adequate statistical confidence in the measured property change. In general, one geometric type (bars/plates or rods/disks) of specimen is used in a single irradiation capsule [see (Campbell and Katoh, 2018) and (Heijna et al., 2017) for examples], but in other cases loading multiple geometries may be more desirable [like that done in (Campbell et al., 2016)]. The number of replicate measurements of each property is driven by the material heterogeneity and grain size. Material heterogeneity plays an important role because obtaining statistically sound property changes for a heterogeneous material requires more replicate measurements than a homogeneous material. Grain size is also a factor because samples that are small, relative to the grain size, are expected to be less representative of the bulk meaning that more replicate measurements are required to adequately capture the statistical variability. For example, a heterogeneous large-grained graphite may require 4-5 capsules per irradiation condition to capture 5 replicate measurements for each property, resulting in a total of 140 capsule, while a homogeneous fine-grained graphite could require as few as 2 capsule per condition to capture triplicate measurements of each property, resulting in 56 capsules total.

3.4 Timeline and cost

The final part of developing these code qualification programs is answering the question that is always asked first: how long will this take and how much will it cost? This is impossible to answer without first developing the program. Multiple factors go into determining the timeline and cost of the program including specimen availability, irradiation capsule design, pre- and post-irradiation property measurements, hot cell availability, with the primary rate limiting factors being maximum dose, MTR capacity and operating schedule, and total number of capsules. The maximum dose provides the minimum amount of time specimens would need to remain in the MTR (17–25 cycles in the HFIR flux trap to accumulate 30 dpa in Figure 1). MTR capacity limits how many capsules can be undergoing irradiation at the same time and how soon initial and replicate property change measurements can be captured, while operating schedule will determine how quickly the target doses are achieved (2.5–5 years for 30 dpa depending on the number of HFIR cycles per year). But the primary issue is the total number of capsules. Referring to the HFIR unstressed capsule example in the previous section, a campaign requiring 56 capsules means a higher percentage of the total number of capsules could be in reactor at the same time compared to a program with 140 capsules (for the same MTR capacity) meaning that the 56 capsule campaign would have all the capsule finishing irradiation possibly years before the larger program. This all assumes that concurrent irradiations of capsules can occur, but in many cases, this is not possible, and things must happen sequentially. Sequential programs can have much longer timelines. For example, the AGC program started development in 2005, it has two irradiation temperatures 600 °C and 800 °C with a maximum dose of 15 dpa, the first capsule started irradiation in 2009, the last capsule is expected to finish irradiation in 2028 and final data reporting is expected in 2030 (Windes, 2022).

All the uncertainties related to program scope make cost estimations impossible even for a hypothetical irradiation campaign. It is not unreasonable to speculate that the $15M that supported the code qualifications of alloy 617 is a lower bound for a graphite irradiation qualification program. But multiple factors can easily raise this number including graphite grade, size of the irradiation specimens, need for capsule instrumentation, location of post-irradiation examination (hot cells versus laboratory), and even whether irradiation in the MTRs requires payment for reactor access (i.e., neutron fees).

4 Final thoughts

“Code qualification” of any material is a non-trivial undertaking as was shown with alloy 617 becoming only the sixth code qualified alloy for high temperature nuclear reactors, 30 years after the fifth was added, and after a 12-year, $15 million dollar investment. This paper has presented and discussed both the practical and technical challenges that will go into “code qualifying” a nuclear graphite grade for use in advanced nuclear reactors. The primary challenge is the amount of time to accumulate all the data for the lifetime of the graphite components. As discussed, the irradiation time alone to reach 30 dpa can be as short as 3–5 years or much longer depending on neutron flux in the MTR, MTR capacity, and other challenges.

These challenges make it impractical to require having a full qualification package for a graphite grade prior to initial advanced reactor construction or operation. Instead, a more sensible approach is to prioritize the data package that will cover the first 5–10 years of reactor operation, possibly for 60%–75% of the replicate measurements to have the general sense of the property changes and the confidence in those values. While the lower dose specimens are being irradiated it would be suggested that a few of the intermediate and higher dose specimens begin dose accumulated as soon as possible so some later-life data is available midway through the program, as this will provide preliminary information about higher dose trends and a possible indication of lifetime. Then, once the full program is complete and the full set of statistical data is available, the lifetime of the components can be determined, and the full code case and reactor license can be evaluated.

This plan of staggering of the data and licensing will allow for advanced reactors to be built and begin operation within a shorter time frame. Rather than being forced to wait on the completion of an irradiation program that could take 10–20 years (or longer) it would be possible to have initial data within the first 5–7 years, which can be captured while the reactor design is finalized and during the initial construction phase. This plan better aligns with the current US Department of Energy push for the construction of demonstration and first-of-the-kind advanced reactors within the next 5–7 years (Advanced Reactor Demonstration ProgramU.S, 2020).

These technical challenges are not exclusively limited to graphite. The use of novel structural and/or solid moderating materials (i.e., silicon carbide composites, carbon composites, metallic hydrides, etc.,) will most likely require irradiation programs with higher demands, since these materials do not have the 75 years of historical use that graphite does. Additionally, it would not be unexpected that similar qualification programs will be developed for materials for fusion reactors as that technology approaches grid deployment and regulatory oversight.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

The author confirms being the sole contributor of this work and has approved it for publication.

Funding

This work was supported by the U. S. Department of Energy, Office of Nuclear Energy, under the Advanced Reactor Technologies (ART) program. Oak Ridge National Laboratory is managed by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 for the U.S. Department of Energy.

Acknowledgments

The author wishes to thank Josina W. Geringer and Caleb P. Masey for their review and commentary on this manuscript.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

“Advanced Reactor Demonstration Program”, U.S. Department of Energy, Office of Nuclear Energy, , Available fom: https://www.energy.gov/ne/advanced-reactor-demonstration-program.2020

Asme Division 5 High Temperature Reactors, . (2021). New York, NY: ASME.Boiler and pressure Vessel code an international code, SECTION III rules for construction of nuclear facility components

Astm C559-16 (2020), 2020, "Standard Test Method for Bulk Density by, (2020). Physical measurements of manufactured carbon and graphite articles. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/C0559-16R20

Astm C651-21, 2020, "Standard Test Method for Flexural, (2020). Strength of manufactured carbon and graphite articles using four-point loading at room temperature. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/C0651-20

Astm C695-21, 2021, , (2021). Standard Test Method for Compressive Strength of Carbon and Graphite West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/C0695-21

Astm C747-16, 2016, "Standard Test Method for Moduli of Elasticity, (2016). And fundamental frequencies of carbon and graphite materials by sonic resonance. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/C0747-16

Astm C749-15 (2020), 2020, "Standard Test Method for, (2020). Tensile stress-strain of carbon and graphite. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/C0749-15R20

Astm C769-15 (Reapproved 2020), 2020, "Standard Test, (2020). Method for sonic velocity in manufactured carbon and graphite materials for use in obtaining young’s modulus. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/C0769-15R20E01

Astm C781-20, 2020, "Standard Practice for, (2020). Testing graphite and boronated graphite materials for high-temperature gas-cooled nuclear reactor components. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/C0781-20

Astm C7972-14 (2020), 2020, , (2020). Standard Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Three-Point Loading at Room Temperature West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/D7972-14R20

Astm D7775-21, 2021, "Standard, (2021). Guide for measurements on small graphite specimens. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/D7775-21

Astm D8289-20, 2020, , "(2020). Standard Test Method for Tensile Strength Estimate by Disc Compression of Manufactured Graphite West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/D8289-20

Astm E1461-13 (2022), 2022, , "(2022). Standard Test Method for Thermal Diffusivity by the Flash Method West Conshohocken, PA: ASTM International. d3d3LmFzdG0ub3Jn. doi:10.1520/E1461-13R22

Astm E228-17, 2017, "Standard Test Method for Linear, (2017). Thermal expansion of solid materials with a push-rod dilatometer. West Conshohocken, PA: ASTM International. www.astm.org. doi:10.1520/E0228-17

Béghein, P., Berlioux, G., Mesnildot, B. d., Hiltmann, F., and Melin, M. (2012). NBG-17 – an improved graphite grade for HTRs and VHTRs. Nucl. Eng. Des. 251, 146–149. doi:10.1016/j.nucengdes.2011.10.060

Campbell, A. A., Katoh, Y., Snead, M. A., and Takizawa, K. (2016). Property changes of G347A graphite due to neutron irradiation. Carbon 109, 860–873. doi:10.1016/j.carbon.2016.08.042

Campbell, A. A., and Katoh, Y. (2018). Summary report on effects of irradiation on material IG-110 - prepared for toyo tanso Co. Oak Ridge, TN, USA: Ltd"Oak Ridge National Laboratory. ORNL/TM-2018/1040.

Grafstar Pcea Grade Graphite Technical Data Sheet, ”, (2022). Amsted Graphite Materials. Available fom:https://www.amstedgraphite.com/wp-content/uploads/2022/01/PCEA.pdf.

Heijna, M. C. R., de Groot, S., and Vreeling, J. A. (2017). Comparison of irradiation behaviour of HTR graphite grades. J. Nucl. Mater. 492, 148–156. doi:10.1016/j.jnucmat.2017.05.012

New Alloy, (2020). Material approved for use in high-temperature nuclear plants”. U.S. Department of Energy, Office of Nuclear Energy. https://www.energy.gov/ne/articles/new-alloy-material-approved-use-high-temperature-nuclear-plants.

Windes, W. (2022). 2022 gas-cooled reactor program review meeting. Presented at DOE-NE Advanced Reactor Technologies.ART advanced graphite creep (AGC) irradiation experimentVirtual

Keywords: nuclear graphite, irradiation effects, ASME code qualifying, materials properties, advanced nuclear reactors, irradiation creep

Citation: Campbell AA (2022) Perspective on “code qualifying” new graphite grades for use in advanced nuclear reactors*. Front. Nucl. Eng. 1:1045607. doi: 10.3389/fnuen.2022.1045607

Received: 15 September 2022; Accepted: 09 November 2022;

Published: 21 November 2022.

Edited by:

Karl Whittle, University of Liverpool, United KingdomReviewed by:

Jun Sun, Tsinghua University, ChinaCopyright © 2022 Campbell. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Anne A. Campbell, Y2FtcGJlbGxhYUBvcm5sLmdvdg==

Anne A. Campbell

Anne A. Campbell