- 1Department of Energy Systems, University of Thessaly, Larisa, Greece

- 2Centre for Research and Technology Hellas, Information Technologies Institute, Thessaloniki, Greece

- 3Foundation for Research and Technology Hellas (FORTH), Heraklion, Greece

The identification of defect causes plays a key role in smart manufacturing as it can reduce production risks, minimize the effects of unexpected downtimes, and optimize the production process. This paper implements a literature review protocol and reports the latest advances in Root Cause Analysis (RCA) toward Zero-Defect Manufacturing (ZDM). The most recent works are reported to demonstrate the use of machine learning methodologies for root cause analysis in the manufacturing domain. The popularity of these technologies is then summarized and presented in the form of visualizing graphs. This enables us to identify the most popular and prominent methods used in modern industry. Although artificial intelligence gains more and more attraction in smart manufacturing, machine learning methods for root cause analysis seem to be under-explored. The literature survey revealed that only limited reviews are available in the field of RCA towards zero-defect manufacturing using AI and machine learning; thus, it attempts to fill this gap. This work also presents a set of open challenges to determine future developments.

1 Introduction

1.1 Motivation and scope

With the onset of Industry 4.0, manufacturing companies are in need of a continuous upgrade of their manufacturing processes in terms of products and operations to become more competitive. In their effort to provide an optimized production operation and consistent delivery of better products, detecting defects and identifying defect causes upstream becomes a crucial factor for the industry. More specifically, defect detection is used by the industry operators to conduct a quality inspection in the production line, while defect source identification is used to further conduct smart quality control by identifying defects or anomalies per root cause.

Product quality improvement has been the cornerstone of Industry 4.0. The technological advances of the modern industry have brought new challenges in the quality improvement stage, which traditional quality control methodologies cannot handle. New concepts have been born, like the development of policies toward Zero-Defect Manufacturing (ZDM) (Psarommatis et al., 2020a), which support the migration to this new era (Psarommatis et al., 2022). ZDM heavily relies on new technologies like virtual metrology, i.e., the ability to inspect product quality from production data without physically measuring it (Dreyfus et al., 2022). An extensive review of ZDM opportunities and shortcomings has been presented in (Psarommatis et al., 2020b). ZDM can be further boosted by the integration of numerous Artificial Intelligence (AI) methods into traditional technologies, such as metrology, digital twins, internet of things, computer vision, augmented reality, quality control, and predictive maintenance; at least 15 EU-funded projects (mostly FoF-11 projects) and numerous individual publications may be identified in the literature (OPTIMAI, 2021–2023; Papageorgiou et al., 2021).

Defect detection aims to monitor the production line and assess the quality of products. The quality requirements and defect specifications are provided by the end-users on a per-case level. Defect detection is mainly oriented along the following two directions i): defect detection from images, which include photographs, 3D scans, point clouds, and every other data format that can be directly converted into a picture, and ii) anomaly detection, through the analysis of time-series data, feature analysis and discovery of unexpected events. In the era of data-driven smart manufacturing (Tao et al., 2018), defect detection procedures may benefit from AI technologies and transform manual operations into semi- or even fully automatic.

Industry 4.0 takes defect detection to the next level by pursuing not only defects but also their causes. Traditional defect detection targets capturing faults and defects; thus, it fails to provide any information about avoiding recurrence or how the defect is related to production processes. Defects may often go unattended and propagate along multiple production stages before being captured. This leads to taking corrective actions at a later stage, which is probably not related to the defect’s actual cause. A systematic methodology has been realized within smart manufacturing to identify the sources of defects, termed Root Cause Analysis (RCA). This methodology can seek among the production stages and determine the primary cause responsible for delivering defective products. The goal of RCA is obviously to prevent the recurrence of failures. RCA can be thought of as an optimization process in smart manufacturing that focuses on minimizing scrapping yields by addressing “what caused the failure?” rather than “what is the failure?” Thus, RCA can become a key asset to ZDM for industrial applications that involve many sequential and complex processes.

Traditional RCA methodologies such as Pareto Analysis, Fishbone Diagram, and Five-Whys have already been established in manufacturing (Murugaiah et al., 2010; Jayswal et al., 2011; Ma et al., 2021). However, these methodologies are highly correlated with expertise and knowledge and thus are hindered by biases, individualism (as they cannot be saved or transferred), and time inefficiency. Moreover, the major drawback of traditional methodologies is the under-exploitation of the information that exists in the data from production processes. The large volume of data that is being gathered through production processes in industry 4.0 is considered very important for ZDM. Nevertheless, research questions arise about how these data can be exploited and what are the proper models for processing them, as these data are often multisensorial, multidimensional, and highly non-linear. Machine learning has proved that it can efficiently treat such types of data and thus, should be considered for AI-based RCA.

The aim of this work is to conduct a systematic review survey demonstrating the use of artificial intelligence methods for RCA in smart manufacturing, with a focus on Machine Learning Methods for RCA toward Zero-Defect Manufacturing. A key objective of the paper is to present the employed survey methodology in detail so as to not only present the current state of the art in a repeatable way but also guide readers on how to extend it in a consistent way and according to their needs.

An extensive literature review revealed the existence of only two surveys that regard RCA in manufacturing (e Oliveira et al., 2022; Solé et al., 2017), none of which deals with AI technologies. The first survey covers a spectrum of RCA techniques applied in various industrial domains, such as the semiconductor and chemical industries (e Oliveira et al., 2022). According to the survey, the most popular methodologies include association/classification rules, control charts, regression models, and principal component analysis. The second survey follows a different approach and categorizes available methodologies based on causality; deterministic and probabilistic methodologies are thoroughly reviewed, targeting mainly information technology applications (Solé et al., 2017). According to this survey, Bayesian networks are among the most popular learning models in this area. The current paper focuses on the integration of ML methodologies into RCA models applied in smart manufacturing, thus, filling a gap in the current literature. The performed survey covers the most recent advances in a 5-year period, from 2017 up to date.

1.2 Models for ML-based root cause analysis

There is a wide range of AI/ML models that could be involved in the RCA process. These models belong either to the deterministic or the probabilistic group of AI-based methodologies. Each class expresses different attributes, may have different implementations and demonstrates different performance implications (Solé et al., 2017). On the one hand, deterministic models are developed by applying statistical learning techniques, which allow these models to identify patterns in the data automatically. To accomplish that, the models need to be trained on large datasets to unearth boundaries and relationships in the data. The more data are used to train the model, the higher the predictive accuracy. On the other hand, probabilistic models can be constructed hierarchically from data, which allows their wide use for RCA. They enable reasoning behind the uncertainties inherent to most data, thus allowing for fully coherent inferences over complex data structures. Representative probabilistic models are those based on Bayesian Networks and probabilistic Fuzzy Cognitive Maps (FCMs). Since no domain knowledge is available to build these models, the only way is to use learning algorithms that exploit the raw data of the examined system. Various learning algorithms have been developed, oriented on either learning both structures and parameters of the model or just learning the parameters in a given structure.

Deep Learning (DL) is a division of ML which has recently displayed remarkable applicability in a range of different applications, as well as in smart manufacturing. In smart manufacturing, DL has found significant applicability for processing and analyzing big manufacturing data. In most cases, DL networks can be trained using supervised learning with large sets of training data. The most popular DL methods are the following:

1) Deep Neural Networks (DNNs). A DNN resembles an Artificial Neural Network (ANN) with many hidden layers. The difference is in the training process. DNN uses deep learning as a class of machine learning algorithms with the following main aspects: (a) use a cascade of multiple layers of non-linear processing units for feature extraction and transformation, (b) learn in supervised (e.g., classification), and/or unsupervised (e.g., pattern analysis) manners, and (c) learn multiple levels of representations that correspond to different levels of abstraction; the levels form a hierarchy of concepts. DNNs have more than three layers trained to model non-linear problems.

2) Convolutional Neural Networks (CNNs). They are among the most powerful deep learning techniques presenting notable capabilities in analyzing and classifying images. They are mainly employed in image processing applications (semantic segmentation, image classification, instance segmentation, object detection, etc.). Their neurons architecture is based on the features of images they process (width, height, depth, etc.). Typical CNNs have a similar structure to ANN and consist of one or more filters (i.e., convolutional layers), followed by aggregation/pooling layers in order to extract features for classification tasks. Since a CNN has similar characteristics to a standard ANN, it uses gradient descent and backpropagation for training tasks, whereas it contains pooling layers along with layers of convolutions. The vector that is sited at the end of the network architecture can deliver the final outputs.

3) Residual Neural Networks (Res-Nets). They are an extension of DNNs. They are highly considered in industrial applications where precision is vital for machinery health-state diagnosis. Res-Nets typically perform better than CNN-based approaches.

4) Recurrent neural networks (RNN). These are ANNs that utilize connections between units in order to form a directed graph along a sequence. RNNs use their internal memory to process such sequences, something that is not met in feed-forward ANNs. However, RNNs suffer from short-term memory and the problem of vanishing gradient during backpropagation. This is resolved by the Long Short-Term Memory (LSTM) algorithm, presented in the following.

5) Long Short-Term Memory networks (LSTMs). LSTMs excel over the original RNN due to their specific cell structure, which allows the algorithm to add or remove information from this cell using entities called gates. These gates control this memorizing process by allowing the model to learn which information to store in the long memory and which to discard. The cell state resembles a conveyor belt. It runs straight down the entire chain, with only some minor linear interactions. Gates are a way to optionally let information through. They are composed of a sigmoid neural net layer and a pointwise multiplication operation. LSTMs have been applied in predictive maintenance and prognostics in manufacturing processes.

DL techniques enable to i) automatically learn from data ii), detect underlying patterns, and eventually, iii) make efficient decisions. With automatic feature learning and high-volume modeling capabilities, DL provides an advanced analytics tool for smart manufacturing in the big data era. It uses a cascade of layers of non-linear processing to learn the representations of data corresponding to different levels of abstraction. The hidden patterns underneath each other are then identified and predicted through end-to-end optimization. Thus, DL offers great potential to boost data-driven manufacturing applications. Several review papers extracted from the related literature show the actual implementations of ML and DL methods in factory operations within the smart manufacturing domain.

2 Systematic literature review

The presented review is based on the “Preferred Reporting Items for Systematic reviews and Meta-Analyses” (PRISMA) principles (Moher et al., 2010). This methodology is globally accepted in the research community as it leads to well-structured article surveys, allowing investigators to perform accurate systematic reviews. According to PRISMA, a predefined set of questions needs to be defined. Then, identified documents are collected, filtered, analyzed, and critically evaluated.

2.1 Research questions

The goals of this review can be outlined as i) to determine what AI-based technologies have been exploited toward RCA within smart manufacturing; ii) to investigate specific applications and find out how these technologies have been implemented; thus, iii) to shed light in current practices so that further improvements may be built. To achieve these goals, the following research questions (RQs) have been posed:

1) What AI algorithms have been employed? This RQ reveals the available tools in the quiver of current smart manufacturing.

2) What is the accommodated industrial application? This RQ reveals the field of application.

3) What is the popularity of each employed methodology? This RQ reveals the trends in the employment of AI for RCA; popular and well-established methods will probably be the foundation for future developments.

Each article found during the search has been reviewed to answer these questions. The answers were compiled in a comprehensive way to give the reader a clear picture of the current state of the art and its potential for future developments.

2.2 Review protocol

The review protocol includes the selection of proper sources, the definition of search terms, and the definition of acceptance/rejection criteria. These are described in the following.

2.2.1 Search sources

Amongst the many available databases and search engines, Google Scholar and Scopus were preferred because i) they are among the most popular in the research society, ii) they provide consistent and reproducible search results, and iii) Google Scholar provides free access, while Scopus is available to most scientists and researchers through institutional subscriptions.

2.2.2 Search terms

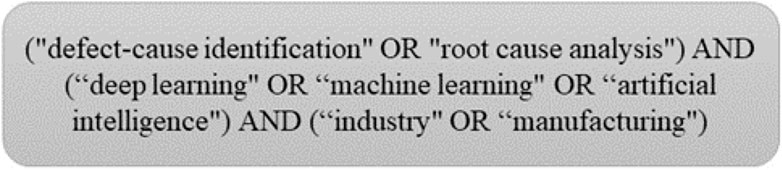

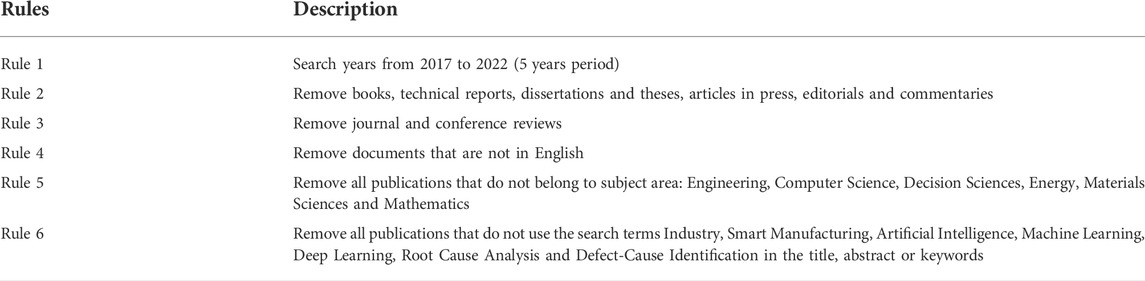

Predetermined search terms were employed for searching the most suitable articles; search terms were pursued in title, abstract, and keywords. The literature search strategy was conducted by utilizing the keywords “defect identification,” “root cause analysis,” “deep learning,” “machine learning,” “artificial intelligence,” “industry,” and “manufacturing,” using the depicted query string (Figure 1).

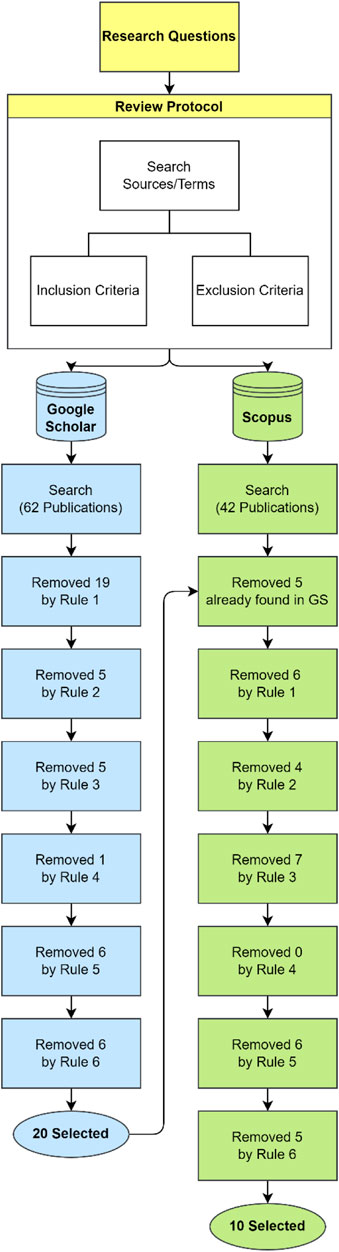

Raw search returned a vast number of results; thus, the inclusion/exclusion criteria needed to be defined so that only the most relevant works were considered for evaluation. The inclusion/exclusion criteria are outlined in the following paragraphs and summarized in Table 1 in the form of acceptance/rejection rules.

2.2.3 Inclusion criteria

This study focuses on ML-based methods for RCA in smart manufacturing. Thus, studies in consideration should include RCA methodologies applied in industrial environments and applications and implementing AI, DL, or ML in any of their flavors. Since the state of the art is investigated, only the latest works within the last 5 years were pursued, namely works published between 1 January 2017, and 15 April 2022 (date of literature search). Only publications in English were considered, as all primary studies are published in English.

The inclusion criteria include: 1) papers published; 2) the process of root cause analysis and defect-cause identification in industry; 3) ML-based algorithms, including both traditional ML and DL techniques incorporated for defect-cause analysis; 4) ML methods for RCA in smart manufacturing.

2.2.4 Exclusion criteria

To reduce the number of articles for investigation and keep this survey within scope, numerous exclusion criteria were set. First, articles published before 2017 were not considered, as they do not reflect the current state of the art. Furthermore, RCA methodologies should be literally based on AI/ML methods; otherwise, they are considered irrelevant. Material of questionable quality content was also neglected; such material includes websites and online material, student theses, book chapters, editorials, commentaries, non-original research articles, protocols, meta-analyses, etc., as well as all non-peer-reviewed content. Journal and conference reviews were omitted as well. Nevertheless, articles published in languages other than English were eliminated by this search.

2.3 Literature collection

After a thorough review of all mined articles, only those fulfilling the established criteria were considered in the industrial or manufacturing domain. After the adoption of the PRISMA method and only those articles that were explicit about the subject of this short review were retrieved. The overall search process is graphically illustrated in Figure 2.

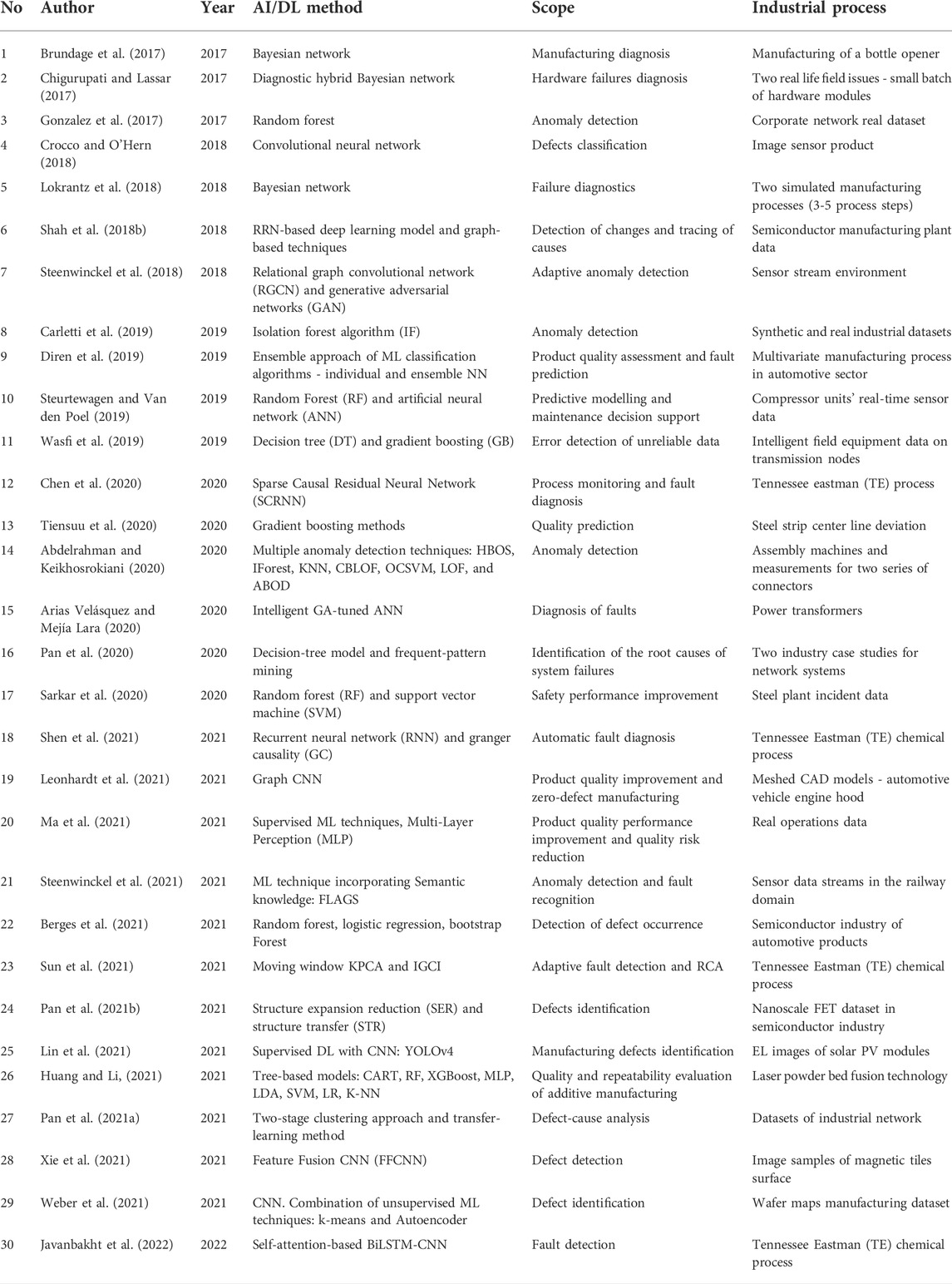

Finally, 30 research papers were selected for further analysis. The selected articles are listed in Table 2, along with the year of publication, the method employed, the scope of the study, and the industrial process in which the methodology is applied.

3 Results

The review for AI-based RCA was divided into two families according to the applied models’ specifications.

The first family of AI methods incorporated for automatic RCA is based on probabilistic models, which comprise several techniques, each one having different implementations and certain performance implications. In this category, the main representatives are the Bayesian and Hybrid Bayesian networks. A Diagnostic Hybrid Bayesian Network is built in (Chigurupati and Lassar, 2017) to model the cause-effect relationship between the degradation parameters (cause) and failure modes (effect) that occur in order to capture the cause-symptom relationship within the examined hardware system. The required step of assigning conditional probabilities for building up the Bayesian network topology is accomplished with the deployment of the linearly varying Weibull and Lognormal distributions. This model was applied in two real-life field use cases concerning a small batch of hardware modules. The utilization of a Bayesian Network is also discussed in (Lokrantz et al., 2018) as part of the proposed framework for automatic root cause analysis and failure diagnostics in two simulated manufacturing processes, which consist of three and five process steps. To build the Bayesian network, various algorithms were utilized for structure learning, parameter learning, and inference. Regarding model training on historical data, the inference is conducted on the causal nodes, whereas the root causes of possible new process failures were determined. Finally, the result of inference was given in the form of conditional probabilities of the desired variables. The next use case involves the determination of possible causes in the manufacturing process of a bottle opener, termed the “Lion’s Jaw” (Brundage et al., 2017). This article introduces a framework for the formal, systematic manufacturing diagnosis of problems arising in manufacturing systems. A Bayesian network was selected because it models the cause-effect (causal) relationship between nodes, increasing the system’s accuracy. The required probabilities for model training were obtained from the Simio simulation model (simi.com).

The second family of methods reported in this review comprises ML and Artificial Neural Networks, which are referred to as deterministic models since there is no involvement of randomness in calculating the output state of the model. In this regard, an ANN classifier tuned with an intelligent Genetic Algorithm (GA) is proposed in (Arias Velásquez and Mejía Lara, 2020) to improve the root cause analysis and diagnosis of faults in power transformers. Moreover, the authors in (Ma et al., 2021) develop a big-data-driven root cause analysis system utilizing ML techniques. More specifically, they apply K-Nearest Neighbor (K-nn) and Neural Network (NN) classifiers to improve the performance of RCA in their effort to enhance product quality performance and reduce quality risk. The proposed framework comprises three distinct modules: Problem Identification (PI), Root Cause Identification (RCI), and Permanent Corrective Action. In the RCI Module, a supervised ML method is deployed to detect possible root causes of the defined quality problem. Then, the Multi-Layer Perception (MLP) model is employed to define quality problems and identify the root causes of the quality problems.

The contribution of another NN for industrial root cause diagnosis is presented in (Chen et al., 2020). The Sparse Causal Residual Neural Network (SCRNN) model is a ML-based method which seeks to figure out the causal relationships and causality lags between multiple variables. It seeks to predict the future state of a target variable using as input the previous state of the multiple time series, behaving in a regressive way, thus directly determining the causal relationship between variables after optimization. SCRNN comprises two modules: Variable selection and Fitting. In the second module, the fault variables are determined, and then the RCA follows by deploying the SCRNN, ending up in the isolation and recovery of the faults.

In the field of manufacturing industry, another ML model was built, which deployed several anomaly detection techniques for improving product quality in two assembly lines (Abdelrahman and Keikhosrokiani, 2020). These techniques include Histogram-Based Outlier Score (HBOS), IForest, K-nn, Cluster-Based Local Outlier Factor (CBLOF), One Class Support Vector Machine (OCSVM), Local Outlier Factor (LOF), and Angular-Based Outlier Detector (ABOD). Their behaviour was assessed through the application of two performance metrics. Among these models, K-nn and ABOD showed the highest performance. The authors performed an RCA using the Pareto chart to identify those variables that cause the anomalies. Also, 2 ML algorithms, namely Random Forest (RF) and Support Vector Machine (SVM) were deployed in (Sarkar et al., 2020) to accurately classify accident reports in a steel plant, using text classification approaches and evaluate their usefulness. The proposed RCA implementation aimed to find hidden causal factors that would help the steel plant company to take proper precautionary measures to minimize injuries, as RCA provides a much deeper insight into the root causes behind the incidents. In the case of RF, such a model was built in (Steurtewagen and Van den Poel, 2019) and further compared with an ANN to determine potential root causes of machinery breakdowns and, more specifically, to identify possible breakage points of compressor units that constitute the examined case study. RCA was performed to implement predictive modelling as well as to accurately predict compressor behaviour based on sensor data. Two more approaches based on RF models were developed in (Gonzalez et al., 2017; Berges et al., 2021) on two different case studies. The first deals with the identification of root causes of errors that happen in a network, and are based on a historical dataset of events, while the second refers to the detection of the signals triggering defect occurrence in the semiconductor industry of automotive products.

Isolation Forest (IF) is another ML approach, and it is proposed in (Carletti et al., 2019) for the task of Anomaly Detection. Specifically, the IF algorithm is involved in the Depth-based Isolation Forest Feature Importance (DIFFI) framework, which is proposed for defining and evaluating feature importance in industrial scenarios and further enables simple RCA. IF is part of the isolation procedure, which defines a tree-like model of decisions, called an Isolation Tree, in which each node is linked with a variable, and its children are determined based on a splitting value. According to it, a feature is defined as important for anomaly detection when it can isolate samples, meaning that it can induce isolation of outliers at small depths and does not contribute to the isolation of inliers. RCA can then be performed based on features that are marked as the most relevant by the proposed approach.

Among the frameworks that belong in the same ML and ANN family of methods, a scheme that consists of a moving window using kernel principal component analysis (KPCA) and an information geometric causal inference (IGCI) is reported in (Sun et al., 2021) and concerns the adaptive fault detection and RCA. Another method for fault root diagnosis is based on Recurrent Neural Network (RNN) and Granger Causality (GC), as proposed in (Shen et al., 2021). The framework comprises three steps. First, a Principal Component Analysis is performed to detect faults. Then, Dynamic Time Warping (DTW) is used to group fault candidate variables based on similarity and perform causality testing. Lastly, the combination of RNN and GC models is used to locate the root cause of faults. In addition, a new methodology for adaptive anomaly detection and RCA was explored in (Steenwinckel et al., 2021), using ML along with expert knowledge. The developed Fused-AI interpretable Anomaly Generation System (FLAGS) framework combines the advantages of both data- and knowledge-driven techniques towards optimizing anomaly detection, fault recognition, and RCA, while providing interpretable causes for the occurred anomalies. The proposed methodology was tested using a predictive maintenance case in the railway domain. This method seems to reduce downtime and provide more insight into frequently occurring problems while it gives the operator a new tool to investigate possible errors in the system.

A ML-guided methodology concerning tree-based models (Decision Tree, RF, and XGBoost) for RCA is demonstrated in (Huang and Li, 2021) to identify influencing production parameters for repeatability improvement and quality evaluation of additive manufacturing printed parts of the laser powder bed fusion (L-PBF) technology. An unsupervised RCA method deploying a decision-tree model is also demonstrated in (Pan et al., 2020), which is combined with frequent-pattern mining to cluster the data. Two case studies from the industry are involved, adopting real-world test data from network systems. In (Wasfi et al., 2019), a Decision Tree (DT) algorithm along with a Gradient Boosting (GB) model were selected to implement pattern recognition algorithms, which target the recognition of those transmission nodes characterized by unreliable data. On the other hand, the GB model was proposed in (Tiensuu et al., 2020) to find root causes behind the center line deviation of the steel strips. Using feature extraction and domain knowledge, the authors performed data reduction and new features construction to train the GB model. Their case study showed a correlation of errors between a former procedure (the hot rolling process) and a latter procedure (the RAP-line process).

In addition to individual ML methods, it is recorded a combination of such methods in the related literature. For example, a NN ensemble technique was developed in (Diren et al., 2019) to determine the root cause of uncontrolled situations in a Multivariate Manufacturing Process in the automotive sector. Five different root causes were identified in the process of painting seats, door panels, and bumper modules, paying attention to surface quality and fluidity. In (Pan et al., 2021a), another AI method based on ensemble learning is built to facilitate transfer learning in order to select the valuable samples from a source product similar to the target product. The examined case studies refer to two industry designs. The aim of the proposed model is to improve the RCA accuracy on the target product.

Apart from the two AI-based families of methodologies, as reported above, there is one more group of models that has a significant contribution to RCA, demonstrating notable performance. This group includes the DL and CNNs models, which are developed and applied in certain case studies as presented in the following lines. More specifically, the authors in (Crocco and O’Hern, 2018) perform a statistical RCA using CNNs for manufacturing quality improvement of an image sensor array. They investigate defects classification in an image sensor product to their corresponding origin. Root cause failure analysis was performed for all pixels exhibiting failures. In another study, a novel process for RCA utilizing unsupervised machine learning techniques for clustering and a CNN deep learning network for classification is proposed (Weber et al., 2021). The use case concerns a known root-cause for specific defect patterns in wafer maps. For automatic defect identification, an end-to-end CNN architecture is also proposed in (Xie et al., 2021), termed fusion feature CNN (FFCNN), consisting of three modules: feature extraction, feature fusion and decision-making. This intelligent machine-vision-based system was developed to detect surface defects on magnetic tiles during the production stage. AlexNet, VGG-16, and Resnet-50 were investigated for the development of the appropriate network. Another CNN model, namely the BiLSTM-CNN classifier, was built in (Javanbakht et al., 2022) to analyze alarm data of the Tennessee Eastman chemical process. After its training, the neural network was used for online fault detection, identifying the root cause of the alarms by the first five alarms of each fault scenario. Its structure includes six layers; input layer, 1D-CNN, BiLSTM, Self-Attention, Dense layer, and output layer.

In an effort to enhance the detection rate and automatically interpret the cause of an anomaly, the author in (Steenwinckel et al., 2018) adds prior experts’ knowledge into ML systems. One such technique is the Relational Graph Convolutional Network (RGCN), which operates on realistic knowledge graphs, fusing both ML and semantics to improve anomaly detection together with the ability to identify root causes inside a stream of data accurately. In another study, a Graph Convolutional Neural Network (GCNN) is also utilized as a part of the proposed model termed Process Estimator Neural Network (PEN), which was developed to tackle the non-linear issue of the state-sparse model (Leonhardt et al., 2021). PEN is actually a NN that uses a single graph convolution layer followed by two fully connected layers and constitutes a novel RCA methodology targeting modern multistage assembly lines for increasing product quality and implementing zero-defect manufacturing.

In order to perform root cause detection, the authors in (Shah et al., 2018a) used an RNN to extract two types of causal relationships (interdependencies and lagged dependencies) among the time-series of the examined system. They used dynamic dependency graphs that have been extracted from multivariate time series data.

A CNN is also utilized in the automatic Segmentation of Cells and Defect Detection (SCDD) system, proposed in (Lin et al., 2021), that aims to visually inspect defects in Electroluminescence (EL) images of single-crystalline silicon solar panels in photovoltaic (PV) industries. ResNet50 was utilized as a classifier, while YOLOv4 contributed as a detector for the panel-based defect detection. By applying cutting-edge deep CNNs, this approach achieves highly accurate defect detection rates from limited training samples of cell images. Finally, two ML models, termed STR (Structure transfer) and SER (Structure Expansion Reduction), and an ensemble (MIX) model were proposed to conduct a failure analysis through defect detection on nanoscale field-effect transistors (FET) of the semiconductor industry (Pan et al., 2021b). These ML models were trained on the same two defect datasets (FinFET and GAA-FET), providing notable accuracy in the identification of failures of the devices, guiding the acceleration of the production process.

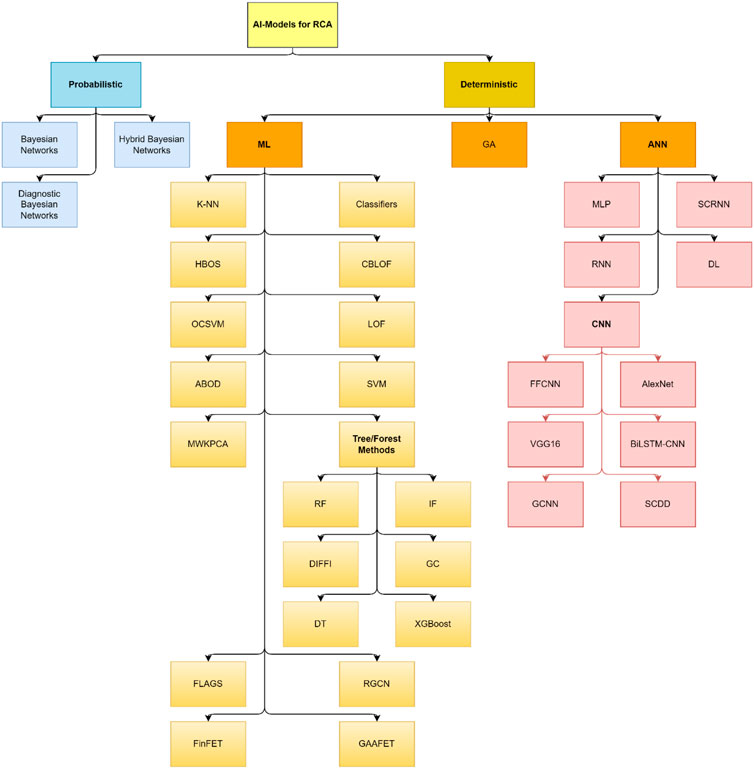

The taxonomy of employed ML-based models is shown in Figure 3.

To sum up, detecting root causes of defected parts in the production process is a highly demanding task in the manufacturing industry and needs extensive knowledge from experts to perform analyses. However, this demands high costs and offers low flexibility (Mueller et al., 2018). In this direction, ML-based techniques are able to model a vast amount of process data empirically, contributing to an automated root cause analysis, also reducing the costs and the necessary expert knowledge. In contrary to manual RCA which was previously conducted also using predefined root causes as training, ML-based algorithms possess the ability of analyzing complex data of different sources and types providing an automated way for root cause analysis. In that case, the abovementioned literature review brings together a number of ML methods that have been exploited toward the automatic RCA within smart manufacturing.

4 Discussion

4.1 Findings

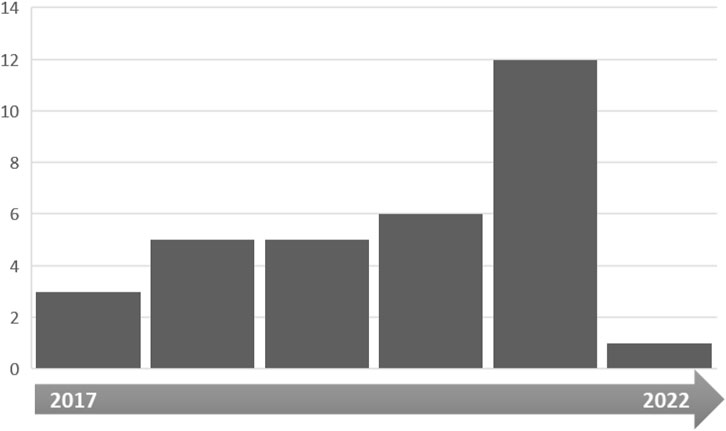

Through the current systematic review, valuable outcomes have been extracted, as illustrated in the following graphs, and further analyzed, evaluated and discussed, so that certain insights are elicited, highlighting the contribution of ML methods for RCA in smart manufacturing. To begin with, Figure 4 shows the distribution of publications during the investigated period. There is an evident increase in the number of publications, reflecting the growing interest in AI/ML-based RCA. As for the limited number of publications in 2022, this is due to the fact that this review was conducted at the beginning of 2022. However, an increasing tendency in the number of publications is anticipated.

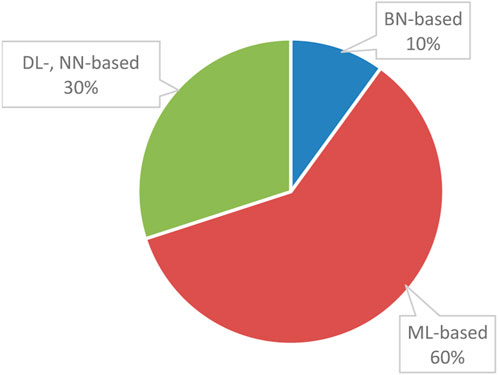

The literature analysis regarding the utilization of various AI technologies dictates that the deterministic methods (ML-, DL-, and NN-based) is the most popular choice (Figure 5) having 90% preference against the family of probabilistic models. In particular, the ML methods and their combinations are by far the most popular choice (60%), followed by DL and CNNs (30%), whereas the group of probabilistic methods (Bayesian and their Hybrid modules) come as the least employed methodologies for RCA with only 10%. This indicates that the major categories (ML, DL and CNNs) demonstrate their dominant presence in almost all case studies (90%) regarding AI-based RCA in smart manufacturing. This preference is attributed to the efficient learning capacity and performance of ANNs and the adequate performance of the traditional ML technologies for lesser amounts of input data.

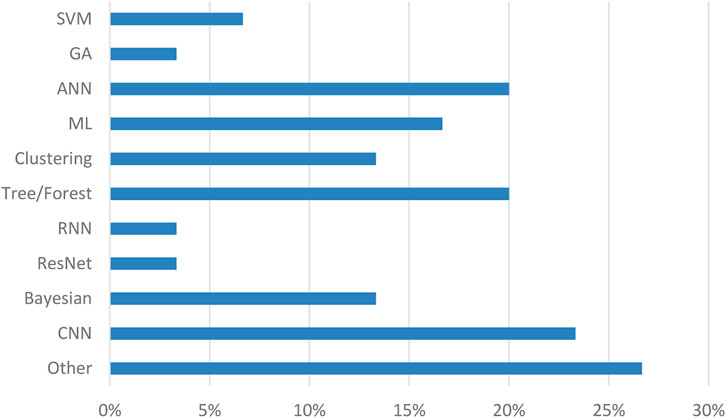

The distribution of AI-based models exploitation shown in Figure 5 is further quantified in Figure 6. CNNs are the most popular architecture (23%), as reported in the reviewed literature. Then, ANNs and Tree/Forest-based methods follow with 20% each, while the third best architecture is ML with 17%. Clustering is also well preferred (13%) either in its traditional forms (K-NN etc.) or combined with some AI architectures. The Bayesian methods also exhibit the same popularity. On the other hand, SVM demonstrates reduced popularity (7%), whereas RNNs, ResNets and GA seem to be the least favored methods (3%). The rest of the examined studies are scattered among other less popular methodologies. This categorization was performed under the consideration that some of the works investigated might employ more than one AI method; thus, the overall sum of the individual ratios exceeds 100%.

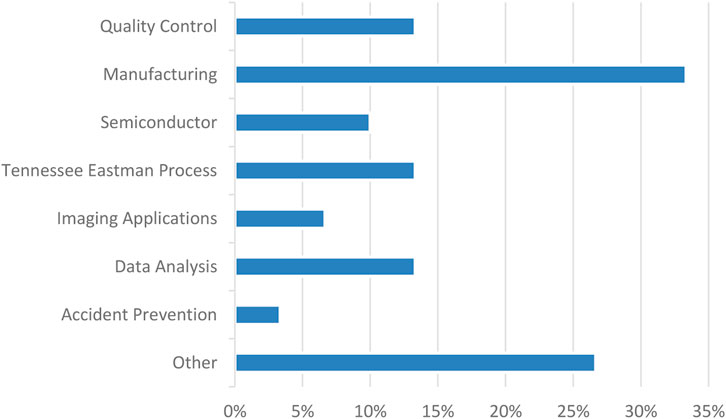

It is noteworthy that AI methods have been exploited in a wide variety of industrial sectors. Figure 7 shows the distribution in the percentage of all the industrial applications involved, considering the reviewed studies. The manufacturing sector is the leader in the use of AI methods as most reviewed papers (33%) concern some sort of manufacturing process. Quality Control/Assessment, Tennessee Eastman Process, and Data Analytics are equally (13%) employing AI techniques. The semiconductor industry follows (10%) along with Imaging applications (7%). One paper is related to Incident Analysis, targeting accident prevention. The rest of the papers (27%) are scattered among various other industrial sectors. It needs to be mentioned again, that the sum of the partial ratios exceeds 100%, as in some papers, more than one industrial sector is involved.

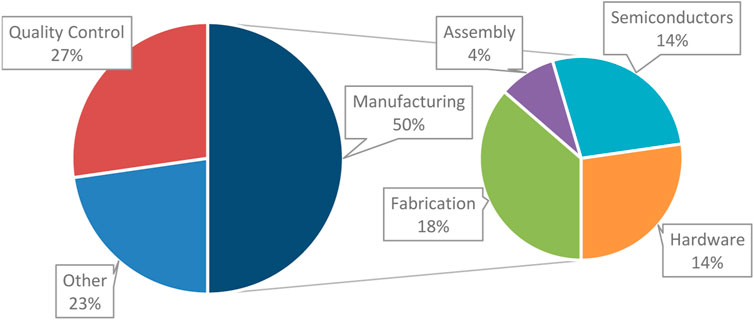

Furthermore, the applications that currently benefit most from the ML-based RCA are summarized in Figure 8. The majority of the ML-based RCA methods seem to be most embraced by Manufacturing (50%) and Quality Control (27%) applications. Manufacturing is further analyzed and categorized into general product fabrication applications (18%), semiconductor fabrication (14%), hardware and devices manufacturing (14%), and assembly line monitoring (4%).

4.2 Lessons learned

This systematic review was conducted to investigate the potential of using AI/ML for RCA in smart manufacturing. An increasing trend is demonstrated (Figure 4) regarding the number of relevant publications in the literature, which proves a growing interest in this area. This review was directed by a set of research questions; the answers to these questions provided insight regarding the developments and popularity of employed methods. First, a taxonomy of AI algorithms and methods has been compiled (Figure 3). This taxonomy lists the available tools, in a manner that considers the relevance among each other. That is, if a tool exhibits weaknesses, a similar one in the list may be exploited to overcome the observed limitations of the previous tool. Second, AI/ML-based RCA is not limited to a few specialized fields, but rather spans a wide range of industrial applications. The heterogeneity of industrial sectors (Figure 7) reveals a growing endeavor for novel AI tools for RCA. Third, Neural Networks in their many variants seem to be the dominant technology in AI-based RCA. This is attributed to their exceptional learning capabilities, their architectural flexibility, and their extraordinary capacity to discover underlying patterns.

4.3 Challenges

Despite the successful use of AI in RCA, there are still challenges to be addressed:

1) Explainability. The domain of AI is considered unclear by humans as regards its behavior, especially in the process of decision-making. This originates from AI models’ high complexity, ambiguity and the increased source of data, along with the inexplicit AI learning methods employed. Hence, the produced results cannot be directly and adequately explained by humans, and this leads to a sort of failure in applying AI models to a number of critical problems, failing overall to configure the best decision-making process. In this direction, Explainable AI (XAI) is a promising domain that allows humans to uncover clarity and reasoning in AI systems in an effort to comprehend AI models’ complex behavior at certain tasks and to arrive at a specific decision. On that basis, the incorporation of XAI into RCA methods would surely strengthen confidence in derived decisions.

2) Quality of Training. The performance of AI algorithms in RCA strongly depends on the availability of high-quality data. However, lack of adequate and suitable sources of data, as well as data scarcity, are common issues in the training process of AI models. Four papers were identified dealing with data for AI-based in RCA, including big-data, feature importance, data streams, etc. Thus, innovative data processing methods (e.g., data augmentation) are highly needed for efficient RCA and should probably be a topic of deeper investigation.

3) Standardization and Interoperability. As demonstrated in the presented graphs, there is a broad range of industrial applications that already benefit from AI-based RCA. Each operator may, of course, use their own protocols and practices. However, the establishment of standard rules and compatible interfaces and protocols would enable broad collaborations and joint efforts.

4) Data Privacy. The progress in AI and especially in DL is the result of a collaboration of multiple contributions, including open-source data offered by the community. Open-source datasets e.g., ImageNet (Deng et al., 2009), played a key role in establishing AI methods and boosted their development and optimization. AI-based RCA can also benefit from such datasets. However, the nature of RCA requires datasets from different production stages that could potentially expose sensitive information about the industrial provider. Thus, obtaining a real industrial benchmark dataset to further evaluate the effectiveness of AI methods for RCA is a real challenge.

5) Security. The industrial environment requires secure transactions. On the one hand, data security would prevent the leakage of sensitive or confidential information. On the other hand, data integrity is also necessary to prevent corruption and information loss. Such issues may be dealt with using current technologies like blockchain, but this certainly is a topic that deserves its own research.

6) New technologies. The development of AI-based methods is progressing at a fast pace and new tools appear every day. Digital twins provide a means to create a digital replica of the manufacturing line, which can be employed to tailor and optimize production parameters without affecting the running production. Digital twins may be exploited towards RCA, but this requires future research on this topic.

4.4 Concluding remarks

AI technologies have demonstrated remarkable efficiency in the implementation of RCA in smart manufacturing. A wide range of AI models is increasingly involved in the manufacturing processes that struggle to provide optimized production operation and consistent delivery of better products. To achieve that, quality inspection and smart quality control become crucial processes in the production line towards conducting detection of defects and defect source identification. This systematic literature review aims to demonstrate the integration of various AI methods into RCA models applied in smart manufacturing, investigating their implementation methodology as well as current practices. To accomplish the goals of this work, the PRISMA method was followed, while proper database sources were selected, including Google Scholar and Scopus, to mine published scientific papers from the year 2017 up to 2022. The followed review protocol also included the search term and the inclusion and exclusion criteria set by the authors. The list of the retrieved papers contains the authors, the year of publication, the AI method employed, the scope of the AI model’s implementation, and the industrial process the AI method was applied in toward defect source identification. The results have shown an increasing trend in the number of publications that report on the contribution of AI methods for RCA in smart manufacturing. The first goal regarding the availability of the ΑΙ tools in the realm of current smart manufacturing was accordingly answered. Based on our study, it was found that several deterministic and probabilistic AI technologies were applied for RCA in industry to identify defect sources in the early stages. Such technologies include ML-, DL- and NN-based models as well as Bayesian and their Hybrid modules. A variety of industrial processes were also reported to comply with the second goal of this review study. These were related to the manufacturing sector, semiconductor industry, data analysis, quality control and several others. Furthermore, this study also revealed the popularity of the AI technologies that have been employed for RCA in smart manufacturing so far. That was the third research question to be answered in this study. The findings showed that CNNs are the most popular architecture, followed by ANNs and Tree/Forest-based methods, while ML, Clustering, and Bayesian come with a smaller percentage in their contribution to RCA in industry 4.0. SVM, RNNs, ResNets, and GA seem to be the least favored methods in the examined field. In addition, this research study pinpoints a number of challenges that need to be considered in the future implementation of AI methodologies in RCA. Among them, explainability, quality of training, interoperability, privacy, and security have a significant share and role when AI-based technologies are exploited towards RCA within smart manufacturing, and thus they need to be further investigated.

5 Summary

To sum up, many AI technologies have already been successfully incorporated within the framework for RCA toward zero-defect manufacturing. In fact, there is a growing interest in further development, as implied by the number of publications per year. To accomplish an efficient literature survey, a set of research questions were initially posed. Then, a systematic literature review protocol was properly chosen to answer the posed queries. The conducted survey was focused on the most popular online, well-respected, and highly available databases, covering a wide range of disciplines, from the theoretical to the applied. Taking a close look at the produced outcomes, it is noted that ML and DL have shown a major contribution to RCA for smart industry applications. Seeking further, it seems that Neural Networks in their many variants (ANNs, CNNs, RNNs, etc.) are the current trend for automatic RCA in smart manufacturing using AI models. However, despite the current success, there are still open issues regarding explainability, data quality, standardization, data security, integrity, etc. These challenges deserve papers of their own and will be dealt with in future extensions of this work.

Author contributions

KP laid the foundation and coordinated with the team to bring out the paper’s content. His significant contributions are establishing the Introduction, AI-based models, systematic literature review, Results, and Discussion of this review paper. AR and TT worked on a systematic literature review and wrote the Results and Discussion of this review paper. The sections Discussion of Results and Conclusion are contributed significantly by EP, TT, and KP. EP made all the edits, referencing, abstract, conclusion, and communication with the group and brought the contents of the manuscript to the current shape. TT has greatly contributed during the conceptualizing phase, and his contributions are greatly in articulating the contents of this manuscript and performing the revisions. ND, DT, and GM have contributed to editing. All authors are involved in discussing the contents/design/flow of the paper. All authors contributed to the article and approved the submitted version.

Funding

This work has been supported by the European Commission through project OPTIMAI, funded by the European Union (H2020-NMBP-TR-IND-2020-singlestage, Topic: DT-FOF-11-2020, GA 958264).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Author disclaimer

The opinions expressed in this paper are those of the authors and do not necessarily reflect the views of the European Commission.

References

Abdelrahman, O., and Keikhosrokiani, P. (2020). Assembly line anomaly detection and root cause analysis using machine learning. IEEE Access 8, 189661–189672. doi:10.1109/access.2020.3029826

Arias Velásquez, R. M., and Mejía Lara, J. V. (2020). Root cause analysis improved with machine learning for failure analysis in power transformers. Eng. Fail. Anal. 115, 104684. doi:10.1016/j.engfailanal.2020.104684

Berges, C., Bird, J., Shroff, M. D., Rongen, R., and Smith, C. (2021). “Data analytics and machine learning: Root-cause problem-solving approach to prevent yield loss and quality issues in semiconductor industry for automotive applications,” in 2021 IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), Singapore, Singapore (IEEE) Available at: https://ieeexplore.ieee.org/document/9617238/.(Accessed on April 18, 2022). doi:10.1109/IPFA53173.2021.9617238

Brundage, M. P., Kulvatunyou, B., Ademujimi, T., and Rakshith, B. (2017). “Smart manufacturing through a framework for a knowledge-based diagnosis system.” in Manufacturing Equipment and Systems, 3. Los Angeles, California, USA: American Society of Mechanical Engineers ASME. Available at: https://asmedigitalcollection.asme.org/MSEC/proceedings/MSEC2017/50749/Los%20Angeles,%20California,%20USA/269585.

Carletti, M., Masiero, C., Beghi, A., and Susto, G. A. (2019). “Explainable machine learning in industry 4.0: Evaluating feature importance in anomaly detection to enable root cause analysis,” in 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy (IEEE). Available at: https://ieeexplore.ieee.org/document/8913901/(Accessed on Feb 18, 2022). doi:10.1109/SMC.2019.8913901

Chen, J., Zhao, C., and Sun, Y. (2020). “Sparse causal residual neural network for linear and nonlinear concurrent causal inference and root cause diagnosis,” in 2020 16th International Conference on Control, Automation, Robotics and Vision (ICARCV), Shenzhen, China (IEEE). Available at: https://ieeexplore.ieee.org/document/9305508/.(Accessed on Feb 18, 2022). doi:10.1109/ICARCV50220.2020.9305508

Chigurupati, A., and Lassar, N. (2017). “Root cause analysis using artificial intelligence,” in 2017 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23-26 January 2017 (IEEE). Available at: http://ieeexplore.ieee.org/document/7889651/.(Accessed on Feb 16, 2022). doi:10.1109/RAM.2017.7889651

Crocco, J. D., and O’Hern, J. R. P. R. (2018). Manufacturing quality improvement through statistical root cause analysis using convolution neural networks. US 2018/0293722 A Available at: https://patentimages.storage.googleapis.com/ae/88/9b/7085b4580621de/US20180293722A1.pdf.(Accessed on Oct 11, 2022).

Deng, J., Dong, W., Socher, R., Li, L. J., Li, K., and Fei-Fei, L. (2009). “ImageNet: A large-scale hierarchical image database,” in 2009 IEEE Conference on Computer Vision and Pattern Recognition, Miami, FL, USA (IEEE), 248–255. doi:10.1109/CVPR.2009.5206848

Diren, D. D., Boran, S., Selvi, I. H., and Hatipoglu, T. (2019). “Root cause detection with an ensemble machine learning approach in the multivariate manufacturing process,” in Industrial engineering in the big data era. Editors F. Calisir, E. Cevikcan, and H. Camgoz Akdag (Cham: Springer International Publishing), 163–174. (Lecture Notes in Management and Industrial Engineering). Available at: http://link.springer.com/10.1007/978-3-030-03317-0_14.(Accessed on April 18, 2022).

Dreyfus, P. A., Psarommatis, F., May, G., and Kiritsis, D. (2022). Virtual metrology as an approach for product quality estimation in industry 4.0: A systematic review and integrative conceptual framework. Int. J. Prod. Res. 60 (2), 742–765. doi:10.1080/00207543.2021.1976433

e Oliveira, E., Miguéis, V. L., and Borges, J. L. (2022). Automatic root cause analysis in manufacturing: An overview & conceptualization. J. Intell. Manuf. Available at: https://link.springer.com/10.1007/s10845-022-01914-3.(Accessed on April 14, 2022). doi:10.1007/s10845-022-01914-3

Gonzalez, J. M. N., Jimenez, J. A., Lopez, J. C. D., and Parada, G. H. A. (2017). Root cause analysis of network failures using machine learning and summarization techniques. IEEE Commun. Mag. 55 (9), 126–131. doi:10.1109/mcom.2017.1700066

Huang, D. J., and Li, H. (2021). A machine learning guided investigation of quality repeatability in metal laser powder bed fusion additive manufacturing. Mater. Des. 203, 109606. doi:10.1016/j.matdes.2021.109606

Javanbakht, N., Neshastegaran, A., and Izadi, I. (2022). Alarm-based root cause analysis in industrial processes using deep learning. Available at: https://arxiv.org/abs/2203.11321.(Accessed on April 18, 2022).

Jayswal, A., Li, X., Zanwar, A., Lou, H. H., and Huang, Y. (2011). A sustainability root cause analysis methodology and its application. Comput. Chem. Eng. 35 (12), 2786–2798. doi:10.1016/j.compchemeng.2011.05.004

Leonhardt, V., Claus, F., and Garth, C. (2021). Pen: Process Estimator neural Network for root cause analysis using graph convolution. J. Manuf. Syst. 62, 886–902. doi:10.1016/j.jmsy.2021.11.008

Lin, H. H., Dandage, H. K., Lin, K. M., Lin, Y. T., and Chen, Y. J. (2021). Efficient cell segmentation from electroluminescent images of single-crystalline silicon photovoltaic modules and cell-based defect identification using deep learning with pseudo-colorization. Sensors 21 (13), 4292. doi:10.3390/s21134292

Lokrantz, A., Gustavsson, E., and Jirstrand, M. (2018). Root cause analysis of failures and quality deviations in manufacturing using machine learning. Procedia CIRP 72, 1057–1062. doi:10.1016/j.procir.2018.03.229

Ma, Q., Li, H., and Thorstenson, A. (2021). A big data-driven root cause analysis system: Application of Machine Learning in quality problem solving. Comput. Industrial Eng. 160, 107580. doi:10.1016/j.cie.2021.107580

Moher, D., Liberati, A., Tetzlaff, J., and Altman, D. G. (2010). Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Int. J. Surg. 8 (5), 336–341. doi:10.1016/j.ijsu.2010.02.007

Mueller, T., Greipel, J., Weber, T., and Schmitt, R. H. (2018). Automated root cause analysis of non-conformities with machine learning algorithms. J. Mach. Eng. 18, 60–72. doi:10.5604/01.3001.0012.7633

Murugaiah, U., Benjamin, S. J., Marathamuthu, M. S., and Muthaiyah, S. (2010). Scrap loss reduction using the 5-whys analysis. Int. J. Qual. Reliab. Manag. 27 (5), 527–540. doi:10.1108/02656711011043517

OPTIMAI (2021–2023). OPTIMAI project. Available from: https://optimai.eu/. GA 958264.

Pan, J., Low, K. L., Ghosh, J., Jayavelu, S., Ferdaus, M. M., and Lim, S. Y. (2021). Transfer learning-based artificial intelligence-integrated physical modeling to enable failure analysis for 3 nanometer and smaller silicon-based CMOS transistors. ACS Appl. Nano Mat. 4 (7), 6903–6915. doi:10.1021/acsanm.1c00960

Pan, R., Li, X., and Chakrabarty, K. (2021). “Unsupervised root-cause analysis with transfer learning for integrated systems,” in 2021 IEEE 39th VLSI Test Symposium (VTS), San Diego, CA, USA. (IEEE). Available from: https://ieeexplore.ieee.org/document/9441030/.(Accessed on April 18, 2022). doi:10.1109/VTS50974.2021.9441030

Pan, R., Zhang, Z., Li, X., Chakrabarty, K., and Gu, X. (2020). “Unsupervised root-cause analysis for integrated systems,” in 2020 IEEE International Test Conference (ITC), Washington, DC, USA (IEEE). Available from: https://ieeexplore.ieee.org/document/9325268/.(Accessed on April 18, 2022). doi:10.1109/ITC44778.2020.9325268

Papageorgiou, E., Theodosiou, T., Papageorgiou, K., Casanovas, P., Charalampous, P., and Dimitriou, N. (2021). State of the art survey. Available from: https://optimai.eu/wp-content/uploads/2021/07/OPTIMAI-D2.3-State-of-Art_V2.0_FINAL_SUBMISSION.pdf.

Psarommatis, F., May, G., Dreyfus, P. A., and Kiritsis, D. (2020). Zero defect manufacturing: State-of-the-art review, shortcomings and future directions in research. Int. J. Prod. Res. 58 (1), 1–17. doi:10.1080/00207543.2019.1605228

Psarommatis, F., Prouvost, S., May, G., and Kiritsis, D. (2020). Product quality improvement policies in industry 4.0: Characteristics, enabling factors, barriers, and evolution toward zero defect manufacturing. Front. Comput. Sci. 2, 26. doi:10.3389/fcomp.2020.00026

Psarommatis, F., Sousa, J., Mendonça, J. P., and Kiritsis, D. (2022). Zero-defect manufacturing the approach for higher manufacturing sustainability in the era of industry 4.0: A position paper. Int. J. Prod. Res. 60 (1), 73–91. doi:10.1080/00207543.2021.1987551

Sarkar, S., Ejaz, N., Kumar, M., and Maiti, J. (2020). “Root cause analysis of incidents using text clustering and classification algorithms,” in Proceedings of ICETIT 2019. Lecture notes in electrical engineering. Editors P. K. Singh, B. K. Panigrahi, N. K. Suryadevara, S. K. Sharma, and A. P. Singh (Cham: Springer International Publishing), 605, 707–718. Available at: http://link.springer.com/10.1007/978-3-030-30577-2_63.(Accessed on April 18, 2022).

Shah, S. Y., Dang, X. H., and Zerfos, P. (2018). “Root cause detection using dynamic dependency graphs from time series data,” in 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA (IEEE), 1998–2003. doi:10.1109/BigData.2018.8622059

Shah, S. Y., Dang, X. H., and Zerfos, P. (2018). “Root cause detection using dynamic dependency graphs from time series data,” in 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA (IEEE). Available at: https://ieeexplore.ieee.org/document/8622059/.(Accessed on April 4, 2022). doi:10.1109/BigData.2018.8622059

Shen, G., Wang, P., Hu, K., and Ye, Q. (2021). “fault root cause diagnosis method based on recurrent neural network and granger causality,” in 2021 CAA Symposium on Fault Detection, Supervision, and Safety for Technical Processes (SAFEPROCESS), Chengdu, China (IEEE). Available at: https://ieeexplore.ieee.org/document/9693579/. doi:10.1109/SAFEPROCESS52771.2021

Solé, M., Muntés-Mulero, V., Rana, A. I., and Estrada, G. (2017). Survey on models and techniques for root-cause analysis. Available at: https://arxiv.org/abs/1701.08546.(Accessed on April 14, 2022).

Steenwinckel, B. (2018). “Adaptive anomaly detection and root cause analysis by fusing semantics and machine learning,” in The semantic web: ESWC 2018 satellite events Lecture notes in computer science. Editors A. Gangemi, A. L. Gentile, A. G. Nuzzolese, S. Rudolph, M. Maleshkova, and H. Paulheim (Cham: Springer International Publishing). Available at: http://link.springer.com/10.1007/978-3-319-98192-5_46. doi:10.23919/PCICEurope46863.2019.9011628

Steenwinckel, B., De Paepe, D., Vanden Hautte, S., Heyvaert, P., Bentefrit, M., and Moens, P. (2021). Flags: A methodology for adaptive anomaly detection and root cause analysis on sensor data streams by fusing expert knowledge with machine learning. Future Gener. Comput. Syst. 116, 30–48. doi:10.1016/j.future.2020.10.015

Steurtewagen, B., and Van den Poel, D. (2019). “Root cause analysis of compressor failure by machine learning,” in 2019 Petroleum and Chemical Industry Conference Europe (PCIC EUROPE), Paris, France (IEEE). Available at: https://ieeexplore.ieee.org/document/9011628/.

Sun, Y., Qin, W., Zhuang, Z., and Xu, H. (2021). An adaptive fault detection and root-cause analysis scheme for complex industrial processes using moving window KPCA and information geometric causal inference. J. Intell. Manuf. 32 (7), 2007–2021. doi:10.1007/s10845-021-01752-9

Tao, F., Qi, Q., Liu, A., and Kusiak, A. (2018). Data-driven smart manufacturing. J. Manuf. Syst. 48, 157–169. doi:10.1016/j.jmsy.2018.01.006

Tiensuu, H., Tamminen, S., Haapala, O., and Röning, J. (2020). Intelligent methods for root cause analysis behind the center line deviation of the steel strip. Open Eng. 10 (1), 386–393. doi:10.1515/eng-2020-0041

Wasfi, B., Alqasimi, M., Al Kadem, M., and Alghamdi, A. (2019). “Innovative machine learning method to locate the root cause of the unreliable data coming from intelligent field equipment,” in Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, November 12, 2019. Available at: https://onepetro.org/SPEADIP/proceedings/19ADIP/2-19ADIP/Abu%20Dhabi,%20UAE/216802.doi:10.2118/197270-MS

Weber, C., Tripuramallu, A., Czerner, P., and Fathi, M. (2021). “Clustering wafer defect patterns within the semiconductor industry based on wafer Maps, using an agile unsupervised deep learning approach,” in 2021 IEEE International Conference on Systems, Man, and Cybernetics (SMC) [Internet], Melbourne, Australia (IEEE). Available at: https://ieeexplore.ieee.org/document/9658907/. doi:10.1109/SMC52423.2021.9658907

Keywords: smart manufacturing (Industry 4.0), root cause analysis, defect identification, artificial intelligence, deep learning, machine learning

Citation: Papageorgiou K, Theodosiou T, Rapti A, Papageorgiou EI, Dimitriou N, Tzovaras D and Margetis G (2022) A systematic review on machine learning methods for root cause analysis towards zero-defect manufacturing. Front. Manuf. Technol. 2:972712. doi: 10.3389/fmtec.2022.972712

Received: 18 June 2022; Accepted: 14 October 2022;

Published: 28 October 2022.

Edited by:

Oscar Lazaro, Innovalia Association, SpainReviewed by:

Alexandros Bousdekis, National Technical University of Athens, GreeceHongbae Jun, Hongik University, South Korea

Copyright © 2022 Papageorgiou, Theodosiou, Rapti, Papageorgiou, Dimitriou, Tzovaras and Margetis. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Elpiniki I. Papageorgiou, ZWxwaW5pa2lwYXBhZ2Vvcmdpb3VAdXRoLmdy

Konstantinos Papageorgiou1

Konstantinos Papageorgiou1 Theodosios Theodosiou

Theodosios Theodosiou Elpiniki I. Papageorgiou

Elpiniki I. Papageorgiou Dimitrios Tzovaras

Dimitrios Tzovaras George Margetis

George Margetis