94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Microbiol., 04 May 2022

Sec. Food Microbiology

Volume 13 - 2022 | https://doi.org/10.3389/fmicb.2022.838416

Probiotics and prebiotics are widely used as functional food ingredients. Viability of probiotics in the food matrix and further in the digestive system is still a challenge for the food industry. Different approaches were used to enhance the viability of probiotics including microencapsulation and layer-by-layer cell coating. The of aim of this study was to evaluate the viability of coated Lacticaseibacillus rhamnosus using a layer-by-layer (LbL) technique with black seed protein (BSP) extracted from Nigella sativa defatted seeds cakes (NsDSC), as a coating material, with alginate, inulin, or glucomannan, separately, and the final number of coating layers was 3. The viable cell counts of the plain and coated L. rhamnosus were determined under sequential simulated gastric fluid (SGF) for 120 min and simulated intestinal fluid (SIF) for 180 min. Additionally, the viability after exposure to 37, 45, and 55°C for 30 min was also determined. Generally, the survivability of coated L. rhamnosus showed significant (p ≤ 0.05) improvement (<4, 3, and 1.5 logs reduction for glucomannan, alginate and inulin, respectively) compared with plain cells (∼6.7 log reduction) under sequential exposure to SGF and SIF. Moreover, the cells coated with BSP and inulin showed the best protection for L. rhamnosus under high temperatures. Edible films prepared with pectin with LbL-coated cells showed significantly higher values in their tensile strength (TS) of 50% and elongation at the break (EB) of 32.5% than pectin without LbL-coated cells. The LbL technique showed a significant protection of probiotic cells and potential use in food application.

The World Health Organization (WHO) has defined probiotics as “live microorganisms which when administered in adequate amounts confer a health benefit on the host” (FAO/WHO, 2001). Later, the definition was reworded as “live microorganisms that, when administered in adequate amounts, confer a health benefit on the host” (Hill et al., 2014).

The term probiotics includes strains belonging to several genera of bacteria and yeasts, such as Lactobacillus, Bifidobacterium, Streptococcus, Enterococcus, Escherichia, Bacillus, and Saccharomyces. These microorganisms could be naturally found in fermented food like yogurt and dairy products, pickles, sauerkraut, kefir, Kombucha, etc. (Dimidi et al., 2019). Besides, they are available in the market in the form of probiotic foods or as supplements. Lacticaseibacillu rhamnosus originally isolated from humans has attracted more attention due to its ability to survive stomach acids and bile salts (Segers and Lebeer, 2014), and to its positive effect on the progression of diseases including gastrointestinal (GI) infections (Capurso, 2019).

The interest of probiotics and its introduction to food is massively increased during the past few years owing to reported evidence about probiotics’ positive effect on the human health. Probiotics promote health status and play an essential role against colonization of pathogenic microbes in the intestine by the production of antimicrobial compounds, increase gut integrity by stimulating mucus production, improve enzyme formation, regulate the composition of (GI) microbiota, and act as immunity modulators. Nowadays, the investigations about the importance of GI microbiota are widely and intensively increased. It was reported that probiotics and GI microbiota composition demonstrate a major role in the progression of many diseases and disorders, such as obesity, allergies, diabetes, inflammations, inflammatory bowel diseases (IBD), cancer, infectious diseases, and even neurodegenerative diseases (Kechagia et al., 2013).

Therefore, the food industry has never missed the chance to increase its profits by producing novel probiotics. From the economic point of view, the global probiotics market is expected to reach USD 77.09 billion by 2025 (Grand View Research, 2021). Moreover, economic analysts have expected an increase in the demand for functional food especially during the COVID-19 pandemic. It has been demonstrated that certain probiotics, such as lactic acid bacteria, produce bioactive peptides, such as angiotensin-converting enzyme inhibitor, which may help manage COVID-19 (Meng et al., 2020; Bhattacharya et al., 2021).

This increase is owing to consumer’s awareness about the benefits of probiotics and its effect on health and, particularly, immunity boosting, and their tendency toward healthier food in general. On the other hand, analysts have expected a depression in the consumption of meat, poultry, and seafood, while the demand for plant and animal protein supplements will increase (Grand View Research, 2021). This may affect the distribution of food items that used to be probioticated, or even under ongoing researches. Furthermore, consumers perceive probioticated food as natural rather than taking it in pharmaceutical forms, i.e., pills, capsules, etc. (Fenster et al., 2019).

To achieve better usefulness, we need to be sure that the probioticated products have taken into account the differences in needs among all population categories, and the consumption of that product in a specific market. For example, (1) if we probioticate bread, we should consider the celiac disease population and gluten-free dieters, (2) milk product probiotication should take into account lactose-intolerant patients, so we think about the probiotication of alternatives suitable for this category, such as almond or soy milk, and (3) take in consideration the coating agents in case of vegan consumers (Grand View Research, 2021). Nevertheless, choosing the right probiotics for specific health conditions is still a challenge for some reasons, such as variations in the mode of action of different probiotics, differences in manufacturing processes, quality control of the products, and differences in the international regulatory requirements of minimum effective dose (Sniffen et al., 2018).

To obtain the maximum health benefits claimed about probiotics, the number of viable probiotic cells should be not lower than 106–107 cfu/ml or g ingested according to the Food and Drug Administration—WHO (Thomas et al., 2014). Unfortunately, the numbers of probiotics ingested are affected by numerous factors, including (1) chemical: Low pH, gastrointestinal conditions, food matrix properties, and (2) physiological factors that affect the adhesion and colonization of probiotics in the intestines, such as rapid transit time. Moreover, probiotics viability may be decreased under thermal conditions during their preparation or shelf life. Therefore, formulations of probiotics should consider the various physicochemical, biopharmaceutical, and biological barriers to make the best of their therapeutic effectiveness and clinical applicability (Baral et al., 2021).

To overcome these problems, the scientists thought of several strategies to improve probiotics viability, including nanoparticles, polymer gels, and microencapsulation to protect the sensitive probiotic cells against the harsh conditions in the gastrointestinal tract and during storage, and to improve the adhesion to the mucosal lining.

In addition, scientists have developed techniques to perform microencapsulation and obtain a proper form of final product with higher viability and stability. These techniques, including extrusion, emulsion, spray drying, spray freezing, spray-freeze drying, and layer-by-layer were investigated (Călinoiu et al., 2019).

The inclusion of prebiotics in such systems played several crucial roles, as these prebiotics increase the stability of the applied systems, help in developing of new food products, and further protect probiotics from harsh conditions. Moreover, prebiotics microencapsulation-based formulations have enhanced the nutritional and functional properties of the final products (Shah et al., 2020).

Layer-by-layer, as a technique, was raised up a few decades ago and proposed by the German chemist Gero Decher in 1991 (Matsusaki et al., 2012). At first, the applications of this technique have been limited in increasing the effectiveness of drugs and pharmaceuticals; then it was outspread until it linked to food processing by coating some types of food pigments and single-cell probiotics (Ram et al., 2001; Priya et al., 2011; Marais et al., 2014; Jung et al., 2015).

The layer-by-layer technique is described by electrostatic attractions and ionic interactions between the layers used in the coating. This approach is based mainly on the alternate exposure of the probiotic cell to negative- and positive-charged substrates. In order to remove the excess of the coating materials, a buffer solution is used as a washing solution after each coating step. In the end, the coated probiotics might be dried depending on the application (Priya et al., 2011).

The main negative-charged molecules used in the coating of probiotics were alginate and pectin polysaccharides, while the studies on the positive-charged layer were covering (1) polysaccharides as chitosan and (2) proteins as milk proteins or, as in the current study, protein concentrate extracted from Nigella sativa defatted cake (NsDSC), which is widely available as a byproduct after oil extraction. Moreover, the compounds used in LbL must be of food grade, for example, biodegradable polysaccharides, and able to tolerate harsh conditions, such as acidic pH, bile salts, digestive enzymes, and storage conditions, including temperature (Alkekhia et al., 2020; Ivanova et al., 2020).

This technique steps ahead of microencapsulation techniques, fulfills the maximum saving of coating materials, and minimizes the wasting that occurs in the bead-form microcapsule. It also allows delivering of probiotics cells, growth, and colonization in the GIT with no need to release apart from the coating material.

Generally, all studies previously published approved the positive effect of LbL on the protection of probiotics in bacteria and yeast. Particularly, the LbL approach also enhanced the viability of probiotics under harsh conditions as detailed in Table 1.

The aim of this study was to coat probiotic single-cell L. rhamnosus (previously Lactobacillus rhamnosus) (Zheng et al., 2020), using protein extracted from NsDSC and different biodegradable polysaccharides (inulin, alginate, or glucomannan) applying the layer-by-layer approach, and, in addition, to also determine the coatings’ effect on the viability of probiotic cells under gastrointestinal conditions and different heating temperatures.

L. rhamnosus powder was purchased from Dicofarm (Italy). Nigella sativa defatted cake was purchased from Al-Hethnawi Company for oil extraction (Jenin, Palestine). Polysaccharides inulin and glucomannan were purchased from NOW Foods, United States, while alginate was from SIGMA, United Kingdom. The enzyme Activa®WM Streptoverticillium transglutaminase (TGase) was supplied by the Ajinomoto Co. (Tokyo, Japan). MRS agar, MRS broth, and 2.5-L anaerobic jars were from the OXOID company (Basingstoke, United Kingdom). Bile salts and bromelain enzyme from pineapple stems were brought from SIGMA (Dorset, United Kingdom). Peptone water was from DIFCO. The pieces of equipment were Memmert CO2 incubator, refrigerated centrifuge (ALC PK120R), Memmert shaking water bath, thermo mix (ONILAB HM100-Pro), drying oven (Raypa), microcentrifuge (Denever Instrument), pH meter 3310 (JENWAY), and autoclave (Hydra). Citrus peel low-methylated (7%) PEC (Aglupectin) was purchased from Silva Extracts s.r.l. (Gorle, BG, Italy). Vegetable glycerol (USP grade) was purchased from Heartlandvapes LLC., OK, United States. All other chemicals and solvents were of analytical grade.

Lyophilized L. rhamnosus was reconstituted in 10 ml of de Man, Rogosa, and Sharpe (MRS) broth, incubated anaerobically at 37°C for 48 h, then the process was repeated twice to assure purity. A 450-ml MRS broth was inoculated with 50 ml of the previous broth. The cultures were incubated as previously mentioned.

Bacterial cells were harvested by centrifugation (ALC PK120R) at 3,800 × g for 20 min at 4°C. The cell pellets were washed twice with sterile peptone water then twice with 0.15 M NaCl. The cell count of L. rhamnosus was performed using a standard plate count method using MRS agar under anaerobic conditions at 37°C for 48 h.

Protein concentrate was extracted from Nigella sativa defatted cake by acid–base extraction method as described by Sabbah et al. (2020) with slight modifications. Dried NsDSC was ground and dispersed in distilled water (DW) (1:20, w/v), pH adjusted to 12.0 with 1 M NaOH, and stirred at room temperature for 2 h at constant speed. The suspension was centrifuged (4,300 × g, 20 min), and the supernatant was collected; then pH was adjusted to 6.0 with 1 M HCl to form a precipitate. The precipitate was collected by centrifugation (3,800 × g, 20 min) and uniformly distributed on an aluminum foil sheet for drying at 30°C and 20% relative humidity. The obtained protein concentrate (PC) was ground to fine particles using household electric grinder.

To enhance the solubility and purity of the protein, the PC was treated with bromelain (Sigma, United Kingdom) as follows: 20 g of PC was suspended in 100 ml of DW, and pH was adjusted to 7.0; then 2.5 g of bromelain was added. The suspension was placed in a shaking water bath at 37°C for 4 h, then was boiled for 2 min to stop the enzymatic reaction. The precipitate was separated by centrifugation (4,000 × g, 20 min) and discarded; the supernatant was freeze dried. The powder that was obtained was named black seed protein (BSP).

To quantify the total protein content in the protein concentrate (PC), the BCA protein assay protocol described by He (2011) was followed. Initially, a working reagent solution (WRS) was prepared by mixing 50 parts of BCA (reagent A) with 1 part of BCA (reagent B) (50:1, A:B). Then 100 μl of PC was dissolved in 2.0 ml of WRS in order to get the sample to a WRS ratio of 1:20. An Eppendorf tube containing the mixture was covered with aluminum foil and incubated at 37°C for 30 min. After that, the tubes were kept at room temperature for 10 min before measurement. Absorbance at 562 nm was measured and compared with BSA standard curve to calculate the protein content and percentage.

Briefly, 2 g of BSP was dissolved in 100 ml of distilled water (DW) and stirred overnight for sufficient hydration. Polysaccharide solutions of inulin, alginate, and glucomannan were prepared by dissolving 2 mg/ml, then sterilizing by microfiltration. pH was adjusted to 6.5 by adding 1 M HCl.

The layer-by-layer encapsulation of L. rhamnosus was conducted according to a previous study (Wang et al., 2019) with some modifications. A cell-to-polymer solution ratio of 1:8 was obtained by adding 5 ml of concentrated cells into 40 ml of BSP. To induce gelation, TGase (8 U/g of protein), which is used to strengthen the BSP layer by catalyzing the formation of isopeptide bonds between glutamine and lysine, was added into the mixture (stirring for 30 min). The protein microcapsules were collected by centrifugation (3,800 × g, 15 min). Then they were washed twice with peptone water and then twice with NaCl (0.15 M), and recollected by centrifugation (3,800 × g, 15 min) after each wash.

Fresh protein microcapsules (2 g) were added into 20 ml of alginate solution, mixed, and stirred at constant speed for 30 min in a prewarmed 40°C water bath. Then microcapsules coated by alginate were collected by centrifugation (3,800 × g, 15 min) and washed twice with sterile peptone water, and then with NaCl solution (0.15 M) twice.

As shown in Figure 1, the obtained microcapsules were coated by BSP to apply the third layer following the same steps. The same procedures were applied for BSP and replacing alginate with either inulin or glucomannan.

Figure 1. Layer-by-layer procedure to coat L. rhamnosus cells. Plain cells were mixed with BSP to apply first positively charged layer, a polysaccharide layer (alginate, glucomannan, inulin) was applied as second negative layer followed by a third layer of B SP.

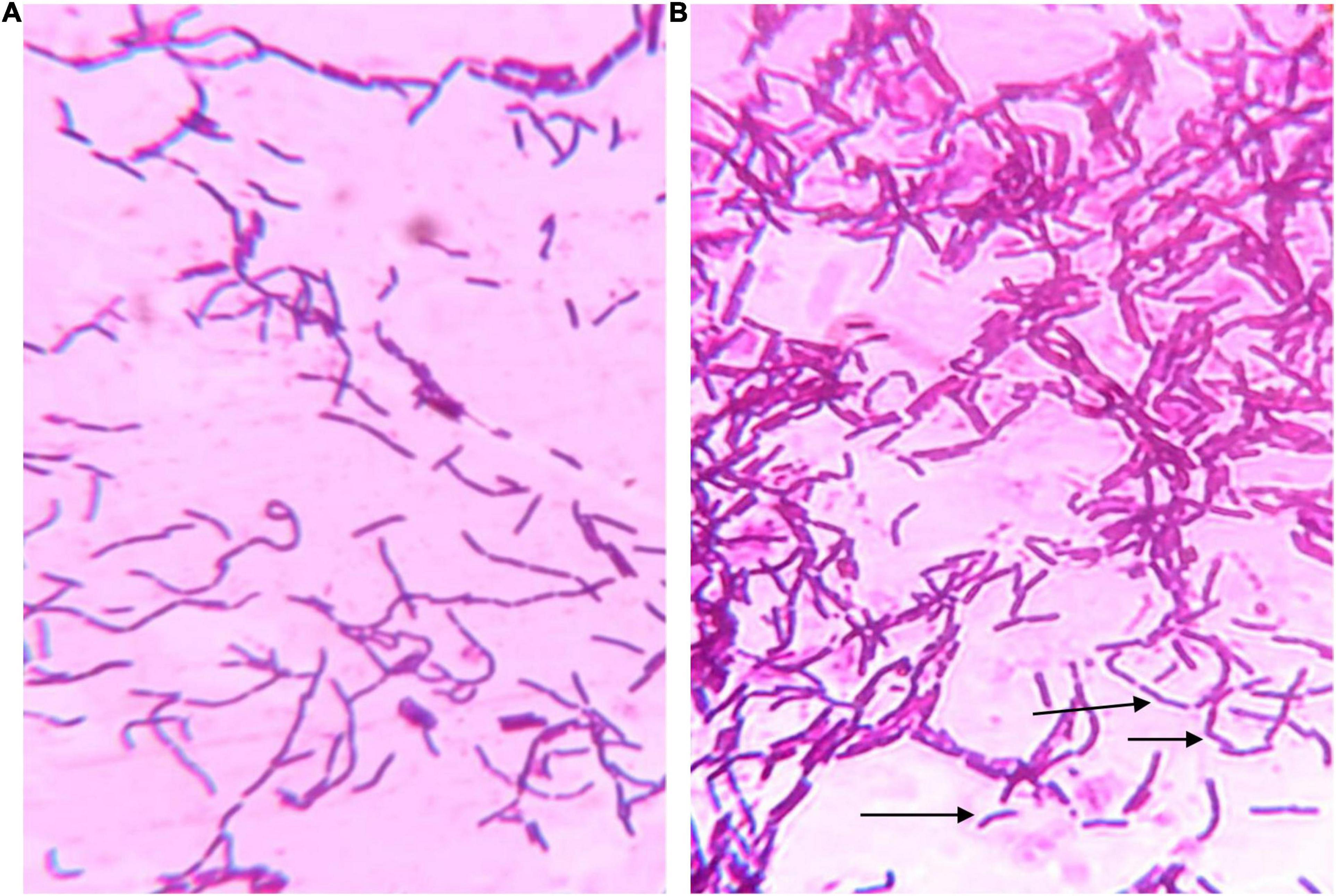

Bacterial cells before coating and after LbL coating were examined under a light microscope (×1,000). Gram staining was applied, and any changes in the morphology of the cells were observed.

Survivability of plain and coated L. rhamnosus was evaluated after sequential exposure to SGF for 2 and 3 h to bile salt solutions (4%, w/v). One liter of stock, simulating gastric fluid solution, was prepared, using a previously reported method (Wang et al., 2019) with a few modifications. The solution contained 16.4 ml of hydrochloric acid (10%, v/v), sodium chloride (2 g), bromelain (10 g), and 983.6 ml of deionized water. The pH was adjusted to 2.8 using 1 M HCl and/or NaOH.

Bile salts (4 g) were added into 100 ml of deionized water, and pH was adjusted to 6.8, using 1 M NaOH and/or HCl, to form bile salt solutions (4%, w/v).

For digestion in SGF, the plain L. rhamnosus or LbL-coated cells were mixed with SGF and placed in a shaking water bath at 37°C. Samples were obtained every 30 min up to 120 min. Cells were pelleted via centrifugation (3,800 × g, 20 min), resuspended, and washed twice in peptone water. The suspension was serially diluted to an appropriate concentration, then the plain L. rhamnosus or coated cells were transferred to MRS agar plates and incubated anaerobically for 48 h at 37°C.

Sequentially, plain L. rhamnosus and coated cells (obtained after gastric simulation) were mixed with the 4% bile salt solution and placed in a water bath at 37°C. Similarly, samples were taken at 30, 60, 120, and 180 min. The cells were collected via centrifugation (4,000 × g, 20 min) and washed twice in peptone water as described previously.

The overall survival rate of L. rhamnosus was calculated after exposure to SGF and SIF by the equation of Li et al. (2016):

Survival (%) = log Nt/No × 100

where Nt is the cell count at the end of different incubation times, and No is the viable cell number prior to exposure to SGF and SIF.

The effect of the layer-by-layer coating on the heat resistance of L. rhamnosus was measured. Pelleted cells (1 g), prepared as mentioned above, were reconstituted in prewarmed peptone water using plain L. rhamnosus, (BSP-INU/BSP) L. rhamnosus, (BSP-ALG/BSP) L. rhamnosus, and (BSP-GLU/BSP) L. rhamnosus placed in water baths at 37, 45, or 55°C for 30 min to represent processing and storage conditions. Samples were diluted, and 1 ml was spread over MRS agar. The viable count of each sample was calculated after 48 h of incubation aerobically at 37°C. The results were expressed as log of cfu/g of the original sample.

The LbL-coated cells were prepared as previously mentioned except that the final cell solution was concentrated to reach > 3 × 1014 cfu/ml, and BSP solution was 4%. Then the first layer was prepared by mixing the cell solution with the BSP solution in a 1:8 ratio. Inulin was used as the second layer followed by the BSP layer. The final LbL-coated cells were harvested and incorporated in a film as described by Giosafatto et al. (2019). Briefly, pectin (PEC)-based film forming solutions (0.8% w/v) were prepared from a PEC stock solution (1% w/v of water), at pH 7.0. LbL-coated cells (1.0%) were added to the PEC under continuous stirring for 30 min; after that, 30% GLY (w/w PEC) was added to the film-forming solution. The film-forming solution was casted onto 8-cm-diameter polycarbonate Petri dishes and allowed to dry in an environmental chamber at 30°C and 50% relative humidity (RH) for 24 h. The dried film was peeled, intact from the casting surface and tested for thickness and mechanical properties. A film of PEC without BSP was used as negative control, while a film of PEC with BSP/no LbL-coated cells was used as positive control for comparison.

To compare the three different films, film thickness was measured with a micrometer screw gauge (0–25 mm, 0.1 μm) at different positions for each film sample. The films’ mechanical characteristics, tensile strength (TS), elongation at the break (EB), and Young’s modulus (YM) were analyzed by using the Brookfield CT3 Texture Analyzer (model CT3 50K, Brookfield, Chandler, United States) as descripted by Yaseen et al. (2021).

The experiment, starting from the LbL synthesis to the simulation process, was carried out in duplicate. In addition, the sampling for bacterial culturing also was performed in duplicate. All results obtained were analyzed using SPSS Statistics 21. Repeated measures, then one-way ANOVA test, with a p-value = 0.05, have been conducted.

The percentage of total protein content in the original protein concentrate after enzymatic hydrolysis of NsDSC was 73.4%.

Figure 2 shows that the LbL-coated cells were surrounded by clear areas. As the stain is positively charged, it can be repelled by the third layer of the coating (BSP), which is also positively charged. This has confirmed that the LbL coating was successfully applied.

Figure 2. Microscopic photos of (A) uncoated cell and (B) LbL coated cells after gram staining. The coated cells were noticed to have clear areas around them as shown by arrows while uncoated cells were representing typical gram-stained bacteria.

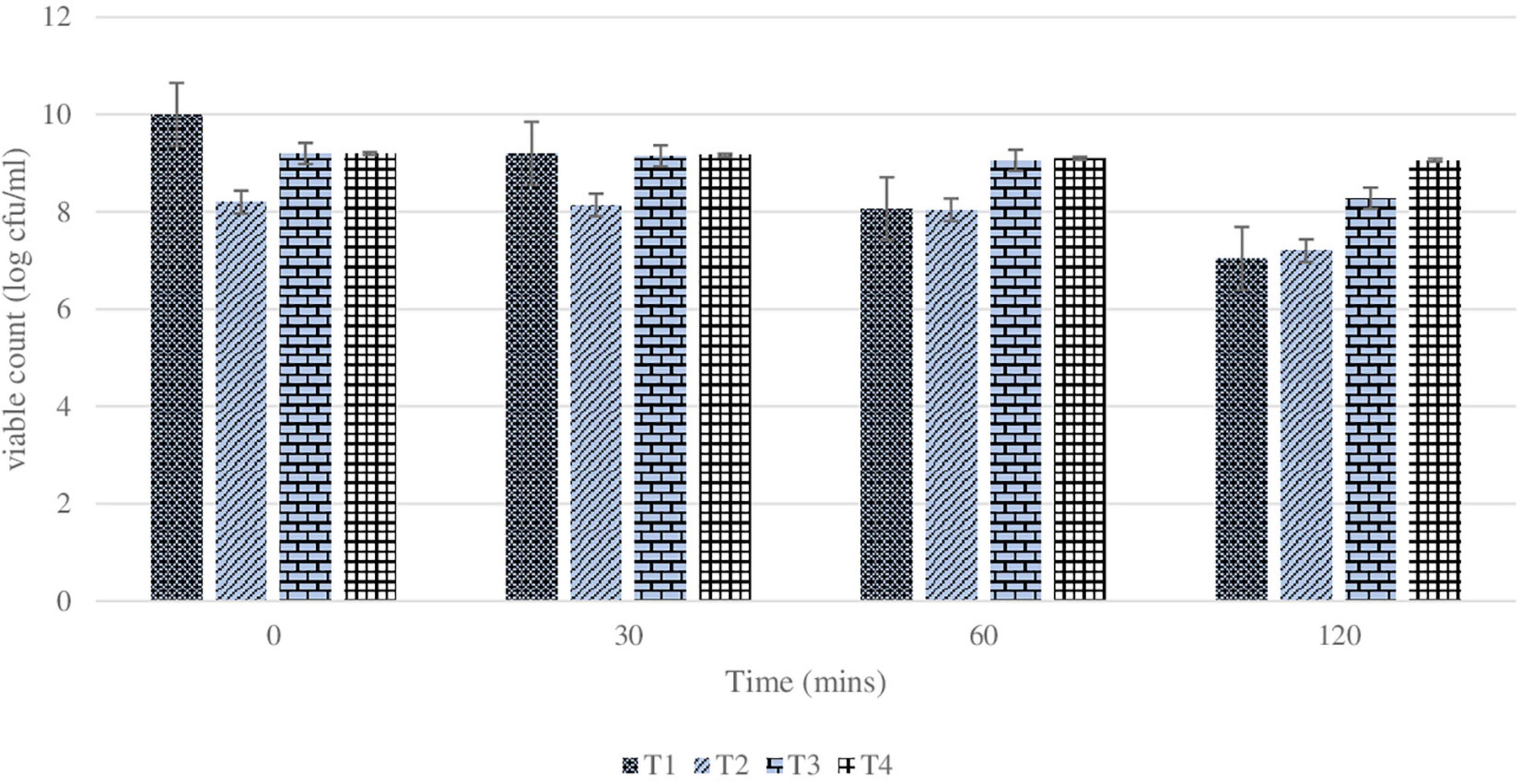

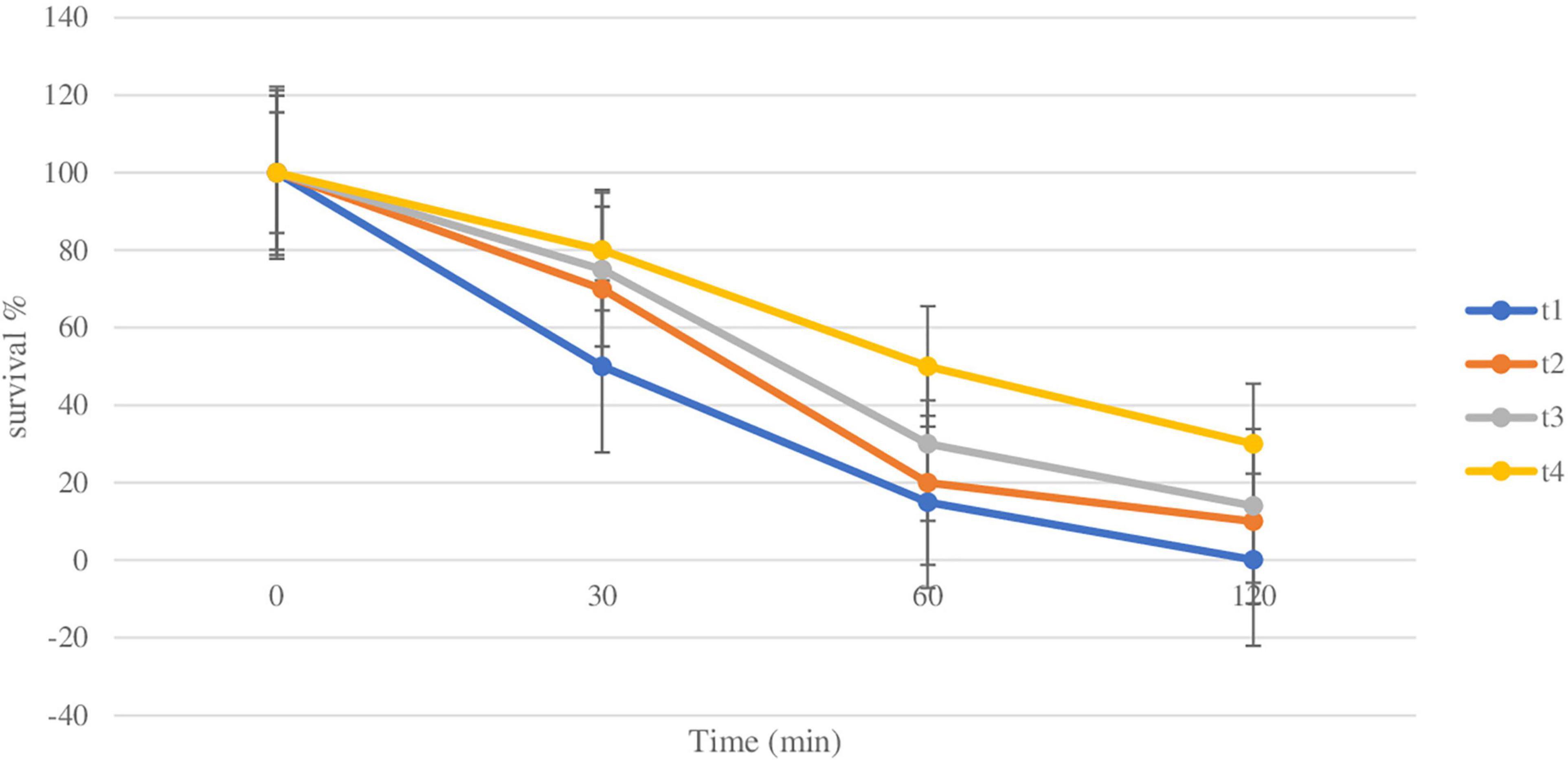

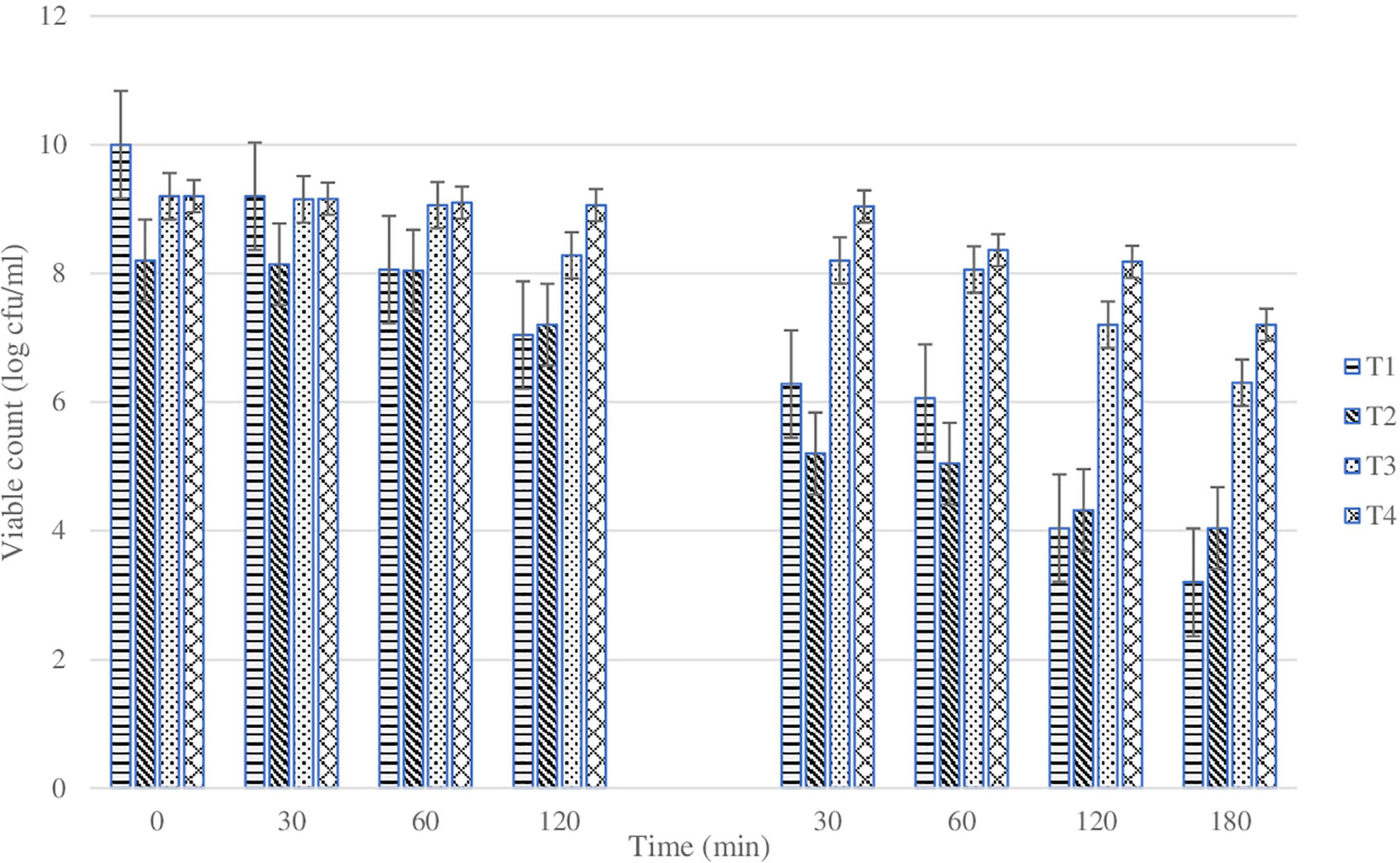

The main purpose of studying the survivability of plain and coated L. rhamnosus in SGF and SIF is to simulate the effect of low pH during transition through the GI tract. The effect of the coating of the L. rhamnosus on protection against SGF was tested by studying the differences in viability between plain and coated L. rhamnosus over varying time periods (30, 60, and 120 min). Since SGF treatment is carried out with fresh plain cells and BSP-based coated cells with inulin, alginate, and glucomannan, the initial cell counts of plain and coated cells were log 9.5 ± 0.5 and log 8.8 ± 0.6 cfu/ml, respectively, with survival rates of 50, 15, and 0.1%. As shown in Figure 3, the viability of plain L. rhamnosus was decreased to log 9.2, log 8.06, and log 7.04 cfu/ml, over 30, 60, and 120 min of exposure to SGF, respectively. While coating of L. rhamnosus with BSP and glucomannan showed better results, the viability reduced to log 8.14, log 8.04, and log 7.2 cfu/ml with survival rates of 70, 20, and 10%, respectively, over the same time periods. On the other hand, using alginate and inulin as coating materials with BSP confers a higher protection against low pH. In BSP/alginate-coated cells, viability reduced to log 9.15, log 9.06, and log 8.28 cfu/ml, and the survival rates were 75, 30, and 14% after 30, 60, and 120 min, respectively. Also, higher readings were obtained, log 9.16, log 9.1, and log 9.06 cfu/ml with% survival of 80, 50, and 30% over same time period, respectively, when L. rhamnosus cells were coated with inulin in the polysaccharide layer. Survival rates for plain and coated L. rhamnosus under SGF are presented in Figure 4.

Figure 3. Changes in viability (cell count) of plain or coated L. rhamnosus cells after exposure to simulated gastric fluids for 30, 60, and 120 min. Tl: plain L. rhamnosus, T2: coated cells with BSP/Glucomannan, T3: coated cells with ESP/Alginate and T4:coated cells with BSP/Inulin.

Figure 4. Survival rate of plain and coated L. rhamnosus under simulated gastric fluids after 30, 60, and 120 min. Tl: plain L. rhamnosus, T2: coated cells with BSP/Glucomannan, T3: coated cells with BSP/alginate and T4: Coated cells with BSP/inulin.

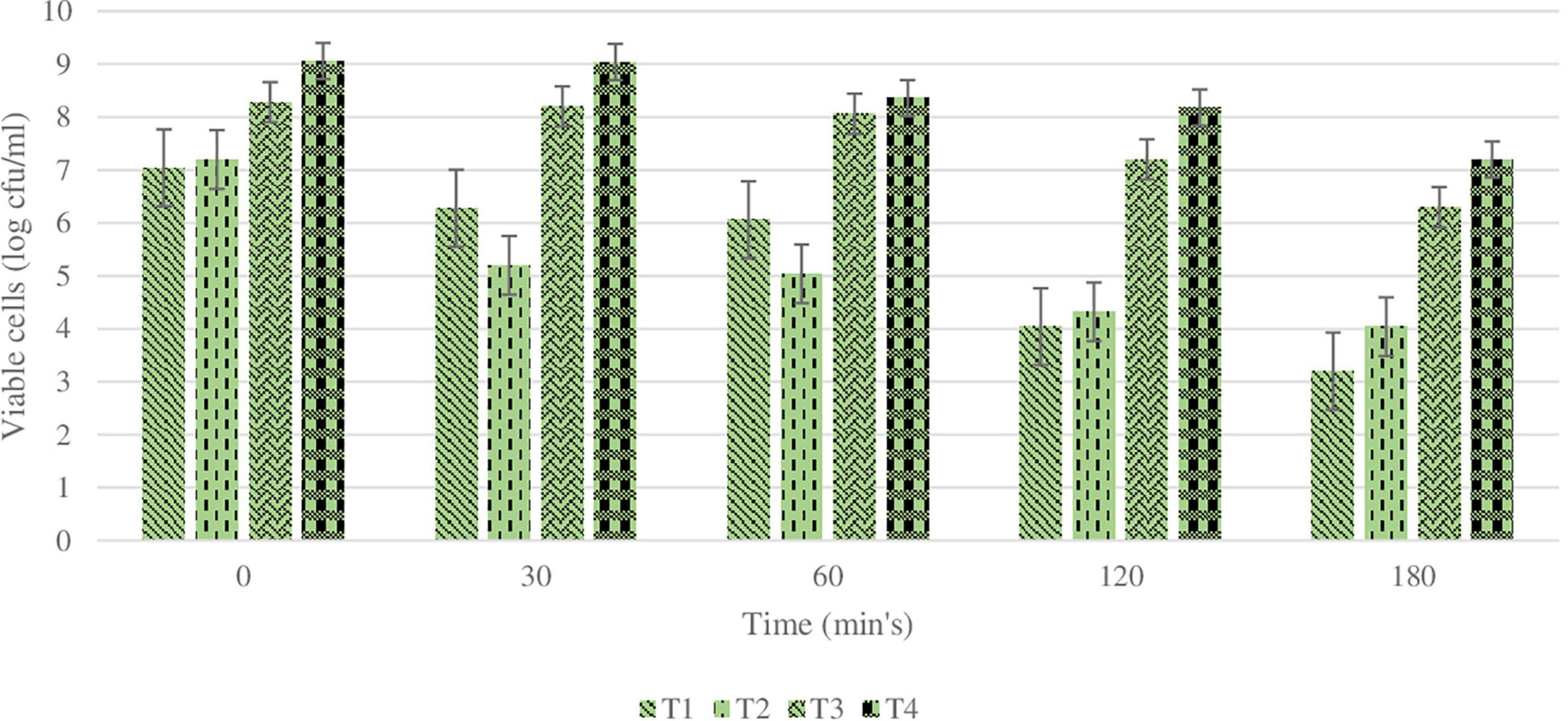

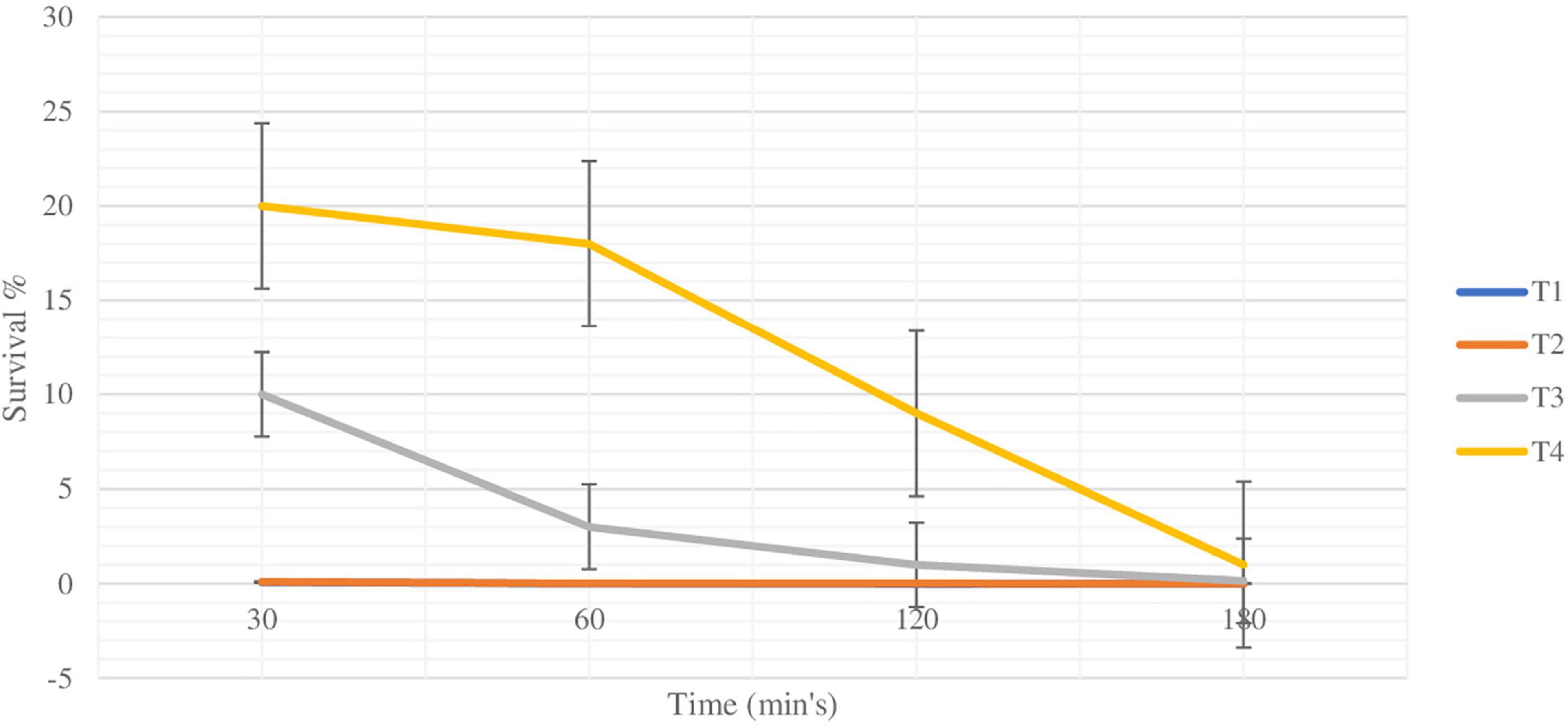

Since the major constituent of SIF is bile salts, the survivability of plain and coated L. rhamnosus in bile salts was assessed over varying time periods (30, 60, 120, and 180 min). As shown in Figure 5, in the presence of bile salts, the viability of the plain cells was reduced to log 6.28 l, log 6.06, log 4.04, and log 3.2 cfu/ml after 30, 60, 120, and 180 min respectively, with survival rates of 0.07%, 0.015%, 1 × 10–4%, and 5 × 10–5%. Over the same time periods, the viability of coated cells with BSP and glucomannan was reduced from log 7.2 to log 5.2, log 5.04, log 4.32, and log 4.04 cfu/ml, respectively, with survival rates of 0.1, 0.02, 0.016, and 0.002%. However, the resistance of cells coated with BSP/ALG or inulin showed higher results under the same conditions, while the BSP and ALG-coated L. rhamnosus’s viability reduced to log 8.2, log 8.06, log 7.2, and log 6.3 cfu/ml after 30, 60, 120, and 180 min, respectively, with survival rates of 10, 3, 1, and 0.15%. The viability of cells coated with BSP and inulin decreased from log 9.06 to log 9.04, log 8.36, log 8.18, and log 7.2 cfu/ml, and the survival rates were 20, 18, 9, and 1%, respectively, over the same time periods. Survival rates for plain and coated L. rhamnosus under SIF are presented in Figure 6.

Figure 5. Changes in viability (cell count) of plain or coated L. rhamnosus cells after exposure to simulated intestinal fluids for 30, 60, 120, and 180 min. Tl : plain L. rhamnosus, T2: coated cells with BSP/Glucomannan, T3: coated cells with BSP/Alginate and T4:coated cells with BSP/Inulin.

Figure 6. Survival rate of plain and coated L. rhamnosus under simulated intestinal fluids after 30, 60 120 and 180 min. Tl: plain L. rhamnosus, T2:coated cells with BSP/Glucomannan, T3: coated cells with ESP/alginate and T4: coated cells with BSP/inulin.

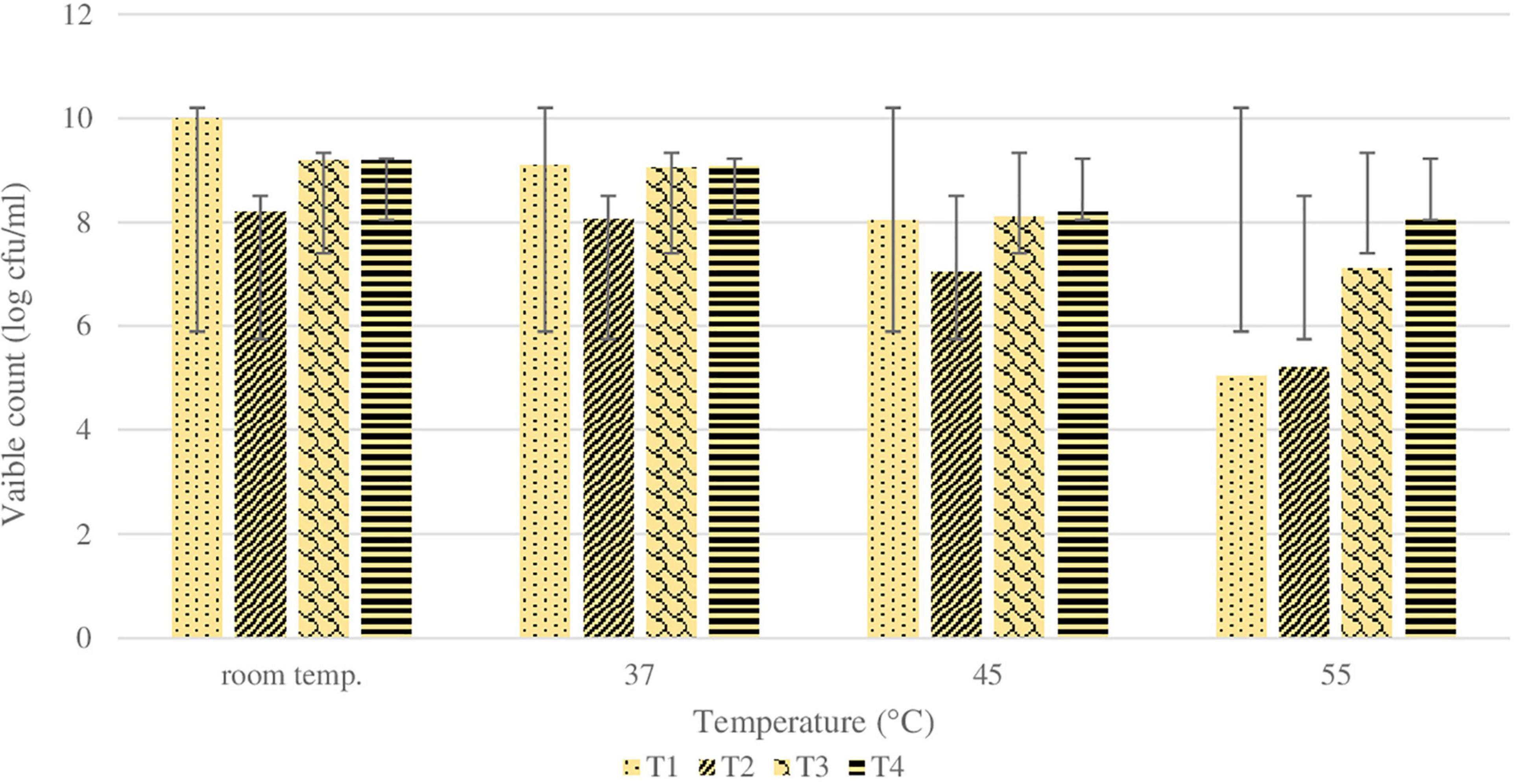

As mentioned previously, the initial count of 1 ml of plain L. rhamnosus was log 9.5 ± 0.5 cfu/gm. As shown in Figure 7, the cell count of coated cells with BSP and different types of polysaccharides (glucomannan, alginate, and inulin) were log 8.0, log 9.2, and log 9.2 cfu/g, respectively. After exposure of all samples to different heating temperatures of 37, 45, and 55°C for 30 min, the viability of both coated and plain L. rhamnosus was decreased differently.

Figure 7. Changes in viability (cell count) of plain or coated L. rhamnosus cells after exposure to different temperature; room temperature, 37, 45 and 55°C for 30 min. Tl : plain L. rhamnosus, T2: coated cells with BSP/Glucomannan, T3: coated cells with BSP/Alginate and T4:coated cells with BSP/Inulin.

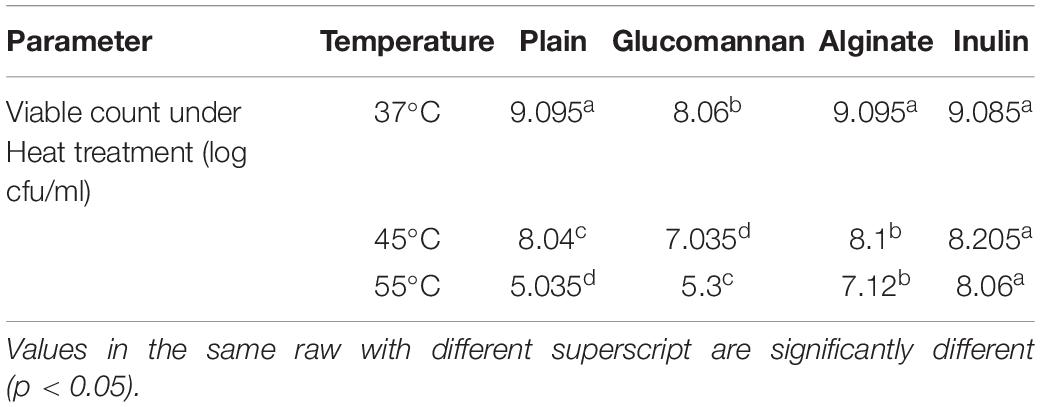

Generally, LbL coating of cells showed higher survivals compared with plain cells. Particularly, survival (%) of plain L. rhamnosus was 25, 1, and 0.001% at 37, 45, and 55°C, respectively. Under the same temperatures, the cells coated with BSP and glucomannan showed 30, 2, and 0.1% survival at 37, 45, and 55°C, respectively. Moreover, the presence of alginate or inulin revealed a higher tolerance against heating temperatures. For BSP and alginate-coated L. rhamnosus, the survivability reduced to 30, 5, and 0.6%, while results for BSP and inulin-coated L. rhamnosus were 40, 10, and 3% at 37, 45, and 55°C, respectively. The statistical analysis results for sequential exposure to SGF and SIF are presented in Figure 8, which clearly shows that there was a huge reduction in the viability of plain L. rhamnosus when exposed sequentially to SGF and bile salts. The viability of plain cells was reduced almost by log 6 cfu/ml along the process, as previously described, while variations in viability reduction were shown depending on the polysaccharide incorporated. There were significant differences (p < 0.05) between treatments under sequential SGF and SIF compared with plain cells, in addition to significant differences (p < 0.05) observed between coating treatments.

Figure 8. Changes in viability (cell count) of plain or coated L. rhamnosus cells after exposure to sequential gastric conditions for 30, 60, and 120 min. Tl: plain L. rhamnosus, T2: coated cells with BSP/Glucomannan, T3: coated cells with BSP/Alginate and T4:coated cells with BSP/Inulin.

Moreover, the significant differences obtained by statistical analysis of viable count of plain and coated cells when exposed to different heating temperatures are presented in Table 2. There were differences that existed between coating treatments and plain cells, in addition to differences between the coating treatments.

Table 2. Viable count of L. rhamnosus (mean log cfu/ml) when exposed to different heating temperatures for 30 min.

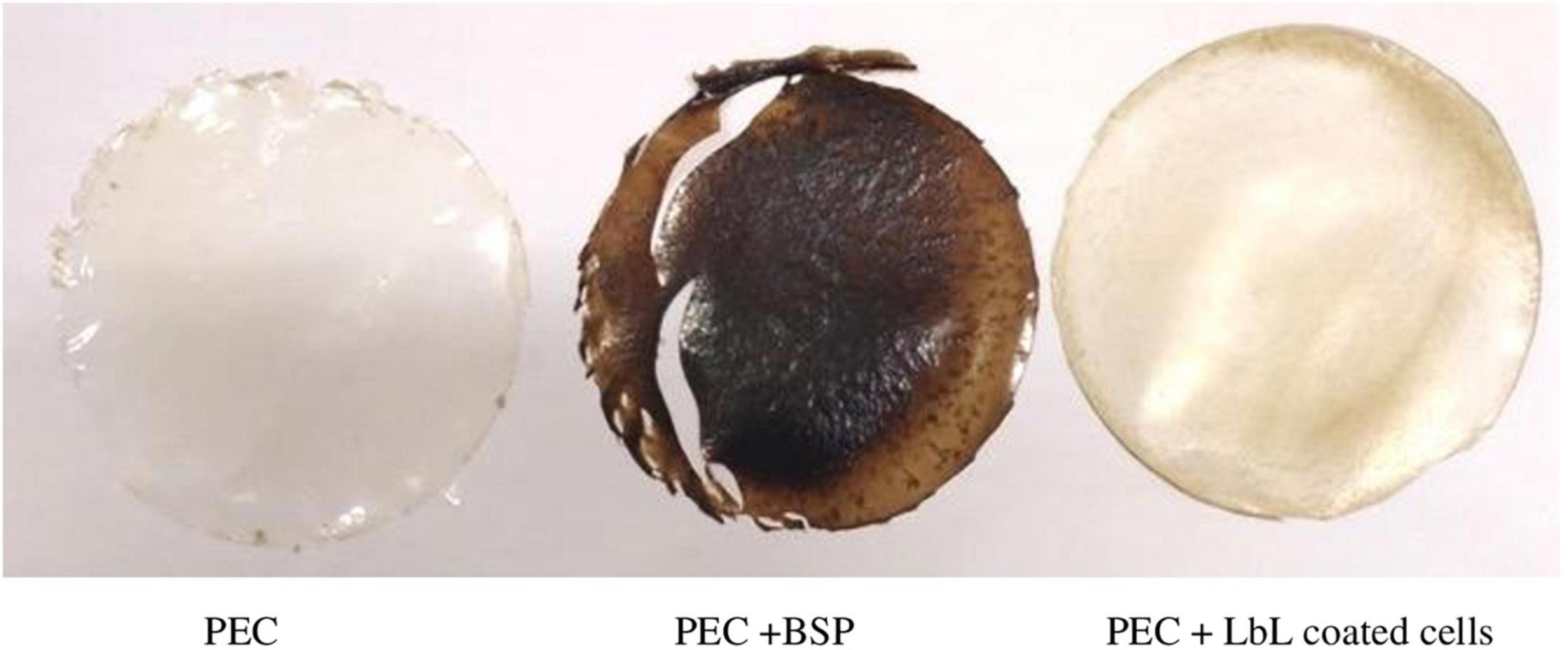

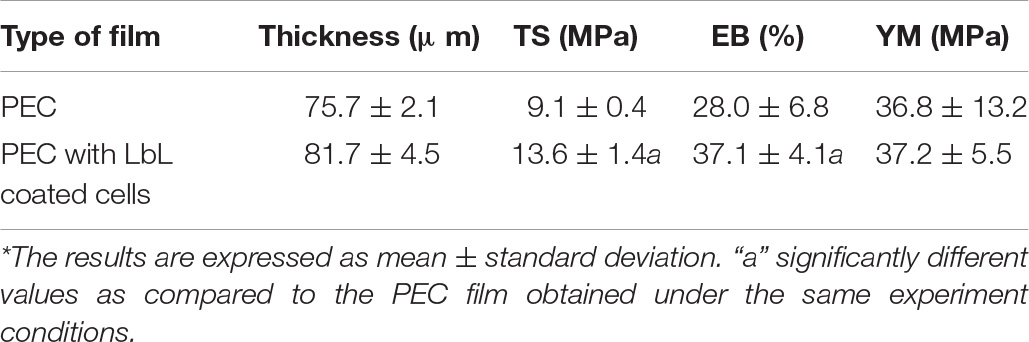

On the other hand, Figure 9 shows the three types of films prepared with or without LbL-coated cells. The results showed that the film containing BSP only was brittle, whereas film containing LbL had good handling properties. Moreover, the results reported in Table 3 indicate that the PEC film containing LbL showed higher thickness and YM values although not significant, while the TS (9.1 ± 0.4 and 13.6 ± 1.4 MPa, for PEC and PEC with LbL-coated cells, respectively) and EB (28.0 ± 6.8% and 37.1 ± 4.1% for PEC and PEC with LbL-coated cells, respectively) values were significantly higher compared with the control film obtained with PEC alone.

Figure 9. Images of pectin films (plain = PEC), with (BSP) or with LbL coated L. rhamnosus. cells were coated with BPS/inulin then used as part of pectin film. LbL containing film was superior over PEC+BSP in terms of handling and brittleness.

Table 3. Effect of incorporation of LbL microencapsulated L. rhamnosus on PEC film thickness and mechanical properties*.

The method used here showed high production of protein from black seed cake. Such high percentage is needed to make sure that the layer will be positively charged, as other impurities may interfere with this property.

Viability of commercial probiotics under the GI conditions was reported to be low (Millette et al., 2013). The effect of LbL coating on the viability of single-cell probiotics and its protective properties against harsh conditions are still under study and not hugely investigated. There were only a few studies regarding this method in the last 10 years. No single study, as far as we know, has investigated the use of the food industry byproducts as LbL coating materials for probiotics.

Generally, all studies previously published approved the positive effect of coating on the protection of probiotics in bacteria and yeast. Particularly, the LbL approach also enhanced the viability of probiotics under harsh conditions. The newest study, as far as we know, was made by Xiao et al. (2020) and published at the beginning of 2020. They investigated the effect of coating of L. bulgaricus and L. paracasei with whey protein isolate and xanthan gum using the LbL technique. The results revealed an increase in survivability and significant decrease in mortality under simulated GI fluids of coated cells compared with plain cells. In addition to higher tolerance to heating reductions have been recorded for coated cells at the same temperature. The same findings were supported temperatures, while 6 log reductions have been obtained when plain cells were exposed to 75°C, only 3 log previously by others (Priya et al., 2011; Cook et al., 2013; Thomas et al., 2014; Wang et al., 2019).

In LbL coating, the role of ionic interaction is essential to get better results. BSP is a positively charged polymer, which can easily form polyelectrolyte complexes with negatively charged polymers including alginate and inulin. Coating, in general, with proteins has a positive effect on the protection of probiotics under gastric conditions, pH 2 and 37°C (Picot and Lacroix, 2004; Gbassi et al., 2009; Doherty et al., 2011; Gerez et al., 2012; Maciel et al., 2014; Chen et al., 2017; De Araújo Etchepare et al., 2020; Maleki et al., 2020). Specifically, reduction of 2.8–3.9 logs of coating Lactobacillus acidophilus La-14, depending on the number of coating layers under gastric conditions, has been obtained, while a 7-log reduction was observed in the case of free cells (De Araújo Etchepare et al., 2020). These results are consistent with that of Gbassi et al. (2009) who found that coating of alginate beads with whey protein significantly improved the survivability of probiotics under acidic pH. Maleki et al. (2020) worked on mixing different encapsulating agents, whey protein isolate, inulin, and crystalline nanocellulose, in different concentrations to investigate the effect on protecting Lactobacillus rhamnosus ATCC 7469. They adduced that a higher WPI concentration mixture conferred a higher protection against simulated gastric conditions.

Alginate is the most widespread negative-charged polysaccharidein microencapsulation research and applications. The importance of alginate is linked to gelation, viscosity, and stabilizing properties, that alginate attributes to the product in which it is used.

On the other hand, the hydrophilicity of alginate may be partially disadvantageous; usage of high molecular-weighed alginate leads to undesirable properties related to viscosity in some products. The LbL technique has proven its ability to overcome this problem by using the minimum quantity of polysaccharides rather than use it as a core material.

Probiotic cells that are coated with only an alginate layer exhibit a higher releasing rate at acidic pH. This is explained by the higher porosity of alginate that has not been treated or coated with other coating material (Chávarri et al., 2010; De Araújo Etchepare et al., 2020). Dehkordi et al. (2020) reported that the survivability of L. acidophilus was 40% higher when the alginates are bead coated with whey protein isolate. In the current study, the alginate incorporation showed a better protection against harsh conditions and heating than the glucomannan did.

Indeed, incorporation of alginate as a coating material of L. rhamnosus showed a no significant reduction compared with plain L. rhamnosus after 30 min of SGF. However, a significant difference (p < 0.05) appeared after 60 min and continued to the end of the SIF process. However, it has a weaker effect compared with inulin, which was acting as alginate until 120 min of SGF; then the significant difference (p < 0.05) appeared with alginate-coated L. rhamnosus until the end of the GI simulation process.

Inulin is a negatively charged non-digestible polysaccharide, which is considered as a prebiotic, that selectively stimulates the growth and activity of probiotics in the colon. The addition of prebiotics significantly provided a better protection with only 3.1 and 2.9 log reduction for L. acidophilus 5 and L. casei 01, respectively, after incubation in simulated gastric juice at pH 1.55 (Krasaekoopt and Watcharapoka, 2014). In the same context, a significant improvement was reported in the viability of L. casei and B. bifidum when the capsules contained prebiotics, such as inulin (Zanjani et al., 2014) and L. lactis encapsulated with alginate and prebiotics (Persian gum), as reported by Nami et al. (2020).

According to Gandomi et al. (2016), incorporation of chitosan–alginate beads with inulin showed significantly (p < 0.05) an additional positive effect in the protection of L. rhamnosus against stringent conditions. Furthermore, the cooperation of inulin with WPI has provided a positive effect on the viability of Lactobacillus rhamnosus ATCC 7469 (Maleki et al., 2020). In the current research, incorporation of inulin as a coating layer beside BSP enhanced significantly the survivability of L. rhamnosus under acidic pH and bile salts as described earlier.

Glucomannan is a natural, water-soluble polysaccharide, which is considered an important component for the food industry, biopharmaceuticals, chemical industries, and other fields associated with human health. However, as shown in the results, the effectiveness of glucomannan on viability under low pH and bile salts was the lowest, owing to its non-ionic nature. These findings were partially in agreement with those of Nualkaekul et al. (2013), who observed the disability of glucomannan to protect alginate beads or improve cell survivability, while in the present study, it has affected positively the survivability but not as well as the other coating polysaccharides. The viability of glucomannan-coated L. rhamnosus was, surprisingly, lower than plain L. rhamnosus during the first 60 min under SIF. Then a significant difference (p < 0.05) was noted after 180 min of the simulation process.

When the plain and coated L. rhamnosus were exposed to different heating temperatures, the effect of temperature has significantly (p < 0.05) decreased viability as shown previously in Table 2. This may relate to the crucial differences in mechanism of protection of each polysaccharide, where glucomannan has a non-ionic nature leading to poor protection, alginate reduces the porosity of the surface, and inulin provides prebiotic activity, enhances the recovery of injured cells, and reduces the porosity.

The obtained mechanical values of PEC film results were in agreement with those of Jantrawut et al. (2017), who found that using 30% GLY with low methylated pectin resulted in a TS of about 5.0 MPa, EB of about 28.0%, and YM value of about 19.0 MPa. In our experiment, TS was increased from 9.1 ± 0.4 to 13.6 ± 1.4 MPa when LbL was incorporated to PEC at pH 7.0. This increase was partly due to the interaction of LbL with PEC polymers (Amor et al., 2021). Finally, production of functionally edible films containing LbL-coated probiotics, such as L. rhamnosus, was successfully achieved with promising properties for food or pharmaceutical applications.

In summary, coating of probiotic strain L. rhamnosus was successfully performed using the layer-by-layer technique with BSP extracted from Nigella sativa defatted seed cakes and different types of polysaccharides (glucomannan, alginate, and inulin). In comparison with plain L. rhamnosus, coating materials have shown significant improvement against sequential exposure to SGF and also when exposed to high temperatures that may represent storing conditions.

A. These findings support that layer-by-layer is a promising technique to maintain high viable count of probiotics through hosts’ GI.

B. Indeed, the polysaccharides used as coating materials affect differently how the probiotics act under the GI conditions. While glucomannan showed the weakest protection, inulin confers the highest protection, significantly.

C. Incorporating LbL-coated cells in an edible film is a promising application that can be used in a variety of food products.

In future studies, the effect of LbL coating of probiotics on adhesion to mucosal lining of the colon and further effect on the gut microbiota are warranted. In addition, more investigations are needed on the coating of probiotic cells with the LbL approach using different coating materials, preferably materials extracted from industrial wastes to reduce the burden on the environment.

Moreover, application of coated cells by LbL technology in food processing, including highly consumed items, such as bread, meat products, fruits, and vegetable-based products, and special-need products like vegan milk, gluten-free, and lactose-free products, with different probiotics strains and coatings is highly recommended.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author/s.

MSb conducted the experiment. MA and GM contributed to the concept design, designed the laboratory work, and approved the writing of the final manuscript. MS contributed to the experiment, discussion, and final writing. All authors contributed to the article and approved the submitted version.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

We would like to thank the lab instructors at the Faculty of Agriculture and Vet Medicine for their help and support.

LbL, layer-by-layer; BSP, black seed protein; NsDSC, Nigella sativa defatted seed cakes; SGF, simulated gastric fluid; SIF, simulated intestinal fluid; IBD, inflammatory bowel diseases; TGase, mTrans-glutaminase; BCA, bicinchoninic acid; IN, inulin; ALG, alginate; GLU, glucomannan.

Alkekhia, D., Hammond, P. T., and Shukla, A. (2020). layer-by-layer biomaterials for drug delivery. Annu. Rev. Biomed. Eng. 22, 1–24. doi: 10.1146/annurev-bioeng-060418-052350

Amor, G., Sabbah, M., Caputo, L., Idbella, M., De Feo, V., Porta, R., et al. (2021). Basil essential oil: composition, antimicrobial properties, and microencapsulation to produce active chitosan films for food packaging. Foods (Basel, Switzerland) 10:121. doi: 10.3390/foods10010121

Anselmo, A. C., McHugh, K. J., Webster, J., Langer, R., and Jaklenec, A. (2016). Layer-by-layer encapsulation of probiotics for delivery to the microbiome. Adv. Mat. 28, 9486–9490.

Baral, K. C., Bajracharya, R., Lee, S. H., and Han, H. K. (2021). Advancements in the pharmaceutical applications of probiotics: dosage forms and formulation technology. Int. J. Nanomed. 16, 7535–7556. doi: 10.2147/IJN.S337427

Bhattacharya, R., Gupta, A. M., Mitra, S., Mandal, S., and Biswas, S. R. (2021). A natural food preservative peptide nisin can interact with the SARSCoV-2 spike protein receptor human ACE2. Virology 552, 107–111. doi: 10.1016/j.virol.2020.10.002

Călinoiu, L. F., Ştefănescu, B. E., Pop, I. D., Muntean, L., and Vodnar, D. C. (2019). Chitosan coating applications in probiotic microencapsulation. Coatings 9:194. doi: 10.3390/coatings9030194

Capurso, L. (2019). Thirty years of Lactobacillus rhamnosus: a review. J. Clin. Gastroenterol. 53, S1–S41. doi: 10.1097/MCG.0000000000001170

Chávarri, M., Marañón, I., Ares, R., Ibáñez, F. C., Marzo, F., and del Carmen, et al. (2010). Microencapsulation of a probiotic and prebiotic in alginate-chitosan capsules improves survival in simulated gastro-intestinal conditions. Int. J. Food Microbiol. 142, 185–189. doi: 10.1016/j.ijfoodmicro.2010.06.022

Chen, H. Y., Li, X. Y., Liu, B. J., and Meng, X. H. (2017). Microencapsulation of Lactobacillus bulgaricus and survival assays under simulated gastrointestinal conditions. J. Funct. Foods 29, 248–255. doi: 10.1016/j.jff.2016.12.015

Cook, M. T., Tzortzis, G., Khutoryanskiy, V. V., and Charalampopoulos, D. (2013). Layer-by-layer coating of alginate matrices with chitosan-alginate for the improved survival and targeted delivery of probiotic bacteria after oral administration. J. Mater. Chem. B 1, 52–60. doi: 10.1039/C2TB00126H

De Araújo Etchepare, M., Nunes, G. L., Nicoloso, B. R., Barin, J. S., Flores, E. M. M., de Oliveira Mello, R., et al. (2020). Improvement of the viability of encapsulated probiotics using whey proteins. LWT 117:108601. doi: 10.1016/j.lwt.2019.108601

Dehkordi, S. S., Alemzadeh, I., Vaziri, A. S., and Vossoughi, A. (2020). Optimization of alginate-whey protein isolate microcapsules for survivability and release behavior of probiotic bacteria. Appl. Biochem. Biotechnol. 190, 182–196. doi: 10.1007/s12010-019-03071-5

Dimidi, E., Cox, S. R., Rossi, M., and Whelan, K. (2019). Fermented foods: definitions and characteristics, impact on the gut microbiota and effects on gastrointestinal health and disease. Nutrients 11:1806. doi: 10.3390/nu11081806

Doherty, S. B., Gee, V. L., Ross, R. P., Stanton, C., Fitzgerald, G. F., and Brodkorb, A. (2011). Development and characterisation of whey protein micro-beads as potential matrices for probiotic protection. Food Hydrocolloids 25, 1604–1617. doi: 10.1016/j.foodhyd.2010.12.012

FAO/WHO (2001). Evaluation of Health and Nutritional Properties of Powder Milk and Live Lactic Acid Bacteria. Córdoba: Report from FAO/WHO Expert Consultation, 1–4.

Fenster, K., Freeburg, B., Hollard, C., Wong, C., Rønhave Laursen, R., and Ouwehand, A. C. (2019). The production and delivery of probiotics: a review of a practical approach. Microorganisms 7:83. doi: 10.3390/microorganisms7030083

Gandomi, H., Abbaszadeh, S., Misaghi, A., Bokaie, S., and Noori, N. (2016). Effect of chitosan-alginate encapsulation with inulin on survival of Lacticaseibacillus rhamnosus during apple juice storage and under simulated gastrointestinal conditions. LWT-Food Sci. Technol. 69, 365–371. doi: 10.1016/j.lwt.2016.01.064

Gbassi, G. K., Vandamme, T., Ennahar, S., and Marchioni, E. (2009). Microencapsulation of Lactobacillus plantarum spp in an alginate matrix coated with whey proteins. Int. J. Food Microbiol. 129, 103–105. doi: 10.1016/j.ijfoodmicro.2008.11.012

Gerez, C. L., Font, de Valdez, G., Gigante, M. L., and Grosso, C. R. F. (2012). Whey protein coating bead improves the survival of the probiotic Lactobacillus rhamnosus CRL 1505 to low pH. Lett. Appl. Microbiol. 54, 552–556. doi: 10.1111/j.1472-765X.2012.03247.x

Giosafatto, C. V. L., Sabbah, M., Al-Asmar, A., Esposito, M., Sanchez, A., Villalonga- Santana, R., et al. (2019). Eeffct of mesoporous silica nanoparticles on glycerol plasticized anionic and cationic polysaccharide edible films. Coatings 9, 172–182. doi: 10.3390/coatings9030172

Grand View Research (2021). Global Probiotic Market. Available online at: https://www.grandviewresearch.com/press-release/global-probiotics-market# [accessed November 8, 2021].

Hill, C., Guarner, F., Reid, G., Gibson, G. R., Merenstein, D. J., Pot, B., et al. (2014). The international scientific association for probiotics and prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat. Rev. Gastroenterol. Hepatol. 11, 506–514. doi: 10.1038/nrgastro.2014.66

Ivanova, A., Ivanova, K., Tied, A., Heinze, T., and Tzanov, T. (2020). Layer-by-layer coating of aminocellulose and quorum quenching acylase on silver nanoparticles synergistically eradicate bacteria and their biofilms. Adv. Funct. Materials 30:2001284. doi: 10.1002/adfm.202001284

Jantrawut, P., Chaiwarit, T., Jantanasakulwong, K., Brachais, C. H., and Chambin, O. (2017). Effect of plasticizer type on tensile property and in vitro indomethacin release of thin films based on Low-Methoxyl pectin. Polymers 9:289. doi: 10.3390/polym9070289

Jung, J., Cavender, G., Simonsen, J., and Zhao, Y. (2015). Investigation of the mechanisms of using metal complexation and cellulose nanofiber/sodium alginate layer-by-layer coating for retaining anthocyanin pigments in thermally processed blueberries in aqueous media. J. Agric. Food Chem. 63, 3031–3038. doi: 10.1021/acs.jafc.5b00616

Kechagia, M., Basoulis, D., Konstantopoulou, S., Dimitriadi, D., Gyftopoulou, K., Skarmoutsou, N., et al. (2013). Health benefits of probiotics: a review. ISRN Nutrition 2013:481651.

Krasaekoopt, W., and Watcharapoka, S. (2014). Effect of addition of inulin and galactooligosaccharide on the survival of microencapsulated probiotics in alginate beads coated with chitosan in simulated digestive system, yogurt and fruit juice. LWT-Food Sci. Technol. 57, 761–766. doi: 10.1016/j.lwt.2014.01.037

Li, C., Wang, C. L., Sun, Y., Li, A. L., Liu, F., and Meng, X. C. (2016). Microencapsulation of Lactobacillus rhamnosus by transglutaminase cross-linked soy protein isolate to improve survival in simulated gastrointestinal conditions and Yoghurt. J. Food Sci. 81, M1726–M1734. doi: 10.1111/1750-3841.13337

Maciel, G. M., Chaves, K. S., Grosso, C. R. F., and Gigante, M. L. (2014). Microencapsulation of Lactobacillus acidophilus La-5 by spray-drying using sweet whey and skim milk as encapsulating materials. J. Dairy Sci. 97, 1991–1998. doi: 10.3168/jds.2013-7463

Maleki, O., Khaledabad, M. A., Amiri, S., Asl, A. K., and Makouie, S. (2020). Microencapsulation of Lactobacillus rhamnosus ATCC 7469 in whey protein isolate-crystalline nanocellulose-inulin composite enhanced gastrointestinal survivability. LWT 126:109224. doi: 10.1016/j.lwt.2020.109224

Marais, A., Utsel, S., Gustafsson, E., and Wågberg, L. (2014). Towards a super-strainable paper using the layer-by-layer technique. Carbohydrate Polymers 100, 218–224. doi: 10.1016/j.carbpol.2013.03.049

Matsusaki, M., Ajiro, H., Kida, T., Serizawa, T., and Akashi, M. (2012). Layer-by-layer assembly through weak interactions and their biomedical applications. Adv. Materials 24, 454–474. doi: 10.1002/adma.201103698

Meng, J., Xiao, G., Zhang, J., He, X., Ou, M., Bi, J., et al. (2020). Renin-angiotensin system inhibitors improve the clinical outcomes of COVID-19 patients with hypertension. Emerg. Microbes Infect. 9, 757–760. doi: 10.1080/22221751.2020.1746200

Millette, M., Nguyen, A., Amine, K. M., and Lacroix, M. (2013). Gastrointestinal survival of bacteria in commercial probiotic products. Int. J. Probiotics Prebiotics 8:149.

Nami, Y., Lornezhad, G., Kiani, A., Abdullah, N., and Haghshenas, B. (2020). Alginate-Persian gum-prebiotics microencapsulation impacts on the survival rate of Lactococcus lactis ABRIINW-N19 in orange juice. LWT 124:109190. doi: 10.1016/j.lwt.2020.109190

Nualkaekul, S., Cook, M. T., Khutoryanskiy, V. V., and Charalampopoulos, D. (2013). Influence of encapsulation and coating materials on the survival of Lactobacillus plantarum and Bifidobacterium longum in fruit juices. Food Res. Int. 53, 304–311. doi: 10.1016/j.foodres.2013.04.019

Picot, A., and Lacroix, C. (2004). Encapsulation of bifidobacteria in whey protein-based microcapsules and survival in simulated gastrointestinal conditions and in yoghurt. Int. Dairy J. 14, 505–515. doi: 10.1016/j.idairyj.2003.10.008

Priya, A. J., Vijayalakshmi, S. P., and Raichur, A. M. (2011). Enhanced survival of probiotic Lactobacillus acidophilus by encapsulation with nanostructured polyelectrolyte layers through layer-by-layer approach. J. Agric. Food Chem. 59, 11838–11845. doi: 10.1021/jf203378s

Ram, M. K., Bertoncello, P., Ding, H., Paddeu, S., and Nicolini, C. (2001). Cholesterol biosensors prepared by layer-by-layer technique. Biosens. Bioelectron. 16, 849–856. doi: 10.1016/S0956-5663(01)00208-1

Sabbah, M., Altamimi, M., Di Pierro, P., Schiraldi, C., Cammarota, M., and Porta, R. (2020). Black edible films from protein-containing defatted cake of Nigella sativa seeds. Int. J. Mol. Sci. 21:832. doi: 10.3390/ijms21030832

Segers, M. E., and Lebeer, S. (2014). Towards a better understanding of Lacticaseibacillus rhamnosus-host interactions. Microbial Cell Factories 13:S7.

Shah, B. R., Li, B., Al Sabbah, H., Xu, W., and Mráz, J. (2020). Effects of prebiotic dietary fibers and probiotics on human health: with special focus on recent advancement in their encapsulated formulations. Trends Food Sci. Technol. 102, 178–192. doi: 10.1016/j.tifs.2020.06.010

Sniffen, J. C., McFarland, L. V., Evans, C. T., and Goldstein, E. J. C. (2018). Choosing an appropriate probiotic product for your patient: an evidence based practical guide. PLoS One 13:e0209205. doi: 10.1371/journal.pone.0209205

Thomas, M. B., Vaidyanathan, M., Radhakrishnan, K., and Raichur, A. M. (2014). Enhanced viability of probiotic Saccharomyces boulardii encapsulated by layer-by-layer approach in pH responsive chitosan-dextran sulfate polyelectrolytes. J. Food Eng. 136, 1–8. doi: 10.1016/j.jfoodeng.2014.03.015

Wang, M., Yang, J., Li, M., Wang, Y., Wu, H., Xiong, L., et al. (2019). Enhanced viability of layer-by-layer encapsulated Lactobacillus pentosus using chitosan and sodium phytate. Food Chem. 285, 260–265. doi: 10.1016/j.foodchem.2019.01.162

Xiao, Y., Han, C., Yang, H., Liu, M., Meng, X., and Liu, B. (2020). Layer (whey protein isolate) -by-layer (xanthan gum) microencapsulation enhances survivability of L. bulgaricus and L. paracasei under simulated gastrointestinal juice and thermal conditions. Int. J. Biol. Macromol. 148, 238–247. doi: 10.1016/j.ijbiomac.2020.01.113

Yaseen, D., Al-Asmar, A., Altamimi, M., Famiglietti, M., Giosafatto, C. V. L., et al. (2021). Functionality of films from Nigella sativa defatted seed cake proteins plasticized with grape juice: use in wrapping sweet cherries. Coatings 11:1383. doi: 10.3390/coatings11111383

Zanjani, M. A. K., Tarzi, B. G., Sharifan, A., and Mohammadi, N. (2014). Microencapsulation of probiotics by calcium alginate-gelatinized starch with chitosan coating and evaluation of survival in simulated human gastro-intestinal condition. Iranian J. Pharmaceutical Res: IJPR 13:843.

Zheng, J., Wittouck, S., Salvetti, E., Franz, C. M., Harris, H. M. B., Mattarelli, P., et al. (2020). A taxonomic note on the genus Lactobacillus: description of 23 novel genera, emended description of the genus Lactobacillus Beijerinck 1901, and union of Lactobacillaceae and Leuconostocaceae. Int. J. Syst. Evol. Microbiol. 70, 2782–2858. doi: 10.1099/ijsem.0.004107

Keywords: layer-by-layer, coating, probiotics, Lactobacillus rhamnosus, food waste protein

Citation: Sbehat M, Altamimi M, Sabbah M and Mauriello G (2022) Layer-by-Layer Coating of Single-Cell Lacticaseibacillus rhamnosus to Increase Viability Under Simulated Gastrointestinal Conditions and Use in Film Formation. Front. Microbiol. 13:838416. doi: 10.3389/fmicb.2022.838416

Received: 17 December 2021; Accepted: 21 February 2022;

Published: 04 May 2022.

Edited by:

Riadh Hammami, University of Ottawa, CanadaReviewed by:

Babak Haghshenas, Kermanshah University of Medical Sciences, IranCopyright © 2022 Sbehat, Altamimi, Sabbah and Mauriello. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mohammad Altamimi, bS5hbHRhbWltaUBuYWphaC5lZHU=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.