- 1Faculty of Medicine, Macau University of Science and Technology, Macau, Macau SAR, China

- 2Guangdong-Hong Kong-Macao Joint Laboratory for Contaminants Exposure and Health, School of Environmental Science and Engineering, Institute of Environmental Health and Pollution Control, Guangdong University of Technology, Guangzhou, China

- 3School of Pharmacy and Food Science, Zhuhai College of Science and Technology, Zhuhai, China

- 4Macau Uni-Win Biotechnology Co., Ltd, Macau, Macau SAR, China

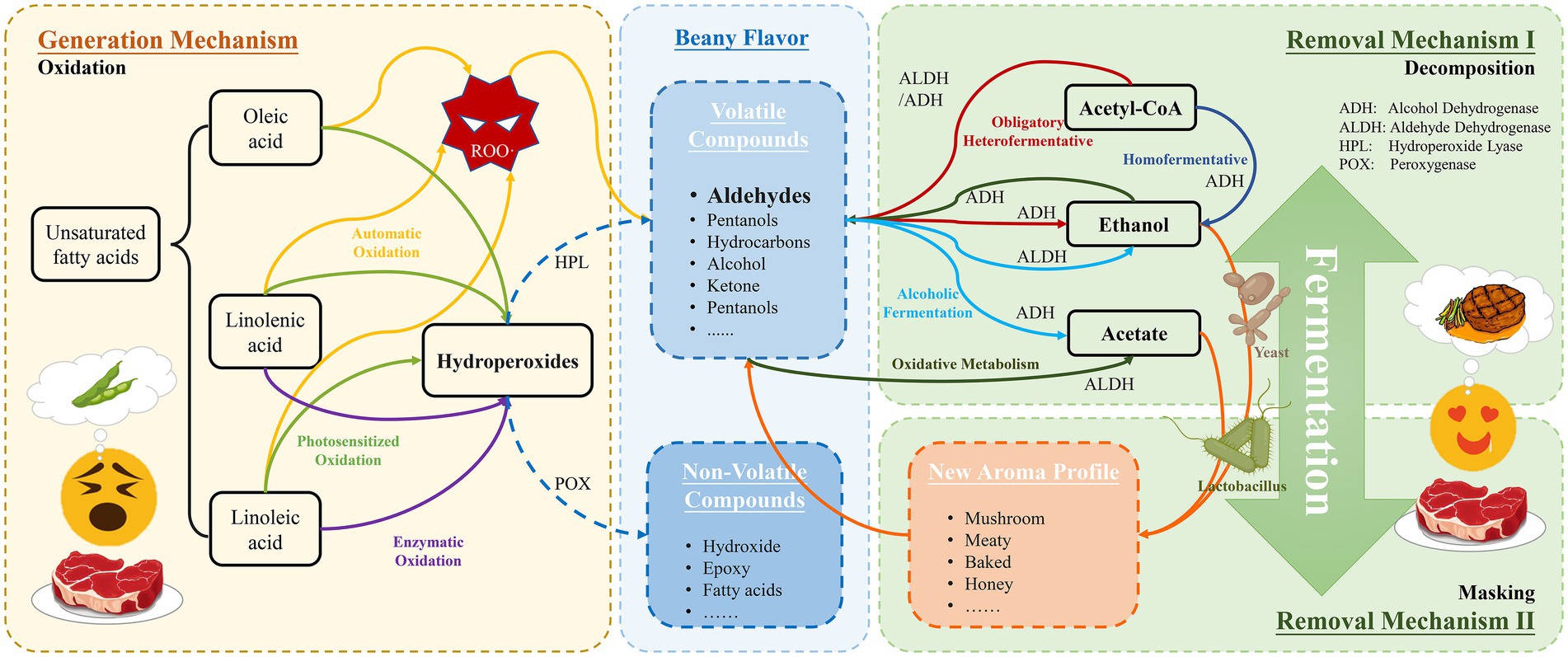

Over the past few decades, there has been a noticeable surge in the market of plant-based meat analogs (PBMA). Such popularity stems from their environmentally friendly production procedures as well as their positive health effects. In order to meet the market demand, it is necessary to look for plant protein processing techniques that can help them match the quality of conventional meat protein from the aspects of sensory, quality and functionality. Bean proteins are ideal options for PBMA with their easy accessibility, high nutrient-density and reasonable price. However, the high polyunsaturated lipids content of beans inevitably leads to the unpleasant beany flavor of soy protein products, which severely affects the promotion of soy protein-based PBMA. In order to solve this issue, various methods including bleaching, enzyme and fermentation etc. are developed. Among these, fermentation is widely investigated due to its high efficiency, less harm to the protein matrix, targeted performance and low budget. In addition, proper utilization of microbiome during the fermentation process not only reduces the unpleasant beany flavors, but also enhances the aroma profile of the final product. In this review, we provide a thorough and succinct overview of the mechanism underlying the formation and elimination of beany flavor with associated fermentation process. The pros and cons of typical fermentation technologies for removing beany flavors are discussed in alongside with their application scenarios. Additionally, the variations among different methods are compared in terms of the strains, fermentation condition, target functionality, matrix for application, sensory perception etc.

Introduction

The Food and Agriculture Organization of the United Nations estimates that in 2019, humans consumed about 3.25 million tons of meat; demand for meat is expected to increase by another 12% by 2029; and by 2050, demand for meat will increase by about 70%. If traditional meat production and management patterns remain unchanged, an additional 30%–50% of the land will be needed for livestock and meat production by then (Chen et al., 2019). Moreover, such situation of undersupply can be further intensified by natural disasters showing up every now and then. Animal diseases such as African swine fever and avian influenza in 2018 caused an increasing number of small and medium-sized livestock companies to exit the market. During the Coronavirus Disease 2019 (COVID-19) pandemic, the meat, poultry, and animal product processing plants were the sectors most affected, which leads to imbalance between global supply and demand for meat products (Chen and Yang, 2021). This situation has now triggered an increase in the price of traditional meat products. The global agriculture and meat industry is facing serious challenges considering factors such as increasing pressure on the natural environment, population growth, consumer trends in health and environmental protection, and food innovation (Kumar et al., 2017). To relieve the supply pressure of meat products, the development of plant-based meat analogs (PBMA) can be an effective way to address the imbalance between meat production and consumption (Taufik et al., 2019; Sun et al., 2022).

Recent PBMA research and development has been focusing on utilizing raw materials such as soy and pea proteins to mimic the flavor, smell, appearance and texture of traditional meats. It is beneficial for the whole mankind not only in terms of promoting a sustainable development, but also from a nutrition aspect (Kyriakopoulou et al., 2021). Compared to traditional meat, the energy, land, and water consumption of plant-based meat is much lowered. That is why this new star can effectively mitigate carbon emissions and moderate global environmental change (Pimentel and Pimentel, 2003). Many epidemiological studies have shown that long-term meat consumption, especially red and processed meats, increases the incidence of digestive cancer, cardiovascular disease and hypercholesterolemia (Cordelle et al., 2022). Conversely pieces of evidence support the health benefits of consuming a plant-based diet and increasing the intake of legumes. Significantly reduces the incidence of heart disease, high blood pressure, stroke, and type 2 diabetes (Polak et al., 2015).

Nevertheless, despite the many benefits of PBMA, their market share is still low at around 1% (Choudhury et al., 2020). The major bottleneck for developing ideal products which can cater the public lies in the texture as well as the taste. Other problems include high energy consumption of the production line, rough finished products and premature control technology. Currently, the key problem with the flavor of PBMA is that soy and pea proteins have an unpleasant beany-flavor which hinders consumer preference and acceptability (Mittermeier-Kleßinger et al., 2021). Flavorings are added during the production process to cover the off flavors as a current mainstream solution. However, the addition of extra seasonings may also have an impact on the overall taste and bring about adverse health issues for the consumers. Other methods to reduce the beany flavor include temperature control, enzyme treatment, acid–base treatment, supercritical CO2 extraction, new cultivars breeding, genetic engineering, etc. (Zhang et al., 2012). However, some of these methods have hidden risks for food safety and quality, while the high cost and extra energy consumption also bring about new problems (Kumari et al., 2015; Nedele et al., 2021; Korma et al., 2022). Therefore, searching for novel technology to remove beany off-flavors instead of covering them is significant to improve the overall taste and future development of PBMA (Sun et al., 2022).

Recently, through the effort of modern microbiologists, it is more and more revealed that fermentation using microorganisms can effectively remove the beany flavor from next-generation plant-based food products such as PBMA. Moreover, a new aromatic taste can be developed during the fermentation to mask or cover the beany flavor sometimes (Wang Z. et al., 2022). Other than that, fermentation has many additional benefits, such as adjusting the gut microbiota and remediating the detriment on the gut epithelium caused by food additives (Yu and Zuo, 2021). This review discusses the mechanism of the formation of beany odors, the mechanism of using fermentation to remove them, and the applications and the differences of various traditional and newly emerged techniques. In the end, summary and discussion are made about the possibilities to utilize and improve current fermentation technique to better develop our food for future signatured by PBMA.

The formation of beany flavor

Unsaturated fatty acids are the main cause of beany flavor formation in legume-based foods. The formation of off-flavor compounds usually results from the oxidation of unsaturated fatty acids and the hydrolysis of lipids (Jelen, 2011). Legume seeds contain a large amount of unsaturated fatty acids, the most abundant being oleic acid, linolenic acid, and linoleic acid (Khrisanapant et al., 2019). The oxidation mechanism generally consists of three categories: automatic oxidation, photo-oxidation, and enzymatic oxidation (Wang Y. Q. et al., 2022).

Automatic oxidation

As shown in the yellow route in Figure 1, automatic oxidation is a free radical chain reaction involving oxygen and unsaturated lipids (Wang Y. Q. et al., 2022). Principally, reactive singlet oxygen attacks H, forming α-methylene near the double bonds, thus forming alkyl radicals (R·). After that, further oxygen absorption leads to the formation of peroxyl radicals (ROO·) and hydrogen peroxide, which ends up with a wide range of volatile and non-volatile secondary products, odor compounds (Wang et al., 2021). Once the chain reaction starts, it is very difficult to be stopped. Therefore, preventing chain reaction initiation is the most effective way to control autoxidation.

Photosensitized oxidation

The left green route in Figure 1 displays the photosensitized oxidation, which differs from automatic oxidation in that during photosensitized oxidation, highly reactive singlet oxygen directly attacks the double bonds of unsaturated fatty acids, resulting in oxygen binding directly to the fatty acids in the formation of hydrogen peroxide. Singlet oxygen is more significant for photosensitized oxidation in the oxidation process than automatic oxidation (Hammond and White, 2011).

Enzymatic oxidation

As illustrated in the purple route in Figure 1, enzymatic oxidation is the main reason to produce most volatiles in legumes, which is the primary way in which off-flavor is generated. Lipoxygenase (LOX) is a major element of enzymatic oxidation (Roland et al., 2017). LOX belongs to the family of nonheme iron-containing enzymes that can effectively catalyze the deoxygenation of polyunsaturated fatty acids (PUFAs) such as linoleic acid (18:2) and linolenic acid (18:3), to produce hydroperoxyl derivative (Alhendi et al., 2018). Because oxidation reactions usually occur in specific regions and oxygen is generally bound within C9 and C13 (Gardner, 1991), Soy LOX isoenzymes are classified into three types: 9-, 13- and 9-/13-LOXs. For example, soy LOX-1 is a 13-LOX, LOX-2 is a 9-/13-LOX, and soy LOX-3 is a 9-LOX or 9-/13-LOX (Wang Y. Q. et al., 2022).

After the formation of hydrogen peroxide derivatives through three processes: automatic oxidation, photosensitized oxidation and enzymatic oxidation. As shown in Figure 1, the main volatile flavor compounds, and nonvolatile lipid oxidation products were produced through three different oxidation mechanisms (Roland et al., 2017; Zhang et al., 2020). Hydroperoxide lyase (HPL), alcohol dehydrogenase (ADH), and peroxygenase (POX) will further catalyze the generation of products and aggregation, resulting in beany flavor. Hydroperoxide lyase (HPL) reacts with hydroperoxyl derivative to form volatiles such as C6 aldehydes and C9 aldehydes, and in the presence of ADH, these aldehydes are reacted to the corresponding alcohols, such as alcohols and acids. And hydroperoxyl derivative forms non-volatile lipid oxidation products such as hydroxy, epoxy, and fatty acids in the presence of POX (Wang Y. Q. et al., 2022).

Therefore, in order to control the production of beany flavor, we have to control the oxidation and degradation of unsaturated fatty acids. In the automatic oxidation process, the concentration of oxygen is extremely important, the higher the concentration of oxygen, the faster the rate of automatic oxidation (Wang et al., 2021). On the contrary, in the photosensitized oxidation process, the oxygen concentration has little effect, and the number and distribution of unsaturated double bonds have a significant effect (Wang et al., 2020). And in the enzymatic reaction process, lox is its limiting factor (Roland et al., 2017; Wang et al., 2021).

The mechanism underlying the fermentation removal of beany off-flavor

There are currently two major types of methods to remove beany flavor from plants. The first way is to use enzymes to decompose the components that produce the beany flavor in plants and use enzymes to decompose the precursor substances of the plants that produce the beany flavor (Zhu and Damodaran, 2018; Fischer et al., 2022). The second way is to generate new aromatic profile which can mask the original beany flavor.

Direct decomposition of compounds with beany off-flavor

It was found that ADH and aldehyde dehydrogenase (ALDH) had the most obvious effect on the removal of beany flavor. Because the selection of compounds involved in the beany flavor included nine aldehydes, one furan, four alcohols, four ketones, three sulfides, and five pyrazines, the compound with the greatest effect on “beany” are aldehydes (Xu et al., 2020). ADH converts aldehydes to primary alcohols and ketones to secondary alcohols. ALDH converts aldehydes to carboxylic acids. Reduces beany flavor by converting odorous compounds (aldehydes and ketones) to less odorous products (alcohols and carboxylic acids; Shi et al., 2021).

As illustrated in the upper right of Figure 1, there are five main ways they remove the beany flavor: (a) The blue route illustrates the homofermentation: For the catabolism that occurs in this type of fermentation, ADH does not participate in basal metabolism, but plays a role in the mixed acid pathway. Such as Lactobacillus acidophilus and Streptococcus thermophiles (Shi et al., 2021). (b) Obligatory heterofermentative Lactic acid bacteria illustrated with the red route (LAB): such as L. fermentum. ADH is present in metabolism as a constitutive enzyme as well as an aldehyde/alcohol dehydrogenase (Ortakci et al., 2015; Verce et al., 2020). (c) Facultative heterofermentative LAB: Only the heterofermentative pathway is inducible. Such as L. plantarum. Its basic metabolism is the homofermentative pathway (Prückler et al., 2015). (d) Alcoholic fermentation illustrated with the cyan route: ADH and aldehyde dehydrogenase are present in the catabolism of the strain as constitutive enzymes. For example Saccharomyces cerevisiae (Mizuno et al., 2006). (e) Oxidative metabolism. “Oxidative fermentation” is the incomplete oxidation of substrates, carried by the dehydrogenases of the respiratory chain, resulting in the extracellular accumulation of oxidized products. The “oxidative system” is located in the cytoplasmic membrane and is connected to the respiratory chain, for example, Gluconobacter suboxydans (Deppenmeier and Ehrenreich, 2009; Lynch et al., 2019).

Breaking down beany flavor precursors in plants

Previous studies have indicated that the beany flavor in legumes is primarily the result of interactions between lipid oxidation products, proteins, and phytochemicals. Lipid-derived off-flavors are believed to be the main cause of beany flavor. Among them, the precursors of the flavor of legumes are mainly phospholipids (PLs) and free fatty acids (FFAs).

Phospholipase can be used to remove such precursors, among which the combined phospholipase A2 (PLA2) and cyclodextrin mixed with soybean meal in a water bath and it is found that the removal rate of phospholipids is more effective (Zhu and Damodaran, 2018).

In previous studies, it was found that the principle of removing beany flavor was mainly divided into two steps: hydrolyzing PLA 2 to decompose PL, and then removing the hydrolyzed product by forming an inclusion complex through β-cyclodextrin (β-CD). PLA2 selectively cleaves the ester bond of the acyl chain at the sn-2 position of PL and generates Lyso-PL and FFA. The product is a non-polar material. β-CD is a cyclic non-reducing oligosaccharide. Its special construction makes its inner cavity hydrophobic. β-CD and other cyclodextrins can form water-soluble inclusion complexes with insoluble non-polar substances. The water-soluble inclusion compound can be dissolved into the supernatant by a polar solvent such as deionized water, so as to achieve the effect of separation from soybean flour.

Additional studies have shown that after the application of Alcalase, papain or a combination of enzymes, the acidic subunits of β-conglycinin and glycinin disappear completely, resulting in the removal of some of the precursors of the beany flavor, thereby reducing the beany flavor (Meinlschmidt et al., 2016).

Odor masking and transformation

As shown in the low right of Figure 1, some strains can produce new aldehydes with aroma after fermentation while reducing the content of compounds with beany smell. In this way, the new aroma can mask the original beany smell to further enhance the total aroma profile of the product. For example, phenylacetaldehyde produced by fermentation of L. rhamose L08 can bring floral and honey-like aromas (Pei et al., 2022). And the main contributors to the aroma profile of A. aegerita fermented soy beverages remain soy-derived compounds. At the same time, ethyl esters and lactones were produced during fermentation, which resulted in increased fruity, floral, and creamy/dairy aromas present in cheese aromas and altered the overall aroma of the samples (Nedele et al., 2022a). Other scents include milky, nutty, and more.

Application of microorganisms to remove beany flavor

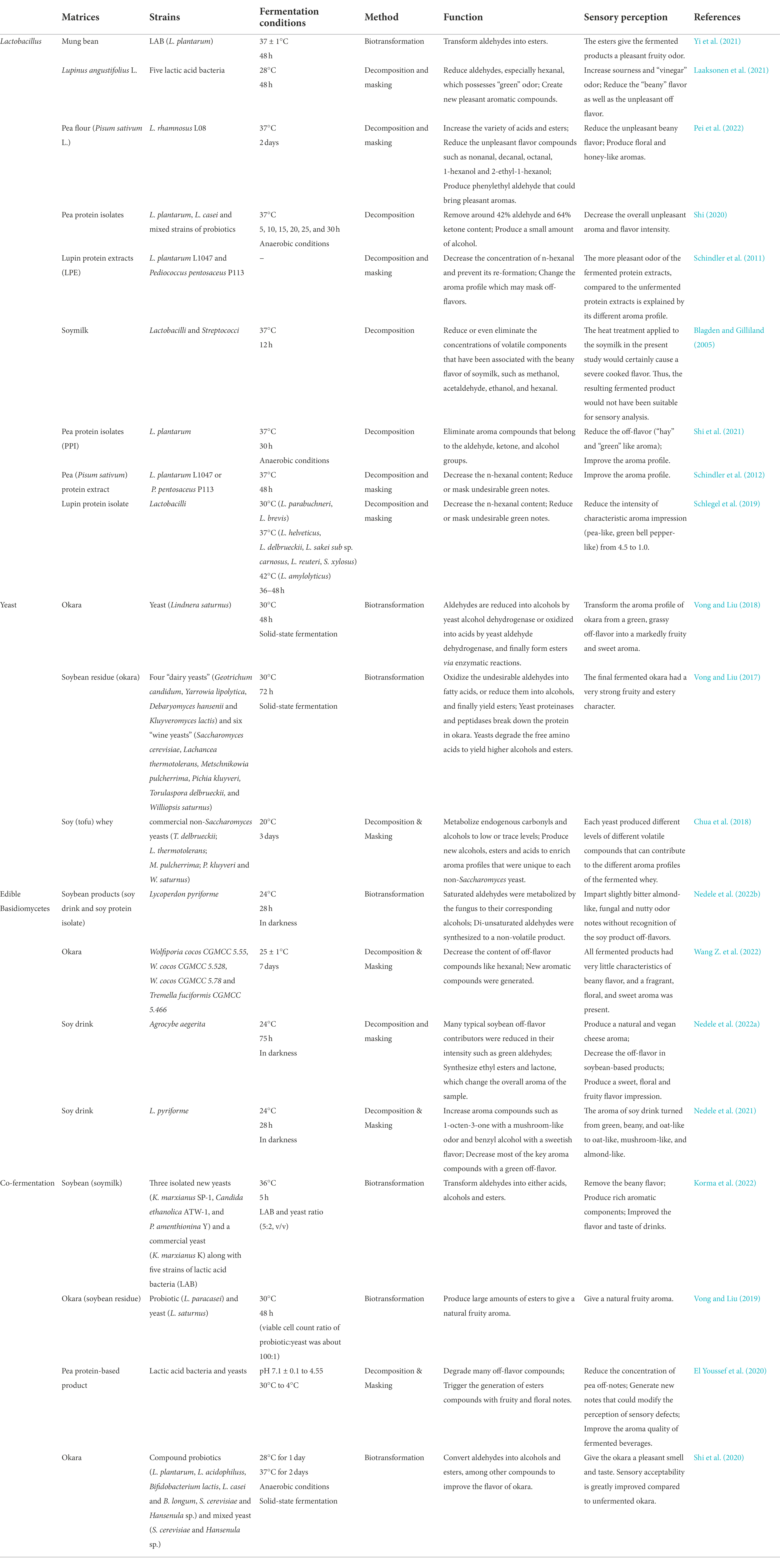

In recent years, fermentation has become the primary method employed in many studies to reduce the beany flavor due to its various advantages. Several strains are discussed below that have shown potential to remove or cover the beany flavor in bean protein-based products (Table 1).

Lactobacillus

Lactic fermentation might be a promising strategy to improve the aroma profile of plant-based food products as it results in a reduction or covering of undesirable flavors. Some Lactobacillus strains can reduce or eliminate aroma compounds that have been linked with the beany flavor which are members of the aldehyde, ketone, and alcohol groups. Several authors demonstrated how fermentation with lactic acid bacteria in pea, lupin protein extract, and soymilk, respectively, reduced the concentration of hexanal, which is primarily responsible for the greeny and beany off-flavor (Blagden and Gilliland, 2005; Schindler et al., 2011, 2012; Shi, 2020). Other researches have shown that lactic fermentation can produce higher aldehydes, alcohols, acids, and ester compounds through further biotransformation to cover the beany flavors (Schindler et al., 2011; Shi et al., 2021; Yi et al., 2021). Lipid degradation, which also contributes to the creation of the odors found in fermented foods, takes place concurrently with this biotransformation. For instance, L. rhamnosus L08 fermentation produced phenylethyl aldehyde that could bring floral and honey-like aromas, phenylethyl alcohol that exhibits a fresh bread-like, rose-like aroma, and several esters with floral and fruity fragrances, which had the effect of covering undesirable flavors (Pei et al., 2022).

Yeast

Some yeasts are also used to modify the odor characteristics of plant-based products by biotransformation. The products of yeast fermentation often carry a pleasant flavor profile of alcohols and esters. Chua et al. fermented soy whey samples using five commercial non-Saccharomyces yeasts. Volatile compounds such as ethanol and 2-phenylethanol were found in the fermented products, giving them a rose-like aromatic character (Chua et al., 2018). Other studies used yeasts to ferment okara and obtained a very strong fruity and estery character since most of the undesirable aldehydes were reduced into alcohols and esters by the yeasts fermentation (Vong and Liu, 2017; Vong and Liu, 2018).

Unfortunately, although fermentation with lactic acid bacteria or yeasts reduces the beany flavor substances, the fermentation process of certain strains inevitably produces acids such as lactic acid and hexanoic acid, causing strong sour and wine flavors, which to some extent aggravate the undesirable flavor of the bean protein-based product (Laaksonen et al., 2021; Nedele et al., 2021; Wang Z. et al., 2022). Thus, the optimization of fermentation conditions is required to prevent the creation of unpleasant flavor compounds.

Edible basidiomycetes

In the food processing industry, edible fungi are common fermentation strains. Among them, basidiomycetes have garnered increasing interest due to their abundance, diversity, accessibility, and nutritional benefits (Mahboubi et al., 2017; Sun et al., 2020; Bentil, 2021). While most conventional starter cultures mainly produce primary metabolites, basidiomycetes are noted for their sensory modification of various food products (Nedele et al., 2021; Rigling et al., 2021; Nedele et al., 2022a). They are able to modify the flavor because their highly sophisticated secretomes produce abundant natural flavor molecules (Bouws et al., 2008). The scientists used four types of edible fungi to reduce the beany flavor and gain new aromatic flavors of okara. These new flavors contain benzene, ethanol, and linalool, which are probably byproducts of enzymatic events occurring during the growth and metabolism of edible fungi. In addition to adding floral, sweet, and orange fragrances, the presence of these compounds can disguise the flavor characteristics of some unwanted components (Wang Z. et al., 2022). Apart from that, recent studies have confirmed that by using a unique fermentation procedure with Lycoperdon pyriforme, the beany flavor of soy beverages was diminished while the nutritional profile was maintained. During this fermentation process, aldehydes, the main off-flavor contributors, were decreased and some pleasant aroma components were created, imparting the finished product an almond- and nutty-like smell (Nedele et al., 2021, 2022b). Therefore, it can be expected that the edible basidiomycetes are likely to be a promising strain for flavor improvement in plant-based foods. Further research is required to ascertain which kind of strains can successfully grow in the various sources of legume dietary fiber systems as well as what fermentation conditions can facilitate the aroma profile improvement.

Conclusion and outlook

In summary, oxidation of unsaturated fatty acids and hydrolysis of lipids are the primary causes of undesirable flavor in a plant protein-base food. At present, masking, biotransformation and enzymatic degradation are the main mechanisms and approaches for removing the beany flavor. Several species of microorganisms including lactobacillus, yeast, and edible basidiomycetes were demonstrated to reduce the level of beany flavor compounds by converting them into less impacting compounds or covering them with new pleasant compounds formed during fermentation. However, different fermentation approaches will produce different final flavor characteristics due to the different metabolic pathways and capacities of the strains. Thus, the strains utilized have a significant impact on how the fermentation affects the fragrance profile of the plant proteins. It should be noted that no technique is perfect, and each method has its own inherent advantages and drawbacks.

In order to further improve the flavor quality of plant-based meat analogs, future product development and application research can mainly focus on the following aspects: (a) Fermentation using some strains may produce products with high acidity, which may not be preferred by consumers. More research is needed to select suitable strains and optimize fermentation process to meet the preferences of consumers (Laaksonen et al., 2021). (b) Aside from legume proteins, other ingredients including microalgae, konjac, and edible mushrooms could be promising substitutes for meat analogs due to their superior production capabilities and high nutritional content. Scientists can process these ingredients using fermentation method to explore the next generation of meat analogs (Jiménez-Colmenero et al., 2012; Fu et al., 2021; Yuan et al., 2022). (c) The fermentation process produces amino acids, sugars, and a series of precursors for Maillard reactions. Therefore, if the fermentation process is properly designed and oriented, it will effectively promote the Maillard reaction, providing better flavor and taste to plant-based meat analogs and eliminating the beany flavor. (d) The metabolomic pathway of fermentation process should be further investigated to demonstrate how the beany flavor is decomposed with the aid of mass spectrometry, nuclear magnetic resonance or isotopic labeling experiments (Ran et al., 2022). And the influence of more volatile compounds exist at low amounts should be further studied to confirm their effect on the aroma change of the fermented product. Improvements of current fermentation techniques will benefit from the results of such research. (e) There is still a lack of comprehensive research on the application of fermentation to remove beany flavor from plant-based meat analog. Not only the technological aspects, but also the safety concerns should be taken into consideration. Possible safety problems such as microbiological stability, allergenic potential and heavy metal and toxic substance contamination during fermentation should be investigated to develop safe and efficient fermentation protocols for the production of plant-based meat analogs.

Author contributions

XY and TZ contributed to conception and design of the study. AT, HZ, and JD wrote the first draft of the manuscript. YX, YL, JL, and JH helped review and revise the manuscript. All authors contributed to the article and approved the submitted version.

Funding

This work was supported by the Science and Technology Development Funds, Macau SAR (0024/2022/A and 0004/2021/ITP), the Science and Technology Planning Project of Guangdong Province (2020B1212030008), Innovation Cultivation Project of Zhuhai College of Science and Technology (2019XJCQ006), and the Open Fund of Guangdong-Hong Kong-Macao Joint Laboratory for Contaminants Exposure and Health (GHMJLCEH-05).

Conflict of interest

JL and JH were employed by Macau Uni-Win Biotechnology Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alhendi, A., Yang, W., and Sarnoski, P. J. (2018). The effect of solution properties on the photochemical ability of pulsed light to inactivate soybean lipoxygenase. Int. J. Food Eng. 14:14. doi: 10.1515/ijfe-2018-0086

Bentil, J. A. (2021). Biocatalytic potential of basidiomycetes: relevance, challenges and research interventions in industrial processes. Sci. Afr. 11:e00717. doi: 10.1016/j.sciaf.2021.e00717

Blagden, T. D., and Gilliland, S. E. (2005). Reduction of levels of volatile components associated with the “beany” flavor in soymilk by lactobacilli and streptococci. J. Food Sci. 70, M186–M189. doi: 10.1111/j.1365-2621.2005.tb07148.x

Bouws, H., Wattenberg, A., and Zorn, H. (2008). Fungal secretomes - Nature's toolbox for white biotechnology. Appl. Microbiol. Biotechnol. 80, 381–388. doi: 10.1007/s00253-008-1572-5

Chen, A., He, H., Wang, J., Li, M., Guan, Q., and Hao, J. (2019). A study on the arable land demand for food security in China. Sustainability 11:4769. doi: 10.3390/su11174769

Chen, J., and Yang, C.-C. (2021). The impact of COVID-19 on the revenue of the livestock industry: a case study of China. Animals 11:3586. doi: 10.3390/ani11123586

Choudhury, D., Singh, S., Seah, J. S. H., Yeo, D. C. L., and Tan, L. P. (2020). Commercialization of plant-based meat alternatives. Trends Plant Sci. 25, 1055–1058. doi: 10.1016/j.tplants.2020.08.006

Chua, J.-Y., Lu, Y., and Liu, S.-Q. (2018). Evaluation of five commercial non-saccharomyces yeasts in fermentation of soy (tofu) whey into an alcoholic beverage. Food Microbiol. 76, 533–542. doi: 10.1016/j.fm.2018.07.016

Cordelle, S., Redl, A., and Schlich, P. (2022). Sensory acceptability of new plant protein meat substitutes. Food Qual. Prefer. 98:104508. doi: 10.1016/j.foodqual.2021.104508

Deppenmeier, U., and Ehrenreich, A. (2009). Physiology of acetic acid bacteria in light of the genome sequence of Gluconobacter oxydans. Microbial Physiol. 16, 69–80. doi: 10.1159/000142895

El Youssef, C., Bonnarme, P., Fraud, S., Péron, A.-C., Helinck, S., and Landaud, S. (2020). Sensory improvement of a pea protein-based product using microbial co-cultures of lactic acid bacteria and yeasts. Foods 9:349. doi: 10.3390/foods9030349

Fischer, E., Cayot, N., and Cachon, R. (2022). Potential of microorganisms to decrease the “beany” off-flavor: a review. J. Agric. Food Chem. 70, 4493–4508. doi: 10.1021/acs.jafc.1c07505

Fu, Y., Chen, T., Chen, S. H. Y., Liu, B., Sun, P., Sun, H., et al. (2021). The potentials and challenges of using microalgae as an ingredient to produce meat analogues. Trends Food Sci. Technol. 112, 188–200. doi: 10.1016/j.tifs.2021.03.050

Gardner, H. W. (1991). Recent investigations into the lipoxygenase pathway of plants. Biochimica et Biophysica Acta (BBA)-lipids and lipid. Metabolism 1084, 221–239. doi: 10.1016/0005-2760(91)90063-N

Hammond, E. G., and White, P. J. (2011). A brief history of lipid oxidation. J. Am. Oil Chem. Soc. 88, 891–897. doi: 10.1007/s11746-011-1761-8

Jelen, H. (2011). Food flavors: Chemical, sensory and technological properties. Boca Raton: CRC press.

Jiménez-Colmenero, F., Cofrades, S., Herrero, A. M., Fernández-Martín, F., Rodríguez-Salas, L., and Ruiz-Capillas, C. (2012). Konjac gel fat analogue for use in meat products: comparison with pork fats. Food Hydrocoll. 26, 63–72. doi: 10.1016/j.foodhyd.2011.04.007

Khrisanapant, P., Kebede, B., Leong, S. Y., and Oey, I. (2019). A comprehensive characterisation of volatile and fatty acid profiles of legume seeds. Foods 8:651. doi: 10.3390/foods8120651

Korma, S. A., Li, L., Ghamry, M., Zhou, Q., An, P., Abdrabo, K. A., et al. (2022). Effect of co-fermentation system with isolated new yeasts on soymilk: microbiological, physicochemical, rheological, aromatic, and sensory characterizations. Braz. J. Microbiol. 53, 1549–1564. doi: 10.1007/s42770-022-00773-7

Kumar, P., Chatli, M., Mehta, N., Singh, P., Malav, O., and Verma, A. K. (2017). Meat analogues: health promising sustainable meat substitutes. Crit. Rev. Food Sci. Nutr. 57, 923–932. doi: 10.1080/10408398.2014.939739

Kumari, S., Dahuja, A., Vinutha, T., Lal, S. K., Kar, A., and Rai, R. D. (2015). Changes in the levels of off-flavor generation in soybean through biotic elicitor treatments. J. Agric. Food Chem. 63, 700–706. doi: 10.1021/jf505199a

Kyriakopoulou, K., Keppler, J. K., and van der Goot, A. J. (2021). Functionality of ingredients and additives in plant-based meat analogues. Foods 10:600. doi: 10.3390/foods10030600

Laaksonen, O., Kahala, M., Marsol-Vall, A., Blasco, L., Järvenpää, E., Rosenvald, S., et al. (2021). Impact of lactic acid fermentation on sensory and chemical quality of dairy analogues prepared from lupine (Lupinus angustifolius L.) seeds. Food Chem. 346:128852. doi: 10.1016/j.foodchem.2020.128852

Lynch, K. M., Zannini, E., Wilkinson, S., Daenen, L., and Arendt, E. K. (2019). Physiology of acetic acid bacteria and their role in vinegar and fermented beverages. Compr. Rev. Food Sci. Food Saf. 18, 587–625. doi: 10.1111/1541-4337.12440

Mahboubi, A., Ferreira, J. A., Taherzadeh, M. J., and Lennartsson, P. R. (2017). Value-added products from dairy waste using edible fungi. Waste Manag. 59, 518–525. doi: 10.1016/j.wasman.2016.11.017

Meinlschmidt, P., Schweiggert-Weisz, U., and Eisner, P. (2016). Soy protein hydrolysates fermentation: effect of debittering and degradation of major soy allergens. LWT 71, 202–212. doi: 10.1016/j.lwt.2016.03.026

Mittermeier-Kleßinger, V. K., Hofmann, T., and Dawid, C. (2021). Mitigating off-flavors of plant-based proteins. J. Agric. Food Chem. 69, 9202–9207. doi: 10.1021/acs.jafc.1c03398

Mizuno, A., Tabei, H., and Iwahuti, M. (2006). Characterization of low-acetic-acid-producing yeast isolated from 2-deoxyglucose-resistant mutants and its application to high-gravity brewing. J. Biosci. Bioeng. 101, 31–37. doi: 10.1263/jbb.101.31

Nedele, A.-K., Bär, A., Mayer, N., Schiebelbein, R., and Zhang, Y. (2022a). Characterization of cheesy odor formed during fermentation of soy drink with Agrocybe aegerita. Food Chem. 381:132170. doi: 10.1016/j.foodchem.2022.132170

Nedele, A.-K., Gross, S., Rigling, M., and Zhang, Y. (2021). Reduction of green off-flavor compounds: comparison of key odorants during fermentation of soy drink with Lycoperdon pyriforme. Food Chem. 334:127591. doi: 10.1016/j.foodchem.2020.127591

Nedele, A.-K., Schiebelbein, R., Bär, A., Kaup, A., and Zhang, Y. (2022b). Reduction of aldehydes with green odor in soy products during fermentation with Lycoperdon pyriforme and analysis of their degradation products. Food Res. Int. 152:110909. doi: 10.1016/j.foodres.2021.110909

Ortakci, F., Broadbent, J. R., Oberg, C. J., and McMahon, D. J. (2015). Growth and gas production of a novel obligatory heterofermentative Cheddar cheese nonstarter lactobacilli species on ribose and galactose. J. Dairy Sci. 98, 3645–3654. doi: 10.3168/jds.2014-9293

Pei, M., Zhao, Z., Chen, S., Reshetnik, E. I., Gribanova, S. L., Li, C., et al. (2022). Physicochemical properties and volatile components of pea flour fermented by lactobacillus rhamnosus L08. Food Biosci. 46:101590. doi: 10.1016/j.fbio.2022.101590

Pimentel, D., and Pimentel, M. (2003). Sustainability of meat-based and plant-based diets and the environment. Am. J. Clin. Nutr. 78, 660S–663S. doi: 10.1093/ajcn/78.3.660S

Polak, R., Phillips, E. M., and Campbell, A. (2015). Legumes: health benefits and culinary approaches to increase intake. Clin. Diabetes 33, 198–205. doi: 10.2337/diaclin.33.4.198

Prückler, M., Lorenz, C., Endo, A., Kraler, M., Dürrschmid, K., Hendriks, K., et al. (2015). Comparison of homo- and heterofermentative lactic acid bacteria for implementation of fermented wheat bran in bread. Food Microbiol. 49, 211–219. doi: 10.1016/j.fm.2015.02.014

Ran, X., Yang, Z., Chen, Y., and Yang, H. (2022). Konjac glucomannan decreases metabolite release of a plant-based fishball analogue during in vitro digestion by affecting amino acid and carbohydrate metabolic pathways. Food Hydrocoll. 129:107623. doi: 10.1016/j.foodhyd.2022.107623

Rigling, M., Yadav, M., Yagishita, M., Nedele, A.-K., Sun, J., and Zhang, Y. (2021). Biosynthesis of pleasant aroma by enokitake (Flammulina velutipes) with a potential use in a novel tea drink. LWT 140:110646. doi: 10.1016/j.lwt.2020.110646

Roland, W. S., Pouvreau, L., Curran, J., van de Velde, F., and de Kok, P. M. (2017). Flavor aspects of pulse ingredients. Cereal Chem. 94, 58–65. doi: 10.1094/CCHEM-06-16-0161-FI

Schindler, S., Wittig, M., Zelena, K., Krings, U., Bez, J., Eisner, P., et al. (2011). Lactic fermentation to improve the aroma of protein extracts of sweet lupin (Lupinus angustifolius). Food Chem. 128, 330–337. doi: 10.1016/j.foodchem.2011.03.024

Schindler, S., Zelena, K., Krings, U., Bez, J., Eisner, P., and Berger, R. G. (2012). Improvement of the aroma of pea (Pisum sativum) protein extracts by lactic acid fermentation. Food Biotechnol. 26, 58–74. doi: 10.1080/08905436.2011.645939

Schlegel, K., Leidigkeit, A., Eisner, P., and Schweiggert-Weisz, U. (2019). Technofunctional and sensory properties of fermented Lupin protein isolates. Foods 8:678. doi: 10.3390/foods8120678

Shi, Y., Singh, A., Kitts, D. D., and Pratap-Singh, A. (2021). Lactic acid fermentation: a novel approach to eliminate unpleasant aroma in pea protein isolates. LWT 150:111927. doi: 10.1016/j.lwt.2021.111927

Shi, H., Zhang, M., Wang, W., and Devahastin, S. (2020). Solid-state fermentation with probiotics and mixed yeast on properties of okara. Food Biosci. 36:100610

Sun, A., Wu, W., Soladoye, O. P., Aluko, R. E., Bak, K. H., Fu, Y., et al. (2022). Maillard reaction of food-derived peptides as a potential route to generate meat flavor compounds: a review. Food Res. Int. 151:110823. doi: 10.1016/j.foodres.2021.110823

Sun, Y., Zhang, M., and Fang, Z. (2020). Efficient physical extraction of active constituents from edible fungi and their potential bioactivities: a review. Trends Food Sci. Technol. 105, 468–482. doi: 10.1016/j.tifs.2019.02.026

Taufik, D., Verain, M. C., Bouwman, E. P., and Reinders, M. J. (2019). Determinants of real-life behavioural interventions to stimulate more plant-based and less animal-based diets: a systematic review. Trends Food Sci. Technol. 93, 281–303. doi: 10.1016/j.tifs.2019.09.019

Verce, M., De Vuyst, L., and Weckx, S. (2020). Comparative genomics of lactobacillus fermentum suggests a free-living lifestyle of this lactic acid bacterial species. Food Microbiol. 89:103448. doi: 10.1016/j.fm.2020.103448

Vong, W. C., and Liu, S.-Q. (2017). Changes in volatile profile of soybean residue (okara) upon solid-state fermentation by yeasts. J. Sci. Food Agric. 97, 135–143. doi: 10.1002/jsfa.7700

Vong, W. C., and Liu, S.-Q. (2018). Bioconversion of green volatiles in okara (soybean residue) into esters by coupling enzyme catalysis and yeast (Lindnera saturnus) fermentation. Appl. Microbiol. Biotechnol. 102, 10017–10026. doi: 10.1007/s00253-018-9396-4

Vong, W. C., and Liu, S.-Q. (2019). The effects of carbohydrase, probiotic lactobacillus paracasei and yeast Lindnera saturnus on the composition of a novel okara (soybean residue) functional beverage. LWT 100, 196–204. doi: 10.1016/j.lwt.2018.10.059

Wang, Z., Gao, T., He, Z., Zeng, M., Qin, F., and Chen, J. (2022). Reduction of off-flavor volatile compounds in okara by fermentation with four edible fungi. LWT 155:112941. doi: 10.1016/j.lwt.2021.112941

Wang, Y., Guldiken, B., Tulbek, M., House, J. D., and Nickerson, M. (2020). Impact of alcohol washing on the flavour profiles, functionality and protein quality of air classified pea protein enriched flour. Food Res. Int. 132:109085. doi: 10.1016/j.foodres.2020.109085

Wang, Y. Q., Tuccillo, F., Lampi, A. M., Knaapila, A., Pulkkinen, M., Kariluoto, S., et al. (2022). Flavor challenges in extruded plant-based meat alternatives: a review. Compr. Rev. Food Sci. Food Saf. 21, 2898–2929. doi: 10.1111/1541-4337.12964

Wang, B., Zhang, Q., Zhang, N., Bak, K. H., Soladoye, O. P., Aluko, R. E., et al. (2021). Insights into formation, detection and removal of the beany flavor in soybean protein. Trends Food Sci. Technol. 112, 336–347. doi: 10.1016/j.tifs.2021.04.018

Xu, M., Jin, Z., Gu, Z., Rao, J., and Chen, B. (2020). Changes in odor characteristics of pulse protein isolates from germinated chickpea, lentil, and yellow pea: role of lipoxygenase and free radicals. Food Chem. 314:126184. doi: 10.1016/j.foodchem.2020.126184

Yi, C., Li, Y., Zhu, H., Liu, Y., and Quan, K. (2021). Effect of lactobacillus plantarum fermentation on the volatile flavors of mung beans. LWT 146:111434. doi: 10.1016/j.lwt.2021.111434

Yu, X., and Zuo, T. (2021). Food additives, Cooking and Processing: Impact on the Microbiome. Frontiers Media SA; p. 731040–7310488.

Yuan, X., Jiang, W., Zhang, D., Liu, H., and Sun, B. (2022). Textural, sensory and volatile compounds analyses in formulations of sausages analogue elaborated with edible mushrooms and soy protein isolate as meat substitute. Foods 11:52. doi: 10.3390/foods11010052

Zhang, Y., Guo, S., Liu, Z., and Chang, S. K. (2012). Off-flavor related volatiles in soymilk as affected by soybean variety, grinding, and heat-processing methods. J. Agric. Food Chem. 60, 7457–7462. doi: 10.1021/jf3016199

Zhang, C. M., Hua, Y. F., Li, X. F., Kong, X. Z., and Chen, Y. M. (2020). Key volatile off-flavor compounds in peas (Pisum sativum L.) and their relations with the endogenous precursors and enzymes using soybean (Glycine max) as a reference. Food Chem. 333:127469. doi: 10.1016/j.foodchem.2020.127469

Keywords: beany-flavor, plant-based meat analogs, fermentation, soy proteins, pea proteins, off-flavor

Citation: Tao A, Zhang H, Duan J, Xiao Y, Liu Y, Li J, Huang J, Zhong T and Yu X (2022) Mechanism and application of fermentation to remove beany flavor from plant-based meat analogs: A mini review. Front. Microbiol. 13:1070773. doi: 10.3389/fmicb.2022.1070773

Edited by:

Changyu Zhou, Ningbo University, ChinaReviewed by:

Hao Dong, Zhongkai University of Agriculture and Engineering, ChinaZhang Jiamin, Chengdu University, China

Liao Guozhou, Yunnan Agricultural University, China

Copyright © 2022 Tao, Zhang, Duan, Xiao, Liu, Li, Huang, Zhong and Yu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Tian Zhong, dHpob25nQG11c3QuZWR1Lm1v; Xi Yu, eHl1QG11c3QuZWR1Lm1v

†These authors have contributed equally to this work

Anqi Tao

Anqi Tao Hongyu Zhang1†

Hongyu Zhang1† Junnan Duan

Junnan Duan Tian Zhong

Tian Zhong Xi Yu

Xi Yu