94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Microbiol., 08 September 2020

Sec. Microbe and Virus Interactions with Plants

Volume 11 - 2020 | https://doi.org/10.3389/fmicb.2020.557119

This article is part of the Research TopicRocks, Plants and MicrobesView all 7 articles

Microbial-Induced Calcite Precipitation (MICP) stimulates soil microbiota to induce a cementation of the soil matrix. Urea, calcium and simple carbon nutrients are supplied to produce carbonates via urea hydrolysis and induce the precipitation of the mineral calcite. Calcium chloride (CaCl2) is typically used as a source for calcium, but basic silicate rocks and other materials have been investigated as alternatives. Weathering of calcium-rich silicate rocks (e.g., basalt and dolerite) releases calcium, magnesium and iron; this process is associated with sequestration of atmospheric CO2 and formation of pedogenic carbonates. We investigated atmospheric carbon fluxes of a MICP treated sandy soil using CaCl2 and dolerite fines applied on the soil surface as sources for calcium. Soil-atmosphere carbon fluxes were monitored over 2 months and determined with an infrared gas analyser connected to a soil chamber. Soil inorganic carbon content and isotopic composition were determined with isotope-ratio mass spectrometry. In addition, soil-atmosphere CO2 fluxes during chemical weathering of dolerite fines were investigated in incubation experiments with gas chromatography. Larger CO2 emissions resulted from the application of dolerite fines (116 g CO2-C m–2) compared to CaCl2 (79 g CO2-C m–2) but larger inorganic carbon precipitation also occurred (172.8 and 76.9 g C m–2, respectively). Normalising to the emitted carbon to precipitated carbon, the environmental carbon cost was reduced with dolerite fines (0.67) compared to the traditional MICP treatment (1.01). The carbon isotopic signature indicated pedogenic carbonates (δ13Cav = −8.2 ± 5.0‰) formed when dolerite was applied and carbon originating from urea (δ13Cav = −46.4 ± 1.0‰) precipitated when CaCl2 was used. Dolerite fines had a large but short-lived (<2 d) carbon sequestration potential, and results indicated peak CO2 emissions during MICP could be balanced optimising the application of dolerite fines.

Microbial-Induced Calcite Precipitation (MICP) is an emerging soil stabilisation technique based on the biomediated precipitation of the mineral calcite within soil by urea hydrolysis. Urease producing microorganisms are stimulated to catalyse urea hydrolysis into carbon dioxide (CO2) and ammonia (NH3). This reaction raises the soil pH leading to a shift in dissolved inorganic carbon (DIC) speciation towards carbonates which precipitate in the presence of divalent cations (Ca, Mg, Fe) as carbonate minerals. Carbonate minerals form on and accumulate around soil grain surfaces and microorganisms, which act as nucleation sites (Gat et al., 2014), and induces a cementation of the soil structure. When applied appropriately, MICP reduces soil porosity and hydraulic conductivity and increases soil-bearing capacity and shear resistance. MICP therefore offers applications within the civil and earthquake engineering sectors (DeJong et al., 2013; Montoya et al., 2013).

MICP is considered to be “environmentally friendly” compared to traditional soil stabilisation techniques, although this statement needs clarity. Firstly, although indigenous soil bacteria are reported equally suitable (Burbank et al., 2010, 2012, 2013), exogenous bacterial communities grown in the laboratory have been typically used for MICP which suffer predation by indigenous bacterial communities once introduced into the soil environment. Secondly, principal chemical components required for MICP such as organic C and N sources (urea, sodium acetate, molasses, yeast and ammonium chloride) and CaCl2 are industry-end products. Thirdly, there is a paucity of information concerning the potential for contamination of aquifers through post-treatment nitrification processes and the soil-atmosphere Greenhouse Gas (GHG) emissions. CO2 sequestration during MICP by certain ureolytic communities has been observed (Okyay et al., 2015, 2016). However, these studies were conducted in an aquatic environment at atmospheric CO2 levels of 10%, which differ from soil environments.

With a global movement towards a circular economy, alternative sources to CaCl2 have been suggested including seawater (Cheng et al., 2014), eggshells (Choi et al., 2016), limestone (Choi et al., 2017), and basic silicate rocks (Casas et al., 2019). Dolerite is a rock of basaltic chemical composition abundant in Ca-rich minerals, which releases Ca and Mg in solution during chemical weathering. Dissolution of basaltic rocks is associated with atmospheric CO2 removal via the formation of carbonate minerals occurring at the mineral surface and underlaying soil layers by downward percolation of divalent cation-rich alkaline solution (Manning et al., 2013). Dolerite fines of large specific surface area originate from crushing and milling processes in quarries and often accumulate in landfill due to limited market options (Mitchell et al., 2008). This material could, however, be suitable for MICP and CO2 capture applications (Casas et al., 2019). Furthermore, induced toxicity by dolerite weathering has not been reported up to now.

Enhanced weathering of basic silicate rocks has been previously reported for the potential mitigation of anthropogenic CO2 emissions (Manning, 2008; Renforth et al., 2009; Renforth, 2012). The need for evaluating CO2 capture strategies, such as the application of basic silicate rocks to soil, combined with detailed environmental monitoring, has been discussed (Beerling et al., 2018). In this context, this paper reports investigations of soil-atmosphere CO2 fluxes during MICP treatment of a natural sandy soil using CaCl2 and dolerite fines originating from quarries to determine stages where the system may act as a source or sink of CO2 and to identify the main drivers of these fluxes. Furthermore, the CO2 sequestration potential of dolerite fines by chemical and biological weathering were investigated.

Sand was obtained from a quarry located in the Lower Rhine Basin, Germany (50°55′18.8184″, 06°46’45.6528″, WGS84; operated by Quarzwerke GmbH, Frechen). The sampling location was selected close to vegetation, thus ensuring that the soil was biologically active. The surface 3 cm were removed and the underlying soil to a depth of 20 cm collected and sealed to prevent moisture loss. The sample consisted of a loose, fairly homogeneous white-greyish fine sand, with no presence of gravels, boulders or fines. Thin plant roots were present. The soil moisture content was determined gravimetrically upon arrival at the laboratory. The grain size distribution was determined by wet sieving on two analytical replicates (ISO11277), and the soil pH was determined in 0.1 M CaCl2 solution for a soil-to-solution ratio of 2.5:1 on three analytical replicates (WTW SenTix 41 PLUS probe with WTW multi 340i pH meter, WTW, Weilheim, Germany; calibrated to pH = 4 and 7).

Dolerite fines were sourced from Barrasford quarry (Barrasford, Hexham, NE48 4AP, United Kingdom; operated by Tarmac Ltd.). The chemical composition and mineralogy of the quarry materials are described in detail in Randall (1989) and the physical properties, chemical composition, and calcium chemical weatherability of the material discussed previously by Casas et al. (2019).

MICP was induced through biostimulation of soil indigenous bacteria. The chemical composition of treatment solutions was defined according to Burbank et al. (2010) and Al Qabany and Soga (2013). The growth solution contained 1 g L–1 of cane molasses (MLS) (Rapunzel Naturkost GmbH, Germany), 0.1 g L–1 yeast extract (Vitasan Bio-Hefeextrakt; VITAM Hefe-Produkt GmbH, Germany), 100 mM anhydrous sodium acetate (SA) (ACS, Merck KGaA, Germany) and 250 mM urea (≥99.5%, Carl Roth GmbH + Co., KG, Germany) in distilled water. The cementation solution contained 0.1 g L–1 of MLS, 100 mM SA, 100 mM urea and either 0 or 20 mM CaCl2 ⋅ 2 H2O (ACS, Merck KGaA, Germany) in distilled water. The MICP treatment sequence consisted of several phases and subphases detailed in section “MICP and the Application of Dolerite Fines” and Supplementary Figure S2.

The CO2 sequestration potential of dolerite fines at low liquid-to-solid (L/S) ratios was investigated by gas chromatography (GC). Samples were prepared by adding a constant mass of dolerite fines (0.1 g) and varying amounts of distilled water in 22 mL GC vials, sealed using butyl rubber septa and aluminium caps, manually stirred, and incubated. The evolution of CO2 concentration during dolerite dissolution by chemical weathering over a 1 h incubation period was measured after 5, 20, 40, and 60 mins, for L/S ratios of 0, 0.6, 1.0, 1.5, 2.5, 5, 10, and 15. The experiments were repeated every 24 h. At the end of each experiment, vials were opened and stored at room temperature. Distilled water equivalent to the evaporated water was then added right before closing the vial to maintain a constant L/S ratio. All experiments were carried out in triplicate. CO2 concentrations were determined by gas chromatography (GC 8610C, SRI Instruments Europe GmbH, Bad Honnef, Germany) interfaced to an HTA-40 autosampler equipped with a packed pre-column (1 m Porapak-Q 1/8″) and a flame ionisation detector (FID) using nitrogen as the carrier gas. Four gas measurements were made on the same vial during a single incubation. The GC sampled 3.5 mL of headspace gas per measurement without control of the vial inner pressure. A pressure drop of 0.2 bar per measurement was determined in a preliminary study. Corrections for this were carried out using an algorithm using python (script available upon request). Vials were brought to 1.3 bar above ambient air pressure with N2 before the first measurement to maintain overpressure conditions within the vial after four measurements. The data was fitted to equation:

where C(t) is the CO2 concentration at time t, C0, and Cx correspond to the CO2 concentration at t0 and at equilibrium, respectively, and a is the exponential constant determined for each L/S ratio.

CO2 fluxes between soil and atmosphere during MICP were investigated in a soil column setup coupled to a soil CO2 efflux monitoring chamber system (LI-8100, LI-COR Biosciences, LI-COR Inc., United States) (Supplementary Figure S1). In a replicate soil column, the effect of a layer of dolerite fines placed on top of the soil surface to be treated with MICP was investigated. The function of the dolerite layer was to release calcium into the soil column when reacting with the poured solution via chemical weathering. This alternative source of calcium was compared against the MICP solution containing industrially manufactured CaCl2. Soil samples were prepared in each column by adding 3 kg of soil, resulting in a soil layer of 8.5 cm. 500 g of dry dolerite fines were placed on top of one of the soil columns resulting in a 1 cm layer. Dolerite fines were applied after the growth phase to maximise calcium availability for precipitation. Top to bottom, the soil column setup consisted of a soil chamber (A = 314.16 cm2) resting on top of a cylindrical PVC tube (11.5 cm height and 20 cm i.d.), with a sieve (0.036 mm mesh) fitted at the bottom, joined to a drainage system composed of a metallic receiver attached to a plastic tube (4 mm i.d.) and a valve. Silicone was used to join and seal the assembled parts.

The MICP treatment consisted of a 4-day growth followed by an 8-day cementation phase. A month after finalising the treatment soil columns were rewetted with distilled water. Solutions were applied by gravitational drainage (percolation) controlled by the outlet valve mechanism. Treatments comprised a reaction time (tr) and rest time interval. During the reaction time the outlet valve was closed to keep soil and solution in contact, and the soil and dolerite surfaces remained submerged. Rest intervals comprised the time between opening the valve for solution drainage and addition of fresh solution. A drying phase was induced when solution drainage was not followed by another treatment consecutively. The reaction time of the growth phase was 96 h. The cementation phase commenced 24 h later and consisted of several individual treatments of 24 h duration, with reaction and rest time intervals of 23 and 1 h, respectively. In total, eight cementation treatments were applied, split in two rounds of four consecutive treatments with a 72-h drying phase in between. For each treatment, a total of 1 l was poured in each soil column, only retaining 500 mL to maximise solution replacement within the soil column. The MICP treatment phase was followed by a drying phase of 28 d. The soil columns were then flushed with 1 l of distilled water, retained for 24 h, and ensued by a third drying phase of 21 d.

CO2 measurements were carried out throughout the MICP treatment and the drying phases that followed, covering a total timespan of 2 months. The chambers of the CO2 efflux monitoring system were open to allow free gas exchange between the soil surface and the atmosphere and closed every full hour for 10 min for a measurement. During this time, CO2 concentration, H2O vapor concentration and temperature inside the chamber were logged at a frequency of 1 s–1, and CO2 efflux or uptake of the sample was computed from the initial slope of a non-linear curve fit to the increase or decrease of humidity-corrected CO2 concentrations. Liquid and solid samples were obtained after each cementation treatment, as well as after re-wetting the soil columns. Liquid samples were tested for pH upon sampling and stored at −20°C until further analysis (see section “Chemical Analyses of Liquid Samples”). Soil samples were obtained pushing down a cylindrical glass tube (4.5 mm i.d.) into the soil profile, oven-dried and analysed for soil total inorganic carbon (TIC) and isotopic composition (see section “Quantitative and Isotopic Analysis of C”).

The chemical composition of soil leachates was determined after the first and last cementation treatments, and after rewetting of soil columns. pH, total organic carbon (TOC), total nitrogen (TN), urea, ammonium, nitrite, nitrate and elements Ca, Na, Mg, K, Mn, Fe, Al, Ti, Si, B, Ba, Cd, Co, Cr, Cu, Mo, Ni, P, S, Se, Sr, V, W, and Zn in solution were determined. Liquid samples were centrifuged for 10 min and the supernatant analysed for TOC and TN (TOC-L Analyser with TNM-L unit, Shimadzu Ltd., United Kingdom) and elements determined by inductively coupled plasma optical emission spectroscopy (IC-OES, Perkin Elmer Avio 500) (James Hutton Ltd., Craigiebuckler, Aberdeen, United Kingdom). For ICP-OES analysis, samples obtained after rewetting of soil columns were pre-treated with a hot acid digest as the presence of amorphous calcium carbonate (ACC) was suspected, all other samples were diluted into a nitric acid matrix. Urea [r2 = 0.999, SDmax = 0.04 mM; Knorst et al. (1997)], ammonium, nitrate and nitrite (cuvette tests LCK303, LCK339 and LCK341, Hach Lange GmbH) were determined colourimetrically in triplicate by spectrophotometer (DR 5000TM UV-Vis Spectrophotometer, United States).

Soil TOC, TN and the C isotopic signature (δ13CTOC) were determined in triplicate by elemental analysis–isotope-ratio mass spectrometry (EA-IRMS) using an elemental analyser (EA; Flash 2000, Thermo Fisher ScientificTM) interfaced with a continuous flow IRMS (CF-IRMS; Delta V Advantage, Thermo Fisher Scientific, Bremen, Germany). Soil TIC and the isotopic composition of C (δ13CTIC) and O (δ18O) were determined by gas chromatography–continuous flow–isotope ratio mass spectrometry (GC-CF-IRMS, GasBench II interfaced with a Delta V Advantage, Thermo Fisher Scientific). Soil TOC and TIC were determined in separate runs. For analysis of TOC, TIC was previously removed by fumigation of pre-weighed samples with concentrated hydrochloric acid vapour (Ramnarine et al., 2011). TIC was determined by analysis of evolved CO2 gas released by the reaction of carbonate and pure phosphoric acid (Debajyoti and Skrzypek, 2007). The CO2 content evolving in the vial headspace (12 mL screw top exetainers sealed with septa) was estimated by comparing peak areas of samples against air samples using GC and IRMS. The isotopic composition of C-containing compounds used for the preparation of growth and cementation solutions (i.e., molasses, urea and sodium acetate) was determined for each individual compound by EA-IRMS. Certified isotopic standards were used for 13C, referenced against the Vienna Pee Dee Belemnite (VPDB).

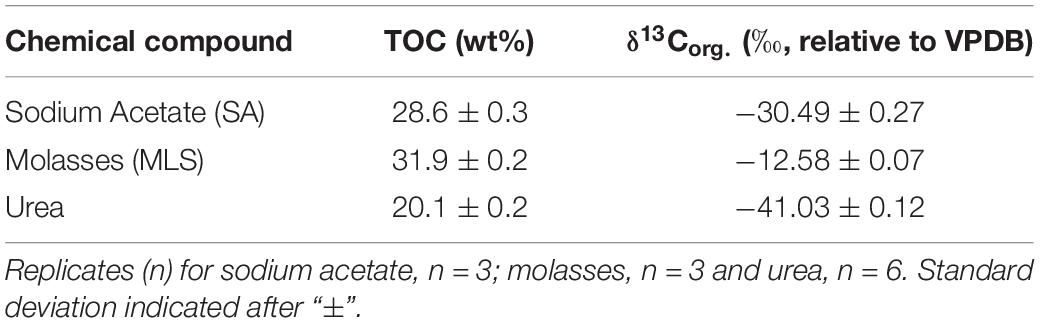

The soil used in this study was classified as poorly graded sand (SP, USCS unified soil classification system) with 29% medium, 67% fine sand, and fines content <4% (Table 1). The moisture content was very low at θ≈ 1%. Soil organic C (CTOC = 0.0211 wt%) and carbonate (CTIC = 0.0003 wt%) content were also low, the C:N ratio was 13 and the soil pH was slightly acidic (pH = 6.4). The isotopic signature of soil organic and inorganic C was δ13CTIC = −14‰ and δ13CTOC = −26‰, respectively (Table 1). The C-containing compounds used for the preparation of the growth and cementation solutions had a similar organic carbon content (Corg = 20–32%) while the Corg isotopic signature differed (δ13Curea = −40‰, δ13CSA = −31‰ and δ13CMLS = −13‰) (Table 2).

Table 2. Total organic carbon and isotopic signature of organic carbon in sodium acetate, urea, and molasses.

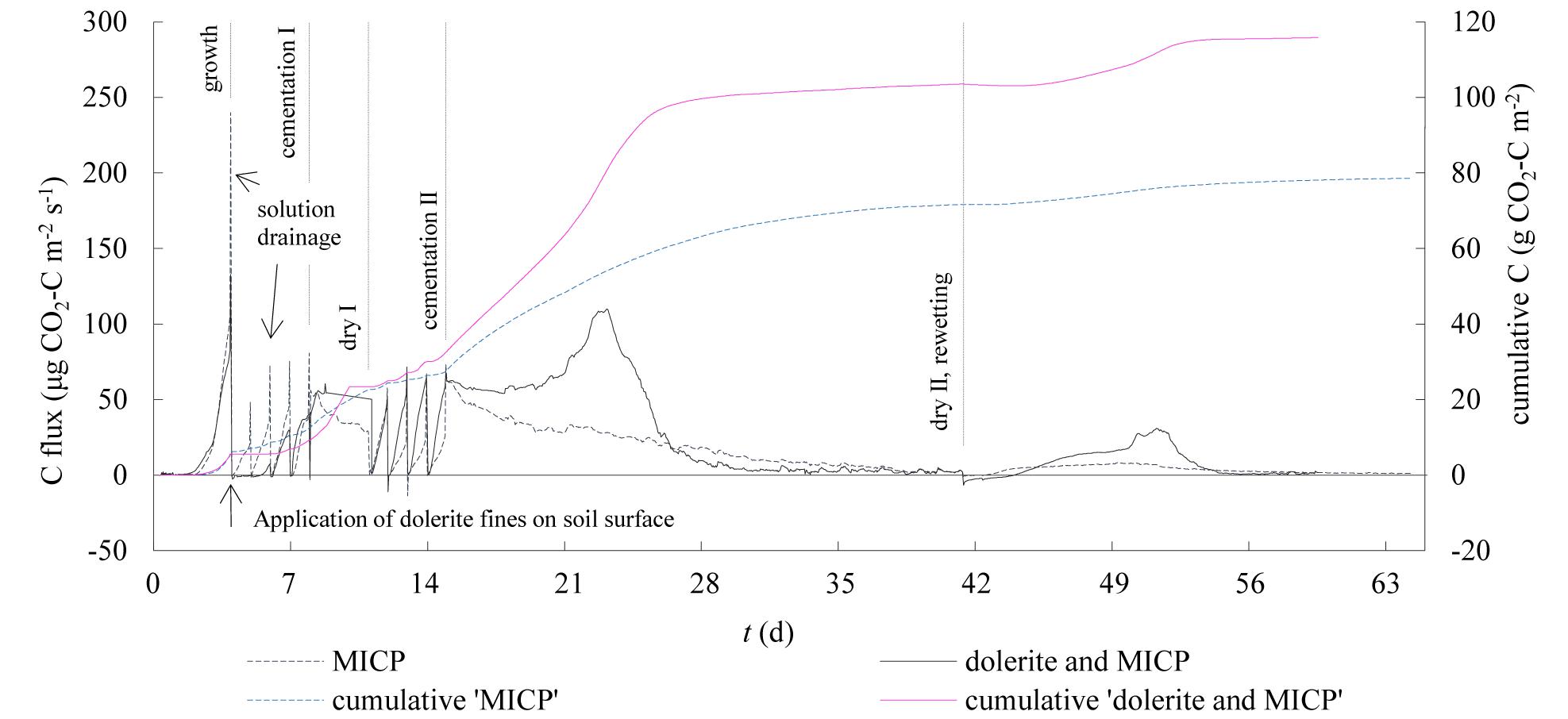

Positive CO2 fluxes indicated emission dominated over the 2-month period comprising MICP treatment and drying phases (Figure 1). CO2 emissions steadily increased during reaction time intervals following linear trends. Sharp CO2 emission peaks were measured at the points of solution drainage. Following drainage, CO2 fluxes fell to near zero if a new treatment was applied but remained high when a drying phase ensued. For the column treated with the traditional MICP solution, CO2 emissions decreased steadily approaching zero following the MICP treatment. Instead, from the column containing dolerite fines, emissions remained steady for a week, followed by increased emissions with a peak occurring 8 d following the beginning of the drying phase prior to decay in CO2 emissions (Figure 1). This pattern was repeated in smaller proportion after rewetting the soil column.

Figure 1. Time series of soil-atmosphere CO2 fluxes of sandy soil columns treated with the traditional MICP treatment (MICP) and using dolerite fines applied on the soil surface as source for calcium (dolerite and MICP). CO2 fluxes and cumulative CO2 emission link to left and right vertical axes, relatively. Divisions on bottom horizontal axis represent 1 d. The application of dolerite is indicated with a vertical arrow and ‘solution drainage’ are pointed as examples. The end of the experiment phases are indicated with dropping vertical dashed lines.

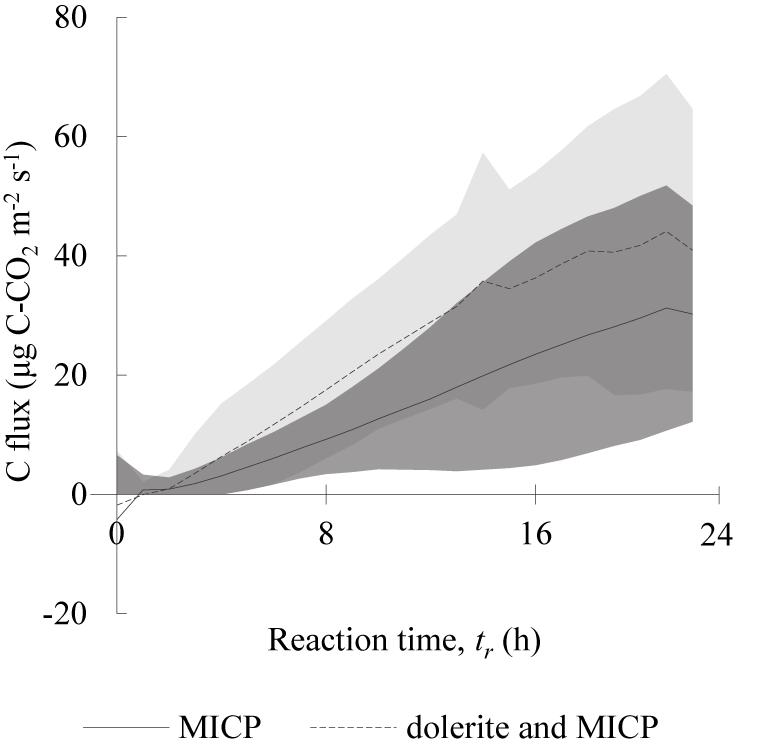

Total emissions were larger for the soil column containing dolerite fines (116 g CO2-C m–2) compared to the soil column treated with the traditional MICP solution (79 g CO2-C m–2). In both cases, most emissions occurred during the drying phases (78–84%), with more than half (55–60%) occurring during the drying phase following the end of the MICP treatment. Notably, near-zero CO2 fluxes in the soil column containing dolerite fines were monitored during the initial two cementation treatments but there were higher CO2 emissions from the third cementation treatment onwards. Cumulative CO2 fluxes indicated overall CO2 emissions were lower for up to 6 days following application of dolerite fines on the soil surface compared to the traditional MICP treatment (Figure 1). The average and standard deviation of discrete CO2 fluxes of a 24 h cementation treatment are presented in Figure 2, were the initial two treatments were removed for comparison purposes. According to the computed averages, 25% of CO2 emissions during reaction time were emitted in the initial 6 and 8 h and 50% in the 10–12 h, for the column treated with traditional MICP and the MICP with dolerite fines treatment, respectively. The computed average soil respiration of a 24 h cementation treatment were of 1.33 ± 0.44 and 2.01 ± 0.55 g CO2-C m2 for the traditional and the MICP treatment with dolerite fines, respectively.

Figure 2. Average CO2 fluxes during 24 h reaction time of soil column treated with traditional (MICP), and for soil column containing dolerite fines added to the MICP treatment (dolerite and MICP). The first and second treatments were excluded from the computed average for both treatments for comparison purposes and to remove the initial near-zero CO2 fluxes not observed in posterior treatments in the soil column containing dolerite fines. Dark and light grey shaded areas indicate ± two standard deviations for MICP and dolerite and MICP, respectively.

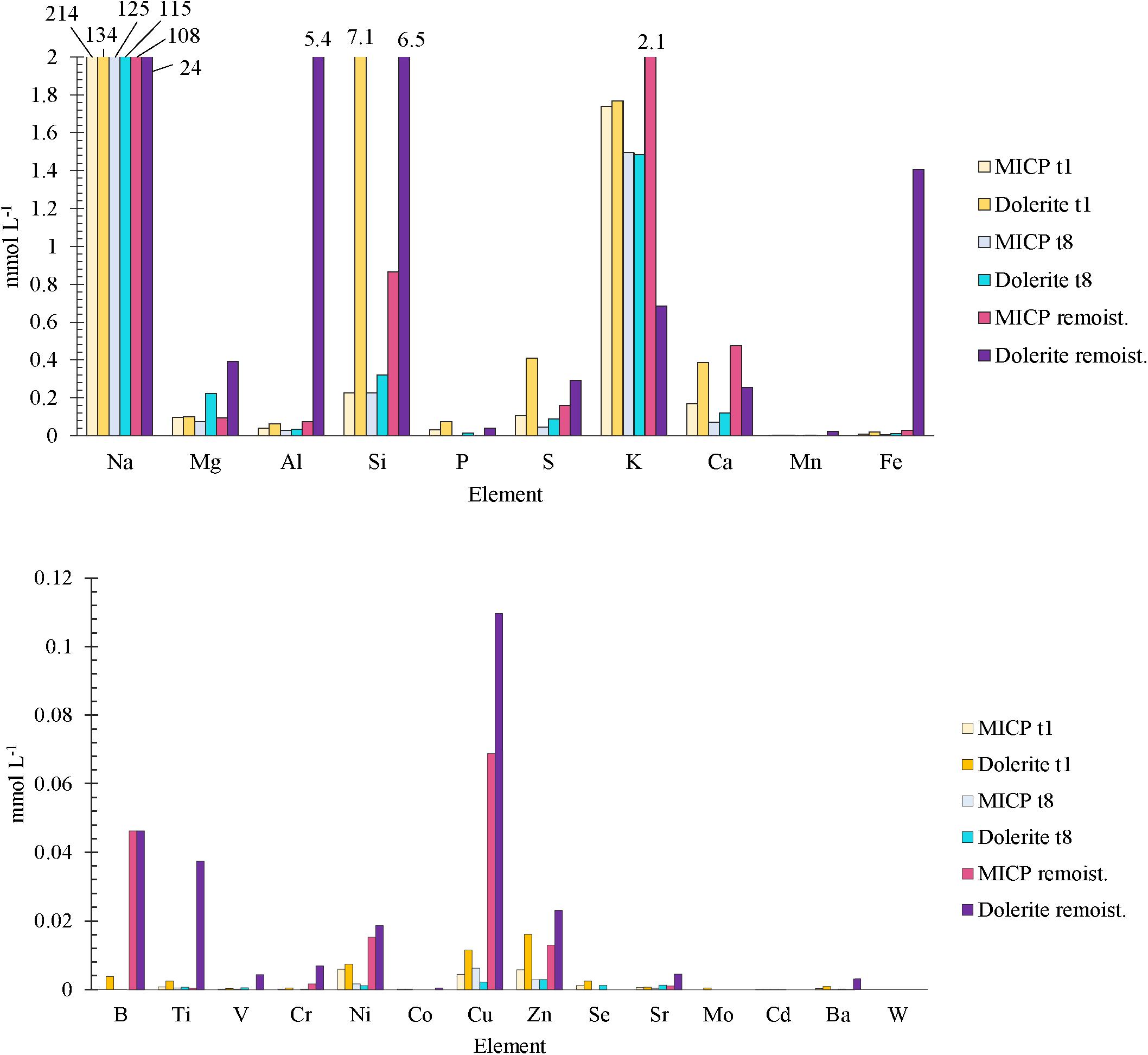

Soil leachates had a pH above 9 indicating urea hydrolysis and favourable environmental conditions for the formation of carbonate minerals (data not shown). ICP-OES analysis indicated Ca (<0.5 mM) was removed from the soil aqueous phase (Figure 3A). Ca, Mg, S, P, Si, and Al, present in both soil leachates at <1 mM, were found in larger concentration in the leachate obtained from the column containing dolerite fines. Si concentration was particularly high (7.8 mM) after the first cementation treatment. A month after finalising the treatment, the soil leachate from the column containing dolerite fines contained Si (6.3 mM), Al (5.4 mM), and Fe (1.4 mM), while for the column treated with the traditional MICP solution these elements remained <1 mM. Further, low concentrations (<0.1 mM) of Cu, Ti, Zn, Ni, Mn and Ba were detected (Figure 3B). Elemental analysis of TN and colorimetric analysis of urea, ammonium, nitrite and nitrate indicated that N, mainly ammonium (>66%), decreased to near-zero values during the drying phase that followed the end of MICP treatment until soil columns were rewetted. Urea hydrolysis rates between 2.038 and 4.374 mM h–1 were determined during the MICP cementation phase. Nitrite (<0.05 mM) and nitrate (<3 mM) were low throughout (Supplementary Table S2).

Figure 3. ICP-OES analysis (n = 1) of common (above) and trace (below) weathered elements dissolved in soil leachate samples obtained after first (t1) and last (t8) cementation treatments and a month after finalising the treatment (rewetting) for columns treated with traditional MICP and soil column containing dolerite fines treated with MICP (Dolerite). Analysis carried out by James Hutton Ltd., Aberdeen, United Kingdom.

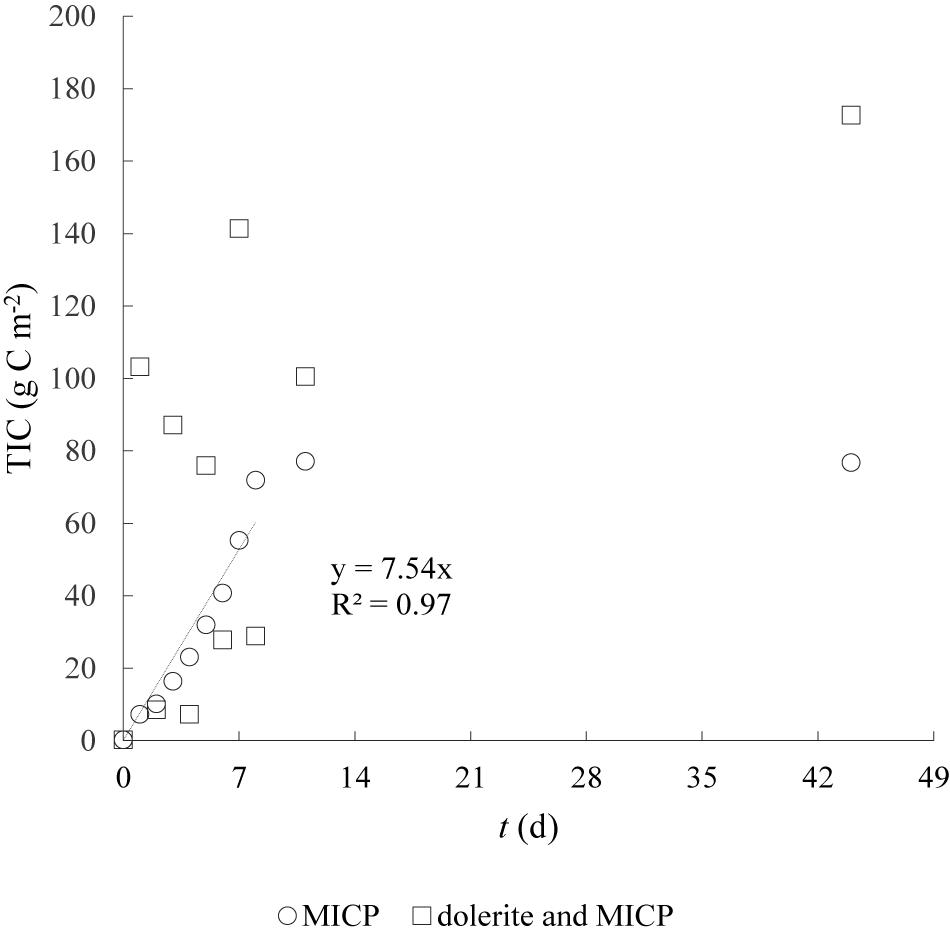

An increase in soil inorganic carbon (TIC) was observed during the treatment phase compared to the untreated soil inorganic C content (Figure 4). This indicated that carbonate minerals formed within the soil matrix in both treatments. For the soil column treated with the traditional MICP solution, TIC content increased linearly (r2 = 0.97) with the number of cementation treatments up to 77.16 g C m–2, with an average TIC accumulation of 7.54 g C m–2 per treatment. A month after finalising the treatment no further change in TIC was detected. For the soil column treated with dolerite fines, TIC (7.2–141.5 g C m–2) content was generally larger compared to the traditional MICP treatment. A month after finalising the treatment, the TIC content had increased further to 172.8 g C m–2. Combining these differences in precipitated C with the emissions reported in section “CO2 Fluxes During MICP,” the environmental cost of C emitted as CO2 per C precipitated was larger for traditional MICP (1.01) than for the dolerite fines treatment (0.67).

Figure 4. Soil total inorganic carbon during the MICP treatment phase for soil column treated with traditional MICP solution (MICP) and soil column containing dolerite fines (dolerite and MICP) determined by EA-IRMS (n = 2; SD < 0.002, SD smaller than markers). Regression line and equation fit of traditional MICP treatment data.

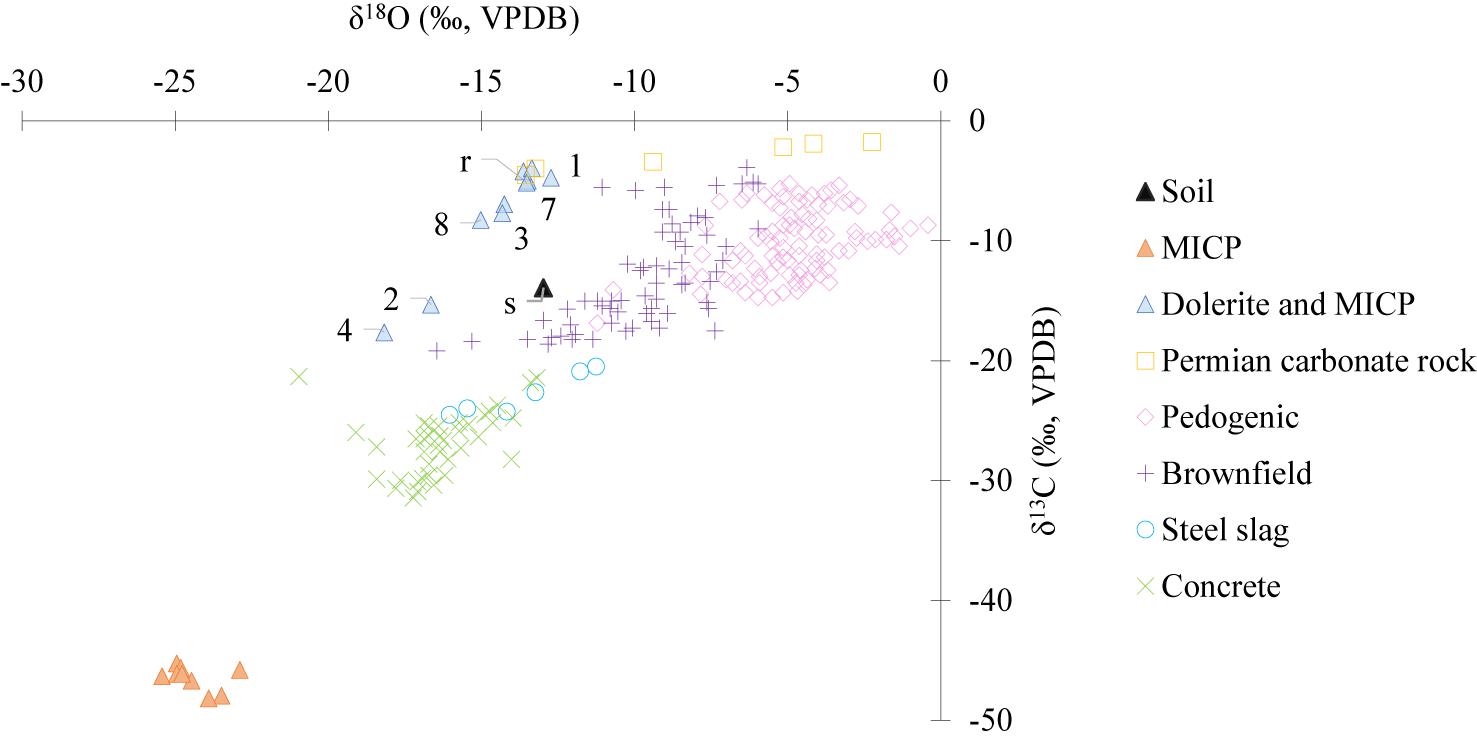

The results of the C and O isotopic analysis of precipitated carbonates differed markedly between the two treatments (Figure 5), with average values of δ18O = −24.1‰ and δ13C = −46.4‰ relative to VPDB for the column treated with the traditional MICP solution, and δ18O = −14.6‰ and δ13C = −8.2‰ for the column treated with dolerite fines and MICP. The isotopic signature of TIC precipitated after treatment with the traditional MICP solution was similar to that of C in urea (δ13C = −41.03‰). In contrast, for the column containing dolerite fines, δ13C values were similar to geological and pedogenic C, although δ18O values were more negative (Figure 5). There was a strong linear correlation (r2 = 0.95) between δ18O and δ13C values with a slope of 2.78 and an intercept of 32.4 for the column containing dolerite fines. In contrast, values of the column treated with the traditional MICP solution formed a cluster without clear linear relationship.

Figure 5. Stable isotopic signature of precipitated carbonates (δ18O ‰ and δ13C ‰, VPDB) (n = 2; SD < 1.9, SD smaller than markers) in soil column treated with traditional MICP (MICP) and soil column containing dolerite fines treated with MICP (dolerite and MICP). Numeric labels indicate the treatment number and “r” label stands for “re-wetting.” Data from concrete (Macleod et al., 1991; Krishnamurthy et al., 2003), steel slag (Renforth et al., 2009), brownfield sites (Washbourne et al., 2015; Jorat et al., 2020), Permian carbonate rock (Harwood and Coleman, 1981), and pedogenic soil carbonates (Salomons et al., 1978) included for comparison.

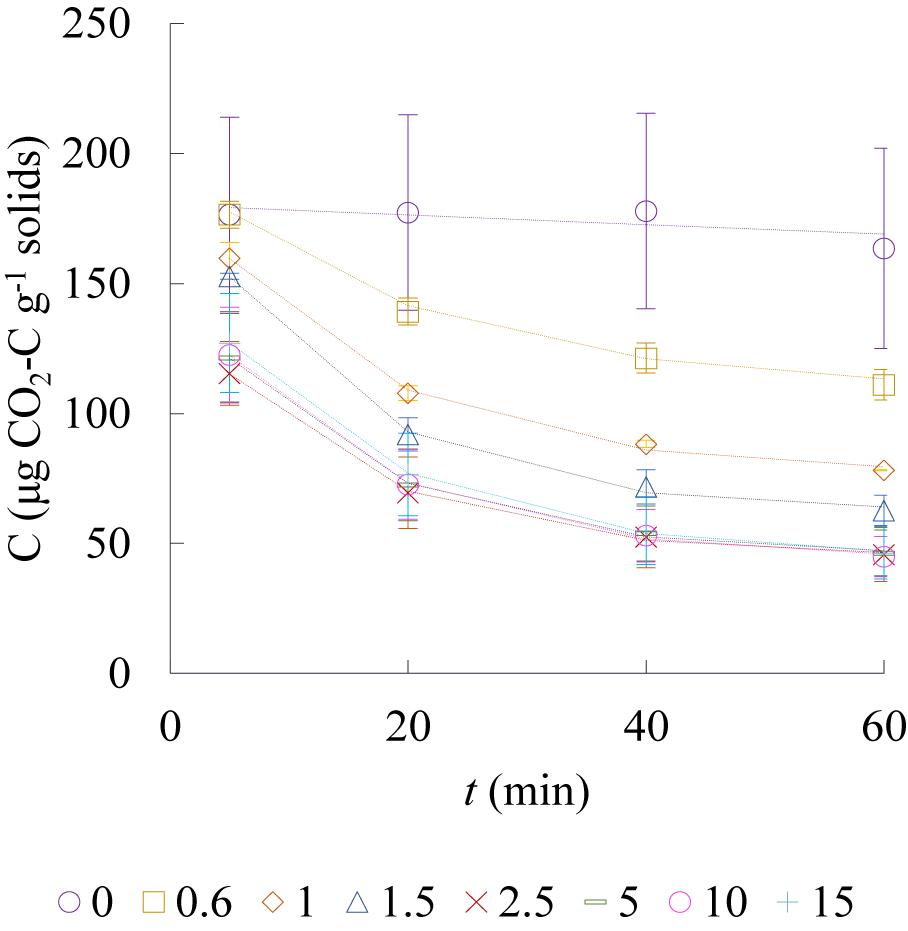

The CO2 sequestration potential of dolerite fines during chemical weathering at low liquid-to-solid ratios was studied in an isolated environment by gas chromatography. Results fitted with Eq. (1) indicated that the concentration at the equilibrium boundary value decreased from almost 170 to around 46 μg CO2-C per g of solids with increasing water content (Figure 6). Repeated water additions on consecutive days led to smaller CO2 variation in the vial headspace such that the exponential fit was found unsuitable due to the flat trends (data not shown). The reaction of CO2 with water and dolerite fines was accelerated with increasing water content up to a L/S ratio of 1.5 and levelled off for higher L/S. Increasing the liquid to solid ratio above 2.5 and up to 15 did not lead to larger CO2 sequestration (Figure 6) but reduced significantly the capacity of the material to sequester CO2 on consecutive water additions via chemical weathering (data not shown).

Figure 6. Evolution of CO2-C normalised to the mass of solids in vial headspace during chemical weathering of dolerite fines in distilled water at fixed liquid-to-solid ratios (L/S = 0, 0.6, 1.0, 1.5, 2.5, 5, 10, and 15) over 60 min, analysed with gas chromatography (n = 3; SD indicated with error bars). Lines correspond to the fitting model described by Eq. (1). Data corresponds to experiment day 1.

Our study on soil-atmosphere CO2 fluxes of a sandy soil treated with MICP showed net CO2 emissions throughout the treatment phase and the following 3 weeks of post-treatment. The reaction time of a cementation treatment and the soil water saturation conditions played an important role in the observed total CO2 emissions, with emissions increasing with time during reaction time intervals and decreasing with the addition of fresh solution. In partially saturated conditions, occurring during the drying phases, emission levels remained high with larger CO2 emissions resulting from partially saturated conditions compared to submerged conditions, similar to observations reported by Rahman (2013). The bacterial activity decayed following the traditional MICP treatment, as indicated by the decreasing CO2 emissions (Figure 1). The linear increase in soil TIC during the MICP treatment indicated that the formation of calcium carbonate was limited by the availability of Ca and, following treatment, TIC built up in soil (Figure 4) was limited by the depletion of divalent cations. The isotopic analysis showed the precipitated carbonate C (−46‰) originating from urea is similar to reported δ13C values of carbonate C precipitated during MICP (Millo et al., 2012).

The low contents of TOC, TIC, fines and low soil moisture indicated that the soil was mainly composed of pure silica sand, and the isotopic signature of TOC (−26‰) and TIC (−14‰) indicated the soil C to be of C3 plant biogenic origin (Cerling, 1984; Manning, 2008). Thus, in the absence of organic matter in decomposition, the differences in CO2 emission trends could be attributable to differences in soil microbial response to the environmental conditions created by the presence or absence of dolerite fines. Applying dolerite fines to the soil surface led to larger CO2 emissions and larger precipitation of inorganic C compared to the traditional MICP treatment. CO2 emissions during the reaction time were found to be on average two times larger than for the common MICP solution treatment (Figure 2). Based on the average values presented in Figure 2, CO2 emissions of a typical MICP cementation treatment could be reduced by 75% with reaction time shorter than 8 h and by 50% with reaction time shorter than 10 h. While urea hydrolysis rates may vary greatly for different soil types and whether MICP is induced by stimulation of indigenous bacteria or by bioaugmentation (introduction of exogenous ureolytic bacterial strains), results on clean silica sand presented by Al Qabany and Soga (2013) indicated 8 h of reaction time were sufficient for optimum degradation of urea and production of carbonates. The larger CO2 emissions observed after treatment pointed to an enhanced biological activity, fuelled by the presence of oxygen and the availability of elements released by biological weathering of dolerite fines. Dolerite fines dissolution in the biologically active environment balanced CO2 emissions induced by the treatment for approximately 1.5 d after application (Figure 1). The pH of outlet liquid samples of both columns was above 9, indicating urea hydrolysis occurred and resulted in CO2 emissions in the column that did not contain dolerite fines. Instead, near-zero CO2 fluxes were monitored for the soil column containing dolerite fines and a large increase in precipitated inorganic carbon was also recorded (Figure 4). This was also observed during chemical weathering experiments, where the large CO2 sequestration capacity of the material decreased dramatically after 24 h. The chemical weathering experiments showed that CO2 sequestration rates increased with increasing water content up to L/S ratios of 1.5–2.5, while larger L/S ratios accelerated the drop in CO2 sequestration capacity resulting in flat trends on the second consecutive day the experiment was run with the same material (data not shown). Calcium carbonate precipitated on silicate mineral surfaces was not found to decrease dissolution kinetics of diopside by Stockmann et al. (2013) suggesting that the weatherability and the CO2 sequestration capacity of dolerite fines were initially controlled by the reactive mineral surface area. Far-from-equilibrium conditions accelerated reactive surface area reduction, therefore decreasing the large short-term CO2 sequestration capacity of the material.

Our data supports biological weathering played significant role in overall rock weathering and TIC accumulation, as dolerite fines showed a large but short-lived chemical weathering capacity and the environmental conditions produced by urea hydrolysis were highly alkaline. The large initial Si release and Ca, Mg and Al determined in soil leachates (Figure 3) indicated a continuous release of elements by dolerite fines during the MICP treatment. CO2 emissions and the large concentration of Al, Si and Fe and of Ca, Mg, P, S and other elements indicated rock weathering and soil biological activity continued throughout the drying phase following the MICP treatment. The Fe was possibly in its oxidised state and thus unable to form carbonates, given the availability of inorganic C and alkaline pH. The application of dolerite fines was not found to significantly enhance nor inhibit the activity of ureolytic microorganisms, as indicated by the similar urea hydrolysis rates, pH, and ammonia levels determined in soil leachates of both treatments. Our data indicate that urea was completely hydrolysed 24 h after application, supporting previous studies (e.g., Haynes and Williams, 1992). Petersen et al. (2004) showed that urea-C, applied at concentrations similar to those in this study, contributed less than 1% of the total soil CO2 emissions 4 days after application. This and the larger CO2 emissions during reaction time of the cementation treatment (Figure 2) indicated that the larger CO2 emissions observed for the column containing dolerite fines may not be solely attributable to the activity of ureolytic microorganisms, but to an overall increased soil respiration. The increased CO2 emissions detected between 6 and 12 days after finalising the MICP treatment may be indicative of favourable environmental conditions, provided by moisture and ammonia removal from the environment by evaporation, volatilisation and nitrification. However, nitrous oxides were determined at low concentrations, and nitrification may have been inhibited as a result of ammonia toxicity (Anthonisen et al., 1976; Smith et al., 1997; Petersen et al., 2004). Whether the availability of elements provided by the treatment and the presence of dolerite was the cause of diversification of stimulated soil microbiota and/or allowed for larger community numbers and was responsible for the larger CO2 emissions observed should be investigated further.

The large variability observed in TIC did not necessarily correspond to soil TIC, but to TIC precipitated on dolerite and soil. The isotopic signature of carbonate C (−8.2‰), similar to carbonates from Permian carbonate rocks (Harwood and Coleman, 1981), pedogenic carbonates formed in soils (Salomons et al., 1978) and brownfield sites (Washbourne et al., 2015; Jorat et al., 2020) and steel slag carbonates (Renforth et al., 2009) indicated the carbonate C was not derived from urea-C. Instead, the data indicated that carbonates formed as a combination of “natural” pedogenic carbonate formation processes combined with carbonates formed in highly alkaline environments by hydroxylation of dissolved CO2, and that both mechanisms were controlled by CO2 gas diffusion in solution (Dietzel et al., 1992; Renforth et al., 2009). This suggested that weathered Ca readily reacted with dissolved inorganic C within the dolerite layer and precipitated on silicate mineral surfaces, while unattached carbonates percolated through the soil column. This may have been additionally favoured by the alkaline conditions induced by urea hydrolysis. While TIC in soil treated with dolerite and MICP was generally higher than in the traditional MICP treatment, slightly lower TIC values observed for some samples in Figure 4 compared to the traditional MICP treatment and may indicate that carbonate precipitation occurred to a lesser extent within the soil layer. However, TIC analysis were not conducted at different depths nor a specific procedure to ensure separation of the different materials (soil and dolerite) was conducted. Additionally, while dolerite was sampled along with soil in some cases, as presented in Supplementary Figure S3 as example, this was not always the case. Therefore, the observed variability in precipitated TIC may be due to several factors. Variability of TIC analysis could be due to non-homogeneity of precipitated TIC produced by the low permeability of dolerite fines (Casas et al., 2019) compared to the soil layer, which could have created preferential paths, resulting in TIC building up in some areas more than others. Similarly, samples taken for TIC analysis could contain variable fractions of dolerite fines that percolated through the soil matrix in some areas more than others. Geotechnical tests were not conducted on soil columns after the treatment, therefore, TIC data suggests that these aspects should be further investigated to elucidate the suitability of dolerite fines for certain applications, such as for soil stabilisation.

Our study on CO2 fluxes during MICP on sandy soil using CaCl2 and dolerite fines as sources for calcium demonstrated large CO2 emission levels are the result of microbial activity induced by the treatment. The emissions were not balanced by the removal mechanism through carbonate precipitation due to the limited availability of divalent cations. The post-treatment biological activity was enhanced by the presence of dolerite fines and resulted in larger CO2 emissions and increased overall TIC content. However, from the present experiments it remains unclear how much TIC formation took place in the soil itself. Biological weathering of dolerite fines was revealed by the presence of Al and Si in the soil leachate and indicated the potential for long-term TIC accumulation. CO2 emissions of MICP treatment were reduced with dolerite fines and isotope data showed atmospheric CO2 was sequestered in the presence of dolerite whereas traditional MICP primarily sequestered C from urea. Overall CO2 emissions could be reduced through optimising the flushing-reaction time sequence. Maintaining submerged conditions and reaction times within 8–10 h could reduce CO2 emissions of a typical MICP treatment by 50–75%. However, reaction time should be adapted to specific soil urea hydrolysis rates to ensure sufficient production of carbonate. Further, CO2 emissions could be directly balanced via chemical weathering by the application of unweathered dolerite fines due to the large reactive surface area of the material. In this aspect, maintaining liquid to solid ratios equal or below 2.5 would maximise the capacity of dolerite to balance CO2 emissions. We postulate that these results are applicable to other fields of research, such as agriculture. The soil environmental conditions induced by the MICP process resemble those generated with the application of natural and synthesised N and Ca-containing fertilisers on land. The effect of soil organic matter and living plants should therefore be incorporated in further studies.

The datasets generated for this study are available upon request.

MEJ and CS were project supervisors. MEJ, AG, NB, and CC contributed to the experimental design. AG and CC carried out the experiments. AG, NB, and CC contributed to the analysis of data. CC wrote the original draft manuscript. MEJ, AG, NB, and CS reviewed and edited the manuscript. All authors contributed to the article and approved the submitted version.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

This research was conducted with the financial support of the Scottish Alliance for Geoscience, Environment and Society (SAGES, www.sages.ac.uk), the Research-led Innovation Nodes for Contemporary Society (Rlincs) programme of Abertay University, the Norman Fraser Design Trust, the Institute of Bio- and Geosciences, Agrosphere (IBG-3), Forschungszentrum Jülich and the SAGES 5th Small Grant Scheme (https://www.sages.ac.uk/graduate-school/small-grants-scheme/) in a collaborative framework between SAGES and ABC/J Geoverbund (www.geoverbund.de) partner organisations.

Special thanks are given to the funding bodies, the laboratory technicians F. Leistner, H. Wissel, S. Kummer, and L. Weihermüller of the Institute of Bio- and Geosciences, Agrosphere (IBG-3), Forschungszentrum Jülich, the James Hutton Institute Aberdeen (Scotland) ICP section lead F. Sturgeon and S. McIntyre, and the managers of Barrasford quarry, S. Bell, and Quarzweke Frechen quarry, A. Graf, for sourcing the materials used in this study.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fmicb.2020.557119/full#supplementary-material

C, Carbon; CO2, Carbon dioxide; DIC, Dissolved inorganic carbon; N, Nitrogen; O, Oxygen; TIC, Total inorganic carbon; TN, Total nitrogen; TOC, Total organic carbon.

Al Qabany, A., and Soga, K. (2013). Effect of chemical treatment used in MICP on engineering properties of cemented soils. Geotechnique 63, 331–339.

Anthonisen, A. C., Loehr, R. C., Prakasam, T. B. S., and Srinath, E. G. (1976). Inhibition of nitrification by ammonia and nitrous acid. J. Water Pollut. Control Fed. 48, 835–852.

Beerling, D. J., Leake, J. R., Long, S. P., Scholes, J. D., Ton, J., Nelson, P. N., et al. (2018). Farming with crops and rocks to address global climate, food and soil security. Nat. Plants 4, 138–147.

Burbank, M. B., Weaver, T., Lewis, L., Williams, T., Williams, B., Crawford, R., et al. (2013). Geotechnical tests of sands following bioinduced calcite precipitation catalyzed by indigenous bacteria. J. Geotech. Geoenviron. Eng. 139, 928–936.

Burbank, M. B., Weaver, T. J., Green, T. L., Williams, B. C., and Crawford, R. L. (2010). Precipitation of calcite by indigenous microorganisms to strengthen liquefiable soils. Geomicrobiol. J. 28, 301–312.

Burbank, M. B., Weaver, T. J., Williams, B. C., and Crawford, R. L. (2012). Urease activity of ureolytic bacteria isolated from six soils in which calcite was precipitated by indigenous bacteria. Geomicrobiol. J. 29, 389–395. doi: 10.1080/01490451.2011.575913

Casas, C. C., Schaschke, C. J., Akunna, J. C., and Jorat, M. E. (2019). Dissolution experiments on dolerite quarry fines at low liquid-to-solid ratio: a source of calcium for MICP. Environ. Geotech. 1–9. doi: 10.1680/jenge.19.00067

Cerling, T. E. (1984). The stable isotopic composition of modern soil carbonate and its relationship to climate. Earth Planet. Sci. Lett. 71, 229–240. doi: 10.1016/0012-821x(84)90089-x

Cheng, L., Shanin, M. A., and Cord-Ruwisch, R. (2014). Bio-cementation of sandy soil using microbially induced carbonate precipitation for marine environments. Géotechnique 64, 1010–1013. doi: 10.1680/geot.14.t.025

Choi, S., Chu, J., Brown, R. C., Wang, K., and Wen, Z. (2017). Sustainable biocement production via microbially induced calcium carbonate precipitation: use of limestone and acetic acid derived from pyrolysis of lignocellulosic biomass. ACS Sustain. Chem. Eng. 5, 5183–5190. doi: 10.1021/acssuschemeng.7b00521

Choi, S., Shifan, W., and Jian, C. (2016). Biocementation for sand using an eggshell as calcium source. J. Geotech. Geoenviron. Eng. 142:06016010. doi: 10.1061/(asce)gt.1943-5606.0001534

Debajyoti, P., and Skrzypek, G. (2007). Assessment of carbonate-phosphoric acid analytical technique performed using GasBench II in continuous flow isotope ratio mass spectrometry. Int. J. Mass Spectrom. 262, 180–186. doi: 10.1016/j.ijms.2006.11.006

DeJong, J. T., Soga, K., Kavazanjian, E., Burns, S., Van Paassen, L. A., Al Qabany, A., et al. (2013). Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Geotechnique 63, 287–301.

Dietzel, M., Usdowski, E., and Hoefs, J. (1992). Chemical and 13C/12C-and 18O/16O-isotope evolution of alkaline drainage waters and the precipitation of calcite. Appl. Geochem. 7, 177–184. doi: 10.1016/0883-2927(92)90035-2

Gat, D., Tsesarsky, M., Shamir, D., and Ronen, Z. (2014). Accelerated microbial-induced CaCO3 precipitation in a defined coculture of ureolytic and non-ureolytic bacteria. Biogeosciences 11, 2561–2569. doi: 10.5194/bg-11-2561-2014

Harwood, G. M., and Coleman, M. L. (1981). Isotopic Evidence from Mineralization in the premian lower magnesian limestone. J. Geol. Soc. 138:219.

Haynes, R. J., and Williams, P. H. (1992). Changes in soil solution composition and ph in urine-affected areas of pasture. J. Soil Sci. 43, 323–334. doi: 10.1111/j.1365-2389.1992.tb00140.x

Jorat, M. E., Goddard, M. A., Manning, P., Lau, H. K., Ngeow, S., Sohi, S. P., et al. (2020). Passive CO2 removal in urban soils: evidence from brownfield sites. Sci. Total Environ. 703:135573. doi: 10.1016/j.scitotenv.2019.135573

Knorst, M. T., Neubert, R., and Wohlrab, W. (1997). Analytical methods for measuring urea in pharmaceutical formulations. J. Pharm. Biomed. Anal. 15, 1627–1632. doi: 10.1016/s0731-7085(96)01978-4

Krishnamurthy, R. V., Schmitt, D., Atekwana, E. A., and Baskaran, M. (2003). Isotopic investigations of carbonate growth on concrete structures. Appl. Geochem. 18, 435–444. doi: 10.1016/s0883-2927(02)00089-6

Macleod, G., Fallick, A. E., and Hall, A. J. (1991). The mechanism of carbonate growth on concrete structures, as elucidated by carbon and oxygen isotope analyses. Chem. Geol. 86, 335–343. doi: 10.1016/0168-9622(91)90015-o

Manning, D. A. C. (2008). Biological enhancement of soil carbonate precipitation: passive removal of atmospheric CO2. Mineral. Mag. 72, 639–649. doi: 10.1180/minmag.2008.072.2.639

Manning, D. A. C., Renforth, P., Lopez-Capel, E., Robertson, S., and Ghazireh, N. (2013). Carbonate precipitation in artificial soils produced from basaltic quarry fines and composts: An opportunity for passive carbon sequestration. Int. J. Greenhouse Gas Control 17, 309–317. doi: 10.1016/j.ijggc.2013.05.012

Millo, C., Dupraz, S., Ader, M., Guyot, F., Thaler, C., Foy, E., et al. (2012). Carbon isotope fractionation during calcium carbonate precipitation induced by ureolytic bacteria. Geochim. Cosmochim. Acta 98, 107–124. doi: 10.1016/j.gca.2012.08.029

Mitchell, C. J., Mitchell, P., and Pascoe, R. D. (2008). “Quarry fines minimisation: can we really have 10mm aggregate with no fines?,” in Proceedings of the 14th Extractive Industry Geology Conference, eds G. Walton, (Exeter: EIG Conferences) 37–44.

Montoya, B. M., DeJong, J. T., and Boulanger, R. W. (2013). Dynamic response of liquefiable sand improved by microbial-induced calcite precipitation. Géotechnique 63, 302–312. doi: 10.1680/geot.sip13.p.019

Okyay, T. O., Nguyen, H. N., Castro, S. L., and Rodrigues, D. F. (2016). CO2 sequestration by ureolytic microbial consortia through microbially-induced calcite precipitation. Sci. Total Environ. 572, (Suppl. C), 671–680. doi: 10.1016/j.scitotenv.2016.06.199

Okyay, T. O., Rodrigues, D. F., and Laanbroek, R. (2015). Biotic and abiotic effects on CO 2 sequestration during microbially-induced calcium carbonate precipitation. FEMS Microbiol. Ecol. 91:fiv017.

Petersen, S. O., Roslev, P., and Bol, R. (2004). Dynamics of a pasture soil microbial community after deposition of cattle urine amended with [13C]urea. Appl. Environ. Microbiol. 70, 6363–6369. doi: 10.1128/aem.70.11.6363-6369.2004

Rahman, M. (2013). Carbon dioxide emission from Soil. Agric. Res. 2, 132–139. doi: 10.1007/s40003-013-0061-y

Ramnarine, R., Voroney, R. P., Wagner-Riddle, C., and Dunfield, K. E. (2011). Carbonate removal by acid fumigation for measuring the δ13C of soil organic carbon. Canad. J. Soil Sci. 91, 247–250. doi: 10.4141/cjss10066

Randall, B. A. O. (1989). Dolerite-pegmatites from the Whin sill near barrasford, Northumberland. Proc. Yorkshire Geol. Soc. 47, 249–265. doi: 10.1144/pygs.47.3.249

Renforth, P. (2012). The potential of enhanced weathering in the UK. Int. J. Greenhouse Gas Control 10, 229–243. doi: 10.1016/j.ijggc.2012.06.011

Renforth, P., Manning, D., and Lopez-Capel, E. (2009). Carbonate precipitation in artificial soils as a sink for atmospheric carbon dioxide. Appl. Geochem. 24, 1757–1764. doi: 10.1016/j.apgeochem.2009.05.005

Salomons, W., Goudie, A., and Mook, W. G. (1978). Isotopic composition of calcrete deposits from Europe, Africa and India. Earth Surf. Process. 3, 43–57. doi: 10.1002/esp.3290030105

Smith, R. V., Burns, L. C., Doyle, R. M., Lennox, S. D., Kelso, B. H. L., Foy, R. H., et al. (1997). Free ammonia inhibition of nitrification in river sediments leading to nitrite accumulation. J. Environ. Qual. 26, 1049–1055. doi: 10.2134/jeq1997.00472425002600040016x

Stockmann, G. J., Wolff-Boenisch, D., Gislason, S. R., and Oelkers, E. H. (2013). Do carbonate precipitates affect dissolution kinetics?: 2: Diopside. Chem. Geol. 337-338, 56–66. doi: 10.1016/j.chemgeo.2012.11.014

Keywords: CO2 sequestration, CO2 emissions, MICP, calcium-rich silicate rock, basaltic quarry fines, weathering, calcite, pedogenic carbonates

Citation: Casas CC, Graf A, Brüggemann N, Schaschke CJ and Jorat ME (2020) Dolerite Fines Used as a Calcium Source for Microbially Induced Calcite Precipitation Reduce the Environmental Carbon Cost in Sandy Soil. Front. Microbiol. 11:557119. doi: 10.3389/fmicb.2020.557119

Received: 29 April 2020; Accepted: 17 August 2020;

Published: 08 September 2020.

Edited by:

David Manning, Newcastle University, United KingdomReviewed by:

Damien Robert Finn, Arizona State University, United StatesCopyright © 2020 Casas, Graf, Brüggemann, Schaschke and Jorat. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Alexander Graf, YS5ncmFmQGZ6LWp1ZWxpY2guZGU=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.