- 1Abstract Landscapes, Montpellier, France

- 2European Organization for Nuclear Research (CERN), Geneva, Switzerland

- 3Department of Physics and Astronomy, KU Leuven, Geel, Belgium

- 4Istituto Nazionale di Fisica Nucleare (INFN), Sezione di Torino, Torino, Italy

- 5Centro Nazionale di Adroterapia Oncologica (CNAO), Pavia, Italy

- 6TRIUMF, Vancouver, BC, Canada

- 7Ludwig Maximilian University of Munich (LMU), Munich, Germany

- 8MedAustron, Wiener Neustadt, Austria

Particle therapy relies on the advantageous dose deposition which permits to highly conform the dose to the target and better spare the surrounding healthy tissues and organs at risk with respect to conventional radiotherapy. In the case of treatments with heavier ions (like carbon ions already clinically used), another advantage is the enhanced radiobiological effectiveness due to high linear energy transfer radiation. These particle therapy advantages are unfortunately not thoroughly exploited due to particle range uncertainties. The possibility to monitor the compliance between the ongoing and prescribed dose distribution is a crucial step toward new optimizations in treatment planning and adaptive therapy. The Positron Emission Tomography (PET) is an established quantitative 3D imaging technique for particle treatment verification and, among the isotopes used for PET imaging, the 11C has gained more attention from the scientific and clinical communities for its application as new radioactive projectile for particle therapy. This is an interesting option clinically because of an enhanced imaging potential, without dosimetry drawbacks; technically, because the stable isotope 12C is successfully already in use in clinics. The MEDICIS-Promed network led an initiative to study the possible technical solutions for the implementation of 11C radioisotopes in an accelerator-based particle therapy center. We present here the result of this study, consisting in a Technical Design Report for a 11C Treatment Facility. The clinical usefulness is reviewed based on existing experimental data, complemented by Monte Carlo simulations using the FLUKA code. The technical analysis starts from reviewing the layout and results of the facilities which produced 11C beams in the past, for testing purposes. It then focuses on the elaboration of the feasible upgrades of an existing 12C particle therapy center, to accommodate the production of 11C beams for therapy. The analysis covers the options to produce the 11C atoms in sufficient amounts (as required for therapy), to ionize them as required by the existing accelerator layouts, to accelerate and transport them to the irradiation rooms. The results of the analysis and the identified challenges define the possible implementation scenario and timeline.

Introduction

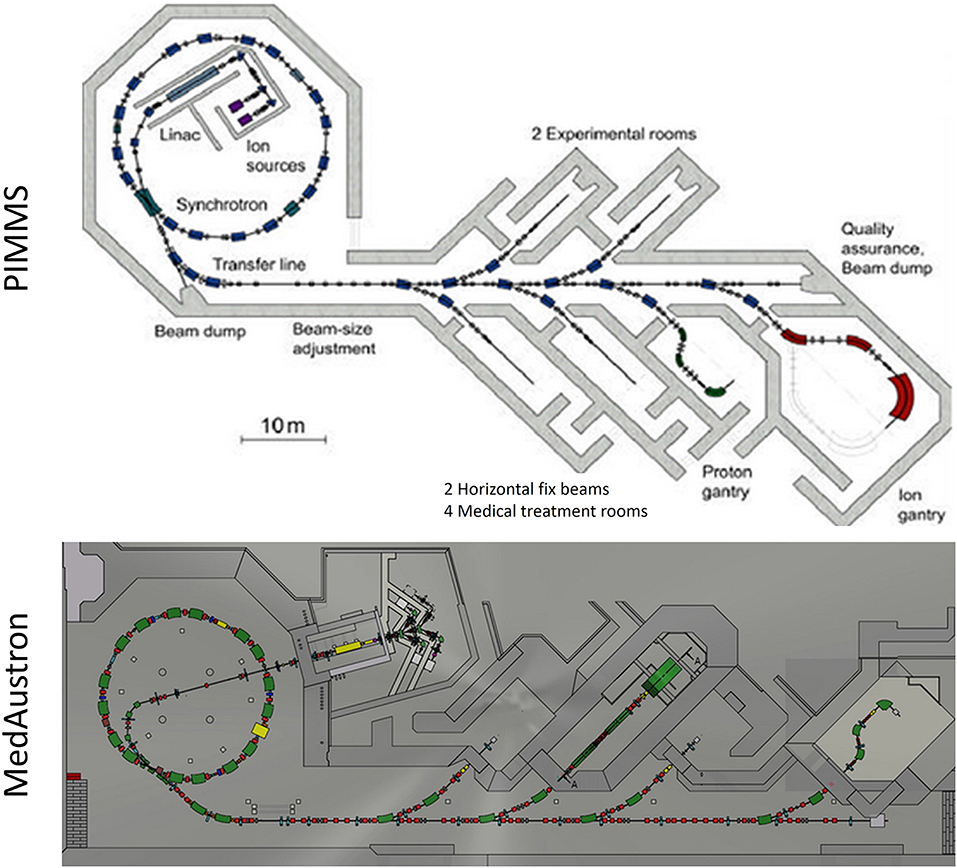

Accelerators are used in a wide range of societal applications, the most notable being those related to external radiotherapy, and particularly with accelerated ion beams. When the first accelerators were developed, nuclear physicists realized soon after that they could trigger a new field of research via purified secondary Radioactive Ion Beams (RIB). This triggered the development and use of so-called Isotope mass Separation OnLine (ISOL) Facilities and Fragmentation facilities. A proof-of-concept application of the RIB to radiotherapy was performed at the Lawrence Berkeley National Laboratory, first at the Bevalac complex (1) and later under the BEARS collaboration, when it was demonstrated that a radioactive carbon ion, emitting positrons, could be used both for radiotherapy and imaging applications, exploiting the PET-imaging which was becoming a mature diagnosis imaging technique (2). Important developments further took place, with the first particle therapy facilities exploiting accelerated carbon ions coming online (based on the PIMMS design (3), as well as with new production and preparation techniques for isotope accelerators allowing the production of accelerated RIBs (notably implemented at REX-ISOLDE at CERN) (4).

The Marie-Curie training network MEDICIS-Promed brought together in a dedicated Work Package 15 young scientists across different institutes with Research Topics covering the chain from production to acceleration of 11C radionuclear beams (5). In strong contrast with stable ion beam facilities, the acceleration and delivery schemes of radioactive ion beams requires careful evaluation and optimized processes, because of the extremely limited quantities produced in the targets as opposed to large excess sources of stable 1H or 12C in case of stable beam facilities. Different production routes were investigated, and their suitability with the low energy preparation steps for injection in the Linac and subsequent acceleration schemes were investigated. Finally, the main scenarios to integrate the isotope production and acceleration into an existing hadron therapy facility were drafted.

Motivation for Carbon-11 Beams: Overview and Modeling

The use of 11C for particle therapy can reduce the overall treatment time and increase the treatment quality (compared to the use of the stable isotope 12C). We detail in the present chapter how these improvements can be achieved, supported by simulation and experimental data.

Particle therapy relies on the advantageous dose deposition which permits to highly conform the dose to the target and better spare the surrounding healthy tissues and organs at risk (OAR) with respect to conventional radiotherapy (6). In the case of treatments with heavier ions (like carbon ions already clinically used and oxygen ions, planned for future clinical use), another advantage is the enhanced Relative Biological Effectiveness (RBE) due to high Linear Energy Transfer (LET) radiation.

These particle therapy advantages are not unfortunately thoroughly exploited due to particle range uncertainties. In fact, heavy charged particles show the characteristic dose distribution with a narrow Bragg Peak at the end of their range. In the most advanced beam delivery implementation of so-called pencil beam scanning, particle pencil beams have to deposit the dose distribution to the Clinical Target Volume (CTV) and Planning Target Volume (PTV) by precisely stopping into the patient body at the required depth. In literature (7), the range uncertainty contributions have been studied, identifying the sources of uncertainty both independent or dependent of dose calculation. Into the first category, there are beam reproducibility, patient positioning and setup, measurements in water for commissioning. In the latter group, there are CT calibration, tissue conversion, mean ionization energy estimation, range degradation for complex inhomogeneities.

In clinics, in order to design a robust treatment plan with respect to range uncertainties, safety margins of about (2.5–3.5)%+(1–3) mm (7) have to be considered during the treatment plan optimization procedure. In particular, this procedure aims at finding the most robust way to deliver the prescribed dose to the CTV and PTV minimizing the dose released in the Planning organ at Risk Volume (PRV) that represents the segmentation of the OAR with an additional margin related to position uncertainty.

Unfortunately, these safety margins are not enough to consider also patient's morphological changes that can occur during therapy (8, 9); such as tumor shrink/growth, inflammation, toxicity, loss of weight, cavities filling or emptying. Even though these variations are a well-known source of sub-optimal irradiation (10), they cannot be easily modeled or quantified because they strongly depend on the pathology and treated district.

To mitigate the unwanted degradation of dose distribution during the treatment course, patients who are affected by pathologies that are more prone to morphological changes, undergo periodic control Computed Tomography (CT) exams in order to check thanks to the Treatment Planning System (TPS) calculation that the actual delivered dose on the new patient morphology is still compliant with the prescription to the CTV and adequate for OARs limits. If necessary, these control CTs can be used to replan the treatment. For example, in (11) a retrospective study over 730 patients, affected by cranial and extracranial tumor, shows that an adaptive replanning was required in 5.5% of cases due to morphological or anatomic changes.

The possibility to monitor the compliance between the ongoing and prescribed dose distribution is a crucial step toward new optimizations in treatment planning and adaptive therapy. Therefore, in the last decades, in vivo treatment verification devices, based on the detection of secondary radiation, have been explored. They detect the products of the nuclear interactions between the primary beam and patient tissues, such as prompt photons obtained from nuclear de-excitation, secondary charged particles generated by nuclear fragmentation, and annihilation photons coming from positron emitters (12–14). Among them, Positron Emission Tomography (PET) is an established quantitative 3D imaging technique for particle treatment verification. The annihilation signal can be acquired both during and after the irradiation and presents a very good correlation to Bragg peak for heavy ions such as carbon or oxygen due to projectile fragmentation and related positron emitter production.

In the case of proton and carbon ion particle therapy, oxygen and carbon positron emitters are the most abundant products and their half-life is of the order of minutes or seconds. In particular, 11C has an half life of 20 min and the distribution of the 11C isotopes induced during 12C ion irradiation shows a peak well correlated with the Bragg Peak position because projectile fragmentation (15). In the case of 12C irradiation, the production of 11C has a small cross section; in total about 2% of the primary carbon ions undergo nuclear reactions for each cm of range in water (16). As a consequence, only about few percent of the primary 12C projectiles have been fragmented in 11C, yielding a PET image that is noisy and may require, depending on the detection efficiency, acquisition strategy and (for in-beam implementations) accelerator duty cycle, long acquisition time with respect to the delivery time to be significant.

Three different workflows for implementing treatment verification by means of a PET device have been explored (17, 18): off-line (PET/CT), in-room (PET or PET/CT) and in-beam (PET).

Off-line PET/CT relies on a commercial full-ring scanner sited outside the treatment room. The integrated CT system is useful for PET image co-registration on the planning CT. This instrumentation has a comparably low costs and PET images have good quality due to the full ring geometry. Nevertheless, the effectiveness of treatment verification is limited by the biological wash-out and the limited counting statistics due to the short decay time of the positron emitters along with positional uncertainties due to the patient repositioning. The clinical workflow into the treatment room is not slowed down with respect to the normal clinical routine. However, the off-line PET image requires long acquisition time for accumulating sufficient counting statistics [up to 30 min (19)] and this aspect has an indirect impact on the clinical routine and requires additional personnel.

In-room PET is based on a stand-alone full-ring PET or PET/CT scanner positioned inside the treatment room. With this configuration, the biological wash-out and the corresponding signal degradation are mitigated and a state-of-the-art PET image can be obtained in a reduced acquisition time with respect to the off-line PET [about 5 min (17)]. In order to minimize the patient repositioning uncertainty, in some in-room solutions, the same treatment couch can be also used. The main drawbacks are the slowing down of the clinical workflow in the treatment room and the need of radiation hard technology.

In-beam PET exploits a custom PET detector, able to acquire data during patient irradiation. In this operational modality, several geometrical constraints must be addressed for compatibility with the beam line and the clinical procedures and, therefore, a dual-head geometry (15, 20–22) or a complex full-ring geometry (23) have been investigated. The in-beam PET approach is the only solution to online verify the compliance of the ongoing and prescribed treatment. Biological wash-out, signal degradation and patient positioning uncertainty are strongly reduced but, on the other hand, since the in-beam PET devices are prototypes, there are high integration costs in the clinical routine.

The PET-based treatment verification can be performed in two ways. First, an inter-fractional comparison can be made by considering the experimental PET images of consecutive days or with respect to the PET image acquired in the first session of therapy (24). This approach relies on the reproducibility of the measurement. Another treatment verification approach is based on Monte Carlo simulations and aims at evaluating both accuracy and reproducibility of the experimental measurement (25). Moreover, some studies (26–29) investigated the possibility to analytically calculate the distribution of the positron emitters from planned dose information and, recently, these fast analytical approaches have been implemented into research Treatment Planning Systems (TPS) and compared with Monte Carlo simulations (27, 30).

In literature, several strategies and algorithms for treatment quality verification by means of PET images have been developed. Most of them rely on the identification of the activity distal fall-off with quantitative and automated methods [e.g., (24, 28, 31)] or visual analysis (32).

The main isotopes important in PET imaging verification in particle therapy are 11C, 10C and 15O. They are characterized by a relatively short half-life: 20 min for 11C, 20 s for 10C and 2 min for 15O.

Among them, the 11C has gained more attention from the scientific and clinical communities for its application as new radioactive projectile for particle therapy. This interest has been driven by its advantageous RBE with respect to protons and its reduced fragmentation with respect to oxygen (33). Moreover, the stable isotope 12C is successfully already in use in clinics. By comparison, the 10C would give a more prompt signal on the beam position but the very short decay time will lead to problems during acceleration to avoid a reduced statistics. 11C distribution can be acquired for minutes also after the irradiation although, in principle, the PET image will be affected by wash-out. Anyway, in the case of radioactive 11C beams, almost all the projectiles become useful probes for treatment verification and therefore the gain in statistics will lead to shorten the acquisition time and mitigate this drawback.

Comparing with its stable counterpart, 11C has the potential of improving PET signal counts by over a factor of 10 in offline PET acquisition mode and up to a factor of two in online mode, at the respective distribution's peak. Notwithstanding that, the signal peak resulting from 11C originates directly from the beam particles whereas the signal from stable carbon ion irradiation proceeds from positron emitters produced via fragmentation reactions. Consequently, the peak of the signal arising from the 11C irradiation tends to be better correlated with the Spread-Out Bragg Peak (SOBP) leading peak range, unlike the 12C case. Even though the effect is less evident in the online acquisition mode, due to relatively long half-life of 11C (~20 min) its use still allows for an easier identification of the SOBP range, overcoming the neutron-induced background, provided a reverse SOBP energy layer order is employed. Thus, this effect can lead to a more straightforward evaluation of the absorbed dose distribution and could have positive impact in range and treatment verification using in-beam PET techniques.

Experimental data pertaining 11C dosimetry and PET imaging performance have been obtained at QST/NIRS-HIMAC in Chiba, Japan. The experimental data consisted of: Bragg peak curves for stable and radioactive carbon ion beams in water; PET scanning and image acquisition, in between synchroton accelerated ion beam delivery (inter-spills) and continuing afterwards, for stable and radioactive carbon ions in PMMA. These data were then subsequently used to benchmark FLUKA code predictions (34). The 11C ion beam was generated via an in-flight fragmentation method in HIMAC's secondary beam course, exploiting the interaction of the synchrotron accelerated main (12C ion) beam with a beryllium target (35–40).

Although this method achieves production rates of almost 1%, which are deemed sufficient for testing purposes, the radioactive ion beams produced are considerably broad and feature larger momentum spreads than the projectile beam (36, 38). Moreover, the production method is also characterized by the presence of impurities in the secondary beam, originating from the projectile fragments. In the presented case, the impurity level reached about 7% (34).

To support this approach and to allow detailed analysis, a Monte Carlo code simulation data can provide a valuable insight into carbon ion hadrontherapy treatment planning, verification, optimization and eventually its outcome (25, 41–47). Recent developments in the FLUKA code have enhanced the accuracy of the models governing ion transport and interactions, resulting in an improved reproduction of the fragmentation mechanisms and thus a more reliable dosimetry and imaging estimate (48–50). Furthermore, the recently developed FLUKA PET tools enable the simulation of a PET scanner performance as well as signal acquisition throughout and after the irradiation, providing a more direct assessment of the imaging gain (51, 52).

A recent example of image performance evaluation used a SIEMENS Biograph mCT PET scanner from Heidelberg Ion Therapy Center as model, as well as a synchrotron-like irradiation with either 11C or 12C ions, simulating SOBP of comparable dose and range delivered to an antropomorphic head voxelized structure (52).

All the above-mentioned factors support the enhanced 11C ion irradiation imaging potential, without dosimetry drawbacks. Furthermore, in studies carried out by QST/NIRS and ANSTO (33), the relative biological effectiveness of radioactive ion beams of 11C (and 10C) has been found to be equivalent to that of their stable counterpart. Moreover, the same study corroborates the higher positron emitter production and comparable dosimetry performance of 11C ions with respect to stable carbon ions.

Also, encouraging results to treat tumors in small animals with radioactive ion beams have been obtained recently at the BARB Experiment at GSI, in the framework of the Super-FRS collaboration (53). The further proof-of-concept will focus on the application of 11C and 15O.

Production of 11C Beams: Overview of Past Results

The possible advantages of using radioactive ion beams for PET-aided hadron therapy already have a long history (54–56). Worldwide, several facilities have attempted to produce 11C beams using different techniques:

• Lawrence Berkeley National Laboratory

• Center de Recherche du Cyclotron

• GANIL

• CERN ISOLDE

• ISAC/TRIUMF

• HIMAC/NIRS.

This chapter aims to provide an overview of how those facilities produced 11C beams, the technical details and the beam properties and particularities, as well as the developments with respect to high intensity 11C beam production. To get a broader picture of the past 11C experiments and future related perspectives, the reader is directed also to a recently-published overview focused on the medical use of the 11C beams produced to this day (57).

Lawrence Berkeley National Laboratory

The Bevalac at the Lawrence Berkeley National Laboratory facility was an accelerator complex, established in 1974 when coupling the SuperHILAC linear accelerator (8.5 MeV/u) and the Bevatron proton synchrotron of 6.2 GeV energy (58, 59). The Bevalac was used for the production of heavy ion beams for both research and radiation therapy and is credited as one of the pioneering facilities for accelerated radioactive ion beams (60). Between 1977 and 1992, 433 patients were treated, where most of the treatments were performed with a 670 MeV/u neon beam (61). Before its decommission in 1993, 11C beams were produced by projectile fragmentation using different initial beams and thin targets. A beam of 2 x 107 ions per pulse was produced by bombarding a 7.8 cm thick Be target with a primary 1.5 x 1010 ions per pulse 12C beam with an average energy of 350 MeV/u. This corresponds to a total efficiency of 1/750 ions per primary. It was reported that the primary beam was expected to suffer from 100 MeV/u energy loss after reaction, yielding a 11C beam with angular spread of approximately ±10 mrad and a momentum spread of ±1% (increased to ±12 mrad and ±2% when considering multiple scattering in the target). It was further reported that an excellent separation from the primary beam was achieved using a magnet with 1/500 resolving power (1). Besides that, a 11C beam was produced by bombarding a 1” (2.5 cm) Be target with 18O beam of 800 MeV/u energy, and the production cross section of 11C from a 375 MeV/u Ne10+ beam hitting in a polystyrene target consisting of two disks with 3” (7.6 cm) diameter and 0.25” (0.64 cm) thickness was measured (62, 63).

In 1998, the BEARS initiative was launched at Lawrence Berkeley National Laboratory, which aimed to expand the RIB capability (64). For this purpose, a 350 m transfer line was built between the 11 MeV PET-cyclotron at the Biomedical Isotope Facility (BIF) and the 88” (~224 cm) cyclotron of the Nuclear Science Division. 11C was produced irradiating for 5 min a 13 ml (80 mm deep) N2 gas target (filled to 22 atm) with 10 MeV protons and ~30 μA intensity of the medical cyclotron (2). 0.2% O2 was mixed into the gas target to produce 11CO2 to allow gaseous transport and cryogenic separation. The concentration of O2 was chosen to have sufficient oxygen available for 11CO2 formation, while avoiding overloading the ion source with non-radioactive chemical species formed during irradiation. The gas mixture was transported via a capillary system to the cryogenic trap for separation and subsequent injection into the AECR-U ECR ion source. It was found that the cryogenic trap was a crucial feature for the performance of the ion source. The AECR-U is a two-frequency (14 and 10 GHz) ECR ion source that provided an ionization efficiency distribution (by ion charge states) of: 3+ = 4%, 4+ = 11%, 5+ = 4%, 6+ = 2% (2). The ion source was operated at pressures of the order of 1 x 10−7 Torr (~1 x 10−7 mbar), and the 6+ charge state was selected using a stripper foil to erase boron contaminations. The entire system was operated by a fully automatized control system, handling the loading of the target, the irradiation and the unloading. Using a 5 min cycle, a final beam intensity of 1 x 108 ions/s with an energy of 120 MeV was achieved (2).

Center de Recherche du Cyclotron

The RIB facility at the Center de Recherche du Cyclotron (CRC) in Louvain-la-Neuve, established in 1989 and in operation until 2009, was the first facility that coupled an ISOL-type RIB production system to a post-accelerator, therefore, providing the first post-accelerated RIBs (65, 66). The accelerator complex comprised three accelerators: CYCLONE30 is a 30 MeV proton accelerator with beam intensities up to 300 μA developed for medical purposes (67), while both CYCLONE44 (K = 40) and CYCLONE110 (K = 110) are cyclotrons for the post-acceleration of nuclei produced with CYCLONE30. Two types of ion sources were in operation: firstly, sputtering ion sources, consisting of a biased electrode containing the material to ionize (67); secondly, a 6 GHz ECR ion source was developed for fast, low charge state ionization. Offline measurements using calibrated CO2 leaks yielded a 15% ionization efficiency for C+, at an in-source pressure of 1 x 10−5 mbar (67). For the production of 11C, two boron based powder targets were tested, boron nitride (BN) and boron oxide (B2O3) (68, 69). For both materials, a release study was performed. B2O3 melts at 450°C but vitrifies to a glass-like substance after cooling. With the initial melting, a strong outgassing and the formation of bubbles was observed, causing the material to expand. However, once vitrified, the material showed normal melting behavior. Hence, prior to irradiation, the material was vitrified by carefully pre-heating to 800°C and cooling subsequently. The release study of B2O3 showed a higher release efficiency at lower temperatures. However, only one cycle could be observed due to the escaping of the powder from the target container. In the case of BN, 6 g of powder was compressed to 0.8 g/cm3 into a graphite cavity and outgassed prior to irradiation. The release of 11C was rather limited at lower temperatures, however an efficiency of 10% could be obtained at 1,000°C in several different runs. It was observed that this characteristic resulted from the lack of free O2 available for the formation of carbon oxides. Therefore, an oxygen leak was added providing a partial pressure of approximately 1 x 10−2 mbar. No improvement was observed, which was probably due to an unpractical placement of the O2 leak and the oxygen strongly reacting with the surrounding carbon of the hot graphite cavity. It was later reported elsewhere that an on-line experiment using a BN target operated with an oxygen leak of 0.1 cm3/h resulted in a 11C beam of 1 x 107 ions/s (70).

CERN ISOLDE

Since 50 years, CERN ISOLDE (Isotope Separator On Line DEvice) (71) produces various radioactive ion beams from the chart of nuclides. ISOLDE receives 1.4 GeV protons from the Proton Synchrotron Booster (PSB) of the CERN accelerator chain with intensities up to 2 μA. Three different types of ion sources are available for 1+ charge state ionization: surface ion sources, plasma ion sources and laser ion sources.

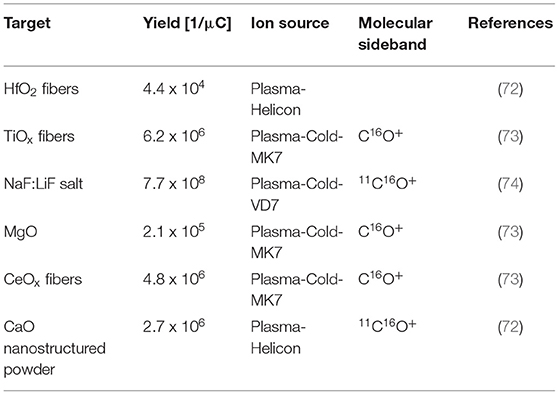

At ISOLDE, many target-ion source combinations have been developed over the years, allowing to produce radioisotopes from more than 74 different elements. For mass separation, two separators are available that are operated with independent target-ion source units. The General Purpose Separator (GPS), equipped with one bending magnet and an electrostatic switchyard, allows to extract three mass separated beams simultaneously. For higher resolving power (>5,000), the High Resolution Separator (HRS) is available, consisting of two bending magnets. The experimental hall of ISOLDE hosts many different experiments that can receive the beam from either GPS or HRS. Several mass separated 11C beams have been produced from different target-ion source units, as can be seen in Table 1. It is remarkable that almost all beams were observed in the CO+ sideband. Furthermore, the oxide targets showed that CO+ was exceeding CO2 by a factor of 10 to 100 (75), and for the NaF:LiF molten salt target, providing so far the highest yield, CO+ was 30 times stronger than CO2 (74).

Besides that, extensive research has been performed for the production and extraction of short-lived carbon beams (75, 76). Adsorption enthalpies of CO and CO2 have been measured for several materials: MgO, Al2O3, SiO2, CaO, TiO2, ZrO2, HfO2 and Y2O3. High adsorption enthalpies result in longer retention/sticking times of CO or CO2 on such surfaces, and therefore, reduce the yields. SiO2 and Al2O3 were investigated as coating materials for transfer lines and ion sources. It was found that for CO the retention times are for both materials negligible, but for CO2 retention on Al2O3 becomes more evident at temperatures below 400°C (76). Diffusion studies of 11C in MgO, TiO2 and HfO2 as pressed powder and pressed fiber pellets showed that diffusion in fiber pellets is faster than in pressed powder pellets. It was furthermore concluded that limitations on the extraction and transport of short-lived carbon isotopes as carbon oxides mainly result from a shortage of oxygen supply, losses on hot tantalum surfaces (>1,000°C) of the target unit and retention due to the adsorption on hot molybdenum surfaces in the ion source delaying the extraction (75).

SPIRAL1/GANIL

Since 2001 SPIRAL1 at GANIL produces radioactive ion beams via the ISOL method (77). The facility hosts five different cyclotrons for the production and acceleration of RIBs (78). The two low-energy cyclotrons C01 and C02 send beams to the irradiation beam line IRRSUD (<1 MeV/u). CSS1 (4 to 13 MeV/u) and CSS2 in series post-accelerate stable beams up to 95 MeV/u, which are then send on a graphite target for radioisotope production. The produced radioisotopes diffuse to a Nanogan-3 ECR ion source for multi-charge ionization (41). After mass separation (250 resolving power), the beam can either be send into the low-energy beam line LIRAT or can be injected into the CIME cyclotron (K = 265) for post-acceleration (1.7 to 25 MeV/u). Two projects are currently ongoing aiming to expand GANIL's RIB inventory:

• Firstly, the SPIRAL1 upgrade is being finalized, containing new target-ion source systems for more 1+ RIBs. Furthermore, a Phoenix type charge booster is being installed for 1+ to n+ charge breeding (77).

• Secondly, the SPIRAL2 project will provide beams produced via the ISOL and the in-flight technique.

Although, no 11C beam has been produced yet at SPIRAL1, studies on CO and CO2 ionization and charge breeding efficiency have been performed (76, 79). A 2.45 GHz ECR ion source for efficient 1+ ionization was developed at GANIL (MONO 1000). Based on this design, a compact version was developed and tested in an off-line study at ISOLDE and measured an ionization efficiency of 14% for CO+.

ISAC/TRIUMF

TRIUMF in Vancouver (Canada) is a national laboratory for nuclear and particle physics. Their main accelerator is a sector-focused cyclotron with four independent beam extraction lines that accelerates H− ions with a total beam current of 300 μA to energies ranging from 70 to 520 MeV (80). One of these extraction lines enters the ISAC facility, providing proton beams of 500 MeV with up to 100 μA beam intensity for radioactive ion beam production. ISAC comprises one target station with three types of ion sources: surface ion source, resonant laser ion source, plasma ion source (FEBIAD). A separator consisting of two magnets in series separates the ions extracted from the ion source. Currently, a new laboratory is under construction, which will add two more target stations to the inventory of ISAC. In detail, this is the Advanced Rare IsotopE Laboratory (ARIEL) project, which will add another 500 MeV, 100 μA proton beam line and a 50 MeV, 500 kW electron beam line (80).

Up to now, many radioactive ion beams have been produced from numerous targets (81). For the production of radioactive 11C beams, a composite NiO/Ni target was developed and tested on-line in 2012 and 2013 (82). The target was operated at a maximum temperature of 1,100°C to prevent high vapor pressures overloading the FEBIAD ion source, which would reduce the ionization efficiency. A high-power target container was used to dissipate the deposited beam power of the 500 MeV proton beam with a maximum intensity of 16 μA. Throughout several runs, a maximum 11CO+ yield of 1 x 107 ions/s was observed. It is worth mentioning that a ratio CO+ to C+ of ~10 was observed, where the C+ beam is presumably originating from molecular breakup in the ion source (80).

HIMAC/NIRS

Since the National Institute for Radiological Sciences (NIRS) completed in 1994 the construction of the Heavy Ion Medical Accelerator (HIMAC) in Chiba (Japan), >10,000 cancer patients have been treated using high-energy carbon beams (83). The original accelerator complex consisted of three ion sources, an RFQ cavity, an Alvarez type Drift-Tube-Linac, a pair of synchrotron rings and beam transport lines. The HIMAC can accelerate heavy ions from protons to xenon up to 800 MeV/u for a charge-over-mass ratio >0.5 (83). In 2010 a new treatment facility was added next to HIMAC, comprising a superconducting rotating-gantry and 3D raster-scanning irradiation techniques. NIRS has a strong R&D programme since 2004 and designed a compact accelerator facility for more cost-effective and size-reduced treatment centers.

At first, 11C beam production was studied using the in-flight projectile fragmentation technique (37). 11C was obtained by sending a primary 430 MeV/u 12C beam onto a Be target. A set of two bending magnets was used for separation and final focusing was achieved by a triplet of quadrupole magnets. This study showed that the yield strongly depends on the target thickness, degrader thickness (when used) and the angular acceptance. Remarkable is that increasing the degrader thickness from 0 to 10.6 mm, the beam purity is increased from 93 to 99%, however, decreasing the yield from 0.97 to 0.76%. For most of the tests, no degrader was used, resulting in a relatively poor beam purity of 93% with contaminations of 12C and 7Be. It was pointed out that these yield dependencies made the end cut of the depth dose distribution vague and not desirable (37). Finally, using a 1.8 x 109 pps 12C beam, 7.2 x 106 pps of 11C were delivered using spot scanning, which is insufficient in respect of dose delivery. Furthermore, large momentum spread and emittance resulted in undesirable beam characteristics.

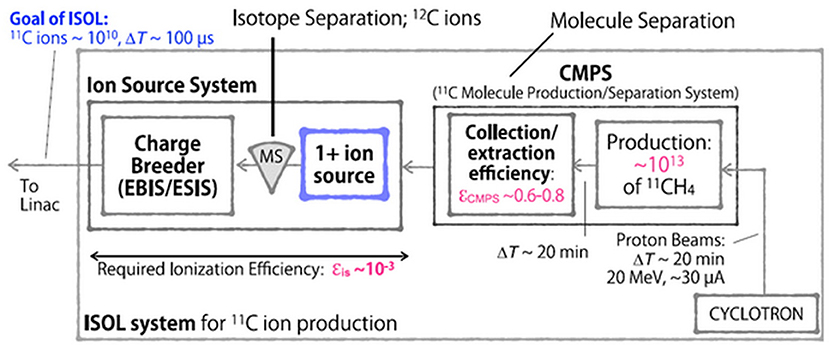

More recently, studies on producing 11C beams using the PET-isotope production scheme from N2 gas targets and using the ISOL method were performed (85, 86). The first route, via the 14N(p,α)11C reaction from N2 gas targets, was a theoretical calculation starting with an 18 MeV proton cyclotron from the NIRS-Cyclotron-Facility. The study included the radioisotope production, gas separation, gas compression, gas pulsing, ionization in an ECR ion source and injection into the HIMAC synchrotron. It was estimated that with the developments discussed in that work, a 11C6+ beam with 1 x 108 ppp intensity could be extracted from the HIMAC (85). However, in subsequent publications (86–88) production via the 14N(p,α)11C reaction and N2 gas targets was discarded due to high N2 impurities (~1 x 1022 for a 0.1 l target) overloading the ion source. Most recently, NIRS investigates 11C beam production via the ISOL method using solid boron-based targets (86, 88). Figure 1 shows the proposed ISOL-type 11C beam production system, comprising a solid NaBH4 target, a driver cyclotron providing 20 MeV protons, a molecule production and separation system (CMPS), a 1+ ion source, a mass separator and an Electron String Ion Source (ESIS) ion source for charge breeding. Since the HIMAC has an acceleration efficiency of 10% (from Linac injection to the treatment room) (86), and ~1 x 109–1 x 1010 11C ions are required for treatment, the ISOL system must be able to provide ~1 x 1010 ions extracted from the ion source system. Three boron-based targets have been tested (86, 89), using 18 MeV protons, a beam intensity of 18 μA for 20 min and an isotope extraction in form of 11CH4. Elemental boron showed highest in-target production yield, however, only 0.2% could be trapped as 11CH4. From a B2O3 target more than 76% of the initially produced 11C activity could be collected as 11CO2, but they report that the carbon oxide separation is too difficult (89). Finally, it was claimed that a NaBH4 target suited best their requirements with 5 x 1012 collected 11CH4 molecules, which corresponds to more than 29% of the in-target production yield. It was projected that this yield can be increased to the order of 1 x 1013 by increasing the proton beam intensity to 30 μA. One major concern of this approach is the low melting point of 400°C and the fact that the target thickness is chosen to absorb the entire proton beam. Consequently, serious complications with respect to heat damage and target endurance should be taken into account.

Figure 1. Possible ISOL-type 11C beam production system, proposed by NIRS (84).

However, based on these findings, the CMPS was developed, comprising two cryogenic traps, which separate the molecular species according to their difference in vapor pressure. Depending on the impurity concentration, a collection/extraction efficiency of 60–80% is reported (92). As a result, the ion source system depicted in Figure 1 has to reach a total efficiency of 0.1% for the proposed 1+ to n+ ionization scheme. Currently, a singly charged ion source based on electron impact ionization is under development (84). Considering an average C4+ ionization efficiency of approximately 10% that was observed in an ESIS (93, 94), the 1+ ion source is designed to provide the required 1% ionization efficiency. However, it must be mentioned that the referred charge breeding efficiency was determined using stable, neutral CH4 gas which was frozen in a cryogenic cell. By heating the cell, the methane was evaporated and part of it was injected into the ion source. A recent study, performed at CERN, yielded that the Electron Beam Ion Source (EBIS) charge breeding efficiency using ion beam injection is considerably lower (95). Since an ESIS ion source is basically a modified EBIS, it is consequently questionable whether this ion source system (Figure 1) will accomplish the desired 0.1% overall ionization efficiency for high intensities.

Required Accelerator Layout

All currently existing carbon therapy accelerators are of synchrotron type and are based on the PIMMS design (3). Their beam specifications at the irradiation room are summarized below:

• Ion species: C6+

• Beam energy: 120 to 400 MeV/u

• Beam intensity: ≤ 4 x 108 particles/spill

• Spill duration: 0.1 to 10 s

• Repetition rate: ≤ 0.2 Hz.

To allow similar treatment times to the existing facilities, a 11C facility would need to deliver a comparable beam intensity per time unit. The main challenges to solve for a 11C facility are to reach the required 11C intensity and to assure a stable and reproducible performance. Several options are possible:

A. Production of 11C via projectile fragmentation, from a beam at the final required energy

B. Upgrade the existing design of a synchrotron-based carbon therapy accelerator, by supplementing the standard 12C injector by a 11C injector, able to inject the required intensities of 11C, with the time structure required by the existing synchrotrons.

C. Accommodate the 11C injector to a Linac-based or cyclotron-based accelerator.

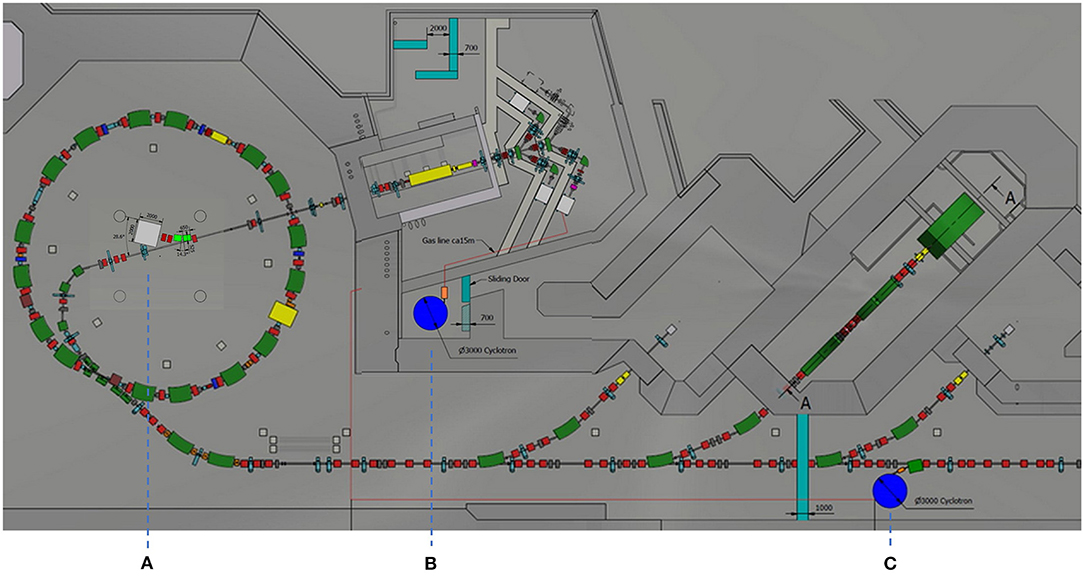

The review of the past results on the production of post-accelerated 11C ion beams (section Production of Carbon-11 Beams: Overview of Past Results of the present report) is showing that the production via the projectile fragmentation method (option A) cannot be considered for therapy, due to low production cross section and undesirable beam characteristics such as large momentum spread, large emittance and poor beam purity. The option C would allow a relaxation of the intensity constraints for the 11C injector, but it represents a “green-field” approach, as currently there is no such Carbon therapy accelerator in operation, due the challenges raised by the acceleration stage. We therefore focus in the present study mainly on the option B, with the goal of identifying and discussing the possible scenarios for the 11C injector. If a satisfactory solution can be implemented for the option B, it can in principle be easily adapted also option C.

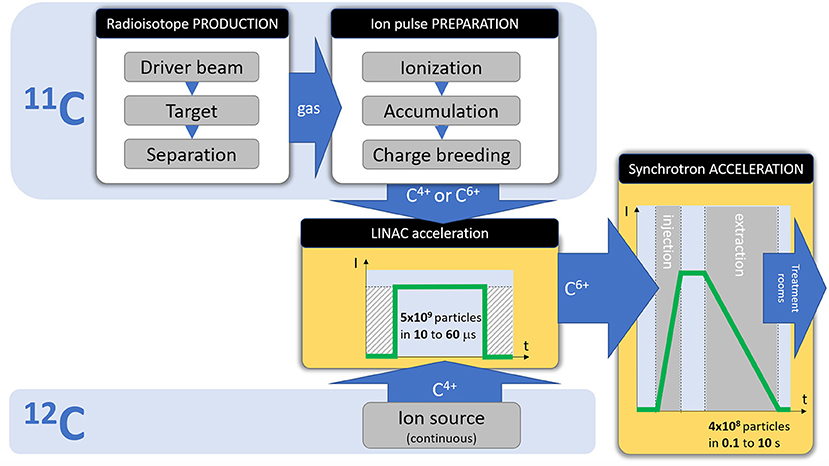

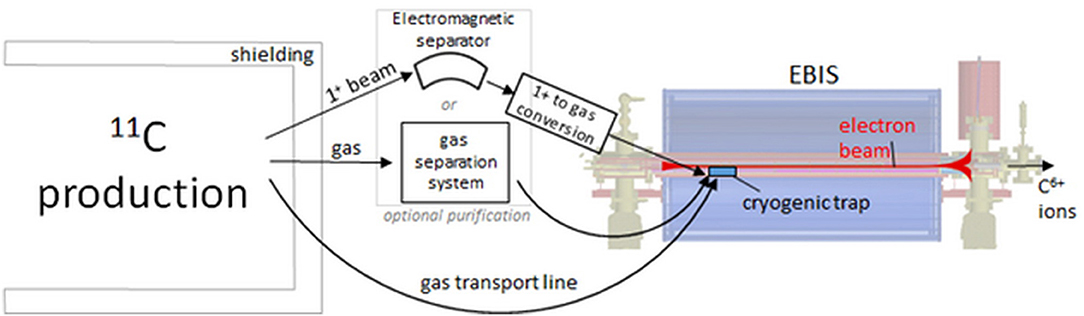

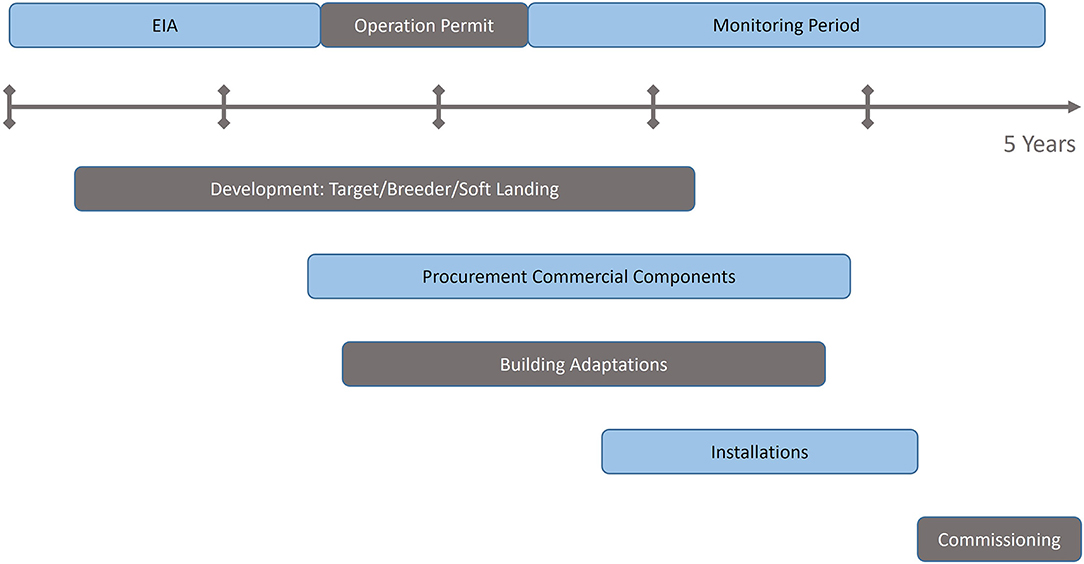

Figure 2 shows the differences between a 11C and 12C injector, and how both must comply to the same pulse requirements for injection into the synchrotron. The focus of the present study is to analyse the feasibility of the 11C injector, with the steps presented in the dedicated 11C box of Figure 2:

• Radioisotope production (11C), achieved by irradiating a target with a driver beam, followed by isotope separation/purification. These production steps are analyzed in section Radioisotope Production of the present study.

• Preparation of the ion pulse for acceleration, consisting in ionization, accumulation (if needed) and charge breeding. These preparation steps are analyzed in section Ion Pulse Preparation of the present study.

Figure 2. Required stages and beam parameters for a therapy accelerator, and the differences between a 12C and 11C injector.

The acceleration stages (Linac and synchrotron) are not detailed in the present study, as they do not present any specificity for the 11C case.

Analysis by Accelerator Component/Stage

Radioisotope Production

To produce 11C, a chosen target is irradiated by a primary light particle beam (driver), followed by isotope extraction from the target and purification (if needed) before the generation of the ion beam pulse to be sent to the Linac for acceleration.

Several possibilities are evaluated for the driver beam, the target and separation, considering their feasibility to achieve the required beam intensity and to be implemented into existing facilities.

The Driver Beam

Three options have been considered as relevant for the present study:

• 7 MeV protons with intensities up to 7 μA, which can be extracted from the Linac of existing therapy facilities.

• 18 MeV protons, as can be provided by a compact cyclotron used for industrial production of radioisotopes. There are several products commercially available. For instance, IBA's 18 MeV proton cyclotron CYCLONE®KIUBE, available in several editions that differ in beam intensity. Furthermore, IBA offers commercial N2 gas target solutions, as well as solid target stations (96);

• 250 MeV protons, as could be provided by a compact proton therapy cyclotron. Such a cyclotron could be used, on the one hand, to produce 11C for PET-aided hadron therapy. On the other hand, it may be used for conventional proton therapy. Consequently, such an approach would increase the throughput of the treatment facility. Such cyclotrons are commercially available, for instance the VARIAN ProBeamTM 250 MeV, 0.8 μA superconducting cyclotron.

The Production Target

The choice of the target is an essential criterion for the accelerator chain. In principle, many choices of beam-energy-target combinations are possible, however mostly two types of beam-target combinations are conceivable with respect to the production of high intensity post-accelerated 11C beams: nitrogen gas targets and boron nitride targets.

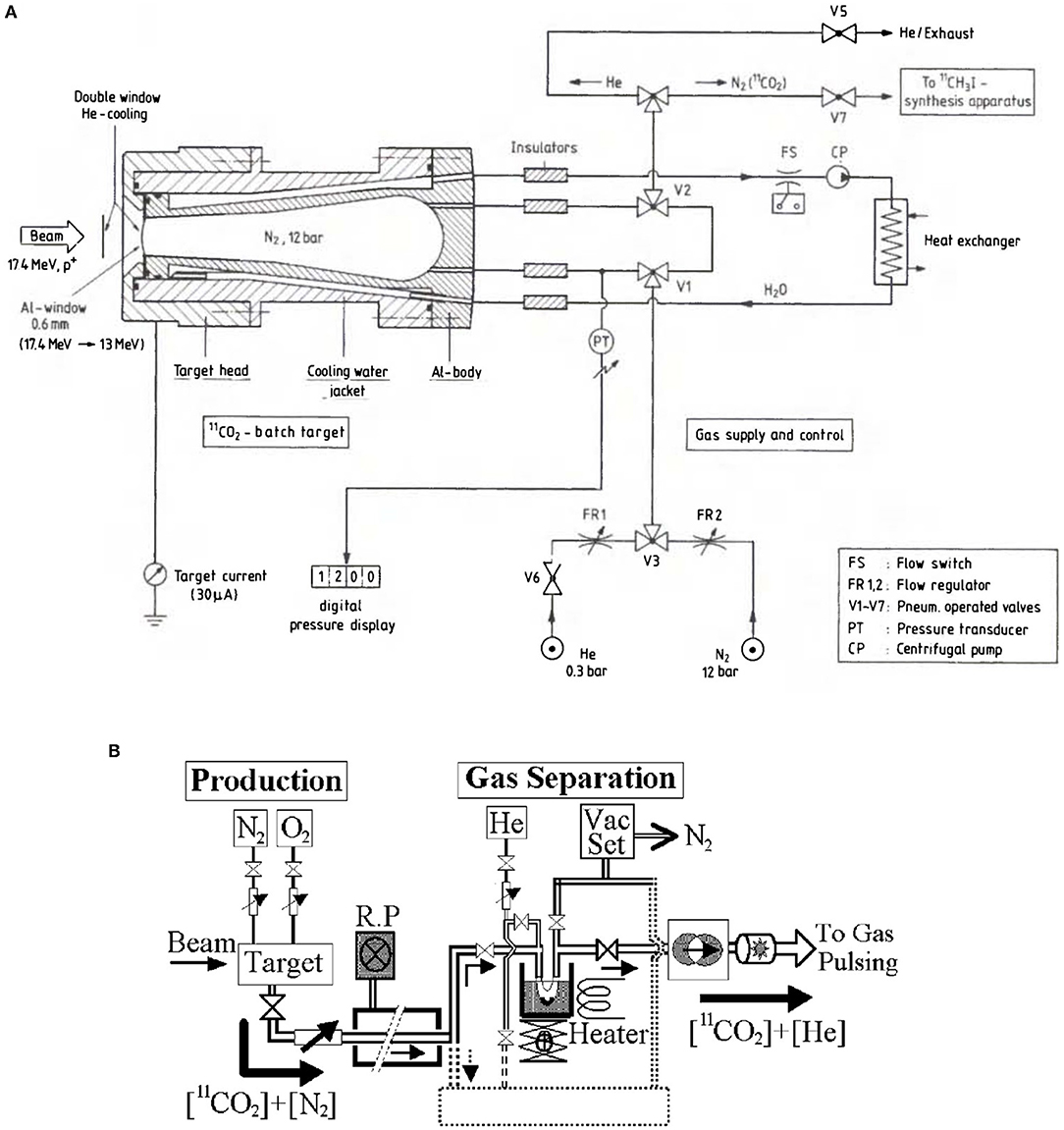

High-pressure N2 targets (several bar) are commonly used to produce 11C for PET-imaging. The gas cells are irradiated with a low-energy proton beam for a duration of several minutes. Subsequently, 11C is separated from the gas mixture by purging it through a chromatography gas separation (CGS) system. Usually, the 11C is extracted in molecular form, as CO2 or CH4. Two examples of typical gas target systems can be seen in Figure 3 (85, 90). It consists of a water-cooled conical cylinder holding the target gas and a tube system for the gas transport (Figure 3A). The target chamber is filled with high purity N2 gas to pressures usually greater than 10 bar. Oxygen or hydrogen is mixed in percentage amounts into the target gas to produce 11CO2 or 11CH4, respectively. Typical gas separation systems (Figure 3B) use cryogenic traps, i.e., stainless-steel tube/coil immersed in liquid nitrogen, which traps CO2. Increasing the trap temperature will then result in their release. Alternatively, chromatography columns (CH4) or molecular sieve (CO2) traps may be used. Chromatography columns, such as Porapak Q columns, separate CH4 from other species based on differential adsorption times on the column's material, which result in different flow rates (97). Molecular sieve traps are pre-activated columns of a selected microporous material, usually measured in Angstrom. Advantage of such traps is that they can trap CO2 at room temperature and release the captured molecule by heating the material to 100–200°C (97, 98). A general disadvantage of gaseous N2 targets is that 11C production is carried out in batch mode. As a result, to ensure a continuous operation, an automatized target loading/unloading system has to be established. To give the reader an idea, such a system was used in the BEARS project in Berkeley (2).

Figure 3. Examples for a typical N2 gas target system (A) and for a chromatography gas separation system (B) using a cryogenic trap (85, 90).

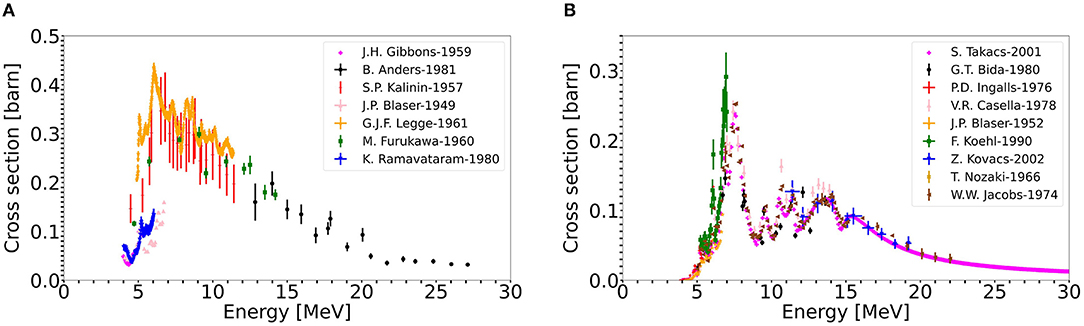

The second possible approach to produce large quantities of 11C is using a solid, boron comprising target. Boron, in comparison with nitrogen, has a higher cross section to produce 11C. The corresponding cross sections, 11B(p,n)11C and 14N(p,α)11C are presented in Figure 4 (91). By using a solid target, higher in-target production yields can be expected, because of the higher cross section and given the material's higher density. Furthermore, a solid target eases target handling and radioactive waste management. As introduced earlier, ISOLDE produces since more than 50 years radioactive ion beams via the ISOL method. In this technique, usually, solid targets are irradiated with a proton driver. The isotope of interest is produced, among others, inside the material. By heating the target close to its melting point, the isotopes are evaporated from the material's surface. High temperatures are an essential criterion, as isotope diffusion and effusion processes depend exponentially on temperature. Once the isotopes are released from the target material, they are separated as will be described in the next section.

Figure 4. 11C production cross sections from the proton induced reactions (A) 11B(p,n)11C, (B) 14N(p,α)11C (91).

In the prospect of producing high intensity mass separated 11C beams, a boron nitride (BN) ISOL-type target was developed and characterized (99). The target was manufactured to provide a controlled microstructure, for short diffusion and effusion times, to enhance the isotope release properties. The isotope release is often considered as a bottleneck in intense RIB production (100, 101). Furthermore, it is foreseen to operate this target with a controlled oxygen leak to extract 11C in the form of CO. Molecular isotope extraction further increases the release efficiency, as carbon is very refractory and easily forms strong bonds with hot metal surfaces.

The expected in-target production yields for the different target-driver combinations can be calculated. For this purpose, simulations were performed with the particle physics Monte Carlo simulation code FLUKA (48, 49).

The target geometries used as an input for the simulations are the following:

• In the case of the N2 gas target, a geometry based on the commercial IBA target (102) was used. This comprises a 40 cm3, conical target container filled with a 20 bar N2/O2 (0.99/0.01 vol%) gas mixture. For the simulation, a 600 μm thick aluminum entrance window was assumed, which is important to address as the proton beam will lose energy in this window.

• In the case of the solid BN target, a cylindrical target pellet was used, with a diameter of 30 mm. The target thickness is varied in each case, such that the proton beam exits the target pellet with a remaining energy of 4-5 MeV. With such a configuration, the deposited power can be reduced, while the in-target production yield is only marginally reduced. This effect is shown in Figure 4, where it's visible that both cross sections significantly drop for energies lower than 5 MeV.

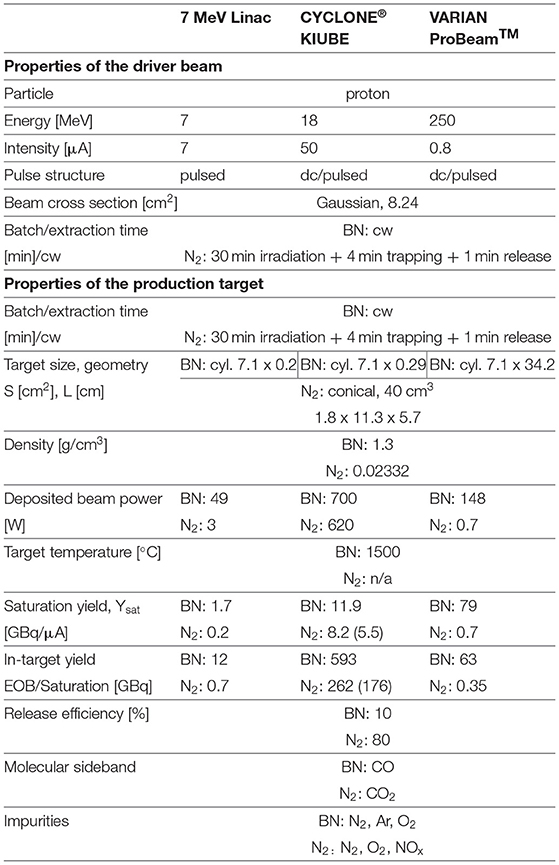

Table 2 gives a comparison of the expected 11C production yields for the different driver-target scenarios. The produced in-target yield is given as an End-Of-Beam (EOB) yield for the N2 target, as this target is operated in batch mode. For the BN target, operated on-line (in cw mode), the quoted yield is the saturation yield reached after 1.5 h.

Table 2. Summary of the selected properties (driver beam and of the production target) and comparison of in-target production yields for different driver-target combinations.

The release efficiency of the BN target was experimentally determined (103), whereas the efficiency for the N2 target was calculated. The listed impurities are only the ones originating from the target material itself and its operation. In the BN case, Ar refers to the carrier gas used with the controlled O2 leak.

Table 2 shows that the N2 gas target generally offers lower yields compared to the BN target, which mainly can be attributed to the higher cross sections when exploiting the (p,n) reaction channel on boron. The discrepancy between these two targets is more pronounced for the 7 MeV Linac and 250 MeV cyclotron as the commercial gas targets are not designed for these energies and consequently do not utilize the nitrogen 11C production cross section adequately. In detail, the 7 MeV Linac loses up to six MeV within the aluminum entrance window, which implies that it is arguable whether any 11C is produced at all, as the cut-off energy of the 14N(p, α)11C reaction is around 3 MeV. The FLUKA simulated yields of the LEBT-Linac-N2 gas target combination should be therefore treated with caution. The 250 MeV cyclotron on the other hand, deposits merely 1 MeV within the N2 target gas, which explains the low yields. Both 7 MeV Linac and 250 MeV cyclotron would benefit from an optimization of the N2 gas target design.

From Table 2, we can see that the 250 MeV VARIAN ProBeam–BN target combination offers the highest saturation yield, when normalized to the primary proton beam current, since a stack of many target pellets is required to slow down the proton beam below 5 MeV (34 cm). However, the CYCLONE®KIUBE cyclotron driver option presents the highest achievable in-target yield due to the much higher proton beam intensity. In standard edition, beam currents up to 150 μA are possible (102). The produced yield scales linearly with the proton current, but the selection of the primary proton current I should be handled with caution as low-energy proton beams deposit considerable power into the target, which result in rapid heating of the target material. Generally, the ISOL-type targets are operated at high temperatures (close to their melting point), to enhance diffusion and effusion processes. Previous studies (99) investigated the high-temperature stability of the BN target in typical ISOL operational conditions. In this respect, BN dissociation was expected at temperatures above 1,000°C. High-temperature studies, probing the developed BN target at temperatures up to 1,500°C demonstrated its applicability in such conditions (99). Eventually, the maximum applicable beam current for the BN target will depend on how efficient the target can be cooled. The commercial IBA N2 target is in practice operated with a 50 μA beam current. In the case of BN, such a beam current would correspond to a power deposition of 700 W. We assume at this point that target cooling techniques are able to prevent the target to exceed the 1,500°C maximum temperature.

The Isotope Separation

Separation of 11C from impurities depends on the target-driver combination, the molecular side band in which 11C is produced, the impurity species and their quantities. The appropriate separation modality is strongly influenced by the requirement of the next stage (ion pulse preparation) of having the amount of 11C not surpassed by orders of magnitude from impurities. For this, there are three possibilities:

• Direct coupling to next stage (ion pulse preparation), i.e., no separation is required

• Application of a CGS system to isolate CO2 from other species

• ISOL-type separation, using a 1+ ECR ion source, electromagnetic mass separation and a deaccelerator.

Direct target coupling would of course be the favorable route, as it would not require further components. If the amount of impurities is considerably larger, chemical separation (e.g., CO2 from N2) by means of a cryogenic or molecular sieve trap may be applicable. On the other hand, if a separation from same chemical elements is required, an electromagnetic mass separation (which enables isotopic separation due to the A/q selectivity) needs to be used.

The nitrogen gas targets are filled to 20 bar, which will further increase during irradiation, therefore a direct coupling is not possible. Consequently, some sort of trapping needs to be implemented, to separate the macroscopic quantities of N2 and O2 from the active target gas. It is therefore reasonable to use a CGS system to separate 11CO2 from these impurities (as already presented in the typical layouts, Figure 3). Since 11C is produced in the CO2 molecular sideband, a cold trap or molecular sieve trap may be used, whereas the commercially available N2 gas target is usually equipped with the former type (102). The trapping efficiency of cold traps depends on the surface area of the coil that is immersed in liquid nitrogen. Usually trapping efficiencies >95% are achievable (104). The trapping of CO2 is carried out over a duration of ~4 min, followed by 1 min of heating to release the trapped molecules. Hence, one batch of 11C is produced and purified in 30 + 4 + 1 min. By considering the decay during trapping, one obtains an isotope specific separation efficiency. Considering the decay of 11C with T1/2 = 20.4 min, approximately 80% of the produced 11C can be recovered as 11CO2. Assuming a transport efficiency to the next stage (ion pulse preparation) of 50%, an overall efficiency of 0.4 can be achieved for 11C. One drawback of such a cold trap is that N2, O2, NOx and CO are trapped to some extent as well (98, 104). Using liquid argon instead of liquid nitrogen resolves the trapping of N2 (104). Alternatively, when using a molecular carbon sieve trap, equal efficiencies can be achieved, while O2, CO, or NO are probably not retained (98). Consequently, a molecular sieve trap might be better suited, since it is not clear how much N2, O2 and NOx is trapped together with the 11CO2 in the CGS system. As mentioned earlier, if these species exceed the quantity of 11CO2 by an order of magnitude or more, this will be problematic for stage of ion pulse preparation.

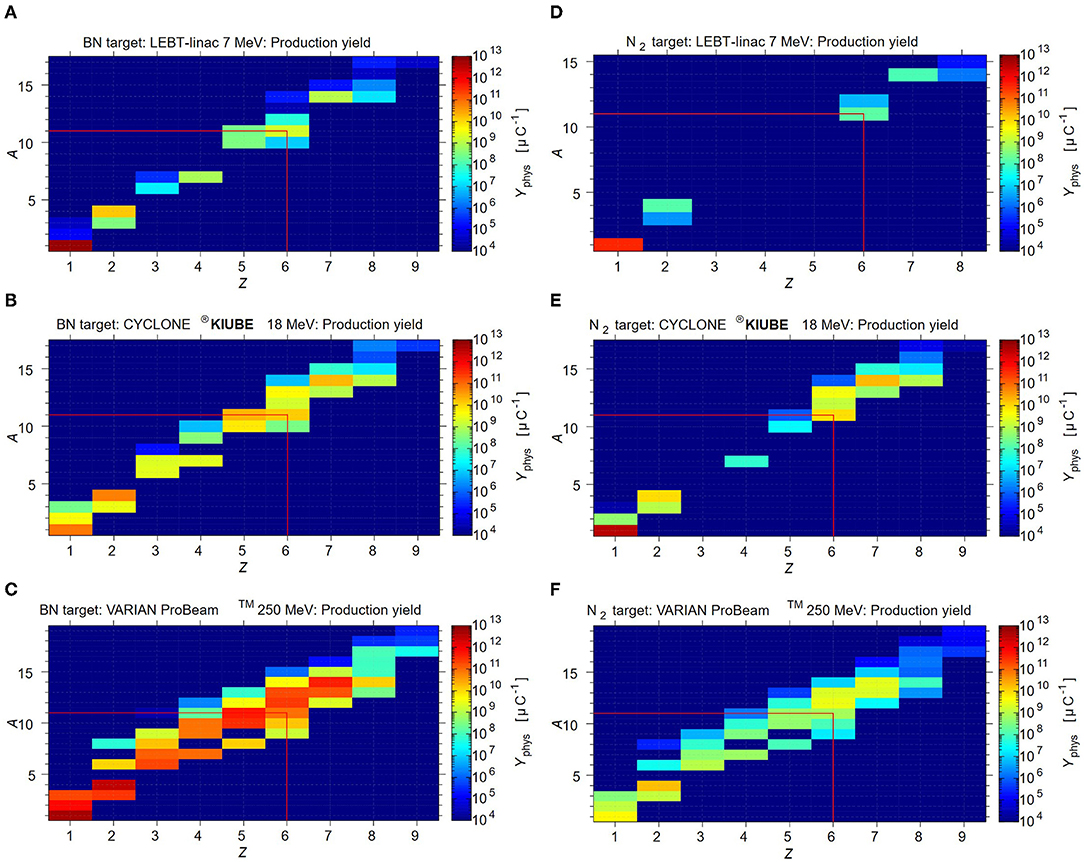

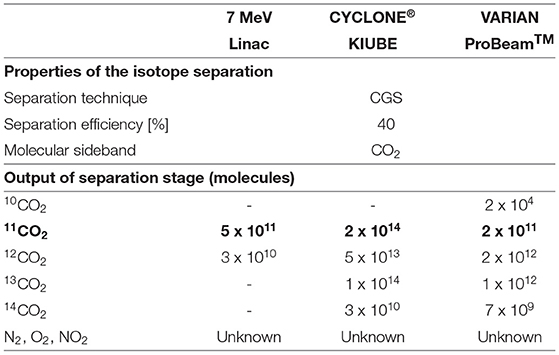

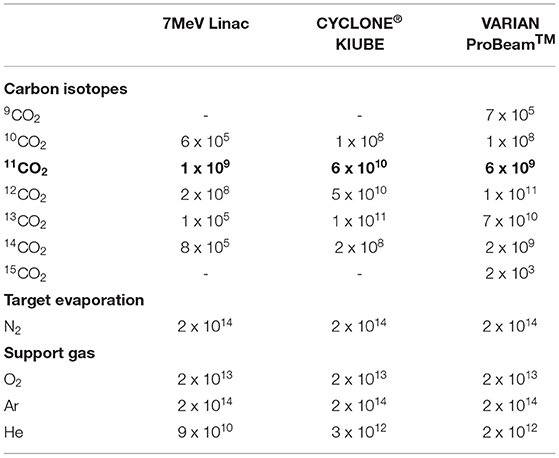

Besides the contamination resulting from the target material itself (N2 and O2), other (radioisotopes are produced during irradiation, which must be considered. Figure 5 shows the simulated physical thick in-target production yields, expressed in nuclei per μC, for an IBA-type N2 target in combination with the different driver options. Minor contaminations are expected for 7 MeV LEBT-Linac due to the low driver beam energy. When employing the more energetic 18 MeV or 250 MeV cyclotrons, considerably more elemental by-products are generated during irradiation, which may form molecules such as NO2F, FNO and H2O. These molecules should easily be removed from 11CO2 using a cold or molecular sieve trap. However, among 11C, other carbon isotopes are produced as well, which cannot be separated by a CGS system due to their identical chemical properties. Depending on their quantity, further separation may be required before the next accelerator stage. Table 3 provides an overview of the expected gas output per batch of a N2 target after CGS-type separation, depending on the proton driver.

Figure 5. FLUKA simulations for the physical production yield for the different target+beam options. The yield is expressed in nuclei per μC. (A) BN target +7 MeV beam, (B) BN target + 18 MeV beam, (C) BN target + 250 MeV beam (D) N2 target + 7MeV beam, (E) N2 target + 18 MeV beam, (F) N2 target + 250 MeV beam.

Table 3. Gas output (molecules per batch) after separation stage for an N2 target: 11C molecular compounds (in bold) and the corresponding impurities.

When using the 7 MeV LEBT-Linac or the 18 MeV CYCLONE®KIUBE cyclotron, the number of produced carbon impurities is either lower or of the same order of magnitude. A direct coupling is therefore feasible, provided that potential trapping of target gas residuals (N2, O2 and NOx) is limited. However, when using the 250 MeV VARIAN ProBeamTM cyclotron for isotope production, Table 3 suggests that 12, 13C are exceeding 11C production by one order of magnitude, which is perceived as inadmissible if not a further separation modality is applied.

In the case of the BN target, its operation will result in a continuous gas flow. To evaluate whether a direct coupling to the next stage is feasible, one needs to estimate the 11CO yield, as well as the amount of impurities that are comprised in this gas flow. The impurities for this target originate from three sources:

• The radioisotopes generated during target irradiation which are evaporated from the target together with the 11CO

• The vapor pressure of the target material due to the 1,500°C target temperature

• The applied gas leak of 1 x 10−5 mbar l/s using a gas mixture of Ar/O2 (90/10 vol.%). The gas leak is applied to enhance the isotope release from the target matrix, with the O2 serving to create an oxidizing atmosphere, while the Ar is added due to safety regulations.

We first discuss the expected 11CO yield and the (radio-) isotope impurities. Figure 5 shows the FLUKA simulated physical thick in-target production yields, expressed in nuclei per μC, considering the BN target employed with the different production driver. The release efficiency for 11CO is calculated to be of 10% and the saturation is reached after 1.5 h. The saturation of stable carbon isotopes will require significantly more time, as no decay is occurring. Therefore, to be able to compare, the expected yields of stable and long-lived carbon radioisotopes are calculated assuming t = 16 h of irradiation. This duration is chosen, considering that in practice the synchrotron is started during the night for beam commissioning and accounting for a full day of operation for therapy. The reader is referred for more information to the corresponding release study (103). The summary of the expected gas output of the BN target due to evaporated radioisotopes is shown in the top part of Table 4.

Table 4. Gas output (molecules per second) from the BN target before separation: 11C molecular compounds (in bold) and the corresponding impurities.

In conclusion, the 7 MeV LEBT-Linac produces xCO impurities of comparable magnitude, whereas the 18 MeV CYCLONE®KIUBE and the 250 MeV VARIAN ProBeamTM cyclotron, generate isotopic contaminants that exceed 11CO by one or two orders of magnitude. In the former case, it has to be investigated whether such a load is admissible for direct injection to the next stage, whereas the latter case most likely prevents the direct injection. Besides carbon, volatile isotopes are produced inside the target (see Figure 5) that are expected to be released very efficiently. Isotopic nitrogen and oxygen will only be traces compared to the impurities resulting from target operation, which will be discussed henceforth. However, hydrogen and helium isotopes are produced in significant amounts, which will most likely be a limiting factor for the next stage. The release of hydrogen is difficult to evaluate as it may form chemical compounds such as HBO. Helium on the other hand should be simply released, where the bottom part of Table 4 indicates the maximum extent by assuming a 100% release efficiency.

The second source of impurities stems from target operation at T = 1,500°C and is attributed to the vaporization of N2 due to BN dissociation: 2BN → 2B + N2(g). This feature was investigated in dedicated high temperature stability studies at the ISOLDE off-line laboratories (99), which showed that no N2 evaporation is detectable at a base pressure of 5 x 10−7 mbar. Assuming ideal gas conditions, room temperature in the gas transfer line and using the 300 l/s throughput of the employed turbo vacuum pump, <3 x 1015 particles per second are vaporized from the target. A residual gas analysis showed that N2 accounts for approximately 7% of the total residual gas composition, which corresponds to 2 x 1014 N2 molecules per second. This is significantly exceeding the expected 11CO yield for all possible proton driver, therefore eliminating a direct coupling scenario.

The third source of impurities originates from the application of the 1e−5 mbar l/s calibrated gas leak using an Ar/O2 (90/10 vol.%) gas mixture. Such a controlled gas supply contributes twofold to the impurities: firstly, a net gas flow of 2 x 1014 molecules per second is associated to the corresponding leak, assuming ideal gas conditions and room temperature in the gas transfer line. It is worth emphasizing that an Ar/O2 gas mixture is employed due to safety regulations, preventing injection of pure O2, which could reduce the gas leak by one order of magnitude while maintaining the same oxygen potential. Moreover, argon could be replaced by helium, considering the charge space limitation of the EBIS charge breeder. Secondly, BN is sensitive to oxidation at high temperatures, resulting in further N2 evaporation: 2BN + 3/2O2(g) = B2O3(l) + N2(g). A quantitative analysis of the oxidation kinetics of such target operation indicated that the external O2 supply results in < 12% enhanced N2 evaporation, which is insignificant considering the order of magnitude estimation that is discussed at this stage.

In summary, Table 4 shows the expected continuous gas output that originates from the BN target, including all types of impurities. As the impurities are exceeding the 11CO flow significantly for all of the discussed proton driver, it is necessary to incorporate a separation modality prior to next stage. The separation technique may be either CGS-type or ISOL-type.

The 11CO separation using a CGS system is challenging as the main impurities are N2, O2 and the carrier gas (Ar) of the oxygen leak. CO and N2 have very similar molecular properties which complicate the separation process. The typical cold traps and molecular sieve traps described earlier are not suited for efficient CO trapping, since CO is, at most, only partly captured (98). There exist a variety of other systems or materials (105) that are used to purify CO-containing gas mixtures. However, often they work under high pressures or they trap significant amounts of N2 and O2 as well, while CO is only trapped to 23%. Alternatively, one could oxidize 11CO to 11CO2 for which the CGS systems described earlier can be applied. Studies on high-temperature CO oxidation suggest that high conversion efficiencies can be achieved in short times (106). In the aforementioned study, hot inert (N2) carrier gas was sent through a cylindrical quartz duct in which CO and water were rapidly mixed. Best results were obtained at temperatures 1,100°C with a water mole fraction of 0.0248. Conversion efficiencies close to 100% were found in a time span <1 s. If we consider such an approach for CO oxidation, this prevents the subsequent application of a cold trap for CO2 separation as water will condense as well. However, carbon molecular sieve traps have a low affinity for water and therefore are a suitable option (98). One drawback of such a separation route is again the fact that trapping results in a batched injection.

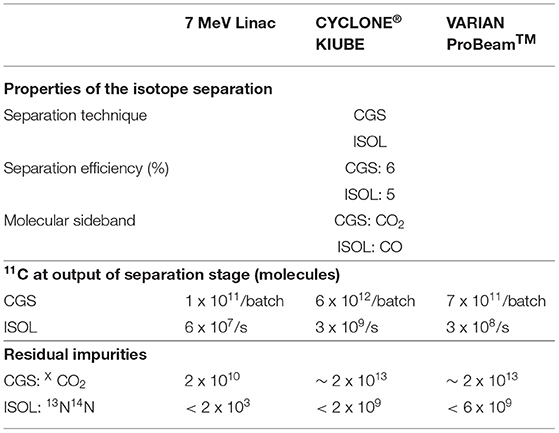

To calculate the amount of recovered isotopes when employing the BN target with such a modified CGS system, one has to account for the accumulation and simultaneous decay of radioisotopes. Considering the application of a molecular sieve trap instead of a cold trap, due to their similar working principle, we can apply the same trapping mechanism as discussed for the cold traps, i.e., trapping and release time of 4 and 1 min, respectively with a trapping efficiency larger than 95%. An overall efficiency of approximately 6% is calculated for 11CO2. Stable carbon contaminants resulting from the BN target will not decay during the 4 min of accumulation and will subsequently be transported to the next stage with an efficiency of 50%. As a result, a deterioration of the 11CO2 to carbon impurity ratio will occur. This feature should be addressed when considering the possible application of a CGS system combined with the BN target, as the impurity level should not exceed the amount of 11CO2 molecules significantly. The expected load of the BN target-CGS system combination is shown in Table 5.

Table 5. Expected 11C available after the separation stage for a BN target, together with the corresponding impurities.

An ISOL-type electromagnetic mass separation system may be used to isolate 11CO from other impurities. This option can be interesting especially because the BN target was developed as an ISOL target. This method relies on the use of a suitable ion source for efficient 1+ ionization and of a dipole magnet with high resolving power. The reference values we use for the 1+ ionization efficiencies of CO and CO2 are respectively 14 and 4%, as reported in (76) for a 2.45 GHz ECR ion source (MONO 1000) developed for efficient 1+ ionization at GANIL and reproduced and tested in an off-line study at ISOLDE.

Dipole magnets, tailored for the A/q of interest typically have separation efficiencies of 90%. Possible residual beam impurities are 13N14N since it shares the same A/q ratio when ionized to the 1+ charge state.

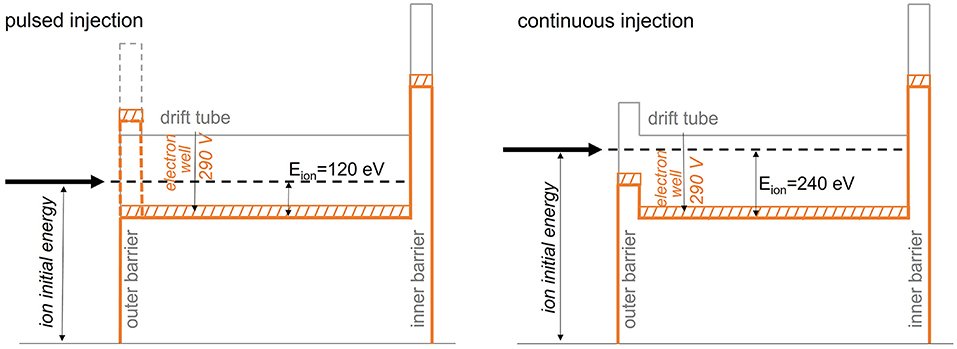

Ion Pulse Preparation

As introduced in Figure 2, the main steps needed to be performed for the preparation of the ion pulse are the ionization (typically 1+), accumulation (typically as ions, but depending on the encountered limitations, transformation in neutral particles might be necessary) and the charge breeding (to 4+ or 6+ charge state). A complete solution will need to address all these steps, but not necessarily in this order (as is also the case in the following analysis), due to the numerous technical constraints to be addressed.

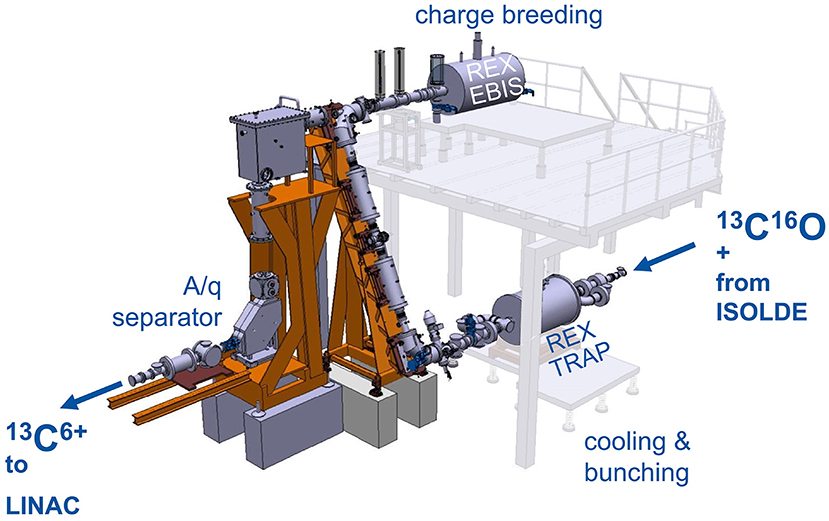

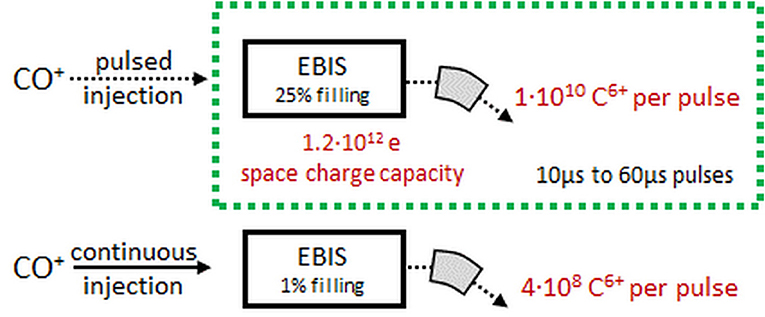

This section summarizes the results presented in (95). The goal is to discuss the possibilities of using a charge breeding scheme, that is ionization of 11C to 6+ charge state, based on an Electron Beam Ion Source (EBIS) for the preparation of the 11C beam. Test measurements under extreme operating conditions were conducted at the REX-ISOLDE facility to explore the limitations of the charge breeder for high-intensity, low-repetition-rate, molecular CO+ beams. Based on these findings, different possible scenarios of coupling a charge breeder with a therapy accelerator are discussed.

Setup and Methodology

The concept of accumulation, breeding and post-acceleration of radioactive carbon beams was tested at REX-ISOLDE (107, 108), which is part of ISOLDE. Here, ISOL-produced radioactive beams are prepared in a charge-breeding stage (see Figure 6) before acceleration in the HIE-ISOLDE linac (4) and further transfer to the experimental stations. The charge breeding stage consists of two main devices, namely a Penning trap and an EBIS. The Penning trap, REXTRAP (109, 110), cools and bunches the quasi-continuous beam from ISOLDE. The bunched beam is transported via an electrostatic transfer section and injected into REXEBIS (111, 112), where the ions' charge state of initially 1+ is increased for an efficient post acceleration. After separation by A/Q in a Nier-type spectrometer (113), the selected beam is accelerated in the HIE-ISOLDE Linac.

Figure 6. REX-ISOLDE low energy stage, comprised of REXTRAP for cooling and bunching of the 1+ ion beam, the electrostatic beam transfer section (BTS), REXEBIS for charge breeding 1+ → N+ and an A/Q separator. The charge breeder stage transforms a continuous 1+ beam into a pulsed beam of higher charge.

At ISOLDE, the efficiency of the charge breeder stage is of major concern. Typically, rare isotopes with small production cross-sections are handled, hence, ion intensities are relatively low (ranging from a few ions/s to >1 x 108 ions/s). In contrast to ISOLDE, a beam preparation stage for hadron therapy has to deal with considerably higher intensities. The efficiency will still play a central role in the design, as the production of the radioactive ions is limited. Furthermore, a synchrotron-based treatment facility would require long storage times of the 1+ ions, which is an additional challenge.

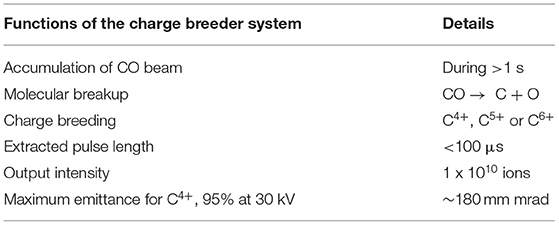

In the detailed report (95), different ways of using a charge breeding stage as a CO beam preparation tool for hadron therapy with a synchrotron have been laid out and investigated with regard to their feasibility and technical limitations. Measurement data was taken at ISOLDE to quantify the behavior and limitations of the Penning trap and EBIS under the extreme conditions of high-intensity, low repetition-rate beams and constraints due to molecular beams. The assumed requirements of the charge breeding stage are summarized in Table 6, and as seen the targeted output intensity is larger compared to the one introduced in Figure 2, as a margin to account for the fact that matching this type of injector to a synchrotron was not yet tested as a whole.

Table 6. Summary of the required functions of the charge breeding system for a hadron therapy facility based on a synchrotron, as used in (95).

All measurements were performed with stable beams, either from the ISOLDE General Purpose Separator GPS (114), or from the local off-line surface ion source in front of the Penning trap (only K, not CO) (115). 13CO+ beams were produced in an ISOLDE target ion-source unit by injecting 13CO gas into a Versatile Arc Discharge Ion Source VADIS (116) via a leak. The measurements were performed with stable 13CO+ as radioactive 11CO+ beams with sufficient intensities cannot be reached with the present ISOL-system. It is assumed that the behavior of the radioactive ions is similar to that of the stable beam. For a radioactive beam, slightly higher loss rates in the Penning trap are expected due to the radioactive decay. However, as the half-life of 11C is relatively long (T1/2 = 20.4 min), only a small fraction of the ions decays during the storing time in the trap (decay constant 5.7 x 10−4 per second). Concerning the space charge limitation, the Brillouin limit for the Penning trap is inversely proportional to the ion mass, therefore the results can be scaled with the mass difference between 13C and 11C. In the EBIS no difference in capacity is expected between radioactive and stable beam as it depends only on the charge and not on the mass of the ions, to the first order.

Furthermore, the breakup of CO was studied for different trap configurations and buffer gases.

Pulsed Injection Into the EBIS

At the start of this study, pulsed injection into the EBIS with prior cooling and bunching in a Penning trap had been proposed as charge breeding scheme for a synchrotron-based 11C therapy facility (117). Within the investigations presented in (95), however, we have found that its working range is strongly limited, which makes it unsuitable for a therapy purpose.

Nevertheless, this scheme serves as an important reference case as it represents the normal operating scheme of the charge breeder system. We describe this operation case in the following of this section, together with the most important results from (95).

When injecting CO+ into REXTRAP, energy is transferred between the injected beam and the neutral buffer gas atoms through collisions. If the energy in the center-of-mass frame of the collision exceeds the dissociation energy of the molecule, there is a possibility that the molecule breaks up into carbon and oxygen. In principle, the CO molecule has to be broken up at some point in the charge breeding system. Therefore, it would be favorable if all molecules could be broken up in the trap such that all oxygen can be removed and an ion beam of atomic carbon is injected into the EBIS, thereby reducing the occupied space charge in the EBIS. The problem, however, is that when the CO+ dissociates in the trap, it is not guaranteed that the carbon atom remains positively charged. In the breakup there are two possible exit channels (95):

• CO+ → C+ + O (neutral)

• CO+ → C (neutral) + O+

where the branching ratio depends, among other things, on the collision energy with the neutral atom, with higher energies leading to an increased O+/C+ ratio (95). In the second channel, the carbon atom is neutralized and lost. When breakup happens, three beam components can exit the Penning trap: C+, O+ and CO+. The beam transfer section (BTS) from the Penning trap to the EBIS is completely electrostatic, so all beams can be transferred to the EBIS and the acceptance window in time is sufficiently large to accommodate the difference in flight time.

In tests with molecular CO+ beams in REXTRAP, the influence of different parameters such as the injection energy, cooling time and choice of buffer gas on the trapping efficiency and breakup were investigated (95), with the following conclusions:

• For the buffer gas, two options were considered: He and Ne. Due to the significantly lower over-all efficiency observed, the idea of using He as buffer gas was discarded. All the further measurements were taken with Ne as buffer gas.

• The breakup of the CO+ molecules inside the Penning trap can partly be avoided by lowering the injection energy into the trapping region. In the normal trap configuration most of the molecules break up, hence, the beam is cooled on A = 13 as atomic carbon ions make up the largest part of the beam extracted from REXTRAP. In the flat trap configuration (see Figure 7), the injection energy is lower in order to reduce the breakup upon injection into the buffer gas, therefore the beam is cooled on A=29 and mostly CO+ molecules are extracted from REXTRAP.

• However, the normal trap configuration has a higher transmission than the flat trap, due to better injection conditions, and faster cooling during the first axial oscillation. For both flat and normal trap configurations, the trap transmission decreases with longer period times due to two effects. First, for longer holding times in REXTRAP the ions suffer more from the high loss rate discussed above. The CO+ beam is lost exponentially with a half-life of around 100 ms. The mechanism behind the losses has not been fully explained. Second, space charge effects in REXTRAP become more relevant, as the injection is continuous and higher integrated intensities need to be accumulated during longer period times (e.g., 2.8 x 108 charges are injected for a 500 ms period time). When the accumulated charge per pulse approaches, and exceeds, the space charge limit of the Penning trap, the efficiency decreases.

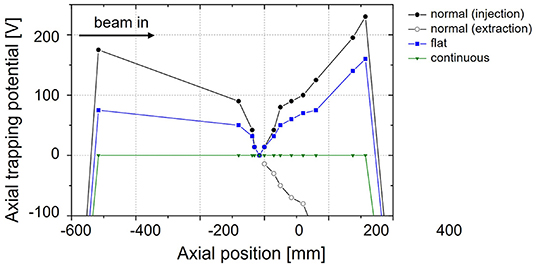

Figure 7. Different configurations of the axial trapping potential in REXTRAP. In the normal trapping configuration, the beam enters from the left side several 10 eV above the barrier or approximately 200 eV above the central trapping electrode (95).

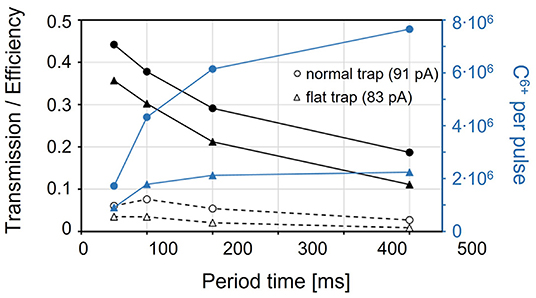

Only the beam species that have been sufficiently cooled can be injected into the EBIS efficiently. Thus, in order to correctly compare the efficiency of the beam preparation inside the Penning trap for the two trap configurations, the beam has to be taken through the EBIS. The overall efficiency (dashed curves in Figure 8) of the charge breeder system for C6+, including REXTRAP and REXEBIS, has an optimum around 100 ms period time and is higher for the normal than for the flat trap configuration. For shorter period times, the breeding time in the EBIS is insufficient, while for longer period times losses and space charge effects in REXTRAP become important and reduce the efficiency. With the normal trap configuration at 100 ms period time, a maximum total efficiency of 8% through REXTRAP and REXEBIS could be achieved, corresponding to 4.3 x 106 extracted C6+ ions per bunch when injecting 91 pA of CO+ beam into the charge breeder system, i.e. into REXTRAP. For longer period times, higher particle numbers up to 7.7 x 106 C6+ ions per pulse could be extracted with a trade-off in efficiency. The measurements showed similar efficiencies and particle numbers for charge states 4+, 5+ and 6+, when optimizing the breeding time in the EBIS. For the lower charge states, the optimum in efficiency is reached at a shorter period time, as a shorter breeding time is sufficient.

Figure 8. Transmission through REXTRAP (black solid line, including exiting C+, O+, H2O+ and CO+ beams) and total efficiency of carbon ions (charge bred to C6+) through REXTRAP and REXEBIS (dashed) for a normal (circle) and a flat (triangle) axial trapping potential in the Penning trap, with an input beam of 91 pA and 83 pA, respectively. The blue curves correspond to the total number of C6+ ions extracted from the charge breeder system (95).

In conclusion, the attempt to keep the molecules intact through REXTRAP using a flat trapping potential can be discarded due to the lower over-all efficiency compared to the normal trap configuration. Furthermore, even if the normal trap configuration has a reasonable maximum efficiency of 8% for the charge breeder system, when going to long period times it decreases significantly. The efficiency decreases even further for higher beam intensities, which is addressed in the next section. Therefore, standard operation charge breeding of CO+ together with a low-repetition-rate synchrotron would be highly inefficient.

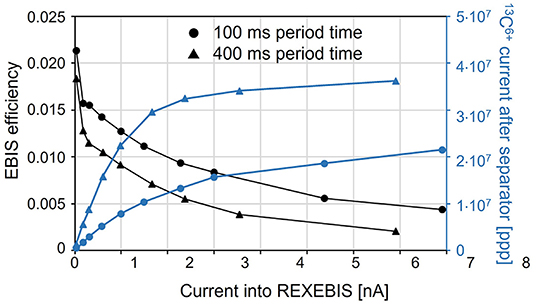

Space Charge Limitations of REXTRAP and REXEBIS

Under normal conditions at ISOLDE, space charge does not play a role as typical ion currents are small compared to the capacity of the devices. As this is not true any longer for the CO+ charge breeding system, where significant currents need to be handled, we have made efforts to determine the intensity limitations in REXTRAP and REXEBIS. Even though the theoretical space charge limits can be calculated [details in (95)], the practical ion holding capacity might differ.

In the REX-ISOLDE case, the Penning trap turns out to be the bottleneck: the number of charges extracted from REXEBIS can go up to 5.8 x 109, while for REXTRAP only up to 7 x 107. This corresponds for EBIS to a filling factor k = 25%. Higher k values can be obtained, but at the cost of efficiency.