95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mech. Eng. , 25 November 2024

Sec. Mechatronics

Volume 10 - 2024 | https://doi.org/10.3389/fmech.2024.1431009

This article is part of the Research Topic Efficient energy utilization in hydraulic systems View all 3 articles

Introduction: With the development of technology, the hydraulic control system for hydro-mechanical continuously variable transmission has also made rapid progress. However, the traditional control system for hydro-mechanical continuously variable transmission has drawbacks such as efficiency loss and slow response speed. The study fused the adaptive and pulse width modulation algorithms to solve these problems effectively, and they were applied to the hydraulic mechanical continuously variable drive control system.

Method: First, the study analyzed the continuously variable transmission control of hydraulic machinery and designed the control scheme on the basis of the analysis. Then, a new scheme fusing adaptive and pulse-width modulation algorithms was proposed on the basis of the control scheme. Finally, simulation experiments and practical tests were carried out to verify the performance of the control scheme.

Results: The results showed that the time to reach the maximum pressure was 2.15 s when the volume of the pilot valve cavity was 5 × 109/L. When the oil flow rate was 70 L/min, the corresponding maximum and minimum values of the main oil circuit pressure were 1.63 MPa and 0.37 MPa, respectively. The time to reach the maximum value of the pressure was 2.05 s, respectively. These values were in line with the design requirements and were better than the comparison values.

Discussion: These results confirm that the system has important theoretical and practical significance, which has a positive promoting effect on the development of the hydraulic machinery industry. This article aims to provide a new approach for research and application in related fields.

Hydro-mechanical continuously variable transmission (HMCVT) technology is an innovative technology that combines hydraulic transmission with mechanical transmission. HMCVT has the advantages of high transmission efficiency, low noise, and high energy utilization, which is widely applied in the engineering (Fan and Kuang, 2021; Maczyszyn, 2019). However, the traditional hydraulic control system for HMCVT has some problems, such as high requirements for transmission efficiency and low control accuracy (Hu et al., 2020; Mazali et al., 2019). A control system for continuously variable transmission combining adaptive and pulse width modulation (PWM) algorithms was proposed to overcome these issues. Adaptive control algorithm can adjust control parameters in real-time and intelligently adjust the transmission process based on the actual operating status of system to optimize transmission efficiency. PWM is a method of controlling the output power by changing the pulse width of signal, which can achieve precise control (Zhang et al., 2022a; Yasien and Wala’a, 2019). The study first analyzed the control of HMCVT and designed relevant solutions. Then a system control scheme combining the adaptive and PWM algorithms was proposed. Finally, simulation experiments and practical tests were conducted, and the experimental results were analyzed and summarized. The research solves the limitations of traditional control methods and realizes the efficient and precise control of the continuously variable transmission system of hydraulic machinery through the innovation of algorithmic level and optimization of control strategy. The article aims to provide a new control method for the further development of HMCVT technology.

The first part of this study introduces the current research of the HMCVT control system and the adaptive and PWM algorithms in the application of the continuously variable transmission. Next, the study constructs the HMCVT control system based on the adaptive and PWM algorithms. Then the performance of the control system is verified by using the continuously variable transmission of the automobile wet clutch transmission as an experimental object. The final part summarizes the experimental results, and the advantages and disadvantages of using the method are analyzed.

HMCVT is a method of adjusting the transmission ratio by controlling the flow and pressure in the hydraulic system, which can make the mechanical transmission process more stable and efficient. Traditional mechanical transmission usually adopts a discrete transmission method, with a fixed transmission ratio that cannot be adjusted according to changes in working conditions. HMCVT can adjust the transmission ratio in real-time according to actual needs, thereby improving the performance and efficiency of mechanical systems. Numerous experts and scholars have conducted research on the HMCVT system. Morabito and Versaci (2001) designed a fuzzy neural method to address the shortcomings of non-intrusive turbine measurements in hydraulic mechanical drive systems. Fuzzy reasoning and the concepts of fuzzy curves and surfaces were utilized to estimate the location of the hole center from a reduced set of features. Hoodorozhkov et al. designed an automatic multi-flow gearbox to improve the dynamic characteristics of the vehicle using a mechanical continuously variable transmission. The transmission was proposed as a five-flow mechanical transmission and the kinematics of the eccentric conversion elements were described in detail. The results showed that the proposed mechanical automatic transmission had a higher total efficiency than a typical mechanical transmission, while there was no power flow interruption due to ratio changes during vehicle acceleration (Hoodorozhkov and Kozlenok, 2021). Zhang et al. (2022b) proposed a power return hydraulic transmission system to develop advanced power performance and reduce energy consumption. The system utilized the mathematical model of the power-train to obtain resonance characteristics. These results confirmed that the power-train resonance frequency of the system was excluded from the operating range of the engine (Zhang et al., 2022b).

Kharytonchyk and Kusyak proposed an adaptive control based on PWM signal frequency to make the dry friction clutch engaging quality ensured. These results confirmed that the algorithm achieved the adaptive control (Kharytonchyk et al., 2021). Ouyang et al. put forward a mathematical model for the electronic hydraulic actuator of heavy-duty automatic transmissions to predict the response performance of wet clutches to reduce fuel consumption and shift quality of heavy-duty automatic transmission vehicles. In this study, PWM was used to control the solenoid valve, pressurization valve, and pilot valve, simplifying the control formula of the clutch model. These results confirmed that the model had certain reference value for performance analysis and optimization of clutch actuators (Ouyang et al., 2019).

In summary, HMCVT can be achieved through hydraulic drive. The HMCVT control system adjusts the working parameters to achieve continuous adjustment of the transmission ratio, thereby meeting the precise transmission requirements under different working conditions. Traditional hydraulic mechanical transmission control systems have drawbacks such as efficiency loss, slow response speed, and high system complexity. Therefore, research is conducted on the fusion of the adaptive and PWM algorithms in a control system for HMCVT based on the summary of existing technologies. The article aims to provide better technical support for developing a hydraulic control system for HMCVT.

A hydraulic control system is a technology that can achieve HMCVT. This system achieves continuously variable speed change and power distribution by adjusting the working parameters of the hydraulic system, thereby achieving precise control of the mechanical transmission system.

HMCVT is a method by using a hydraulic system to achieve continuously variable transmission. In the hydraulic control system for HMCVT, the speed ratio of the transmission device is controlled by changing the working pressure and flow rate of the hydraulic system, thereby achieving continuously variable transmission. There is a certain difference in power transmission between the mechanical part and the former, and the power transmission of the mechanical part varies in a step wise manner (Chen et al., 2019; Chen et al., 2021). In HMCVT, there are positive and negative phase conditions. Positive phase condition refers to the condition where the overall speed of the transmission system increases according to the output of the continuously variable transmission when the forward converging planetary array is running, which can be expressed by Formula 1 (Yan et al., 2022).

In Formula 1,

In Formula 2,

In Formula 3,

In Formula 4,

In Formula 5,

In Figure 1, the HMCVT system is a transmission meshing mechanism consisting of a number of pairs of fixed-shaft gears assembled on top of the autonomous shift meshing casing a, casing b, the movement shafts 1 and 2, and the output shaft 3 at the bottom. Meanwhile, the system is designed with four working gears, i.e., four forward working transmission segments I, II, II, and IV and one reverse working segment R. The system is designed with four working gears.

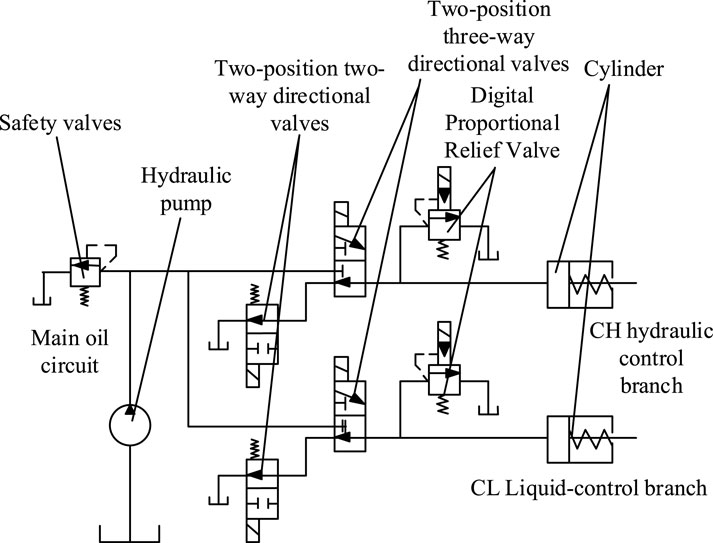

A control system for HMCVT is a device that utilizes hydraulic flow and pressure to achieve HMCVT. A control system that integrates the adaptive and PWM algorithms can achieve precise control of HMCVT. When designing a hydraulic control system, it is necessary to address issues such as torque fluctuations in HMCVT to improve the quality of shifting. For this reason, the hydraulic control system needs to meet some requirements, such as being able to achieve buffering pressure increase and decrease, control the minimum pressure to zero, have overload protection function, and have no interference between various hydraulic control branches (Yuan et al., 2022; Zeng et al., 2020). A hydraulic control system scheme is designed based on the above requirements in Figure 2. Due to the same structure of CH and CL hydraulic control branches, CH hydraulic control branch is chosen as the research object to study its working process in the buffered boosting state, sliding and bonding state, and buffered depressurization state.

Figure 2. Hydraulic machinery continuously variable drive hydraulic control system schematic diagram.

It is necessary to consider the main oil circuit safety valve to protect the hydraulic system from overload damage when designing a hydraulic control system for HMCVT. The overflow pressure should be greater than the maximum control pressure of the digital proportional overflow valve to ensure that the safety valve does not affect the system pressure. The diameter of the inlet and outlet can be calculated through parameters such as nominal pressure, nominal flow rate, main valve opening pressure, and unloading pressure. The calculation of the diameter can be expressed by Formula 6 (Han et al., 2021).

In Formula 6,

In Formula 7,

In Formula 8,

In Formula 9,

In Formula 10,

In Formula 11,

In Formula 12,

According to Figure 3, the hydraulic mechanical continuously variable drive control system that fuses the adaptive and PWM algorithms is simplified to some extent to adapt it to practical use. The first is a linear simplification of the nonlinear characteristics. Because many components in a hydraulic system, such as pumps, valves, and motors, exhibit nonlinear characteristics. These nonlinear relationships are often approximated as linear to simplify the mathematical model. Then the dynamic response is simplified. In a real system, the dynamic response may be affected by a variety of factors, such as the viscosity of the hydraulic fluid, the damping, and the inertia of the system. These complex factors may be ignored or approximated to simplify the model. Finally, parameter simplification, a large number of parameters may need to be considered when building the mathematical model, such as the density of the hydraulic fluid, viscosity, leakage coefficients, and so on. It is assumed that these situations do not occur during the experiment to simplify the model. The mathematical model can be applied more effectively to analyze and optimize the performance of the HMCVT control system through these simplification measures.

This study took HMCVT of a wet clutch transmission as the experimental object to verify the performance and application effectiveness of the constructed system.

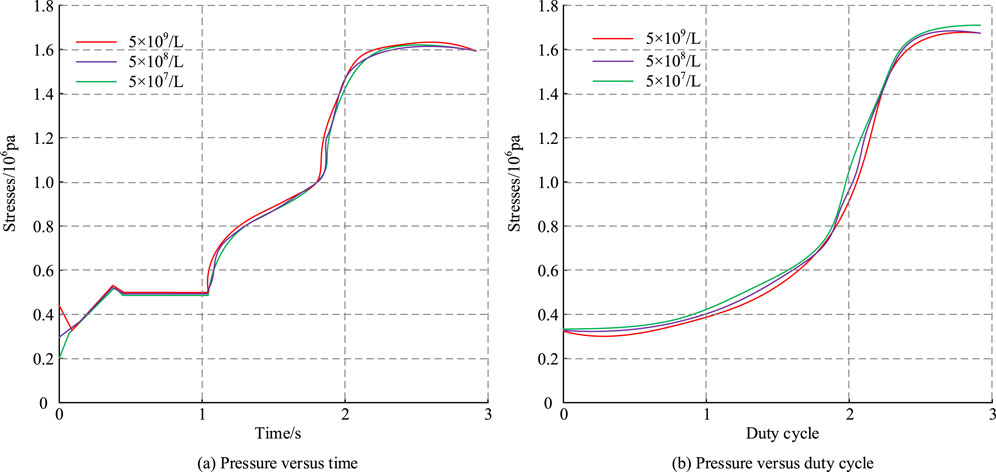

A digital proportional relief valve model was studied to verify the performance of this control system. Digital proportional relief valve is a proportional control component used in hydraulic systems to achieve continuously variable transmission control of hydraulic machinery by controlling the flow rate of the hydraulic system. Specifically, the digital proportional relief valve controls the movement speed of the hydraulic motor or cylinder by adjusting the flow rate in the hydraulic system, thereby achieving transmission control of hydraulic machinery. The performance of the digital proportional relief valve was optimized to improve the control accuracy, response speed, and stability of the continuously variable transmission control system of hydraulic machinery by reasonably selecting and designing the volume of the pilot valve cavity. Figure 4 shows the effect of different pilot valve chamber volumes on the characteristics of digital proportional relief valves. The pilot valve chamber volume selected for this study was 5 × 109/L.

Figure 4. Comparison results of digital proportional relief valve characteristics with different pilot valve cavity volumes. (A) Pressure versus time (B) Pressure versus duty cycle.

According to Figure 4A, as the volume of the pilot valve chamber increased, the pressure response rate slowed down, and the pressure fluctuation also decreased. The time for main oil circuit to reach maximum pressure corresponding to 5 × 107, 5 × 108, and 5 × 109/L volumes was 2.15, 2.35, and 2.51 s, respectively. According to Figure 4B, as the volume of pilot valve chamber changed, there was not much difference in the pressure curves under three volumes. This indicated that the volume change of pilot valve chamber did not affect the duty cycle of continuous pressure changes, which verified that the volume of pilot valve chamber selected in this study met the design requirements. The high-speed development valve is an important component, used to control this hydraulic system’s flow and pressure. The overall flow of this hydraulic system can be controlled by adjusting the valve port diameter of the high-speed development valve. Precise flow adjustment was achieved by combining it with the digital proportional relief valve control.

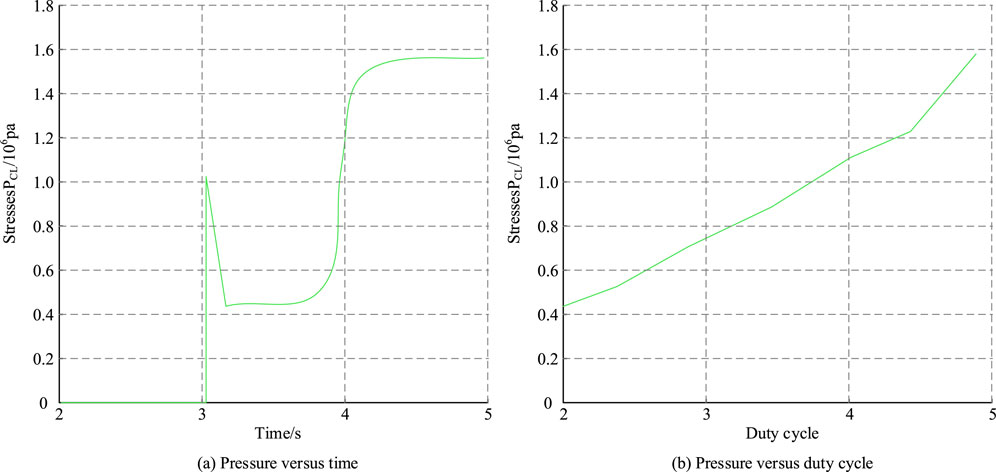

Research was conducted on applying the control system to HMCVT of automotive wet clutch transmissions to further verify the application effect of the control system. In the control system for HMCVT, the boost buffering characteristics were adopted. This effectively reduced hydraulic pulsation and impact in the system, thereby enhancing the stability and reliability of the transmission system and improving the work efficiency and service life of the mechanical transmission system. Figure 5 shows the results of the hydraulic control system’s boosting and buffering characteristics.

Figure 5. Hydraulic control system boost buffer characterization results. (A) Pressure versus time (B) Pressure versus duty cycle.

According to Figure 5A, within 0–3 s, the CL hydraulic control branch was connected to the fuel tank, and the oil circuit’s pressure was 0. After 3 s, the directional valve changed direction. At this point, the oil circuit was connected, and the oil pressure began to rise, reaching the maximum pressure value at 4.09 s. According to Figure 5B, when buffering between pressure and duty cycle, the range of duty cycle varied between 20% and 81% when the pressure continuously changed. When the duty cycle was less than 20%, the corresponding pressure value was 0.4 MPa, and the maximum value was 1.61 MPa. This indicated that the buffering characteristics in the control system designed in the study met the requirements of practical applications. The stability and smoothness of the system were improved by optimizing the boost buffer characteristics, the pressure shock and transmission instability were reduced, and the work quality and efficiency were improved. The static characteristics describe the relationship between the input and output of a system in a stable state. In the control system for HMCVT, the static characteristics reflect the impact of the control input signal on the system output. Static characteristics are mainly used to evaluate the performance of a hydraulic system in non-operating or stable operating conditions. The results of the static characteristics are important for understanding system performance, optimizing system design, and predicting system behavior. This study was validated by combining the dynamic characteristics of pressure reduction and buffering to further verify the control effect of the system on the displacement of each hydraulic control branch and clutch piston. Figure 6 shows the corresponding control effect.

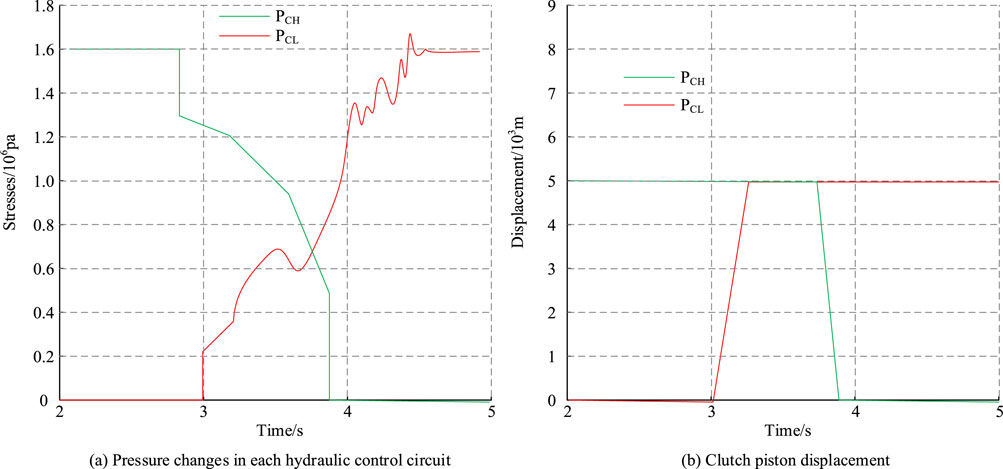

Figure 6. Results of the hydraulic control system on the displacements of each branch and clutch piston in the buck cushioning dynamic. (A) Pressure changes in each hydraulic control circuit (B) Clutch piston displacement.

According to Figures 6A, B, the end time of CH clutch sliding was 3.9 s, and the directional time of the corresponding 2-way directional valve was also 3.9 s. At this time, the duty cycle of PWM control signal decreased. After 3.9 s, the duty cycle reached 100%. The time for both clutches to slip and wear simultaneously was adjusted by adjusting the release time of CH clutch. This indicated that the constructed hydraulic control system adjusted the pressure buffering according to the actual pressure situation. This helped to reduce pressure shocks, improve transmission smoothness, increase system reliability and safety, providing guidance for further system optimization. The efficiency loss of the clutch under different states is further compared, and the results are shown in Table 1.

Table 1 shows the comparison of efficiency loss values under different CH clutch states. The results show that when CH clutch is in a combined state, all its parameter values are 0. At the same time, compared with other parameters, it can be seen that the speed difference, strip torque, power loss and efficiency loss of CH clutch are proportional to each other, that is, when the speed is at the minimum of 40 rad/s, the corresponding remaining parameters are also the smallest, in which the strip torque is 15 N-m, the power loss is 1,200 W, and the efficiency loss is 10%. At the same time, when the maximum speed is 80 rad/s, the corresponding other parameter values are also maximum, where the strip torque is 40 N-m, the power loss is 3,200 W, and the efficiency loss is 20%. The results show that the disengaging state of the clutch has a significant impact on the efficiency of the system, while the engaged state of the clutch has a negligible impact on the efficiency. According to the research results of F Concli, we compare the loss shares under different allocation (Concli and Gorla, 2013). The relevant results are shown in Table 2.

Table 2 is a comparison of the loss share of five different configurations, the results show that the different configurations of the load-related losses, load-independent losses, other losses and total losses are somewhat different, by comparing the relevant configuration of the CVT can be found in the form of a combination of the load-related losses of the highest value of 30%, and at the same time, three kinds of CVT configurations of the load-independent losses are close to the value of the value of the CVT configurations, the maximum value of 18% of other losses and total losses are located in the maximum value level. The torque converter with lock-up clutch has the highest value of load-independent losses, with a value of 18%, while the other losses and total losses of this configuration are at the maximum level, with the other losses and total losses being 12% and 50%, respectively, so this configuration is suitable for driving conditions that require high efficiency, and the combination of the CVT and the hydrodynamic coupler has low load-independent losses, which makes it suitable for occasions with frequent start-ups.

In the research results, with the increase of the pilot valve chamber volume, the pressure response rate as well as the pressure fluctuation are gradually reduced, and at this time, the time to reach the maximum pressure of the main oil circuit corresponding to the three volumes of 5 × 107/m3, 5 × 108/m3, and 5 × 109/m3 are 2.15 s, 2.35 s, and 2.51 s, respectively; meanwhile, the pressure of the oil circuit in the time of 0–3 s is 0, and 3 s after the reversing valve changes direction, the oil pressure starts to rise, and reaches the maximum value of pressure at 4.09 s. Secondly, in the process of buffering between the pressure and the duty cycle, the range of the duty cycle varies between 20% and 81% when the pressure changes continuously, and when the duty cycle is less than 20%, the pressure corresponds to the value of 0.4 MPa, and the maximum value of 1.61 MPa. Also there are some differences in the values of efficiency losses for different CH clutch states and in the share of losses for different configurations. At this stage, Y ZHAO et al. have designed a simple design for improving the tractor’s fuel economy, a simple single planetary gear was designed to consolidate the power and analyzed the energy as well as fuel consumption, the results show that the parasitic power is obtained when the variable pump displacement is negative and at the same time the maximum power of this hydro-mechanical transmission can reach to 87% as well as 89%, which is simpler in structure as compared to the hydro-mechanical transmission with Simpson’s planetary gears and consumes less energy as well as less fuel, the transmission is similar to the transmission is similar to the hydraulic transmission scheme described in the study (Zhao et al., 2023). Wang et al. (2024) designed a new type of variable structure dual-motor hydrostatic transmission system to improve the control performance and energy efficiency of the hydrostatic transmission system of the wheel loader, and also proposed a fuzzy sliding-mode control based multi-control strategy, which verified the stability of the transmission system by establishing a simulation model of the transmission system, and it was more effective than the traditional control strategy, and was able to actively adapt to disturbances, and was more efficient than traditional control strategy, and was able to actively adapt to disturbances, and was able to actively adapt to disturbances. And it can actively adapt to disturbances, and its transmission efficiency is improved by 30% compared with the traditional torque converter loader transmission system, which is important for reducing energy consumption, which is more similar to the research results (Wang et al., 2024). In summary, the research proposed stepless transmission system for hydraulic machinery has high accuracy and shows good performance in the control of hydraulic machinery.

The traditional control system for HMCVT has problems such as efficiency loss, slow response speed, and high system complexity. In this regard, a control system for HMCVT was designed by integrating the adaptive and PWM algorithms in the experiment. These results confirmed that there was a significant decrease in pressure when the CH hydraulic control branch was buffered. When the pressure of CL hydraulic control branch and the pressure of CH hydraulic control branch were at 0.58 MPa, there was a time crossing situation, with a time of 3.35 s. The end time of CH clutch sliding wear was 3.9 s, and the corresponding reversing time of two-way directional valve was also 3.9 s. At this time, the duty cycle of PWM control signal decreased. After 3.9 s, the duty cycle reached 100%. In summary, the research results of a control system for HMCVT that integrated the adaptive and PWM algorithms provided new solutions for the development of the hydraulic machinery industry. The design and implementation of this system fully utilized the advantages of adaptive control and PWM, improved the control accuracy and performance of hydraulic mechanical transmission, and had important theoretical and practical significance. However, there are still shortcomings in this research. Strategies related to pressure buffering control are designed, and the characteristics of the strategies are only open-loop control strategies. More algorithms can be combined to study closed-loop control strategies in the next step to achieve better system control effects. The paper can continue to deepen the research on the adaptive and PWM algorithms to explore more advanced and efficient control strategies. Meanwhile, this paper can focus on the reliability and safety of the system and develop a more stable and reliable HMCVT system to meet the needs of various complex application scenarios.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

JC: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Project administration, Resources, Supervision, Writing–original draft, Writing–review and editing.

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Aikhuele, D. (2022). Development of a statistical reliability-based model for the estimation and optimization of a spur gear system. J. Comput. Cognitive Eng. 2 (2), 168–174. doi:10.47852/bonviewjcce2202153

Chen, D. F., Cheng, A. B., Chiu, S. P. C., and Ting, J. C. (2021). Electromagnetic torque control for six-phase induction motor expelled continuously variable transmission clumped system using sage dynamic control system. Int. J. Appl. Electromagn. Mech. 65 (3), 579–608. doi:10.3233/jae-201512

Chen, W., Lin, Y., Li, W., Liu, H., Tu, L., and Meng, H. (2019). Study on speed and torque control of a novel hydromechanical hybrid transmission system in wind turbine. IET Renew. Power Gener. 13 (9), 1554–1564. doi:10.1049/iet-rpg.2018.6105

Concli, F., and Gorla, C. (2013). Influence of lubricant temperature, lubricant level and rotational speed on the churning power loss in an industrial planetary speed reducer: computational and experimental study. Int. J. Comput. Methods Exp. Meas. 1 (4), 353–366. doi:10.2495/cmem-v1-n4-353-366

Du, J., Yai, D., Xue, Y., Liu, T., and Quan, W. (2019). Analysis of dual-rotor pm machine incorporating intelligent speed control suitable for CVT used in HEVs. IEICE Trans. Electron. 102 (1), 83–90. doi:10.1587/transele.e102.c.83

Fan, P., and Kuang, Y. C. (2021). A novel line type optimization and theoretical equilibrium method analysis for common hypocycloid screw motor. Industrial Lubr. Tribol. 73 (6), 911–921. doi:10.1108/ILT-12-2020-0446

Gao, J., Lou, D., Zhang, T., Fang, L., and Zhang, Y. (2022). Multivariable predictive functional control of a compound power-split hybrid electric vehicle. J. Automob. Eng. 236 (8), 1775–1794. doi:10.1177/09544070211046690

Han, L., Ren, L., and Zhao, W. (2021). Safety threshold of the oil film stiffness of a CVT pulley–sheet friction pair based on mixed lubrication theory. Tribol. Trans. 64 (4), 633–643. doi:10.1080/10402004.2021.1893419

Hoodorozhkov, S. I., and Kozlenok, A. V. (2021). Dynamics of a vehicle equipped with mechanical self-regulating stepless transmission. Int. Rev. Mech. Eng. 15 (1), 13–22. doi:10.15866/ireme.v15i1.19912

Hu, X., Jing, C., and Li, P. Y. (2020). Modeling and experimental testing of the hondamatic inline hydromechanical transmission (iHMT). J. Dyn. Syst. Meas. Control 142 (5), 22–37. doi:10.1115/1.4046101

Huang, M., Shi, C., Zhu, Y., Zhang, J., and Zhang, F. (2021). Design of gerotor pump and influence on oil supply system for hybrid transmission. Energies 14 (18), 5649–5713. doi:10.3390/en14185649

Kharytonchyk, S. V., Kusyak, V. A., and Le, N. V. (2021). Control of pneumatic actuator for automated mechanical transmission dry friction clutch base on the pulse width modulation signal. Наука и техника 6 (1), 26–32. doi:10.21122/2227-1031-2021-20-1-26-32

Li, J., Zhai, Z., Song, Z., Fu, S., Zhu, Z., and Mao, E. (2022). Optimization of the transmission characteristics of an HMCVT for a high-powered tractor based on an improved NSGA-II algorithm. J. Automob. Eng. 236 (13), 2831–2849. doi:10.1177/09544070211067961

Maczyszyn, A. (2019). Energy loss coefficients i in a displacement pump and hydraulic motor used in hydrostatic drives. Pol. Marit. Res. 26 (3), 47–55. doi:10.2478/pomr-2019-0045

Mazali, I. I., Husain, N. A., Tawi, K. B., Husain, N. A., and Asus, Z. (2019). Review of latest technological advancement in electro-mechanical continuously variable transmission. Int. J. Veh. Des. 81 (3-4), 166–190. doi:10.1504/ijvd.2019.10033893

Morabito, E. C., and Versaci, M. (2001). A fuzzy neural approach to localizing holes in conducting plates. IEEE Trans. Magnetics 37 (5), 3534–3537. doi:10.1109/20.952655

Ouyang, T., Li, S., Huang, G., Zhou, F., and Chen, N. (2019). Mathematical modeling and performance prediction of a clutch actuator for heavy-duty automatic transmission vehicles. Mech. Mach. Theory 136, 190–205. doi:10.1016/j.mechmachtheory.2019.03.003

Pang, D., Zeng, G., Li, X., Guo, L., Zhao, F., and Sun, Z. C. (2021). Transient temperature field of planetary gear system in electro-mechanical transmission under different working conditions. Acta Armamentarii 42 (10), 2268–2277. doi:10.3969/j.issn.1000-1093.2021.10.023

Thenathayalan, D., and Park, J. H. (2019). Individually regulated multiple-output WPT system with a single PWM and single transformer. IEEE J. Emerg. Sel. Top. Power Electron. 8 (4), 3542–3557. doi:10.1109/jestpe.2019.2925190

Wang, X., Wang, Z., L Xie, L., Wang, S., and Ma, W. (2024). Research on the new hydrostatic transmission system of wheel loaders based on fuzzy sliding mode control. Energies 17 (3), 565–579. doi:10.3390/en17030565

Yan, Z., Yin, D., Chen, L., and Shen, W. (2022). Research on the torsional vibration performance of a CVT powertrain with a dual-mass flywheel damper system. J. Automob. Eng. 236 (6), 1144–1154. doi:10.1177/09544070211036679

Yao, J., Duan, C., Lee, C., and Zhou, Y. (2021). Study of wedge-actuated continuously variable transmission. SAE Int. J. Passeng. Cars-Mechanical Syst. 14 (6), 151–167. doi:10.4271/06-14-02-0010

Yasien, F. R., and Wala’a, H. N. (2019). Speed controller of three phase induction motor using sliding mode controller. J. Eng. 25 (7), 118–133. doi:10.31026/j.eng.2019.07.07

Yuan, C., Plummer, A., and Pan, M. (2022). Switching characteristics of a high-speed rotary valve for switched inertance hydraulic converters. Proc. Institution Mech. Eng. Part I J. Syst. Control Eng. 236 (7), 1421–1441. doi:10.1177/09596518221082445

Zeng, X., Li, X., and Dong, B. (2020). Coordination control strategy for mode switching of a parallel hybrid electric system based on continuously variable transmission. SAE Int. J. Commer. Veh. 13 (2), 145–156. doi:10.4271/02-13-02-0010

Zhang, Z., Ji, W., Yang, B., Hou, J., and Li, X. (2022a). Dynamic analysis and vibration reduction of mechanical-hydraulic coupled tunnel boring machine (TBM) main drive system. J. Mech. Eng. Sci. 236 (1), 115–125. doi:10.1177/09544062211029330

Zhang, Z., Wang, H., Ge, S., and Li, M. (2022b). Torsional vibration analysis of a powertrain with a power reflux hydraulic transmission system. J. Vibroengineering 24 (3), 405–415. doi:10.21595/jve.2022.22237

Keywords: pulse width modulation, mechanical hydraulic, hydro-mechanical continuously variable transmission, control system, hydraulic control branch

Citation: Cui J (2024) A hydraulic control system integrating adaptive and PWM algorithms for hydro-mechanical continuously variable transmission. Front. Mech. Eng. 10:1431009. doi: 10.3389/fmech.2024.1431009

Received: 11 May 2024; Accepted: 06 November 2024;

Published: 25 November 2024.

Edited by:

Liselott Ericson, Linköping University, SwedenReviewed by:

Franco Concli, Free University of Bozen-Bolzano, ItalyCopyright © 2024 Cui. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jingjun Cui, Y2pqMDQzMUAxMjYuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.