- Department of Industrial Design and Technology, Faculty of Engineering and Technology, University of Botswana, Gaborone, Botswana

Manufacturing has provided growth and employment opportunities to many developed countries. Digital technologies have further enhanced these opportunities and diversified manufacturing activities. However, it has not been as successful in developing countries, such as Botswana, due to the low absorptive capacity, lagging digital infrastructure, and the slow development of people who need upskilling or an entirely new skill set. The increase in access to the Internet and the extensive adoption of information and communication technologies by manufacturing companies are driving competition and disrupting the present circumstances. This study aims to assess the digital skills students acquire when studying an industrial design programme and compare them with the skills needed by digital manufacturing small and medium enterprises. A case study was adopted for this study because it can capture the relationship among the phenomena, context, and people in the lived realities of the participants. The findings indicate an alignment of the skills students acquire during their studies with those needed by digital manufacturing small and medium enterprises. However, the level at which students are exposed to these digital manufacturing skills is skewed towards basic awareness, with very few students reporting competency in digital manufacturing skills, such as using a laser cutter, plasma cutter, 3D printing, and a router machine. The emphasis could be shifted to developing digital manufacturing skills, as this is the future of manufacturing in the fourth and fifth industrial revolutions.

1 Introduction

Digital manufacturing refers to using digital technologies to transform how manufacturing processes are designed, monitored, and controlled. It involves the integration of advanced technologies, such as artificial intelligence, the Internet of Things (IoT), automation, cloud computing, big data analytics, and robotics, to optimise manufacturing processes and create smart factories. It could also refer to cloud-based services that enable digital manufacturing processes, such as production, planning, machine learning for process optimisation, and real-time data tracking and analysis. These technologies are substantially impacting manufacturing and production globally. Digitalisation has created new prospects in manufacturing. These include increases in efficiency, creating jobs, optimising supply chains, reducing costs, diversification into more value-added products, lower production costs, improving the quality of the product or service, expansion in regional and global trade, and improved export competitiveness (Accenture, 2015; Naudé, 2017; Mabotja, 2018; Cariolle and Carroll, 2020). Moreover, Industry 4.0 leads to mass personalisation as an emerging manufacturing approach focussing on uniquely made products for individuals at the scale level (Aheleroff et al., 2021).

For digital manufacturing technologies to work efficiently, they should be accompanied by a robust infrastructure, government policies, and skill development to advance the manufacturing sector into the digital economy (Pathak and Zewdie, 2019). To take this leap into digital manufacturing, governments in developing economies could incentivise innovation and manufacturing and could provide a conducive business environment for the private sector to lead this digital economic transformation. Governments could invest in innovation, digital infrastructure, and fourth and fifth Industrial Revolution technologies to promote smart technology and incentivise industrial innovation and transformation. The basic technology and communication systems that make it possible for digital services, applications, and networks to function are called digital infrastructure. It includes all the networks, data centres, hardware, and software required to sustain the contemporary digital economy and society. Digital infrastructure enables the movement, storage, processing, and administration of data and information. It is significant for digital manufacturing to take a localised approach to be successful.

The African Union, in its 2063 Agenda, reiterated the desire to industrialise the continent through manufacturing by small and medium enterprises (SMEs), which hold a promising position to achieve this goal. In Botswana, digital manufacturing is a rapidly growing area as the country moves towards modernising its industrial processes. However, the literature on digital manufacturing in Botswana is scanty, as this area is still emerging. The absence of a reputable manufacturing industry in Botswana means the country relies on expensive imports of 3D printers, laser printers, routers, etc. The versatility of 3D printing technology enables Botswana to manufacture items such as objects, tools, parts, medical implants, and devices domestically. This reduces dependence on costly imports and greatly benefits the country’s economy. The future of Botswana’s prosperity depends on the adoption and diffusion of digital technology. For example, digital manufacturing activities around the processing and refining of raw commodities are an untapped area in Botswana.

Digital manufacturing can benefit Botswana’s industrial landscape and economy. For example, Botswana is the world’s leading diamond-producing country, with its economy predominately being centred around mining, especially diamonds. Botswana has depended mainly on diamond mining; however, there is a growing need to diversify the economy because diamonds are not forever (Modungwa, 2018; Weldegiorgis et al., 2023). The mining sector contributes approximately 35% to the gross domestic product (GDP), with diamonds contributing approximately 94% of the total mining share in the GDP (Statistics Botswana, 2022). Investing in digital infrastructure in this sector is essential. This could reduce reliance on imports as the country imports many manufactured goods. For example, Botswana’s significant imports from South Africa were US $5.03 Billion in 2022 (Trading Economics, 2023). With digital manufacturing, the country could produce more products and services domestically, reducing import costs and increasing self-sufficiency. For example, one SME has been engaged by one of the diamond mines to produce various nuts and bolts using CNC machines. Establishing digital manufacturing SMEs could create skilled jobs in programming, design, manufacturing, maintenance, and quality control (Chenoy et al., 2019; Pomp et al., 2022). This contributes to developing a skilled workforce and a more substantial job market. Establishing digital SMEs, the backbone of many developing economies, could lead to export market potential (Belyakova et al., 2019). If SMEs produce high-quality and technologically advanced products, Botswana could explore opportunities for exporting its digitally manufactured products to regional and global markets. This will position Botswana as a globally competitive player in the digital manufacturing industry.

The other benefits that Botswana could gain from digital manufacturing include reducing the country’s reliance on minerals and imported products and systems, investments in education and training programmes focussing on relevant technical skills, design, programming, and data analysis. Digital manufacturing could stimulate innovation, research, and development activities within the country, leading to optimised products and services. However, some challenges need to be addressed, such as infrastructure development, access to technology and education, and the establishment of supportive policies and a regulatory framework. The government, private sector, and educational institutions would need to collaborate to create an ecosystem conducive to the growth of digital manufacturing in Botswana. Additionally, investment in research, development, and innovation is crucial to driving the country’s adoption and advancement of digital manufacturing technologies.

The manufacturing sector could invest in cutting-edge technology and the personnel who will use it. A quadruple helix model must be created to advance digital manufacturing involving the public sector, business, academia, and civil society. Governments could enhance opportunities for expanding the manufacturing base by developing industrial innovation policies and addressing policy gaps related to intellectual property, data protection, and privacy. Financial support from the government needs to be readily accessible. In addition to conducting research that enhances digital manufacturing, academia can offer the government and industry the required skill base. The industry could utilise academic research to develop digital manufacturing and produce competitive products and services. The civic society provides the market and research base for products and services, and the industry could satisfy the needs of the society.

Despite these promising developments, there are some challenges to the growth of digital manufacturing in Africa. The challenges include a lack of infrastructure, electricity, internet access, necessary technologies, skills, and other critical resources. Moreover, skilled labour is scarce in Botswana and other African countries, so many digital manufacturing jobs require special training. Because SMEs still represent Africa’s largest source of employment and income creation, their low dissemination and adoption among SMEs severely limit the development potential of digital technology (Cariolle and Carroll, 2020). Moreover, there is a fear that jobs will be replaced by automation, robotics, and artificial intelligence (Prakash, 2019). To address these challenges, there is a need for increased investment in digital infrastructure and training programmes to support the development of a skilled workforce capable of driving the growth of digital manufacturing on the continent. Against this background, this paper addresses why SMEs in Botswana could consider digitising their industry and the necessity for the education system to align with the 21st-century digital skills. Furthermore, this paper discusses the University of Botswana’s industrial design programme’s contribution in acquiring digital manufacturing skills. The paper then discusses the research method adopted for the study, its findings, and conclusion. The study’s significance stems from its potential to transform industrial design education, create a workforce ready for Industry 5.0, increase SME competitiveness, foster innovation, and support sustainable economic growth. Integrating digital manufacturing skills catalyses beneficial changes in industry and education, laying the groundwork for a technologically sophisticated and economically prosperous future focused on mass personalisation and other enabling technologies.

2 Significance of Botswana’s SMEs to digitally industrialise

In Africa, SMEs employ approximately 80% of the subcontinent’s workforce (World Economic Forum, 2020). In Botswana, SMEs outside the agricultural sector account for 95% of all firms. They comprise 35% of the gross domestic product and 75% of formal sector employment (BIHL Group, 2023). This study is crucial because this industry is a significant part of the nation’s economy. The fourth industrial revolution unquestionably resulted in significant changes in the SME workforce landscape, technological advancements, and industry relations, affecting all aspects of society and the economy (Mabotja, 2018). Consequently, SMEs could transition from traditional manufacturing methods to smart factories that are effective and generate high-quality goods and services that are globally competitive. SMEs can become more competitive and efficient due to Industry 4.0 technologies (Naudé, 2017).

Evidence from the literature suggests that nations more dependent on producing and exporting manufactured goods have a more stable growth than other nations (Naudé, 2017). Digital manufacturing contributes to national growth through the production and demand for products, services, and related skills that did not exist in pre-digital economies. It also contributes to producing digitally skilled future citizens. Digital manufacturing helps SMEs grow and increase their performance to become more effective and efficient, increase the scale of their operations, and access new markets (Rockefeller Foundation, 2013). SMEs in Botswana could transition to digital manufacturing to usher in a more competitive and efficient form of manufacturing through tools that enable additive manufacturing, mass customisation, mass personalisation, cheaper automation, and reduced input costs (Naudé, 2017).

Industry 4.0 has brought opportunities for specific skills in the SME sector, such as creative, innovative, social, and entrepreneurial skills. Such skills have ushered in a new business model that aligns with society’s needs, greater accessibility to products and services, better use of natural resources, and less waste (Naudé, 2017). The key emerging technologies, such as automation (robotics and artificial intelligence), additive manufacturing (3D printing), and the Internet of Things, drive digital manufacturing in Africa and Botswana, respectively. For example, 3D printers have been used to print prosthetic limbs for amputees and develop agriculture tools, medical equipment, and implants. In collaboration with the Botswana Institute of Technology Research Institute and the Central University of Technology in South Africa, the University of Botswana is working on a project to develop customised medical implants for various patients. This has proven that developing customised medical implants locally is cheaper than buying off-the-shelf standard implants, which may not fit the patient’s requirements. Therefore, digital manufacturing in Africa can provide affordable and efficient solutions to local manufacturing challenges. For instance, 3D printing can produce spare parts and components locally, reducing the cost and time needed for importing these parts from other countries. This can support local businesses and industries and create new opportunities for innovation and entrepreneurship. Another advantage of digital manufacturing in the SME sector is its potential to reduce waste and increase sustainability. Manufacturers can minimise their environmental impact and improve their bottom line by optimising the manufacturing process and using advanced technologies to reduce material waste.

The declining costs of robots are paving the way for manufacturing SMEs to adopt robots due to their efficiency and increased labour productivity. Robots are more efficient than humans at doing dull, dangerous, and dirty work (Naudé, 2017). Robots and automation can replace low-skilled workers while increasing the productivity of the highly competent ones (Prakash, 2019). Furthermore, the IoT is a new technology in Africa, and it has significant benefits for improving the competitiveness of African manufacturing SMEs. The IoT connects individuals to numerous objects, including computers or cellphones, home appliances, automobiles, and homes, using information and communication technology. In Africa, the IoT is starting to impact the following areas: machinery, electrical and electronic equipment, transportation equipment production, utilities (energy and construction), and healthcare services (Naudé, 2017). SMEs have established businesses in some of the areas mentioned previously. Smart technologies in manufacturing assist in reducing maintenance and repair costs, improving energy efficiency, reducing risks, and improving regulatory compliance (Accenture, 2015).

3 Integrating digital skills into the education system

Industrial 4.0 has resulted in an incremental change in job complexity and skill requirements (Maisiri and van Dyk, 2021). The patterns and geographic distribution of industries, employment, and economic growth have all been impacted by the digitisation and automation of the manufacturing environment. Countries can address the opportunities and disruptions in the employment sector through development strategies focussing on technology-aided industrialisation, education and training, skill development, and trade facilitation (Prakask, 2020). It has been observed that there is a growing market for digital manufacturing in Botswana as the country continues to grapple with increasing unemployment and underemployment, a lack of infrastructure, and a scarcity of skilled labour. To address the issue of the scarcity of skilled labour, Mabotja (2018) argues that technology embracing new advancements and machinery must be embedded into the education system. A change in the education system will help create a supply of future skills needed in the digital manufacturing sector and Industry 4.0. This alignment of digital skills should start with basic education, unlike the case where learners are taught such technologies at tertiary institutions. In support of the latter, Maisiri and Van Dyk (2021) argue that a curricular alignment to Industry 4.0 skill requirements should start from early childhood training to tertiary education.

As digital technology increases more rapidly than the skills, the risk of a skill mismatch also rises in developing economies. Botswana could develop complementary digital skills to cope with the development and impact of digitalisation on the economy. This can be carried out through on-the-job training, industry-led short training programmes, short courses from academic institutions and revision of the curriculum by vocational and academic institutions to align it to the needs of Industry 4.0, and reorientation towards the 21st-century skills. Against this background, academia should prepare the workforce for the current and future needs of digital manufacturing. The University of Botswana offers a Bachelor of Design (industrial design) programme that provides the industry, especially small- and medium-sized enterprises in the manufacturing sector, with graduates who possess digital skills. This paper presents an empirical case study analysis of the potential impact of the growing digitalisation in Botswana’s metal, plastic, and wood manufacturing sectors.

SMEs remain the foundation of Botswana’s economy. They account for 50% of private sector employment and 15%–20% of Botswana’s gross domestic product. Local SMEs must have access to data-based solutions to transition to global markets and e-commerce, which will save costs, boost revenues, and manage risks. In order to expand their operations, gain access to new markets, and build their pipelines, SMEs in Botswana increasingly rely on digital manufacturing and data-driven business intelligence solutions. Digital manufacturing SMEs contribute positively to a country’s economic performance and competitiveness (Mabotja, 2018). SMEs are drivers of economic growth, innovation, and job creation. Unskilled and semi-skilled workers characterise Botswana’s SME manufacturing sector. According to Mabotja (2018), staying current with Industry 4.0 necessitates continuous training and upskilling of the workforce in new technology. A critical element that significantly impacts the adoption of Industry 4.0 is the development of skills (Maisiri and van Dyk, 2021). Training costs are challenging for SMEs, and they often lose talent to large global manufacturers. Considering their vital economic role, universities can develop tailored programmes for SMEs to close this gap. One of the obstacles to SMEs’ development and adoption of Industry 4.0 is the demand for increased financial help to purchase the most modern automated machinery, which requires experienced human resources to operate it.

Industry 4.0 and Education 4.0 require the education sector to develop institutions with a solid link to the industry, to accelerate investment in technology and science, technology, engineering, and mathematics (STEM) skills and to shift learning towards acquiring 21st-century skills, such as complex problem-solving skills. Education 4.0 is an education system integrating Industry 4.0 technologies to develop instructional, pedagogical, and technological processes. It aims to equip students with cognitive, social, interpersonal, and technical skills, among others, to meet the needs of Industry 4.0 and global challenges (Oliveira and de Souza, 2022). Education 4.0 represents an ideal approach to aligning Industry 4.0 with education. Universities are challenged to produce graduates using these new ways of teaching, where students and educators collaborate in an environment that is on par with Industry 4.0 (Barreiro, 2021). Educational and training systems must respond to market demands flexibly (Prakash, 2019). The most critical driver of digital manufacturing competitiveness includes graduates possessing the right skills. If there is a skill mismatch or failure of the education system to respond to the needs of Industry 4.0, then the fear that automation is replacing workers sets in. Due to a skill mismatch, many graduates will not be absorbed into the job market. The misalignment of the educational curricula with the needs of the labour market has been extensively reported by Naudé (2017), the World Bank (2014), and UNECA (2015). The World Bank (2014) notes that there appears to be little knowledge transfer and collaboration between African academics and the corporate sector, especially in STEM disciplines.

Universities could promote self-employment and entrepreneurship through business training, skill development, and on-the-job and vocational training (Prakash, 2019). Employees could be retrained and upskilled when their occupations incorporate disruptive technologies more frequently. The World Economic Forum (2020) developed four types of future workspace skills that will be highly in demand by 2025: problem solving, self-management, working with people, and technology use and development.

The category of problem-solving skills includes the following: analytical thinking and innovation, complex problem solving, critical thinking and analysis, creativity, originality and initiative, and reasoning, problem solving, and ideation.

Self-management is a category that contains the skills of resilience, stress tolerance, and flexibility.

Working with people includes the following: leadership, social influence, and soft skills, such as empathy, conflict resolution, communication, and decision making, are essential.

The criteria of technology use and development embrace skills such as technology use, monitoring and control, active learning and learning strategies, and technology design and programming. For example, data science, artificial intelligence, machine learning, and deep learning are essential skills for future jobs.

Higher education learning institutions should align their learning programmes to the 21st-century skills as outlined by the World Economic Forum. Such an alignment will assist digital manufacturing SMEs in remaining competitive, as they will receive graduates with the required skills.

4 University of Botswana’s industrial design programme

The main aim of the Bachelor of Industrial Design programme is to create excellence in the production of products and services through developing creativity, innovation, and imagination. The curriculum emphasises quality in designing and learner-driven experience. The industrial design curriculum was developed after extensive consultation with the design and manufacturing industries. Industry leaders comprise the Industry Advisory Board of the University of Botswana’s Department of Industrial Design and Technology. The involvement of the industry in curriculum development is to prevent the production of graduates who cannot be absorbed into the job market. The programme is structured into 10 semesters spread across five academic years. The first 2 years are foundational years, where students learn design principles, elements, creative tools (both manual and digital), design processes, prototyping techniques, and design sustainability. During these years, students are introduced to design skills and ways of thinking, focussing on building practical competencies in creative skills from modules, such as product styling, communication skills, graphical communication and technical skills, design materials, and processes. A combination of soft and technical skills is built as students learn in a versatile project-based learning environment with group tasks and individual tasks appropriately deployed in the learning experience. Digital skills are also developed early through digital graphical communication modules, introducing them to the Adobe Suite.

In the next 2 years (levels 300 and 400), the focus is on developing high-order cognitive and psychomotor skills to develop design practice. There is a range of skills developed, such as teamwork, through modules that encourage working together but playing different roles; leadership through appointments to such roles as a team leader in group work; and decision making through the autonomy given to students to assign resources to their individual or group projects. During these years, the use of technology has intensified, and design and prototyping activities have transitioned from manual to digital and high technology-focused activities. Students learn design research methods, and they must apply them through design research activities and transfer the knowledge and skills to other areas where they have to use design research to inform decisions about a product. The product development process is intensified through activity-based learning for the fuzzy front-end and downstream design activities. This segmentation of the design process helps build the right skills with the right tools that support such activities. A hybrid approach to sketching and ideation is adopted as a skilful way of combining manual and digital sketching to inform creative solutions (Rapitsenyane et al., 2022). In order to show the transfer of knowledge, outcomes are used as inputs into computer-aided design (CAD) modules to introduce reverse engineering principles and computer-aided design and manufacture (CAD/CAM) and assembly. Students are exposed to CAD software (SOLIDWORKS) and digital manufacturing technology equipment, such as laser cutting machines, plasma cutters, router machines, and 3D printers in this block of years.

The final year is the culmen artes year, where students work independently and showcase their skills through a major design project with the research, prototype, and evaluation components. This end-to-end product development process involves working with people, managing the project independently, requiring self-management skills, using technology, and deploying technical skills to solve an identified need. This journey relies heavily on problem-solving skills. At the end of the major project, students produce a prototype that looks like and works like the final product as the first-generation prototype. The programme also includes a 6-month internship split into three 8-week sessions at the end of level 200, level 300, and level 400 to allow the industry to impart skills to learners. This approach assists in preventing a mismatch of skills between industry and academia.

Industrial design education plays a crucial role in developing the digital manufacturing industry. For example, it fosters creativity and innovative thinking. Designers are trained to develop new ideas and concepts to advance digital manufacturing technology and techniques (Arlbjørn et al., 2023). Digital manufacturing is not just about producing functional products but about creating products that provide value and great user experiences. Industrial designers understand user needs and preferences, ensuring that digital products are technically sound, user-friendly, and aesthetically pleasing (Yavari, 2017; Abrell, 2021). Industrial designers bridge the gap between technology and aesthetics. They can effectively integrate cutting-edge technologies, such as 3D printing, CNC machining, and the IoT, into the design process, resulting in technologically advanced and visually appealing products (Zhang et al., 2022). Digital manufacturing enables greater customisation and personalisation of products. Industrial designers can leverage their education to create effortlessly personable and customisable designs based on individual customer needs, which is particularly important in industries such as fashion, consumer electronics, and healthcare (Yavari, 2017; Aheleroff et al., 2021). Design for Sustainability is gaining importance in today’s manufacturing landscape. Industrial designers can incorporate eco-friendly materials, energy-efficient features, and designs that promote product longevity, contributing to a more sustainable digital manufacturing industry (Aheleroff et al., 2022). As digital manufacturing technologies continue to advance, there is a need to ensure that designers humanise technology. Industrial designers consider a design’s emotional, cultural, and social aspects, resulting in products that resonate with users on a deeper level (Moalosi et al., 2023). In essence, industrial design education prepares designers to leverage the potential of digital manufacturing technologies while maintaining a strong focus on user needs, aesthetics, and sustainable practices. As the digital manufacturing industry evolves, the role of industrial designers will become even more crucial in shaping the future of products and technology.

5 Research method

The purpose of the study was to assess the digital skills students acquire when studying in industrial design programmes and compare them with the skills needed by digital manufacturing small and medium enterprises. A case study approach was adopted for this study because it can capture the relationship among the phenomena, context, and people in the lived realities of participants. It is an empirical investigation of a contemporary phenomenon in depth within its natural context, especially when the borders between the phenomenon and context are unclear (Yin, 2014). A qualitative approach was adopted, as this is an exploratory study. An inductive approach was adopted to allow new insights to emerge in the data during the data collection and analysis processes. Data collection methods, therefore, involved participants expressing themselves and evidencing what participants produce. This was carried out to search for new insights to inform practice rather than test existing practices.

Purposive sampling was used to select study participants to allow the researchers to collect information from the best-fit participants so that the results are relevant to the research context. The study was a single case with multiple units of analysis. The case was acquiring digital manufacturing skills and 21st-century soft skills. The units of analysis were from level 300 to level 500 of the Bachelor of Industrial Design students at the University of Botswana and SMEs in Botswana’s wood and metal manufacturing sectors. The same online questionnaire collected data from design students and SME participants. This similarity in the methodological approach was to explore digital manufacturing skills and 21st-century soft skills in a population with similar professional characteristics or profiles, although at different levels. This approach allowed the researchers to measure whether the university is carrying out adequate training in these skill sets to inform and supply the industry with the relevant graduates. No incentives were offered for participation.

5.1 Students’ questionnaire

The main research questions for the students’ questionnaire were as follows:

1. Which digital manufacturing and 21st-century soft skills were the students perceived to have acquired by the end of their study?

2. To what level of threshold were the students perceived to have acquired digital manufacturing and 21st-century soft skills by the end of their study period?

The student questionnaire was structured in two main parts. The first part was focused on assessing the soft skills or graduate attributes on a Likert scale. Part 2 was focused on assessing the technical skills. A Likert scale was also used in part 2 of the questionnaire. Participants were asked to rate their perceived level of skills as aware, basic, practised, competent, or proficient, where aware represents a low-level skill and proficient represents a high-level skill.

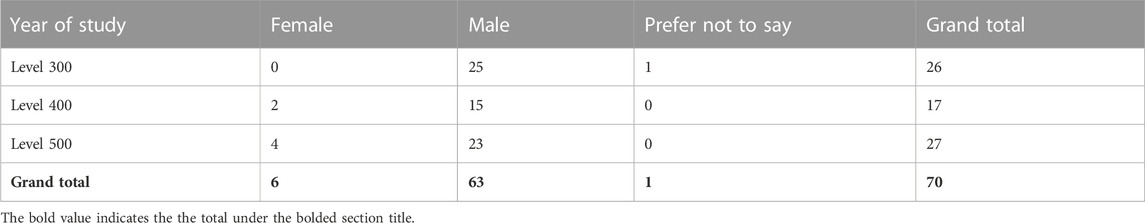

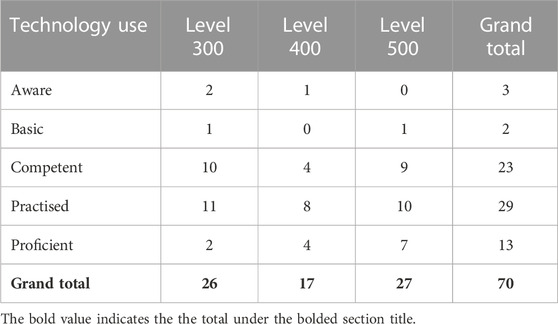

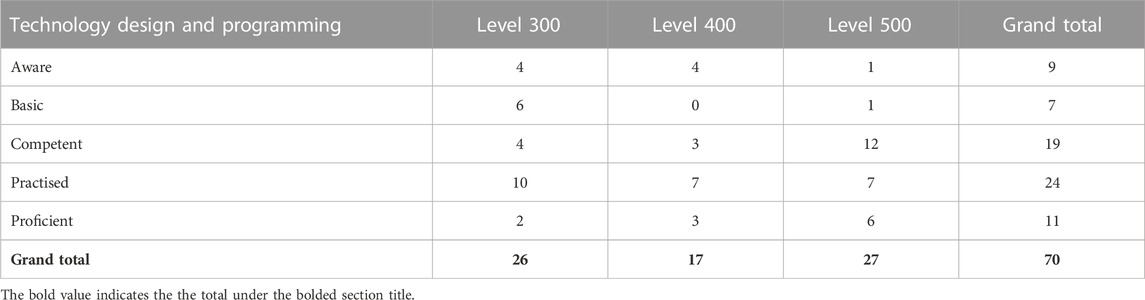

Seventy students took part in the survey. The selection of undergraduate industrial design students was based on the carried out modules related to digital manufacturing, such as CAD and CAD–CAM. These modules were carried out at level 300 and level 400, with the inevitable application of the knowledge and skills at level 400 and level 500. Seventy industrial design students were assessed through an online rating-scale questionnaire on their perceived acquisition of digital and soft skills (see Table 1 for the students’ sample). The respondents were contacted through module lecturers via their Microsoft Teams classes. The link to the questionnaire was shared in the classes’ Teams channels for all students in the class to access it.

Students’ projects produced through digital skills were also selected for their typicality as the work carried out by students exposed them to digital manufacturing.

5.2 Consultation with SMEs

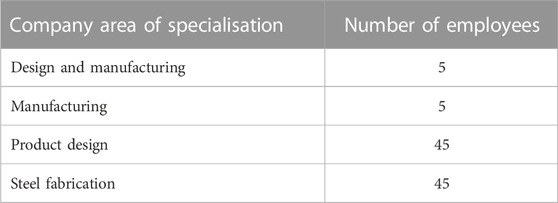

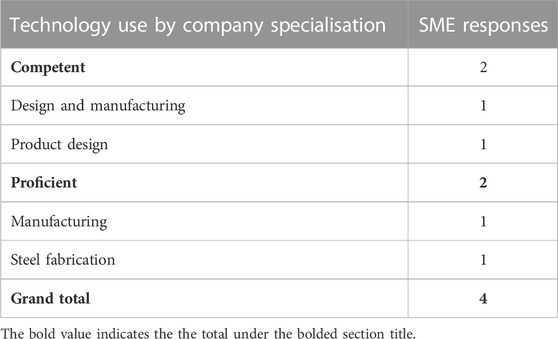

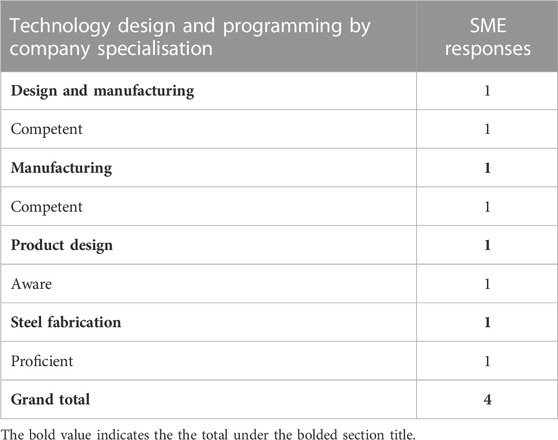

The questionnaire for SMEs was structured the same way as the students’ questionnaire reported in Section 5.1. The questionnaire for SMEs was shared via email with the targeted respondents. The SMEs were selected as typical SMEs in the digital manufacturing space. All respondents had to have had prior exposure to additive manufacturing or related technologies. Four SMEs in the digital manufacturing space were purposively sampled to assess their digital skills needs (Etikan et al., 2016) by understanding their perception of acquiring digital manufacturing skills and 21st-century soft skills (Table 2). This sample size was representative of the SME companies owned by the graduates, but as typical businesses owned by industrial design graduates in Botswana. SME owners/managers who are graduates of the Bachelor of Industrial Design programme at the University of Botswana responded to the survey.

5.3 Data analysis

A systematic method of data analysis was upheld to ensure the rigour of the study’s findings. SPSS version 28 was used to minimise the chances of bias in the analysis. The purpose of the analysis was not to compare the level of skill acquisition by students and SME professionals but to identify gaps in between to propose ideas on how they could be closed. Data from the questionnaire were analysed by listing descriptive statistics using SPSS version 28. The listing headings were based on the Likert scale items in the online questionnaire. The Likert scale item headings of the online questionnaire were used as a priori codes to organise data analysis into themes. Organising data analysis as thematic analysis was adopted in this study instead of other data analysis approaches because it allows the researcher to stay close to the data, “with minimal transformation during the analysis” and with minimum inference (Kim et al., 2017). Responses were analysed cumulatively regarding how participants rated an item along the scale from aware to proficient. The skills rated as aware and basic were perceived to be poorly acquired, while the skills rated as practised, competent, and proficient were perceived adequately acquired.

6 Results

6.1 Problem-solving skills

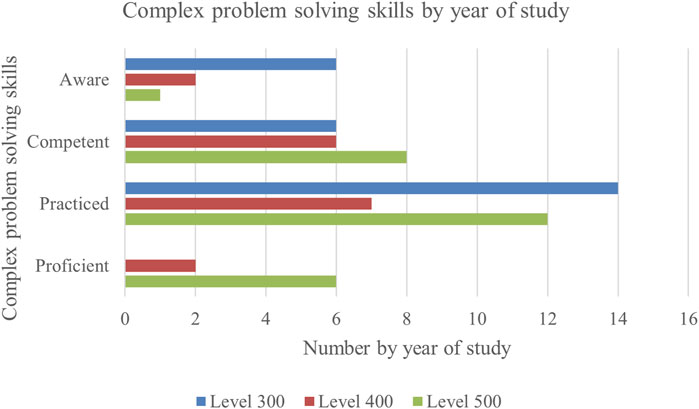

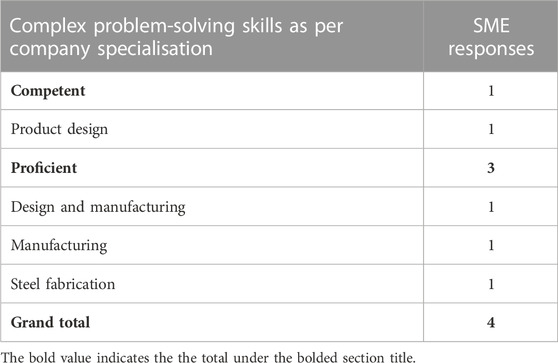

Complex problem-solving skills are generally well developed in students and SMEs, with very few students reporting awareness. However, only nine students reported awareness, and all SMEs reported high-level skills. Level 500 students’ skills range from competent to proficient (Figure 1). This was expected as they would have undergone several projects, further rehearsing their skills until they work on the major project. Seventy-five percent of the SMEs reported proficiency in these skills (Table 3). SMEs who reported proficiency have their core business as manufacturing. This allows them to explore several ways of delivering the product to clients.

6.2 Self-management skills

6.2.1 Resilience

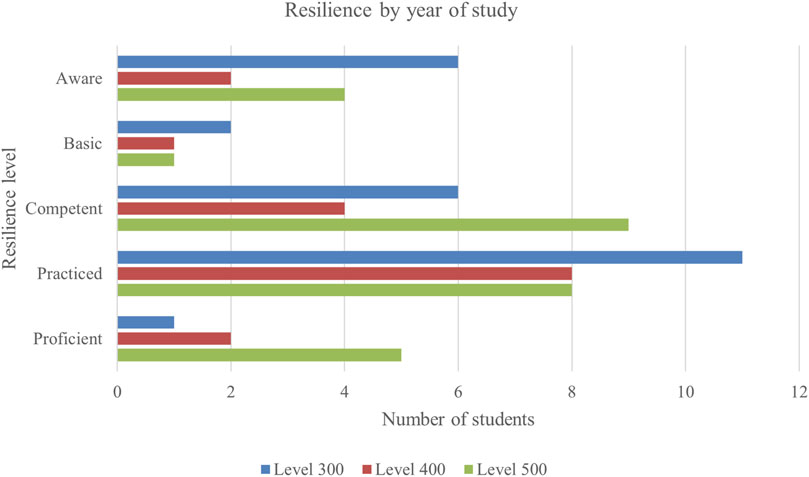

Most level 300 students (27) were perceived to have displayed or practised resilience (Figure 2). This is the transition year from the foundation years and the demand for work changes. Students start working for extended hours outside the classroom, denying themselves their comfortable social lifestyles. This is an ongoing adjustment in the students’ lifestyles until level 500. Unsurprisingly, even students at level 500 report their level of resilience at the awareness level. This could be attributed to students who continuously fail to adjust their lifestyles to accommodate the increasing demands of their degree work.

In Table 4, the SMEs report this skill at high levels. No SME reported their level of resilience as basic or aware. The culture of meeting different clients’ demands on tight deadlines could have already developed amongst the SMEs’ employees.

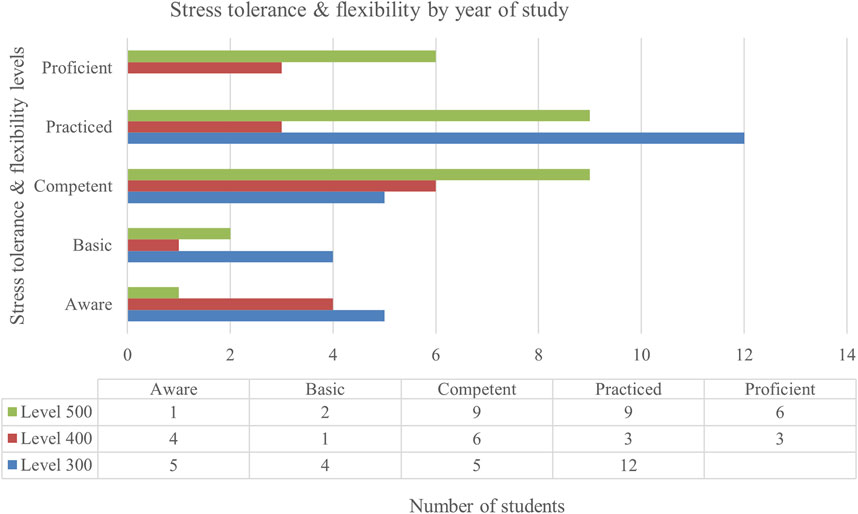

6.2.2 Stress tolerance and flexibility

Stress tolerance and flexibility have been reported in Figure 3, such as resilience, by level 300 students in Figure 2. Working under duress must be practised so that by the time the students reach level 500, they are competent and proficient. Most level 500 students have reported their perceived stress tolerance and flexibility skills as being more practised, competent, and proficient than any other year group. At level 500, the students have already adjusted to the work demands and can be flexible at breaking points when dealing with multiple deadlines and difficulty levels of the coursework.

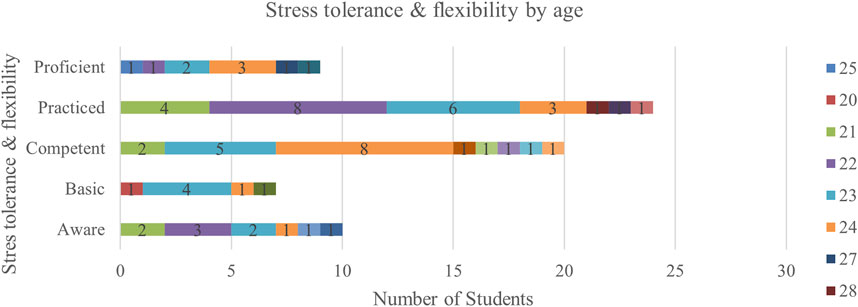

When looking at a stress tolerance and flexibility balance by their age, in Figure 4, 23 and 24-year-olds reported being more stress tolerant and flexible. Students in this age bracket are at levels 400 and 500 and would have started practising their skills in their early years of study.

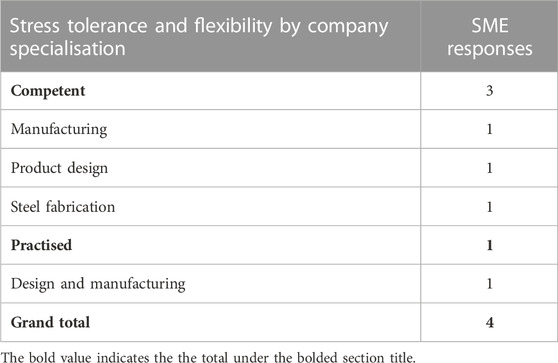

Three SME professionals are competent regarding stress tolerance and flexibility, as reported in Table 5. Interestingly, the product design SME reports the two self-management skills as being at highly rehearsed levels of proficiency, in Table 4, and competency, in Table 5. Industrial design education has built this skill in training. Maintaining it in practice could see product design companies performing better than others in the same space.

6.3 Working with people skills

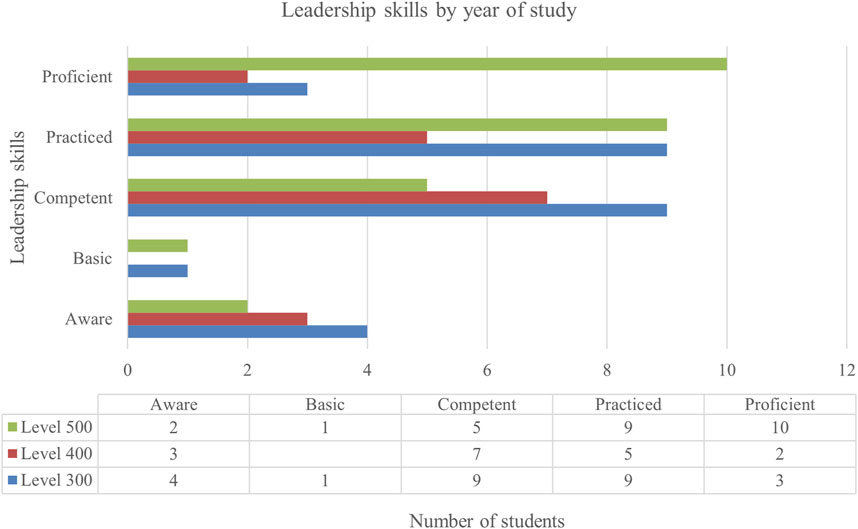

6.3.1 Leadership skills

At level 500, students begin to become dominant in taking initiative and leading in their learning. This is reported in Figure 5, as 24 students at level 500 reported their leadership skills as practised, competent, and proficient. At level 300, the students were perceived to have acquired the skill through structured group work assignments and projects. At level 400, leadership is embedded in many modules, and almost all the students in this year’s group have reported this skill as being practised, competent, and proficient, with only three reporting it as aware (see Figure 5).

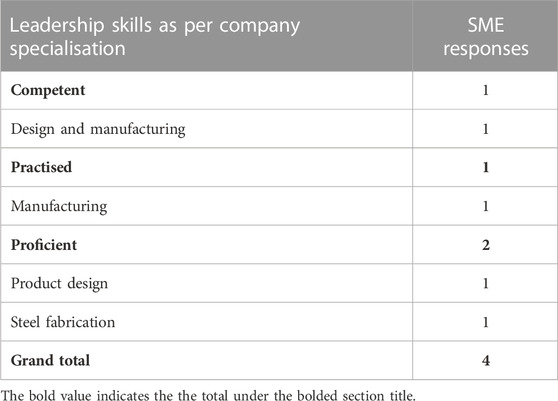

In Table 6, SMEs reported their leadership skills at high levels only. Product design and steel fabrication SMEs reported proficiency in this skill.

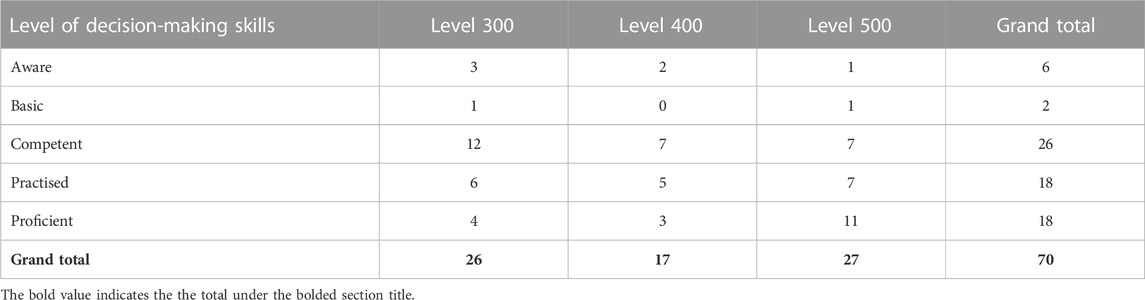

6.3.2 Decision-making skills

Cumulatively, 27 students who participated in the study, irrespective of their level of study, reported being competent in decision making (see Table 7). Out of the 70 participants, only eight reported basic awareness regarding decision making. Four of these students were at level 300.

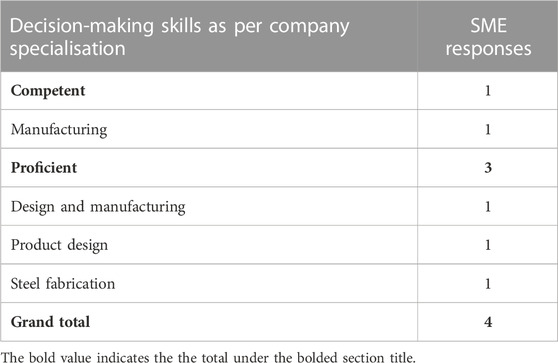

Decision making is a highly rehearsed skill amongst the SMEs who participated in this study. All SMEs reported competence and proficiency, with three out of four reporting their decision-making level as being proficient (Table 8).

6.4 Technology use and development

6.4.1 Technology use

A total of 29 out of 70 student participants perceived their technology use level as practised (Table 9). Thirteen students perceived themselves to be proficient in technology use. Of the 13 who reported that they are proficient, 11 were at level 500 and only two were at level 300. This could mean that students are exposed late to technological equipment.

Technology is competently and proficiently used by SMEs (Table 10). SMEs do not report lower-level skills and the evidence of the learning level (practised).

6.4.2 Technology design and programming

The technology design and programming skill is high in industrial design students, as only 16 out of 70 students who participated in the study reported being at basic and awareness levels (Table 11). The influence of technology modules on the programme is evident from level 300, with only 10 out of 26 level 300 students reporting awareness and basic skills.

Surprisingly, the product design SME reported their technology design and programming at an awareness level (Table 12). Only the steel fabrication SME reported a proficiency level. This could be attributed to their advanced use of technology equipment for digital steel fabrication.

6.5 Technical skills

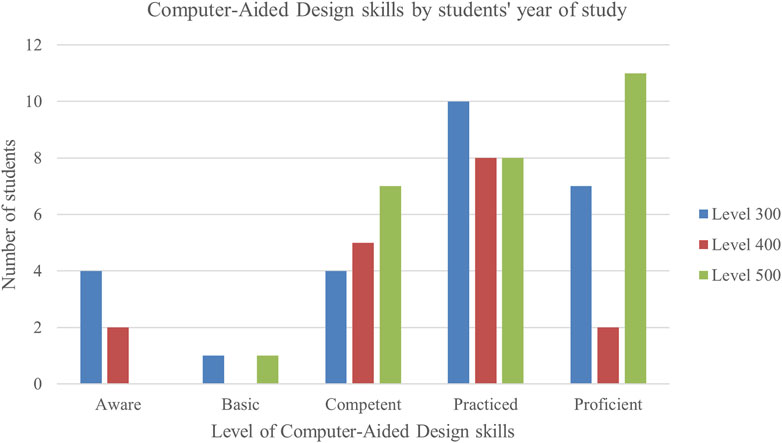

6.5.1 Computer-aided design skills

Computer-aided design (CAD) is introduced at level 300 to students. The skill development level of the students is interesting and expected, as the 3D digital space can also be fascinating. Figure 6 shows that at level 500, students were comfortable with using CAD. Only one level 500 student reported the level of the skill as basic. Level 400 students perceived themselves to be competent and practised with the skill, with only two at the awareness level (Figure 6).

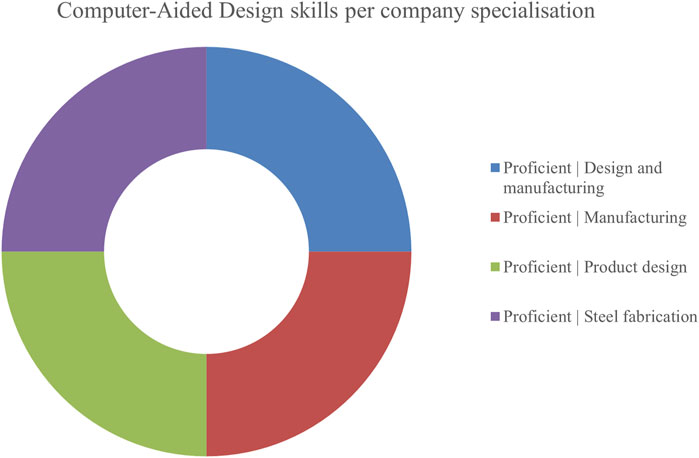

All SMEs are proficient in the use of CAD (Figure 7). This shows that SMEs intensely use CAD for various applications. This is a direct input of digital manufacturing in the design and manufacturing space.

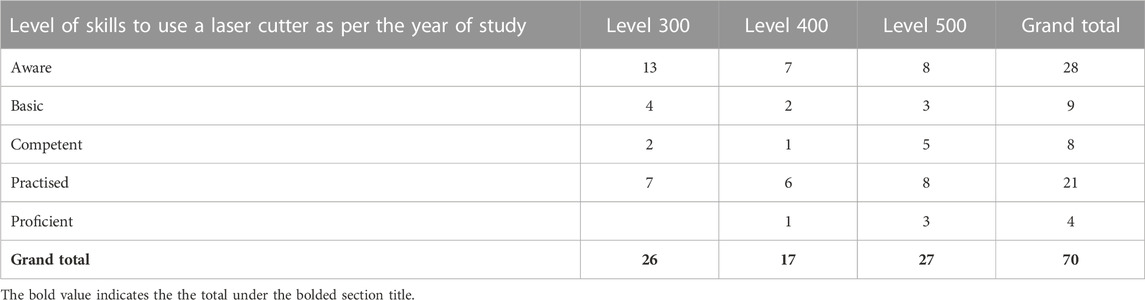

6.5.2 Skills to use a laser cutter

The use of laser cutters is generally not well developed among industrial design students (see Table 13). A total of 37 students out of 70 student participants were reported as being aware of their skill and being at a basic level. Only one level 400 and three level 500 students reported proficiency and competency, respectively. This gap area will need to be developed within the programme.

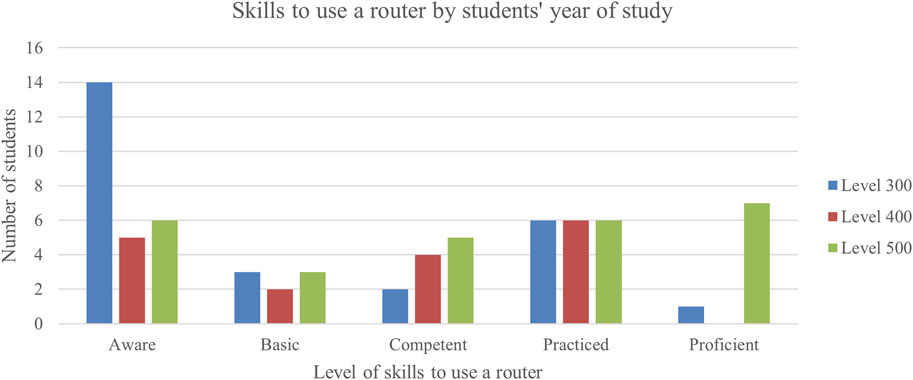

6.5.3 Skills to use a router

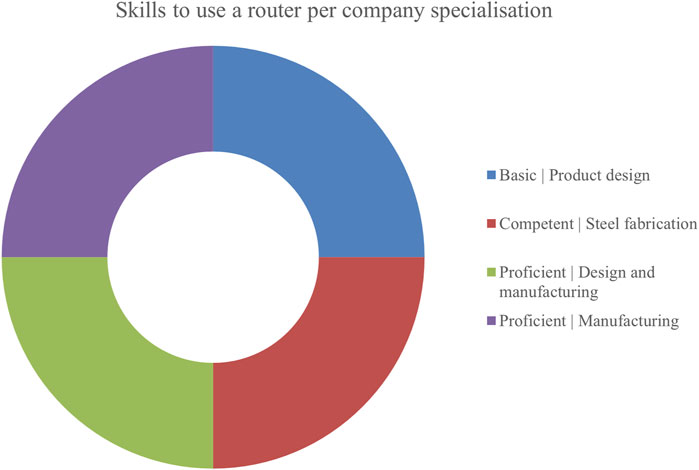

Cumulatively, 37 students perceived themselves to be practised, competent, and proficient in using a router (Figure 8). However, the number of students was slightly over 50% of the participants’ population (37). Levels 300, 400, and 500 each show numbers below 10 students for this skill. No level 300 student reported proficiency in the use of a router.

Safe for the product design SME, all SMEs were competent and proficient in using a router (Figure 9). This means that a router is one of the technical equipment used by the SMEs in the sample population, except for the product design company.

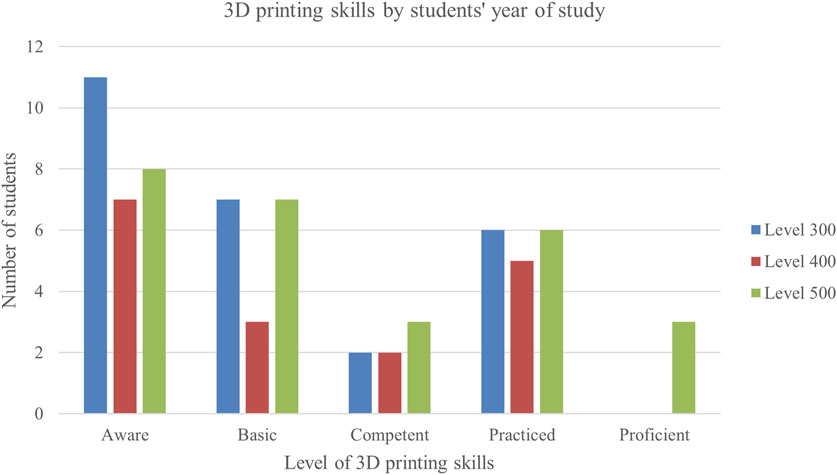

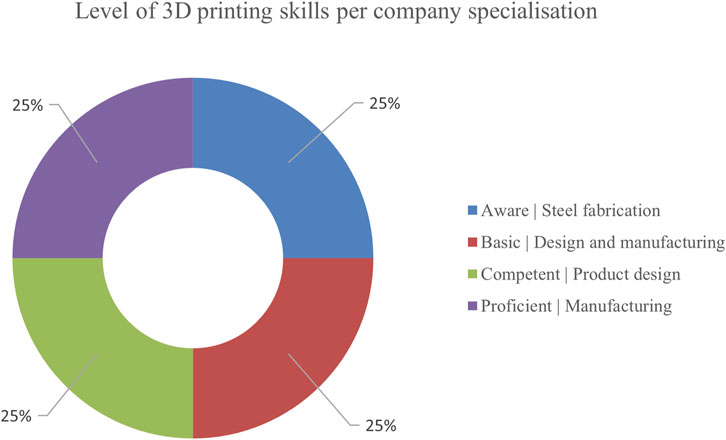

6.5.4 3D printing skills

3D printing skills in industrial design students were also rehearsed (see Figure 10). Only eight students perceived themselves to have been exposed to 3D printing at practised, competency, and proficiency levels. Eighteen students were at awareness and basic levels in terms of 3D printing. Since there is not much 3D printing usage in the university due to the cost of the printing material, very few modules require 3D printed outcomes. This stifles the development of the skills. Awareness is built during demonstrations of how to use a 3D printer, and basic exercises develop the skill to a basic level. Hence, 42 students out of 70 students were perceived to be at awareness and basic levels.

In SMEs, 3D printing skills are at different levels. The steel fabrication SME is at the awareness level and the design and manufacturing SME at the basic, while product design and manufacturing SMEs were competent and proficient (Figure 11). This could be attributed to SMEs’ access to 3D printing facilities.

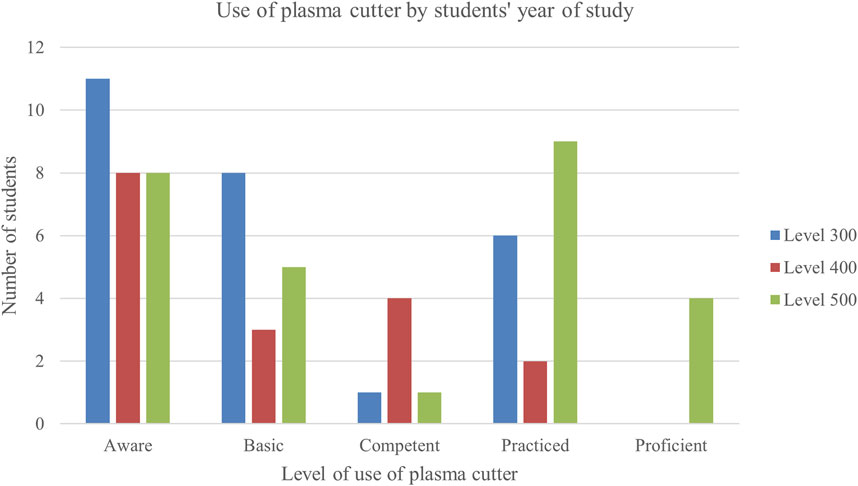

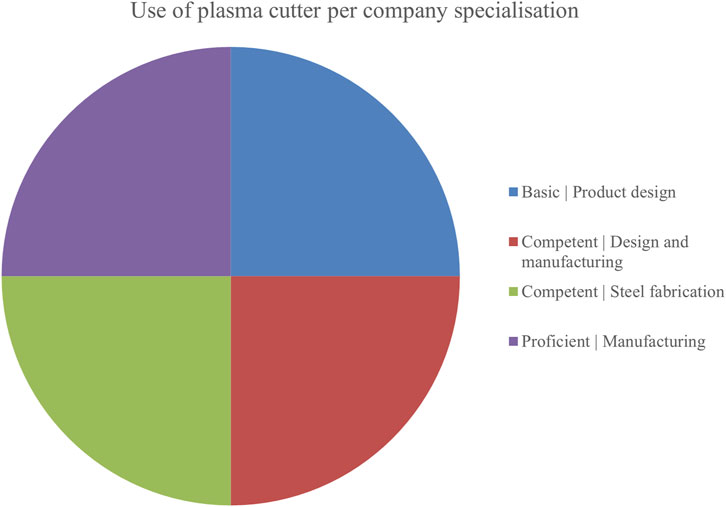

6.5.5 Use of a plasma cutter

The use of a plasma cutter was also moderate, according to the report in Figure 12. In the students’ learning experience, a plasma cutter builds awareness and basic skills. Only nine and four students report the skill development as practised and proficient, respectively. All the students were at level 500.

In Figure 13, only the product design SME reported using a plasma cutter at a basic level. Most SMEs were competent and proficient in using a plasma cutter.

7 Discussion

Although the sample size from the industry was small, there is some alignment between the students’ skills acquired at the university and what is being carried out in the industry. This is particularly true with soft skills of the 21st century (World Economic Forum, 2020). Complex problem solving, self-management, and working with people skills were well mirrored by the industry from the university. The nature of problem solving in design is exploratory. This is the exposure that design education and training provide to industrial design students. Exploratory problem-solving tools and methods make design students versatile and adaptable to complex, real problem-solving environments. This could be attributed to why self-management skills were also reported at levels similar to those reported by the SMEs. Development of working with people skills, such as leadership and decision making, could also have been reported at comparable levels with the SMEs because design education training is an end-to-end experience involving working with people at different levels. Real people are usually consulted from design research at the end of the product development process with user trials and final testing of prototypes. At different stages of the product development process and different years of the learning programme, students lead projects and project teams and make decisions about the project’s direction and technical inputs into the prototype.

Generally, industrial design students comparably use technology compared to industry professionals. The product design SME shows only awareness of technology design and programming. This is a contradiction compared to the level of the development of the same skill reported by industrial design students. The contradiction could be caused by the SME not having the right technology and programming equipment.

There is a huge gap between the students and the industry regarding digital manufacturing skills involving using a router, 3D printer, and plasma cutter. The students’ skills are developed at awareness and basic levels at the university. In the industry, the skills are reported as being at competency and proficiency levels. The number of students who reported this skill as practised, competent, and proficient could be due to their exposure to the same during industrial attachment to companies that use digital manufacturing skills. This exposure could have given the students the confidence to work with these tools in their final-year projects since they all were at level 500.

There could be opportunities for university–industry collaborations regarding digital manufacturing technologies. In mature industries, cutting-edge technologies are pioneered there and adopted by universities to ensure a supply and demand fit in the skills. Even though the SMEs report using digital manufacturing technologies at higher levels than students, it is noted that the level of technologies could be market-entry technologies, as is the case in developing countries. The technology company’s mindset could be created in manufacturing SMEs to inspire universities to thrive and meet their requirements regarding graduate profiles matching their skill demand.

The industrial design programme can be enhanced to constantly respond to digital manufacturing needs by exposing students to digital manufacturing technologies to enable them to develop the skills at practised, competency, and proficiency levels. This could mean revising how the related modules can be changed to accommodate exposure to industry equipment during specific modules. In this way, the university could build the capacity to transfer the skills in real time to the industry and offer modules with no limited equipment availability.

8 Conclusion

Manufacturing SMEs need to scale-up, embrace new business, and adapt quickly by embracing digitisation, robotics, and advanced technology throughout their business operations. A complete revamp of the educational system is necessary to address this shift, particularly in fostering valuable digital skills. Industry 4.0 demands higher digital skills than traditional manufacturing skills, and SMEs should take the lead in facilitating the upskilling and reskilling of their employees. They can collaborate with universities to facilitate the upskilling and reskilling of employees to preserve jobs. The University of Botswana’s graduates from the Industrial Design programme contribute to the digital economy by possessing the digital skills needed by manufacturing SMEs. Universities could introduce agile changes in the curriculum to constantly realign their graduate skills with Industry 4.0 and 5.0. The education system could significantly reduce Industry 4.0 skills challenges in the manufacturing sector. The potential lies in aligning skill development with industry requirements through, for example, work-integrated learning.

Education institutions in Botswana and other African countries may shift toward imparting 21st-century skills, as stated by the World Economic Forum (2020). This may include complex problem-solving skills, creative, and social skills, such as self-management, leadership, change management, collaboration, critical thinking, curiosity, risk taking, communication, marketing, sales, working with people, and technology use and development. These skills can be gained through a hands-on approach, such as workplace-integrated learning, rather than lectures in lecture halls.

In Botswana, the rising usage of digital manufacturing will have profound economic and societal effects. Digital manufacturing contributes to national growth through the production and demand for products, services, and related skills that did not exist in pre-digital economies. It also contributes to producing future digitally skilled citizens. Digital manufacturing will enable SMEs to gain greater visibility and control over their production processes, improve efficiency and productivity, reduce costs, improve product quality, and access new markets. Digital tools will simulate and optimise manufacturing processes, design and test new products, and monitor and analyse production data in real time.

Despite challenges, the potential benefits of digital manufacturing in Botswana are significant, and with the proper support and investment, the country has the potential to grow the digital manufacturing sector. It will facilitate the growth of the digital economy in Botswana and other developing economies and create new digitally driven employment opportunities for the youth, who are highly affected by unemployment. Digital jobs hold great potential in Botswana and other developing economies to produce transformative prospects for many African youths (Rockefeller Foundation, 2013). The digital economy, including digital manufacturing, promises to generate formal employment, particularly for young people. Finally, most SMEs can transition to digital manufacturing. In this situation, there will be plenty of chances to boost regional output and exports, cut production costs, and create new employment opportunities that require digital skills, enabling small- and medium-sized businesses to compete in high-tech markets at lower trade costs. All these require a responsive curriculum that aligns with Industry 4.0 and 5.0.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Ethics statement

The studies involving humans were approved by the University of Botswana Ethics Review Board. The studies were conducted in accordance with the local legislation and institutional requirements. The participants provided their written informed consent to participate in this study.

Author contributions

YR: writing–original draft, methodology, visualisation, and writing–review and editing. RM: writing–original draft, formal analysis, and project administration. OS: validation, visualisation, and writing–review and editing. VR: investigation, data curation, visualisation, and writing–review and editing. TM: methodology, investigation, validation, and writing–original draft. BM: formal analysis, visualisation, validation, and writing–review and editing.

Funding

The authors declare that no financial support was received for the research, authorship, and/or publication of this article

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abrell, T. (2021). “Business-centred, data-centred, or user-centred? A perspective on the role of designerly approaches to user centricity in big data innovation,” in Smart services summit. Progress in IS. Editors S. West, J. Meierhofer, and C. Ganz (Cham, Germany: Springer). doi:10.1007/978-3-030-72090-2_12

Accenture (2015). Industrial internet insights report 2015. Accessed https://cdn.smartindustry.com/files/base/ebm/smartindustry/document/2022/08/1660252861375-iwpgeindustrialinternetinsights.pdf.

Aheleroff, S., Huang, H., Xu, X., and Zhong, R. Y. (2022). Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2, 951643. doi:10.3389/fmtec.2022.951643

Aheleroff, S., Mostashiri, N., Xu, X., and Zhong, R. Y. (2021). Mass personalisation as a service in industry 4.0: a resilient response case study,. Adv. Eng. Inf. 50, 101438. doi:10.1016/j.aei.2021.101438

Arlbjørn, J. S., Wickstrøm, K. A., Haug, A., and Philipsen, K. (2023). Additive manufacturing-enabled innovation in small- and medium-sized enterprises: the role of readiness in make-or-buy decisions. Industrial Manag. Data Syst. 123, 1768–1788. doi:10.1108/imds-11-2022-0700

Barreiro, A. V. S. (2022). Education 4.0 and its impact on the educational system during the pandemic and post pandemic Covid 19 in Ecuador. Sinergias Educ. 7 (1), 110–123.

Belyakova, G. Y., Belyakov, S. A., Fokina, D. A., and Shpak, A. (2019). Formation the management methodology for developing an export potential of the EAEU machine-building enterprises. J. Phys. Conf. Ser. 1399, 033024. doi:10.1088/1742-6596/1399/3/0330241399

BIHL Group (2023). Small medium enterprises (SMEs) sector – a key opportunity for achieving economic diversification and sustained economic growth. https://www.bihl.co.bw/small-medium-enterprises-smes-sector-%E2%80%93-key-opportunity-achieving-economic-diversification.

Cariolle, J., and Carroll, D. A. (2020). Digital technologies for small and medium enterprises and job creation in sub-saharan africa. https://hal.archives-ouvertes.fr/hal-03004583.

Chenoy, D., Ghosh, S. M., and Shukla, S. K. (2019). Skill development for accelerating the manufacturing sector: the role of ‘new-age’ skills for ‘Make in India’. Int. J. Train. Res. 17, 112–130. doi:10.1080/14480220.2019.1639294

Etikan, I., Musa, S. A., and Alkassim, R. S. (2016). Comparison of convenience sampling and purposive sampling. Am. J. Theor. Appl. Statistics 5, 1–4. doi:10.11648/j.ajtas.20160501.11

Kim, H., Sefcik, J. S., and Bradway, C. (2017). Characteristics of qualitative descriptive studies: a systematic Review: QUALITATIVE description: SYSTEMATIC review. Res. Nurs. Health 40 (1), 23–42. doi:10.1002/nur.21768

Mabotja, L. L. (2018). Is South African manufacturing SMMEs ready for the fourth industrial revolution? J. Educ. Vocat. Res. 9 (2), 20–26. doi:10.22610/jevr.v9i2(v).2798

Maisiri, W., and Van Dyk, L. (2021). Industry 4.0 skills: a perspective of the South African manufacturing industry. South Afr. J. Hum. Resour. Manag. 19 (0), a1416. doi:10.4102/sajhrm.v19i0.1416

Moalosi, R., and Rapitsenyane, Y. (2023). African industrial design practice: perspectives on ubuntu philosophy. London: Routledge. doi:10.4324/9781003270249

Modungwa, B. (2018). Beyond the Sparkle: diversification of mineral-rich economies: the case of Botswana. https://open.uct.ac.za/handle/11427/27978.

Naudé, W. (2017). Entrepreneurship, education, and the fourth industrial revolution in africa. https://docs.iza.org/dp10855.pdf.

Oliveira, K. K. S., and de Souza, R. A. C. (2022). Digital transformation towards education 4.0. Inf. Educ. 21 (2), 283–309. doi:10.15388/infedu.2022.13

Pathak, R., and Zewdie, A. E. (2019). Implementation aspect of industry 4.0 in Ethiopian manufacturing industry. Int. J. Tech. Res. Sci. 4 (5), 33–39. doi:10.30780/IJTRS.V04.I05.005

Pomp, A., Burgdorf, A., Paulus, A., and Meisen, T. (2022). Towards unlocking the potential of the internet of Things for the skilled crafts. https://pdfs.semanticscholar.org/fce4/cf2052631dc3ba0105ab13ea8ee2c4afcca8.pdf?_gl=1*i7p9l4*_ga*MTAwNDk3NTIyLjE2Nzg0NTYzNjY.*_ga_H7P4ZT52H5*MTY5MzE1NjY3NC4yMy4xLjE2OTMxNTc1NDYuNjAuMC4w.

Prakash, A. (2019). Industrialization and Growth in Digital Age: disruptions and opportunities for employment led growth in asia and africa. https://www.g20-insights.org/wp-content/uploads/2019/05/t20-japan-tf7-2-industrialization-and-growth-in-digital-age.pdf.

Rapitsenyane, Y., Moalosi, R., and Mosepedi, T. (2022). “A hybrid design sketching approach that can drive critical thinking in design and technology,” in Debates in design and technology education. Editors A. Hardy, and G. Owen-Jackson (London, UK: Routledge), 221–237. doi:10.4324/9781003166689-19

Rockefeller Foundation (2013). Digital Jobs in Africa: catalyzing inclusive opportunities for youth. https://www.rockefellerfoundation.org/report/digital-jobs-in-africa-catalyzing-inclusive-opportunities-for-youth/.

Statistics Botswana (2022). Gross domestic product: fourth quarter of 2021. https://www.statsbots.org.bw/sites/default/files/publications/Gross%20Domestic%20Product%20Q4%202021.pdf.

Trading Economics (2023). Botswana imports from South Africa. https://tradingeconomics.com/botswana/imports/south-africa.

UNECA (2015). Industrializing through trade. Geneva, Switzerland: United Nations Economic Commission.

Weldegiorgis, F. S., Dietsche, E., and Ahmad, S. (2023). Inter-Sectoral Economic Linkages in the Mining Industries of Botswana and Tanzania: analysis using partial hypothetical extraction method. Resources 12, 78. doi:10.3390/resources12070078

World Bank (2014). A decade of development in sub-saharan african science, technology. Washington, D.C., United States: World Bank.

World Economic Forum, (2020). Future Jobs Rep., https://www3.weforum.org/docs/WEF_Future_of_Jobs_2020.pdf.

Yavari, H. (2017). User perspective on AM-enabled mass customisation toolkits. Thesis. Loughborough, England: Loughborough University. https://hdl.handle.net/2134/25682.

Yin, R. (2014). Case study research: design and methods, Thousand Oaks, CA, USA: Sage Publications, Inc.

Keywords: case study, digital manufacturing, digital skills, industrial design, forth industrial revolution, small and medium enterprises

Citation: Rapitsenyane Y, Moalosi R, Sealetsa OJ, Ruele V, Mosepedi T and Matake B (2023) Integration of digital manufacturing skills in industrial design education and its impact on small and medium enterprises. Front. Mech. Eng 9:1254866. doi: 10.3389/fmech.2023.1254866

Received: 07 July 2023; Accepted: 03 October 2023;

Published: 18 October 2023.

Edited by:

Sipiwe Trinity Nyadongo, National University of Science and Technology, ZimbabweReviewed by:

Shohin Aheleroff, SUEZ Smart Solutions, New ZealandZbigniew Wisniewski, Lodz University of Technology, Poland

Copyright © 2023 Rapitsenyane, Moalosi, Sealetsa, Ruele, Mosepedi and Matake. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Richie Moalosi, bW9hbG9zaUB1Yi5hYy5idw==

Yaone Rapitsenyane

Yaone Rapitsenyane Richie Moalosi

Richie Moalosi Oanthata Jester Sealetsa

Oanthata Jester Sealetsa Victor Ruele

Victor Ruele