- MIT Art Design and Technology University, Pune, India

Conventional cold storage systems increase the risk of damage and are no longer used for the long-term storage of agricultural products. Thus, newer affordable and energy-efficient storage systems are required for enhancing the shelf life of farm produce. We investigated the coefficient of performance (COP) of an earthen clay pot refrigerator with a thermoelectric cooler (TEC) and explored cooling strategies to enhance cooling and electrical performance for increasing the shelf life of farm produce. We used MATLAB Simulink to analyze Peltier TEC module efficiency. The intrinsic characteristics, including the Seebeck coefficient (α), thermal conductivity (K), and electrical resistance (R), were determined, forming the basis of the Peltier module in MATLAB Simulink. Thermal characteristics such as COP and cooling capacity were studied as a function of system voltage (Vin) and current (Iin). The model was equipped with a 12 V/6 A, 60 W TEC and was verified by simulation investigation. We also used psychrometric measures (e.g., wet bulb, dry bulb, and dew point temperatures and relative humidity) to determine the extent of wetness or dryness of an object and monitor other temperatures of the clay pot refrigerator. The results revealed that the ambient temperature and cold and hot side temperatures fundamentally affected TEC performance. The TEC extended the shelf life of tomatoes, potatoes, and spinach by 60% compared to those stored under ambient conditions, thereby reducing their wastage. In conclusion, earthen refrigeration using TEC doubled the shelf life of farm produce compared to storage under ambient conditions, saving money, resources, labor, and supplies and enabling the development of efficient and environmentally friendly refrigeration systems.

1 Introduction

A successful agricultural business is impossible without refrigeration because of the essential processing requirements after harvesting, that is, storage of farm produce at lower temperatures to reduce its wastage and losses. However, maintaining the quality of fruits and vegetables before, during, and after shipment is a daunting task to accomplish using conventional cold storage systems like those involving ice refrigeration. Several moving elements involved in these storage systems increase the risk of damage, resulting in their discontinuation from long-term storage of perishable agricultural products (Fadeyibi, 2023). Therefore, newer affordable and energy-efficient ways of storing farm produce are being developed. A previous study analyzed the effective use of evaporative cooling technology for the storage of farm produce like tomatoes using different types of earthen refrigerators. The shelf life of farm produce stored using the earthen refrigerator was compared with that stored under ambient conditions, revealing that earthen refrigeration increased the shelf life of farm produce (Fred, 2018). Solar power has been used for operating the TEC used for preserving farm produce. Notably, an earthen refrigerator with TEC increased the shelf life of farm produce more than an earthen refrigerator alone (Waziri Rutta, 2022).

TEC consists of two or more semiconductor components, preferably of the N&P-type doping, constituting a thermoelectric module. To increase voltage, these parts are connected serially and thermally in an equal plan to reduce the general warm coefficient. Such cooling-controlled modules may be built from a wide range of components and can be mounted in several different configurations (Hamid et al., 2014). Input DC electric flow strength and temperature conditions on each side of the component are directly related to the cooling capacity. The Peltier module’s surface temperature can be modified by adjusting the input current from its lowest to maximum value. High-powered thermoelectric modules are responsible for thermoelectric cooling performance in electronic packages. Iterative features are chosen to solve the problem of selecting a thermoelectric module in MATLAB Simulink; intrinsic parameters, such as the Seebeck coefficient (α), thermal conductance (K), and electrical resistance (R), are vital for monitoring TEC performance. A simulation using MATLAB is cost-effective and can boost heat exchange efficiency. The convective form of heat transmission is equally efficient at removing heat from a system (Tsai and Lin, 2010; Pradeep Mohan Kumar et al., 2018).

The full-wave bridge rectifier technology is a suitable standalone power input for operating the TEC module. It is reliable and durable and is considered for integration with TEC as the conversion of 220 V DC to 12 V AC is required to power the module (Sivaprakash et al., 2020). Thus, improving a zero-discharge refrigeration framework using a Peltier TEC module is crucial for sustainable cooling (Krishnan et al., 2023).

Thermoelectric material performance is typically determined by its inherent qualities. Very high Seebeck coefficients are required to produce thermoelectric elements of highest quality. Electrical and thermal conductivity must be excellent (Nadimuthu and Victor, 2021). The efficiency and effectiveness of the thermoelectric module are determined by the Seebeck coefficient. Materials with low thermal conductivity are needed for producing thermoelectric devices to limit the convective heat loss that occurs during operation. Because of boundary scattering effects, nanomaterials typically have very low thermal conductivity, making them poor candidates for use as a heat transfer medium in conventional electrical devices. These semiconductor materials are best used when their electrical resistivity ranges from 10–3 m to 10–2 m (Hamid et al., 2014). Thus, nanomaterials with a low coefficient of parasitic heat should be used to avoid the drastic reduction of thermoelectric module performance.

The thermoelectric effects, more specifically the Peltier and Seebeck effects, demonstrate a material’s ability to produce charge carriers within its volume when it is exposed to temperature inclination. An appropriate combination of these two effects is essential to construct a sturdy, stable, and incredibly adaptable TEC module. Similar TEC modules have been used as reliable power sources in cutting-edge NASA systems for the last 40 years. In addition, one can exploit the thermoelectric impact and customize different kinds of modules for various applications in many working temperatures, like cooling frameworks in vehicles (improving the coefficient of execution and coefficient of performance [COP] of the whole cooling framework and vehicle execution), gathering leftover intensity from nearby planet groups and photograph voltaic transformation cells, and collecting lingering heat from heat exchangers and changing it completely to helpful power sources at industry and power supply modules for on-location sensor frameworks.

A photovoltaic (PV) system design, process parameters, and choice and use of cooling technologies are crucial for achieving peak performance (Satpute and John Rajan, 2018). Electricity efficiency is decreased, and PV module temperature is increased due to absorbed incident solar radiations. Therefore, the use of an appropriate substance to absorb heat and keep the PV module’s temperature constant is necessary to counteract this detrimental effect. An analytical model was developed to study the electrical and thermal behavior of a PV solar module with water cooling. The mathematical calculations were performed under the weather conditions prevailing in Chennai, India (13.06° north [latitude] and 80.11° east [longitude]). Three types of heat transfer mechanisms were considered in the thermal model and calculated using improved correlations. The validation of the model against the experimental data showed good agreement. The daily average total electrical and thermal efficiencies of a PV module with water flowing from the top were found to be 14.29% and 45.44%, respectively. The water flow on the top of the PV module decreased the average module temperature per day from 56.67°C to 39.44°C, and the average daily electrical efficiency of the module increased to 14.29%, compared to the 12.74% efficiency of a PV module without cooling (Senthil Kumar et al., 2019).

This study aimed to explore many cooling strategies used to enhance cooling and electrical performance. Design and operational considerations, such as absorber configuration, flow pattern, flow rates, weather, radiation intensity, wind speed, thermal conductivity, glazing, and emphasis on electrical and thermal qualities, were the main points of attention. The research comprised onsite investigations, computer simulations, solar simulators, and theoretical analysis.

In order to increase the turbulence of the steam–water mixture and prevent the tube walls from burning out, steam boilers use fluted evaporation tubes. The steam boiler of the Serbian Electric Power Company’s “Kolubara B” thermal power plant uses fluted evaporation tubes and forced circulation of the working media. Simulation and analysis of the intricately coupled thermal processes on the combustion gas side and the thermal hydraulics in the evaporator tubes were performed for the full range of operating loads envisioned for the plant to study the operating characteristics of the steam boiler of such an advanced design. This study presented the approach for forced circulation circuit hydraulic calculations. Calculations were made on the corrugated tubes’ thermal hydraulics. Even with a high vacancy percentage of the coolant, an appropriate temperature of the evaporating tube wall was achieved. Corrugated tubes avoid creating dangerous heat transfer conditions. For uniform and varying heat loads between the walls of the boiler furnace, the achieved increased thermal safety margin of the fluted tubes was compared with the safety margin of the plain tubes. The effect of the fluted tubes was analyzed on the increase in hydraulic resistance in the circulation circuit (Tucakovic et al., 2008).

The investigation of an earthen clay pot refrigerator with a TEC is identified as a significant research gap. MATLAB Simulink is developed for reducing the design cycle and integrating solar photovoltaics with the TEC. The optimal operating point is identified through simulation and validated through experimental analysis (Nadimuthu et al., 2021).

2 Materials and methods

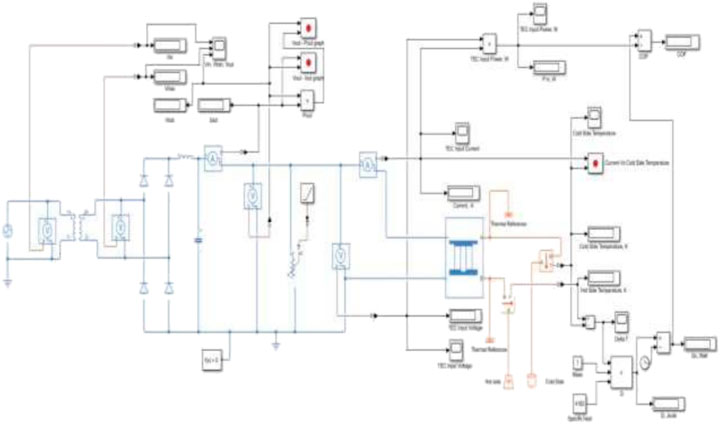

An analytical method was used to determine the thermoelectric module’s intrinsic parameters, such as its Seebeck coefficient, thermal conductivity (K), and electrical resistance (R). The TEC was designed in MATLAB Simulink using the aforementioned intrinsic parameters. The model was built assuming the worst-case scenario.

MATLAB Simulink analysis determines how well the circuit performs in terms of electricity and heat. The performance analysis involves gathering data on several different parameters, such as the operating voltage (Vout), operating current (Iout), operating power (Pout), and their respective properties. The model’s cold side temperature (Tc), hot side temperature (Th), ambient temperature (Tamb), cooling capacity (Qc), and COP were all deduced for the thermal power analysis (Nadimuthu et al., 2021). To validate the Simulink model’s integrity, the last step was an error analysis of the simulation and experiment findings. To enhance the shelf life of farm food, an experimental study was performed by considering psychometric characteristics like dry bulb temperature (DBT), wet bulb temperature (WBT), and relative humidity (RH).

2.1 TEC-integrated earthen refrigerator

Getting your hands on a thermoelectric element is a key part of the math involved in building a working earthen refrigerator. The material used in the module was carefully chosen to provide a perfect fit between the design specifications and the material’s actual performance characteristics. The components of the module are directly proportional to the figure of merit and a powerful factor considering their huge Seebeck coefficient, high electrical conductivity, and very low thermal conductivity. The module is also chemically, thermally, and structurally stable.

Energy conversion efficiency, which is based on the dimensionless figure of merit (ZT), is defined as ZT = α2T/ρκ, where α, T, ρ, and κ are the Seebeck coefficient, absolute temperature, electrical resistivity, and thermal conductivity, respectively, and makes up a minor portion of Carnot efficiency. Even after extensive research, large work on assessing the mechanical properties, thermomechanical properties, and electrical domain remains pending while focusing on the entire TEC module integrity challenges as well, for example, thermal stability and metalized contact layer durability (Hacini et al., 2021; Dhass and Patel, 2022).

The experimental setup was powered by a TEC which was selected due to its capability of withstanding very high temperatures when housed in an appropriately insulated container, as illustrated in Figure 1.

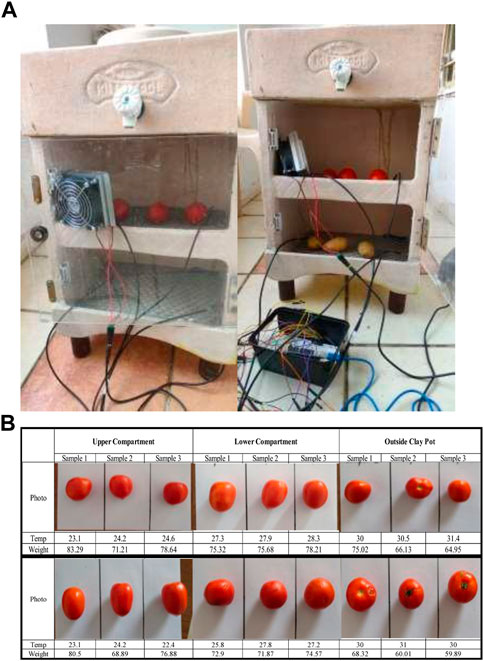

In the data logging step, we employed a K-type thermocouple with the assistance of an Arduino DAQ. When the data logger’s sample interval is set, it will begin to collect data. Figure 2A shows the setup in a ready state to analyze the TEC model’s thermal and electrical performance.

FIGURE 2. (A) TEC setup used in the earthen refrigerator model. (B) Tomato samples stored in the upper and lower compartments of the earthen refrigerator and outside the refrigerator model.

The TEC in the setup was powered via a 12 V/6 A charge controller for effective integration. An aluminum heat sink was installed on the filter element’s hot side. The heat sink measured 4 cm × 4 cm x 2.6 cm. A 3-W, 12 V/0.25 A cooling fan was also mounted on the top of the heat sink to aid in convective heat transmission. Using the setup (Figure 2A), the shelf life of tomatoes (Figure 2B), potatoes, and spinach was tested based on psychrometric parameters. Figure 2B shows the photographs of tomatoes kept in the upper and lower compartments of the earthen refrigerator and those kept outside the refrigerator on the third day of investigation.

The iterative method was used to obtain estimates of intrinsic attributes. To extract the parameters from the DC manufacturer’s datasheet, the analytical modeling Eqs 1, 2, 3 were used. The following equation was used to obtain the necessary information (Nadimuthu et al., 2021):

According to the heat flow governing equations, a MATLAB Simulink model of a Peltier device was constructed. Eqs 4, 5 provide the formulas for the development of thermal port A and thermal port B, respectively. Eqs 6, 7 can be used to determine the Qc and efficiency (COP) of the Peltier device. The examination of the percentage error provided a measure of precision. The error analysis for the validation may be calculated using Eq. 8.

A, Thermal port A; B, Thermal port B; ho, Hot side of the module; In, Input; M, Module; Max, Maximum given capacity; Cp, Specific heat (Jkg−1K−1); COP, Coefficient of performance (dimensionless parameter); V, Voltage given in the manufacturer’s datasheet (V); A, Current given in the manufacturer’s datasheet (A); K, Thermal conductivity for the TEC module (Wm−1K−1); m, Mass of the loaded substance in the TEC (kg); P, Operating thermoelectric power (W); Q, Heat flow of the Peltier device (W); Qc, Cooling capacity (W); R, Electrical resistance of the TEC module; S, Seebeck coefficient of the TEC module (VK−1); T, Temperature of the Peltier device (K or °C); α, Seebeck coefficient

The TEC Peltier module was integrated into the setup for the post-harvest loss analysis, and experimental verification was performed using psychrometric parameters like DBT, WBT, and RH, with the results presented via a graphical method.

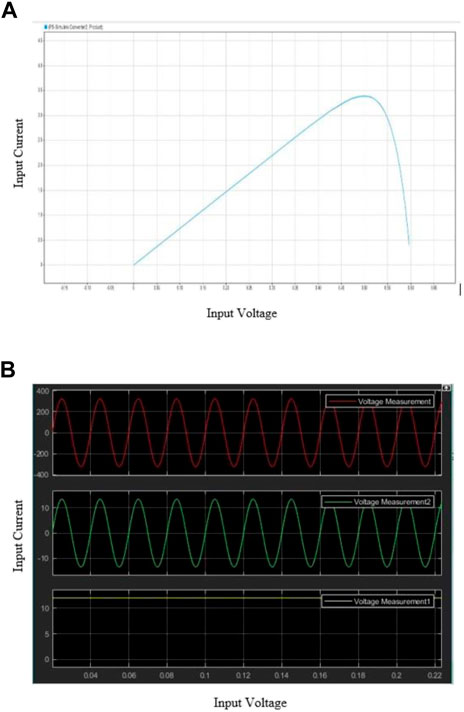

Figure 3 shows the modeling of a bridge rectifier-integrated TEC in MATLAB Simulink using electrical and nuclear power change conditions executed in MATLAB Simscape and Simulink. The rectifier module, the Peltier device, and its control blocks are the important parts of the modeling block (Tsai and Lin, 2010). The bridge rectifier module is useful because a DC input is required for a Peltier module; therefore, the AC input from the power source must be converted to DC to operate our thermoelectric module. This circuit takes the AC input, steps it down up to the desired voltage using a transformer, and then uses the full-wave rectifier to convert the AC input to 12 V DC output.

3 Results

3.1 Simulation analysis results

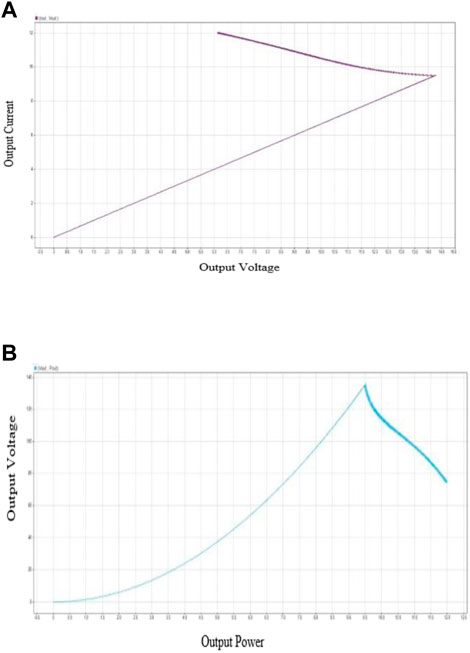

Figure 4A shows the current versus voltage quality bend of the produced power. The voltage versus power characteristics of the TEC are considered to achieve maximum power. Input power to the TEC was graphically represented by a curve, as shown in Figure 4B.

FIGURE 4. (A) IV characteristics of the electrical circuit. (B) Operative parameters for the AC to DC conversion. Red: AC input voltage; green: voltage at the secondary side of the transformer; and yellow: DC voltage of the full-wave bridge rectifier.

As per the Peltier effect, the cooling capacity is directly proportional to the amount of current flowing through the system. Figure 4A illustrates the IV characteristics of the electrical circuit, and Figure 4B illustrates the operative conversion parameters for the AC to DC conversion.

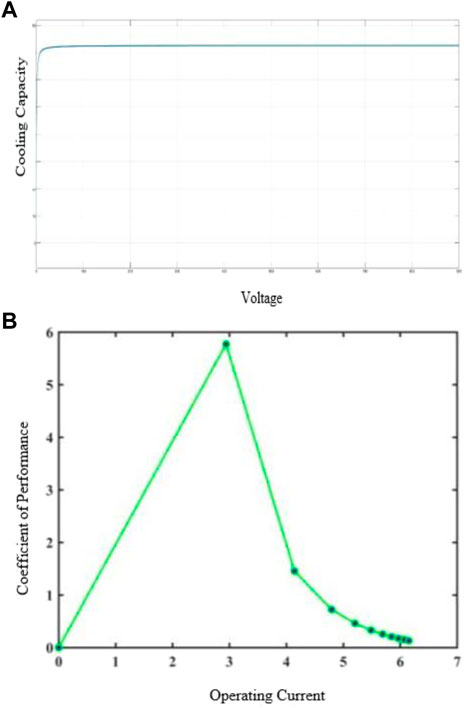

Figure 5A shows the TEC’s voltage vs. current characteristic (a) and voltage vs. power characteristic (b). The 73 W power consumption of the TEC was due to its high working current and voltage (Figure 5B). For TEC to function well, the input electrical power must be supplied reliably. The coefficient of execution is proportional to the cooling framework’s effectiveness. However, it is difficult to simultaneously obtain maximum levels of cooling capacity and COP; therefore, finding the optimal spot is crucial for improving TEC performance. The COP is affected by the module’s efficiency, driving power, and temperature variation. A lower temperature is suitable for maximizing both COP and cooling capacity, allowing for larger COPs at lower temperatures (Nadimuthu et al., 2021).

Figure 6A illustrates the cooling capacity, and Figure 6B illustrates the COP.

After the analysis of the produce subject by random sampling, the results were obtained, and an economic analysis of the post-harvest losses was performed.

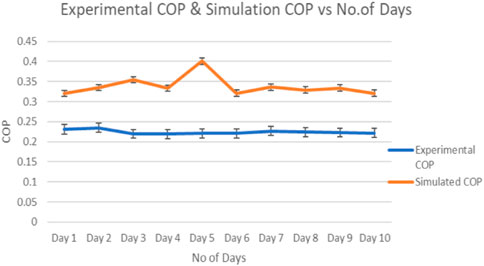

During the trial period, a temperature difference of 6°C was obtained on the cold side. This indicated that the TEC module was effective, as evidenced by the decrease in heat in the heat sink and the quantity of heat released at the hot side of the module. The exterior and ambient temperatures and RH have a considerable impact on the temperature within the cold chamber. As the temperature on the hot side decreases, thermal efficiency improves. The lowering of the cold side temperature guarantees a diminishing cooling capability over time. We found that we could cool at a maximum of 65 W. The COP was the highest during the first burst of work to remove heat from the TEC’s cold side. The highest COP was generated at the point when the side temperature decreased and the temperature difference between the two sides, T, was the greatest. This indicated that the average COP of 0.21 was reached during the experimental phase, as shown in the figure. Figure 7 shows the comparison between experimental and simulated COP over 10 days.

The modeling and experimental findings were analyzed for percentage and error. As a measure of precision, the margin of error was expressed as a percentage. In terms of COP and cooling capacity, the computed differences between the actual and simulated findings were 0.10% and 12.13%, respectively. The COP highlights the importance of finding the appropriate current for improving the TEC model’s performance. Hence, the analytical approach to performance evaluation has some relevance.

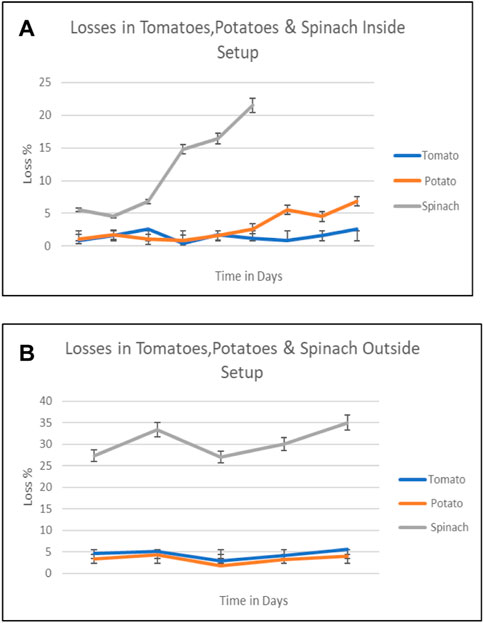

Psychrometric parameter analyses revealed that the tomatoes, potatoes, and spinach inside the setup remained fresh for 3 days; tomatoes and potatoes lost approximately 2 g of weight and spinach lost approximately 15 g of weight (Figure 8A) compared to those kept outside, which lost a huge amount of weight over the same duration (Figure 8B).

FIGURE 8. (A) Comparative graph for weight loss of farm produce when stored inside the setup. (B) Comparative graph for weight loss of farm produce when stored outside the setup.

Water has to drip down the walls of the clay pot refrigerator; it was observed that less water dripped in the lower compartment than in the upper compartment, increasing the evaporation rate in the upper compartment. This higher evaporation rate in the upper compartment leads to a higher temperature difference and increased relative humidity. Thus, the upper compartment best suited for storing tomatoes as they remained freshest for the longest period because the moisture retention capacity was the highest for the upper compartment. For potatoes, the lower compartment was the best as it provided the cold storage required for potatoes. The upper compartment was best suited for storing spinach as it provided the required moisture to keep the spinach fresh compared to that stored at the ambient temperature. Furthermore, tomatoes, potatoes, and spinach stored outside the setup showed more weight loss than those stored inside the setup.

4 Discussion

Our study investigated the COP of an earthen clay pot refrigerator with a TEC and explored cooling strategies to enhance cooling and electrical performance for increasing the shelf life of farm produce. To the best of our knowledge, this is the first study where the seasonal effect on earthen clay pot refrigeration is also evaluated, and we concluded that it works well in the summer season, so we applied TEC for further improvement of results. Our results suggest that the TEC was effective, as evidenced by the decrease in heat in the heat sink and the quantity of heat released at the hot side of the module. The farm produce remained fresh for a long time and lost little weight over a period of time.

A previous study conducted in Tanzania used solar-powered cold storage to increase the shelf life of farm produce as half of the total harvested tomatoes perished because of ineffective post-harvest management (Waziri Rutta, 2022). Another study in India used different methods of evaporative cooling to reduce post-harvest losses (Sibanda, 2023).

However, our study has some limitations. Appropriate cleaning methods for the clay pot refrigerator are required to maintain the porosity of the material, thus increasing performance. Frequent monitoring of the water tank level is needed for proper heat transfer.

5 Conclusion

Our results suggest that understanding and managing the TEC are essential requirements for a practical approach to a sustainable manner of employing thermoelectric materials and proceeding to higher technological readiness levels. This method shortens trial times and saves money, resources, labor, and supplies. The constants can provide information of the thermoelectric material such as stiffness, usability, conductivity, performance coefficient, efficiency, and cooling coefficient. The effective removal of heat from the hot side of the TEC, which in turn lowers the temperature on the cold side, ensures the TEC’s optimal thermal performance. As a result, the hot side temperature, ambient temperature, and cold side temperature all have a huge impact on the temperature decline in the TEC. The integrated TEC may be employed in a variety of refrigeration applications, including the preservation of agricultural and, in certain circumstances, dairy goods. Additionally, it creates fresh opportunities for the creation of environmentally friendly refrigeration systems.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

NP: conceptualization, methodology, and experimentation. VB and SP: validation, resources, and supervision. All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Acknowledgments

NP would like to thank VB and SP for their technical mentorship and guidance on methodological support.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Dhass, D., and Patel, D. R. (2022). Thermodynamic analysis of reflected solar radiation on tilted PV module in south India. FME Trans. 50, 158–167. doi:10.5937/fme2201158D

Fadeyibi, A. (2023). “Chapter 13 - advances in utilization of carbon-dioxide for food preservation and storage,” in Green sustainable process for chemical and environmental engineering and science. Elsevier, Nigeria, 297–310.

Fred, N. (2018). Manyozo, Effectiveness of evaporative cooling technologies to preserve the postharvest quality of tomato. Int. J. Agron. Agric. Res. (IJAAR), ISSNhttp://www.innspub.net 13(2), 114–127.

Hacini, K., Ali, B., Harrouz, A., and Belatrache, D. (2021). Efficiency assessment of an earth-air heat exchanger system for passive cooling in three different regions - the Algerian case. FME Trans. 49, 1035–1046. doi:10.5937/fme2104035H

Hamid, M., Shnawah, D. A., Sabri, M. F. M., Said, S. B. M., Haji Hassan, M., Ali Bashir, M. B., et al. (2014). A review on thermoelectric renewable energy: Principle parameters that affect their performance. Renew. Sustain. Energy Rev. 30, 337–355. doi:10.1016/j.rser.2013.10.027

Krishnan, R., Arshinder, K., Vandore, J., Ramanathan, U., and Aishwarya, M. (2023). Management of postharvest losses and wastages in the Indian tomato supply chain—a temperature-controlled storage perspective. Sustainability 15 (2), 1331. doi:10.3390/su15021331

Nadimuthu, L. P. R., and Victor, K. (2021). Performance analysis and optimization of solar-powered E- rickshaw for environmental sustainability in rural transportation. Environ. Sci. Pollut. Res. 28, 34278–34289. doi:10.1007/s11356-021-12894-x

Nadimuthu, L. P. R., Selvaraj, D. A., and Victor, K. (2021). Simulation and experimental study on performance analysis of solar photovoltaic integrated thermoelectric cooler using MATLAB Simulink. Therm. Sci. 00, 301.

Pradeep Mohan Kumar, K., Vijayan, V., Suresh Kumar, B., Vivek, C. M., and Dinesh, S. (2018). Computational analysis and optimization of spiral plate heat exchanger. J. Appl. Fluid Mech. 11, 121–128.

Satpute, J. B., and John Rajan, A. (2018). Recent advancement in cooling technologies of solar photovoltaic (PV) system. FME Trans. 46, 575–584. doi:10.5937/fmet1804575s

Senthil Kumar, R., Nagarajan, P. K., Subramani, J., and Natarajan, E. (2019). A detailed mathematical modelling and experimental validation of top water cooled solar PV module. FME Trans. 47, 591–598. doi:10.5937/fmet1903591s

Sibanda, S. (2023). Determination of performance and associated economic costs of indirect air-cooling combined with evaporative cooling for storage of tomatoes in South Africa. Afr. J. Food, Agric. Nutr. Dev. 23.

Sivaprakash, M., Krishnaswamy, H., Thanikodi, S., Sundaresan, D., Venkatraman, V., and Thermal, S. (2020). Support vector machine for modelling and simulation of heat exchangers. ThermalSciences 20, 499–503. doi:10.2298/TSCI190419398M

Tsai, H., and Lin, J. (2010). Model building and simulation of thermoelectric module using matlab/Simulink. J. Electron. Mater. 39 (9), 2105–2111. doi:10.1007/s11664-009-0994-x

Tucakovic, D., Stevanovic, V., and Zivanovic, T. (2008). Thermal-hydraulics of evaporating tubes in the forced circulation loop of a steam boiler. FME Trans. 36.

Keywords: thermoelectric cooler, MATLAB Simulink, dry bulb temperature, shelf life extension, post-harvest losses, earthen refrigeration, shelf life of farm produce

Citation: Patel NS, Pawar S and Bhojwani V (2023) Use of an earthen clay pot refrigerator with a thermoelectric cooler for extending farm produce shelf life. Front. Mech. Eng 9:1189860. doi: 10.3389/fmech.2023.1189860

Received: 20 March 2023; Accepted: 09 May 2023;

Published: 23 May 2023.

Edited by:

Abhishek Sharma, Birsa Institute of Technology Sindri, IndiaReviewed by:

Ankur Srivastava, Manipal University Jaipur, IndiaRahul Kumar, Lovely Professional University, India

Copyright © 2023 Patel, Pawar and Bhojwani. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Nishigandha Sandeep Patel, bmlzaGlnYW5kaGEucGF0ZWxAbWl0dW5pdmVyc2l0eS5lZHUuaW4=

Nishigandha Sandeep Patel

Nishigandha Sandeep Patel Sachin Pawar

Sachin Pawar Virendra Bhojwani

Virendra Bhojwani