95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater. , 25 April 2024

Sec. Biomaterials and Bio-Inspired Materials

Volume 11 - 2024 | https://doi.org/10.3389/fmats.2024.1407507

This paper investigates the effects of freeze-thaw cycles on the performance of asphalt mixtures containing 60% rejuvenated asphalt pavement (RAP). Two rejuvenation processes, traditional and bio-graded recycling, are compared regarding high-temperature performance, low-temperature performance, dynamic stability, flexural tensile strength, split tensile strength, water stability, and fatigue performance after various freeze-thaw cycles. The results indicate that bio-graded rejuvenation, compared to traditional rejuvenation, effectively enhances the high-temperature performance, low-temperature performance, water stability, and fatigue performance after freeze-thaw cycles. Both rejuvenations initially meet the dynamic stability requirements but show a decreasing trend with increasing freeze-thaw cycles, with traditional rejuvenation exhibiting more severe degradation. The flexural tensile strength initially exceeds that of conventional asphalt mixtures but decreases significantly with freeze-thaw cycles, especially in traditional rejuvenation. Additionally, freeze-thaw action increases the internal void ratio, affecting water stability and anti-freezing ability, particularly in traditional rejuvenated mixtures. These findings underscore the impact of freeze-thaw cycles on rejuvenated asphalt mixtures and emphasize the importance of innovative rejuvenation techniques for sustainable pavement.

As one of the effective ways to address the current energy crisis, the development and utilization of sustainable and renewable resources will encompass various aspects of human social production in the future. In the transportation industry, particularly in asphalt pavement projects that heavily rely on non-renewable resources such as stone and petroleum asphalt, a considerable amount of waste and aged asphalt mixture is generated during construction and maintenance. Disposal of this waste resource contributes to environmental damage, including pollution and land space occupation. In order to promote the recycling of waste and aged asphalt mixtures, ongoing research involves adding a certain proportion of new aggregates and new asphalt to the aged asphalt mixture and remixing it to produce a rejuvenated asphalt mixture, commonly referred to as RAP (Reclaimed Asphalt Pavement) (Tarsi et al., 2020). This rejuvenation technology, as an efficient means for handling aged asphalt mixtures, holds significant potential for development. It not only aligns with the green and environmentally friendly principles of pavement construction but also reduces the economic costs associated with pavement construction while fostering the sustainable development of the transportation industry. Consequently, this field has gathered increasing attention in recent years.

Over the course of lifespan, asphalt pavement undergoes gradual aging due to external factors such as solar radiation, rain erosion, and tire friction. The properties of the asphalt within aged asphalt mixtures, when initially milled, tend to become more brittle and harder, leading to a decreased utilization rate and lower-than-expected performance (Zhu et al., 2020; Hu et al., 2022; Hu et al., 2023; Adwani et al., 2024). By restoring the colloidal structure and rheological properties of aged asphalt, rejuvenators can promote the blending uniformity of aged asphalt and new asphalt, thereby enhancing the performance of rejuvenated asphalt mixtures to meet secondary utilization standards (Rajib et al., 2022). Presently, petroleum-based rejuvenators (such as aromatic oil extracts and naphthenic oils) are widely utilized in rejuvenating aged asphalt mixtures. However, their application presents certain drawbacks: the high-temperature mixing environment accelerates the volatilization of light components in the rejuvenator, reducing rejuvenation efficiency; moreover, petroleum-based rejuvenators, due to their high aromatic content and abundance of unsaturated bonds, tend to accelerate oxidation at high temperatures, thereby diminishing the expected rejuvenation effect. Consequently, the aging resistance and durability of rejuvenated asphalt are relatively insufficient to meet performance requirements. Additionally, the extraction of petroleum-based rejuvenators from petroleum contradicts the principles of green construction and hinders the sustainable development of rejuvenated aged asphalt mixtures (Zadshir et al., 2018; Yang et al., 2022).

Bio-oil, a viscous substance obtained from biomass such as straw, livestock manure, and grease through processes like rapid pyrolysis, hydrothermal liquefaction, or filtration and centrifugation, shares chemical similarities with petroleum asphalt and offers numerous advantages, including high yield and low cost (Zhang et al., 2017). Bio-oils typically exhibit acidity, with a pH value ranging from one to 6, and their density and viscosity vary based on the content of different compounds, with a density between 0.9 and 1.3 and a viscosity lower than that of commonly used asphalt mixtures (Baloch et al., 2018). Bio-oils have been successfully applied to modified asphalt or asphalt binder, with different types of bio-oils exhibiting varying effects on asphalt properties. For instance, bio-oils derived from waste wood and waste cooking oil can enhance the low-temperature cracking resistance of asphalt but may compromise its high-temperature performance (Yang and You, 2015; Al-Sabaeei et al., 2020). Given that most bio-oils contain amide polar groups and nitrogen-containing functional groups that can deconstruct the structure of asphaltene aggregates, relevant research reports suggest that bio-oils can serve as highly efficient asphalt rejuvenators (Zadshir et al., 2019; Hu et al., 2021). Unlike petroleum-based rejuvenators, which consume non-renewable resources, the utilization of bio-oil as a rejuvenator in aged asphalt mixtures enables the utilization of dual waste materials, yielding significant sustainability benefits (Fang et al., 2021).

To facilitate the application of bio-rejuvenators in aged asphalt mixtures, studies have explored two primary methods for preparing asphalt mixtures that meet pavement performance standards: hot mix and warm mix asphalt (HMA and WMA) mixed in mixing plants, which have been widely employed over the past 2 decades, and in-situ recycling for pavement rehabilitation, including hot-in-place recycling (HIR) and cold-in-place recycling (CIR) (Lv et al., 2020; Ma et al., 2020; Bowers and Powell, 2021; Yousefi et al., 2021). Among these, plant mix hot recycling technology is favored due to its straightforward preparation process and precise temperature and material control (Li et al., 2023). This technology not only maximizes the utilization of RAP resources but also rapidly produces rejuvenation material with properties comparable to those of hot mix asphalt mixtures (Yu et al., 2022; Rout et al., 2023; Xing et al., 2023). Furthermore, it boasts wide applicability, including use in the surface structure of highways of all grades, making it the preferred technology for asphalt pavement rejuvenation. However, studies indicate that an increase in the amount of rejuvenator in rejuvenated asphalt mixtures significantly alters mix performance: while cracking resistance increases, rutting resistance decreased (Babagoli et al., 2021; Roja et al., 2021; Barraj and Elkordi, 2022). Consequently, there is considerable research interest in quantifying the availability of bio-rejuvenators and assessing their mixing efficiency based on the performance of rejuvenated asphalt mixtures.

With the increasing scale of asphalt pavements approaching the end of their service life, coupled with the gradual depletion of crushed aggregate resources, environmental pressures, and economic considerations, there is an urgent need to increase the amount of RAP in rejuvenated asphalt mixtures (Magar et al., 2022; Zhang et al., 2022). However, as RAP dosage increases, the impact of variation in waste material properties expands, significantly reducing the pavement performance of rejuvenated asphalt mixtures (Guo et al., 2020). Studies have shown that while the mix design of thermally recycled asphalt mixtures is minimally affected by RAP dosage when it's below 15%, detailed mix design adjustments are necessary when RAP dosage exceeds 25% to mitigate the effect of RAP variability on recycled asphalt mixture performance. Evaluations of fatigue and rutting resistance of rejuvenated asphalt mixtures with different RAP dosages suggest that rutting resistance improves with increasing RAP dosage, albeit at the expense of reduced fatigue performance, with the recommended RAP dosage falling within 40%. Performance testing of hot mix asphalt mixtures with varying RAP dosages (0%, 15%, and 25%) in hot regions like Arizona revealed that the addition of 15% and 25% RAP to recycled asphalt mixtures did not significantly enhance the stiffness of asphalt mixtures but improved their rutting resistance, meeting water stability requirements (Shah et al., 2007; Sabouri, 2020; Zalghout et al., 2022).

Given the significance of bio-rejuvenators and RAP dosage on recycled asphalt mixtures, coupled with the expanding output scale of waste aged asphalt mixtures, this study elucidates the characteristics of bio-rejuvenators and RAP dosage on the performance of hot-mixed recycled asphalt mixtures from both material composition and performance perspectives. Utilizing CT scanning technology, the study elucidates the pavement performance and mechanical properties of hot-mix rejuvenated asphalt mixtures at a fine scale, followed by an analysis of performance damage mechanisms, thereby providing insights for the large-scale application of RAP in asphalt pavements.

In this study, experiments were carried out using asphalt mixtures recycled on site, and their properties were recovered using a bio-rejuvenator, and basalt fibers were added to improve their performance. The basic technical specifications of the bio-rejuvenator selected in this study are shown in Table 1. The new coarse aggregate is limestone, the new fine aggregate is artificially crushed sand, and the mineral powder is limestone powder.

The new asphalt was penetration grade 90# asphalt, the properties are shown in Table 2.

The traditional process of preparing rejuvenated asphalt mixtures operates on the principle that the old RAP asphalt gradually separates from the RAP during the heating and mixing process, subsequently blending with the new asphalt before being distributed onto the aggregate. However, it's observed that the actual blend states of new and old asphalt in rejuvenated asphalt mixtures can vary, encompassing unblended, partially blended, and fully blended states. Under traditional rejuvenation methods, a significant portion of new and old asphalt tends to exist between unblended and partially blended states. Preparation of rejuvenated asphalt mixtures under these conditions adversely affects their performance.

The traditional rejuvenation method follows these steps for molding specimens: firstly, heated RAP material is poured into the mixing pot and mixed evenly for 20 s; secondly, recycled aggregate is added and mixed for 60 s to ensure uniform distribution of RAP and recycled aggregate; then, preheated new asphalt is added, and RAP and recycled aggregate are mixed to ensure complete wrapping of the new asphalt around the RAP material and recycled aggregate, with a mixing time of 60 s; finally, mineral powder is added and mixed evenly for 20 s, resulting in a total mixing time of 160 s.

Bio-graded recycling enhances the traditional rejuvenation process based on RAP grading. In this improved approach, different grades of RAP material are treated with varying ratios of bitumen and aggregates, resulting in RAP material being divided into binder-rich fine material and coarse material. Subsequently, each type of material undergoes rejuvenation using a bio-rejuvenator before mineral powder is added to form the rejuvenated material. The process is shown in Figure 1. In this study, a hot-mixed hot rejuvenation asphalt mixture with 60% RAP content was prepared using bio-graded recycling. Performance was analyzed comparatively. The types of rejuvenation materials used are detailed in Table 3.

This study selected the 60% RAP plant-mixed hot rejuvenated asphalt mixture under the bio-graded recycling process as the research object and compared it with the traditional 60% RAP rejuvenated material and AC-20 mixture. Firstly, considering meteorological parameters in cold areas, the research team employed a self-made freeze-thaw testing machine to conduct 0, 5, 10, 15, and 20 indoor freeze-thaw cycle tests on the above three mixtures. Then, from a macro perspective, the mechanical properties of the large-volume factory-mixed hot recycled asphalt mixture under different freeze-thaw times are tested, along with pavement performance tests. Finally, based on CT tomography technology, the performance evolution of the mixture under freezing and thawing is analyzed from a microstructural perspective.

This study employed a CLD-D freeze-thaw cycle test machine developed by the research group to subject the hot-mixed recycled asphalt mixture with 60% RAP content and the AC-20 asphalt mixture under two rejuvenation processes to freeze-thaw cycle processing.

(1) Uniaxial compressive strength

The compressive strength is calculated according to test method T0713-2000 in the Testing Procedures for Asphalt and Asphalt Mixtures in Highway Engineering, at a temperature of 20°C and a loading rate of 2 mm/min, using the formula 1:

Where, Rc is the compressive strength, in MPa; P is the maximum failure load during test failure, in N; d is the specimen diameter, mm.

(2) Splitting strength

Also known as the indirect tensile test, the splitting test determines the elastic mechanical properties of asphalt mixtures under specific temperature conditions and loading rates. The splitting strength was measured according to test method T0716-2011, at a temperature of 15°C ± 0.5 °C and a loading rate of 50 mm/min. The split tensile strength is calculated using the formula (2).

Where, R is the split tensile strength, in MPa; P is the maximum failure load during test failure, in N; h is the specimen height, in mm.

This paper evaluated the high-temperature stability of the hot-mixed recycled asphalt mixture through a 60°C rutting test. A recycled material specimen was prepared and subjected to high-temperature conditions. Stability is calculated using the formula (3):

Where, DS is the stability, D60 is the deformation of specimen at 60 min, D45 is the deformation of specimen at 45 min, N is the round trips per minute, C1 is the correction factor; C2 is the specimen coefficient.

In this paper, a low-temperature bending test of small beams at −10°C was conducted to evaluate the low-temperature stability performance of large-volume hot-mixed recycled asphalt mixtures. The ultimate bending and tensile strength, ultimate bending and tensile strain, and stiffness modulus of the specimen are calculated using the formula (4–6).

Where, RB is the ultimate bending and tensile strength of the specimen, in MPa, εB is the ultimate bending and tensile strain of specimen, in με, SB is the ultimate bending stiffness modulus of specimen, in MPa; b is the width of specimen spanned section, in mm; h is the height of specimen spanned section, mm; L is the specimen span; PB is the ultimate load of specimen, N; d is the mid-span deflection when specimen fails, in mm.

Water stability of asphalt mixtures is crucial for improving pavement durability. This paper evaluated water stability using immersion Marshall tests and freeze-thaw splitting tests, comparing large-volume hot-mixed hot-regenerated asphalt mixtures prepared by two rejuvenation methods with AC-20 asphalt mixtures.

(1) Immersion Marshall test

The residual stability after immersion in water for specific durations was evaluated as an indicator of the asphalt mixture’s anti-stripping ability and durability. The residual stability is calculated using formula (7).

Where, S1 is the stability after immersion in water for 0.5 h, in KN; S2 is the stability after immersion in water for 48 h, in KN; S3 is the sample residue stability ratio, %.

(2) Freeze-thaw splitting test

The freeze-thaw splitting test evaluated the water stability of asphalt mixtures after freeze-thaw cycles. Splitting tensile strength before and after freeze-thaw cycles was compared to determine water stability. The splitting tensile strength can be calculated as per Eqs 8–10.

Where, R1 is the splitting tensile strength of specimens without freeze-thaw cycles, in MPa; R2 is the splitting tensile strength of specimens under freeze-thaw cycle, in MPa; TSR is the freeze-thaw splitting strength ratio, %; h1 is the height of the first set of specimens, in mm; h2 is the height of the second set of specimens, in mm.

X-ray CT tomography technology is utilized to obtain three-dimensional images of the asphalt mixtures’ microstructure. CT images are processed using Digital Image Processing (DIP) techniques for noise reduction, enhancement, segmentation, and feature extraction. Avizo analysis software is employed for CT image processing and analysis, enabling detailed analysis of the internal structure of asphalt mixtures. The image processing flow is shown in Figure 2.

Figure 3 displays the results of uniaxial compressive strength index tests for two rejuvenation processes of 60% RAP dosage plant-mix hot recycled asphalt mixtures and AC-20 mixtures. It is evident that the compressive strength indicators of all three types of asphalt mixtures decrease with an increase in the number of freeze-thaw cycles, with the rate of decline gradually increasing with more cycles. In AC-20 mixtures, the decline rate remains at 10% after 5 and 10 freeze-thaw cycles, but it reaches 20% after 20 cycles, indicating a significant decrease in strength. This decline is primarily attributed to the viscoelastic nature of asphalt mixtures, which are significantly affected by temperature. During freezing and thawing, water can penetrate the mixture, reducing the adhesion between asphalt and aggregate, resulting in a noticeable decline in strength, a trend that becomes more pronounced with repeated freeze-thaw cycles. Compared to AC-20 asphalt mixtures, the compressive strength of the two types of recycled asphalt mixtures exhibits different decreasing trends. In the traditional recycled 60% RAP mixture, the index decline reaches 10.21%, 14.32%, 21.22%, and 25.31% after 5, 10, 15, and 20 freeze-thaw cycles, respectively. Conversely, the corresponding decline in the Bio-graded recycling recycled material is 5.23%, 8.87%, 13.55%, and 19.31% under the same freeze-thaw cycles. This suggests that the compressive capacity of 60% RAP recycled material is improved under Bio-graded recycling rejuvenation compared to traditional rejuvenation. The better blending of old and new asphalt in the Bio-graded recycling rejuvenation method results in a more solid three-dimensional mesh structure with basalt fiber, enhancing the bond with aggregate and increasing compressive strength.

As depicted in Figure 4, the splitting strength of AC-20 asphalt mixtures and two rejuvenation processes under the 60% RAP dosage of plant-mixed hot recycled asphalt mixtures follows a similar trend to the compressive strength indicators, declining with an increase in the number of freeze-thaw cycles. However, unlike compressive strength, the decrease in splitting strength becomes more pronounced with more freeze-thaw cycles. AC-20 asphalt mixture exhibits a decrease of over 10% after five freeze-thaw cycles, reaching 28.86% after 25 cycles, indicating significant degradation in mechanical properties. Bio-graded recycling rejuvenation of 60% RAP recycled material shows a more gradual decrease in splitting strength compared to traditional rejuvenation. Under 5, 10, 15, and 20 freeze-thaw cycles, the index decline is 13.31%, 20.13%, 25.41%, and 33.91%, respectively. Conversely, the decrease in Bio-graded recycling regenerated material is more significant, reaching 36.44% after 20 freeze-thaw cycles. This emphasizes the advantage of 60% RAP recycled material under Bio-graded recycling rejuvenation, highlighting its resilience to repeated freeze-thaw cycles.

As illustrated in Figure 5, the dynamic stability index of the 60% RAP-infused recycled material prepared using both rejuvenation processes consistently exceeds the requirement stipulated by the Technical Specification for Highway Asphalt Pavement Rejuvenation (>800 times/mm) after 5, 10, 15, and 20 freeze-thaw cycles. Overall, the stability index of recycled asphalt mixtures under both rejuvenation methods appears similar to that of AC-20 asphalt mixtures, diminishing with an increase in the number of freeze-thaw cycles. However, the decline in stability is more gradual for AC-20 mixtures, while the rate of decrease for the two types of recycled mixtures is more significant. In general, plant-mix hot recycled asphalt mixtures demonstrate superior high-temperature performance due to the presence of RAP. However, this advantage is compromised under multiple freeze-thaw cycles, with the deterioration of high-temperature performance becoming more pronounced with an increasing number of cycles. Once the number of freeze-thaw cycles reaches 20, the dynamic stability indicators of plant-mix hot recycled asphalt mixtures fall below those of AC-20 mixtures.

From the perspective of the rejuvenation process, although the dynamic stability index of recycled material under both recycling processes exhibits a declining trend, the difference in the rate of decrease is substantial. The conventional 60% RAP rejuvenated material experiences a decline of 21.23%, 52.36%, 56.89%, and 73.42%, whereas the corresponding Bio-graded recycling rejuvenated material experiences declines of 25.36%, 38.51%, 47.56%, and 61.91%. This indicates that, in terms of the recycling process, the high-temperature stability of 60% RAP plant-mix hot recycled asphalt mixtures prepared using the Bio-graded recycling process surpasses that of the corresponding traditional recycled mixtures.

Under the influence of 0 and five cycles of freeze-thaw, the high-temperature performance of traditional recycled mixtures is superior. However, when the number of freeze-thaw cycles exceeds 10, issues arise with the insufficient integration of old and new asphalt, exacerbating the problems of poor adhesion between recycled asphalt and aggregates during freeze-thaw cycles, resulting in a significant decline in high-temperature performance. Conversely, the Bio-graded recycling rejuvenation process proves more effective in enhancing the high-temperature performance of recycled materials.

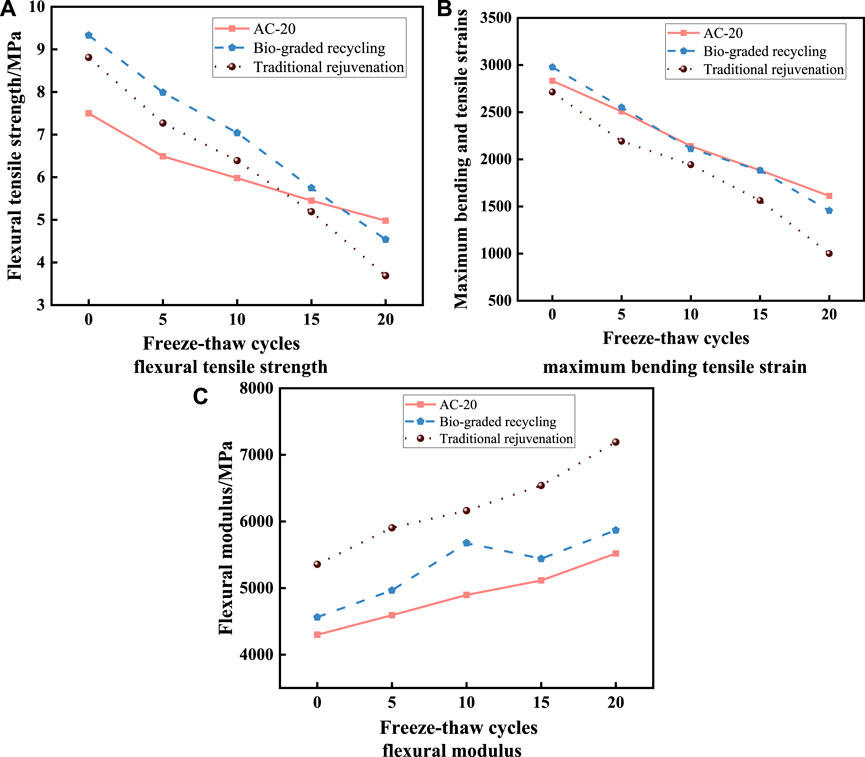

As can be seen from Figure 6, the flexural tensile strength and flexural modulus of 60% RAP recycled materials prepared by the two recycling processes are negatively correlated with the number of freeze-thaw cycles, while the maximum flexural strain is positively correlated with the number of freeze-thaw cycles.

Figure 6. Comparison of low temperature performance under two rejuvenation processes. (A) flexural tensile strength, (B) maximum bending tensile strain, (C) flexural modulus.

In Figure 6A, before experiencing 10 freeze-thaw cycles, the flexural tensile strength of both recycled materials processed through the two rejuvenation methods surpasses that of the AC-20 mixture. This superiority is primarily attributed to the reinforcement provided by basalt fiber, enhancing the low-temperature performance of the recycled material. Additionally, the higher flexural tensile strength of the 60% RAP recycled material processed through the Bio-graded recycling method compared to traditional material suggests the effectiveness of Bio-graded recycling in facilitating the integration of old and new asphalt within the material. This integration fosters the formation of a more robust three-dimensional network structure with basalt fiber, promoting better adhesion with aggregates and consequently, superior low-temperature cracking performance. As the number of freeze-thaw cycles increases, the low-temperature flexural tensile strength of traditional recycled material declines below that of AC-20 after 15 cycles. By the time 20 cycles are reached, the flexural tensile strength of recycled materials falls below that of AC-20, signifying a severe impact of high freeze-thaw cycles on the internal structural stability of recycled material, leading to deteriorated low-temperature performance.

Figure 6B demonstrates a decrease in the maximum bending tensile strain of all materials with an increase in the number of freeze-thaw cycles. Notably, the 60% RAP recycled materials processed through both AC-20 mixture rejuvenation and Bio-graded recycling exhibit a relatively gentle decreasing trend, while traditional recycled materials experience a significant decrease in bending tensile strain under 15 and 20 freeze-thaw cycles, with decreasing rates of 42.5% and 63.1%, respectively. Flexural modulus of strength reflects a material’s resistance to deformation, with lower values indicating better performance.

As depicted in Figure 6C, the freeze-thaw cycle adversely affects the low-temperature performance of 60% RAP dosage plant-mixed hot recycled asphalt mixtures and AC-20 mixes. With an increase in freeze-thaw cycles, the low-temperature performance deteriorates further. However, overall, the sequence remains AC-20 > 60% RAP dosage Bio-graded recycled mix >60% RAP conventional recycled mix.

In Figure 7, both the 60% RAP recycled asphalt mixture and AC-20 asphalt mixture prepared through the two recycling processes exhibit a freeze-thaw splitting strength ratio (TSR) of over 75% before experiencing 10 freeze-thaw cycles, meeting specification requirements. However, when the number of cycles reaches 15, the TSR of 60% RAP recycled material under the traditional process drops to 62%, failing to meet specifications. By 20 freeze-thaw cycles, TSR for all materials declines below requirements: 64%, 57%, and 46%, respectively. This reduction underscores the detrimental effect of high freeze-thaw action on water temperature performance. Additionally, the recycled material indicators during freeze-thaw cycles are lower than those of AC-20, mainly due to the higher content of aged asphalt in the 60% RAP mixture, leading to increased brittleness. Moreover, water ingress during freeze-thaw cycles decreases asphalt-aggregate adhesion, while freezing and expansion contribute to volume expansion, increasing the risk of cracking.

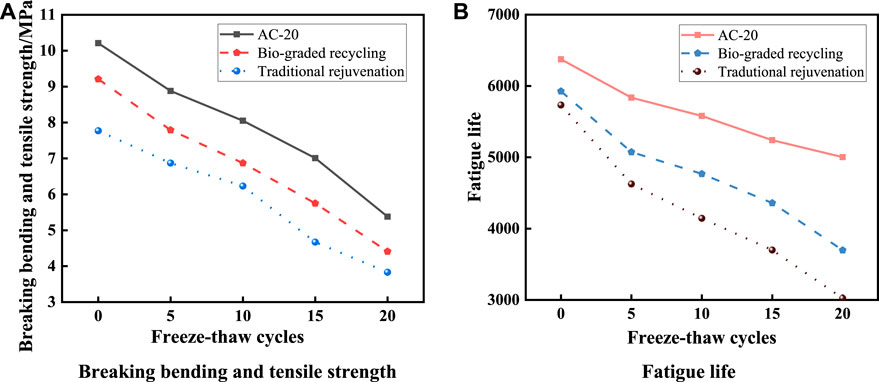

Figure 8A illustrates the change in breaking tensile strength of 60% RAP mixed plant mix hot recycled asphalt mixtures and AC-20 mixtures at 15°C under different freeze-thaw cycle times for two recycling processes. Overall, the breaking bending strength index of the two recycled materials is similar to that of AC-20 asphalt mixtures, which decreases with the increase of the number of freezing and thawing cycles. Under the action of the number of freezing and thawing cycles, the size of the three kinds of mixtures’ breaking bending strength indexes follows the sequence: AC-20 asphalt mixtures > Bio-graded recycled materials > traditional recycled materials. The presence of RAP in the plant-mixed hot recycled asphalt mixture introduces aging molecules, leading to hardening and brittleness of the mixture, which adversely affects the stability of the material and decreases its fatigue performance. Moreover, the effect of multiple freeze-thaw cycles accelerates the degradation of fatigue performance of recycled materials. The degradation of fatigue performance of recycled materials is more significant with higher numbers of freezing and thawing cycles.

Figure 8. Comparison of fatigue performance under two rejuvenation processes. (A) Breaking bending and tensile strength, (B) Fatigue life.

Figure 8B shows the fatigue life trends of the three types of mixtures under different numbers of freeze-thaw cycles, consistent with the trend of Figure 8A. All of them exhibit a decreasing trend. Under the traditional rejuvenation process, the fatigue life of 60% RAP recycled material decreases significantly with the increase of the number of freeze-thaw cycles. The decreases under each number of cycles reach 19.33%, 27.75%, 35.56%, and 47.34%, respectively. Conversely, Bio-graded recycling rejuvenation mitigates this reduction, with decreases in fatigue life of 14.3%, 19.33%, 26.47%, and 37.55% under the corresponding freeze-thaw cycles. The significant reduction in fatigue life under a high number of freezing and thawing cycles in the traditional process indicates that the internal adhesion ability of the mixture composed of large doses of RAP, new and old asphalt, and aggregate further diminishes, adversely affecting fatigue performance. Conversely, the fatigue performance of 60% RAP Bio-graded recycling rejuvenated material is reduced within 20% in 10 freeze-thaw cycles and is controlled at 37.55% in 20 freeze-thaw cycles. This suggests that compared with traditional rejuvenation, Bio-graded recycling rejuvenation effectively improves the fatigue performance of large doses of RAP rejuvenated material.

Figure 9 shows the CT images and 3D views before and after the treatment of bio-graded recycling materials under different freeze-thaw cycles. It can be seen that through comparative analysis, the CT images processed by Avizo can meet the requirements for analyzing microstructural features.

Under the bio-graded recycling process, CT images of the middle part height of asphalt mixture specimens containing 60% RAP blended in a plant-mixed hot rejuvenated asphalt mixture, asphalt mixture with 60% RAP blended using traditional rejuvenation process, and AC-20 conventional asphalt mixture after 0, 5, 10, 15, and 20 freeze-thaw cycles are shown in Figure 10.

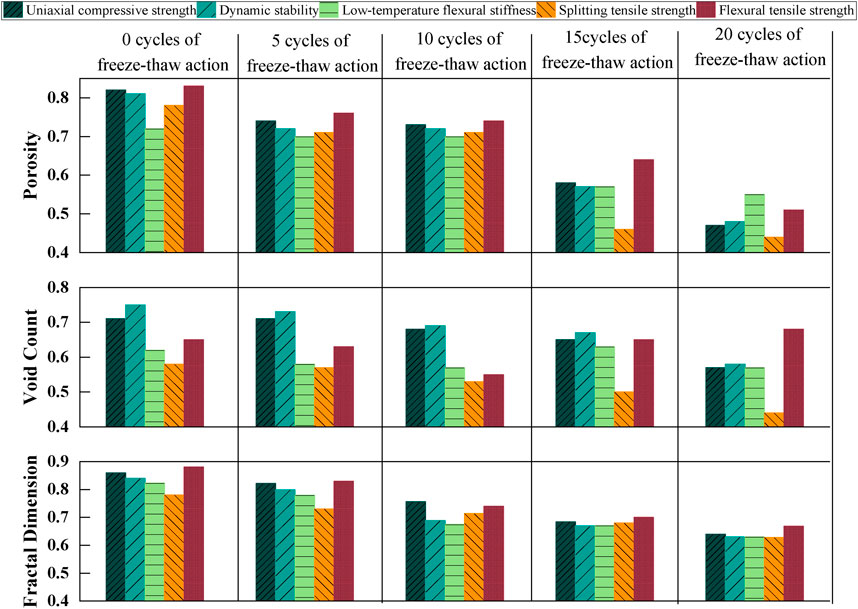

From Figure 10, it can be observed that with the increase in the number of freeze-thaw cycles, the micro-pore structure of both rejuvenated materials and AC-20 mixture gradually changes: under freeze-thaw cycles, existing voids continuously expand and interconnect, while new voids keep emerging. These changes indicate a progressive enlargement of the mixture’s freeze-thaw damage. Among them, the structure of the AC-20 mixture is the most stable, while the micro-void changes in traditional rejuvenated asphalt mixtures are the most significant under different freeze-thaw cycles, indicating poor structural stability and insufficient resistance to freeze-thaw damage; compared with traditional rejuvenated materials, the micro-void changes in bio-graded recycling materials are relatively stable, demonstrating better resistance to freeze-thaw damage. To analyze the microscopic structure of basalt fiber-reinforced asphalt mixtures accurately and quantitatively, analysis is conducted based on three typical microscopic characteristic parameters: porosity, pore quantity, and fractal dimension.

(1) Porosity

The porosity of asphalt mixtures is calculated for different freeze-thaw cycles by determining the percentage of pixels representing internal voids within the total number of pixels in the cross-section. The variation of porosity with the number of freeze-thaw cycles is shown in Figure 11.

From Figure 11, it can be observed that with the increase in the number of freeze-thaw cycles, the porosity of the 60% RAP hot-mix asphalt mixtures with two rejuvenation processes and the AC-20 mixture specimens also increases, indicating that the freeze-thaw cycles continuously generate new voids within the mixtures. Compared to the specimens without freeze-thaw treatment, the increases in porosity for AC-20 and bio-graded recycling materials under 5, 10, 15, and 20 freeze-thaw cycles are 13.2%, 22.3%, 31.5%, 44.3% and 16.1%, 27.2%, 38.5%, 49.5%, respectively. The curves of both show relatively gentle changes and are closer under low-cycle freeze-thaw conditions, while the change in traditional rejuvenated materials is more significant, especially at 15 and 20 cycles, reaching 45.7% and 59.6%, respectively. This indicates that the internal structure of bio-graded recycling materials, which exhibit more thorough fusion between old and new asphalt, is more stable under high-cycle freeze-thaw conditions compared to traditional rejuvenated materials.

(2) Void Count

The void count of asphalt mixtures at different freeze-thaw cycles was statistically analyzed, and the variation of void count with the number of freeze-thaw cycles is shown in Figure 12.

As shown in Figure 12, with the increase in the number of freeze-thaw cycles, the variation in void count for the three types of mixtures exhibits a similar trend, namely, a decrease followed by an increase with relatively low amplitudes. However, the nodes of decrease and increase in void count show different patterns. For AC-20 mixture and 60% RAP bio-graded recycling mixture, the void count decreases initially after five freeze-thaw cycles, followed by an increase. In contrast, for the 60% RAP traditional rejuvenation mixture, the void count continues to decrease during the first 5 and 10 freeze-thaw cycles and then shows a slight increase at the 15th cycle. The decrease in void count observed at lower freeze-thaw cycles is attributed to the fusion of existing voids within the material under freeze-thaw action, resulting in a reduction in void count. However, at higher freeze-thaw cycles, the fusion process of existing voids is essentially complete, and the main reason for the increase in void count is the generation of new voids and micro-cracks induced by freeze-thaw action. Nonetheless, the increase in void count is relatively low due to fewer new voids and cracks induced by higher freeze-thaw cycles. However, the continuous increase in void count for the traditional rejuvenation mixture at 5 and 10 cycles indicates that the internal structure of the 60% RAP rejuvenation material under this rejuvenation process is unstable, and it is most significantly affected by freeze-thaw action. In contrast, the void count for the bio-graded recycling material decreases initially after five cycles and then continues to increase, following a trend similar to that of the AC-20 mixture. This suggests that the fusion process of existing voids in the bio-graded recycling material under freeze-thaw action is the shortest, and its performance is stable. This is partly due to the more thorough fusion of old and new asphalt in the composition of the rejuvenated material and partly relies on the reinforcing, crack resistance, and toughening effects of basalt fiber.

(3) Fractal Dimension

Figure 13 shows the variation of fractal dimension of 60% RAP rejuvenated asphalt mixture and AC-20 mixture under different freeze-thaw cycles. From the figure, it can be observed that the fractal dimension of the AC-20 mixture initially increases and then decreases. This is mainly due to the expansion of voids and the partial detachment of components such as aggregates under the influence of freeze-thaw cycles, leading to an increase in fractal dimension. As the number of freeze-thaw cycles increases, the complexity of the void boundaries decreases, resulting in a decrease in fractal dimension. For the rejuvenated materials, similar to the AC-20 mixture, there is an initial increase followed by a decrease in fractal dimension. However, during the 15th and 20th freeze-thaw cycles, the fractal dimension continues to increase, mainly due to severe internal detachment of materials.

According to the grey correlation analysis theory, the grey correlation calculation results between the microscopic characteristic parameters of bio-graded recycling materials and the macroscopic performance are shown in Figure 14.

Figure 14. Shows the grey correlation between the void ratio of hot-mix rejuvenated asphalt mixture and the macroscopic mechanical performance parameters under various freeze-thaw cycles.

As shown in Figure 14, under different freeze-thaw cycles, the influence of various microscopic parameters of the 60% RAP hot-mix rejuvenated asphalt mixture under the bio-rejuvenation process on its macroscopic performance varies.

Regarding the void ratio parameter analysis, within 0, 5, and 10 freeze-thaw cycles, this parameter exhibits a good correlation with various macroscopic mechanical performance parameters, all above 0.7, and the correlation pattern is obvious, inversely proportional to the freeze-thaw cycle number. This is mainly because under low freeze-thaw cycles, the structure of the bio-graded recycling material is relatively stable, consistent with the analysis results of macroscopic performance. At the same time, it can be observed that under these freeze-thaw cycles, the correlation degrees from high to low are: fracture bending strength, uniaxial compressive strength, dynamic stability, splitting tensile strength, and low-temperature bending stiffness. This indicates that the change in void ratio significantly affects the fatigue performance of the bio-graded recycling material under different freeze-thaw cycles. However, when the freeze-thaw cycle reaches 15 times, severe damage occurs to the rejuvenated material, and the gray correlation between the void ratio and various macro parameters significantly decreases, showing no obvious correlation pattern. Nevertheless, the gray correlation between fracture bending strength and void ratio remains the highest. When the freeze-thaw cycle reaches 20 times, the damage to the rejuvenated material intensifies, and at this point, the correlation between void ratio and various macroscopic mechanical performance indicators is very low, with an average gray correlation distributed around 0.5, indicating that the change in void ratio is not significantly correlated with the change in macroscopic mechanical performance of the rejuvenated material.

Regarding the analysis of void quantity parameters, compared with the void ratio, the correlation between its change within 0, 5, and 10 freeze-thaw cycles and macroscopic mechanical performance parameters decreases. Only the gray correlation with dynamic stability index is higher than 0.7. The correlation degrees between void quantity and various macroscopic mechanical performance parameters from high to low are: dynamic stability, uniaxial compressive strength, fracture bending strength, low-temperature bending stiffness, and splitting tensile strength. This indicates that under these freeze-thaw cycles, the change in void quantity significantly affects the high-temperature performance of the rejuvenated material. Additionally, it can be observed that under 15 and 20 freeze-thaw cycles, except for splitting tensile strength, the gray correlation between void quantity and other macroscopic mechanical parameters is at a level of about 0.6. Among them, the correlation with fracture bending strength is the highest, with correlation coefficients of 0.65 and 0.68 respectively, indicating that under high freeze-thaw cycles, the change in void quantity is closely related to the fatigue performance of the rejuvenated material.

Regarding the analysis of the fractal dimension parameter of the void profile of bio-graded recycling mixtures, it can be found that under each freeze-thaw cycle, the fractal dimension of the bio-graded recycling material shows a good correlation with various macroscopic mechanical performance indicators. Within 0, 5, and 10 freeze-thaw cycles, the correlation is above 0.7, and even under 15 and 20 high-cycle freeze-thaw actions, the correlation remains above 0.6. This indicates that the change in fractal dimension can comprehensively reflect the change in macroscopic mechanical performance. It can also be observed that under each freeze-thaw cycle, the macroscopic mechanical parameters with relatively good correlation with fractal dimension are uniaxial compressive strength and fracture bending strength, indicating a close relationship between fractal dimension and the macroscopic mechanical performance as well as the fatigue performance of the bio-graded recycling material.

(1) Both types of rejuvenation processes result in 60% RAP rejuvenated materials that meet dynamic stability requirements after various freeze-thaw cycles. However, dynamic stability decreases with increasing cycle numbers. Traditional rejuvenated materials exhibit a greater decrease compared to bio-graded recycling materials. This deterioration is attributed to the freeze-thaw action, affecting the inherent performance advantages of aged asphalt in RAP. After 20 freeze-thaw cycles, dynamic stability of rejuvenated materials is lower than that of AC-20 asphalt mixture.

(2) Initially, flexural tensile strength of rejuvenated materials is higher than AC-20 mixture due to basalt fibers enhancing low-temperature performance. However, with more freeze-thaw cycles, flexural tensile strength decreases. At 15 cycles, traditional rejuvenated materials fall below AC-20; at 20 cycles, both types of rejuvenated materials are lower than AC-20, indicating significant freeze-thaw effects on low-temperature performance. Maximum flexural strain decreases with freeze-thaw cycles, with AC-20 and bio-graded recycling materials declining more gently compared to traditional rejuvenated materials.

(3) Freeze-thaw action increases internal void ratio of rejuvenated materials, leading to water ingress that damages asphalt-aggregate bond. Freezing and expansion effects further increase material volume, raising the risk of cracking and reducing anti-freezing ability. Freeze-thaw action significantly reduces water temperature performance of rejuvenated mixtures, with a more pronounced decrease in anti-freezing performance due to inherent aging components.

Due to the time limitation, this study only employed one type of bitumen and one type of rejuvenator. It is recommended to investigate different types of rejuvenator to validate the applicability of this method, thereby to improve the performance of recycled RAP materials and to optimize mix designs, subsequently to enhance the durability and longevity of rejuvenated asphalt materials considering freeze-thaw conditions.

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

LH: Data curation, Formal Analysis, Investigation, Methodology, Writing–original draft. YL: Data curation, Formal Analysis, Investigation, Writing–original draft. MX: Formal Analysis, Investigation, Writing–original draft. RL: Formal Analysis, Supervision, Writing–original draft, Writing–review and editing. QG: Formal Analysis, Writing–original draft. XL: Formal Analysis, Writing–review and editing. XZ: Formal Analysis, Writing–review and editing.

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Author LH was employed by YCIC Highway Construction Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Adwani, D., Pipintakos, G., Mirwald, J., Wang, Y., Hajj, R., Guo, M., et al. (2024). Examining the efficacy of promising antioxidants to mitigate asphalt binder oxidation: insights from a worldwide interlaboratory investigation. Int. J. Pavement Eng. 25 (1), 2332363. doi:10.1080/10298436.2024.2332363

Al-Sabaeei, A. M., Napiah, M. B., Sutanto, M. H., Alaloul, W. S., and Usman, A. (2020). A systematic review of bio-asphalt for flexible pavement applications: Coherent taxonomy, motivations, challenges and future directions. J. Clean. Prod. 249, 119357. doi:10.1016/j.jclepro.2019.119357

Babagoli, R., Norouzi, N., and Ameli, A. (2021). Laboratory investigation of the influence of aging and compaction effort on low temperature performance of asphalt mixture containing different percentage of RAP. Constr. Build. Mater. 298, 123899. doi:10.1016/j.conbuildmat.2021.123899

Baloch, H. A., Nizamuddin, S., Siddiqui, M., Riaz, S., Jatoi, A. S., Dumbre, D. K., et al. (2018). Recent advances in production and upgrading of bio-oil from biomass: a critical overview. J. Environ. Chem. Eng. 6 (4), 5101–5118. doi:10.1016/j.jece.2018.07.050

Barraj, F., and Elkordi, A. (2022). Investigating the effect of using unclassified fractionated reclaimed asphalt pavement materials on the properties of hot mix asphalt. Constr. Build. Mater. 353, 129099. doi:10.1016/j.conbuildmat.2022.129099

Bowers, B. F., and Powell, R. B. (2021). Use of a hot-mix asphalt plant to produce a cold central plant recycled mix: production method and performance. Transp. Res. Rec. 2675 (11), 451–459. doi:10.1177/03611981211017904

Fang, Y., Zhang, Z., Yang, J., and Li, X. (2021). Comprehensive review on the application of bio-rejuvenator in the regeneration of waste asphalt materials. Constr. Build. Mater. 295, 123631. doi:10.1016/j.conbuildmat.2021.123631

Guo, M., Liu, H., Jiao, Y., Mo, L., Tan, Y., Wang, D., et al. (2020). Effect of WMA-RAP technology on pavement performance of asphalt mixture: a state-of-the-art review. J. Clean. Prod. 266, 121704. doi:10.1016/j.jclepro.2020.121704

Hu, D., Gu, X., Dong, Q., Lyu, L., Cui, B., and Pei, J. (2021). Investigating the bio-rejuvenator effects on aged asphalt through exploring molecular evolution and chemical transformation of asphalt components during oxidative aging and regeneration. J. Clean. Prod. 329, 129711. doi:10.1016/j.jclepro.2021.129711

Hu, Y., Si, W., Kang, X., Xue, Y., Wang, H., Parry, T., et al. (2022). State of the art: Multiscale evaluation of bitumen ageing behaviour. Fuel 326, 125045. doi:10.1016/j.fuel.2022.125045

Hu, Y., Xia, W., Xue, Y., Zhao, P., Wen, X., Si, W., et al. (2023). Evaluating the ageing degrees of bitumen by rheological and chemical indices. Road Mater. Pavement Des. 24 (Suppl. 1), 19–36. doi:10.1080/14680629.2023.2180289

Li, X., et al. (2023). Analysis of the impact of Reclaimed asphalt pavement Agglomeration on the performance of hot-recycled asphalt pavement: a perspective on Diffusion-fusion. Available at SSRN 4672845.

Lv, S., Peng, X., Liu, C., Ge, D., Tang, M., and Zheng, J. (2020). Laboratory investigation of fatigue parameters characteristics of aging asphalt mixtures: a dissipated energy approach. Constr. Build. Mater. 230, 116972. doi:10.1016/j.conbuildmat.2019.116972

Ma, Y., Polaczyk, P., Park, H., Jiang, X., Hu, W., and Huang, B. (2020). Performance evaluation of temperature effect on hot in-place recycling asphalt mixtures. J. Clean. Prod. 277, 124093. doi:10.1016/j.jclepro.2020.124093

Magar, S., Xiao, F., Singh, D., and Showkat, B. (2022). Applications of reclaimed asphalt pavement in India–A review. J. Clean. Prod. 335, 130221. doi:10.1016/j.jclepro.2021.130221

Rajib, A. I., Samieadel, A., Zalghout, A., Kaloush, K. E., Sharma, B. K., and Fini, E. H. (2022). Do all rejuvenators improve asphalt performance? Road Mater. Pavement Des. 23 (2), 358–376. doi:10.1080/14680629.2020.1826348

Roja, K. L., Masad, E., and Mogawer, W. (2021). Performance and blending evaluation of asphalt mixtures containing reclaimed asphalt pavement. Road Mater. Pavement Des. 22 (11), 2441–2457. doi:10.1080/14680629.2020.1764858

Rout, M. D., Biswas, S., Shubham, K., and Sinha, A. K. (2023). A systematic review on performance of reclaimed asphalt pavement (RAP) as sustainable material in rigid pavement construction: current status to future perspective. J. Build. Eng. 76, 107253. doi:10.1016/j.jobe.2023.107253

Sabouri, M. (2020). Evaluation of performance-based mix design for asphalt mixtures containing Reclaimed Asphalt Pavement (RAP). Constr. Build. Mater. 235, 117545. doi:10.1016/j.conbuildmat.2019.117545

Shah, A., McDaniel, R. S., Huber, G. A., and Gallivan, V. L. (2007). Investigation of properties of plant-produced reclaimed asphalt pavement mixtures. Transp. Res. Rec. 1998 (1), 103–111. doi:10.3141/1998-13

Tarsi, G., Tataranni, P., and Sangiorgi, C. (2020). The challenges of using reclaimed asphalt pavement for new asphalt mixtures: a review. Materials 13 (18), 4052. doi:10.3390/ma13184052

Xing, C., Li, M., Liu, L., Lu, R., Liu, N., Wu, W., et al. (2023). A comprehensive review on the blending condition between virgin and RAP asphalt binders in hot recycled asphalt mixtures: mechanisms, evaluation methods, and influencing factors. J. Clean. Prod. 398, 136515. doi:10.1016/j.jclepro.2023.136515

Yang, C., Wu, S., Cui, P., Amirkhanian, S., Zhao, Z., Wang, F., et al. (2022). Performance characterization and enhancement mechanism of recycled asphalt mixtures involving high RAP content and steel slag. J. Clean. Prod. 336, 130484. doi:10.1016/j.jclepro.2022.130484

Yang, X., and You, Z. (2015). High temperature performance evaluation of bio-oil modified asphalt binders using the DSR and MSCR tests. Constr. Build. Mater. 76, 380–387. doi:10.1016/j.conbuildmat.2014.11.063

Yousefi, A., Behnood, A., Nowruzi, A., and Haghshenas, H. (2021). Performance evaluation of asphalt mixtures containing warm mix asphalt (WMA) additives and reclaimed asphalt pavement (RAP). Constr. Build. Mater. 268, 121200. doi:10.1016/j.conbuildmat.2020.121200

Yu, X., Tang, W., Jiang, M., Huang, J., and Wang, D. (2022). Refined decomposition: a new separation method for RAP materials and its effect on aggregate properties. Constr. Build. Mater. 358, 129452. doi:10.1016/j.conbuildmat.2022.129452

Zadshir, M., Hosseinnezhad, S., and Fini, E. H. (2019). Deagglomeration of oxidized asphaltenes as a measure of true rejuvenation for severely aged asphalt binder. Constr. Build. Mater. 209, 416–424. doi:10.1016/j.conbuildmat.2019.03.090

Zadshir, M., Oldham, D. J., Hosseinnezhad, S., and Fini, E. H. (2018). Investigating bio-rejuvenation mechanisms in asphalt binder via laboratory experiments and molecular dynamics simulation. Constr. Build. Mater. 190, 392–402. doi:10.1016/j.conbuildmat.2018.09.137

Zalghout, A., Castro, S., Karam, J., and Kaloush, K. (2022). Laboratory and field evaluation of plant produced asphalt mixtures containing RAP in hot climate: a case study from Phoenix, Arizona. Constr. Build. Mater. 351, 128322. doi:10.1016/j.conbuildmat.2022.128322

Zhang, R., Sias, J., Dave, E., Hanz, A., Reinke, G., and Wang, Z. (2022). Comprehensive laboratory evaluation of recycling agent treated plant-produced asphalt mixtures. Transp. Res. Rec. 2676 (9), 620–634. doi:10.1177/03611981221088225

Zhang, R., Wang, H., You, Z., Jiang, X., and Yang, X. (2017). Optimization of bio-asphalt using bio-oil and distilled water. J. Clean. Prod. 165, 281–289. doi:10.1016/j.jclepro.2017.07.154

Keywords: bio-graded recycling, RAP, hot mixture asphalt, low-temperature performance, freeze-thaw

Citation: He L, Li Y, Xia M, Liu R, Gu Q, Luo X and Zhang X (2024) Bio-graded recycling for hot asphalt mixtures with high RAP content considering freeze-thaw. Front. Mater. 11:1407507. doi: 10.3389/fmats.2024.1407507

Received: 26 March 2024; Accepted: 09 April 2024;

Published: 25 April 2024.

Edited by:

Jianmin Ma, Queen’s University, CanadaReviewed by:

Lei Luo, RWTH Aachen University, GermanyCopyright © 2024 He, Li, Xia, Liu, Gu, Luo and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Rui Liu, cnVpLmxpdWNoZEBvdXRsb29rLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.