- 1Department of Civil Engineering, Qingdao University of Technology, Qingdao, China

- 2Department of Civil, Architectural and Environmental Engineering, Missouri University of Science and Technology, Rolla, MO, United States

- 3School of Materials Science and Engineering, China University of Petroleum, Qingdao, Shandong, China

Editorial on the Research Topic

Nanoscale insight into the hydration products of cementitious materials: from theory to engineering

Introduction

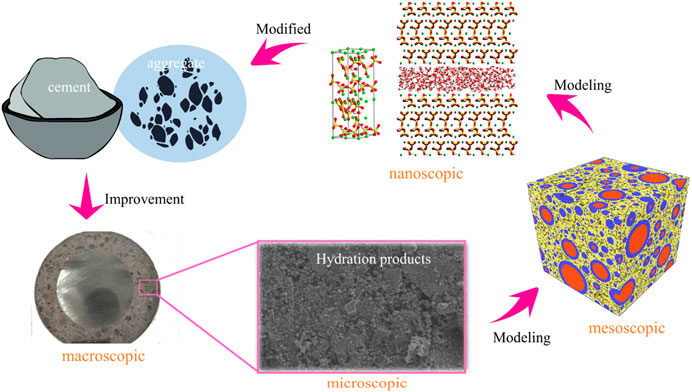

Concrete is the second most consumed material in the world after water. Its superior durability, plasticity, and cost-effectiveness make it one of the most common construction materials in the world. The improvement of performance, innovation, and sustainable development of traditional concrete has always been a focal point of scholars’ attention (Flatt et al., 2012). Although the performance of concrete is generally described on the macroscale, it essentially depends on the nanoscale structure of the hydration products of the cementitious binder (Scrivener and Kirkpatrick, 2008). In other words, fully understanding of the nanoscale properties of cement hydration products can facilitate the design of the macroscopic performance of cement (Manzano et al., 2009). This is also the key reason why we need to focus on the nanoscale properties of cementitious materials. The nanoscale insight into the hydration products of cementitious materials can be regarded as the outpost of Nano-Engineering (Wang et al., 2022). Corresponding to one macroscopic performance with one or several nanoscale properties is the first concern of “nanoscale insight”. Meanwhile, identifying the types of hydration products of different kinds of cementitious materials is also a concern of “nanoscale insight”. The ultimate goal of “nanoscale insight” is hopefully nanoscale design, which transforms the traditional relationship flow of raw materials-performance into the relationship flow of raw materials-nanoscale structures-performance. The multi-scale design and interconnection of cement materials from macro to nano are shown in (Figure 1).

Centered around the aforementioned research goals, we are honored to introduce the Research Topic, “Nanoscale Cement Hydration Products: From Theory to Engineering.” The current Research Topic includes 4 articles reporting on the chemical reactions related to hydration, volcanic ash, and alkali activation processes in cement production. It also explores experimental techniques revealing the characteristics of hydration products and presents interesting research findings on the nanoscale properties and performance of cementitious materials. We hope that these studies will further promote the connection between the macroscopic properties and microscopic performance of concrete.

A clear understanding of the hydration reactions and formation mechanisms of different types of cement is crucial for advancing the design and optimization of cementitious materials, as well as controlling the rheology, pore structure, strength, and durability of concrete (Aretxabaleta et al., 2023). The addition of mineral admixtures in cement is an effective method to enhance the performance of concrete, improve its durability, and slow down the rate of cement hydration reactions. Dong et al. employed density functional theory (DFT) to investigate the impact of [H2SiO4]2- on the adsorption and dissociation of water on the surface of C3S during the initial hydration process. The study revealed that [H2SiO4]2- ions in mineral admixtures could promote the hydration process of C3S by adsorbing hydrogen atoms in water, increasing the active oxygen sites on the C3S surface, and influencing the charge transfer and bonding mechanisms of the C3S hydration shell. This research delves into the molecular-level mechanisms of mineral admixtures in cement hydration, contributing to a deeper understanding of the role of mineral admixtures in cement.

With the rapid development of the economy, environmental Research Topic cannot be ignored. Green and eco-friendly cement, as well as low-carbon cement, have emerged to achieve the goal of material recycling and environmental protection. The incorporation of mineral waste contributes to improved cement properties and has the added advantage of significantly reducing greenhouse gas emissions. Although research in this field mainly focuses on applications, equal attention should also be paid to the formation mechanism and process of hydration products of composite materials and their micro-nano structures (Duxson et al., 2007; Provis, 2018). Wang et al. investigated the impact of silt modification on the properties of magnesium phosphate cement (MPC). The study utilized dredged sludge (DS) as a mineral admixture for modified MPC. The results indicated that, compared to fly ash (FA) and metakaolin (MK), DS exhibited the most significant retarding effect on MPC. Additionally, the incorporation of DS improved the water resistance of MPC. The paper discusses the potential of using dredged sludge (DS) as an additional cementitious material for construction purposes, highlighting its potential to reduce MPC raw material costs and enhance MPC performance. Li et al. investigated the basic properties and hydration products of cement blended with sintered fly ash (SSA) obtained from treated dredged sludge. Through a combination of experiments and thermodynamic simulation methods, the study examined the influence of adding 5%–30% SSA to Portland cement on the fundamental properties and hydration products of the cement. The results indicated that 10% SSA content densified the cementitious gel structure, leading to more complete cement hydration. The thermodynamic simulation results aligned well with the experimental findings, providing a numerical simulation foundation for predicting the behavior of other SSA content levels. Wang et al. investigated the application and influence of superplasticizer (SP) in ultra-high-performance concrete (UHPC) and ultra-high-performance fiber-reinforced concrete (UHPFRC) through experimental means, focusing on its effects on the flowability of cement. The results indicated that the addition of SP improved the flowability of UHPC at extremely low water-to-cement ratios and enhanced the mechanical properties of UHPFRC. The particle packing theory mentioned in the paper explained the flow mechanism of cement paste at the molecular level, providing an intriguing perspective. These studies encourage a nanoscale understanding and deeper contemplation of the flowability of cement paste.

With the in-depth study of the microscopic and nanoscale properties of concrete, more research directions related to cementitious materials need attention. This includes but is not limited to various types of cementitious materials (including hydraulic cement and supplementary cementitious materials), encompassing all relevant Research Topic and techniques from structural characteristics and activation methods to material preparation and performance enhancement. The guest editorial team believes that the combination of these research topics with nanoscale research methods will promote a deeper understanding and active development of cementitious material properties.

Author contributions

HS: Writing–original draft. MW: Conceptualization, Writing–review and editing. HM: Writing–review and editing. XW: Writing–review and editing. BP: Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aretxabaleta, X. M., López-Zorrilla, J., Etxebarria, I., and Manzano, H. (2023). Multi-step nucleation pathway of CSH during cement hydration from atomistic simulations. Nat. Commun. 14, 7979. doi:10.1038/s41467-023-43500-y

Duxson, P., Fernández-Jiménez, A., Provis, J. L., Lukey, G. C., Palomo, A., and van Deventer, J. S. J. (2007). Geopolymer technology: the current state of the art. J. Mat. Sci. 42, 2917–2933. doi:10.1007/s10853-006-0637-z

Flatt, R. J., Roussel, N., and Cheeseman, C. R. (2012). Concrete: an eco material that needs to be improved. J. Eur. Ceram. Soc. 32, 2787–2798. doi:10.1016/j.jeurceramsoc.2011.11.012

Manzano, H., Dolado, J. S., and Ayuela, A. (2009). Elastic properties of the main species present in Portland cement pastes. Acta Mater 57, 1666–1674. doi:10.1016/j.actamat.2008.12.007

Provis, J. L. (2018). Alkali-activated materials. Cem. Concr. Res. 114, 40–48. doi:10.1016/j.cemconres.2017.02.009

Scrivener, K. L., and Kirkpatrick, R. J. (2008). Innovation in use and research on cementitious material. Cem. Concr. Res. 38, 128–136. doi:10.1016/j.cemconres.2007.09.025

Keywords: concrete, cement, nanoscale, hydration product, modelling, nanoengineering

Citation: Sun H, Wang M, Ma H, Wang X and Pang B (2024) Editorial: Nanoscale insight into the hydration products of cementitious materials: from theory to engineering. Front. Mater. 10:1356717. doi: 10.3389/fmats.2023.1356717

Received: 16 December 2023; Accepted: 29 December 2023;

Published: 11 January 2024.

Edited and reviewed by:

John L. Provis, Paul Scherrer Institut (PSI), SwitzerlandCopyright © 2024 Sun, Wang, Ma, Wang and Pang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Muhan Wang, d2FuZ211aGFuQHF1dC5lZHUuY24=

Huiwen Sun1

Huiwen Sun1 Muhan Wang

Muhan Wang Xiao Wang

Xiao Wang Bo Pang

Bo Pang