- 1Guangxi Key Lab of Road Structure and Materials, Guangxi Transportation Science and Technology Group Co., Ltd., Nanning, China

- 2(Special Glass Key Lab of Hainan Province) and (State Key Laboratory of Marine Resource Utilization in South China Sea), Hainan University, Haikou, China

The physical and mechanical properties of recycled aggregates (RA) among different particle sizes are compared. Results demonstrate that adhesive mortar content is a significant factor in determining the properties of recycled aggregate concrete (RAC). The adhesive mortar content on the surface of recycled aggregates is critical in selecting the most efficient strengthening treatment, and effects of the strengthening treatment on properties of RA with different particle sizes was reported. The utilization of RA was suggested to classify into fine powder aggregate, fine aggregate, coarse aggregate based on the particle size, i.e., the multi-scale grading utilization. The most suitable strengthening treatment was reviewed for RA with various particle size to improve the it’s utilization efficiency.

1 Introduction

Excessive carbon dioxide emissions have a negative impact on global economy, society, ecology (Pierrehumbert, 2019). Nowadays, many countries are implementing energy-saving and emission reduction policies (Eurostat, 2017; Eurostat, 2018), because the shortage of natural resources and the reduction of carbon emissions have become a global consensus. However, with the rapid improvement of urban housing and transportation, the demand for building materials such as cement, reinforced steel, sand, and gravel is ever-increasing, leading to their continuous reduction. In addition, defects of early urban planning and architectural functions led to the demolition of a large number of old buildings with the improvement of urban housing and transportation, resulting in a huge amount of construction waste. It is estimated that the annual emission of construction waste in China, United States, and European Union exceeds 2.3 billion tons (Zheng et al., 2017), 700 million tons (Wu et al., 2019), and 800 million tons (Ajayi et al., 2016), respectively. Therefore, the improvement of utilization of construction waste and reduction of carbon emissions is serious to the sustainable development of construction industry.

The most effective treatment process for construction waste presently includes crushing, magnetic separation, screening, and washing steps, resulting in the classification of recycled aggregates. The type of recycled aggregates differs due to the structural form of the demolished building and crushing method, which can be recycled concrete aggregate (RA), recycled clay brick aggregate, or recycled mixed aggregate. Recycled aggregates are the most extensively used in the construction industry due to impurities such as wood blocks, reinforced steel, and plastics present in recycled mixed aggregate. It is poor Los Angeles abrasion resistance and water absorption rate of recycled brick aggregate than natural aggregates (Vegas et al., 2015; Xie et al., 2015; Ossa et al., 2016). Additionally, the properties and applications of recycled aggregates was reviewed in this paper.

The cement mortar layer attached on the surface of recycled aggregates leads to the degradation of its properties compared to natural aggregates primarily. Generally speaking, the thickness of the adhesive mortar layer decreases as the number of crushing increases, which makes the apparent density and water absorption of RA trend to natural aggregates (Won and Park, 2010). Therefore, the quality of recycled aggregates is directly related to the crushing process and the number of crushing (Fang et al., 2020; Cho et al., 2021). However, an increase in the number of crushing causes a reduction in the particle size of the aggregates, leading to poor particle size distribution and lower recovery rate (Yonezawa et al., 2001). Choi et al. (2017) crushed waste concrete three times via a cone crusher, and obtained recycled aggregate with a particle size of 5–10 mm. Nagataki et al. (2004) found that with the increase of crushing times, the recycled coarse aggregate produced by 1 ton of waste concrete decreased from 0.6 ton to 0.35 ton.

In order to improve the property of recycled aggregate without reducing the recovery rate of waste concrete, the crushing technology and the method of removing the adhesive mortar layer on the surface of recycled aggregate are combined and optimized by many researchers, among which the representative methods are as follows: Heat and rubbing (Hideo et al., 2019), acid and ball milling (Fumoto et al., 2000), microorganism (Feng et al., 2020) and carbonation (Chinzorigt et al., 2020), all the methods achieved an expected effect. However, the equipment used in the above methods is relatively expensive, and the process of removing the mortar layer consumes a lot of energy, resulting in economic and ecological problems (Al-Bayati et al., 2016), which makes the combined treatment technology have more hindered than the single crushing technology in the actual use. For example, using of acidic solution in acid and ball milling method may be harmful to the environment during the storage and disposal process (Wang et al., 2017). The CO2 emissions of a single mechanical crushing process are 1.5–4.5 kg/t, but reach 200 kg/t for the heat and rubbing process (Quattrone et al., 2014). Therefore, the production process of high-quality recycled aggregate should to be low-carbon, environmental protected, and economical.

The construction waste can be used as filling waste after grinding. In addition, a higher value-added utilization method for construction waste can be divided into two aspects according to the particle size: 1) The activity of fine powder can be stimulated by mechanical activation, chemical activation, and heat treatment, prior to using as cementitious materials (Florea et al., 2014; Xiao et al., 2018), which can reduce the energy consumption and environment pollution during the cement production process; 2) The construction waste can be crushed to obtain recycled aggregate. This is an effective way to solve the shortage of sand and stone resources in producing concrete, and can solve the secondary pollution and occupation of cultivated land caused by landfill and open stacking (Jiménez et al., 2016; Braga et al., 2017; Feng et al., 2019). Therefore, recycled aggregates were reclassified in this study. The physical and mechanical performance of recycled aggregates with different particle sizes were analyzed. Effect of various strengthening method on properties of RA was summarized. These report is expected to provide direction for multi-scale grading utilization of recycled aggregates and the subsequent research.

2 Recycled concrete aggregates

2.1 Properties of recycled aggregates

The recycled aggregate is composed of the natural aggregate and the mortar layer adhered on its surface. The difference between the recycled aggregate and the natural aggregate is due to the existence of adhesion mortar layer and internal micro-cracks. The mortar layer is difficult to be separated from the surface of aggregates, which makes its apparent density and water absorption significantly different from that of natural aggregate (Otsuki et al., 2003; Poon et al., 2004; Etxeberria et al., 2006; Pradhan et al., 2020). The crushing index, apparent density, and water absorption of natural aggregate (Gokce et al., 2004; de Juan and Gutiérrez, 2009; Butler et al., 2014; Duan and Poon, 2014; Fan et al., 2014; Sidorova et al., 2014; Arezoumandi et al., 2015; Pandurangan et al., 2016; Afroughsabet et al., 2017; McGinnis et al., 2017; Kim et al., 2016; Yang and Lee, 2017; Dimitriou et al., 2018; Gholampour and Ozbakkaloglu, 2018; Fan et al., 2020; Sasanipour and Aslani, 2020; Mi et al., 2021) are about 6%, 2,600–2,700 kg/m³, and 0.5%–1.8% respectively, while those of recycled aggregate (Gokce et al., 2004; de Juan and Gutiérrez, 2009; Butler et al., 2014; Duan and Poon, 2014; Fan et al., 2014; Sidorova et al., 2014; Arezoumandi et al., 2015; Pandurangan et al., 2016; Afroughsabet et al., 2017; McGinnis et al., 2017; Kim et al., 2016; Yang and Lee, 2017; Dimitriou et al., 2018; Gholampour and Ozbakkaloglu, 2018; Fan et al., 2020; Sasanipour and Aslani, 2020; Mi et al., 2021) are about 14%, 2,100–2,580 kg/m³, and 2%–10%, respectively. Researchers (Nassar and Soroushian, 2012; Suryawanshi et al., 2015) found that the thickness of mortar layer increases as the particle size decreases. Partial mortar layers on the surface of recycled aggregates can be separated during the crushing process, and larger aggregates transform into smaller particles. Consequently, recycled fine aggregates increase while a portion of the bonded mortar blends with the fine aggregates, resulting in lower apparent density and significantly higher water absorption rate than that of natural aggregates (Akbarnezhad et al., 2011; Gokce et al., 2011).

2.2 Research status of recycled aggregate reuse

The substitution rate of recycled aggregate is an important index in determining the properties of recycled aggregate concrete. Etxeberria et al. (Etxeberria et al., 2007a) reported that the mechanical property of recycled aggregate concrete decreased as the dosage of recycled aggregate increased. The 28 days compressive strength and flexural strength of the pervious concrete prepared entirely by recycled aggregates were reduced by 56% and 64%, respectively, compared to the natural aggregate pervious concrete (Toghroli et al., 2020). Dilbas et al. (2019) found that the 40% dosage of recycled coarse aggregate was suitable, because the compressive strength, tensile strength, and flexural strength of recycled aggregate concrete just reduced by 2%, 4%, and 9% respectively. Mechanical properties of recycled aggregate concrete can be improved by decreasing the water-cement ratio reported by Zaben et al. (2021). It should be noticed that the shrinkage of recycled aggregate concrete gradually increased with increasing of the dosage. Thus, based on the 7 days dry shrinkage strain less than 500 μm, it is recommended that the dosage of recycled aggregates should not exceed 20% and 40% when produced low strength (20–30 MPa) and medium strength (30–50 MPa) recycled aggregate concrete, respectively. The freezing-resistance of recycled aggregate concrete was studied by El-Hawary et al. (2021), and results showed that mass loss of recycled aggregate concrete increased as the dosage of coarse aggregate increased.

The strength of concrete is influenced by obvious mineral admixtures. Habibi et al. (2021) reported that recycled aggregate concrete reached an optimal 90 days compressive strength when cement was replaced by 10 wt% of silica fume; Recycled aggregate concrete had a better durability when the ratio of silica fume: granulated blast furnace slag: cement was 6.67: 23.83: 49.49. The glass powder was ground into fine powder (less than 75 μm) and used as mineral admixture by Salahuddin et al. (Salahuddin et al., 2019). Results showed that the compressive strength and splitting tensile strength of recycled aggregate concrete increased when the dosage of the fine glass powder was 20 wt%.

2.3 Optimal particle size of recycled aggregates

Table 1 lists the physical properties of recycled aggregates used for discussion in `Section 2.2. Most of the literature does not reveal the strength grade of the original concrete, but literature (Etxeberria et al., 2007a) specifies that the recycled concrete source is roller compacted concrete (RCC). This RCC contains approximately 49.1% natural aggregates and 43% bound mortar. After crushing, 10–25 mm natural aggregates have an apparent density of 2.67 g/cm³ and a water absorption rate of 0.886%, while 4–10 mm aggregates contain a mixture of natural aggregates and bound mortar with an apparent density of 2.43 g/cm³ and a water absorption rate of 4.445%. This indicates that the thickness of adhesive mortar is a key factor in leading to the decrease of apparent density and the increase of water absorption rate.

Recycled aggregates had a particle size of 8–16 mm, but its original particle of size was 11.2–22.4 mm reported in literature (Dilbas et al., 2019), indicating that the aggregates had secondary crushed. Table 1 shows that the apparent density and water absorption rate were 2.47 g/cm³ and 0.84%, respectively, indicating a small amount of adhesive mortar in recycled aggregates. Nevertheless, some mortar still clung to the surface of aggregates. Adhesive mortar is removed from the recycled aggregates during secondary crushing. This indicates that adherent mortar content of aggregates with a particle size of 5–8 mm increased after the second crushing. Consequently, recycled aggregates with a particle size range of 10–16 mm shows an excellent apparent density and water absorption rate after direct crushing.

3 Strengthened recycled concrete aggregate

3.1 Research status of recycled aggregate reuse after strengthening

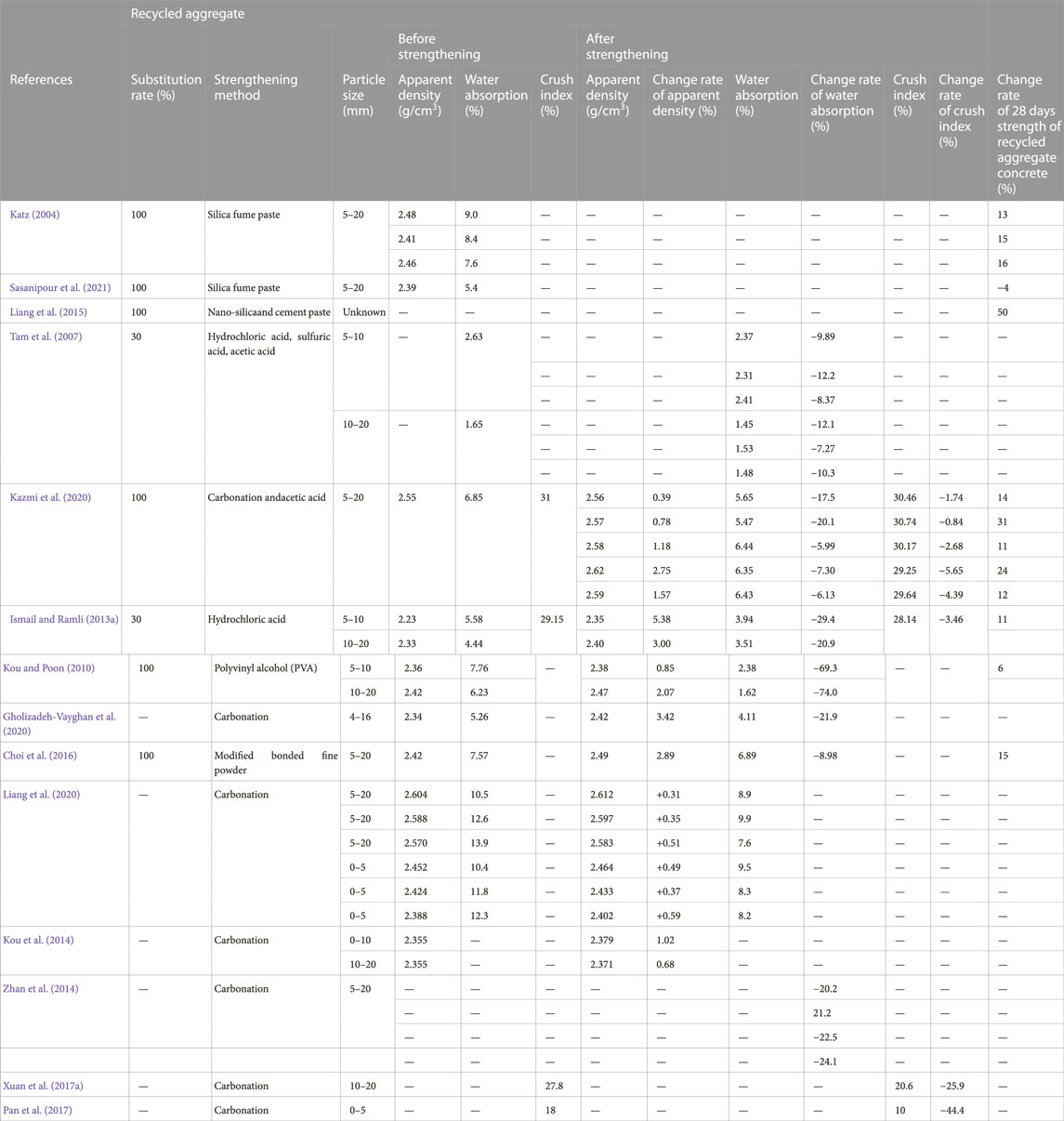

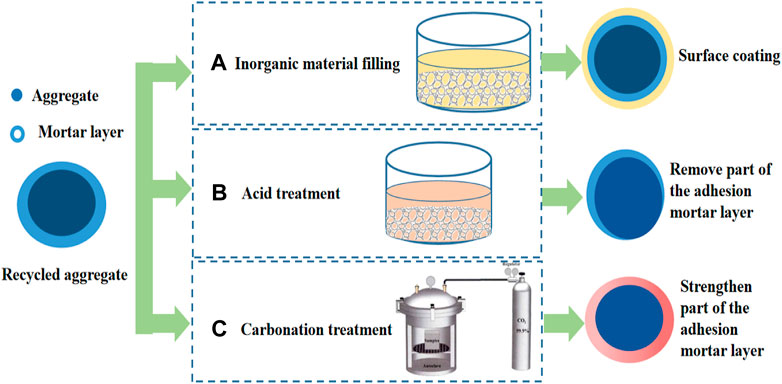

The adhesion of mortar layer on the surface of recycled aggregate leads to a decrease in mechanical properties and durability of recycled aggregate concrete. Strengthening treatment of recycled aggregate is effective for removing or strengthening the mortar layer, which can be narrow the gap between recycled aggregate and natural aggregate (Evangelista et al., 2015; Esmaeeli et al., 2019; Evangelista and Guedes, 2019; Pawluczuk et al., 2019). Filling pre-wetting, pickling, inorganic material filling, and carbonation are the major methods to strengthen recycled aggregates. Katz, (2004) soaked the recycled coarse aggregate in the silica fume slurry, and made the 7 and 28 days compressive strength of prepared recycled aggregate concrete increased by 28% and 15%, respectively. The recycled aggregate is pretreated with silica fume slurry by Sasanipour et al. (2021), leading to an improvement of resistivity of relevant recycled aggregate concrete. Recycled coarse aggregate was pretreated with nano-silica solution and cement slurry by Liang et al. (2015), and the 28 days compressive strength of recycled coarse aggregate concrete increased from 27.6 to 41.4 MPa with a water-cement ratio of 0.43. Acidic solution can effectively remove the mortar adhesion on the surface of recycled coarse aggregate (Tam et al., 2007). The adhesion of mortar layer of recycled aggregate can be strengthened by a carbonation treatment. Recycled coarse aggregate was strengthened by soaking with 3% acetic acid for 24 h and an accelerated carbonation process, and results showed that the frost resistance and sulfate resistance of the recycled aggregate concrete were improved (Kazmi et al., 2020). Recycled coarse aggregate was strengthened with a combination immersion method of hydrochloric acid and sodium silicate by Ismail and Ramli (2013a); Ismail and Ramli (2013b), and the 28 days compressive strength of the prepared C30 recycled aggregate concrete increased by 11.1%. Kou and Poon (2010) reported that 10% polyvinyl alcohol (PVA) can effectively strengthen the recycled coarse aggregate. Gholizadeh-Vayghan et al. (2020) reported that both water absorption and porosity of recycled aggregates showed a downward trend treated by carbonation. The modified inorganic bonded fine powder was used to enhance the surface of recycled coarse aggregates, accompany by an increase in mechanical properties and impermeability of the prepared recycled aggregate concrete (Choi et al., 2016).

The water absorption rates of recycled coarse aggregates obtained from crushed mortar (water-cement ratios of mortar is 0.3, 0.4, and 0.5, respectively) were 10.5%, 12.6%, and 13.9%, respectively. This water absorption rates decreased to 8.9%, 9.9%, and 7.6% after treated by a 10 days carbonation (Liang et al., 2020). This indicates that the minimum water absorption of different recycled fine aggregates trend to a same level after carbonation, that is, the higher water absorption of recycled fine aggregates is, the more obvious the effect of carbonation. Kou et al. (2014) found that the smaller the particle size of recycled aggregate is, the more beneficial it is to the increase of apparent density after carbonation. The water absorption of recycled aggregates obtained from crushing of C30, C45, C60, and C80 concrete after carbonation decreased by 20.2%, 21.2%, 22.5%, and 24.1%, respectively (Zhan et al., 2014). The crushing value of natural aggregate with a particle size of 10–20 mm was 18% measured by Xuan et al. (2017a), and that of recycled coarse aggregate was 27.8%. The crushing value of this recycled coarse aggregate decreased to 20.6% after treating by carbonation, a decrease of 25.9%. Pan et al. (2017) reported that the crushing value of recycled fine aggregate can decrease from 18% to 10% (a decrease of 44.4%) after carbonation treatment. The working performance and 28 days compressive strength of recycled aggregate concrete was improved when the recycled aggregate was pretreated by carbonation (Zhang et al., 2015; Tam et al., 2016; Xuan et al., 2017b; Luo et al., 2018; Lu et al., 2019), followed by a decrease in the corrosion resistance (Poursaee and Hansson, 2007; De Weerdt et al., 2019).

3.2 Influence of strengthening methods on performance of recycled aggregate

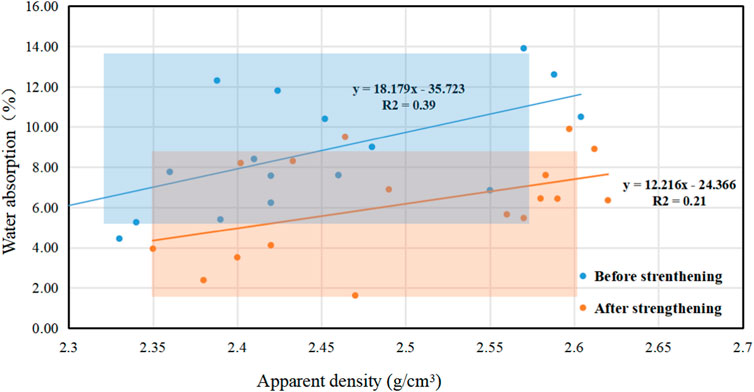

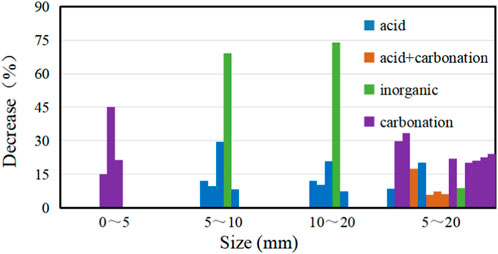

Performance indicators of recycled aggregate before and after strengthening are shown in Table 2. The relationship between apparent density and water absorption of recycled aggregate can be seen in Figure 1. The apparent density showed an approximate linear relationship with water absorption of recycled aggregate. The apparent density increased after strengthening, while water absorption decreased. The untreated recycled aggregate (the blue region in Figure 1) showed a higher water absorption compared to the strengthened recycled aggregate (the orange region in Figure 1). The strengthening effects of water absorption, crushing value, and apparent density of recycled aggregate can be found in Figures 2–4. The treatment methods of inorganic material filling and carbonation showed an obvious effect for decreasing the water absorption. The crushing value of recycled aggregate showed a sharp decrease after carbonation strengthening. The treatment methods of inorganic material filling and acid treatment are effective in increasing the apparent density of recycled aggregate.

3.2.1 Effect of inorganic material filling on properties of recycled aggregate

Strengthening methods such as silica slurry, cement slurry, polyvinyl alcohol (PVA), and modified adhesive fine powder fill and reinforce the surface of aggregates. As shown in Figures 2, 4, a PVA coating method lead to an increase of 69.3% and 74.0% in the water absorption rate of 5–10 mm and 10–20 mm recycled aggregates, respectively, corresponding a decrease in the apparent density of 0.85% and 2.07%, respectively. This indicates that PVA can minimize water absorption rate but has a minimal impact on improving the apparent density. The hydrophobic filler material forms a water-repellent layer on the surface of the aggregate. Therefore, the measured water absorption rate represents the surface value of the strengthened recycled aggregate. Refer to Figure 5A for more specific details on the strengthening process.

3.2.2 Effect of acid treatment on properties of recycled aggregate

The water absorption of recycled aggregates with particle size ranges of 5–10 mm and 10–20 mm decreased about 12% and 10%, respectively, as shown in Figure 2. The apparent density of recycled aggregates with particle size ranges of 5–10 mm and 10–20 mm increased by 5.38% and 3.00%, respectively, as shown in Figure 4. This indicates that acid treatment can effectively remove the bonding mortar on the surface of the recycled aggregates. Refer to Figure 5B for more specific details on the strengthening process. The apparent density of recycled aggregates is related to the water-cement ratio and mineral admixture dosage of the original concrete, indicating that the properties of adhesive mortar on the surface of aggregates showed key role in determining the water absorption and apparent density (Etxeberria et al., 2007b). The content of adhesive mortar increased as the particle size of recycled aggregate decreased (Nassar and Soroushian, 2012; Suryawanshi et al., 2015). This is the main reason for the better improvement effect of 5–10 mm recycled aggregates after acid treatment compared to that of 10–20 mm aggregates. Therefore, recycled aggregate with a particle range of 5–10 mm is suitable for acid treatment.

3.2.3 Effect of carbonation treatment on properties of recycled aggregate

Figure 6 shows the relationship between the apparent density and water absorption of recycled aggregates before and after carbonation. It shows that the apparent density and water absorption of untreated recycled aggregate with a particle size of 5–20 mm were 2.55–2.60 g/cm3 and 6.9%–13.9%, respectively, which changes into 2.56–2.62 g/cm3 and 5.5%–9.9% after strengthening. The apparent density and water absorption of untreated recycled aggregate with a particle size of 0–5 mm were 2.39–2.45 g/cm3 and 10.4%–12.3%, respectively, which changes into 2.40–2.46 g/cm3 and 8.2%–9.5% after strengthening. This indicates that the apparent density showed a little change but the water absorption decreased significantly after carbonation. The water absorption of recycled aggregates with an apparent density of less than 2.42 g/cm3 and more than 2.57 g/cm3 was reduced by about 3.5%. The crushed value of recycled aggregates with a particle size of 0–5 mm is reduced from 18% to 10% (a decrease of 44.4%) after carbonation, as shown in reference (Pan et al., 2017). This shows that carbonation can effectively reduce the crushing index of recycled aggregate and the internal porosity of aggregates (Fang and Chang, 2015; Jang and Lee, 2016; Liang et al., 2019). Refer to Figure 5C for more specific details on the strengthening process. Therefore, recycled aggregates with a particle size of 0–5 mm should be treated by carbonation strengthening.

3.3 Relationship between particle size and strengthening methods of recycled aggregates

It can be concluded that: 1) Recycled aggregates with a particle size of more than 5 mm should be treated by an inorganic material filling process, which significantly decreased the water absorption; 2) Recycled aggregates with a particle size of less than 5 mm should be treated by a carbonation process, which effectively decreased the water absorption and crushing value; 3) Recycled aggregates with a particle size of 5–10 mm should be treated by an acid treatment, and the effect of acid treatment on apparent density and water absorption is related to the content of adhesive mortar on the surface of recycled aggregates.

4 Classification of recycled aggregate

In addition to surface adhesion mortar of aggregates (Liu et al., 2019; Nie et al., 2019), recycled aggregates of different particle sizes have significantly different performance compared to nature aggregates. For example, recycled aggregates with a particle size 0–5 mm shows a good crushing value after carbonation treatment. Recycled aggregates with a particle size of 10–20 mm shows a good apparent density and crushing value after direct crushing. Recycled aggregates with a particle size of 5–10 mm shows a good crushing value. The different characteristic of particle sizes should be taken into consideration for the better utilization of recycled aggregates. Recycled aggregates can be divided into three scales: fine powder aggregate (particle size less than 5 mm), fine aggregate (particle size of 5–10 mm), and coarse aggregate (particle size of 10–20 mm) for the multi-scale hierarchical utilization.

5 Reclassification and reuse of recycled aggregates

5.1 Fine powder aggregate and fine aggregate

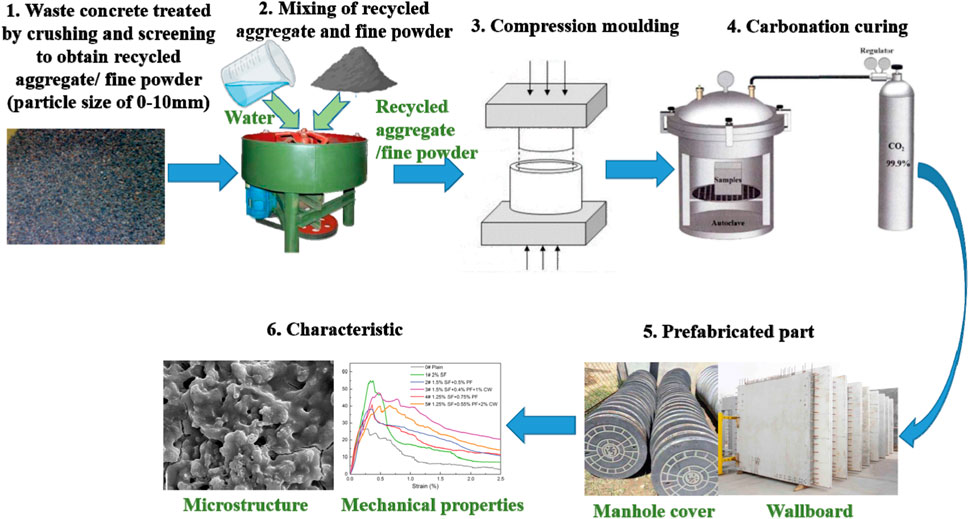

Recycled fine powder aggregate contains high weight of adhered mortar, resulting in a high water absorption rate and low apparent density that is markedly different from natural aggregates. This recycled fine powder shows a high carbonation activity, which can be used to prepare pre-products such as sound insulation board, heat insulation board and small block by a carbonation process, as shown in Figure 7. These products were prepared using Recycled fine powder aggregate via a compression moulding method. The strength of pre-products can be significantly improved during the carbonation process.

5.2 Coarse aggregate

Coarse aggregate is a viable coarse aggregate for recycled concrete, as its water absorption rate and apparent density are comparable to those of natural aggregates, and it contains a small amount of bonding mortar. However, the content of adhered mortar on the surface of the aggregate is a crucial factor affecting the workability, mechanical properties, and durability of freshly mixed and hardened concrete.

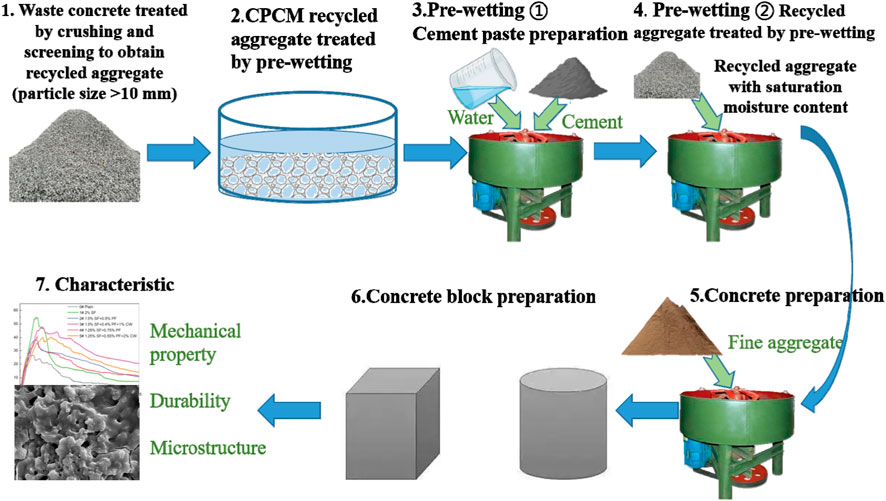

Therefore, the method of digital image (Gu et al., 2014) is selected to divide and label mortar and aggregate based on color differences, and quantify the mortar adhesion rate and shape coefficient of recycled coarse aggregate were quantified., the shape coefficient is used to match the natural aggregate, as shown in Figure 8 when the mortar adhesion rate does not exceed 30%. When the adhesion rate of mortar exceeds 30%, the adhesion rate of mortar is reduced by two times of “low-temperature heating—particle molding.” The recycled aggregate should be soaked and dried by CPCM (cement based permeable material) before preparing recycled aggregate concrete if this two times treatment was not enough. It is necessary to mix the cement slurry first, and then add other aggregates. It should be noted that the recycled aggregates should be pre-wet, as shown in Figure 9.

A multi-scale classification method for utilization of recycled aggregate was proposed in this study, and has the following advantages compared with previous studies: 1) Increase the level of recycling utilization of RA; 2) An appropriate strengthening method was chosen according to the particle size of RA; 3) Utilization the best performance of RA.

6 Results

A review regarding researches on the utilization of recycled aggregates was conducted in this paper. The effects of reinforcement technology on the performance of recycled aggregates were summarized. The relationship between various reinforcement technologies and particle size of aggregates was reported. The main findings are as follows:

(1) For directly crushed recycled aggregates, the optimal particle size range for apparent density and water absorption rate is between 10 and 16 mm.

(2) Recycled aggregates with a particle size of more than 5 mm should be treated by an inorganic material filling process, which significantly decreased the water absorption. Recycled aggregates with a particle size of less than 5 mm should be treated by a carbonation process, which effectively decreased the water absorption and crushing value. Recycled aggregates with a particle size of 5–10 mm should be treated by an acid treatment, and the effect of acid treatment on apparent density and water absorption is related to the content of adhesive mortar on the surface of recycled aggregates.

(3) According to the performance advantages of the recycled aggregates before and after strengthening, it is re-classified, mainly including three scales of recycled fine powder, mortar aggregate, and bonded mortar aggregate. The recycled fine powder can be directly prepared products after carbonation treatment. Mortar aggregate has better water absorption and more internal pores after inorganic material filling or acid treatment, which can be used as the aggregate of soundproof board, heat insulation board, and other prefabricated boards. The binder mortar aggregate has similar water absorption, apparent density and crushing value to the natural aggregate, and can directly replace the natural aggregate to produce recycled aggregate concrete. The multi-scale grading utilization of recycled aggregate can be realized.

7 Future work

A classifying and utilizing method for recycled aggregate was proposed according its particle size in this study for a higher utilization level of construction waste. However, a specific replacement rate of RA cannot be provided during the classification and utilization, and the process parameters should to be further confirmed. Therefore, a combined method of experiment and simulation should be conducted in the subsequent research to determine the replacement rate and process parameters.

Author contributions

QF and DW contributed to the conception of the study; QF, BL, and YZ contributed significantly to analysis and manuscript writing with constructive discussions; QF and CZ performed the data analyses. All authors contributed to the article and approved the submitted version.

Funding

This work was financed by the Nanning innovation and entrepreneurship leading talents “Yongjiang plan” funded project (2019009), and Hainan Provincial Natural Science Foundation of China (522QN279).

Conflict of interest

QF, BL, YZ, CZ were employed by Guangxi Transportation Science and Technology Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Afroughsabet, V., Biolzi, L., and Ozbakkaloglu, T. (2017). Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 181, 273–284. doi:10.1016/j.compstruct.2017.08.086

Ajayi, S. O., Oyedele, L. O., Akinade, O. O., Bilal, M., Owolabi, H. A., Alaka, H. A., et al. (2016). Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 5, 185–193. doi:10.1016/j.jobe.2015.12.007

Akbarnezhad, A., Ong, K. C. G., Zhang, M. H., Tam, C. T., and Foo, T. W. J. (2011). Microwaveassisted beneficiation of recycled concrete aggregates. Constr. Build. Mat. 25, 3469–3479. doi:10.1016/j.conbuildmat.2011.03.038

Al-Bayati, H. K. A., Das, P. K., Tighe, S. L., and Baaj, H. (2016). Evaluation of various treatment methods for enhancing the physical and morphological properties of coarse recycled concrete aggregate. Constr. Build. Mat. 112, 284–298. doi:10.1016/j.conbuildmat.2016.02.176

Arezoumandi, M., Smith, A., Volz, J. S., and Khayat, K. H. (2015). An experimental study on flexural strength of reinforced concrete beams with 100% recycled concrete aggregate. Eng. Struct. 88, 154–162. doi:10.1016/j.engstruct.2015.01.043

Braga, A. M., Silvestre, J. D., and de Brito, J. (2017). Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 162, 529–543. doi:10.1016/j.jclepro.2017.06.057

Butler, L. J., West, J. S., and Tighe, S. L. (2014). Towards the classification of recycled concrete aggregates: Influence of fundamental aggregate properties on recycled concrete performance. J. Sustain. cem.-based Mat. 3, 140–163. doi:10.1080/21650373.2014.909752

Chinzorigt, G., Lim, M. K., Yu, M., Lee, H., Enkbold, O., and Choi, D. (2020). Strength, shrinkage and creep and durability aspects of concrete including CO2 treated recycled fine aggregate. Cem. Concr. Res. 136, 106062. doi:10.1016/j.cemconres.2020.106062

Cho, S., Kim, K., Seon, S., and Park, J. (2021). A study on aggregate waste separation efficiency using adsorption system with rotating separation net. J. Korean Recycl. Constr. Resour. Inst. 9, 85–91. doi:10.14190/JRCR.2021.9.1.85

Choi, H., Choi, H., Lim, M., Inoue, M., Kitagaki, R., and Noguchi, T. (2016). Evaluation on the mechanical performance of low-quality recycled aggregate through interface enhancement between cement matrix and coarse aggregate by surface modification technology. Int. J. Concr. Struct. Mat. 10, 87–97. doi:10.1007/s40069-015-0124-5

Choi, W. Y., Lee, S. H., and Kim, S. H. (2017). A comparative study on the quality of recycled aggregate for concrete by crushing method. J. Korean Recycl. Constr. Resour. Inst. 5, 121–129. doi:10.14190/JRCR.2017.5.2.121

de Juan, M. S., and Gutiérrez, P. A. (2009). Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mat. 23, 872–877. doi:10.1016/j.conbuildmat.2008.04.012

De Weerdt, K., Plusquellec, G., Belda Revert, A., Geiker, M. R., and Lothenbach, B. (2019). Effect of carbonation on the pore solution of mortar. Cem. Concr. Res. 118, 38–56. doi:10.1016/j.cemconres.2019.02.004

Dilbas, H., Çakır, Ö., and Atiş, C. D. (2019). Experimental investigation on properties of recycled aggregate concrete with optimized ball milling method. Constr. Build. Mat. 212, 716–726. doi:10.1016/j.conbuildmat.2019.04.007

Dimitriou, G., Savva, P., and Petrou, M. F. (2018). Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mat. 158, 228–235. doi:10.1016/j.conbuildmat.2017.09.137

Duan, Z. H., and Poon, C. S. (2014). Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mat. Eng. 58, 19–29. doi:10.1016/j.matdes.2014.01.044

El-Hawary, M., Al-Yaqout, A., and Elsayed, K. (2021). Freezing and thawing cycles: Effect on recycled aggregate concrete including slag. Int. J. Sustain. Eng. 14, 800–808. doi:10.1080/19397038.2021.1886374

Esmaeeli, H. S., Shishehbor, M., Weiss, W. J., and Zavattieri, P. D. (2019). A two-step multiscale model to predict early age strength development of cementitious composites considering competing fracture mechanisms. Constr. Build. Mat. 208, 577–600. doi:10.1016/j.conbuildmat.2019.02.134

Etxeberria, M., Vázquez, E., Marí, A., and Barra, M. (2007a). Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 37, 735–742. doi:10.1016/j.cemconres.2007.02.002

Etxeberria, M., Vazquez, E., Marí, A., and Barra, M. (2007b). Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 37 (5), 735–742. doi:10.1016/j.cemconres.2007.02.002

Etxeberria, M., Vázquez, E., and Marí, A. (2006). Microstructure analysis of hardened recycled aggregate concrete. Mag. Concr. Res. 58, 683–690. doi:10.1680/macr.2006.58.10.683

Eurostat, (2018). CO2 emissions in the EU decreased compared with 2017 . Belgium: European Comission: Bruselss.

Eurostat, (2017). CO2 emissions in the EU estimated to have increased compared with 2016 . Belgium: European Comission: Bruselss.

Evangelista, L., and Guedes, M. (2019). “Microstructural studies on recycled aggregate concrete,” in New trends in eco-efficient and recycled concrete (Amsterdam, Netherlands: Elsevier), 425–451.

Evangelista, L., Guedes, M., de Brito, J., Ferro, A. C., and Pereira, M. F. (2015). Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mat. 86, 178–188. doi:10.1016/j.conbuildmat.2015.03.112

Fan, Y., Niu, H., and Zhang, X. (2020). Impact of the properties of old mortar on creep prediction model of recycled aggregate concrete. Constr. Build. Mat. 239, 117772. doi:10.1016/j.conbuildmat.2019.117772

Fan, Y., Xiao, J., and Tam, V. W. Y. (2014). Effect of old attached mortar on the creep of recycled aggregate concrete. Struct. Concr. 15, 169–178. doi:10.1002/suco.201300055

Fang, H.-Y., Liu, F.-L., and Yang, J.-H. (2020). High-quality coarse aggregate recycling from waste concrete by impact crushing. J. Mat. Cycles Waste Manag. 22, 887–896. doi:10.1007/s10163-020-00984-w

Fang, Y., and Chang, J. (2015). Microstructure changes of waste hydrated cement paste induced by accelerated carbonation. Constr. Build. Mat. 76, 360–365. doi:10.1016/j.conbuildmat.2014.12.017

Feng, P., Chang, H., Xu, G., Liu, Q., Jin, Z., and Liu, J. (2019). Feasibility of utilizing recycled aggregate concrete for revetment construction of the lower yellow river. Mater. (Basel) 12, 4237. doi:10.3390/ma12244237

Feng, Z., Zhao, Y., Zeng, W., Lu, Z., and Shah, S. P. (2020). Using microbial carbonate precipitation to improve the properties of recycled fine aggregate and mortar. Constr. Build. Mat. 230, 116949. doi:10.1016/j.conbuildmat.2019.116949

Florea, M. V. A., Ning, Z., and Brouwers, H. J. H. (2014). Activation of liberated concrete fines and their application in mortars. Constr. Build. Mat. 50, 1–12. doi:10.1016/j.conbuildmat.2013.09.012

Fumoto, T., Imose, Y., and Yamada, M. (2000). Effects of improving recycled fine aggregate by ball. Mill. Mem. Fac. Eng. Osaka City Univ. 4, 65–72.

Gholampour, A., and Ozbakkaloglu, T. (2018). Time-dependent and long-term mechanical properties of concretes incorporating different grades of coarse recycled concrete aggregates. Eng. Struct. 157, 224–234. doi:10.1016/j.engstruct.2017.12.015

Gholizadeh-Vayghan, A., Bellinkx, A., Snellings, R., Vandoren, B., and Quaghebeur, M. (2020). The effects of carbonation conditions on the physical and microstructural properties of recycled concrete coarse aggregates. Constr. Build. Mat. 257, 119486. doi:10.1016/j.conbuildmat.2020.119486

Gokce, A., Nagataki, S., Saeki, B., and Hisada, M. (2011). Identification of frost-susceptible recycled concrete aggregates for durability of concrete. Constr. Build. Mat. 25 (5), 2426–2431. doi:10.1016/j.conbuildmat.2010.11.054

Gokce, A., Nagataki, S., Saeki, T., and Hisada, M. (2004). Freezing and thawing resistance of airentrained concrete incorporating recycled coarse aggregate: The role of air content in demolished concrete. Cem. Concr. Res. 34, 799–806. doi:10.1016/j.cemconres.2003.09.014

Gu, X., Tran, Y., and Hong, L. (2014). Quantification of coarse aggregate shape in concrete. Front. Struct. Civ. Eng. 8, 308–321. doi:10.1007/s11709-014-0266-6

Habibi, A., Ramezanianpour, A. M., Mahdikhani, M., and Bamshad, O. (2021). RSM-based evaluation of mechanical and durability properties of recycled aggregate concrete containing GGBFS and silica fume. Constr. Build. Mat. 270, 121431. doi:10.1016/j.conbuildmat.2020.121431

Hideo, K., Yosihiro, M., Toshiyuki, I., Hisashi, T., Hisanobu, A., Takafumi, N., et al. “Research and standardization of high-quality recycled aggregates for concrete in nuclear power plants,” in Proceedings of the 25th Conf. Struct. Mech. React. Technol., IASMiRT, Charlotte, NC, USA, August 2019.

Ismail, S., and Ramli, M. “Effect surface treatment of recycled concrete aggregate on properties of fresh and hardened concrete,” in Proceedings of the 2013 IEEE Business Engineering and Industrial Applications Colloquium (BEIAC), Langkawi, Malaysia, April 2013, 651–656.

Ismail, S., and Ramli, M. (2013a). Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mat. 44, 464–476. doi:10.1016/j.conbuildmat.2013.03.014

Jang, J. G., and Lee, H. K. (2016). Microstructural densification and CO2 uptake promoted by the carbonation curing of belite-rich portland cement. Cem. Concr. Res. 82, 50–57. doi:10.1016/j.cemconres.2016.01.001

Jiménez, J. R., Fernández-Ledesma, E., Ayuso, J., Corinaldesi, V., and Iglesias-Godino, F. J. (2016). A proposal for the maximum use of recycled concrete sand in masonry mortar design. Mat. Constr. 66, e075. doi:10.3989/mc.2016.08414

Katz, A. (2004). Treatments for the improvement of recycled aggregate. J. Mat. Civ. Eng. 6, 597–603. doi:10.1061/(asce)0899-1561(2004)16:6(597)

Kazmi, S. M. S., Munir, M. J., Wu, Y.-F., Patnaikuni, I., Zhou, Y., and Xing, F. (2020). Effect of different aggregate treatment techniques on the freeze-thaw and sulfate resistance of recycled aggregate concrete. Cold Reg. Sci. Technol. 178, 103126. doi:10.1016/j.coldregions.2020.103126

Kim, N., Kim, J., and Yang, S. (2016). Mechanical strength properties of RCA concrete made by a modified EMV method. Sustainability 8, 924. doi:10.3390/su8090924

Kou, S.-C., and Poon, C.-S. (2010). Properties of concrete prepared with PVA-impregnated recycled concrete aggregates. Cem. Concr. Compos. 32, 649–654. doi:10.1016/j.cemconcomp.2010.05.003

Kou, S.-C., Zhan, B.-J., and Poon, C.-S. (2014). Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates. Cem. Concr. Compos. 45, 22–28. doi:10.1016/j.cemconcomp.2013.09.008

Liang, C., Lu, N., Ma, H., Ma, Z., and Duan, Z. (2020). Carbonation behavior of recycled concrete with CO2-curing recycled aggregate under various environments. J. CO2 Util. 39, 101185. doi:10.1016/j.jcou.2020.101185

Liang, C., Ma, H., Pan, Y., Ma, Z., Duan, Z., and He, Z. (2019). Chloride permeability and the caused steel corrosion in the concrete with carbonated recycled aggregate. Constr. Build. Mat. 218, 506–518. doi:10.1016/j.conbuildmat.2019.05.136

Liang, Y.-C., Ye, Z.-M., Vernerey, F., and Xi, Y. (2015). Development of processing methods to improve strength of concrete with 100% recycled coarse aggregate. J. Mat. Civ. Eng. 27, 04014163. doi:10.1061/(asce)mt.1943-5533.0000909

Liu, C., Fan, J. C., Bai, G. L., Quan, Z. G., Fu, G. M., Zhu, C., et al. (2019). Cyclic load tests and seismic performance of recycled aggregate concrete (RAC) columns. Constr. Build. Mat. 195, 682–694. doi:10.1016/j.conbuildmat.2018.10.078

Lu, B., Shi, C., Cao, Z., Guo, M., and Zheng, J. (2019). Effect of carbonated coarse recycled concrete aggregate on the properties and microstructure of recycled concrete. J. Clean. Prod. 233, 421–428. doi:10.1016/j.jclepro.2019.05.350

Luo, S., Ye, S., Xiao, J., Zheng, J., and Zhu, Y. (2018). Carbonated recycled coarse aggregate and uniaxial compressive stress-strain relation of recycled aggregate concrete. Constr. Build. Mat. 188, 956–965. doi:10.1016/j.conbuildmat.2018.08.159

McGinnis, M. J., Davis, M., de la Rosa, A., Weldon, B. D., and Kurama, Y. C. (2017). Strength and stiffness of concrete with recycled concrete aggregates. Constr. Build. Mat. 154, 258–269. doi:10.1016/j.conbuildmat.2017.07.015

Mi, R., Liew, K. M., Pan, G., and Kuang, T. (2021). Carbonation resistance study and inhomogeneity evolution of recycled aggregate concretes under loading effects. Cem. Concr. Compos. 118, 103916. doi:10.1016/j.cemconcomp.2020.103916

Nagataki, S., Gokce, A., Saeki, T., and Hisada, M. (2004). Assessment of recycling process induced damage sensitivity of recycled concrete aggregates. Cem. Concr. Res. 34, 965–971. doi:10.1016/j.cemconres.2003.11.008

Nassar, R.-U.-D., and Soroushian, P. (2012). Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mat. 29, 368–377. doi:10.1016/j.conbuildmat.2011.10.061

Nie, Xingxin, Feng, Shanshan, Zhang, Shudu, and Gan, Quan (2019). Simulation study on the dynamic ventilation control of single head roadway in high-altitude mine based on thermal comfort. Adv. Civ. Eng. 2019, 1–12. doi:10.1155/2019/2973504

Ossa, A., García, J. L., and Botero, E. (2016). Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 135, 379–386. doi:10.1016/j.jclepro.2016.06.088

Otsuki, N., Miyazato, S.-I., and Yodsudjai, W. (2003). Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. J. Mat. Civ. Eng. 15, 443–451. doi:10.1061/(asce)0899-1561(2003)15:5(443)

Pan, G., Zhan, M., Fu, M., Wang, Y., and Lu, X. (2017). Effect of CO 2 curing on demolition recycled fine aggregates enhanced by calcium hydroxide pre-soaking. Constr. Build. Mat. 154, 810–818. doi:10.1016/j.conbuildmat.2017.07.079

Pandurangan, K., Dayanithy, A., and Om Prakash, S. (2016). Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mat. 120, 212–221. doi:10.1016/j.conbuildmat.2016.05.093

Pawluczuk, E., Kalinowska-Wichrowska, K., Bołtryk, M., Jiménez, J. R., and Fernández, J. M. (2019). The influence of heat and mechanical treatment of concrete rubble on the properties of recycled aggregate concrete. Mater. (Basel) 12, 367. doi:10.3390/ma12030367

Pierrehumbert, R. (2019). There is No plan B for dealing with the climate crisis. Bull. At. Sci. 75, 215–221. doi:10.1080/00963402.2019.1654255

Poon, C. S., Shui, Z. H., Lam, L., Fok, H., and Kou, S. C. (2004). Influence of moisture States of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 34, 31–36. doi:10.1016/s0008-8846(03)00186-8

Poursaee, A., and Hansson, C. M. (2007). Reinforcing steel passivation in mortar and pore solution. Cem. Concr. Res. 37, 1127–1133. doi:10.1016/j.cemconres.2007.04.005

Pradhan, S., Kumar, S., and Barai, S. V. (2020). Multi-scale characterisation of recycled aggregate concrete and prediction of its performance. Cem. Concr. Compos. 106, 103480. doi:10.1016/j.cemconcomp.2019.103480

Quattrone, M., Angulo, S. C., and John, V. M. (2014). Energy and CO2 from high performance recycled aggregate production. Resour. Conserv. Recycl. 90, 21–33. doi:10.1016/j.resconrec.2014.06.003

Salahuddin, H., Nawaz, A., Maqsoom, A., Mehmood, T., and Zeeshan, B. ul A. (2019). Effects of elevated temperature on performance of recycled coarse aggregate concrete. Constr. Build. Mat. 202, 415–425. doi:10.1016/j.conbuildmat.2019.01.011

Sasanipour, H., and Aslani, F. (2020). Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mat. 236, 117540. doi:10.1016/j.conbuildmat.2019.117540

Sasanipour, H., Aslani, F., and Taherinezhad, J. (2021). Chloride ion permeability improvement of recycled aggregate concrete using pretreated recycled aggregates by silica fume slurry. Constr. Build. Mat. 270, 121498. doi:10.1016/j.conbuildmat.2020.121498

Sidorova, A., Vazquez-Ramonich, E., Barra-Bizinotto, M., Roa-Rovira, J. J., and Jimenez-Pique, E. (2014). Study of the recycled aggregates nature’s influence on the aggregate–cement paste interface and ITZ. Constr. Build. Mat. 68, 677–684. doi:10.1016/j.conbuildmat.2014.06.076

Suryawanshi, S. R., Singh, B., and Bhargava, P. (2015). Characterization of recycled aggregate concrete. Adv. Struct. Eng. , 1813–1822.

Tam, V. W. Y., Butera, A., and Le, K. N. (2016). Carbon-conditioned recycled aggregate in concrete production. J. Clean. Prod. 133, 672–680. doi:10.1016/j.jclepro.2016.06.007

Tam, V. W. Y., Tam, C. M., and Le, K. N. (2007). Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 50, 82–101. doi:10.1016/j.resconrec.2006.05.012

Toghroli, A., Mehrabi, P., Shariati, M., Trung, N. T., Jahandari, S., and Rasekh, H. (2020). Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mat. 252, 118997. doi:10.1016/j.conbuildmat.2020.118997

Vegas, I., Broos, K., Nielsen, P., Lambertz, O., and Lisbona, A. (2015). Upgrading the quality of mixed recycled aggregates from construction and demolition waste by using near-infrared sorting technology. Constr. Build. Mat. 75, 121–128. doi:10.1016/j.conbuildmat.2014.09.109

Wang, L., Wang, J., Qian, X., Chen, P., Xu, Y., and Guo, J. (2017). An environmentally friendly method to improve the quality of recycled concrete aggregates. Constr. Build. Mat. 144, 432–441. doi:10.1016/j.conbuildmat.2017.03.191

Won, C., and Park, S. J. (2010). The material properties on the crushing effect of recycled aggregates. J. Korean Recycl. Constr. Resour. Inst. 5, 125–130.

Wu, H., Zuo, J., Zillante, G., Wang, J., and Yuan, H. (2019). Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 240, 118163. doi:10.1016/j.jclepro.2019.118163

Xiao, J., Ma, Z., Sui, T., Akbarnezhad, A., and Duan, Z. (2018). Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 188, 720–731. doi:10.1016/j.jclepro.2018.03.277

Xie, J. H., Guo, Y. C., Liu, L. S., and Xie, Z. H. (2015). Compressive and flexural behaviours of a new steel-fibre-reinforced recycled aggregate concrete with crumb rubber. Constr. Build. Mat. 79, 263–272. doi:10.1016/j.conbuildmat.2015.01.036

Xuan, D., Zhan, B., and Poon, C. S. (2017a). Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 84, 214–221. doi:10.1016/j.cemconcomp.2017.09.015

Xuan, D., Zhan, B., and Poon, C. S. (2017b). Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 84, 214–221. doi:10.1016/j.cemconcomp.2017.09.015

Yang, S., and Lee, H. (2017). Mechanical properties of recycled aggregate concrete proportioned with modified equivalent mortar volume method for paving applications. Constr. Build. Mat. 136, 9–17. doi:10.1016/j.conbuildmat.2017.01.029

Yonezawa, T., Kamiyama, Y., Yanagibashi, K., Kojima, M., Arakawa, K., and Yamada, M. (2001). Structural materials. A study on a technology for producing high quality recycled coarse aggregate. J. Soc. Mat. Sci. Jpn. 50, 835–842. doi:10.2472/jsms.50.835

Zaben, A., Maslehuddin, M., Al-Amoudi, O. S. B., and Al-Dulaijan, S. U. (2021). Influence of mix composition on the properties of recycled aggregate concrete. Struct. Concr. 22, 2939–2951. doi:10.1002/suco.202000062

Zhan, B., Poon, C. S., Liu, Q., Kou, S., and Shi, C. (2014). Experimental study on CO2 curing for enhancement of recycled aggregate properties. Constr. Build. Mat. 67, 3–7. doi:10.1016/j.conbuildmat.2013.09.008

Zhang, J., Shi, C., Li, Y., Pan, X., Poon, C.-S., and Xie, Z. (2015). Influence of carbonated recycled concrete aggregate on properties of cement mortar. Constr. Build. Mat. 98, 1–7. doi:10.1016/j.conbuildmat.2015.08.087

Keywords: fine powder aggregate, fine aggregate, coarse aggregate, strengthening, grading utilization

Citation: Feng Q, Liu B, Zhang Y, Zhang C and Wang D (2023) Multi-scale grading utilization based on the characteristics of recycled concrete aggregates: a review. Front. Mater. 10:1219075. doi: 10.3389/fmats.2023.1219075

Received: 08 May 2023; Accepted: 10 July 2023;

Published: 26 July 2023.

Edited by:

Jing Yu, Sun Yat-sen University, ChinaReviewed by:

Yiren Wang, Dongguan University of Technology, ChinaPing Duan, China University of Geosciences Wuhan, China

Jie Ren, University of Colorado Boulder, United States

Copyright © 2023 Feng, Liu, Zhang, Zhang and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dan Wang, d2FuZ2RfZGx1dEAxNjMuY29t

Qi Feng

Qi Feng Binqing Liu1

Binqing Liu1