- 1School of Housing, Building and Planning, Universiti Sains Malaysia, Penang, Malaysia

- 2Disaster Management Institute (DMI), School of Technology Management and Logistics, Universiti Utara Malaysia, Sintok, Kedah, Malaysia

- 3Department of Construction Management, Faculty of Technology Management and Business (FPTP), Universiti Tun Hussein Onn Malaysia (UTHM), Parit Raja, Malaysia

- 4Department of Civil Engineering, University of Warith Al-Anbiyaa, Karbala, Iraq

- 5School of Civil Engineering and Built Environment, Liverpool John Moores University, Liverpool, UK, United States

- 6Department of Civil Engineering, Zakir Husain Engineering College, Aligarh Muslim University, Aligarh, India

- 7Department of Civil Engineering, College of Engineering, University of Duhok, Duhok, Iraq

- 8Peter the Great St. Petersburg Polytechnic University, St Petersburg, Russia

The use of foamed concrete (FC) in the construction sector has been rapidly growing over the past few years as a result of the several advantages it possesses in comparison to traditional high-strength concrete. FC, on the other hand, suffers from a number of deficiencies, such as brittleness, limited ductility, high porosity, excessive drying shrinkage, little resistance to cracking and deformation. To improve the tensile strength and fracture resistance of FC, engineers usually opt for steel fibre or polymer fibre as the reinforcement material of choice. Hence this research aims to investigate the potential utilization of synthetic twisted bundle macro-fibers (SF) in FC to enhance its durability, mechanical and thermal properties. The SF were included in the FC in varied amounts of weight fractions, including 0%, 1%, 2%, 3%, 4%, and 5% respectively. FC was produced at three low densities, precisely 1,000, 1,300, and 1,600 kg/m3, which were all prepared. Compression, flexural, splitting tensile, flow table, porosity, water absorption and thermal conductivity tests were conducted to establish the thermal, mechanical and durability properties of SF-reinforced FC. The findings imply that the integration of SF into FC results in a significant enhancement of the material’s strength and thermal conductivity properties while simultaneously lowering the material’s capacity for water absorption and porosity. For the purpose of improving the material’s mechanical, durability and thermal properties, the weight percentage of SF that was ideal ranged from 3% to 4%. The incorporation of SF into FC resulted in a rise in the material’s ductility, and the specimens maintained their integrity from the loading stage to failure. The SF is able to lessen the cracks that were already present in the FC and prevent the formation of additional cracks in the FC.

1 Introduction

These days, foamed concrete (FC) is one of the most extensively employed materials owing to its distinctive properties (Mydin et al., 2014a; Nawi et al., 2018; Chica and Alzate, 2019). FC offers various benefits over normal-strength concrete, including lower self-weight, rapid production and high sound insulation and absorption capacities (Ganesan et al., 2014; Saeed et al., 2022a; Zeybek et al., 2022). FC has a high workability and is a lightweight composite (Amran et al., 2016; Qaidi et al., 2022a; Saeed et al., 2022b). A pre-foam is inserted in preparation for FC, creating a network of voids inside the FC-hardened composite (Mugahed Amran et al., 2018). However, FC is prone to fractures and cracks because it has fairly minimal failure strain. Foamed concrete (FC) is considerably more fragile and possesses a low bending performance contrasted to other materials like normal-weight concrete, metals and polymers (Mohamad et al., 2018; Qaidi et al., 2022b; Martínez-García et al., 2022). When compared to FC in terms of fracture toughness, steel is at least one hundred fifty times more resistant to crack propagation. As a consequence, cracks may often appear in FC that have been put into use, allowing harmful substances to readily penetrate the material and cause premature saturation (Serri et al., 2015; Maglad et al., 2022; Çelik et al., 2022).

However, because of several flaws, most notably brittleness, reduced strength, and a poor capacity to manage fractures, the development of FC in building construction has been constrained. FC’s usage is restricted to non-structural applications because of its weak mechanical and physical qualities (Castillo-Lara et al., 2020; Ahmed et al., 2021; Althoey et al., 2022). Reinforcing FC using polymer fibres of different materials reduces the concerns and uncertainties associated with its weak fracture toughness (Pakravan et al., 2017). Natural fibre-reinforced FC describes the resultant material, which has a random distribution of small, discontinuous fibres, and is gradually becoming a widely recognised mainstream building medium (Wan Ibrahim et al., 2014). When synthetic fibres are evenly dispersed throughout a quantity of FC, the weak matrix in the FC is greatly strengthened, and the concrete begins to act more like a composite material with quite different qualities than unreinforced FC (Mydin et al., 2014b; Ahmed et al., 2021; Althoey et al., 2022; Tayeh et al., 2022a; Unis Ahmed et al., 2022).

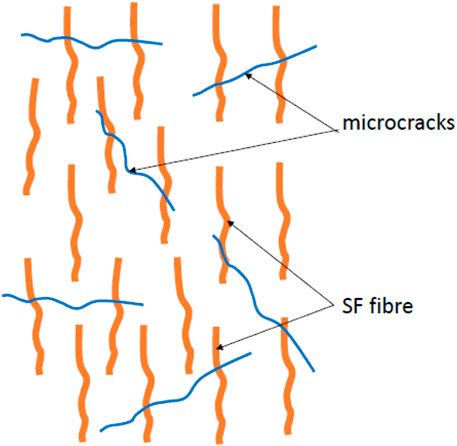

Synthetic fibre may be utilized reasonably and beneficially in several contexts due to the substantial enhancements gained by the presence of fibres in concrete for properties enhancement (Tayeh et al., 2022b; Qaidi et al., 2022c). Many major building projects around the world have already made use of these polymer fibres in the form of cladding, highway intersections, plank, paving and others. These fibres are a viable alternative to reinforcing steel structures and are also employed in the manufacturing of continuous fibres (Yap et al., 2014). The process of fracture in FC is a multi-scale process, beginning with the initiation and propagation of micro-cracks and progressing all the way up to macro-cracks (Murad et al., 2019; Al-Faqra et al., 2021). The inclusion of synthetic fibres that have a diameter that is on the smaller side and an aspect ratio that is on the larger side has a greater impact on limiting the initiation, extension, and coalescence of micro-cracks that occur as a result of stress. However, the use of an excessive amount of synthetic fibres in FC might result in poor adherence to the matrix, which could cause the pulling out and spread of macro cracks in FC cementitious composites (Akil et al., 2011; Tayeh et al., 2022c; Qaidi et al., 2022d; Qaidi et al., 2022e).

A great number of investigations were executed in order to enhance the FC’s mechanical properties. The findings shown that the incorporation of synthetic fibres in a random distribution may significantly enhance the flexural and tensile strengths, toughness, and impact resistance of FC (Ramezanianpour et al., 2013). The efficacy of the enhancement varies depending on the material of the fibres, the geometry of the fibres, the distribution, the orientation, and the content. Studies on synthetic fiber-reinforced FC have offered useful information and methods for a broad variety of technical applications. According to the research that has been conducted, the volume percentage of the synthetic fibre may range anywhere from 0.1 to 4.5% (Rasheed and Prakash, 2018; Abd et al., 2022; Ahmed et al., 2022). The larger volume percentage may result in the synthetic fiber-reinforced FC having a higher tensile strength; however, this may come at the expense of an increased cost and a decreased ability to be worked with. Therefore, improvement of the mix is required for a wider use of fibre-reinforced composites made using synthetic fibres. In addition, the fibres in FC have an effect on the process of fracture, which causes a modification in the material’s mechanical characteristics, in particular the correlations between those mechanical qualities (Behfarnia and Behravan, 2014). When contrasted with studies on the connections between the mechanical characteristics of normal-strength concrete, however, the study on the correlations between the mechanical properties of synthetic fiber-reinforced FC is limited.

It is possible that the inclusion of synthetic twisted bundle macro-fibres (SF) may have a synergistic effect, which will result in an increase in the strengths and mechanical characteristics of cement-based materials (Akeed et al., 2022a; Almeshal et al., 2022). The randomly dispersed SF in concrete has the ability to prevent the coalescence and spread of microcracks while also bridging macrocracks. The nature, form, and composition of SF all have a role in the manifestation of these effects. The insertion of polypropylene fibres into FC resulted in an improvement in the material’s tensile strength in comparison to FC that did not include polypropylene fibres. The best percentage of PP fibres was found to be 0.05% for both 1,600 kg/m3 and 1800 kg/m3 of material. The flexural strength of FC reduced by about 16% due to the addition of 0.4% polypropylene fibres, however the bending strength improved by up to 26% as a result of the addition (Mydin and Soleimanzadeh, 2012; Aisheh et al., 2022a; Abd et al., 2023). Both the fracture resistance and drying shrinkage of FC are improved when polypropylene fibres are added to the mix. On the other hand, the reduction in elastic modulus of polypropylene fibres has not resulted in a reduction in concrete creep (Liu et al., 2021). Propylene fibres typically have a length of 19 mm, tensile strengths ranging from 240 to 740 N/mm2, and ultimate elongations ranging from 15 to 74% (Ranjbar and Zhang, 2020). As a result of the addition of polypropylene fibre (PPF) fibres, the porosity of the concrete was reduced, and its resistance to fracture was significantly increased (Liu et al., 2021; Aisheh et al., 2022b; Akeed et al., 2022b). Polypropylene fibres have very high endurance despite their low modulus of elasticity, which ranges from 2 to 11 gigapascals (GPa). Polypropylene fibres are an ideal option for usage in FC since they have an even lower density than polyvinyl alcohol, which ranges from 0.89 to 0.94 g/cm3.

Based on the review above, it seems that FC may benefit greatly from the incorporation of synthetic fibers. This research looked at how using FC reinforcement with SF affected the mechanical, durability, and thermal properties performance of concrete by analyzing its fresh workability, compressive strength, flexural strength, tension splitting strength, porosity, water absorption, and thermal conductivity. The influence of the varying SF weight fractions on the FC properties was determined. The properties of FCs with densities of 1,000, 1,300, and 1,600 kg/m3 were examined, with varying weight fractions of SF (Al-Bodour et al., 2022; Ashteyat et al., 2022; Murad and Abdel-Jabbar, 2022). The novelty of this laboratory investigation work is to improve the understanding of the durability, mechanical and thermal properties of SF-FC composites. There is currently a knowledge gap regarding the properties of medium-density FC (1,000 kg/m3—1,600 kg/m3) reinforced with SF at different weight fractions. The employment of SF, which are low-cost additives, is of great value currently, i.e., it is increasingly essential to explore and expand innovative cement-based materials for applications in the construction industry.

2 Experimental work

This section describes the constituent materials used to produce FC, as well as the mix proportions and laboratory test procedures. First, the preparation of materials is thoroughly discussed. The mix proportions, mixing methods, and experimental approaches for the LFC samples reinforced with SF were then determined. The purpose of this study was to investigate the impact of SF at six different weight fractions specifically 0%, 1%, 2%, 3%, 4% and 5% on FC durability, mechanical and thermal properties. Three medium densities FC densities were prepared, namely 1000 kg/m3, 1300 kg/m3, and 1600 kg/m3. The medium densities of FC were taken into account in this study because they are employed for semi-structural components in building construction and can gain from SF reinforcement. Durability, mechanical and thermal properties were the three main parameters investigated. Slump, density, water absorption and porosity were the four main parameters studied for durability properties. Mechanical properties have been examined in three areas specifically compressive strength, splitting tensile strength and flexural strength. Additionally, to establish the thermal property, the FC-SF composite’s thermal conductivity was determined. The correlation between durability and mechanical properties was then revealed to quantify how closely the two parameters are associated.

2.1 Materials

This study focuses on fabricating and testing high-density FC specifically 1,000, 1,300 and 1,600 kg/m3 with different weight fractions of SF ranging from 0% to 4%. A control FC was also made for comparison purposes. Ordinary Portland cement (CEM1) was employed as cementitious material to make FC. The cement utilized in the research for the production of various densities of FC mixes was commercially available ordinary Portland Cement (OPC) CEM-I under the brand name Lafarge. The fine sand utilized was acquired commercially from one of the top quarries. The sand fulfilled the Bs 882(1992), 1992 specifications. In this investigation, clean and drinking tap water was used, as well as a commercial surfactant (foaming agent), Noraite PA-1. A consistent pore structure was established by homogeneous foam dispersion in cement paste, and the foam had to be produced by shearing the foaming agent at a high speed.

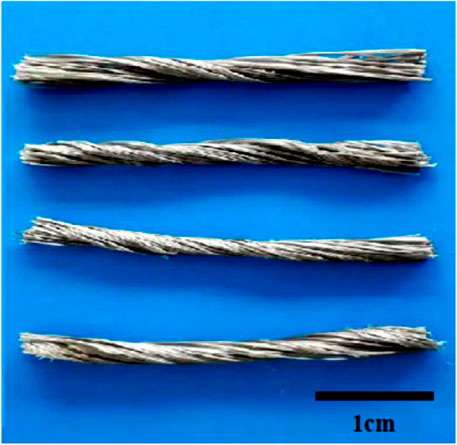

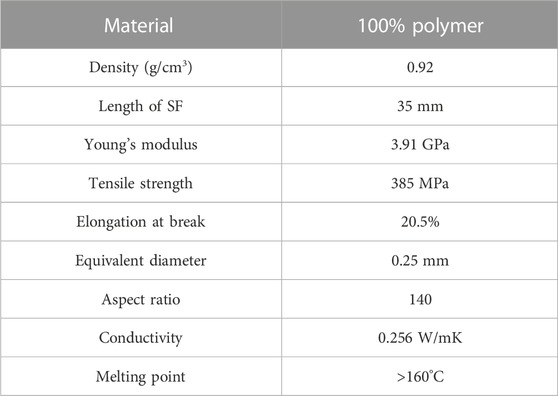

In this experiment, synthetic twisted bundle macro-fibers (SF) were selected to be employed in FC. As a reinforcement in cement-based materials, SF provides numerous benefits. Each SF has its own unique anchorage system, and this, combined with a higher aspect ratio, boosts performance in the FC matrix. By incorporating the SF into the FC, the strength, resilience, and toughness are all augmented. Moreover, unlike steel, SF offers additional crack control without the associated corrosion risk. These innovative SF work wonderfully in FC applications because of the enhanced adhesion they provide and the superior bond they form with the cementitious matrix. Greater energy absorption, an efficient rock section profile, increased ductility, fracture toughness, and fewer logistical complications are all benefits of SF-reinforced FC. Figure 1 visualizes the SF employed in this study. The SF was added to the FC with varying weight fractions of 0%, 1%, 2%, 3% and 4%; Table 1 displays the SF’s essential details and properties of synthetic twisted bundle macro-fibers (SF).

2.2 FC mix design

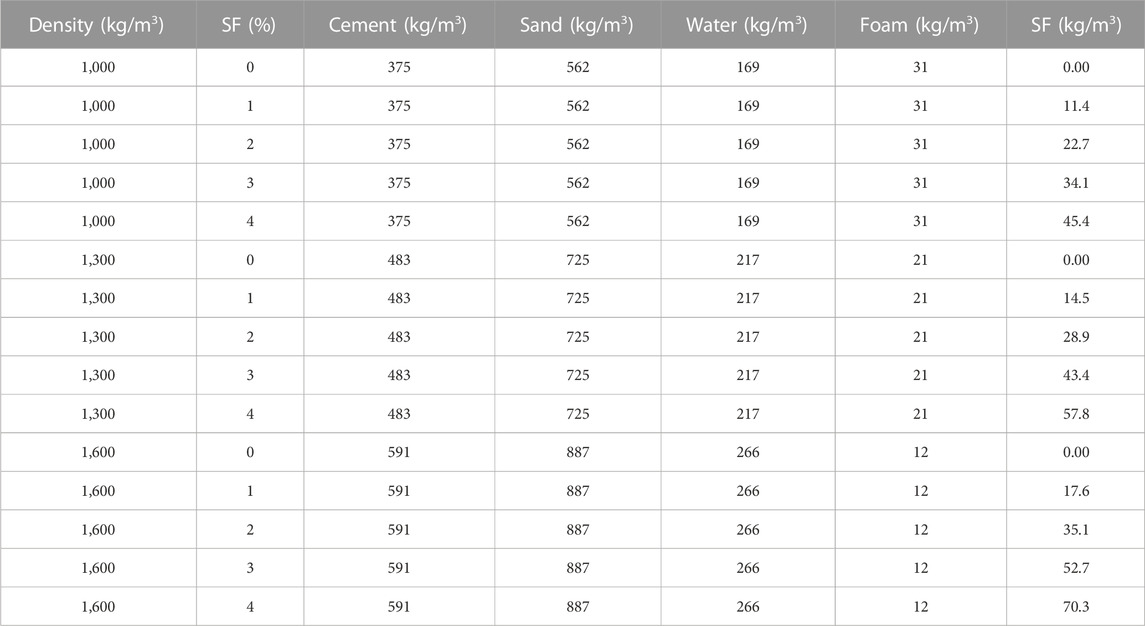

Three different densities (1,000, 1,300, and 1,600 kg/m3) were created and evaluated in this research. Both the water-to-cement and cement-to-filler ratios were held constant at 0.45 for all mixtures, while the cement-to-filler ratio was kept at 1:1.5. Eighteen different FC concoctions were created. In Table 2 you’ll see the FC mixture layout. After the mixing was finished, a slump test was performed in accordance with (B. Standard and Part-102, 1983) requirements to evaluate the FC mixes’ workability (slump).

2.3 Details of experimental tests

2.3.1 Mechanical properties tests

The parameters evaluated for FC mechanical properties were compressive strength, flexural strength, and tensile strength. The compression test was done on a FC cube of 100 × 100 × 100 mm in line with (B.E. 12390-3, 2009), flexural strength was performed on a prism of 100 × 100 × 500 mm in accordance with (P.-E. 12390-5, 2011), and tensile strength was executed on FC cylinder (100 mm diameter and 200 mm in height) in compliance to (B. EN and 12390-6, 2002). For each test, the loading rate remained constant at 0.30 MPa/sec. Each test was performed on days 7, 28 and 56. The result was calculated by taking the average of three FC specimens. Figures 2, 3 and 4 demonstrate the apparatus for compressive, flexural and tensile strength tests.

2.3.2 Fresh and durability properties tests

For the fresh and durability properties tests, the parameters evaluated were FC’s slump flow, water absorption capacity and porosity. A slump flow test was accomplished to ascertain how the addition of SF affected the workability of FC. Using a long cylinder, the FC’s spreadability was evaluated. After the FC stopped flowing, the average spread diameter of FC mixtures was determined. Figure 5 depicts the spreadability measurement of FC. The vacuum-saturated approach was used during the porosity evaluation as shown in Figure 6. The diameter of the cylinder specimens that were cast was 45 mm, and their height measured 50 mm. On day 28, this test was carried out by putting the FC specimens into a vacuum desiccator and letting them sit there for 24 h. Next, FC’s water absorption enables the transfer of carbon dioxide, oxygen and chlorine resulting in the corrosion of FC’s reinforcing steel. This study’s water absorption test was achieved in line with the (B. -122, 2011) standard. The preparation of FC cylinder specimens of 75 mm in diameter and 100 mm in height.

2.3.3 Thermal conductivity test

The thermal conductivity of FC was measured using the hot guarded plate technique, as shown in Figure 7. A sample of FC measuring 35 mm × 35 mm × 12 mm was prepared and evaluated. The sample’s thickness was sandwiched s by stacking two composite discs on top of the sensor and two more below. Consequently, the researchers were able to confirm that the axis-parallel heat diffusion assumption was true and that the sample domain was unlimited.

3 Results

3.1 Slump flow

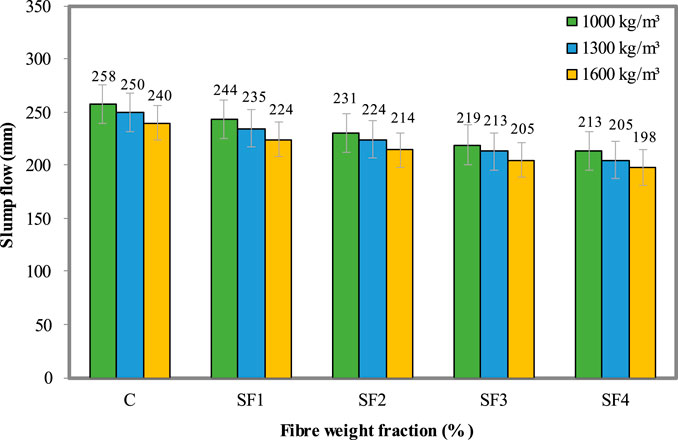

Figure 2 presents the slump flow of FC mixtures with different weight fractions of SF. It is evident that when the water-cement ratio was kept constant at 0.45 for entire mixtures, the slump flow reduced with the increase of SF weight fractions. The slump flow of control FC (no fibre addition) attained a slump of 258 mm (1,000 kg/m3), 250 mm (1,300 kg/m3) and 240 mm (1,600 kg/m3). While the FC mixtures with the addition of 4% SF had the lowest slump values of 213 mm (1,000 kg/m3), 205 mm (1,300 kg/m3) and 198 mm (1,600 kg/m3). This is mainly because the higher weight fraction of SF will increase the water necessity of the fresh FC mixture, which headed to a reduction in slump flow compared to the control FC sample. Additionally, it can be observed the lower FC density accomplished a higher slump value compared to the higher densities (Al-Tayeb et al., 2022; Akeed et al., 2022b; Emad et al., 2022; He et al., 2022). For instance, the 1,000 kg/m3 control density with a 3% weight fraction of SF achieved a slump of 219 mm whereas the 1,600 kg/m3 density with the same weight fraction of SF attained a slump of 205 mm.

3.2 Density

Figure 3 visualizes the variation of densities with various weight fractions of SF. The density of FC mixtures recorded a slight reduction with the addition of SF from 1% to 4% for 1,000 kg/m3, 1,300 kg/m3 and 1,600 kg/m3. The lowest densities were attained with the presence of 4% SF whereas the highest densities were accomplished for the control FC specimens (no addition of fibre). Due to the porous characteristic of FC, compaction was more difficult to be achieved when it was blended with larger weight fractions of SF, resulting in a lower density of the mixed specimen equated to the control specimen. Anyway, the range of the dry densities achieved for entire FC densities is still within the allowable boundary of ±45 kg/m3.

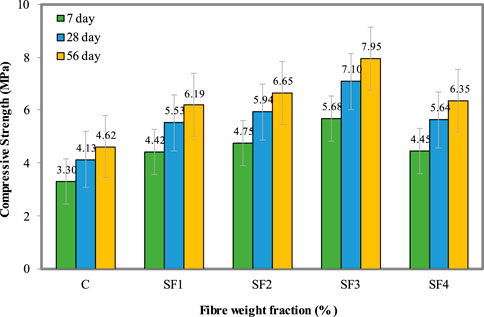

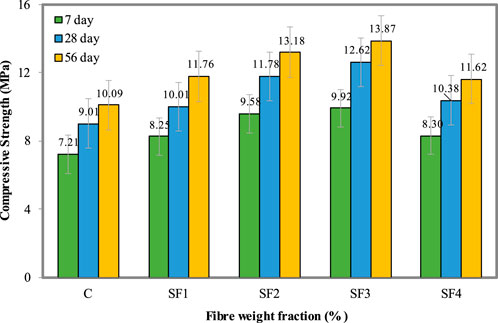

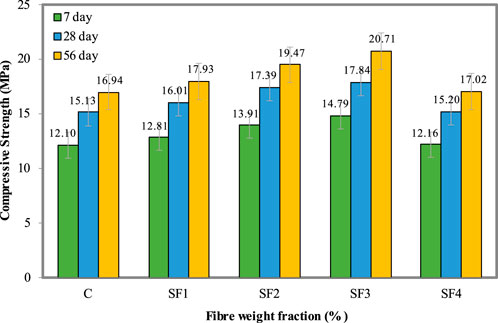

3.3 Compressive strength

The compression test was accomplished on days 7, 28 and 56. The test was carried out for each mixture of FC’s compositions. The variation of compressive strength results for 1,000, 1,300 and 1,600 kg/m3 densities with varying weight fractions of SF are shown in Figures 4–6. From these three figures, it is noted that for all three densities considered in this study, an increment in compressive strength is observed with the inclusion of SF. For the control FC sample, the compressive strengths attained on day 28 were 4.13 MPa, 9.01 MPa, and 15.13 MPa for the 1,000 kg/m3, 1,300 kg/m3, and the 1,600 kg/m3 mix respectively. The utmost compressive strength was accomplished with the inclusion of 3% SF in FC mixtures. The compressive strengths recorded were 7.10 MPa, 12.62 MPa, and 17.84 MPa for the 1,000 kg/m3, 1,300 kg/m3, and the 1,600 kg/m3 mix respectively on day 28. The percentages of enhancement were 72%, 40% and 17% for these three densities. Lower FC densities attained a higher percentage of compressive strength enhancement with the inclusion of 3% SF. Because of their higher surface energy, hydrated cement products tend to cluster near SF when they are evenly propagated in FC at the appropriate weight fraction. In response to the FC’s contraction, the SF attracts tensile energy at the interface between the SF and FC cementitious matrix and distributes it to the neighbouring matrix, therefore lowering the localized tensile stress and increasing the fracture resistance (Amran et al., 2020; Qaidi et al., 2022f; Qaidi et al., 2022g; Qaidi et al., 2022h). Once SF-reinforced FC specimens reached their compressive peak strength, they were able to bear loads at progressively larger strains. It should be pointed out that at a 4% weight fraction of SF, the compressive strengths started to decrease for entire densities tested. This might be due to the fact that when the SF weight fraction surpasses the critical fibre percentage, it readily forms balls.

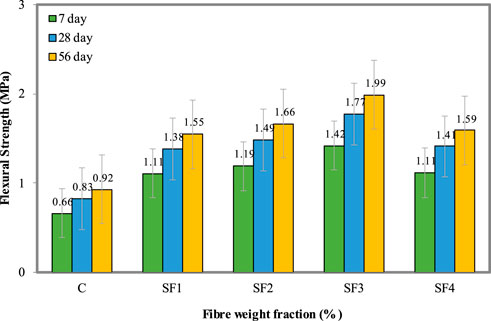

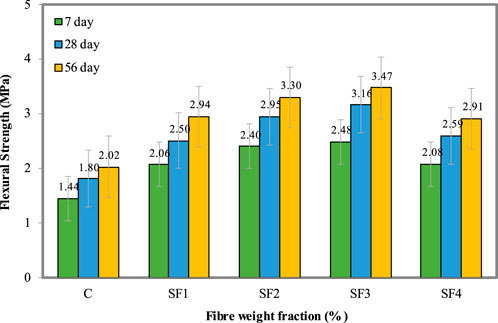

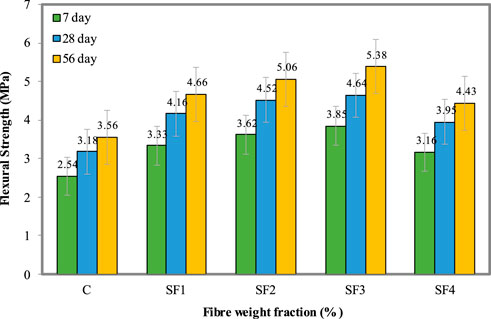

3.4 Flexural strength

Figures 7–9 show the flexural strength results for different densities at varying SF weight fractions. The flexural test was completed on days 7, 28 and 56 for each mixture of FC’s compositions. Generally, FC mixtures with 3% inclusion of SF exhibited greater flexural strength in comparison to control FC and FC with other weight fractions of SF. The flexural strengths recorded on day 28 with the presence of 3% of SF were 1.77 MPa, 3.16 MPa, and 4.64 MPa for the 1,000 kg/m3, 1,300 kg/m3, and the 1,600 kg/m3 mix respective. These were 113%, 76% and 46% higher than the control FC specimens of 1,000, 1,300 and 1,600 kg/m3 densities. As per observed in the compressive strength result, at 4% weight fraction of SF, the flexural strength of FC reduced dramatically. SF and foam cement slurry will typically form an interfacial transition zone (ITZ) (Yu et al., 2021). If the water-cement ratio is held constant, excess addition of FC will lead to an increase in the ITZ area as well as the porosity of FC, which will ultimately result in a loss in flexural strength. Additionally, the high weight fraction of SF in the cementitious matrix will make it difficult to scatter evenly and will lead to agglomeration. Even with the presence of 4% SF, the flexural strength was still higher than that of the control specimen. In the course of fracture propagation, the SF will be progressively ejected from the matrix until the bonding intensity is completely exceeded within the FC matrix (Roslan et al., 2013; Murad et al., 2022; Murad et al., 2023). Although the matrix was fractured, the essential form may still be maintained. The presence of SF in FC is essential for reinforcing the FC. This does aid in the reduction of fractures in FC, specifically in the bottom section of the specimen that is stretched during the test. This enabled the residual resistance to be improved (Akeed et al., 2022c; Tayeh et al., 2022c; Qaidi et al., 2022d; Faraj et al., 2022; Prakash et al., 2022).

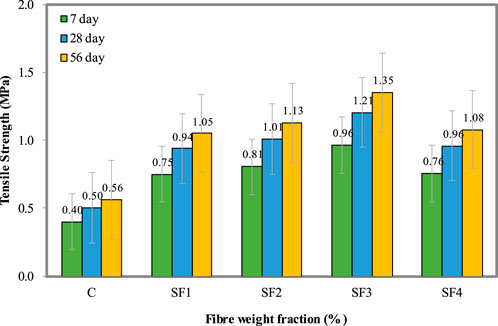

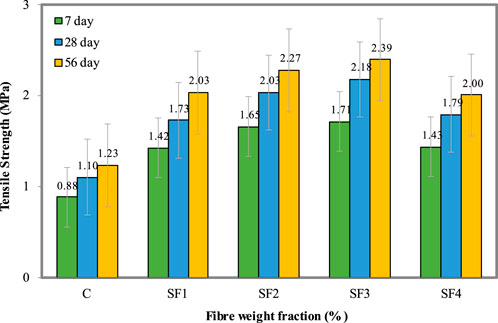

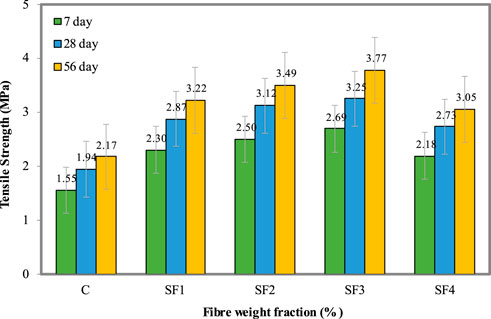

3.5 Splitting tensile strength

Figures 10–12 demonstrate the results of the splitting tensile strength test on the FC mixtures containing varying weight fractions of SF at 7, 28 and 56 days. The splitting tensile results largely imply that using SF in FC mixtures has a positive effect on the tensile strength enhancement as a whole. For the control FC specimen, the splitting tensile strengths attained on day 28 were 0.50 MPa, 1.10 MPa, and 1.94 MPa for the 1,000 kg/m3, 1,300 kg/m3, and the 1,600 kg/m3 mix respectively.

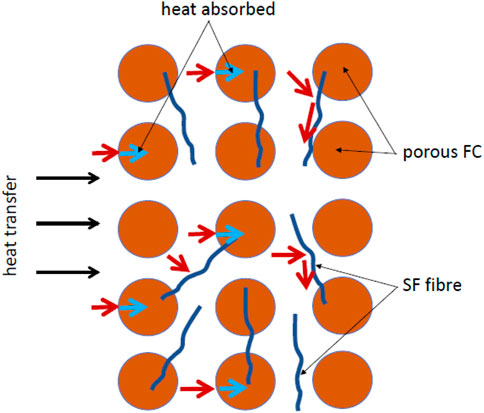

. The highest splitting tensile strength was achieved with the addition of 3% SF in FC mixtures. The splitting tensile strengths recorded were 1.21 MPa, 2.18 MPa, and 3.25 MPa for the 1,000 kg/m3, 1,300 kg/m3, and the 1,600 kg/m3 mix respectively on day 28. These three densities had percentages of augmentation that were respectively 142%, 98%, and 68% correspondingly in comparison to the control FC. With the addition of 3% SF, lower FC densities were able to achieve a larger percentage of compressive strength augmentation than higher densities. The incorporation of SF in FC mixtures ensures that it will perform the function of a fastener when the FC develops microcracks as shown in Figure 13. This prevents the matrix elastic modulus from instantaneously decreasing to zero once the direct boundary strain has been attained. When fractures start to appear, the SF will take all the tension on itself and then gradually transfer it to the cementitious matrix (Wang et al., 2019; Qaidi et al., 2021; Emad et al., 2022; Qaidi et al., 2022h). Nevertheless, above the 4% weight fraction of SF, the splitting tensile strength of FC reduced dramatically. A high amount of SF in FC will lead to ununiform dispersion of fibre in the matrix of FC.

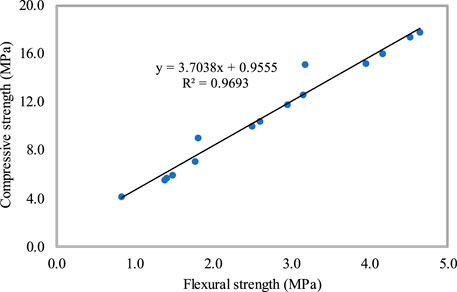

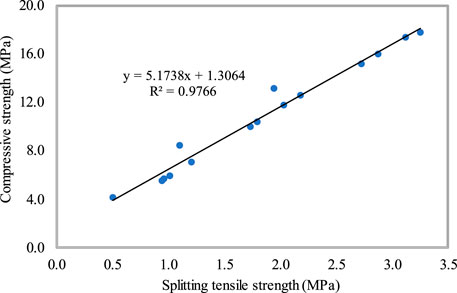

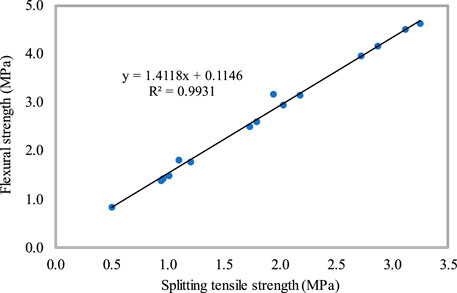

3.6 Relationship between mechanical properties

This section intended to observe the correlation between the mechanical properties of FC with varying weight fractions of SF. The results of the correlation analysis may be utilized to extrapolate future FC characteristics based on the available data and information, as well as to assess the prevalence and correlations between the FC properties. Additionally, the results of correlational studies may shed light on intricate real-world associations between cement-based material properties, paving the way for new hypotheses and predictions. Figures 14–16 show the correlation between compressive-flexural strength, compressive-splitting tensile strength, and flexural-splitting tensile strength. From these three figures, the distribution of data lends credence to the proposition that there is, in fact, an excellent correlation between the strength properties of FC reinforced with SF. With R-squared values of 0.9693 (compressive-flexural strengths), 0.9766 (compressive-splitting tensile strengths), and 0.9931 (flexural-splitting tensile strength), it is clear that there is a strong linear correlation. This indicates that changes in the predictors are connected to changes in the response variable and that the obtained prediction models explain a large portion of the variability in the response.

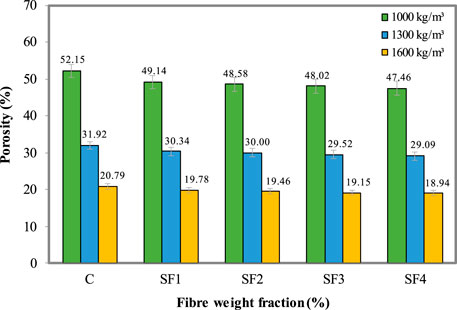

3.7 Porosity

The result of the porosity test of FC with different weight fractions of SF is shown in Figure 17. From Figure 17, it is apparent that the FC porosity reduces gradually with the inclusion of SF from 1% to 4%. The FC mix with a 4% weight fraction of SF attained the ideal porosity for all densities. For the control FC specimen, the recorded porosities via vacuum saturation test on day 28 were 52.15% (1,000 kg/m3), 31.92% (1,300 kg/m3) and 20.79% (1,600 kg/m3). The lowest porosity was achieved with the addition of 4% SF in FC mixtures. The porosities recorded were 8.99% (1,000 kg/m3), 29.09% (1,300 kg/m3) and 18.94% (1,600 kg/m3) on day 28. The percentage of enhancements were 47.5%, 29.1% and 18.9% for 1,000 kg/m3, 1,300 kg/m3 and 1,600 kg/m3 densities respectively. Through the incorporation of 4% weight fractions of SF, it is possible to improve the compactness of the FC and cut down on the number of large pores that are interconnected pores (Chung et al., 2017).

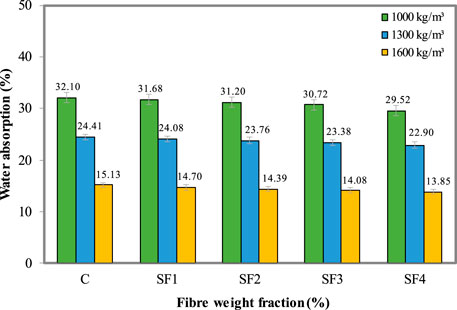

3.8 Water absorption

FC water absorption testing analyses the rate of unidirectional water flow by capillary action. Figure 18 shows the water absorption capacity of FC with different weight fractions of SF. In general, all FC densities had a reduction of water absorption capacity after the initial 28 days of curing with the inclusion of SF. The highest water absorption was recorded for the control specimen whereas the lowest water absorption was attained with the inclusion of a 4% weight fraction of SF. Because synthetic fibres are hygroscopic, moisture absorption causes volume changes in the fibres (Hou et al., 2021). Within the FC composite, this component may encourage fibre separation. It should be pointed out that the lower density FC tends to have higher water absorption capacity compared to higher density. As water evaporates from an FC-SF composite, the fibres shrink, creating spaces and voids inside the porous material. In light of this, it has been shown that low-density FC (1,000 kg/m3) has a greater absorption rate than higher-density FC.

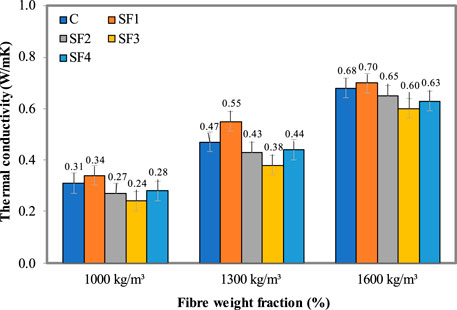

3.9 Thermal conductivity

Figure 19 reveals the thermal conductivity of FC with varying weight fractions of SF. It can be seen from Figure 19 that the inclusion of SF in FC can assist in reducing the thermal conductivity of FC. The ideal thermal conductivity result was obtained with the presence of a 3% weight fraction of SF. The thermal conductivities of control specimens were 0.31 W/mK, 0.47 W/mK and 0.68 W/mK for 1,000 kg/m3, 1,300 kg/m3 and 1,600 kg/m3 densities in that order. With the addition of a 3% weight fraction of SF, the thermal conductivities of FC were reduced dramatically to 0.24 W/mK, 0.38 W/mK and 0.60 W/mK for 1,000 kg/m3, 1,300 kg/m3 and 1,600 kg/m3 densities respectively. Because of the porous nature of the FC with the inclusion of SF, which allows it to absorb heat (Figure 20), the thermal conductivity of the material improves as the weight fraction of the SF in the material rises (Suhaili et al., 2021). The ideal weight percentage of the material is 3%. The inclusion of SF also contributes to the redistribution and development of a smaller uniform pore void, both of which are further explanations for the very low thermal conductivity of FC (Serri et al., 2014; AL-Rakhameen et al., 2022; Murad, 2022; Murad and Abdel-Jabar, 2022). The occurrence of this event led to the formation of a greater number of numerous isolated pore voids when compared to the control, which has no fibre addition (Nensok et al., 2021). The findings also showed that the SF has a significant amount of untapped potential for use in cement-based materials, in which it has the ability to play a vital part in lowering the thermal inducing property of manufactured concrete or increasing its heat transmission. In addition to this, the FC that is made with SF has the potential to save a significant amount of energy when it is used as a green construction material.

4 Conclusion

This study focuses on the potential utilization of synthetic twisted bundle macro-fibers (SF) in foamed concrete (FC) mixtures to enhance the thermal, durability and mechanical properties. Five varying weight fractions of SF of 0%, 1%, 2%, 3% and 4% were introduced in FC. This investigation concentrates on FC densities of 1,000 kg/m3, 1,300 kg/m3 and 1,600 kg/m3. The findings of this investigation provide the following conclusions on the FC properties reinforced with SF:

1. The addition of SF in FC has proven to be effective in increasing the mechanical, thermal and durability properties of FC, allowing for improved FC performance as well as better deployment of material capacities

2. The percentage of improvements for compressive strength for these three densities evaluated were 72%, 40%, and 17%. With the addition of 3% SF, lower FC densities achieved a larger percentage of compressive strength improvement. Hydrated cement products have a tendency to cluster close to SF due to their greater surface energy when they are equally distributed in FC at the proper weight percentage. When the FC contracts, the SF at the interface between the SF and FC cementitious matrix absorbs tensile energy and transfers it to the nearby matrix, reducing the localized tensile stress and boosting fracture resistance.

3. The bridging effect of SF, which improves the brittleness of the FC matrix, was identified in the splitting tensile and flexural tests. The flexural strengths of FC with the inclusion of 3% SF increased by up to 113%, 76% and 46% for FC specimens of 1,000, 1,300 and 1,600 kg/m3 densities compared to FC without SF (control sample). While the splitting tensile strength increased by up to 142%, 98%, and 68% correspondingly for 1,000, 1,300 and 1,600 kg/m3 densities in comparison to the control FC.

4. The addition of SF increased the water absorption capacity of all FC densities after the first 28 days of curing. The control specimen had the lowest water absorption, whereas adding 4% SF increased it to its maximum. SF absorbs moisture from the air and expands or contracts as a result. Within the FC matrix, this component may promote fiber separation.

5. With the SF inclusion, FC porosity steadily decreases from 1% to 4%. For all densities, the FC mixture with a 4% weight fraction of SF reached the optimal porosity. It is feasible to increase the FC’s compactness and decrease the number of large pores and interconnected pores by adding 4% weight fractions of SF.

6. Incorporating SF into FC may help lessen the material’s thermal conductivity. Adding 3% SF by weight produced the best thermal conductivity results. The relatively low thermal conductivity of FC may also be attributed to the incorporation of SF, which helps redistribute and generate a smaller uniform pore void.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding authors.

Author contributions

Conception and design of the study: MO, MM, RO, HN, SM, and MS; acquisition of data: MO, MM, and RO; analysis and/or interpretation of data: HN, SM, AD, and MS; drafting the manuscript: MO,MM, RO, HN, SM, AD, and MS; revising the manuscript critically for important intellectual content: MO, MM, AD, and RO; and approval of the version of the manuscript to be published: MO, MM, RO, HN, SM, AD, and MS.

Funding

The research is partially funded by the Ministry of Science and Higher Education of the Russian Federation under the strategic academic leadership program “Priority 2030” (Agreement 075-15-2021-1333 dated 30 September 2021).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abd, S. M., Mhaimeed, I. S., Tayeh, B. A., Najm, H. M., and Qaidi, S. (2022). Flamingo technique as an innovative method to improve the shear capacity of reinforced concrete beam. Case Stud. Constr. Mater. 17, e01618. doi:10.1016/j.cscm.2022.e01618

Abd, S. M., Mhaimeed, I. S., Tayeh, B. A., Najm, H. M., and Qaidi, S. (2023). Investigation of the use of textile carbon yarns as sustainable shear reinforcement in concrete beams. Case Stud. Constr. Mater. 18, e01765. doi:10.1016/j.cscm.2022.e01765

Ahmed, H. U., Mohammed, A. A., Rafiq, S., Mohammed, A. S., Mosavi, A., Sor, N. H., et al. (2021). Compressive strength of sustainable geopolymer concrete composites: A state-of-the-art review. Sustainability 13 (24), 13502. doi:10.3390/su132413502

Ahmed, H. U., Mohammed, A. S., Faraj, R. H., Qaidi, S. M. A., and Mohammed, A. A. (2022). Compressive strength of geopolymer concrete modified with nano-silica: Experimental and modeling investigations. Case Stud. Constr. Mater. 16, e01036. doi:10.1016/j.cscm.2022.e01036

Aisheh, Y. I. A., Atrushi, D. S., Akeed, M. H., Qaidi, S., and Tayeh, B. A. (2022). Influence of polypropylene and steel fibers on the mechanical properties of ultra-high-performance fiber-reinforced geopolymer concrete. Case Stud. Constr. Mater. 17, e01234. doi:10.1016/j.cscm.2022.e01234

Aisheh, Y. I. A., Atrushi, D. S., Akeed, M. H., Qaidi, S., and Tayeh, B. A. (2022). Influence of steel fibers and microsilica on the mechanical properties of ultra-high-performance geopolymer concrete (UHP-GPC). Case Stud. Constr. Mater. 17, e01245. doi:10.1016/j.cscm.2022.e01245

Akeed, M. H., Qaidi, S., Ahmed, H. U., Emad, W., Faraj, R. H., Mohammed, A. S., et al. (2022). Ultra-high-performance fiber-reinforced concrete. Part III: Fresh and hardened properties. Case Stud. Constr. Mater. 17, e01265. doi:10.1016/j.cscm.2022.e01265

Akeed, M. H., Qaidi, S., Ahmed, H. U., Faraj, R. H., Majeed, S. S., Mohammed, A. S., et al. (2022). Ultra-high-performance fiber-reinforced concrete. Part V: Mixture design, preparation, mixing, casting, and curing. Case Stud. Constr. Mater. 17, e01363. doi:10.1016/j.cscm.2022.e01363

Akeed, M. H., Qaidi, S., Ahmed, H. U., Faraj, R. H., Mohammed, A. S., Emad, W., et al. (2022). Ultra-high-performance fiber-reinforced concrete. Part II: Hydration and microstructure. Case Stud. Constr. Mater. 17, e01289. doi:10.1016/j.cscm.2022.e01289

Akil, H., Omar, M., Mazuki, A. M., Safiee, S., Ishak, Z. M., and Bakar, A. A. (2011). Kenaf fiber reinforced composites: A review. Mater. Des. 32 (8-9), 4107–4121. doi:10.1016/j.matdes.2011.04.008

Al-Bodour, W., Murad, Y., Imam, R., and Smadi, Y. (2022). Shear strength investigation of the carbon fiber reinforced polymer-wrapped concrete beams using gene expression programming and finite element analysis. J. Struct. Integr. Maintenance 7 (1), 15–24. doi:10.1080/24705314.2021.1971891

Al-Faqra, E., Murad, Y., Abdel Jaber, M. t., and Shatarat, N. (2021). Torsional behaviour of high strength concrete beams with spiral reinforcement. Aust. J. Struct. Eng. 22 (4), 266–276. doi:10.1080/13287982.2021.1962489

AL-Rakhameen, A., Murad, Y., Jaber, M. t. A., and Shatarat, N. (2022). Torsional behavior of spirally reinforced concrete beams. Innov. Infrastruct. Solutions 7 (6), 334. doi:10.1007/s41062-022-00927-4

Al-Tayeb, M. M., Aisheh, Y. I. A., Qaidi, S. M. A., and Tayeh, B. A. (2022). Experimental and simulation study on the impact resistance of concrete to replace high amounts of fine aggregate with plastic waste. Case Stud. Constr. Mater. 17, e01324. doi:10.1016/j.cscm.2022.e01324

Almeshal, I., Al-Tayeb, M. M., Qaidi, S. M. A., Abu Bakar, B. H., and Tayeh, B. A. (2022). Mechanical properties of eco-friendly cements-based glass powder in aggressive medium. Mater. Today Proc. 58 (2022), 1582–1587. doi:10.1016/j.matpr.2022.03.613

Althoey, F., Hakeem, I. Y., Hosen, M. A., Qaidi, S., Isleem, H. F., Hadidi, H., et al. (2022). Behavior of concrete reinforced with date palm fibers. Materials 15 (22), 7923. doi:10.3390/ma15227923

Amran, M., Fediuk, R., Vatin, N., Huei Lee, Y., Murali, G., Ozbakkaloglu, T., et al. (2020). Fibre-reinforced foamed concretes: A review. Materials 13 (19), 4323. doi:10.3390/ma13194323

Amran, Y. M., Ali, A. A., Rashid, R. S., Hejazi, F., and Safiee, N. A. (2016). Structural behavior of axially loaded precast foamed concrete sandwich panels. Constr. Build. Mater. 107, 307–320. doi:10.1016/j.conbuildmat.2016.01.020

Ashteyat, A. M., Al Rjoub, Y. S., Murad, Y., and Asaad, S. (2022). Mechanical and durability behaviour of roller-compacted concrete containing white cement by pass dust and polypropylene fibre. Eur. J. Environ. Civ. Eng. 26 (1), 166–183. doi:10.1080/19648189.2019.1652694

Behfarnia, K., and Behravan, A. (2014). Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 55, 274–279. doi:10.1016/j.matdes.2013.09.075

B. EN, 12390-6 (2002). Testing hardened concrete; part 6: Split tensile strength of test specimens. European Committee for Standardization.

B. Standard, Part-102 (1983). Testing concrete method for determination of slump, London: British Standard Institution. (1881).

Castillo-Lara, J. F., Flores-Johnson, E. A., Valadez-Gonzalez, A., Herrera-Franco, P. J., Carrillo, J. G., Gonzalez-Chi, P., et al. (2020). Mechanical properties of natural fiber reinforced foamed concrete. Materials 13 (14), 3060. doi:10.3390/ma13143060

Çelik, A. İ., Özkılıç, Y. O., Zeybek, Ö., Karalar, M., Qaidi, S., Ahmad, J., et al. (2022). Mechanical behavior of crushed waste glass as replacement of aggregates. Materials 15 (22), 8093. doi:10.3390/ma15228093

Chica, L., and Alzate, A. (2019). Cellular concrete review: New trends for application in construction. Constr. Build. Mater. 200, 637–647. doi:10.1016/j.conbuildmat.2018.12.136

Chung, S.-Y., Lehmann, C., Abd Elrahman, M., and Stephan, D. (2017). Pore characteristics and their effects on the material properties of foamed concrete evaluated using micro-CT images and numerical approaches. Appl. Sci. 7 (6), 550. doi:10.3390/app7060550

Emad, W., Mohammed, A. S., Bras, A., Asteris, P. G., Kurda, R., Muhammed, Z., et al. (2022). Metamodel techniques to estimate the compressive strength of UHPFRC using various mix proportions and a high range of curing temperatures. Constr. Build. Mater. 349, 128737. doi:10.1016/j.conbuildmat.2022.128737

Faraj, R. H., Ahmed, H. U., Rafiq, S., Sor, N. H., Ibrahim, D. F., and Qaidi, S. M. A. (2022). Performance of self-compacting mortars modified with nanoparticles: A systematic review and modeling. Clean. Mater. 4, 100086. doi:10.1016/j.clema.2022.100086

Ganesan, S., Mydin, M. A. O., Sani, N. M., and Ani, A. I. C. (2014). Performance of polymer modified mortar with different dosage of polymeric modifier. MATEC Web Conf. 15, 01039. EDP Sciences. doi:10.1051/matecconf/20141501039

He, X., Yuhua, Z., Qaidi, S., Isleem, H. F., Zaid, O., Althoey, F., et al. (2022). Mine tailings-based geopolymers: A comprehensive review. Ceram. Int. 48 (17), 24192–24212. doi:10.1016/j.ceramint.2022.05.345

Hou, L., Li, J., Lu, Z., and Niu, Y. (2021). Influence of foaming agent on cement and foam concrete. Constr. Build. Mater. 280, 122399. doi:10.1016/j.conbuildmat.2021.122399

Liu, Y., Wang, L., Cao, K., and Sun, L. (2021). Review on the durability of polypropylene fibre-reinforced concrete. Adv. Civ. Eng. 2021, 1–13. doi:10.1155/2021/6652077

Maglad, A. M., Zaid, O., Arbili, M. M., Ascensão, G., Șerbănoiu, A. A., Grădinaru, C. M., et al. (2022). A study on the properties of geopolymer concrete modified with nano graphene oxide. Buildings 12 (8), 1066. doi:10.3390/buildings12081066

Martínez-García, R., Jagadesh, P., Zaid, O., Șerbănoiu, A. A., Fraile-Fernández, F. J., de Prado-Gil, J., et al. (2022). The present state of the use of waste wood ash as an eco-efficient construction material: A review. Mater. A Rev. Mater. 15 (15), 5349. doi:10.3390/ma15155349

Mohamad, N., Samad, A. A. A., Lakhiar, M. T., Mydin, M. A. O., Jusoh, S., Sofia, A., et al. (2018). Effects of incorporating banana skin powder (BSP) and palm oil fuel ash (POFA) on mechanical properties of lightweight foamed concrete. Int. J. Integr. Eng. 10 (9). doi:10.30880/ijie.2018.10.09.013

Mugahed Amran, Y., Rashid, R. S., Hejazi, F., Abang Ali, A., Safiee, N. A., and Bida, S. M. (2018). Structural performance of precast foamed concrete sandwich panel subjected to axial load. KSCE J. Civ. Eng. 22, 1179–1192. doi:10.1007/s12205-017-1711-6

Murad, Y., and Abdel-Jabbar, H. (2022). Shear behavior of RC beams prepared with basalt and polypropylene fibers. Case Stud. Constr. Mater. 16, e00835. doi:10.1016/j.cscm.2021.e00835

Murad, Y., Ashteyat, A., and Hunaifat, R. (2019). Predictive model to the bond strength of FRP-to-concrete under direct pullout using Gene expression programming. J. Civ. Eng. Manag. 25 (8), 773–784. doi:10.3846/jcem.2019.10798

Murad, Y., Hajar, H. A., and Azim, I. (2022). Machine learning applications in Civil engineering. Front. Media. SA.

Murad, Y. (2022). Poly-lactic acid and carbon fibers 3D printed bars for seismic retrofitting RC beam-to-column joints subjected to elevated temperature. Structures 43, 1530–1547. Elsevier. doi:10.1016/j.istruc.2022.07.066

Murad, Y. Z., and Abdel-Jabar, H. (2022). Flexural behavior of RC beams made with basalt and polypropylene fibers: Experimental and numerical study. Comput. Concr. 30 (3), 165–173.

Murad, Y. Z., Tarawneh, A., Saleh, E. F., Musmar, M., AlMashaqbeh, A., Alfaouri, Q. T., et al. (2023). Mechanical properties of heat damaged oil shale ash concrete. Innov. Infrastruct. Solutions 8 (1), 23. doi:10.1007/s41062-022-00995-6

Mydin, M. A. O., and Soleimanzadeh, S. (2012). Effect of polypropylene fiber content on flexural strength of lightweight foamed concrete at ambient and elevated temperatures. Adv. Appl. Sci. Res. 3 (5), 2837–2846.

Mydin, M. O., Phius, A., Sani, N. M., and Tawil, N. M. (2014). Potential of green construction in Malaysia: Industrialised building system (IBS) vs traditional construction method. E3S Web Conf. 3, 01009. EDP Sciences. doi:10.1051/e3sconf/20140301009

Mydin, M. O., Shajahan, M. M., Ganesan, S., and Sani, N. M. (2014). Laboratory investigation on compressive strength and micro-structural features of foamed concrete with addition of wood ash and silica fume as a cement replacement. MATEC Web Conf. 17, 01004. EDP Sciences. doi:10.1051/matecconf/20141701004

Nawi, M., Lee, A., Mydin, M. A. O., Osman, W. N., and Rofie, M. K. (2018). Supply chain management (SCM): Disintegration team factors in Malaysian industrialised building system (IBS) construction projects. Int. J. Supply Chain Manag. 7 (1), 140–143.

Nensok, M. H., Mydin, M. A. O., and Awang, H. (2021). Investigation of thermal, mechanical and transport properties of ultra-lightweight foamed concrete (ULFC) strengthened with alkali treated banana fibre. J. Adv. Res. Fluid Mech. Therm. Sci. 86 (1), 123–139. doi:10.37934/arfmts.86.1.123139

Pakravan, H., Latifi, M., and Jamshidi, M. (2017). Hybrid short fiber reinforcement system in concrete: A review. Constr. Build. Mater. 142, 280–294. doi:10.1016/j.conbuildmat.2017.03.059

Prakash, R., Raman, S. N., Subramanian, C., and Divyah, N. (2022). “Eco-friendly fiber-reinforced concretes,” in Handbook of sustainable concrete and industrial waste management (Elsevier), 109–145.

Qaidi, S. M. A., Dinkha, Y. Z., Haido, J. H., Ali, M. H., and Tayeh, B. A. (2021). Engineering properties of sustainable green concrete incorporating eco-friendly aggregate of crumb rubber: A review. J. Clean. Prod. 324, 129251. doi:10.1016/j.jclepro.2021.129251

Qaidi, S. M. A., Mohammed, A. S., Ahmed, H. U., Faraj, R. H., Emad, W., Tayeh, B. A., et al. (2022). Rubberized geopolymer composites: A comprehensive review. Ceram. Int. 48 (17), 24234–24259. doi:10.1016/j.ceramint.2022.06.123

Qaidi, S. M. A., Sulaiman Atrushi, D., Mohammed, A. S., Unis Ahmed, H., Faraj, R. H., Emad, W., et al. (2022). Ultra-high-performance geopolymer concrete: A review. Constr. Build. Mater. 346, 128495. doi:10.1016/j.conbuildmat.2022.128495

Qaidi, S. M. A., Tayeh, B. A., Ahmed, H. U., and Emad, W. (2022). A review of the sustainable utilisation of red mud and fly ash for the production of geopolymer composites. Constr. Build. Mater. 350, 128892. doi:10.1016/j.conbuildmat.2022.128892

Qaidi, S. M. A., Tayeh, B. A., Isleem, H. F., de Azevedo, A. R. G., Ahmed, H. U., and Emad, W. (2022). Sustainable utilization of red mud waste (bauxite residue) and slag for the production of geopolymer composites: A review. Case Stud. Constr. Mater. 16, e00994. doi:10.1016/j.cscm.2022.e00994

Qaidi, S. M. A., Tayeh, B. A., Zeyad, A. M., de Azevedo, A. R. G., Ahmed, H. U., and Emad, W. (2022). Recycling of mine tailings for the geopolymers production: A systematic review. Case Stud. Constr. Mater. 16, e00933. doi:10.1016/j.cscm.2022.e00933

Qaidi, S., Najm, H. M., Abed, S. M., Ahmed, H. U., Al Dughaishi, H., Al Lawati, J., et al. (2022). Fly ash-based geopolymer composites: A review of the compressive strength and microstructure analysis. Materials 15 (20), 7098. doi:10.3390/ma15207098

Qaidi, S., Najm, H. M., Abed, S. M., Özkılıç, Y. O., Al Dughaishi, H., Alosta, M., et al. (2022). Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 15 (18), 6222. doi:10.3390/ma15186222

Qaidi, S., Yahia, A., Tayeh, B. A., Unis, H., Faraj, R., and Mohammed, A. (2022). 3D printed geopolymer composites: A review. Mater. Today Sustain. 20, 100240. doi:10.1016/j.mtsust.2022.100240

Ramezanianpour, A., Esmaeili, M., Ghahari, S.-A., and Najafi, M. (2013). Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 44, 411–418. doi:10.1016/j.conbuildmat.2013.02.076

Ranjbar, N., and Zhang, M. (2020). Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 107, 103498. doi:10.1016/j.cemconcomp.2019.103498

Rasheed, M. A., and Prakash, S. S. (2018). Behavior of hybrid-synthetic fiber reinforced cellular lightweight concrete under uniaxial tension–Experimental and analytical studies. Constr. Build. Mater. 162, 857–870. doi:10.1016/j.conbuildmat.2017.12.095

Roslan, A. F., Awang, H., Azree, M., and Mydin, O. (2013). Effects of various additives on drying shrinkage, compressive and flexural strength of lightweight foamed concrete (LFC). Adv. Mater. Res. 626, 594–604. Trans Tech Publ. doi:10.4028/www.scientific.net/AMR.626.594

Saeed, A., Najm, H. M., Hassan, A., Qaidi, S., Sabri, M. M. S., and Mashaan, N. S. (2022). A comprehensive study on the effect of regular and staggered openings on the seismic performance of shear walls. Buildings 12 (9), 1293. doi:10.3390/buildings12091293

Saeed, A., Najm, H. M., Hassan, A., Sabri, M. M. S., Qaidi, S., Mashaan, N. S., et al. (2022). Properties and applications of geopolymer composites: A review study of mechanical and microstructural properties. Materials 15 (22), 8250. doi:10.3390/ma15228250

Serri, E., Mydin, M. O., and Suleiman, M. (2015). The influence of mix design on mechanical properties of oil palm shell lightweight concrete. J. Mater. Environ. Sci. 3, 607–612.

Serri, E., Suleiman, M. Z., and Mydin, M. A. O. (2014). The effects of oil palm shell aggregate shape on the thermal properties and density of concrete. Adv. Mater. Res. 935, 172–175. Trans Tech Publ. doi:10.4028/www.scientific.net/AMR.935.172

Suhaili, S. S., Mydin, M. A. O., and Awang, H. (2021). Influence of mesocarp fibre inclusion on thermal properties of foamed concrete. J. Adv. Res. Fluid Mech. Therm. Sci. 87 (1), 1–11. doi:10.37934/arfmts.87.1.111

Tayeh, B. A., Akeed, M. H., Qaidi, S., and Bakar, B. H. A. (2022). Influence of microsilica and polypropylene fibers on the fresh and mechanical properties of ultra-high performance geopolymer concrete (UHP-GPC). Case Stud. Constr. Mater. 17, e01367. doi:10.1016/j.cscm.2022.e01367

Tayeh, B. A., Akeed, M. H., Qaidi, S., and Bakar, B. H. A. (2022). Influence of the proportion of materials on the rheology and mechanical strength of ultrahigh-performance concrete. Case Stud. Constr. Mater. 17, e01433. doi:10.1016/j.cscm.2022.e01433

Tayeh, B. A., Akeed, M. H., Qaidi, S., and Bakar, B. H. A. (2022). Ultra-high-performance concrete: Impacts of steel fibre shape and content on flowability, compressive strength and modulus of rupture. Case Stud. Constr. Mater. 17, e01615. doi:10.1016/j.cscm.2022.e01615

Unis Ahmed, H., Mahmood, L. J., Muhammad, M. A., Faraj, R. H., Qaidi, S. M. A., Hamah Sor, N., et al. (2022). Geopolymer concrete as a cleaner construction material: An overview on materials and structural performances. Clean. Mater. 5, 100111. doi:10.1016/j.clema.2022.100111

Wan Ibrahim, M. H., Jamaluddin, N., Irwan, J., Ramadhansyah, P., and Suraya Hani, A. (2014). Compressive and flexural strength of foamed concrete containing polyolefin fibers. Adv. Mater. Res. 911, 489–493. Trans Tech Publ. doi:10.4028/www.scientific.net/AMR.911.489

Wang, J., Dai, Q., Si, R., and Guo, S. (2019). Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 234, 1351–1364. doi:10.1016/j.jclepro.2019.06.272

Yap, S. P., Bu, C. H., Alengaram, U. J., Mo, K. H., and Jumaat, M. Z. (2014). Flexural toughness characteristics of steel–polypropylene hybrid fibre-reinforced oil palm shell concrete. Mater. Des. 57, 652–659. doi:10.1016/j.matdes.2014.01.004

Yu, B., Zhou, J., Cheng, B., and Yang, W. (2021). Compressive strength development and microstructure of magnesium phosphate cement concrete. Constr. Build. Mater. 283, 122585. doi:10.1016/j.conbuildmat.2021.122585

Keywords: foamed concrete, polypropylene twisted fibers, synthetic fiber, durability, strength, porosity, water absorption

Citation: Othuman Mydin MA, Mohd Nawi MN, Omar R, Dulaimi A, Najm HM, Mahmood S and Sabri Sabri MM (2023) Mechanical, durability and thermal properties of foamed concrete reinforced with synthetic twisted bundle macro-fibers. Front. Mater. 10:1158675. doi: 10.3389/fmats.2023.1158675

Received: 04 February 2023; Accepted: 20 February 2023;

Published: 02 March 2023.

Edited by:

Yasmin Murad, The University of Jordan, JordanReviewed by:

Yazeed S. Jweihan, Mutah University, JordanYee Ling Lee, Tunku Abdul Rahman University, Malaysia

Ahmad N. Tarawneh, Hashemite University, Jordan

Copyright © 2023 Othuman Mydin, Mohd Nawi, Omar, Dulaimi, Najm, Mahmood and Sabri Sabri. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Md Azree Othuman Mydin, YXpyZWVAdXNtLm15; Hadee Mohammed Najm, Z2s0MDcxLm15YW11LmFjLmluQGdtYWlsLmNvbQ==; Shaker Mahmood, c2hha2VyNzMwQHlhaG9vLmNvbQ==

Md Azree Othuman Mydin

Md Azree Othuman Mydin Mohd Nasrun Mohd Nawi2

Mohd Nasrun Mohd Nawi2 Shaker Mahmood

Shaker Mahmood