95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater. , 27 March 2023

Sec. Structural Materials

Volume 10 - 2023 | https://doi.org/10.3389/fmats.2023.1152492

This article is part of the Research Topic Sustainable raw materials for innovative concretes and structures View all 5 articles

Paul O. Awoyera1*

Paul O. Awoyera1* Fadi Althoey2

Fadi Althoey2 Hephzibah Ajinomisan1

Hephzibah Ajinomisan1 Md Azree Othuman Mydin3*

Md Azree Othuman Mydin3* Naraindas Bheel4

Naraindas Bheel4 Mohanad Muayad Sabri Sabri5

Mohanad Muayad Sabri Sabri5 Haitham M. Hadidi6

Haitham M. Hadidi6 V. Jayanthi7

V. Jayanthi7 Mahmood Ahmad8

Mahmood Ahmad8The improvement of cement mortar’s thermal and mechanical properties has been greatly impacted by the addition of polymeric materials. However, polymers added to mortar shouldn’t impair either its mechanical or thermal conductivity properties. The main idea of this project is to insulate buildings by reinforcing their constituent mix with natural rubber latex (NRL) to reduce thermal conductance from excessive solar radiation which causes discomfort to building occupants. Consequently, this study presents experimental findings on the influence of natural rubber latex (NRL) on the properties of NRL-modified mortar. Five varying percentages of NRL (0.5%, 1.0%, 1.5%, 2.0% and 2.5%) were added into the mortar. Properties such as thermal conductivity, water absorption capacity, compressive and flexural strengths were evaluated. In addition, scanning electron microscopy was employed for the microstructural investigation. The experimental findings demonstrated that adding 2.5% NRL to mortar increased its thermal conductivity of mortar significantly thus enhancing its insulative properties. Even though adding NRL to mortar decreased the compressive and flexural strengths of some mixes, this wasn’t too substantial nor substandard. The tests that were executed demonstrate that the NRL has a huge potential to insulate cement mortar.

The need for thermal protection in modern buildings arose at the end of the 19th century when technological advances in the construction industry were met with the challenge of the thermal expansion (resulting in cracks) of the materials used in modern building construction (Mydin et al., 2014; Nawi et al., 2018; Awoyera et al., 2022; Baskar et al., 2022). According to Bozsaky, 2010, the need for reduction in heat losses from buildings and some other facilities and also light frame structures were amongst the introduction of thermal insulating materials in industrial construction design (Serri et a., 2014; Serri et al., 2015). As technology improved, the need for the improvement of human comfort in buildings was evidently making the role of thermal insulation in buildings significant (Othuman Mydin et al., 2014). From this time onwards, the use of thermal insulating materials started getting used by people. Naturally occurring materials were in use initially but as time went on artificial materials that were suitable for thermal insulation were found (Nensok et al., 2021). Thermal insulating mortar (TIM) is used in both tropical and cold regions for the purpose of cooling and keeping warm respectively (Zhang and Li, 2022). Aside from the issues of keeping a conducive surrounding for occupants of a building, thermal insulating mortar aims at energy saving. Thermal insulation is a worldwide solution to the issue of energy consumption in buildings, research has shown that 30%–40% of all primary energy is used in buildings (Huovilla, 2007). Over the years materials have been used to achieve this purpose of thermal insulation with mortar such as olive stones, date palm fibers, iron ore, and plant fiber composites (Tambichik et al., 2018). Thermal insulating mortar helps in maintaining the warmness and coldness of the internal part of a building to make it comfortable for the occupants of the building to live. It facilitates in energy conservation well by lessening the cost spent on cooling or using heaters to keep the internal part of the building at the appropriate temperature (Du et al., 2021).

Cement mortar (CM) is a construction material used for plastering, rendering, and other purposes, and is made by combining cement (Portland cement in this case), fine aggregate (river sand), and water. Recent research has shown that iron ore sand and other fine aggregates could enhance the CM properties (Singh, et al., 2015). In the cement industry, it is common knowledge that using too much, or too little water can negatively affect the strength and workability of CM. The heat conduction of concrete and mortar can be altered by replacing some of their constituent materials with those that are better suited to either insulating or conducting heat (Liu et al., 2015). Thermal insulation refers to a material’s capacity to reduce the rate at which heat is transferred to or from the body. Since CM is not a homogeneous material and is porous even when solid, heat is typically conducted through it at typical working temperatures. Mortar and concrete paste conductivities are highly sensitive to admixture types and the water to cement ratio (Kim et al., 2003; Awoyera et al., 2023). The use of CM in building construction would mean that the interior of the building would be as hot as the exterior during the hot seasons, especially in tropical regions, due to the predominant conduction of heat in CM. Therefore, the incorporation of thermal insulating substances into CM is essential for lowering its conductivity.

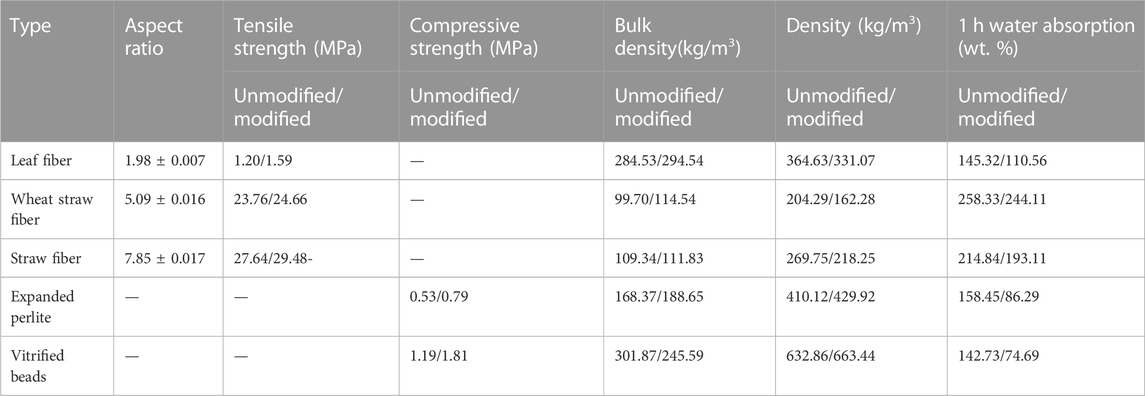

Organic insulating materials have been commonly used as compared to inorganic and composite thermal insulating materials, but organic materials have a poor resistance when exposed to very high temperatures, e.g., fire (Yang et al., 2019). While vitrified beads and closed-pore expanded perlite were employed as inorganic thermal insulation components to create plant fiber cement-based composite thermal insulation mortar, straw and fallen leaf fibers were used as organic thermal insulation components to increase the resource level of agricultural and forestry waste materials. It is a composite thermal insulating mortar because it comprises both organic and inorganic components. Plant fibers are suitable for thermal insulation materials in thermal insulating mortar as it possesses certain characteristics of which being lightweight is one of the few, it can either be used singly or it can be combined. Plant fiber composite is applied in the making of thermal insulating composite. Table 1 demonstrates the properties of composites. The thermal insulation functionality of a material generally depends on its ability to conduct heat that is applied to it. Jiang, et al. (2020) carried out a practical experiment to examine the thermal conductivity of different mixtures of plant fiber on thermal insulating mortar made from vitrified microbeads and expanded perlite. Vitrified beads and expanded perlite wouldn’t suffice for thermal insulating mortar while mixtures including wheat straw, leaf, and straw fibers produced a better thermal insulating mortar with that of straw fiber being the lowest. But a composite of all three plant fibers gave the lowest thermal insulating result making plant fiber composite a good material for thermal insulating mortar production.

TABLE 1. Mechanical and physical properties of thermal insulating composites before and after modification (Jiang, et al., 2020).

Date palm fiber (DPF) is an organic plant material. Investigation into the mechanical characteristics and its use as a thermally insulating material when mixed with mortar was carried out by Benmansour et al. (2014). From the test, two samples of date palm fiber were used (DPF3 and DPF6). The results show that DPF3 absorbs more water than DPF6 when the water absorption test was executed for the two samples. In general, it can be noted that date palm fiber could absorb large quantities of water and it can also absorb three times of its dry weight. The date palm fibers’ heat conductivity was also studied. Results demonstrated that the size of the date palm fiber was negligible. The concentration of date palm fiber affects the thermal conductivity of mortar. Three mixes were used in this experiment (MDP3, MDP6 and MDPmix) and the result showed that when the concentration of date palm fiber was less than 15% MDP6 was higher compared to that of MDP3 and MDPmix. Besides, Barreca and Fichera (2015) carried out an experiment on cement lime mortar mixed with olive stone to check its thermal conductance. From the experiment, the thermal conductance of the mortar reduces given as the proportion of olive stone in the mixture rises. The proportion of olive stone used in the experiment was up to 70%.

Many different disciplines of practice use natural rubber latex, which has numerous applications such as the engineering and medical fields and since it’s natural, it has applications that can’t be replaced using synthetic rubber materials (Diab et al., 2013). The applications of natural rubber latex include heavy-duty tires for trucks, buses, airplanes, gloves, catheters, condoms, adhesives, rubber bands, drive couplings, and anti-vibration mounts. The insulating component of the CM-latex blend should be natural rubber latex (NRL). NRL is a natural latex liquid derived from the extraction of rubber from the rubber tree (Li et al., 2020; Althoey et al., 2022). Due to its origin in the gum of rubber trees and other plants, NRL is typically impure. The rubber tree, Hevea brasiliensis, from which NRL is extracted is primarily cultivated in tropical regions, for instance, Thailand, Indonesia, Malaysia, China, and India amongst others (Hong and Blackmore, 2015). About 36% of the latex from Hevea Brasiliense is made of rubber, 5% of it is made of non-rubber substances, and the remaining 59% is made of water (Sansatsadeekul, et al., 2011). Natural rubber latex particles are found in the milk cells of the natural rubber tree, and the process of extracting this rubber latex is known as bleeding (Guerra, et al., 2021). NRL could coagulate and degrade rapidly, therefore, it is stabilized with the aid of chemical agents with ammonia being the most common one.

High energy efficiency in buildings is achieved primarily through thermal insulation (Rabbat et al., 2022). Thermal insulation on the exterior of buildings reduces their CO2 output. Buildings with better insulation use less fossil fuel for heating and cooling, which reduces emissions of carbon dioxide and sulphur dioxide, particularly at the micro- and mesoscale levels (Cao et al., 2016). The chemical or physical structure of insulating materials can be used to categorize them, as stated by Papadopoulos et al., 2022, In this study, NRL would be used as a thermally insulating material; it is organic and has good thermal insulation, but it would be flammable and easily damaged by fire. It doesn't weigh much. The incompatibility of NR latex and cement prevents its use in infrastructure applications without the addition of a surfactant admixture, such as sodium dodecyl sulphate (SDS) (Sukmak, et al., 2020).

It should be pointed out that CM made from a mixture of cement, fine filler (sand), and water tends to have a high heat conductivity property in its solid form. Heat is transferred in solids by the vibration of molecules and free electrons present. In tropical areas, the high heat conductivity of cement mortar causes an increase in temperature both on the internal and external of the building (Brien and Mahboub, 2013). It also causes an increase in energy consumption. Besides, natural rubber latex as compared to other synthetic polymers is friendly to the surrounding environment and is also a sustainable material for use in the construction industry (Li et al., 2018). NRL is an organic thermal insulating material, and it possesses good thermal insulation although poor when it comes in contact with fire. Additionally, using this NRL with mortar provides thermal insulation for building envelopes, especially in tropical regions. It would also decrease air pollution caused by the release of carbon dioxide and this thermal insulation provided by the NRL also reduces the cost of power consumption for air conditioning by reducing the energy consumption in buildings.

From the above review of thermal insulating materials for thermal insulation, little or no work has been done on the utilization of NRL incorporated with mortar as a thermal insulating material in buildings. This research would focus on using this natural rubber latex as a thermally insulating material when incorporated with cement mortar. Therefore, the goal of this research is to identify if natural rubber latex added to mortar can serve as a means of thermal insulation in buildings. Thus, it is important as the high degree of heat in the tropical regions causes discomfort to the occupants of the building, a means of thermal insulation would provide a cooler and more comfortable internal environment to the occupants of the building.

Using mortar that has been modified with NRL has a significant number of prospects for the construction industry. When it comes to both cost and performance, NRL can provide a superior alternative for creating mortar in a manner that is less harmful to the environment while maintaining the same level of effectiveness. Because of the chemical composition of NRL, it is also beneficial to use it as a partial replacement for cement and water or as an additive in the production of mortar mixes. These applications give NRL added flexibility. However, there have not been a lot of studies done on the investigation of NRL mix compositions and their influence on the mechanical and durability properties. This research will be carried out so that it may be determined how different weight fractions of NRL effect the compressive strength, flexural strength, water absorption, and thermal conductivity of NRL-mortar composites. The outcomes of the study will offer recommendations on the proportions of a mortar mix that can be used in the application of masonry units for a variety of uses.

This section discusses the materials employed in the process of preparing the mortar mix design, sample preparations and the tests carried out on these samples. This research work is aimed at determining the thermal conductivity, water absorption coefficient, compressive strength, flexural strength and microstructural behavior of mortar incorporated with NRL. The procedures and apparatus for the various tests are discussed as well.

Ordinary Dangote Portland cement was the binding material adopted in this research. It’s a CEM1 cement conforming to the ASTM C150 requirements. The fine aggregate used was sharp sand passing through a 4.75 mm sieve to prepare the concrete samples. Besides, potable water was employed for mixing. Rubber latex was utilized in this research work as an admixture. The natural rubber latex was sourced from. Table 2 shows the NRL chemical assessment.

Batching is the method of measuring and mixing concrete components by the mix design. This procedure can be done in two ways: by volume or by weight. In this research work, the batching was done by weight. NRL was added in ratio to the total volume of the sample at different percentages, it was added at 0.5%, 1%, 1.5%, 2% and 2.5%.

The mix ratio used for this study was ratio 1:1.5 and the water-cement ratio is 0.45. The mixing was done manually, by hand mix, with the use of a shovel, and the dry constituents were first mixed till uniform distribution was attained. The natural rubber latex was mixed with the portable water and gradually added to obtain a thorough and workable mix. The casting takes place immediately after the mixing is completed. Five different mortar specimens were produced for examination in this study as appeared in Table 3.

To keep the concrete moist while it is strengthening, curing is primarily intended to stop moisture loss from it. Curing is necessary for all concrete made because it allows for the hydration process which in turn allows for the development of its strength and other characteristics develop (Raheem et al., 2013). Total immersion in water has been chosen as the curing method for this research. This method is excellent for meeting all curing criteria, including promoting hydration, removing shrinkage, and absorbing heat from hydration.

Using the heat conduction base unit, the thermal conductivity of composites made of mortar and NRL was measured. A steady-state approach is employed to ascertain the thermal conductivity in line with British Standards Institution and BS EN 1745 (2020). The specimen size has a thickness of 18 mm and a diameter of 30 mm. The top and bottom surfaces of the latter are kept at constant temperatures to create a one-dimensional temperature gradient and heat flow between a hot surface plate and a cold surface plate, allowing for accurate measurement of the sample’s thermal conductivity. The intention of this test is to ascertain the thermal conductivity of the mortar sample when mixed with NRL, which acts as an insulator. The duration of the experiment is dependent on the individual carrying out the experiment, and the power used is also dependent on the individual. In this experiment, the value of power used was 10 W and the experiment was done for 45 mins per sample. The thermal conductivity test is done in accordance with Fourier law using Eq. 1

where Q is the supplied heat (watts), k is the thermal conductivity of the material (W/mK), A is the area of the sample (m2),

A water absorption test was accomplished to assess the durability of concrete by testing the water permeability of the mortar. The greater the durability of mortar, the lower its water absorption. In this test, a 40 mm × 40 mm x 160 mm mortar cube was utilised. The water absorption test was performed according to British Standards Institution and BS EN 1015-18 (2019). The face of a mortar sample was completely saturated by submerging it in 5–10 mm of water. The water absorption of mortar was determined using Eq. 2

Where Wa is the water absorption (%), Wsat is the saturated surface dry weight (g), Wdry is the oven-dried weight (g), and Wwet is the weight the of sample in water (g).

Compressive strength is quantified by its ability to endure compressive forces. It is a measurement of the concrete’s resistance to failure when subjected to compressive pressures. Specimens measuring 40 mm × 40 mm × 160 mm were cast and tested in accordance with British Standards Institution and BS EN 1015-11 (2019). After 28 days of curing, the samples were tested. The compressive strength of the hardened concrete sample was calculated by dividing the load applied at the failure point by the cross-sectional area of the hardened concrete sample. The final result was based on averaging the compressive strength of the two samples.

A flexural strength test was executed to investigate the tensile strength of mortar by evaluating the mortar sample’s ability to withstand failure due to bending. Prism mortar sample of 40 mm × 40 mm × 160 mm in size we prepared and assessed under a three-point bending test in conformity with British Standards Institution and BS EN 1015-11 (2019). The prism sample was loaded continuously till the point at which it fails at a constant rate. The average flexural strength of these two replicate samples was taken into account as the result.

Scanning electron microscopy (SEM) examines the surfaces of materials to measure and assess fine details through image analysis. Through the use of an electron focused beam and image analysis, scanning electron microscopy examines and scans the surface of the material to measure and evaluate minute details. The signals that are created when electrons interact with the sample’s atoms can be employed to establish the chemical composition and surface topography of the sample. The assessment of the mortar-NRL composite specimen was conducted using a Philips XL-30 SEM device.

In this section, the results attained from the various tests would be presented and discussed. Five mortar mix ratio designs were considered in batching the mortar. Natural rubber latex (NRL) was added at different percentages as follows: 0.5%, 1.0%, 1.5%, 2.0% and 2.5%. Each of the variants was subjected to tests, and the results were tracked down and examined.

Figure 1 demonstrates the thermal conductivity of mortar with varying percentages of NRL. In general, it can be seen that the inclusion of NRL into mortar plays an important role to improve the thermal conductivity of mortar. From Figure 1, 2.5% NRL added into mortar shows an ideal result of thermal conductivity having a value of 0.93 W/mK. The control mortar specimen gives a thermal conductivity result of 1.76 W/mK. This shows that a 2.5% mix of NRL in the mortar specimen produces a better thermal insulation property as compared to the other mixes of NRL incorporated in the mortar specimens. It can also be noted that there’s an irregularity in the trend of the thermal conductivity result of the test. This could be attributed to a reduced pore volume, as demonstrated in the water absorption test. The mortar specimen containing 2.5% NRL has fewer pore spaces than the control mortar specimen validating the test result specifying that it possesses the optimal thermal insulating properties.

Figure 2 depicts the mortar water absorption capacityar with various percentages of NRL. The figure shows that when 0.5% NRL was added to the mortar, the absorption value increased when compared to the control mortar specimen. However, adding more than 1.0% NRL reduces the water absorption coefficient of the mortar. The ideal water absorption coefficient was attained with the inclusion of 1.5% NRL into the mortar. The nature of the hydrophobic NRL causes a reduction in absorption rate when NRL is added above 1.0% (Harahap et al., 2015). NRL can also create a thin matrix stratum that surrounds and covers the porosity of the mortar matrix. However, as the percentage of NRL above 1.5% increases, so does the absorption value of the mortar. The tendency of NRL to agglomerate was the primary cause of an increase in the water absorption coefficient (Boondamnoen et al., 2012). NRL compound is hard to spread through the mortar, and it doesn’t fill the spaces in the mortar as expected, allowing water to enter the cavities. The slurry flow required a combination of surface water (the layer of water film that forms on the surfaces of the mortar particles) and filled water (the water that filled the spaces between the mortar particles). The raw water absorption results gave a t-statistic value of 10.90, a p-value of 0.0001125 and a standard deviation of 1.1198. With this data, it is an indication that the mean values are significant.

There was a reduction in cement slurry flow and a thickening of the surface water after NRL was added to the mortar slurry (Figure 3). When NRL was added to the mortar, the pore water in the cementitious matrix had less surface tension (Figure 3A) and the pore fluid was more viscous (Figure 3B). Comparably, modifications above 1.5% showed poor water absorption capacity, possibly as a result of having too much NRL rather than just enough for the best void filling. In fact, excess NRL that is greater than what is required to fill capillary pores may appear at interface boundaries and prevent the proper compaction of aggregates. Thus, more voids could develop as the NRL merges, which is typically supplemented by a volume decrease.

Figure 4 demonstrates the compressive strength results of mortar with different percentages of NRL. According to the test results presented in Figure 4, the mortar’s capacity to withstand compressive loading is influenced by the percentage of NRL added to the mix. Following 7, 14, and 28 days of curing the mortar specimens, the compressive strength determined by the test was obtained. The optimum compressive strength was obtained with the addition of 1.0% NRL which gave a strength of 14.06 N/mm2 on day 28. The low absorption value seen in the previous section’s water absorption study, which explains for the 1.0% improvement in compressive strength, also indicates NRL’s ability to spread along and cover the mortar voids. Furthermore, sulphur particles in the NRL can help improve the mechanical properties of cement-based materials (Gawlicki and Czamarska, 1992). However, as the percentage of NRL rises above 1.0%, compressive strength begins to fall. This is due to the nature of the NRL, which agglomerates, weakening the bond between the aggregates (Khamput and Suweero, 2011). Furthermore, the presence of organic particles on the surface of NRL degraded the composite properties. Also, it is important to state that from Figure 5, no specific correlation was seen between compressive strength and the thermal conductivity of the mortars.

The flexural strength of mortar containing various NRL percentages is depicted in Figure 6. The flexural test result reveals a decreasing trend as the percentage of NRL increases after 28 days of curing. With a value of 4.75 N/mm2, the control mortar specimen had the greatest flexural strength of the other samples after curing for 28 days. From this test, it can be concluded that adding NRL to mortar weakens its bending resistance, making it susceptible to failure under bending stresses. This is a result of NRL compounds’ propensity to quickly aggregate when mixed. These lumps have the potential to damage the binding between the aggregate and the cement, as well as between the aggregate itself, lowering the flexural strength of the mortar. The NRL layers will cause coagulation between the cement matrix gelling products and the NRL layers (Jansen et al., 2012; Grinys et al., 2021). As a result, the development of mechanical strength is impeded. The raw flexural strength results gave a t-statistic value of 6.36, a p-value of 0.00142 and a standard deviation of 1.448. With this data, it is an indication that the mean values are significant.

Figure 7 demonstrates the morphologies of mortar with different percentages of NRL. It can be seen there’s a distinct difference in the roughness of the surface of the mortar specimens which indicates the presence of natural rubber latex in the mortar. Figure 7B–D depicts features that indicate the presence of gaps and cavity chains in the mortar with NRL. Because this is a typical longitudinal capture, it is expected that more gaps will be found on the traverse planes, which will eventually result in the formation of a honeycomb network of mortar particles connected by ducts. Normally, air will be present in these spaces because there is no moisture present. However, depending on how much NRL is added to the mortar mixture, the NRL’s finer qualities typically help to fill in the gaps that exist.

From Figure 7A, it can be seen that the control specimen has a rougher surface as compared to the mortar specimens with NRL present in them (Figure 7B, D). Besides, it can also be inferred from the morphologies of mortar the difference in the homogeneity of the mixes. The control mortar specimen shows a more consistent uniformity of materials than the mixes with the presence of NRL. The inconsistent homogeneity in the specimens with the addition of NRL may be a possible justification for the decrease in the NRL mortar’s mechanical properties.

A further inference is that the mortar mixtures’ compactness is a factor that influences the thermal conductivity of the mortar made with NRL. It can be seen from Figure 7D that the mortar specimen with the inclusion of 2.5% NRL has fewer pore spaces than the control mortar specimen (Figure 7A) which corroborates the test result that shows it has the ideal thermal insulating properties.

For instance, the morphology of mortar with 1.5% NRL (Figure 7C) showed that the NRL coats were present in the form of a jelly-like substance around voids and on mortar particles. This led to a partial filling of the previously noted roughness on the control mortar (Figure 7A). Meanwhile, mortar with 2.5% NRL produced the morphology shown in (Figure 7D). Mortar particles were embedded in this matrix, possibly because of higher NRL content. Indeed, all voids and cavities were filled. Because this mix contains the highest percentage of NRL in the mortar (2.5%), the effect of the NRL as it alleviates is more likely to be felt than with mortar containing lower NRL percentages.

The performance of masonry structures can be maintained at a consistent level by using a mortar mix ratio proportioning that is comprised of cement, sand, water, and NRL. A mortar’s strength, workability, and yields can be more consistently regulated if the materials are mixed in the correct proportions. Considering the results obtained and presented in sections 4.1–4.5, this section will propose a mortar mix proportion that can be utilized in the application of masonry units of different purposes.

i. The sand-to-cement ratio of 1:1.5 and the water-cement ratio of 0.45 is satisfactory to achieve the desired workability of mortar with the inclusion of NRL.

ii. For load-bearing purposes, it is recommended to employ NRL of less than 1% by weight fraction in cement mortar, especially under compression.

iii. NRL-modified mortar is not suitable to be used for structural members under flexural load.

iv. If the masonry unit is to be employed as a non-loadbearing element or as the façade of a building with the purpose to have sufficient thermal conductivity value, a higher weight fraction of NRL of approximately 2.5% ca be employed.

The results collated in this research give a complete analysis of the NRL mortar after 28 days of curing, showing its mechanical strength, water absorption properties, microstructural analysis, and its thermal conductivity. Increases in the proportion of NRL integrated in the mortar sample resulted in a drop in both the compressive and flexural strengths, although contradictory results were found for the mortar sample’s thermal conductivity and water absorption characteristics. From the current research, it can be summarized that:

1. The mechanical properties of the mortar samples incorporated with NRL in comparison to the control samples revealed poor mechanical properties, especially with the rise in the NRL percentage.

2. The water absorption property of the mortar samples with varying percentages of NRL gave an inconsistent trend. It showed the highest penetration of water at 0.5% percent mix of NRL and could be a result of increased pore volumes and poor homogeneity of the mix.

3. The thermal conductivity of the mortar samples showed inconsistency in its result as well. At 1.5% NRL, the sample showed great heat conductivity i.e., the heat flow through this sample was highest. At 2.5% NRL, the sample showed the least value of thermal conductivity meaning that it has the best thermal insulating ability as compared to the other samples.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

PA—Conceptualization, supervision, draft article, FA—Supervision and final draft, HA—Investigation, MO—Final draft, NB Editing and final draft, MS—Funding acquisition, HH—Supervision, VJ—Proof reading, MA—Editing.

The research was funded by the Ministry of Science and Higher Education of the Russian Federation as the grant Self-Healing Construction Materials (Contract No 075-15-2021-590 dated 04.06.2021).

The authors are thankful to the Deanship of Scientific Research at Najran University for funding this work under the Research Groups Funding program grant code (NU/RG/SERC/12/13).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Althoey, F., Awoyera, P. O., Inyama, K., Khan, M. A., Mursaleen, M., Hadidi, H. M., et al. (2022). Strength and microscale properties of bamboo fiber-reinforced concrete modified with natural rubber latex. Front. Mat. 9, 1064885. doi:10.3389/fmats.2022.1064885

Awoyera, P. O., Akinrinade, A., Galdino, A. G., Althoey, F., Kirgiz, M. S., and Tayeh, B. A. (2022). Thermal insulation and mechanical characteristics of cement mortar reinforced with mineral wool and rice straw fibers. J. Build. Eng. 53 (2022), 104568. Article 104568. doi:10.1016/j.jobe.2022.104568

Awoyera, P. O., Enemchukwu, N. G., and Karri, R. R. (2023). Performance validation of low-cost building insulation materials via the thermal characteristics and costs of insulation materials. AIP Conf. Proc. 2643 (1), 030029. doi:10.1063/5.0110350

Barreca, F., and Fichera, C. (2015). Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 62, 507–513. doi:10.1016/j.enbuild.2013.03.040

Baskar, I., Prabavathy, S., Jeyasubramanian, K., Anuradha, R., and Po, A. (2022). Thermal and mechanical characterization of microencapsulated phase change material in cementitious composites. Iran. J. Sci. Technol. Trans. Civ. Eng. 46 (2), 1141–1151. doi:10.1007/s40996-021-00636-5

Benmansour, N., Agoudjil, B., Gherabil, A., Kareche, A., and Boudenne, A. (2014). Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 81, 98–104. doi:10.1016/j.enbuild.2014.05.032

Boondamnoen, O., OshimaAzura, M. A. R., Chuajuljit, S., and Ariffin, A. (2012). Recycling waste natural rubber latex by blending with polystyrene – characterization of mechanical properties. Int. J. Mod. Phys. Conf. Ser. 6, 391–396. doi:10.1142/S2010194512003492

Bozsaky, D. (2010). The historical development of thermal insulation materials. Period. Polytech. 41, 49–56. doi:10.3311/pp.ar.2010-2.02

Brien, J. V., and Mahboub, K. C. (2013). Influence of polymer type on adhesion performance of a blended cement mortarfluence of polymer type on adhesion performance of a blended cement mortar. Int. J. Adhes. Adhes. 43, 7–13. doi:10.1016/j.ijadhadh.2013.01.007

British Standards InstitutionBS EN 1745 (2020). Mansory and mansory products – methods for determining thermal properties. London: British Standard Institute. 1–98.

British Standards InstitutionBS EN 1015-18 (2019). Methods of test for mortar for masonry - Part 18: Determination of water absorption coefficient due to capillary action of hardened mortar. London: British Standard Institute. 1–12.

British Standards InstitutionBS EN 1015-11 (2019). Methods of test for mortar for masonry. Determination of flexural and compressive strength of hardened mortar. London: British Standard Institute. 1–18.

Cao, X., Dai, X., and Liu, J. (2016). Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 128, 198–213. doi:10.1016/j.enbuild.2016.06.089

Diab, A. M., Elyamany, H. E., and Ali, A. H. (2013). Experimental investigation of the effect of latex solid/water ratio on latex modified co-matrix mechanical properties. Alex. Eng. J. 52, 83–98. doi:10.1016/j.aej.2012.11.002

Du, Y., Yang, W., Ge, Y., Wang, S., and Liu, P. (2021). Thermal conductivity of cement paste containing waste glass powder, metakaolin and limestone filler as supplementary cementitious material. J. Clean. Prod. 287, 125018. doi:10.1016/j.jclepro.2020.125018

Gawlicki, M., and Czamarska, D. (1992). Effect of ZnO on the hydration of portland cement. J. Therm. Anal. 38, 2157–2161. doi:10.1007/bf01979629

Grinys, A., Balamurugan, M., Augonis, A., and Ivanauskas, E. (2021). Mechanical properties and durability of rubberized and glass powder modified rubberized concrete for white topping structures. Materials 14, 2321. doi:10.3390/ma14092321

Guerra, N. B., Pegroin, G. S., Boratto, M. H., Barros, N. R., Graeff, C. F., and Herculano, R. D. (2021). Biomedical applications of natural rubber latex from the rubber tree Hevea brasiliensis. Mater Sci. Eng. C Mater Biol. Appl. 126, 112126. doi:10.1016/j.msec.2021.112126

Harahap, H., Hadinatan, K., Hartanto, A., Surya, I., and Ginting, M. (2015). The effect of drying temperature on mechanical properties of natural rubber latex products with cassava peel waste powder modified alkanolamide. J. Eng. Sci. Technol., 53–63.

Hong, D. Y., and Blackmore, S. (2015). The plants of China: A companion to the flora of China. Cambridge: Cambridge University Press, 1–488.

Huovilla, P. (2007). Buildings and climate change: Status, challenges, and opportunities. Virginia: Science for Environment Policy, 71. Available at: https://wedocs.unep.org/20.500.11822/7783.

Jansen, D., Neubauer, J., Goetz-Neunhoeffer, F., Haerzschel, R., and Hergeth, W. D. (2012). Change in reaction kinetics of a portland cement caused by a superplasticizer calculation of heat flow curves from XRD data. Cem. Concr. Res. 42, 327–332. doi:10.1016/j.cemconres.2011.10.005

Jiang, D., Lv, S., Chi, S., Sun, S., Song, X., He, S., et al. (2020). Effect of thermal insulation components on physical and mechanical properties of plant fibre composite thermal insulation mortar. J. Mat. Res. Technol. 9, 12996–13013. doi:10.1016/j.jmrt.2020.09.009

Khamput, P., and Suweero, K. (2011). Properties of mortar mixing with medium ammonia concentrated latex. Energy Procedia 9, 559–567. doi:10.1016/j.egypro.2011.09.065

Kim, K. H., Jeon, S. E., Kim, J. K., and Yang, S. (2003). An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 33, 363–371. doi:10.1016/s0008-8846(02)00965-1

Li, L., Huang, W., Ma, Y., and Hou, C. (2020). Experimental study on the effect of graphene on the thermal conductivity of natural rubber latex. E3S Web Conf. 145, 02074. doi:10.1051/e3sconf/202014502074

Li, Y., Li, W., Deng, D., Wang, K., and Duan, W. H. (2018). Reinforcement effects of polyvinyl alcohol and polypropylene fibers on flexural behaviors of sulfoaluminate cement matricesfibers on flexural behaviors of sulfoaluminate cement matrices. Cem. Concr. Compos. 88, 139–149. doi:10.1016/j.cemconcomp.2018.02.004

Liu, K., Wang, Z., Jin, C., Wang, F., and Lu, X. (2015). An experimental study on thermal conductivity of iron ore sand cement mortar. Constr. Build. Mat. 101, 932–941. doi:10.1016/j.conbuildmat.2015.10.108

Mydin, M. A. O., Phius, A. F., Sani, N. Md., and Tawil, N. M. (2014). Potential of green construction in Malaysia: Industrialised building system (IBS) vs traditional construction method. E3S Web Conf. 3, 01009. doi:10.1051/e3sconf/20140301009

Nawi, M. N. M., Lee, A., O Mydin, M. A., Osman, W. N., and Rofie, M. K. (2018). Supply chain management (SCM): Disintegration team factors in Malaysian Industrialised Building System (IBS) construction projects. Int. J. Supply Chain Manag. 7 (1), 140–143.

Nensok, M. H., Mydin, M. A. O., and Awang, H. (2021). Investigation of thermal, mechanical and transport properties of ultra lightweight foamed concrete (ULFC) strengthened with alkali treated banana fibre. J. Adv. Res. Fluid Mech. Therm. Sci. 86 (2021), 123–139. doi:10.37934/arfmts.86.1.123139

Othuman Mydin, M. A., Mohamed Shajahan, M. F., Ganesan, S., and Sani, N. M. (2014). Laboratory investigation on compressive strength and micro-structural features of foamed concrete with addition of wood ash and silica fume as a cement replacement. MATEC Web Conf. 17, 01004. doi:10.1051/matecconf/20141701004

Papadopoulos, A. M., Karamanos, A., and Avgelis, A. (2022). “ Environmental impact of insulating materials at the end of their useful lifetime,” in Proceedings of the Conference Protection and Restoration of the Environment VI, vol. III, Skiathos, Greece, July 1–5, 2002, 1625–1632.

Rabbat, C., Awad, S., Villot, A., Rollet, D., and Andres, Y. (2022). Sustainability of biomass-based insulation materials in buildings: Current status in France, end-of-life projections and energy recovery potentials. Renew. Sustain. Energy Rev. 156 (2022), 111962. doi:10.1016/j.rser.2021.111962

Raheem, A. A., Soyingbe, A. A., and Emenike, A. J. (2013). Effect of curing methods on density and compressive strength of concrete. Int. J. Appl. Sci. Technol. 3, 55–64.

Sansatsadeekul, J., Sakdapipanich, J., and Rojruthai, P. (2011). Characterization of associated proteins and phospholipids in natural rubber latex. J. Biosci. Bioeng. 111, 628–634.

Serri, E., Othuman Mydin, M. A., and Suleiman, M. Z. (2015). The influence of mix design on mechanical properties of oil palm shell lightweight concrete. J. Mater. Environ. Sci. 6 (6), 607–612.

Serri, E., Suleiman, M. Z., and Mydin, M. A. O. (2014). The effects of oil palm shell aggregate shape on the thermal properties and density of concrete. Adv. Mat. Res. 935, 172–175. doi:10.4028/www.scientific.net/amr.935.172

Singh, S., Munjal, P., and Thammishetti N, P., N. (2015). Role of water/cement ratio on strength development of cement mortar. J. Build. Eng. 4, 94–100. doi:10.1016/j.jobe.2015.09.003

Sukmak, G., Sukmak, P., Horpibulsuk, S., Yaowarat, T., Kunchariyakun, K., Orasa Patarapaiboolchai, A. A., et al. (2020). Physical and mechanical properties of natural rubber modified cement paste. Constr. Build. Mat. 244, 118319. doi:10.1016/j.conbuildmat.2020.118319

Tambichik, M. A., Abdul Samad, A. A., Mohamad, N., Mohd Ali, A. Z., Othuman MydinMohd Bosro, M. A. M. Z., Iman, M. A., et al. (2018). Effect of combining palm oil fuel ash (POFA) and rice husk ash (RHA) as partial cement replacement to the compressive strength of concrete. Int. J. Integr. Eng. 10, 61–67. doi:10.30880/ijie.2018.10.08.004

Yang, Y., Deng, Y., and Li, X. (2019). Uniaxial compression mechanical properties and fracture characteristics of brucite fiber reinforced cement-based compositesfiber reinforced cement-based composites. Compos. Struct. 212, 148–158. doi:10.1016/j.compstruct.2019.01.030

Keywords: cement mortar, rubber latex, thermal insulation, compressive strength, conductivity, water absorption

Citation: Awoyera PO, Althoey F, Ajinomisan H, Othuman Mydin MA, Bheel N, Sabri Sabri MM, Hadidi HM, Jayanthi V and Ahmad M (2023) Potential of natural rubber latex in cement mortar for thermal insulating material in buildings. Front. Mater. 10:1152492. doi: 10.3389/fmats.2023.1152492

Received: 27 January 2023; Accepted: 14 March 2023;

Published: 27 March 2023.

Edited by:

Neven Ukrainczyk, Darmstadt University of Technology, GermanyReviewed by:

Marinela Barbuta, Gheorghe Asachi Technical University of Iași, RomaniaCopyright © 2023 Awoyera, Althoey, Ajinomisan, Othuman Mydin, Bheel, Sabri Sabri, Hadidi, Jayanthi and Ahmad. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Paul O. Awoyera, cGF1bC5hd295ZXJhQGNvdmVuYW50dW5pdmVyc2l0eS5lZHUubmc=; Md Azree Othuman Mydin, YXpyZWVAdXNtLm15

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.