- 1Sports Department, Beijing Institute of Technology, Beijing, China

- 2Lincoln Univesity College, Petaling Jaya, Selangor, Malaysia

In boxing, the wrong training methods can easily cause physical injury, so many sports protective clothing will use new materials to reduce the impact of boxing training. The aim of this paper is to design a boxing suit based on graphene composite fiber seamless knitted fabric, so as to reduce the injury of boxers during training. In this paper, the head yarn, inner yarn and knitting structure of graphene composite fiber seamless knitted fabrics are discussed, and nine kinds of fabrics are determined by orthogonal matrix method; then, a comprehensive evaluation of the wear resistance of fabrics was proposed based on sequence entropy weight technology, and the ideal solution similarity (TOPSIS) method was used to calculate the wear resistance; finally, this paper designed the boxing protective suit according to the best combination of performance. The experimental results in this paper showed that the veil of sample No. 7 is 70D/48F graphene nylon, the inner yarn is 30D graphene spandex/70D graphene nylon covered yarn, and the fabric with the knitted structure of 1 + 3 false rib has the best comprehensive performance and the highest relative proximity, reaching 0.862. The actual wearing test proves that the comfort of anti-impact boxing suit is slightly better than that of ordinary boxing suit. The clothing designed in this paper has good anti-impact effect. Therefore, on the whole, the boxing suit with graphene composite fiber seamless knitted fabric has good protective effect and can be used for boxing training.

1 Introduction

Sports injury refers to the damage to the human body’s tissues and organ structures, or the dysfunction of the body due to mechanical, physical and other reasons during or after exercise. In short, it is the physical injury caused by sports. With the rapid development of sports, especially competitive sports, sports injury accidents are increasing day by day, and the causes are complex and diverse, so they are very common in mass sports and competitive sports. The health hazards of sports injuries to athletes cannot be ignored. It not only has a high incidence rate, but also causes serious damage to the muscles, bones, and organs of the human body. Severe cases would endanger the sports life of athletes, and may even threaten the lives of athletes (Jin et al., 2020; Wei et al., 2022). Especially in boxing, the rules of free fighting and the power of punching to the flesh make sports injuries more common in boxing.

At present, the research on sports protective equipment is mainly based on protective gear. When athletes perform vigorous and fast sports activities, they often need to wear protective gear in order to prevent the body from being seriously injured by impact. However, in addition to these intense and high-speed sports, many sports that are not high-speed sports, such as boxing, wrestling, gymnastics, cycling, etc., would cause certain damage to the body. This is an interdisciplinary subject involving biomechanics, clothing materials science, ergonomics, etc. There are many types of sports injuries and different protection needs, because some sports are less lethal and lack sufficient research and focus on. Therefore, in view of the above problems, this paper researched and developed protective sportswear from the perspective of anti-collision performance, made up for the blank of protective sportswear in addition to protective gear, and provided a basis for improving the safety of popular sports and competitive sports.

The application of graphene composite fibers to fabrics can improve various properties of fabrics, which has been studied by many scholars. Tian et al. (2019) aimed to develop a new type of knitted seamless structure filter material with high production efficiency and excellent filtration performance. He developed a new type of weft-knitted seamless weft-inserted fabric filter material on an improved circular knitting machine. Wu et al. (2020) proposed a new modeling method to predict the deformation of knitted fabrics, that is, to establish a virtual fiber model, which is used to build a weft knitting model at the microscopic scale. To study the thermal comfort of tight-knit knitted running sportswear, Wu et al. (2018) selected several fibers and yarns and developed 35 weft knitted fabrics consisting of five knit structures. Yu et al. (2018) studied new toughening materials based on graphene, and toughened polycarbonate was formed by composite short carbon fibers and graphene sheets. Hessami et al. (2019) has studied the composite method of graphene on plants. He compared the two methods of biaxial and rib weft knitting. It can be found that relevant scholars are very interested in graphene composite fiber materials. They not only analyze the various performance advantages of graphene composite fiber materials in detail, but also design more new materials based on graphene composite fibers. However, there are not many studies on the application of graphene composite materials to boxing protective clothing, and the research content is not enough.

Boxing is a passionate sport and is deeply loved by young and middle-aged people. There are also many researches on the protection of boxing training sports injuries. Perkins et al. (2018) studied boxing gloves that can adequately transmit the impact force to the opponent, thereby making boxing safer. Since there have been many cases of intracranial injuries caused by boxing in the United States in recent years, Wolfe et al. (2021) evaluated the safety and effectiveness of protective equipment such as boxing helmets for concussions. Liu et al. (2021) has studied the damage caused by boxing from a biochemical point of view, and he believed that glycine can be used to reduce the physical damage caused by boxing. However, they still focus on the protective effect of boxing gloves for injury protection in boxing training, and there are not many studies on the protective performance of body clothing.

In this paper, according to the advantages of graphene composite materials, the design and development of impact-resistant boxing suits were carried out. Compared with traditional seamless fabrics, graphene nylon, graphene spandex covered silk, and graphene nylon covered silk were used in this paper.

2 Materials and methods of boxing protective clothing and sports injuries

2.1 Boxing sports injuries

According to the sports injury rate survey of students in physical education others, it was found that the probability of sports injury accounted for 53.86%, which mainly occurred in the limbs and trunk (Rajesh and Pitchaimani, 2018). Sports injury is the research content of many disciplines such as medicine, sports training, sports anatomy, physical education and so on. Medicine focuses on the prevention and treatment of sports injuries. The focus of the sports world is to carry out physical training scientifically to prevent the occurrence of sports injuries. Physical training, physical education, etc., are working hard to design a set of scientific training plans and methods to improve and reduce sports injuries (Liu, 2020).

2.2 Graphene composite fibers in the textile field

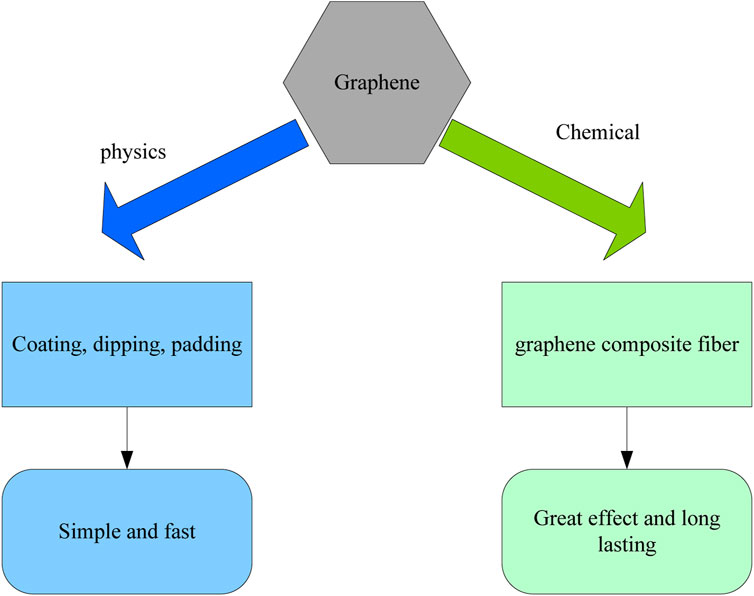

Graphene has a unique hexagonal crystal structure, which makes it possess many excellent properties (Guo et al., 2020). Its special properties can make up for the defects of many current materials. There are two main applications of graphene in textiles, as shown in Figure 1. One is to combine graphene and fabric by methods such as coating, dipping, and finishing. The other is a new fiber material developed based on graphene. The advent of graphene composites has opened up new avenues for its application in textiles. Researchers mixed graphene with polyacrylonitrile fibers, polyester fibers, polyamide fibers, viscose fibers, etc., to make graphene fibers suitable for the textile field (Pereira et al., 2020).

Seamless knitting technology originated in the 1980s. It uses computers to design the structure and physiological functions of the human body, and then uses a special seamless knitting machine to realize production (Ren et al., 2020). The seamless weaving technology was originally used to make socks, and later, due to the development and improvement of seamless weaving technology, it has been widely used in the fields of boxing suits, swimwear, casual wear, sportswear, outerwear, medical supplies, and car interior decoration products. Seamless knitted fabric is a product produced by a seamless knitting machine. Compared with traditional knitted fabrics, the biggest feature of seamless knitted fabrics is that there is no need to cut and sew, so that there are no stitches on the neck, shoulders, waist, hips, armpits, etc., and it is more comfortable to wear. In addition, according to the structural characteristics of the human body, various parts of the clothes can be designed so that they would be subjected to different pressures during the wearing process, so as to play a role in self-cultivation, body shaping and health care.

2.3 Comprehensive evaluation method of fabrics

2.3.1 Entropy weight method

The entropy weight method is an objective weighting method, and its basic principle is to determine the weight by evaluating the disorder degree of the evaluation value of the target index and the amount of reflected information (Morch et al., 2019; Karaoglu and Alpyildiz, 2021). Information is used to measure the order of a system; while entropy is used to measure the chaos of the system, and the absolute quantity of the two is equal, but the sign is just the opposite. The information entropy of each index can be obtained by using the entropy weight method. The greater the information entropy, the greater the chaotic degree of information. That is to say, the lower the weight of the information utility value or index, the smaller the impact on the comprehensive performance evaluation. Conversely, the lower the information entropy, the weaker the information clutter, and the higher the proportion of information utility value or index, the more it can affect the overall performance.

2.3.2 The principle of TOPSIS method

TOPSIS (Technique for Order Preference by Similarity to an Ideal Solution) is a multi-objective decision-making method. The basic idea of the TOPSIS method is to sort the relative distance between the evaluation value of the evaluation target and the positive and negative targets of the comprehensive evaluation, so as to measure the pros and cons of its performance. The reason why the optimal solution is optimal is that all indicators can meet the best indicators; the worst solution is the worst, that is, all indicators have reached the worst indicators. When the index evaluation value of the evaluation target is close to the positive ideal solution and far from the negative ideal solution, the performance of the evaluation target is more perfect (Kim, 2018). TOPSIS method avoids the subjectivity of data, does not need objective function, does not pass the test, and can well describe the comprehensive impact of multiple impact indicators. There are no strict restrictions on data distribution, sample size and indicators. It is not only suitable for small sample data, but also for large systems with multiple evaluation units and multiple indicators. It is more flexible and convenient. However, other methods cannot meet the requirement, such as GRA. If GRA must use this method, the system must be gray.

2.3.3 Decision-making steps based on entropy weight TOPSIS method

In this paper, the entropy weight method is combined with the TOPSIS method to conduct a comprehensive evaluation of the fabric, so as to make an objective and effective analysis of the performance of the fabric.

(1) Determination of the initial decision matrix

The initial evaluation objective and evaluation index are set as the initial evaluation objective m and the evaluation index n. Each evaluation index is

In the initial decision matrix, the greater the difference between the evaluation values of each evaluation index, the greater the impact of the evaluation index on the comprehensive evaluation; instead, it would play less of a role. If the evaluation value of an evaluation index is the same, it indicates that the index cannot be used for comprehensive evaluation, and it can be eliminated and included in the entropy weight (Wang et al., 2022).

(2) Specification of the decision matrix:

In the comprehensive evaluation, the dimensions of various indicators are different. In order to facilitate comparison, different standardization methods must be adopted to standardize various indicators into values belonging to [0, 1].

If the evaluation index is a benefit index and a cost index, the formulas are:

If the evaluation index is a moderate index, and the optimal value range is set to

The normalized matrix can be expressed as:

(3) Simultaneous quantification of each indicator

The relative proportion of the evaluation value of the ith evaluation object under the jth evaluation index is calculated using the following formula:

Among them:

It can be represented by a matrix as:

(4) The entropy value

Among them:

(5) Weights are calculated

First, the coefficient of variance for the jth indicator is calculated:

In the jth index, if all

According to the entropy value, the weight of the jth indicator is calculated:

(6) The construction of the weighted normalization matrix:

In the comprehensive evaluation, the weights of each index are different. It is necessary to consider the entropy weight of each index, weight each index, establish a weight standardization matrix, and use the following formula:

It can be represented by a matrix as:

(7) Positive ideal solution

(8) The distance is calculated:

To calculate the distance between the evaluation object and the positive and negative ideal solutions, the following formulas are used, respectively:

(9) The relative proximity index

The relative proximity of the evaluation object to the ideal solution is:

According to the calculation result of relative proximity

3 Preparation of graphene composite fiber seamless knitted fabric

3.1 Establishment of the sample scheme of graphene composite fiber seamless knitted fabric

This paper focuses on the structure and properties of graphene composites, and compares the appearance of graphene nylon with conventional nylon. The properties of graphene nylon, graphene nylon/graphene amino spandex coated yarn, graphene nylon spandex coated yarn, nylon, and nylon coated yarn were compared, and analyzed from the aspects of moisture absorption and tensile fracture. It provides a reference for further exploring the properties of seamless knitted fabrics. Graphene also has good impact properties.

Experimental equipment: JSM-5610LV scanning electron microscope, conductive glue, collodion, etc.

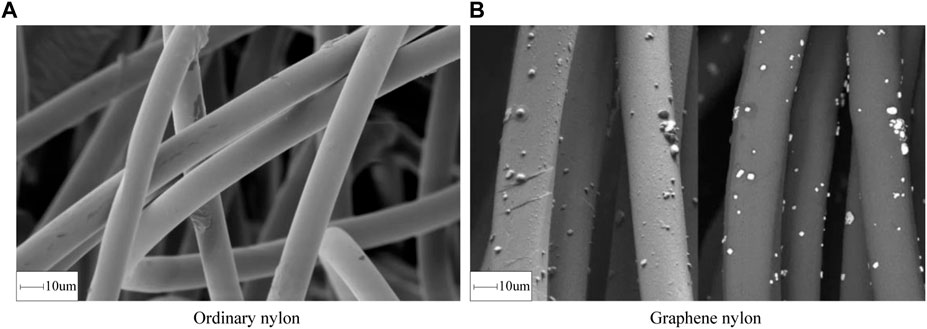

Experimental procedure: Before the test, the samples were wetted in standard temperature and humidity for 24 h, then coated with conductive glue, and then observed with a JSM-5610LV scanning electron microscope. Figure 2 shows the results of the test, wherein Figure 2A is a common nylon, and Figure 2B is a graphene nylon.

FIGURE 2. Electron microscope photos of ordinary nylon and graphene nylon. (A) Ordinary nylon. (B) Graphene nylon.

It can be seen from Figure 3 that the surface of conventional nylon fiber is smooth and flat, while compared with conventional nylon, a large number of particles adhere to the surface of graphene nylon fiber, which makes the surface of the fiber rougher.

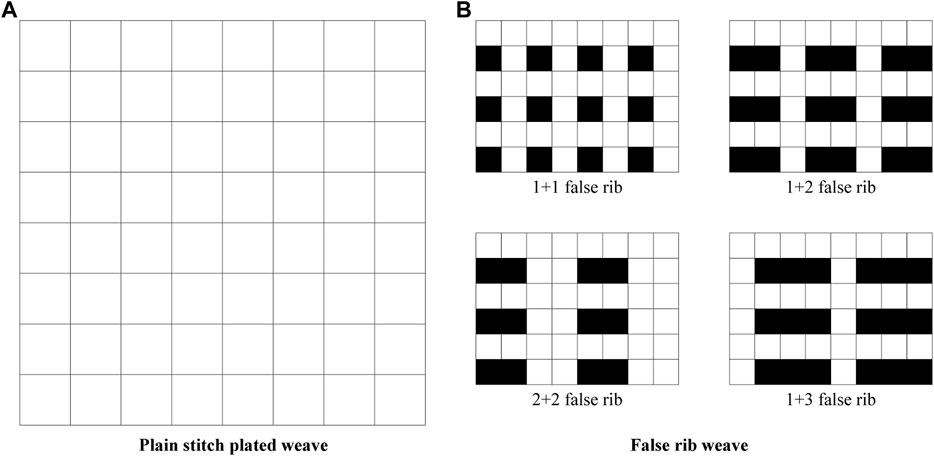

The organizational structure of the fabric has a great influence on the performance of the fabric. It would not only affect the appearance quality of the fabric, but also have a certain impact on the fluffing, pilling, air permeability and moisture permeability of the fabric. Single jersey seamless knitting machines usually knit two yarns at the same time, a face yarn and an inner yarn, as shown in Figure 3. Usually, the knitted of plain knitted yarn is more common, as shown in Figure 3A, and the knitted of false rib is shown in Figure 3B.

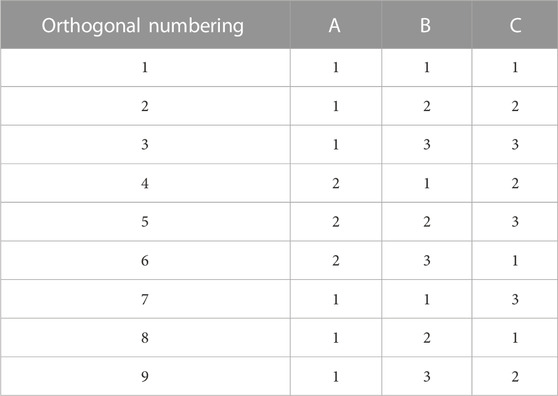

The purpose of this paper is to explore the effects of veil material, lining material and tissue structure on the function and wearability of fabrics. Orthogonal experimental design method was adopted, and representative factors and grades were selected according to the comparability of the dispersion characteristics and integrity of the samples. This method not only has good representativeness, but also can greatly reduce the experimental workload, save materials and save time. The raw materials of a veil are divided into three aspects: A veil raw materials, B veil raw materials, and C organizational structure. A veil raw materials are divided into two grades: Graphene nylon and ordinary nylon; B grade inner yarn raw materials are divided into three types: Graphene nylon Graphene-coated yarn, graphene-nylon-coated yarn, and common nylon-coated yarn; C-type knitted is divided into three levels: Plain stitch yarn-enhancing knitted, 1 + 1 false rib knitted, and 1 + 3 false rib knitted.

The image of the actual fabric during the study is shown in Figure 4.

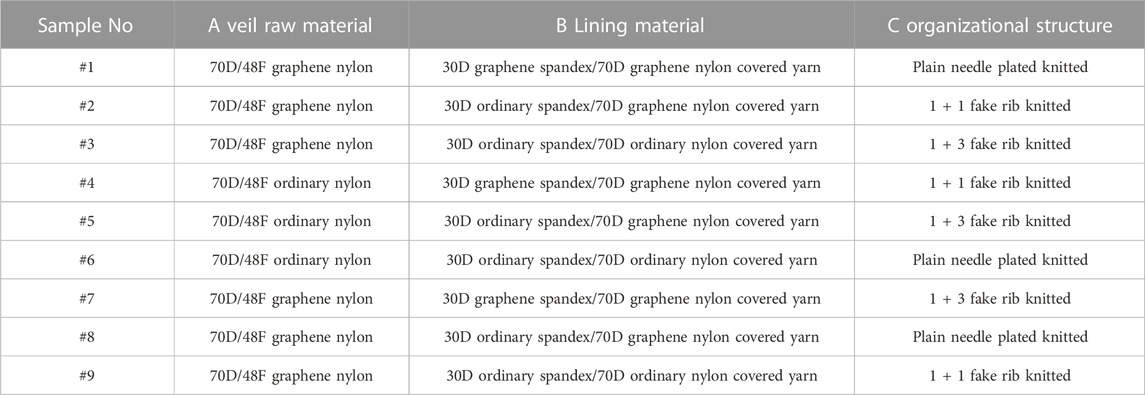

Since the yarn raw material in factor B and the organizational structure of factor C are all three-level, and the raw material of A has only two levels. Therefore, the orthogonal matrix method is used to repeat the 70 D/48 F graphene nylon in the A factor as the third level. The details are shown in Table 1.

Combined with various factors and levels, nine experimental samples were knittedd, and the specific sample specifications are shown in Table 2.

According to the basic parameters of the fabric, the thickness and gram weight of nine samples were measured, which provided a reference for the analysis of the fabric properties in the future. The fabric samples were measured using a digital fabric thickness gauge, and each sample was tested 10 times and averaged to determine the fabric thickness. A fiber sample of 10 by 10 mm was weighed with an electronic scale, the gram weight was calculated, five measurements were made for each sample, and the average value was taken. Specific test results are shown in Table 3.

3.2 Functional evaluation of graphene composite fiber seamless knitted fabric

This paper focuses on the functions of graphene seamless knitted fabrics, especially far-infrared, anti-static, anti-ultraviolet, etc. On this basis, the factors such as raw material and organizational structure are analyzed.

The far-infrared radiation was measured by EMS-302M far-infrared reflectivity tester. The test refers to FT/T64010-2000 (Ghazanlou et al., 2021). First, each fiber sample was cut into a size of 2 mm × 2 mm, and then it was tested for far-infrared radiation with a far-infrared reflector. Three tests were carried out on different samples, respectively, and the average value was calculated to obtain their far-infrared radiation coefficient. Each fiber sample was cut into a size of 4 mm × 6 mm, placed at 18 °C and 38% relative humidity, and equilibrated for 6 h, and the half-life of the sample was measured by an instrument. Three tests were performed on different samples, and the average value was calculated to obtain the half-life of the sample. The results are shown in Figure 6A:

The test refers to GB/T18830-2009. First, the samples were cut into five pieces, and the samples were placed in a dry place for 24 h under certain temperature and humidity conditions. Under the test conditions of 290–400 nm band and 1 nm wavelength interval of 1 nm, various samples were heated for 30 min and 5 times for each test, and the average value was taken. In Figure 5B, the UVA, UVB transmittance and Ultraviolet Resistance Factor (UPF) values for each fabric are shown.

FIGURE 5. Functional test results of the fabric. (A). Far-infrared and antistatic properties of fabrics. (B). UV resistance of fabrics.

As shown in Figure 5A, the No. 7 fabric has the highest infrared emissivity and the shortest half-life, indicating that the No. 7 fabric has better far-infrared and antistatic properties. From Figure 5B, it can be found that, except for the fabric No. 6, which has poor UV resistance, other fabrics have good performance in UV resistance.

3.3 Wearability of graphene composite fiber seamless knitted fabrics

3.3.1 Wrinkle recovery of fabrics

When clothing is worn and stored, due to external forces such as friction and extrusion, the fabric would be wrinkled, which would affect the appearance of the product. The shrinkage rate of the fabric refers to the recovery performance of the fabric after being affected by external forces. The wrinkle recovery angle is an index to measure the wrinkle recovery rate of the fabric. The larger the wrinkle recovery angle, the better the wrinkle recovery ability, and vice versa.

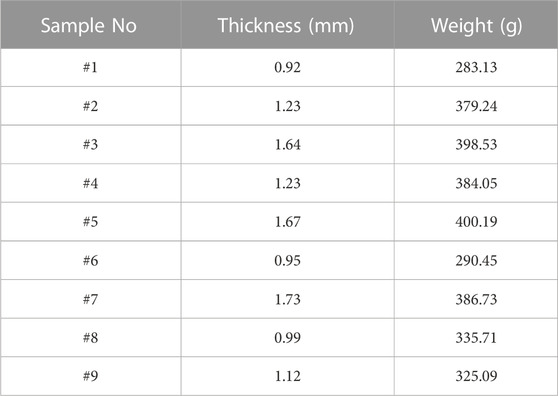

Each fabric was cut with five convex specimens in the transverse and longitudinal directions. After 24 h under certain temperature and humidity conditions, the elastic recovery angle on the fabric crease was measured and the average value was taken. The wrinkle recovery test for each fabric is shown in Figure 6.

By comparing Figures 6A, B, it can be found that in the transverse direction, the recovery angles of the elastic and slow elastic folds of the fibers are larger than those in the longitudinal direction, indicating that the shrinkage rate of the fabric in the transverse direction is relatively good.

3.3.2 Analysis of water permeability, breathability, and moisture absorption of fabrics

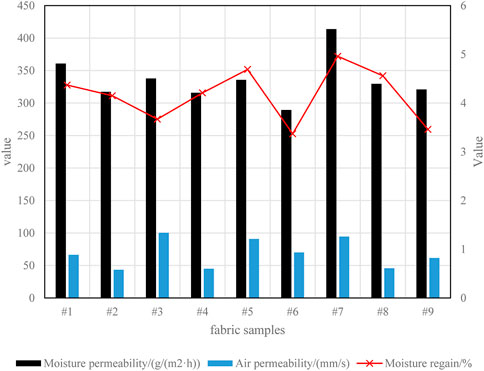

The hygroscopicity of fabrics is an important index to measure the comfort of fabrics, and it is also the key to affecting fabric processing and dyeing and finishing processes. Moisture permeability refers to the water penetration characteristics through fibers, which has a great influence on the comfort of fabrics. The body releases a large amount of water vapor during exercise, and these water vapor cannot be transported into the surrounding air in time, which would cause discomfort. The property of the air passing through the fiber is called “the breathability of the fabric”, which is directly related to the comfort and hygiene of the fabric. Therefore, it is necessary to ensure that the fabric has a certain air permeability, and can discharge the exhaust gas in the human skin in time, so that the clothes can be kept clean and comfortable. Air permeability is an indicator that can reflect its air permeability. The higher the air permeability, the better the air permeability; on the contrary, the air permeability of the fabric is poor. The fabrics were tested in these three aspects according to the standard, and the experimental results are shown in Figure 7:

FIGURE 7. Experimental results of water permeability, air permeability and moisture absorption of fabrics.

It can be found from Figure 8 that the moisture absorption performance of the No. 7 fabric is the first, and the air permeability is the second. This shows that the No. 7 fabric has better wearing performance, and has better performance in water permeability, breathability and moisture absorption.

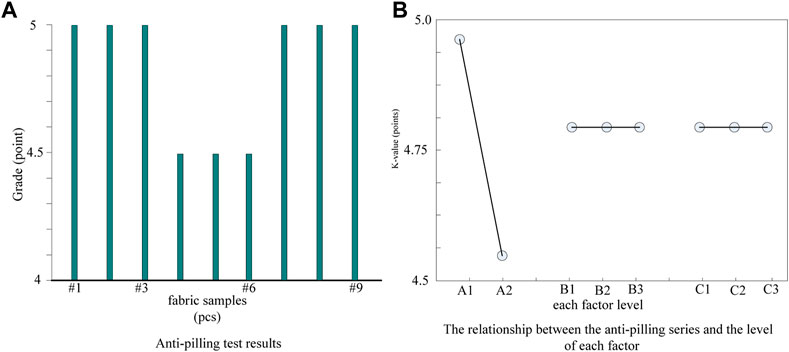

FIGURE 8. Test results of anti-pilling function. (A) Anti-pilling test results. (B) The relationship between the anti-pilling series and the level of each factor.

3.3.3 Anti-pilling of fabrics

When textiles are used and washed, they rub against other objects, resulting in fuzzing and blistering on the surface of the fabric, which affects the appearance, feel and luster of the fabric. Therefore, the anti-puffing performance of the fabric is also a good evaluation index. First, the samples were cut to a diameter of about 113 mm and placed in a standard temperature and humidity hanger for 24 h. After the test, the fabric samples were scored in the evaluation box, 5 times for each sample, and the average value was taken. The results are shown in Figure 8.

As shown in Figure 8A, the veils of the three fabrics 4, 5, and six were common materials and were rated 4.5 on the anti-pilling ball. As shown in Figure 8B, in the orthogonal experiment, it can be found that the performance of the veil is directly related to the anti-pilling performance.

3.4 Comprehensive evaluation of fabrics

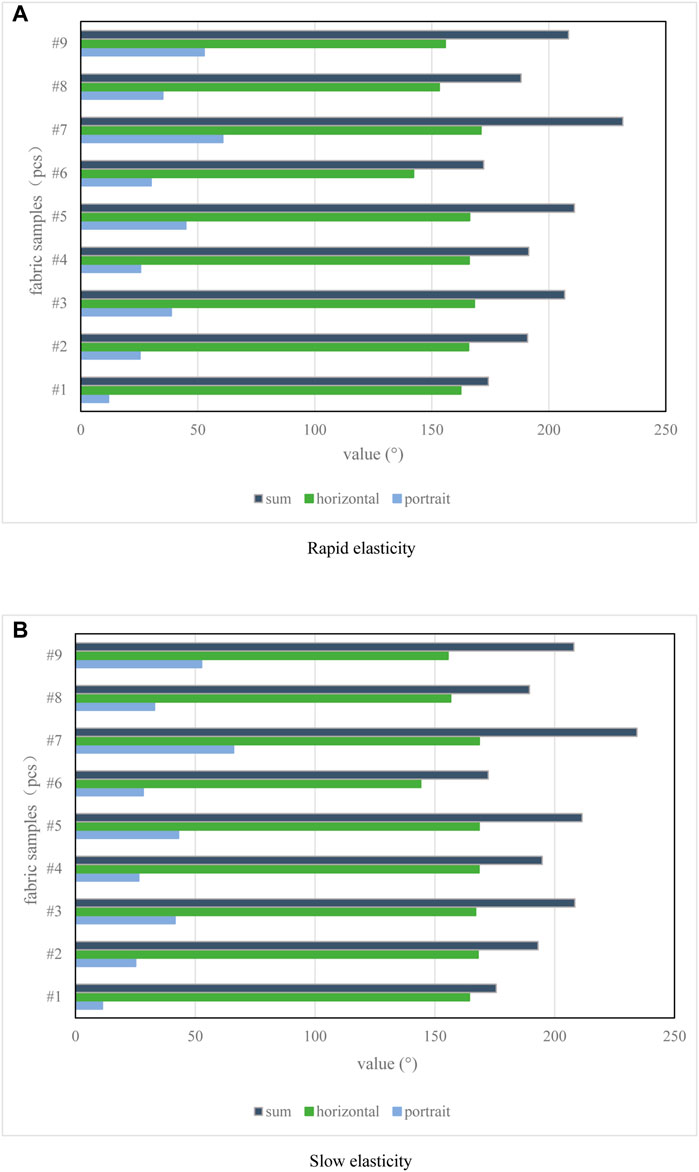

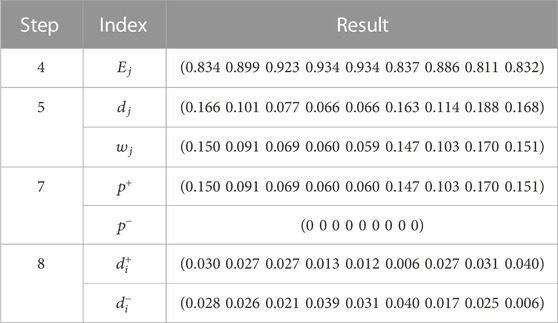

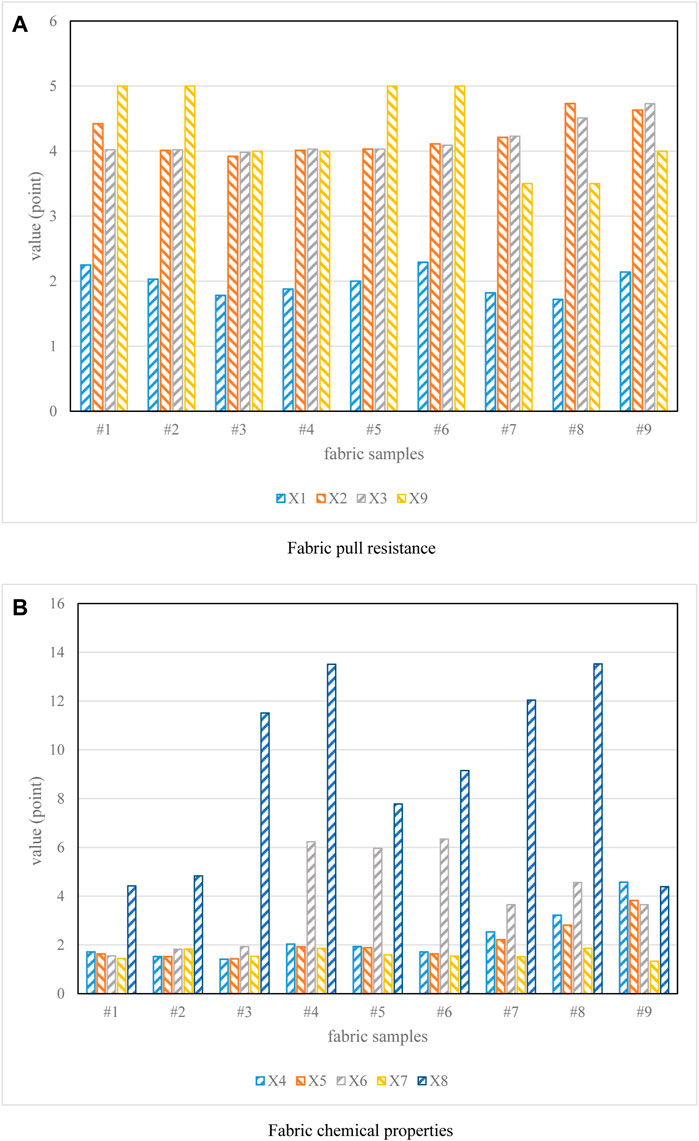

Based on the data obtained from the experiment, this paper conducts an evaluation study on the relevant performance indicators. The specific experimental test data is shown in Figure 9, in which Figure 9A shows the data of X1, X2, X3, and X9; Figure 9B shows the raw data of five aspects of X4, X5, X6, X7, and X8.

FIGURE 9. Wearing properties of fabrics. (A) Fabric pull resistance. (B) Fabric chemical properties.

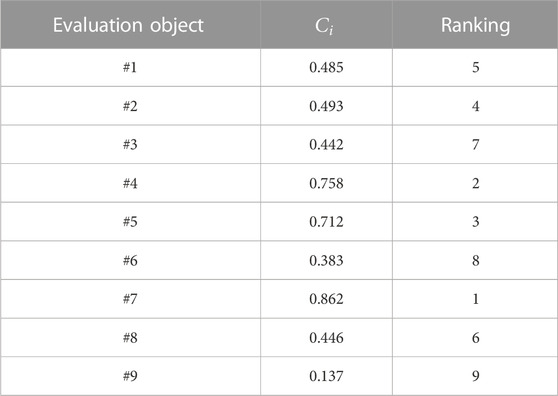

According to the decision-making steps based on the entropy weight TOPSIS method, the comprehensive performance evaluation of the fabric is carried out. The calculated index results are shown in Table 4:

The relative proximity can be calculated from the indicators in Table 4 according to Formula 22, and the results are shown in Table 5:

It can be seen from Table 5 that the No. 7 fabric has the best performance, has better wearability, and has the highest comprehensive evaluation. Therefore, the best fabric veil is 70D/48F graphene nylon, the inner yarn is 30D graphene spandex/70D graphene nylon covered silk, and the knitted structure is 1 + 3 false rib knitted.

4 Design and development of protective sports clothing

4.1 Investigation content and object

The questionnaire includes sports injuries and design preferences. Sports injury status includes the number of injuries, vulnerable parts, types, etc., and clothing design preferences include clothing function, color, style, and other issues. This paper selects male members of Jiangxi Boxing Association and online boxing forums as research objects, which has strong pertinence, professionalism and credibility. A survey of 20 fighters participating in boxing matches was conducted.

4.2 Investigation and evaluation on boxing suits

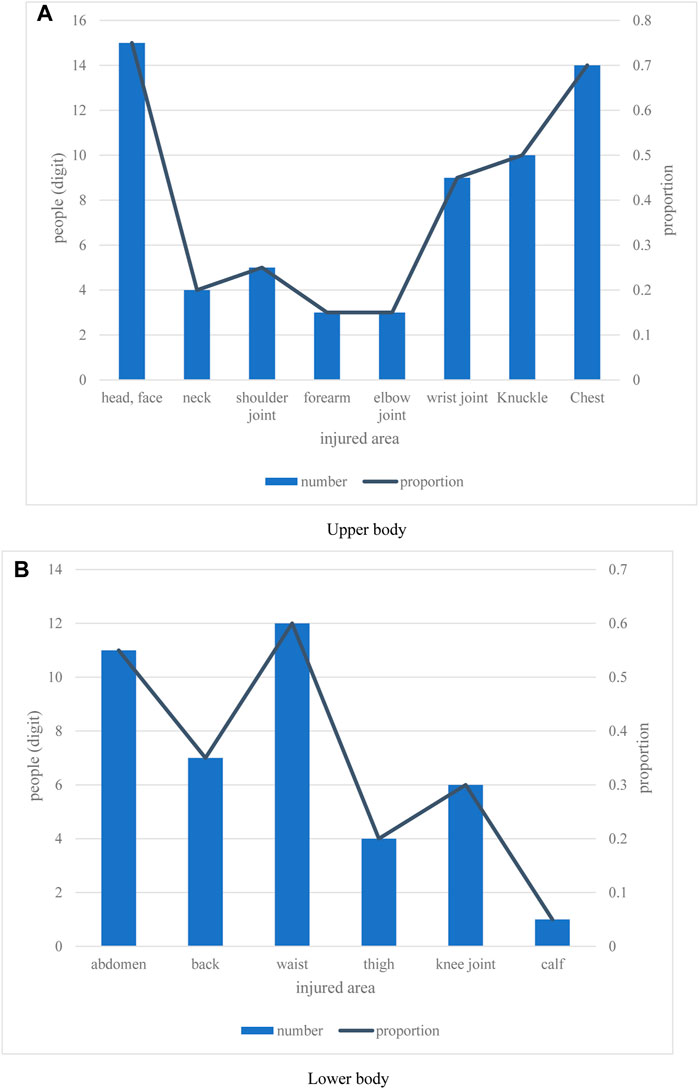

According to statistics about injuries suffered since participating in boxing matches, 20 respondents were injured to varying degrees, and all of them were injured 5 times or more. 100% of those surveyed said that injuries are possible in boxing. This is because boxing is a kind of fighting, often hitting opponents with fists, so there is a high chance of injury.

In the investigation of injured parts after participating in a boxing match, 20 people were injured in the head, chest, waist, abdomen, finger joints and other parts. Among them, the proportion of head, face and chest is the highest, 75% and 70%, respectively. This is because in boxing, if there is no obstruction, the punch would hit the opponent’s head or the front or side of the waist to score. Therefore, the main target of attack is the head and forequarters, which is easy to cause sports injuries. In boxing competitions, in order to reduce the degree of physical injury, when developing boxing clothing, attention should be paid to the chest, waist, abdomen and other parts. Among them, Figure 10A shows the injury situation of the upper body, and Figure 10B shows the injury situation of the lower body.

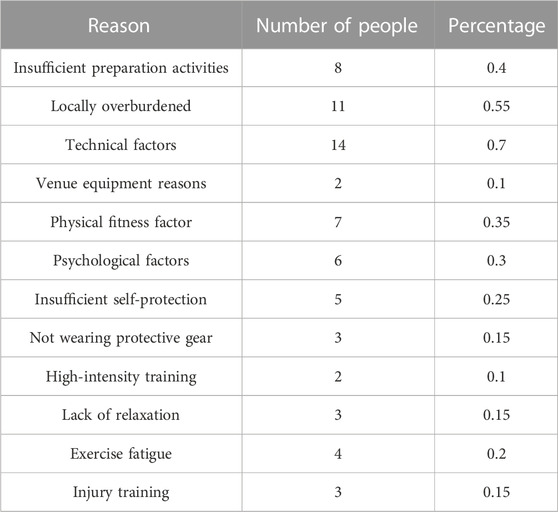

In the investigation of the causes of injuries after participating in boxing, the causes of injury among the 20 subjects include technical factors, partial loads, insufficient preparation activities, physical fitness factors, etc., as shown in Table 6.

In addition, 14 respondents said that sports injuries would affect their lives and work, and the proportion is as high as 70%. Among the 20 subjects surveyed, 17 chose to use protective equipment and had a good awareness of protection. 80% agreed that protective gloves must be worn.

4.3 Boxing suit design

According to the use characteristics of the above-mentioned test samples, combined with the investigation of boxers, a seamless protective boxing suit that conforms to the shock resistance of the human body and is comfortable to wear is developed. Through the test and data analysis of the previous fabric wearing performance, the wearing characteristics of the test fabric are studied, so as to provide a basis for the design of sports apparel fabrics. Through the investigation and analysis of the sports injuries of boxers, the vulnerable parts are found out, so as to provide the basis for the design of the anti-collision parts of sports clothing. Through the investigation on the preference of boxer sportswear, the style, style and color of the boxer are researched, and the appearance design is guided. Because boxing suits are mostly tights, in the design and development, attention should be paid to the functionality and comfort of the clothing, as well as the aesthetics.

Based on the performance analysis of the graphene composite material described above, the comprehensive wear performance of the graphene fabric was obtained, and the No. 7 fabric was the best. This article uses No. 7 fabric as the main fabric (Uyor et al., 2022).

According to the sports injury survey, boxers are most vulnerable to impact injuries during boxing training in the lower back and back. The chest and abdomen are second, and the thighs and shoulders are less. Therefore, the front, back waist and trouser legs of boxing suits use spaced 1 + 3 false rib knitted, which has the best shock-proof protection. This boxing suit also has a separating decorative line, which has good moisture permeability, breathability and moisture absorption, and can greatly improve the wearability of the clothes. In addition, the crotch is made of tight fabric with high strength and high fastness. The collar, cuffs, and trousers are all closed with a ring structure, and the double-layered tie makes it more compact and not easy to deform.

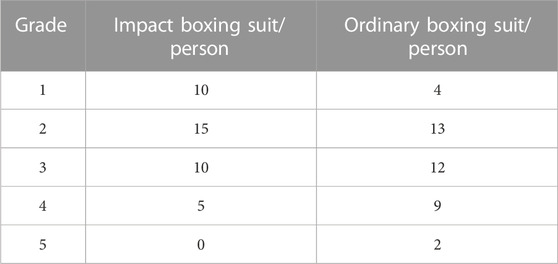

The boxing clothing developed in this paper must be verified by subjective comfort evaluation. In this paper, the overall comfort of clothing is discussed using field tests and subjective assessments. The test samples were made of size M boxing clothes, compared with ordinary size M boxing clothes, and tested by athletes for subjective comfort evaluation. The subjective comfort was assessed on a five scale: 5 (very comfortable), 4 (comfortable), 3 (average), 2 (average), and 1 (uncomfortable). Through the questionnaire survey, the number of materials selected by different levels of players in the subjective comfort evaluation of boxing suits is obtained, as shown in Table 7.

As can be seen from Table 7, the comfort of shockproof boxing suits is better than that of general boxing suits. In the three grades, the boxing clothing material in this paper is higher than that in the ordinary materials, but in the fourth and fifth grades, the ordinary boxing clothing material is higher than that in this paper. According to the subjective comfort evaluation results in Table 7, the comfort of ordinary boxing suit in human impact boxing suit is significantly worse than that of the materials selected in this paper. Therefore, In short, there is no significant difference in comfort between the shockproof suit developed in this paper and the general boxing suit, and its comfort level is even higher than that of ordinary boxing suits, and the shockproof and defensive suit developed in this paper is stronger, which proves its practicality.

Of course, the impact of cost on boxing clothing materials cannot be ignored. Due to the limited space of the article, this paper will focus on comparing the impact of the cost of different materials on boxing clothing materials in future research.

5 Conclusion

In this paper, the orthogonal test method is used to study the influence of the material, material and structure of the veil on the properties of the fabric. Finally, according to the characteristics of boxing injuries, a graphene composite fiber seamless boxing suit with excellent impact resistance was developed. However, this article also has shortcomings. First of all, cost comparison is the blind spot of this paper. Secondly, the number of samples selected in this study is limited, and the results may not be representative. In the future, the research scope will be expanded to make contributions to the application of graphene composite fiber seamless knitted fabric in boxing clothes.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

All work in this article is completed by TL.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Da Silva, R. I., and Cecilia, D. S. F. K. (2022). Incorporation of graphene oxide on thin film composite polysulfone/polyamide membranes. Braz. J. Chem. Eng. 39 (2), 319–325. doi:10.1007/s43153-021-00098-2

Ghazanlou, S. I., Eghbali, B., and Petrov, R. (2021). Microstructural evolution and strengthening mechanisms in Al7075/graphene nano-plates/carbon nano-tubes composite processed through accumulative roll bonding[J]. Mater. Sci. Eng. A. Struct. Mater. Prop. Misrostructure Process. 2021 (807), 46–60. doi:10.1016/j.msea.2021.140877

Guo, D., Wang, S., Yin, Y., Luo, J., Meng, C., Liu, Q., et al. (2020). Preparation of three-dimensional multilayer ECM-simulated woven/knitted fabric composite scaffolds for potential tissue engineering applications:[J]. Text. Res. J. 90 (7-8), 925–936. doi:10.1177/0040517519883958

Hessami, R., Yazdi, A. A., and Mazidi, A. (2019). Investigation of tensile and flexural behavior of biaxial and rib 1 × 1 weft-knitted composite using experimental tests and multi-scale finite element modeling. J. Compos. Mater. 53 (23), 3201–3215. doi:10.1177/0021998319839855

Jin, H., Ting, F., Zhu-wei, G., Yan-qing, Z., Jie-qiong, W., Yang, C., et al. (2020). Characteristics of photothermal conversion performance of graphene oxide composite non-woven fabric based on electrospinning experiment. Chin. J. Luminescence 41 (2), 134–139. doi:10.3788/fgxb20204102.0134

Karaoglu, L., and Alpyildiz, T. (2021). Impact performances of monoaxial knitted fabric composites:[J]. J. Compos. Mater. 55 (17), 2275–2287. doi:10.1177/0021998320988877

Kim, H. (2018). Inflammability characteristics and wear comfort property of modacrylic composite yarn and knitted fabrics. J. Korean Soc. Cloth. Text. 42 (3), 397–410. doi:10.5850/jksct.2018.42.3.397

Liu, X. Y. (2020). Design of seamless knitted health care pants for knee arthritis based on grey correlation analysis. J. Fiber Bioeng. Inf. 13 (2), 79–87. doi:10.3993/jfbim00334

Liu, Y., Sun, B., Zhang, S., Li, J., Qi, J., Bai, C., et al. (2021). Glycine alleviates fluoride-induced oxidative stress, apoptosis and senescence in a porcine testicular Sertoli cell line. Reproduction Domest. Animals 56 (6), 884–896. doi:10.1111/rda.13930

Morch, A., Astruc, L., Witz, J. F., Lesaffre, F., Lecomte-Grosbras, P., Soulat, D., et al. (2019). Modeling of anisotropic hyperelastic heterogeneous knitted fabric reinforced composites. J. Mech. Phys. Solids 127, 47–61. doi:10.1016/j.jmps.2019.03.006

Pereira, A. C., Lima, A. M., Demosthenes, L., Oliveira, M. S., Pinheiro, W. A., Bezerra, W. B. A., et al. (2020). Ballistic performance of ramie fabric reinforcing graphene oxide-incorporated epoxy matrix composite. Polymers 12 (11), 2711–2719. doi:10.3390/polym12112711

Perkins, P., Jamieson, A., Ferguson, G., Spratford, W., and Hahn, A. (2018). Iterative design of impact-damping gloves for safer boxing. Open J. Saf. Sci. Technol. 8 (3), 49–97. doi:10.4236/ojsst.2018.83005

Rajesh, M., and Pitchaimani, J. (2018). Dynamic mechanical and free vibration behavior of natural fiber braided fabric composite: Comparison with conventional and knitted fabric composites. J. Vinyl Addit. Technol. 39 (7), 2479–2489. doi:10.1002/pc.24234

Ren, W., Yu, D., Sun, Z., Duan, H., Su, M., Ren, M., et al. (2020). Influence of graphite/graphene on the tribological behaviors of self-lubricating fabric composite. J. Mater. 13 (1), 232–241. doi:10.3390/ma13010232

Tian, F., Jiang, G., and Gao, Z. (2019). Preparation and filtration performance of the circular weft-knitted seamless weft-insertion fabric materials[J]. J. Industrial Text. 50 (8), 152–163. doi:10.1177/1528083719855320

Uyor, U. O., Popoola, A., Popoola, O. M., and Aigbodion, V. (2022). Microelectrostatic simulation of insulated graphene–polymer nanocomposites using COMSOL Multiphysics:[J]. J. Thermoplast. Compos. Mater. 35 (3), 337–351. doi:10.1177/0892705719886922

Wang, X., Fan, P., and Wang, S. (2022). Nanotubular polyaniline/reduced graphene oxide composite synthesized from a natural halloysite template for application as a high performance supercapacitor electrode[J]. Chem. Sel. 7 (5), 1–7. doi:10.1002/slct.202104402

Wei, D., Liu, X., Lv, S., Liu, L., Wu, L., Li, Z., et al. (2022). Fabrication, structure, performance, and application of graphene-based composite aerogel[J]. Materials 15 (1), 299–312. doi:10.3390/ma15010299

Wolfe, E. M., Pierrot, R. G., Slavin, B. R., Plotsker, E. L., Samaha, G. J., Gishen, K., et al. (2021). Rolling with the punches: A national electronic injury surveillance system database study of craniofacial injuries in boxing. J. Craniofacial Surg. 32 (4), 1576–1580. doi:10.1097/scs.0000000000007640

Wu, L., Zhao, F., Xie, J., Wu, X., and Lin, J. H. (2020). The deformation behaviors and mechanism of weft knitted fabric based on micro-scale virtual fiber model. Int. J. Mech. Sci. 187 (19), 105929–105935. doi:10.1016/j.ijmecsci.2020.105929

Wu, M. Q., Shi, L. M., and Zhao, Y. X. (2018). Thermal comfort evaluation of knitted fabric for tight running sportswear[J]. J. Beijing Inst. Cloth. Technol. Nat. Sci. Ed. 38 (1), 19–25.

Keywords: graphene composite fiber, seamless knitted fabric, boxing training, composite fiber performance research, boxing protective clothing

Citation: Liu T (2023) Properties of graphene composite fiber seamless knitted fabric and its application in boxing training. Front. Mater. 10:1098652. doi: 10.3389/fmats.2023.1098652

Received: 15 November 2022; Accepted: 03 February 2023;

Published: 17 February 2023.

Edited by:

Jianlei Cui, Xi’an Jiaotong University, ChinaReviewed by:

Khubab Shaker, National Textile University, PakistanHafsa Jamshaid, National Textile University, Pakistan

Copyright © 2023 Liu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Tianyue Liu, NjEyMDIxMDE1NUBiaXQuZWR1LmNu

Tianyue Liu

Tianyue Liu