- 1School of Qilu Transportation, Shandong University, Jinan, China

- 2Shandong Chambroad Petrochemicals Co., Ltd., Binzhou, China

- 3State Key Laboratory of Heavy Oil Processing, China University of Petroleum, Qingdao, China

- 4Shandong Hi-Speed Infrastructure Construction Co., Ltd., Jinan, China

Compatibility and mechanical performance of crumb rubber (CR)-modified asphalt and mixtures prepared by the dry method are poor at present, which limits the application of dry-mixed asphalt rubber in paving engineering. To solve this problem, various activated treatments for CR were performed, and the modified asphalt binder was prepared by the dry process in this study, aiming to activate the CR as the modifier and improve the compatibility of CR-asphalt blends. The effects of pre-treating methods of high temperature, pre-swelling, and microwave treatment on rutting resistance and compatibility of the asphalt binder and asphalt mixture were evaluated. Furthermore, the dynamic shear rheometer (DSR) of temperature sweep, Brookfield rotary viscosity, physical properties, rutting resistance, and microstructure of modified asphalt were measured. The results indicated that the three treatments have a pronounced effect on the high temperature performance of the crumb rubber-modified asphalt (CRMA) binder in the dry process and modified asphalt storage stability improvement. The high-temperature and microwave pre-treatment for CR lead to the largest complex modulus, viscosity, and rutting factor. Moreover, high-temperature, pre-swelling, and microwave treatment for CR significantly increases the dynamic stability of dry-mixed asphalt mixtures, which indicates the enhanced resistance to permanent deformation. In microscopy, homogeneous and compatible states were obtained for asphalt modified by high temperature-treated CR and pre-swelled CR, in which the strong interaction occurs among rubber molecules and the asphalt component. The microstructure of dry CR-asphalt blends sheds light on the mechanical performance. Consequently, activated CR modification for the asphalt binder by the dry process in this study is a promising technology, and other properties need to be verified in the future.

1 Introduction

Asphalt is widely used as a binder in high-grade road pavement. Approximately 92% of four million kilometers of road were surfaced with asphalt in the United States (Wang et al., 2018), and more than 90% of 5.2 million kilometers of highways were estimated to be surfaced with asphalt materials as of 2020 in China. The axle load in highways reached 13.6 million tons at the end of 2019, which has brought a great challenge for asphalt pavement.

In recent years, asphalt pavement has suffered from various damages (rutting, cracking, and water damage) because of the adverse climate and enormous traffic volume (Qin et al., 20092009; Lu et al., 2013; Behnood and ModiriGharehveran, 2019; Du et al., 2020). Therefore, rutting, load-induced permanent deformation, is one of the most serious distresses in asphalt pavement (Witczak et al., 1997). Rutting is divided into three types, wearing, shear, and configuration rutting (Li, 2020). Shear rutting is the main type in recent research because of the insufficient performance of asphalt mixtures at high temperature. A large number of strategies have been proposed for improving the rutting resistance performance of asphalt pavement at high temperature. At present, reducing the heat absorption of asphalt pavement (Ameri et al., 2018; Shanbara et al., 2020), optimizing the asphalt pavement structure combination (Jiang et al., 2020), and improving the high-temperature performance of asphalt binders (Al-Hadidy and Tan, 2010; Geng et al., 2013; Dong et al., 2014; Hajikarimi et al., 2015) and mixtures (Wu et al., 2007; Nazirizad et al., 2015) have been used to improve the rutting resistance of asphalt mixtures. Using modified asphalt is one of the most popular methods. Additives such as styrene-butadiene-styrene (SBS) and anti-rutting additives are the most popular modifiers. However, these additives are expensive and lead to big performance variation in rutting resistance.

With the development of the economy, millions of industrial tires were generated. About 1.4 billion tires are sold worldwide each year, which fall into the end of life after several years (Lo Presti, 2013). These waste tires are generally disposed of by burning, landfill, or stacking, which may cause a potential threat to human health in some cases. To improve the utilization of waste tires, many researchers attempted to focus on the production and application of crumb rubber for asphalt pavement to reduce its environmental burden (Bahia and Davies, 1994; Jang et al., 1998; Navarro et al., 2002). The crumb rubber (CR) modifier could improve the mechanical and rheological properties of asphalt binders (Xiao et al., 2007a; Ameri et al., 2020; Yazdipanah et al., 2021). It has been confirmed that CR can improve the rutting resistance properties of asphalt mixtures (Cao, 2007; Lee et al., 2008; Bessa et al., 2019). The main two productive process for producing crumb rubber-modified asphalt mixtures are the wet process and dry process. Nearly all these reports adopted the “wet process” to prepare the CR-modified asphalt mixture. In wet processes, crumb rubber is added to the paving asphalt before it is blended with aggregates and delivered to the drum mixer. Light fractions in asphalt are absorbed by rubber particles during this process (Xiao et al., 2007b; Cheng et al., 2011; Li et al., 2018). However, the wet process has poor storage stability and higher construction temperature (Xiang and Huang, 2014; Liang et al., 2015; Chavez et al., 2019). In dry processes, crumb rubber is added to the aggregate in a plant as the fine aggregate before adding the asphalt binder (Cheng et al., 2011). The compatibility of CR and asphalt binders in the dry process is expected to be worse than the wet process, but the dry process is economically and environmentally better due to the short reaction time (Shook and Inc, 1990; Lawrence et al., 1991; Buncher, 1995; Moreno et al., 2011). It was agreed that using fine rubber and high asphalt binder content can obtain the stronger rubber-asphalt interaction (Picado-Santos et al., 2020). Several methods, such as optimizing aggregates gradation (Xie and Shen, 2013), utilizing additives (Zhu and Jiang, 2013), and chemical treating for CR (Yin et al., 2020), have been applied to improve the properties of CR-asphalt mixtures in the dry process. However, the blends’ compatibility depends on the interaction among rubber molecules and the asphalt component (Li et al., 2021). If rubber particles are subjected to deep treatment, the inert surface could be activated. In this situation, the compatibility of CR-asphalt blends can be enhanced and a good performance that is equivalent to the wet process can be achieved by the dry process. In addition, the researchers believed that the dry process had more prospects because of its sampling process and economic value, etc. (Rodríguez-Fernández et al., 2020). In recent years, crumb rubber asphalt produced by other methods has also been widely used, such as warm mix asphalt mixtures (Hu et al., 2022) and stable crumb rubber asphalt (SCRA) (Ding et al., 2019). SCRA was obtained by a special manufacturing technique to make the rubber particles sufficiently dissolve in the asphalt, which was different from the traditional wet process (Ding et al., 2019). Thus, the effective treatment for CR needs to be promoted. Even though some literature reported other activating methods for CR to improve the properties of asphalt and mixtures in the dry process, these methods are insufficient for the demands of easy processing, low-cost, and effective treatment for CR.

In this study, various treating methods, including microwave, pre-swelling, and high-temperature treatment, were used to activate the crumb rubber, with the aim of improving the compatibility of crumb rubber and the asphalt binder in the dry process. The influence of high-temperature treatment, pre-swelling, and the two combinations, as well as microwave treatment for CR on the physical performance, viscosity, rheology, and rutting performance of the modified asphalt and mixture were studied through the dry process. The compatibility of activated CR-modified asphalt was evaluated by fluorescence microscopy and the relationship of compatibility, microstructure, and mechanical performance was discussed.

2 Materials and Experimental Method

2.1 Aggregate and Asphalt Matrix

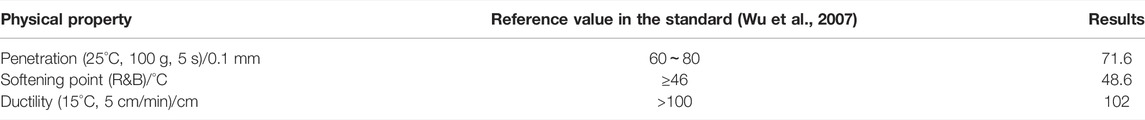

In this study, Qilu AH-70 asphalt provided by Shandong Hi-speed Huarui Road Materials Technologies Co. Ltd. was used as the asphalt matrix. Table 1 summarizes the basic properties of the selected asphalt matrix.

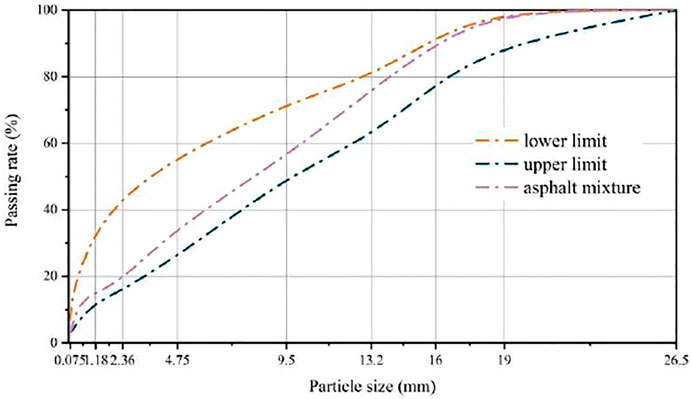

The aggregates used in this research were obtained from the limestone quarry in Wenzu Town, Jinan, China. The aggregates gradation of the final blend, based on the limitation of the JTG E20-2011 (JTGE20-2011, 2011) specification for dense-graded aggregates, is shown in Figure 1.

2.2 Treatment of Crumb Rubber

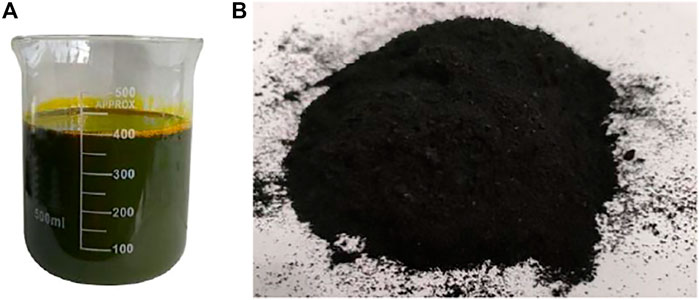

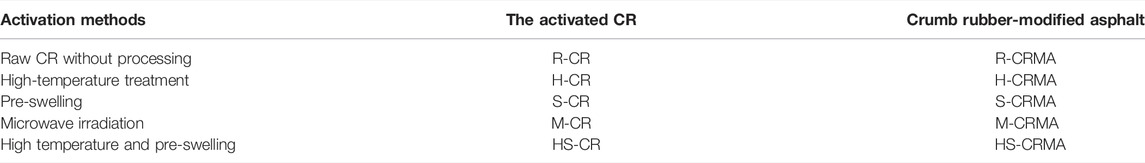

Crumb rubber (40 mesh) was provided by Shandong An-zhitai Environmental Protection Technology Co. Ltd. Several treatment methods were adopted to activate the raw crumb rubber, including high-temperature processing, pre-swelling, microwave irradiation, and their combinations. In high-temperature treatment, the scrap tires were heated at 300°C for 6 h after adding the resin tackifier and antioxidant. After that, the waste fiber was filtered and finally, the tires were grinded. During pre-swelling treatment, 0.5 g of aromatic oil was first sprayed on 100 g of CR and then the blends were heated to 200°C for 1.5 h (as shown in Figure 2A). As for the microwave irradiation, 50 g of crumb rubber was irradiated for 5 min each time in a microwave oven at 700 W (as shown in Figure 2B). The microwave frequency was 2,450 MHz. The abbreviations of CR treated by various methods are summarized in Table 2.

2.3 Preparation of CRMA and Mixture

The modified asphalt was prepared using a motor stirrer in the laboratory. The base asphalt was heated in a cylindrical container until it became fluid. Then the activated CR (18% by weight of the asphalt matrix) was added into the container, after that, the CR/asphalt was blended at 170°C for 10 min. It is worth mentioning that the CR/asphalt mixture was only stirred for 10 min to evaluate the compatibility of activated CR and asphalt, to distinguish it from the traditional wet process with high-speed shear for CR/asphalt blends for a long time.

The dry method was applied to prepare the activated CR-modified asphalt mixture, which mixes activated CR with mineral aggregates before incorporating asphalt. AC-20 dense asphalt mixtures were designed in the study. The preparation of the CR asphalt mixture was conducted as follows. The mixing machine was preheated until the temperature reached 175°C; then the aggregates were put into the pot and blended for 90 s. After that, the rubberized asphalt was added into the pot and blended for 90 s; finally, the mineral powder was added into the pot for 90 s.

2.4 Measurements

2.4.1 The Test of Basic Physical Properties

The basic physical properties tests were carried out for asphalt with various activated CR mixtures, including penetration (25°C) (T0604-2011), softening point (T0606-2011), and ductility (10°C) (T0605-2011) according to the Chinese specification JTG E20-2011 (JTGE20-2011, 2011). Three virgin samples were used and averaged for three parallel sample data. Three replicates were measured and the average of measured data was achieved.

2.4.2 Brookfield Rotary Viscosity Test

A Brookfield viscometer was employed to characterize the viscosity-temperature properties of the activated asphalt based on the Chinese specification JTG E20-2011 of T0625-2011 (JTGE20-2011, 2011). The 27th rotor was selected and the test temperature rose from 120 to 180°C with a temperature interval of 10°C.

2.4.3 Oscillatory Shear Test

The rheological properties of asphalt modified with activated CR were evaluated by oscillatory shear tests using a dynamic shear rheometer (CV0100, Malvern, United Kingdom). A temperature sweep test was conducted from 30 to 80°C at the 10 Hz frequency based on the AASHTO T315 test protocol (AASHTO, 2013). A parallel plate with a diameter of 25 mm and a gap of 2 mm was selected.

2.4.4 Fluorescence Microscopy

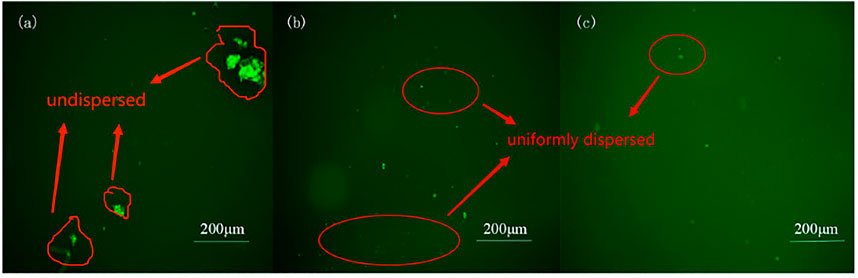

The dispersion state in microscopy of the CR particles in asphalt was evaluated by fluorescence microscopy in this study, which can further reflect the interaction between CR particles and the asphalt component. The two glass slides sandwiched with a drop of CR-modified asphalt were manufactured previously and the surface of the glass was kept clean. The glass slides with the sample were observed with fluorescence microscopy under blue light irradiation with a magnification ratio of 200 at 25°C. The photographs of swelled CR particles were recorded by a high definition camera.

2.4.5 Wheel-Tracking Test

It is important to evaluate the influence of different CR activation methods on rutting resistance of crumb rubber-modified asphalt mixtures. A laboratory wheel-tracking test was conducted to assess the high-temperature rutting resistance of CRMA mixtures in accordance with Chinese standard JTG E20-2011 (JTGE20-2011, 2011). The asphalt mixture slab with the dimensions of 300 × 300 × 50 mm was compacted by a roller compactor. After that, they were placed in an oven at 60°C for at least 6 h to ensure a homogeneous temperature. In the test, the contact tire pressure of 0.7 MPa was set between the slab surface and rubber tire wheel. The standard rubber wheel was reciprocated on the surface of the slab with a speed of 42 rpm and a traveling distance of 230 mm. The rutting depth (RD) was recorded automatically by a Linear Variable Differential Transformer (LVDT) sensor. Dynamic stability was defined as the ratio of 15*42 and the difference between rutting depth at 60 min and 45 min. The higher value of dynamic stability corresponds to the better rutting stability at high temperatures.

2.4.6 Marshall Stability Test

It is important to design the mix ratio of the asphalt mixture and examine the quality of asphalt pavement by a Marshall stability test according to the Chinese standard JTG E20-2011 (JTGE20-2011, 2011). This test aims to evaluate the maximum load sustained by the bituminous material at a constant loading rate of 50 mm/min ±5 mm/min. The diameter and height of the Marshall specimen was 101.6 ± 0.2 mm, 63.5 ± 1.3 mm, respectively. Then the sample was placed in the thermostatic water bath at 60°C for 30–40 min. Four parallel samples were used and averaged for parallel sample data.

3 Results and Discussion

3.1 Conventional Properties

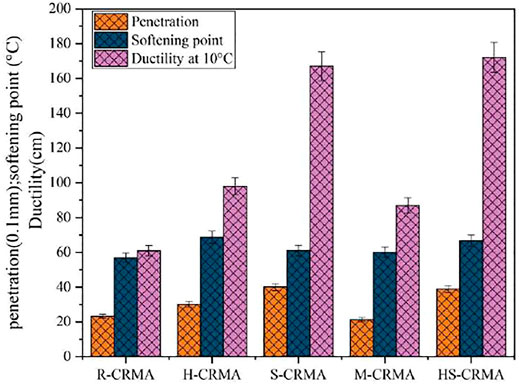

The penetration, softening point, and ductility of CRMA modified with different activated CR mixtures are shown in Figure 3. Compared with R-CRMA (23.3), the penetration of H-CRMA, S-CRMA, M-CRMA, and HS-CRMA increased by nearly 29.6%, 72.1%, −8.6%, and 67%, respectively, which suggests that the consistency performance of the modified asphalt has been improved compared with raw asphalt. The penetration of microwave-activated CR-modified asphalt was lower than that the asphalt modified by raw CR, indicating the hardness effect of the resulting asphalt by microwave treatment. The softening point of activated CR-modified asphalt increased more than 3.1°C, and the largest softening point of CRMA was 68.7°C of H-CRMA, compared with that of raw CR. Therefore, the high-temperature treatment for CR was most effective to enhance the softening point of CRMA, followed by pre-swelling with high temperature. It is indicated that high-temperature treatment for CR improved the high-temperature stability of modified asphalt. The ductility of modified asphalt with different activated CR mixtures showed a similar increasing tendency, indicating improved flexibility and tensile performance at low temperature. Particularly, pre-swelling and high-temperature/pre-swelling methods can significantly improve the low temperature ductility of modified asphalt. Therefore, high-temperature, pre-swelling, and both combinations, as well as microwave treatment for CR benefitted the physical properties of modified asphalt. These treatment methods in this study are related to the desulfurization of CR (de Sousa et al., 2017; Dong et al., 2017; Dong et al., 2019a), meanwhile, the fracture of the three-dimensional network structure of rubber molecules promotes the low-temperature performance.

3.2 Viscosity-Temperature Property

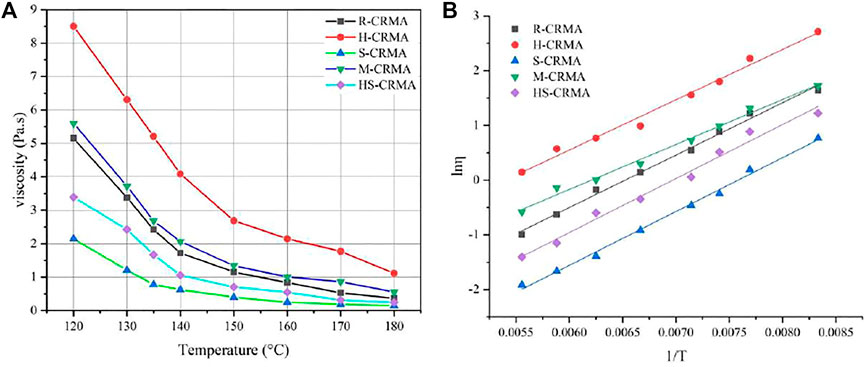

The viscosity-temperature property of CR-modified asphalt needs to be confirmed in order to obtain good workability, since the incorporation of rubber particles generally results in the evident increase of viscosity. As shown in Figure 4, the viscosity of the modified asphalt decreased with temperature increasing, but the decrease rate was different for asphalt with various activated CR mixtures. Compared with R-CRMA, modified asphalt with CR treated by high-temperature and microwave treatment showed higher viscosity, while pre-swelling and high-temperature/pre-swelling for CR led to the lower viscosity of asphalt. The viscosity changes caused by incorporation of different CR were weakened with increasing temperature.

The variation of viscosity as a function of temperature was described by the Arrhenius equation in this study, as shown in Eq. 1 (Jiang et al., 2019). The fitting results are listed in Table 3.

Where the η is the viscosity, Pa s; A is the regression coefficient; Eη is the viscous activation energy, J/mol; R is the universal gas constant, 8.314 J mol-1 K−1; and T is the absolute temperature, K. As displayed in Figure 4B, there was a good linear relationship between ln η and 1/T and the correlation coefficient was more than 0.98. The dependence of viscosity on temperature of CR-modified asphalt in the study was well described by the Arrhenius equation. Eη was related to the energy of asphalt flow deformation and the larger Eη implied the better property of resistance deformation of asphalt. Sensitivity of viscosity to temperature change can be evaluated from the slope of linear fitting results as shown in Figure 4B. According to, M-CRMA had the lowest value of 6,834.4 J/mol of Eη while HS-CRMA showed the highest Eη: 8,211.0 J/mol. The lower absolute value of the slope corresponded to the lower sensitivity of viscosity to temperature change. Figure 4B clearly shows that the slope value of S-CRMA and HS-CRMA were lower than the R-CRMA, which indicated that pre-swelling and pre-swelling/high-temperature treatment decreased the viscosity of asphalt compared to the untreated CR-modified asphalt. It is noteworthy that the incorporation of aromatic oil during pre-swelling for CR contributed to the lower viscosity. The M-CRMA and H-CRMA presented higher viscosity compared to R-CRMA at the same temperature, indicating more interactions among rubber molecules and the asphalt component.

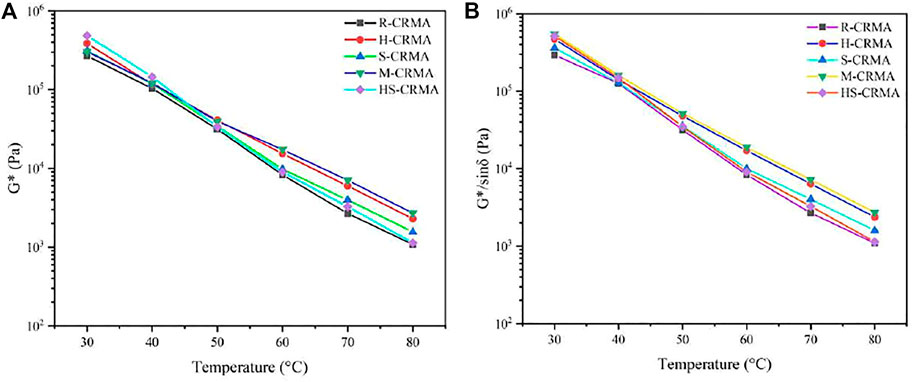

3.3 Rheological Properties: Temperature Dependence

As a temperature-sensitive material, asphalt shows different temperature-dependent rheological behaviors, which is crucial for the service performance of asphalt pavement (Yang et al., 2021). The parameters of complex modulus G* and G*/sin δ were obtained from the temperature sweep test. G* is the stress-strain ratio of viscoelastic materials subjected to sinusoidal loads. G*/sin δ is the rutting factor. The larger the rutting factor, the stronger the resistance of asphalt to permanent deformation. The influence of temperature on the viscoelastic properties of various CR-modified asphalt mixtures with a constant frequency of 10 rad/s is shown in Figure 5.

FIGURE 5. The temperature sweep results of DSR at 10 Hz. (A) The complex modulus G*; (B) the rutting factor G*/Sin δ.

As shown in Figure 5, the dynamic viscoelastic parameters of various crumb rubber-modified asphalt mixtures had a similar change curve with temperature in the logarithmic coordinate. S-CRMA and HS-CRMA had a sharp drop at high temperatures, while asphalt modified by high-temperature and microwave treatment showed a gentle reduction in the range of high temperature. Within the test temperatures ranging from 30–60°C, the complex modulus G* and rutting factor G*/sin δ distinctly decreased, respectively, with the temperature increasing, which shows that temperature had a great influence on the complex modulus and rutting resistance. The G*/sin δ change rate (binder thermal sensitivity) decreased for all the modified binders compared to the base binder, which means an increase in the rutting resistance at high temperatures.

The complex modulus G* and rutting factor G*/sin δ of activated CR-modified asphalt were higher than that of raw CR-modified asphalt. This indicates that the activated CR had a great advantage on improving the high-temperature performance of asphalt, meanwhile activated CR had significant environmental benefits. Such increments in G* and G*/sin δ of activated CR-modified asphalt were pronounced in the interval of 50–80°C, which demonstrated that activated CR significantly improved the mechanical properties of the asphalt matrix and its resistance to deformation. The range of modified asphalt value |G*|/sin δ was 545.9 KPa–1.14 KPa which was greater than 1 KPa. The value of |G*|/sin δ≥ 1 KPa was considered to be sufficient to resist rutting and the failure temperature can be calculated at the critical point. The G* and G*/sin δ corresponding to the microwave activation method were the largest and the changing rate of G*/sin δ was the lowest. This indicated that the microwave activation method can significantly decrease the deformation and improve the elastic recovery performance in the medium temperature, because the microwave activation broke the cross-linked chemical bonds of rubber molecules and enhanced the chemical activity of rubber particles and the elasticity of the rubber asphalt (de Sousa et al., 2017; Rodríguez-Fernández et al., 2020). Whereas, the HS-CRMA had the smallest complex modulus G* and G*/sin δ and the largest changing rate. The pre-swelling and high-temperature treatment promoted the degree of desulfurization and degradation of rubber molecules at high temperature, which improved the compatibility of crumb rubber and the asphalt binder. Figure 5B shows the decreasing trend of G*/sin δ with the increasing temperature. Treated CR-modified asphalt had the higher value of G*/sin δ, which denoted improved rutting resistance. Microwave and high-temperature treatment had the most benefits on the high-temperature rheological property of CR-modified asphalt.

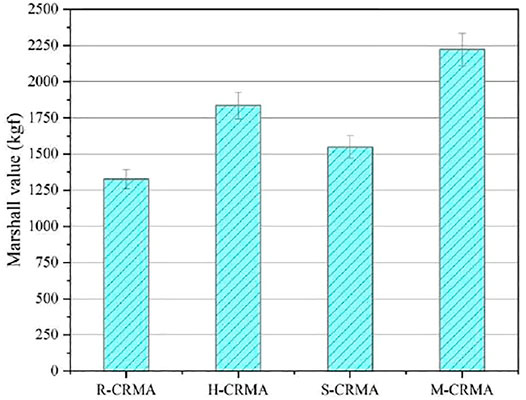

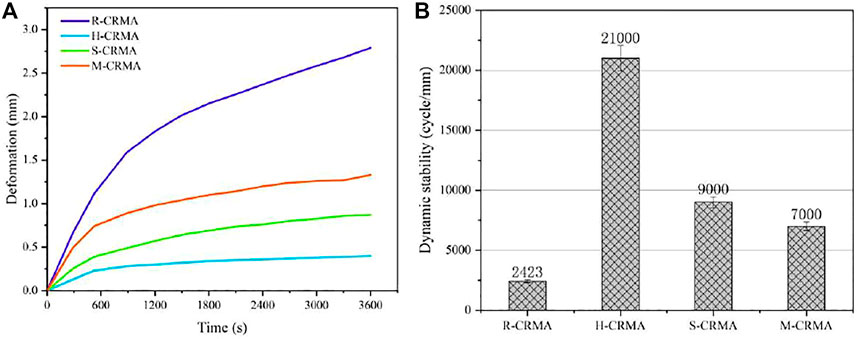

3.4 Rutting Resistance

The influence of activated CR on the rutting resistance of asphalt mixture was evaluated by the wheel-tracking test, as shown in Figure 6. As shown, R-CRMA had the highest permanent deformation (2.8 mm), and the curve of deformation versus loading time had an obvious constant increasing trend. After treating CR, the deformation of the asphalt mixture track showed a dramatic decrease, meanwhile, the rutting depth curves gradually increased. The H-CRMA samples showed the minimum deformation, followed by S-CRMA and M-CRMA. Specifically, compared with R-CRMA, the H-CRMA rutting depth reduced by 598%, followed by S-CRMA and M-CRMA with a reduction of 221 and 110%, respectively.

FIGURE 6. The wheel-tracking test results: (A) the deformation against loading time; (B) the dynamic stability of various asphalt mixtures.

Based on the curve of rutting depth against loading time, dynamic stability was obtained by calculating the proportion of 15*42 with the difference between rutting depth at 60 and 45 min, as displayed in Figure 6A. It can be seen from Figure 6B that for AC20, the dynamic stability of different activated CR-modified asphalt mixtures was 2,423, 21,000, 9,000, and 7,000 cycle/mm. Among these studied samples, the high-temperature treatment for CR led to significantly increased dynamic stability, which indicated the obviously enhanced resistance to permanent deformation of the asphalt mixture. In the stirring process, the aromatic components were reduced, and the resins and asphaltenes increased. As a result, the CRMA mixture became harder and the dynamic stability increased. The dynamic stability results were well in line with the temperature sweeping results for H-CRMA. The viscoelastic properties of H-CRMA changed and the elasticity increased at high temperature, which means improved recoverable deformation ability under the load and the reduced rutting depth. Besides, high viscosity of H-CRMA means the strong adhesion among asphalt and aggregates, which benefits the anti-rutting ability.

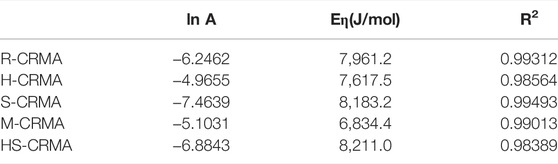

3.5 Marshall Stability

The results of Marshall stability are shown in Figure 7. As can be seen, the activated crumb rubber presented an increasing effect on the strength performance of the asphalt mixture. Among these samples, the crumb rubber activated by microwave ameliorated the strength up to 2,223.6 kgf which was 1.5 times more than the untreated CRMA. And the Marshall values of the crumb rubber-modified asphalt mixture by high-temperature treatment and pre-swelling were both higher than the untreated CRMA mixture, which could help to determine the improving effect of crumb rubber activation methods. These can be attributed to the elastic behavior of crumb rubber (Saberi.K et al., 2017), because microwave irradiation can only break the C-S and S-S bonds, not C-C bonds. The process of high-temperature treatment includes shallow cracking that can greatly maintain the elastic property of crumb rubber. As for the pre-swelling activation method, the viscosity of S-CRMA was lower than R-CRMA which is the reason for the low Marshall value of S-CRMA. The viscosity of the asphalt mixture was lower, therefore the strength was worse.

3.6 Fluorescence Microscopy

To figure out the above results, fluorescence observation was conducted to shed light on the microstructure of various CR-modified asphalt mixtures. The fluorescence microstructures of R-CRMA, H-CRMA, and S-CRMA are presented in Figure 8. As shown, the dark green area is the asphalt phase and the light green spot is the rubber phase. For R-CRMA, the rubber particles were large and assembled with each other, which indicates the inhomogeneity and incompatibility. This indicated that the mechanical behavior of rubber cannot be delivered to the asphalt matrix due to the poorly dispersed raw rubber particles. Moreover, the chemical inert surface of raw CR with activation led to fewer interactions between rubber molecules and the asphalt component (Adhikari et al., 2000), which accounts for the poor rheological properties and rutting resistance. Contrary to this, homogeneous and compatible states were obtained for asphalt modified by high temperature-treated CR and pre-swelled CR. In Figure 8, it can be seen that the uniformly dispersed rubber particles are nearly round and the dimensions of dispersed particles are much smaller than that of untreated CR. For H-CRMA, the blends had few large rubber particles and the compatibility evidently improved. This is related to the desulfurization effect of CR when subjected to high-temperature treatment and rubber particle surface activation effect. Thus, the strong interaction among rubber molecules and the asphalt component results in the continuous and homogeneous asphalt phase formed with a few light green spots. For S-CRMA, the addition of aromatic oil accelerated the swelling of CR in the asphalt binder, so the dispersive and homogenous composite asphalt phase was formed. Consequently, the blends became more compatible systems after activation treatment for CR. The microstructure of asphalt blends explains their mechanical performance.

4 Conclusion

In this study, the effects of activating treatment for CR on rutting resistance of modified asphalt were evaluated. The correlation of fluorescence microscopy with mechanical behavior was discussed, the following findings can be given:

1) The activated CR increased the high temperature performance of the CRMA binder. The microwave and high-temperature pre-treating methods had the largest of complex modulus G* and rutting factor G*/sin δ. While, pre-swelling and pre-swelling/high-temperature treatment for CR decreased the viscosity of asphalt compared to raw CR-modified asphalt. Microwave and high-temperature treatment benefitted the high-temperature rheological property of CR-modified asphalt.

2) The high temperature pre-treating method significantly improved the rutting resistance of the CR asphalt mixture, followed by the pre-swelling and microwave treatment. Homogeneous and compatible states were obtained for asphalt modified by high temperature-treated CR and pre-swelled CR.

3) The microstructure of asphalt blends explains their mechanical performance. Further investigations are needed to complement the findings of this study, such as fatigue behavior and the low temperature properties. Lastly, high-temperature, pre-swelling, and microwave treatment on CR are highly recommended for asphalt modification in paving engineering.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

ML: Data curation, Writing - original draft, Writing - review & editing. ZQ: Data curation,Writing – original draft, Writing - review & editing, Funding acquisition. XL: Investigation. CQ: Methodology. NG: Project administration, Supervision. ZL: Drafting and review. LS: Investigation. Zhanyong Yao: Methodology. JZ: Project administration. All authors have read and agreed to the published version of the manuscript. We confirm that the order of authors listed in the manuscript has been approved by all named authors.

Funding

The authors acknowledge the financial support of the National Natural Science Foundation of China (No. 51908330), the Qilu Young Scholars Program of Shandong University (No. 202099000060), the Fundamental Research Funds of Shandong University (No. 2020GN059), and State Key Laboratory of Heavy Oil Processing.

Conflict of Interest

Author CQ was employed by the company Shandong Chambroad Petrochemicals Co., Ltd. Author ZL was employed by the company Shandong Hi-Speed Infrastructure Construction Co. Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aashto, (2013). T315 Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials.

Adhikari, B., De, D., and Maiti, S. (2000). Reclamation and Recycling of Waste Rubber. Progr. Polym. Sci. 25, 909–948. doi:10.1016/s0079-6700(00)00020-4

Al-Hadidy, A. I., and Tan, Y. Q. (2010). Effect of Styrene-Butadiene-Styrene on the Properties of Asphalt and Stone-Matrix-Asphalt Mixture. J. Mater. Civil Eng. 23 (4), 504–510.

Ameri, M., Afshin, A., Ebrahimzadeh, M., and Yazdipanah, F. (2020). Effect of Wax-Based Warm Mix Additives on Fatigue and Rutting Performance of Crumb Rubber Modified Asphalt. Construction Building Mater. 262. doi:10.1016/j.conbuildmat.2020.120882

Ameri, M., Mirzaiyan, D., and Amini, A. (2018). Rutting Resistance and Fatigue Behavior of Gilsonite-Modified Asphalt Binders. J. Mater. Civil Eng. 30 (11), 1–9. doi:10.1061/(asce)mt.1943-5533.0002468

Bahia, H. U., and Davies, R. (1994). Effect of Crumb Rubber Modifiers (CRM) on Performance-Related Properties of Asphalt Binders. Asphalt Paving Technol. 63, 414–449.

Behnood, A., and Modiri Gharehveran, M. (2019). Morphology, Rheology, and Physical Properties of Polymer-Modified Asphalt Binders. Eur. Polym. J. 112, 766–791. doi:10.1016/j.eurpolymj.2018.10.049

Bessa, I. S., Vasconcelos, K. L., Castelo Branco, V. T. F., and Bernucci, L. L. B. (2019). Fatigue Resistance of Asphalt Binders and the Correlation with Asphalt Mixture Behaviour. Road Mater. Pavement Des. 20, S695–S709. doi:10.1080/14680629.2019.1633741

Buncher, M. S. (1995). Evaluating the Effects of the Wet and Dry Processes for Including Crumb Rubber Modifier in Hot Mix Asphalt.

Cao, W. (2007). Study on Properties of Recycled Tire Rubber Modified Asphalt Mixtures Using Dry Process. Construction Building Mater. 21 (5), 1011–1015. doi:10.1016/j.conbuildmat.2006.02.004

Chavez, F., Marcobal, J., and Gallego, J. (2019). Laboratory Evaluation of the Mechanical Properties of Asphalt Mixtures with Rubber Incorporated by the Wet, Dry, and Semi-wet Process. Construction Building Mater. 205 (APR.30), 164–174. doi:10.1016/j.conbuildmat.2019.01.159

Cheng, G., Shen, B., and Zhang, J. (2011). A Study on the Performance and Storage Stability of Crumb Rubber Modified Asphalts. Pet. Sci. Technology 29. doi:10.1080/10916460903070421

de Sousa, F. D. B., Scuracchio, C. H., Hu, G.-H., and Hoppe, S. (2017). Devulcanization of Waste Tire Rubber by Microwaves. Polym. Degrad. Stab. 138 (APR), 169–181. doi:10.1016/j.polymdegradstab.2017.03.008

Ding, X., Chen, L., Ma, T., Ma, H., Gu, L., Chen, T., et al. (2019). Laboratory Investigation of the Recycled Asphalt concrete with Stable Crumb Rubber Asphalt Binder. Construction Building Mater. 203, 552–557. doi:10.1016/j.conbuildmat.2019.01.114

Dong, R., Liang, W., Tang, N., and Zhao, M. (2019a). Composition and Viscoelasticity of Asphalt Modified with Crumb Rubber Pre-desulfurized by Waste Cooking Oil. China J. Highw. Transp. 32, 226–234.

Dong, R., Qi, C., and Zheng, K. (2017). Test on Low- Temperature Performance for High 3temperature Pyrolytic Rubber Modified Asphalt. China J. Highway Transp. 30, 32–38. doi:10.19721/j.cnki.1001-7372.2017.10.005

Dong, Z. J., Xiao, G. Q., and Gong, X. B. (2014). Analysis on Impact of Gradation and Anti-rutting Additive on Rutting Resistance of Asphalt Mixture. J. Highw. Transportation Res. Development.

Du, C., Sun, Y., Chen, J., Gong, H., Wei, X., and Zhang, Z. (2020). Analysis of Cohesive and Adhesive Damage Initiations of Asphalt Pavement Using a Microstructure-Based Finite Element Model. Construction Building Mater. 261 (1), 119973. doi:10.1016/j.conbuildmat.2020.119973

Geng, H., Clopotel, C. S., and Bahia, H. U. (2013). Effects of High Modulus Asphalt Binders on Performance of Typical Asphalt Pavement Structures. Construction Building Mater. 44 (jul), 207–213. doi:10.1016/j.conbuildmat.2013.03.035

Hajikarimi, P., Rahi, M., and Nejad, F. M. (2015). Comparing Different Rutting Specification Parameters Using High Temperature Characteristics of Rubber-Modified Asphalt Binders. Road Mater. Pavement Des. 16 (4), 1–16. doi:10.1080/14680629.2015.1063533

Hu, J., Ma*, T., Yin, T., and Zhou, Y. (2022). Foamed Warm Mix Asphalt Mixture Containing Crumb Rubber: Foaming Optimization and Performance Evaluation. J. Clean. Prod.. doi:10.1016/j.jclepro.2021.130085

Jang, J. W., Yoo, T. S., Oh, J. H., and Iwasaki, I. (1998). Discarded Tire Recycling Practices in the united states, japan and Korea. Resour. Conservation Recycling 22 (1-2), 1–14. doi:10.1016/s0921-3449(97)00041-4

Jiang, X., Li, P., Ding, Z., Yang, L., and Zhao, J. (2019). Investigations on Viscosity and Flow Behavior of Polyphosphoric Acid (PPA) Modified Asphalt at High Temperatures. Construction Building Mater. 228, 116610. doi:10.1016/j.conbuildmat.2019.07.336

Jiang, Y., Zhang, Y., Deng, C., Yi, Y., Tian, T., and Yuan, K. (2020). High-temperature Rutting Resistance of Inverted Asphalt Pavement Structure. Adv. Civil Eng. 2020 (2), 1–10. doi:10.1155/2020/1937508

Jtg E20-2011, . (2011). Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering JTG E20-2011. Beijing: Chinese Communications Press.

Lawrence, C., Killackey, B., and Lynch, D. (1991). Experimental Hot Mix Pavement with Scrap Tire Rubber at Thamesville. Ontario.

Lee, S.-J., Akisetty, C. K., and Amirkhanian, S. N. (2008). The Effect of Crumb Rubber Modifier (CRM) on the Performance Properties of Rubberized Binders in HMA Pavements. Construction Building Mater. 22 (7), 1368–1376. doi:10.1016/j.conbuildmat.2007.04.010

Li, C. M. (2020). “Application of Ground Penetrating Radar in the Analyzing of Rut Type of Asphalt Pavement,” in 5th International Symposium on Test and Measurement.

Li, J., Chen, Z., Xiao, F., and Amirkhanian, S. N. (2021). Surface Activation of Scrap Tire Crumb Rubber to Improve Compatibility of Rubberized Asphalt. Resour. Conservation Recycling 169, 105518. doi:10.1016/j.resconrec.2021.105518

Li, R., Guo, Q., Shi, Z., and Pei, J. (2018). Effects of Conductive Carbon Black on PZT/PVDF Composites. Ferroelectrics 526 (1), 176e186. doi:10.1080/00150193.2018.1456308

Liang, M., Xin, X., Fan, W., Sun, H., Yao, Y., and Xing, B. (2015). Viscous Properties, Storage Stability and Their Relationships with Microstructure of Tire Scrap Rubber Modified Asphalt. Construction Building Mater. 74 (jan.15), 124–131. doi:10.1016/j.conbuildmat.2014.10.015

Lo Presti, D. (2013). Recycled Tyre Rubber Modified Bitumens for Road Asphalt Mixtures: A Literature Review. Construction Building Mater. 49 (6), 863–881. doi:10.1016/j.conbuildmat.2013.09.007

Lu, W., Sascha, K., and Frohmut, W. (2013). Impact of Surface Temperature on Fatigue Damage in Asphalt Pavement[J]. J. Highw. Transportation Res. Development 7 (3), 1–6.

Moreno, F., Rubio, M. C., and Martinez-Echevarria, M. J. (2011). Analysis of Digestion Time and the Crumb Rubber Percentage in Dry-Process Crumb Rubber Modified Hot Bituminous Mixes. Construction Building Mater. 25 (5), 2323–2334. doi:10.1016/j.conbuildmat.2010.11.029

Navarro, F. J., Partal, P., Martnez-Boza, F., Valencia, C., and Gallegos, C. (2002). Rheological Characteristics of Ground Tire Rubber-Modified Bitumens. Chem. Eng. J. 89 (1-3), 53–61. doi:10.1016/s1385-8947(02)00023-2

Nazirizad, M., Kavussi, A., and Abdi, A. (2015). Evaluation of the Effects of Anti-stripping Agents on the Performance of Asphalt Mixtures. Construction Building Mater. 84, 348–353. doi:10.1016/j.conbuildmat.2015.03.024

Picado-Santos, L. G., Capito, S. D., and Neves, J. (2020). Crumb Rubber Asphalt Mixtures: A Literature Review. Construction Building Mater. 247, 118577. doi:10.1016/j.conbuildmat.2020.118577

Qin, R., Li, Y., and Li, Z. (20092009). Analyzing the Cause of Asphalt Pavement Rut Damage of Heng-Zao Freeway. GeoHunan Int. Conf.. doi:10.1061/41047(354)7

Rodríguez-Fernández, I., Cavalli, M. C., and Poulikakos, L. D. (2020). Long-Term Aging Behaviour of Asphalt Mixtures Modified with Crumb Rubber Using the Dry Process. Int. Symp. Asphalt Pavement Environ.. 48. doi:10.1007/978-3-030-29779-4_22

Saberi.K, F., Fakhri, M., and Azami, A. (2017). Evaluation of Warm Mix Asphalt Mixtures Containing Reclaimed Asphalt Pavement and Crumb Rubber. J. Clean. Prod. 165 (nov1), 1125–1132. doi:10.1016/j.jclepro.2017.07.079

Shanbara, H. K., Shubbar, A., Ruddock, F., and Atherton, W. (2020). Characterizing the Rutting Behaviour of Reinforced Cold Mix Asphalt with Natural and Synthetic Fibres Using Finite Element Analysis. Adv. Struct. Eng. Rehabil. 38. doi:10.1007/978-981-13-7615-3_20

Shook, James., and Inc, A. (1990). Experimental Construction of Rubber-Modified Asphalt Pavements in new york State - Final Report.

Wang, T., Xiao, F., Zhu, X., Huang, B., Wang, J., and Amirkhanian, S. (2018). Energy Consumption and Environmental Impact of Rubberized Asphalt Pavement. J. Clean. Prod. 180 (APR.10), 139–158. doi:10.1016/j.jclepro.2018.01.086

Witczak, M. W., Quintas, H. V., and Schwartz, C. W. (1997). Superpave Support and Performance Models Management: Evaluation of the SHRP Performance Models System. Proc. Eighth Int. Conf. Asphalt Pavements III, 175–195.

Wu, S., Xue, Y., Ye, Q., and Chen, Y. (2007). Utilization of Steel Slag as Aggregates for Stone mastic Asphalt (SMA) Mixtures. Building Environ. 42 (7), 2580–2585. doi:10.1016/j.buildenv.2006.06.008

Xiang, S., and Huang, B. (2014). Recycling of Waste Tire Rubber in Asphalt and portland Cement concrete: an Overview. Construction Building Mater. 67 (B), 217–224.

Xiao, F., Amirkhanian, S., and Juang, C. H. (2007). Rutting Resistance of Rubberized Asphalt concrete Pavements Containing Reclaimed Asphalt Pavement Mixtures. J. Mater. Civ. Eng. 19 (6), 475e483. doi:10.1061/(asce)0899-1561(2007)19:6(475)

Xiao, F., Amirkhanian, S., and Juang, C. H. (2007). Rutting Resistance of Rubberized Asphalt concrete Pavements Containing Reclaimed Asphalt Pavement Mixtures. J. Mater. Civ. Eng. 19 (6), 475–483. doi:10.1061/(asce)0899-1561(2007)19:6(475)

Xie, Z., and Shen, J. (2013). “Long-term Performance of SMA Mixtures Added with Crumb Rubbers in Dry Process,” in Airfield and Highway Pavement (American Society of Civil Engineers), 1145–1155. doi:10.1061/9780784413005.096

Yang, Q., Qian, Y., Fan, Z., Lin, J., Wang, D., Zhong, J., et al. (2021). Exploiting the Synergetic Effects of Graphene and Carbon Nanotubes on the Mechanical Properties of Bitumen Composites. Carbon 172, 402–413. doi:10.1016/j.carbon.2020.10.020

Yazdipanah, F., Ameri, M., Shahri, M., Hasheminejad, N., and Haghshenas, H. F. (2021). Laboratory Investigation and Statistical Analysis of the Rutting and Fatigue Resistance of Asphalt Mixtures Containing Crumb-Rubber and Wax-Based Warm Mix Asphalt Additive. Construction Building Mater. 309, 0950–0618. doi:10.1016/j.conbuildmat.2021.125165

Yin, L., Yang, X., Shen, A., and Bo, L. (2020). Mechanical Properties and Reaction Mechanism of Microwave-Activated Crumb Rubber-Modified Asphalt before and after thermal Aging. Construction Building Mater. 267, 120773. doi:10.1016/j.conbuildmat.2020.120773

Keywords: crumb rubber, modified asphalt, dry process, rutting resistance, pre-treating methods

Citation: Liang M, Qiu Z, Luan X, Qi C, Guo N, Liu Z, Su L, Yao Z and Zhang J (2022) The Effects of Activation Treatments for Crumb Rubber on the Compatibility and Mechanical Performance of Modified Asphalt Binder and Mixture by the Dry Method. Front. Mater. 9:845718. doi: 10.3389/fmats.2022.845718

Received: 30 December 2021; Accepted: 23 February 2022;

Published: 29 April 2022.

Edited by:

Han-Cheng Dan, Central South University, ChinaReviewed by:

Tao Ma, Southeast University, ChinaPeiwen Hao, Chang’an University, China

Xianyong Ma, Harbin Institute of Technology, China

Jian Ouyang, Dalian University of Technology, China

Copyright © 2022 Liang, Qiu, Luan, Qi, Guo, Liu, Su, Yao and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jizhe Zhang, aml6aGUuemhhbmdAc2R1LmVkdS5jbg==

†These authors have contributed equally to this work

Ming Liang

Ming Liang Zhengmei Qiu1†

Zhengmei Qiu1† Jizhe Zhang

Jizhe Zhang