- 1Highway and Transportation Administration Center of Huzhou, Huzhou, China

- 2School of Civil Engineering, Central South University, Changsha, China

- 3Nanjing Xingyou Transportation Technology Co., Ltd., Nanjing, China

In order to match the color difference between black asphalt mixture and light-colored cement grouting paste in semiflexible pavement, carbon black (CB) with four mass ratios (i.e., 2, 4, 6, and 8%) was incorporated into a rapid-hardening cement grouting paste. The fluidity, color difference, spectrum reflectance, thermal conductivity, and flexural and compressive strength of the aforementioned cement pastes were experimentally investigated. The results show that the mass ratios of the component in cement paste could ensure the good fluidity of cement grouting paste. Three parameters such as thermal conductivity, flexural strength, and compressive strength all reduced, compared with control paste. However, the compressive strength of the 8% CB paste was still much higher than that of the asphalt mixture. According to the color difference results, CB significantly improved the black color of cement paste, of which the black color of the asphalt mixture was between that of 6 and 8% CB cement paste. Besides, the spectrum reflectance of all the pastes reduced, especially the average reflectance of 2% CB cement paste was 51.7% lower than that of control paste. The findings in this study are expected to help design more advanced cement grouting materials to improve the optical and mechanical performances of semiflexible asphalt pavement.

1 Introduction

Asphalt pavement is the most used pavement type because of its high driving comfort, easy maintenance, low cost, and so on. In summer, the maximum temperature of asphalt pavement can reach up to 60–70°C because of its low solar reflectance (generally lower than 0.1) (Santamouris, 2013; Qin, 2015). The temperature-sensitive asphalt mixture will generate permanent deformation or rutting, which is one of the two most serious pavement distresses (Du et al., 2018). The rutting distress is generally solved by improving the high-temperature performance of the asphalt mixture, including applying high modulus asphalt (Zou et al., 2015) and optimizing aggregate gradation (Aragão et al., 2016). Optimizing the asphalt pavement structure was also proved to be able to reduce rutting depth (Lee et al., 2015).

A novel composite pavement which is paved using a semiflexible mixture was proved to have a rather high ability to resist rutting, compared to conventional hot mix asphalt (Cai et al., 2017; Gong et al., 2019; Hassani et al., 2020; Luo et al., 2020). This kind of mixture usually uses a porous asphalt mixture (air voids content of over 20%) as a flexible aggregate skeleton to carry rigid cement paste or mortar (Fang et al., 2016; Pei et al., 2016; Zhang et al., 2016; Wang et al., 2018). However, these published works usually used ordinary Portland cement as a binder to prepare light-colored grouting material, which resulted in the following two deficiencies: first, the resultant semiflexible pavement needs a very long curing period before it opens to traffic (Chen et al., 2020), second, the color inconsistence between the light-colored grouting material and black asphalt mixture led to the very poor appearance of the pavement surface (An et al., 2018).

To this end, this work aims at preparing a special kind of cement grouting paste, which is featured of black color and rapid hardening. Additionally, the cement paste should also have a high flow degree, which allows the cement paste to be easily grouted in the porous asphalt mixture. For this purpose, four mass contents of carbon black (CB) are blended with a kind of rapid-hardening cement. To achieve an equivalent color with the asphalt mixture, the color of the cement paste with different contents of CB was measured using a color-difference meter. Due to the color change, the spectrum reflectance of cement paste was then evaluated. The thermal properties of cement paste were evaluated by an indicator of thermal conductivity. Compressive and flexural strength tests of the paste at different curing ages were performed to investigate the influence of CB addition.

2 Materials and Test Methods

2.1 Materials

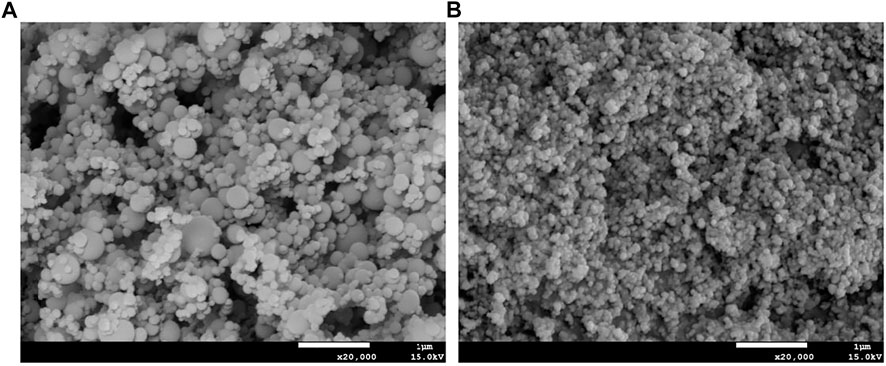

A kind of rapid-hardening cement was used as a binder to prepare cement grouting paste. This cement could increase the early-age strength of cement grouting paste and then rapidly open to traffic. The water-reducing agent β -naphthalene sulfonic acid was used to increase the workability of the composite. Tributyl phosphate defoamer was used to decrease the number of air bubbles. In total, four contents of CB (2–8 wt% of cement (Li et al., 2008)) were used as a functional filler to change the color and thermal property of the grouting material. The scanning electron microscope (SEM) images of silica fume and CB were compared, as shown in Figure 1. It can be found that the used CB had smaller particle sizes than silica fume. Additionally, the micromorphology of CB was similar to that of silica fume.

2.2 Preparation of Cement Grouting Paste

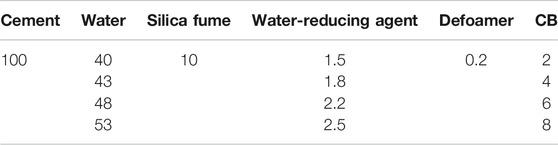

The detailed component proportions of cement paste are shown in Table 1.

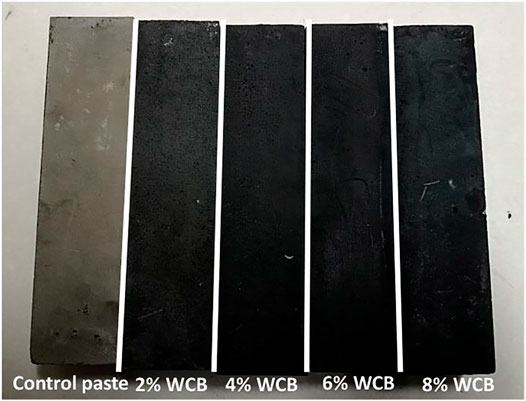

CB and other additives were first added into cement and mixed together in a dry state for 2 min, and then water was added to the dry mix. The total mixing time was kept at 5 min to ensure homogenous mixing. The paste was casted into a prismatic mold (size of 40 mm × 40 mm × 160 mm) and vibrated to prepare the cement paste specimen, as shown in Figure 2. After 2 h, the specimen was demolded and ready to cure in the standard curing conditions (temperature of 20°C and humidity of more than 90%). For each kind of component proportion, three specimens were prepared as a group for the same experiment.

2.3 Test Methods

2.3.1 Fluidity Test

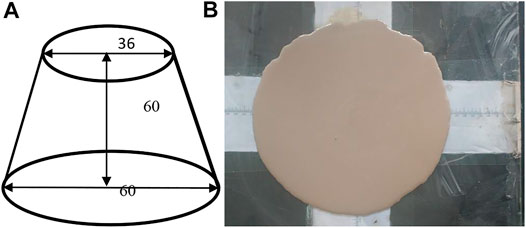

The just-mixed paste was first casted into a cone as shown in Figure 3A. The redundant paste was craped to ensure the cone was filled up with paste, and then the cone was placed onto a glass board and lifted vertically to allow the paste to flow freely for 30 s (Figure 3B). The averaged diameter was referred to as the measured fluidity.

2.3.2 Scanning Electron Microscope (SEM) Test

An SEM (Quanta 200, FEI Co. Ltd., America) was used to characterize the microscope images of the control, 2, 4, and 6% CB cement pastes. The broken paste samples were immersed into ethyl alcohol to prevent the hydration process. The samples were then sprayed with gold. In order to obtain clear SEM images, the voltage was maintained at 20.00 kV. All the images were magnified by 10,000 times.

2.3.3 Color-Difference Test

The color of each paste sample (at the age of 7 days) was measured using a potable color-difference meter (NR20XE, 3nh Technology Co., Ltd. of Shenzhen, China). The color could be described by three parameters of L*, a*, and b*. Specifically, L* represented the lightness. The negative value of L* means that the color was more like black. a* represented the degree of redness (-a* greenness) and b* of yellowness (-b* blueness). A reference plate that had known absolute color values was introduced to compare the color of the cement paste. The relative color values (i.e., ΔL, Δa, and Δb) could be automatically obtained (Zhang et al., 2018).

2.3.4 Thermal Conductivity Test

A thermal conductivity meter (DRE-2C, Xiangtan Instruments and Meters, China), which is based on the transient plane heat source method, was used to measure the thermal conductivity of the CSA paste. The fractured specimens after the flexural strength test were cut into small pieces (thickness of about 5 cm) with smooth surfaces. A test probe was sandwiched between two sample pieces.

2.3.5 Spectrum Reflectance Test

The fractured prismatic cement paste specimens were cut into small samples with a thickness of less than 2 cm. A UV–VIS–NIR spectrophotometer (Cary 5,000, Agilent Technologies (Malaysia) Company) was used to measure the global (direct + diffuse) spectrum reflectance in the range of 190–2,500 nm. The samples were clamped in the integrating sphere to receive light radiation. The specific solar reflectance in the UV–VIS–NIR band was computed in accordance with the ASTM Standard G173-03 (ASTM, 2012).

2.3.6 Mechanical Performance Test

The three prismatic samples (size of 40 mm × 40 mm × 160 mm) of each kind of paste were used for the flexural strength test after having been cured for 4 h, 1, 3, and 7 days. The fractured samples were then cut into cubic samples with smooth surfaces for the compressive strength test. The aforementioned two mechanical tests were performed in accordance with the Chinese national standard method T 0506-2005 in JTG E30-2005.

3 Results and Discussion

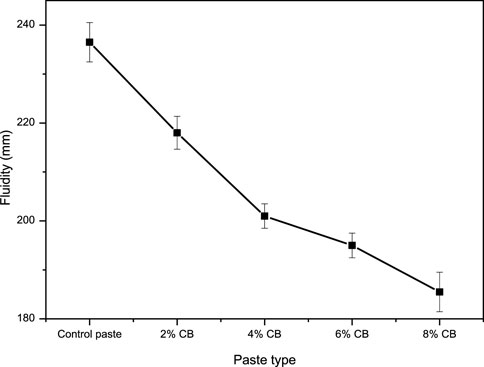

3.1 Fluidity

The fluidity results of different cement pastes are shown in Figure 4. It can be found that the fluidity basically reduced with the increase of the CB content. When 8% CB was added in the cement paste, the fluidity was only about 21% of that of control paste. The result indicates that the influence of CB addition on paste fluidity should be carefully considered in order to easily grout cement paste into a porous asphalt mixture, and the mass ratios of the component in cement paste shown in Table 1 could be optimized to have a desirable fluidity for cement pastes with different CB additions. In future studies, the appropriate CB content should be determined by observing the paste distribution in a porous asphalt mixture.

3.2 Microstructure

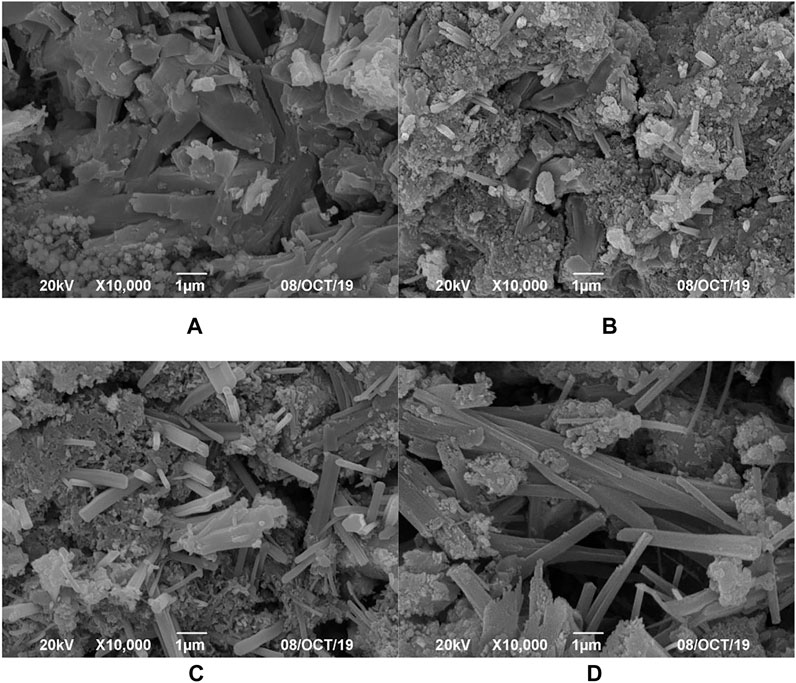

In order to illustrate the influence of CB addition on the microstructure of cement paste, the SEM images (×10,000) of control paste, 2, 4, and 6% CB are presented, as shown in Figure 5.

Obviously, the microstructure of control paste looked much denser than those of other pastes. The hydration products connected with each other to form a relatively stable microstructure. The silica fume filled into the micro-voids, which would reduce the micro–air voids, thus increasing the strength of control paste. The addition of CB changed the hydration process of cement paste. By comparing the images shown in Figures 5B,D, it can be found that the microstructure of cement paste became looser with a higher CB addition content. In addition, many CB particles adhered to the cement hydration products, especially the phenomenon of CB gathering took place in 4 and 6% CB cement pastes.

3.3 Color Characteristic

The color consistence between cement paste and asphalt mixture is one of the main subjects in this study. As a result, the color characteristics of different cement pastes were evaluated. The absolute values of the reference sample are shown in Table 2, and the color difference results of cement pastes are shown in Table 3.

It can be found that the parameter ΔL showed the largest varying rate for different cement pastes, compared with the other two parameters Δa and Δb. Additionally, this study focused on discussing the black color difference between cement paste and asphalt mixture. As a result, only ΔL was discussed in the following paragraph.

Compared with the reference plate, all the cement pastes looked more like the black color because of their negative values of ΔL. With the increase of the CB content, ΔL gradually reduced, indicating that CB could improve the black color of cement paste. The color of asphalt mixture was between that of 6 and 8% CB. It should be noted that after a period of service, asphalt generally experiences aging, where an asphalt pavement presents lighter color and higher solar reflectance (Sen and Roesler, 2016). From the prospective of color consistence between cement paste and asphalt mixture, the ΔL of cement paste can be determined to be lower than that of the fresh asphalt mixture. In future studies, this result can be considered to optimize the mix design.

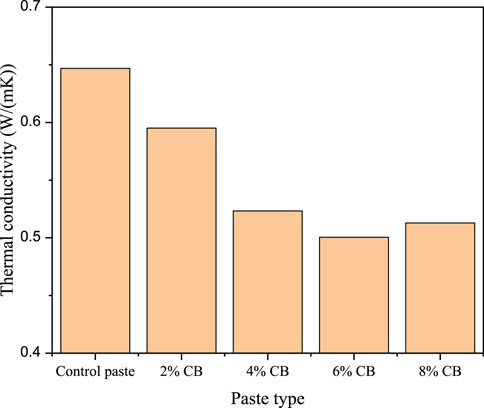

3.4 Thermal Conductivity

The thermal conductivity results of different cement pastes are shown in Figure 6. It can be found that the thermal conductivity of cement paste decreased first and then increased with the increase of the CB content. As discussed in Section 3.2, the addition of CB increased the air voids content of cement paste. So, when the content of CB was lower than 6%, the thermal conductivity of cement paste gradually reduced, although the thermal conductivity of CB was generally higher than that of cement hydration products (Dong et al., 2019). The ultimate thermal conductivity indicated that the high thermal conductivity of CB had a higher influence on the thermal conductivity of cement paste than the increasing air voids content.

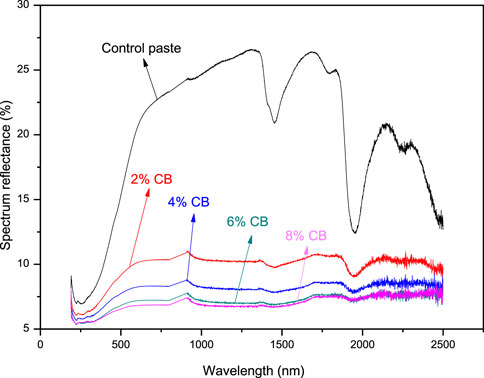

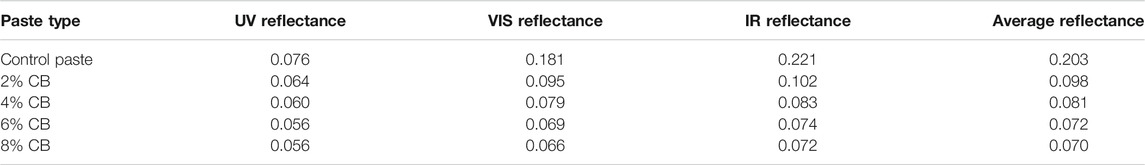

3.5 Spectrum Reflectance

The spectrum reflectance of different cement pastes in the UV–VIS–NIR band is shown in Figure 7, according to which the specific reflectance was calculated and shown in Table 4. The detailed calculation method can be found in ASTM Standard G173-03 (ASTM, 2012).

Overall, the spectrum reflectance of cement pastes decreased with the increase of CB content. This is because the addition of CB caused the color of cement paste to be more like black. Generally, the materials with black color had lower spectrum reflectance (Xie et al., 2019).

Specifically, the UV reflectance of the five cement pastes was similar to each other, indicating that CB had a small influence on this parameter. By contrast, the VIS reflectance and IR reflectance of these cement pastes changed with a relatively large range. For example, after adding 2% CB, the IR reflectance reduced by over 50%, and in terms of average reflectance, CB also reduced this parameter to a large extent. The addition of 2% CB reduced the average reflectance from 0.203 to 0.098. The reducing ratio was 51.7%. After that, the reflectance changed very little with the increase of CB content.

The semiflexible asphalt pavement comprises asphalt mixture and cement paste. The influence of CB addition on the overall spectrum reflectance of asphalt pavement should be further studied.

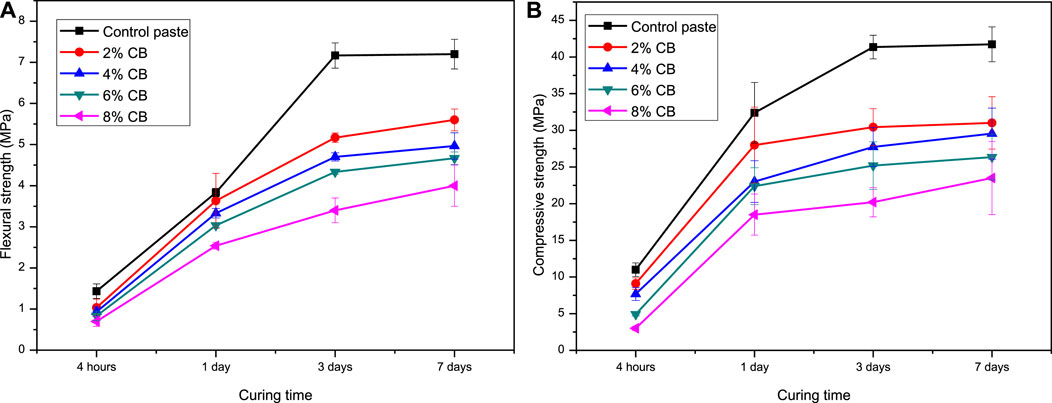

3.6 Mechanical Performances

From the results discussed in the aforementioned sections, it can be found that CB addition could indeed influence the optical and thermal performances of cement paste. In order to investigate the mechanical performances of these pastes, two indicators of flexural and compressive strength were used. The results are shown in Figure 8.

FIGURE 8. Mechanical performances of cement paste. (A) Flexural strength and (B) compressive strength.

Overall, the flexural and compressive strength of cement pastes both increased with increasing curing time. In particular, the two kinds of strength increased with a very high rate during the curing time of 4 h–1 day, while they changed in a very small range during the curing time of 3–7 days. The results might be attributed to the early hydration characteristic of the used cement. The flexural and compressive strength of control paste at the curing time of 4 h reached up to 1.4 and 11.0 MPa, respectively.

The addition of CB had negative effects on the flexural and compressive strength of cement paste, which is in part because CB addition increased the air voids content of cement paste. Take the 1 day-strength for example. When 6% CB paste was added in cement paste, the flexural and compressive strength reduced by 20.9 and 30.9%, respectively. Nevertheless, these strength values could meet the compressive strength requirement of asphalt pavement. It was reported that the compressive strength of an in-service asphalt mixture was approximately 6 MPa (Wu et al., 2018). By contrast, the 1-day compressive strength of 8% CB paste was 18.5 MPa. This indicates that the semiflexible asphalt pavement grouted with the cement paste prepared in this study could be open to traffic in less than 1 day, and the composite asphalt pavement may have higher strength than conventional asphalt pavement.

4 Conclusion

Traditional semiflexible asphalt pavement presents a bad appearance because of the color inconsistence between black asphalt mixture and light-colored cement paste. Carbon black (CB) was introduced in this study to prepare black cement paste that was grouted in a porous asphalt mixture. The optical, thermal, and mechanical performances of the aforementioned cement pastes were then investigated. The following conclusions were drawn:

(1) By designing the mass ratios of the component, the fluidity of cement grouting paste containing CB could be ensured in a high level. When 8% CB was added to the cement paste, the fluidity was only about 21% of that of control paste.

(2) According to the SEM images of the cement paste, CB caused the microstructure to become looser, and when the CB content was higher than 4%, the CB particles began to gather.

(3) CB improved the black color of cement paste. As a result, the cement paste presented lower spectrum reflectance. The 2% CB cement paste had an average reflectance 51.7% lower than that of control paste.

(4) Due to having higher air voids contents, the cement pastes with CB had lower thermal conductivity, although the thermal conductivity of CB is higher than that of cement hydration products.

(5) The addition of CB reduced the flexural and compressive strength of cement pastes. Nevertheless, the compressive strength value was still much higher than that of the asphalt mixture, indicating that the prepared composite asphalt pavement may have higher strength than conventional asphalt pavement.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author Contributions

DY contributed to methodology; DH and WS contributed to validation; DH contributed to formal analysis; DH, WS, and LY contributed to the investigation; WS contributed to data curation; DH and LY contributed to writing—original draft preparation; DY contributed to writing—review and editing; WT contributed to supervision; WT contributed to project administration; and LY contributed to funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Project of Zhejiang Highway and Transportation Administration Center, China (Grant number 2020H05), National Natural Science Foundation of China (Grant number 51808562), and Natural Science Foundation of Hunan Province, China (Grant number 2020JJ5723).

Conflict of Interest

Author WT is employed by Nanjing Xingyou Transportation Technology Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

An, S., Ai, C., Ren, D., Rahman, A., and Qiu, Y. (2018). Laboratory and Field Evaluation of a Novel Cement Grout Asphalt Composite. J. Mater. Civ. Eng. 30 (8), 04018179. doi:10.1061/(asce)mt.1943-5533.0002376

Aragão, F. T. S., Pazos, A. R. G., Motta, L. M. G. d., Kim, Y.-R., and Nascimento, L. A. H. d. (2016). Effects of Morphological Characteristics of Aggregate Particles on the Mechanical Behavior of Bituminous Paving Mixtures. Constr. Build. Mater. 123, 444–453. doi:10.1016/j.conbuildmat.2016.07.013

ASTM (2012). Standard Tables for Reference Solar Irradiance: Direct normal and Hemispherical on 37 Tilted Surface. West Conshohocken, PA: ASTM International.

Cai, J., Pei, J., Luo, Q., Zhang, J., Li, R., and Chen, X. (2017). Comprehensive Service Properties Evaluation of Composite Grouting Materials with High-Performance Cement Paste for Semi-flexible Pavement. Constr. Build. Mater. 153, 544–556. doi:10.1016/j.conbuildmat.2017.07.122

Chen, X., Wang, Y., Chong, H., and Huang, J. (2020). Use of Sulphoaluminate Cement in Grouted Macadam as Sustainable Pavement Material. J. Transp. Eng. Part. B Pavements 146 (2), 04020018. doi:10.1061/jpeodx.0000167

Dong, W., Li, W., Lu, N., Qu, F., Vessalas, K., and Sheng, D. (2019). Piezoresistive Behaviours of Cement-Based Sensor with Carbon Black Subjected to Various Temperature and Water Content. Compos. B: Eng. 178, 107488. doi:10.1016/j.compositesb.2019.107488

Du, Y., Chen, J., Han, Z., and Liu, W. (2018). A Review on Solutions for Improving Rutting Resistance of Asphalt Pavement and Test Methods. Constr. Build. Mater. 168, 893–905. doi:10.1016/j.conbuildmat.2018.02.151

Fang, B., Xu, T., and Shi, S. (2016). Laboratory Study on Cement Slurry Formulation and its Strength Mechanism for Semi-flexible Pavement. J. Test. Eval. 44 (2), 907–913. doi:10.1520/jte20150230

Gong, M., Xiong, Z., Chen, H., Deng, C., Chen, X., Yang, J., et al. (2019). Evaluation on the Cracking Resistance of Semi-flexible Pavement Mixture by Laboratory Research and Field Validation. Constr. Build. Mater. 207, 387–395. doi:10.1016/j.conbuildmat.2019.02.064

Hassani, A., Taghipoor, M., and Karimi, M. M. (2020). A State of the Art of Semi-flexible Pavements: Introduction, Design, and Performance. Constr. Build. Mater. 253, 119–196. doi:10.1016/j.conbuildmat.2020.119196

Lee, J., Kim, Y. R., and Lee, J. (2015). Rutting Performance Evaluation of Asphalt Mix with Different Types of Geosynthetics Using MMLS3. Int. J. Pavement Eng. 16 (10), 894–905. doi:10.1080/10298436.2014.972916

Li, H., Xiao, H., and Ou, J. (2008). Electrical Property of Cement-Based Composites Filled with Carbon Black under Long-Term Wet and Loading Condition. Compos. Sci. Tech. 68 (9), 2114–2119. doi:10.1016/j.compscitech.2008.03.007

Luo, S., Yang, X., Zhong, K., and Yin, J. (2020). Open-graded Asphalt concrete Grouted by Latex Modified Cement Mortar. Road Mater. Pavement Des. 21 (1), 61–77. doi:10.1080/14680629.2018.1479290

Pei, J., Cai, J., Zou, D., Zhang, J., Li, R., Chen, X., et al. (2016). Design and Performance Validation of High-Performance Cement Paste as a Grouting Material for Semi-flexible Pavement. Constr. Build. Mater. 126, 206–217. doi:10.1016/j.conbuildmat.2016.09.036

Qin, Y. (2015). A Review on the Development of Cool Pavements to Mitigate Urban Heat Island Effect. Renew. Sust. Energ. Rev. 52, 445–459. doi:10.1016/j.rser.2015.07.177

Santamouris, M. (2013). Using Cool Pavements as a Mitigation Strategy to Fight Urban Heat Island-A Review of the Actual Developments. Renew. Sust. Energ. Rev. 26, 224–240. doi:10.1016/j.rser.2013.05.047

Sen, S., and Roesler, J. (2016). Aging Albedo Model for Asphalt Pavement Surfaces. J. Clean. Prod. 117, 169169–175175. doi:10.1016/j.jclepro.2016.01.019

Wang, D., Liang, X., Jiang, C., and Pan, Y. (2018). Impact Analysis of Carboxyl Latex on the Performance of Semi-flexible Pavement Using Warm-Mix Technology. Constr. Build. Mater. 179, 566–575. doi:10.1016/j.conbuildmat.2018.05.173

Wu, J., Li, D., Zhu, B., and Wu, C. (2018). Milling Process Simulation of Old Asphalt Mixture by Discrete Element. Constr. Build. Mater. 186, 996–1004. doi:10.1016/j.conbuildmat.2018.08.015

Xie, N., Li, H., Abdelhady, A., and Harvey, J. (2019). Laboratorial Investigation on Optical and thermal Properties of Cool Pavement Nano-Coatings for Urban Heat Island Mitigation. Building Environ. 147, 231–240. doi:10.1016/j.buildenv.2018.10.017

Zhang, J., Cai, J., Pei, J., Li, R., and Chen, X. (2016). Formulation and Performance Comparison of Grouting Materials for Semi-flexible Pavement. Constr. Build. Mater. 115, 582–592. doi:10.1016/j.conbuildmat.2016.04.062

Zhang, Y., Sun, Q., and Yang, X. (2018). Changes in Color and thermal Properties of Fly Ash Cement Mortar after Heat Treatment. Constr. Build. Mater. 165, 72–81. doi:10.1016/j.conbuildmat.2018.01.029

Keywords: cement grouting paste, carbon black, color difference, thermal conductivity, strength

Citation: Haibin D, Shungui W, Yingchen L, Yinfei D and Tangzhong W (2022) Matching the Color Difference Between Asphalt Mixture and Cement Grouting Paste Used in Semi-flexible Pavement. Front. Mater. 9:816247. doi: 10.3389/fmats.2022.816247

Received: 16 November 2021; Accepted: 06 January 2022;

Published: 21 February 2022.

Edited by:

Weina Meng, Stevens Institute of Technology, United StatesCopyright © 2022 Haibin, Shungui, Yingchen, Yinfei and Tangzhong. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Du Yinfei, eWZkdV9jc3VAY3N1LmVkdS5jbg==

Deng Haibin1

Deng Haibin1 Wang Shungui

Wang Shungui Du Yinfei

Du Yinfei